Multifunctional lotus nut screening machine

A core screening machine and lotus seed technology, which is applied in the direction of filtering, solid separation, grille, etc., can solve the problems of high labor intensity, poor working environment, and inconvenient manual core-seeking and core-taking, and achieve reduced labor intensity, simple structure, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

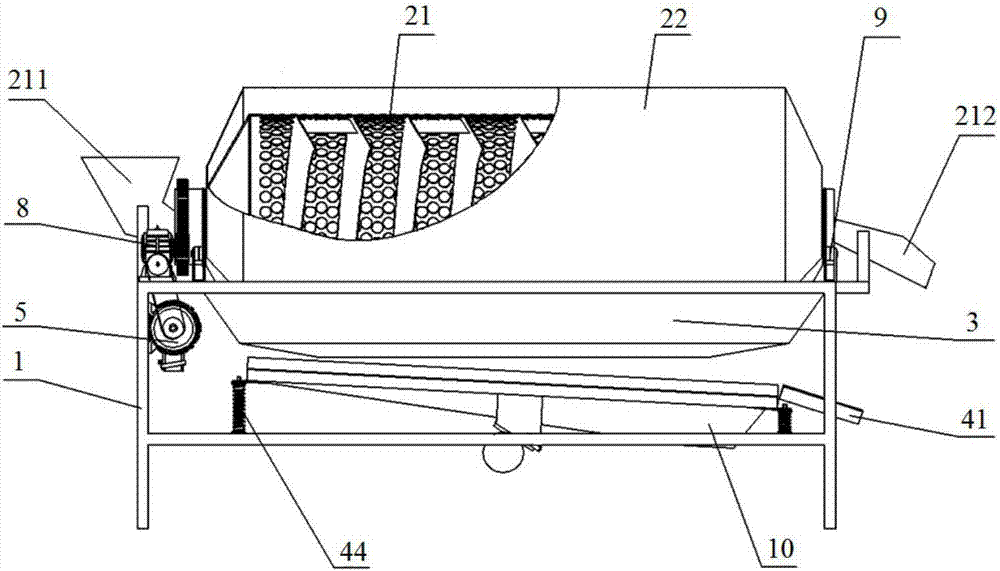

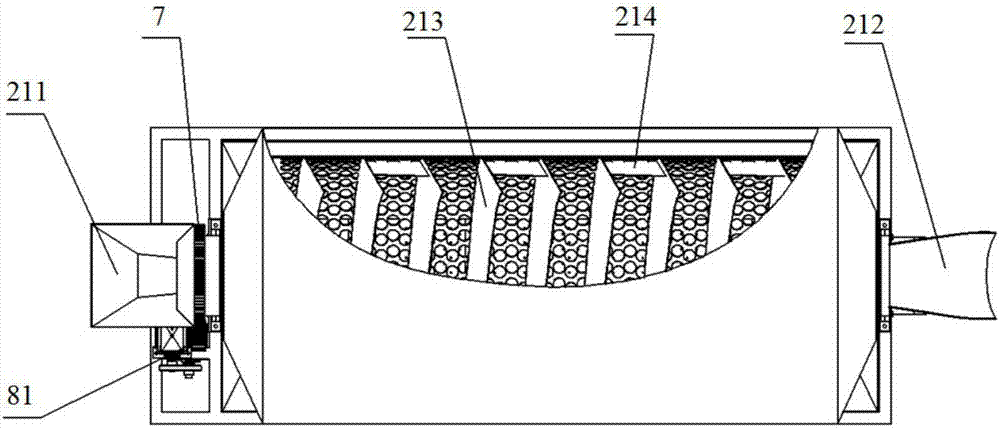

[0026] Such as Figure 1-Figure 6 As shown, the embodiment of the lotus seed core sieving machine of the present invention includes: a frame 1; a core removal drum 2, which is arranged on the frame 1, and the core removal drum 2 includes a hole screen bucket 21 and the hole screen bucket 21 a housing cover 22 arranged on the outer periphery, and the hole screen bucket 21 rotates along the axis of the hole screen bucket 21 in the housing cover 22;

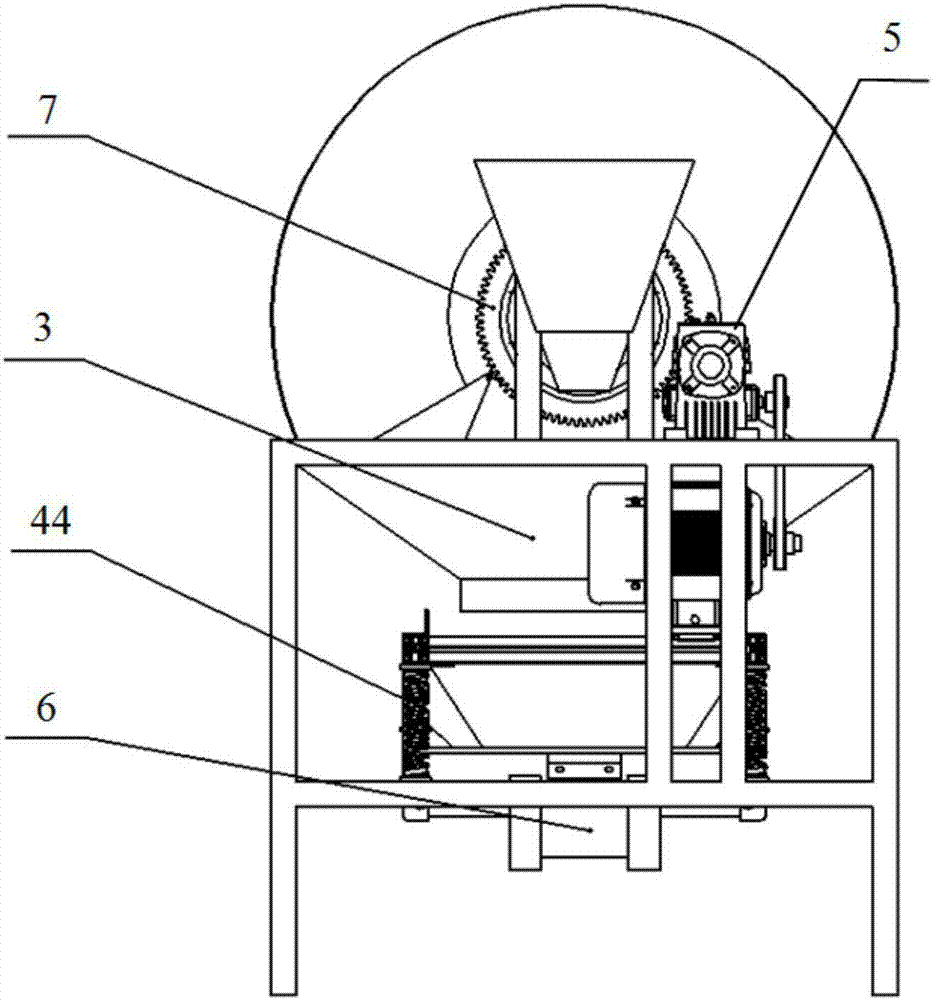

[0027] The first core hopper 3 is arranged on the side of the core throwing drum 2 close to the frame 1, and a vibrating screen 4 is arranged on the side of the first core hopper 3 away from the hole screen bucket 21. , the vibrating screen 4 is provided with the second core bucket 41 at one end;

[0028] The driving device 5 includes a driving motor 51 and a driving control circuit 52;

[0029] The vibrating device 6 includes a vibrating motor 61 and a vibrating control circuit 62;

[0030] One end inlet of the hole screen barrel 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap