Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Fineness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The fineness of a precious metal object (coin, bar, jewelry, etc.) represents the weight of fine metal therein, in proportion to the total weight which includes alloying base metals and any impurities. Alloy metals are added to increase hardness and durability of coins and jewelry, alter colors, decrease the cost per weight, or avoid the cost of high-purity refinement. For example, copper is added to the precious metal silver to make a more durable alloy for use in coins, housewares and jewelry. Coin silver, which was used for making silver coins in the past, contains 90% silver and 10% copper, by mass. Sterling silver contains 92.5% silver and 7.5% of other metals, usually copper, by mass.

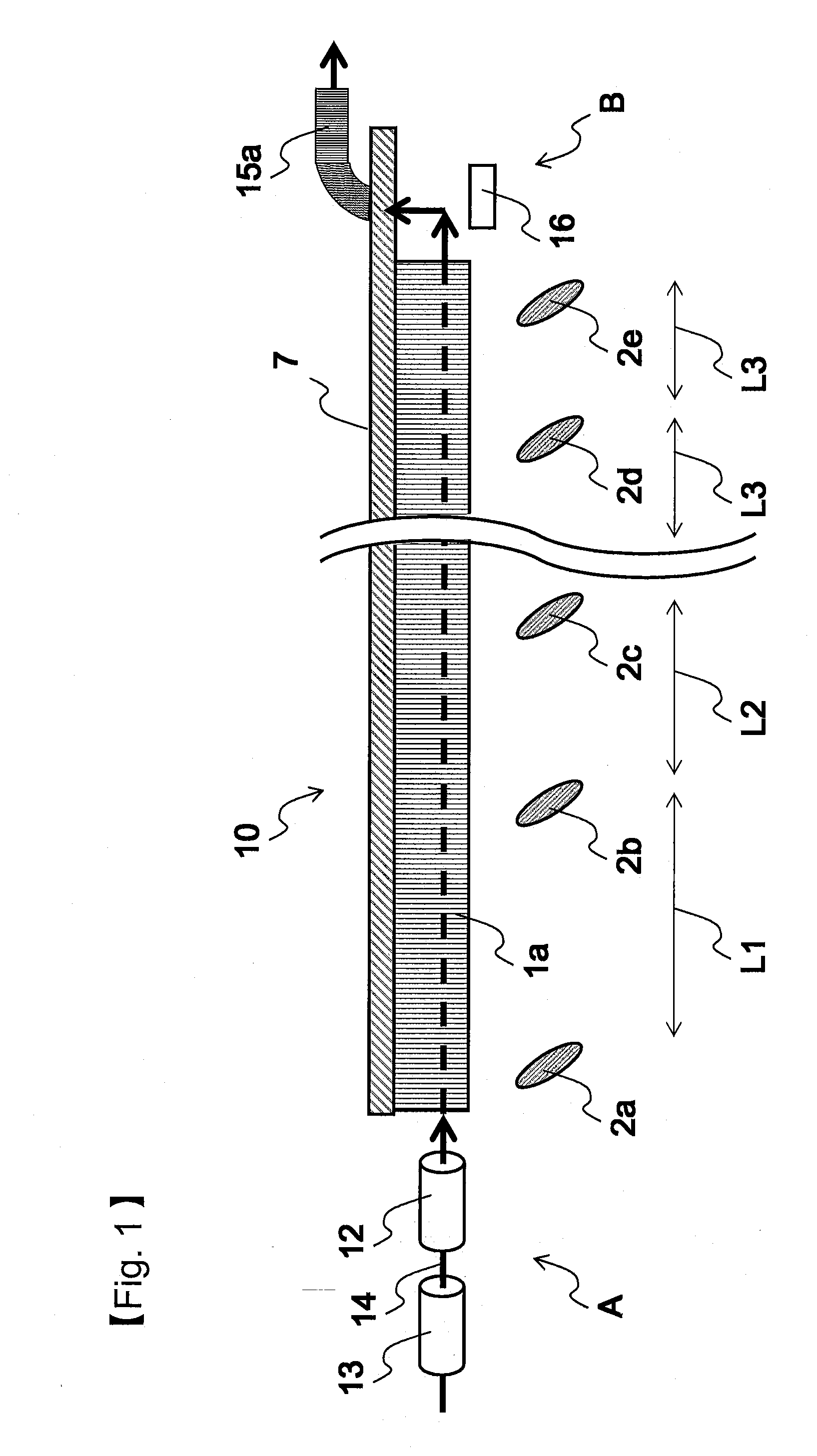

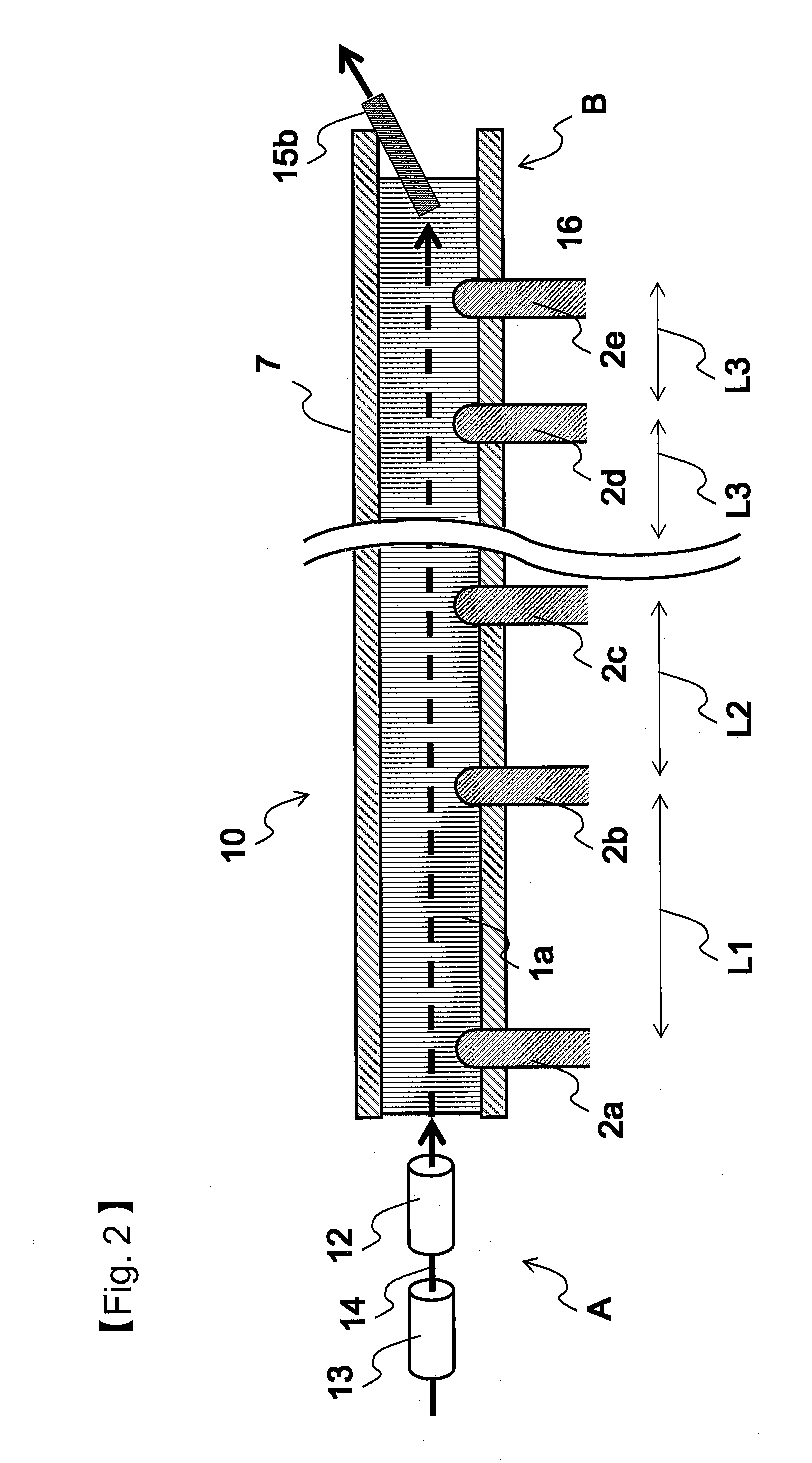

Method for producing carbon fiber woven fabric

ActiveUS20100032049A1Quality improvementImprove productivityLoomsWoven fabricsProduction rateCarbon fibers

Owner:TORAY IND INC

Wool and rabbit fur coat

The invention discloses a wool and rabbit fur coat. Warps of the wool and rabbit fur coat are pure cashmere yarns smaller than 1.0% in roving ratio, while wefts are composite wool yarns formed by blending wool fiber and milk protein fiber according to a mass ratio of 10:1-10:3. The wool fiber is 18-22 micrometers in fineness and 22-25mm in length. The milk protein fiber is 25-32 micrometers in fineness and 33-38mm in length. The wool and rabbit fur coat is fine in quality, light and soft with no hair slip, and antistatic.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

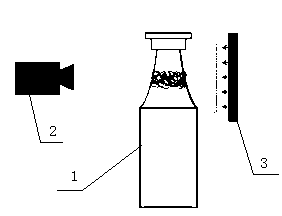

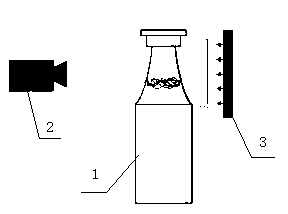

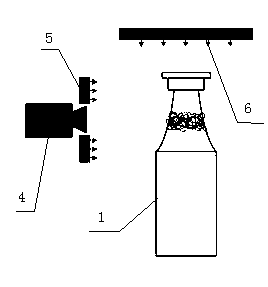

Foam-appearance-based on-line beer detection method

ActiveCN103278509AAvoid labor intensitySpeed blockMaterial analysis by optical meansBottleComputer science

Owner:SHANDONG MINGJIA TECH

Solid micro-powder fuel

The present invention relates to fuel, in particular to solid micro powder fuel, the micro powder particle is cellulosine and (or) straw, the degree of fineness is not larger than 30 micro meter, the fuel is a mixture, which contains combustion improver and catalyst, 1 to 3 percent calcium carbonate powder, 3to 5 percent epoxide resin powder, 2 to 4 percent organobentonite powder, 1 to 3 percent magnesium powder, 1 to 2 percent phenolic resin powder and 0.2 to 0.6 percent titanium pigment, the waste cellulosine and (or) the straw is dehydrated through hot wind (dryer) and degreased, the crasher is adopted for crashing, and 60 to 100 mu sieve is applied, the calcium carbonate powder, the epoxide resin powder, the organobentonite powder, the coal powder, the phenolic resin powder and the titanium pigment are added according to the ratio and mixed sufficiently, after the mixture is dried by hot wind (dryer) through continuous high temperature, the mixture can be fractionally packed. The fuel has the advantages of low cost, clean and environmental friendly and high thermal efficiency.

Owner:吕尧波 +1

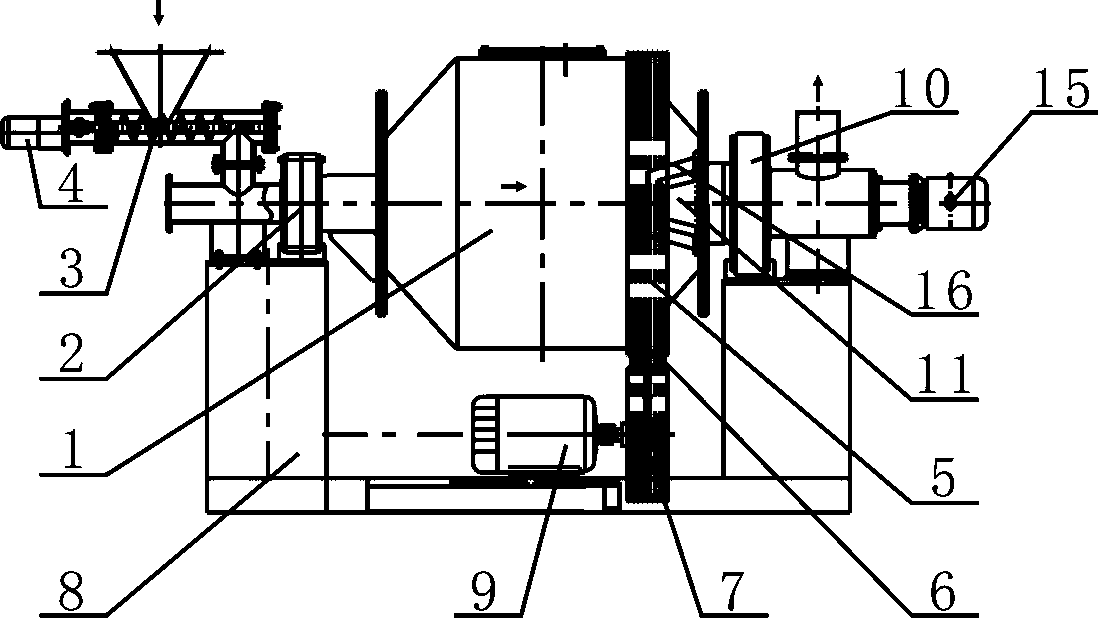

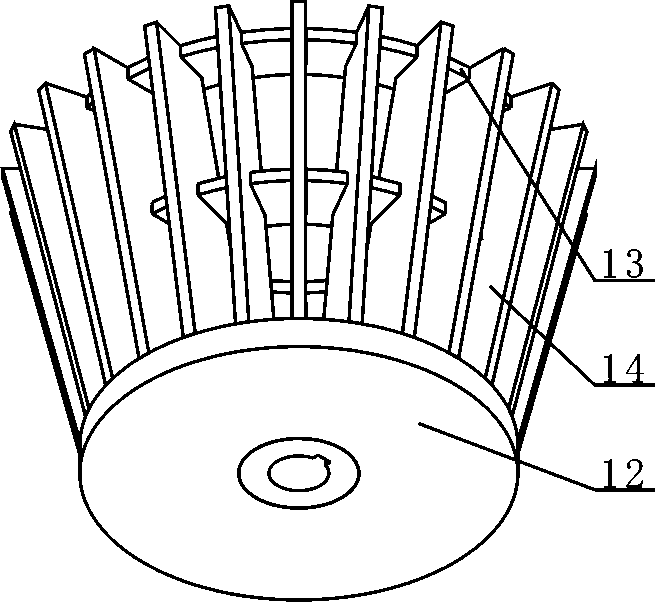

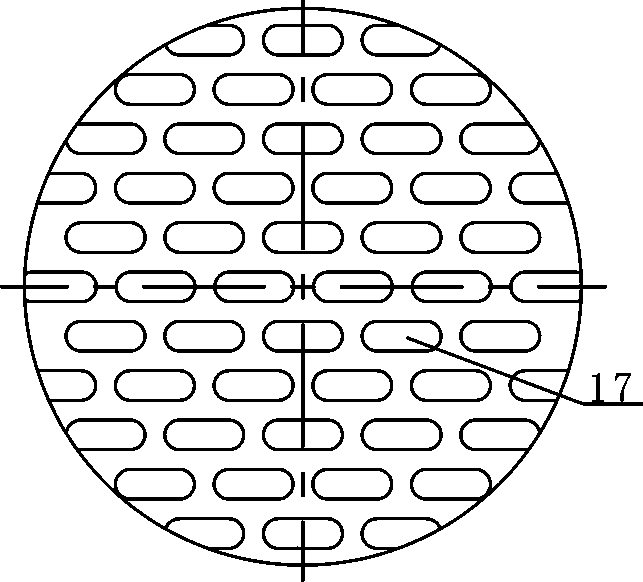

Continuous feeding air separation device

PendingCN108405089AIncrease productionImprove particle size uniformityGrain treatmentsEngineeringAir separation

Owner:LUOYANG SHENGYUAN HIGH TECH MATERIALS

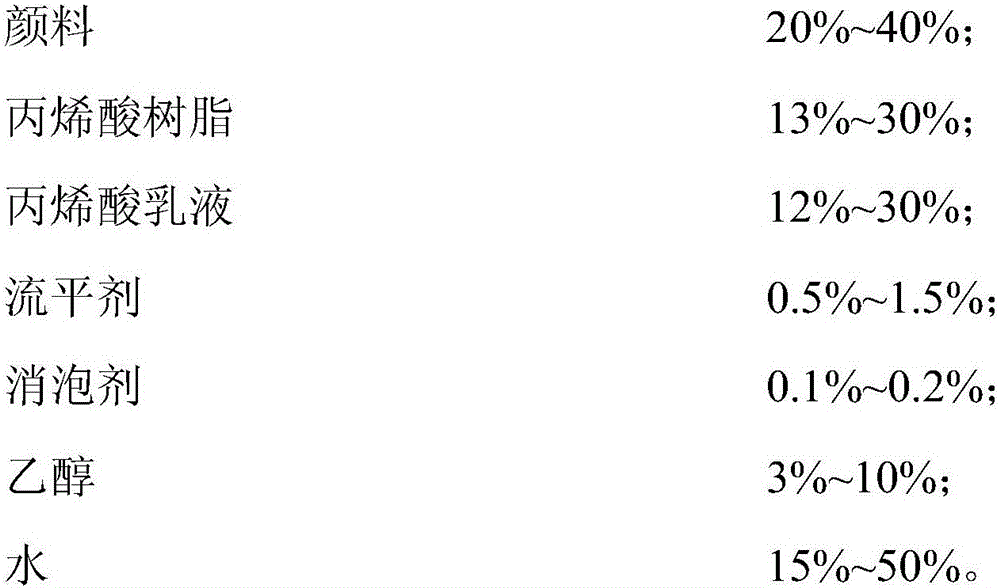

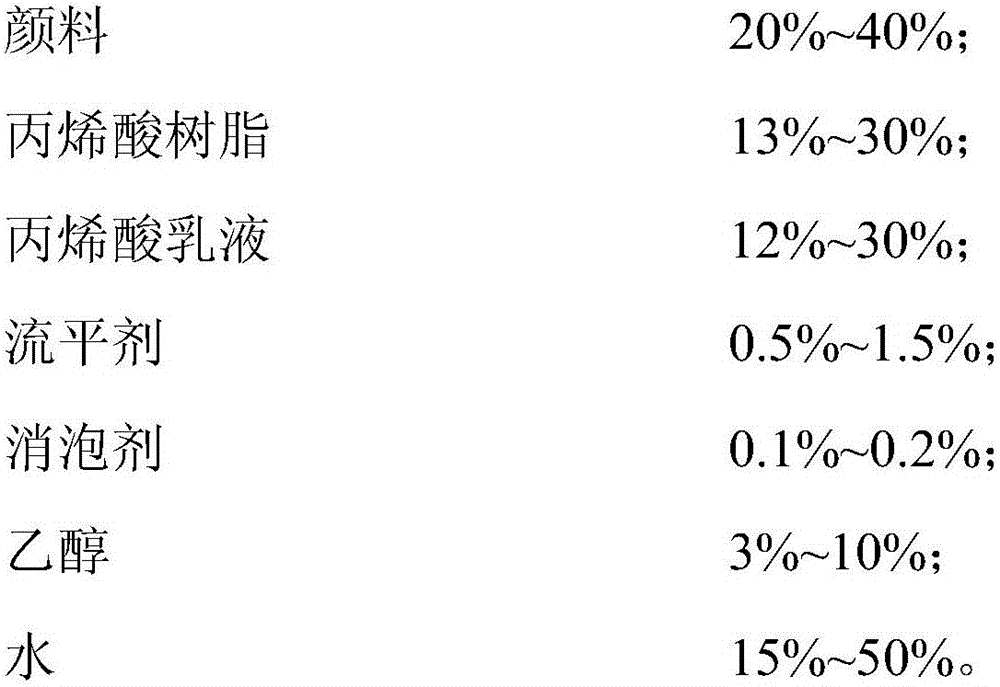

Waterborne printing ink for food package printing and preparation method of printing ink

Owner:JINAN UNIVERSITY

Processing technology of maca superfine powder

InactiveCN106509709AImprove dissolution rateHigh dissolution rateFood freezingFood shapingFreeze thawingBULK ACTIVE INGREDIENT

Owner:北京桔色控股集团股份有限公司 +1

Novel ink

Owner:陈雁

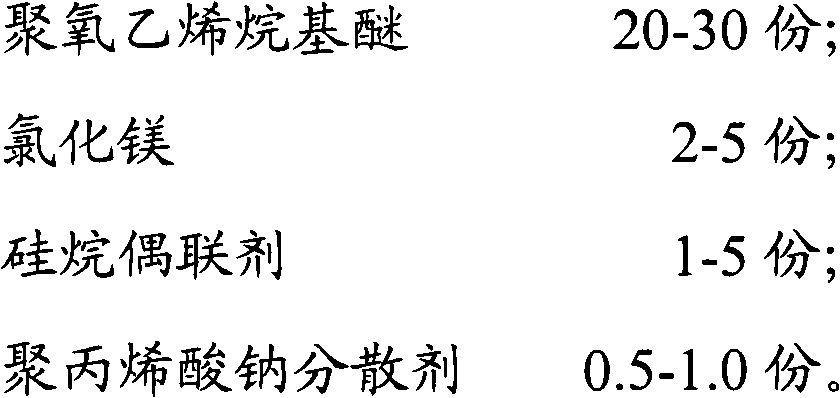

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

Waterborne fireproof paint and preparation method thereof

ActiveCN107641387ALong fire resistanceReduce manufacturing costFireproof paintsCarvacryl acetateStabilizing Agents

Owner:山东七维新材料有限公司

Monocomponent thermoplastic acrylic surfacer

Owner:广东花王涂料有限公司

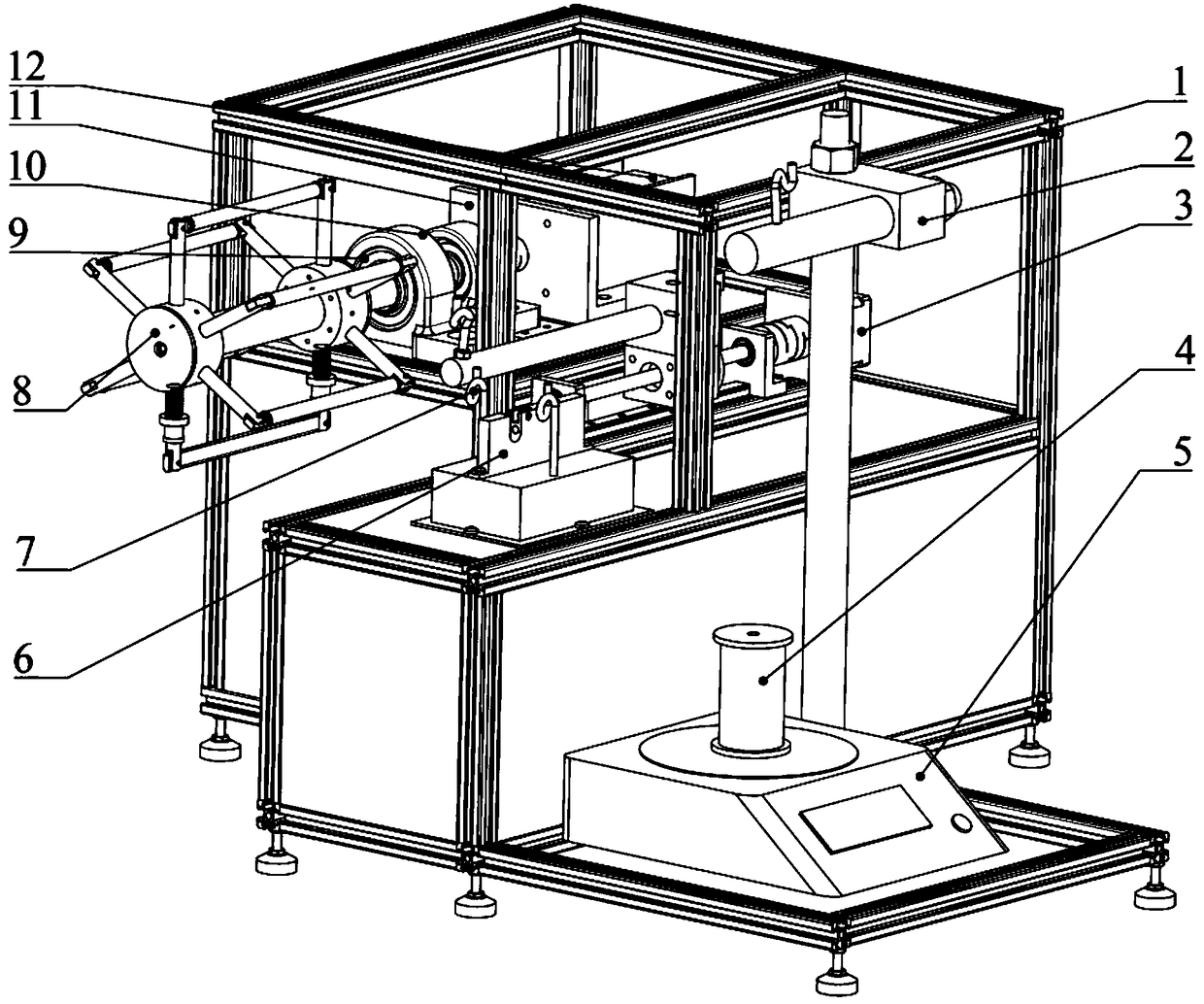

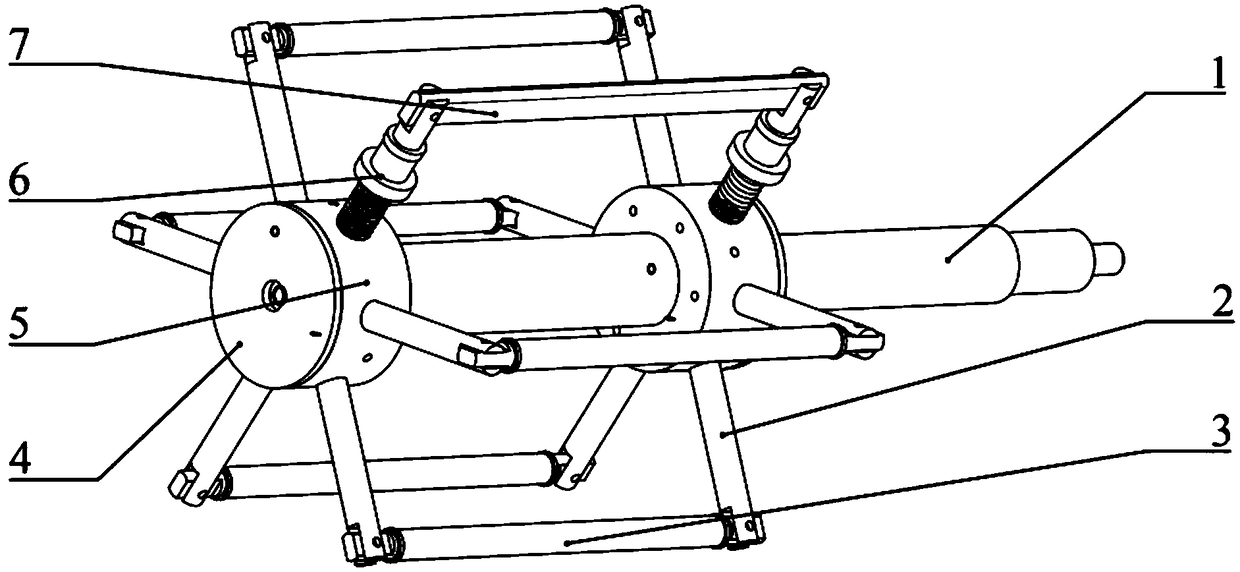

Small raw silk fineness inspection device for silk reeling enterprises

Owner:CHINA JILIANG UNIV

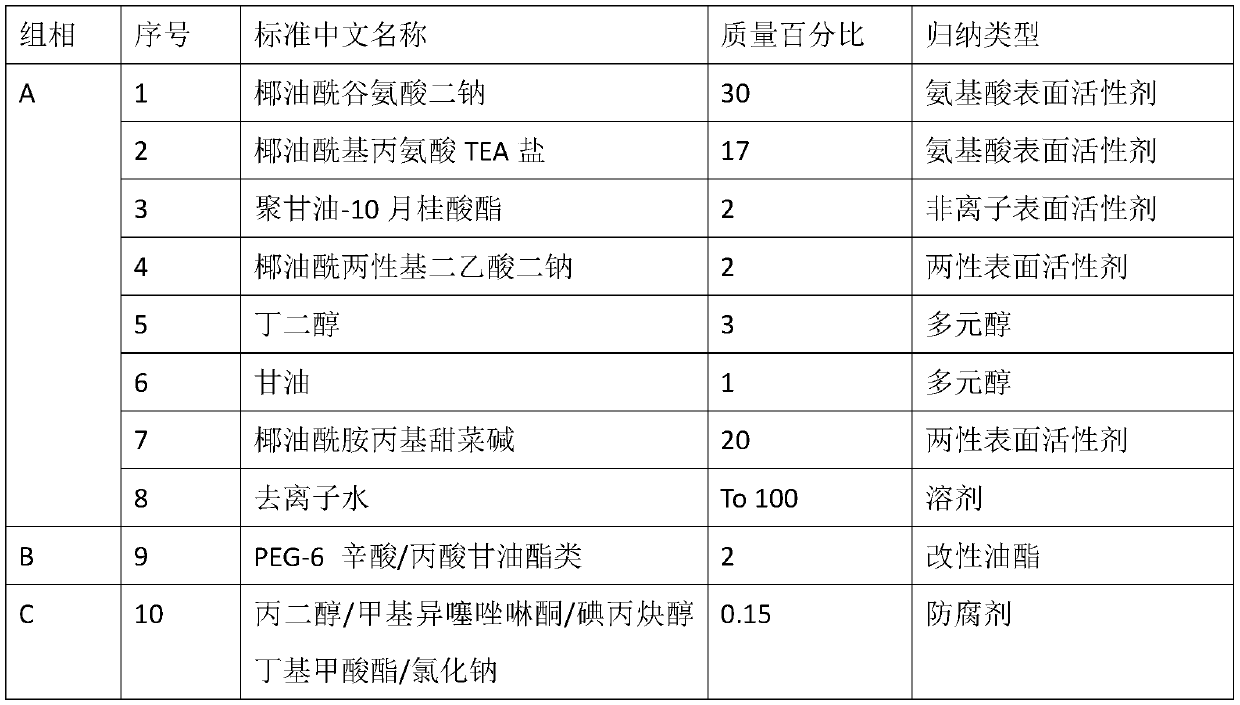

Foam-type face cleaning composition

Owner:GUANGDONG YALGET FINE CHEM +1

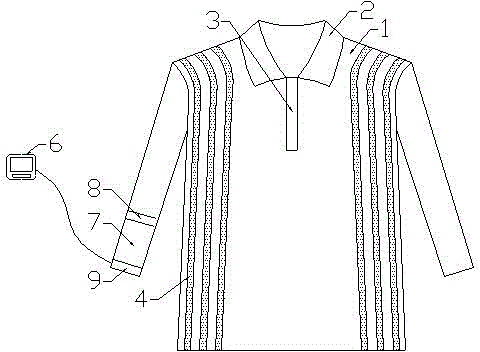

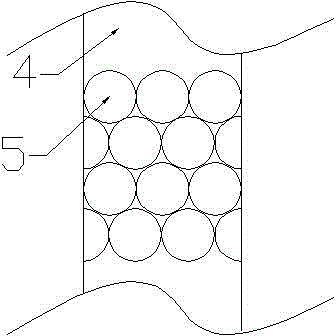

Rationally-structured sweat-absorbing clothes capable of prompting via color changes

InactiveCN105559172AReasonable structureAchieve internal and external ventilationProtective garmentSpecial outerwear garmentsDisplay deviceEngineering

Owner:冯爱华

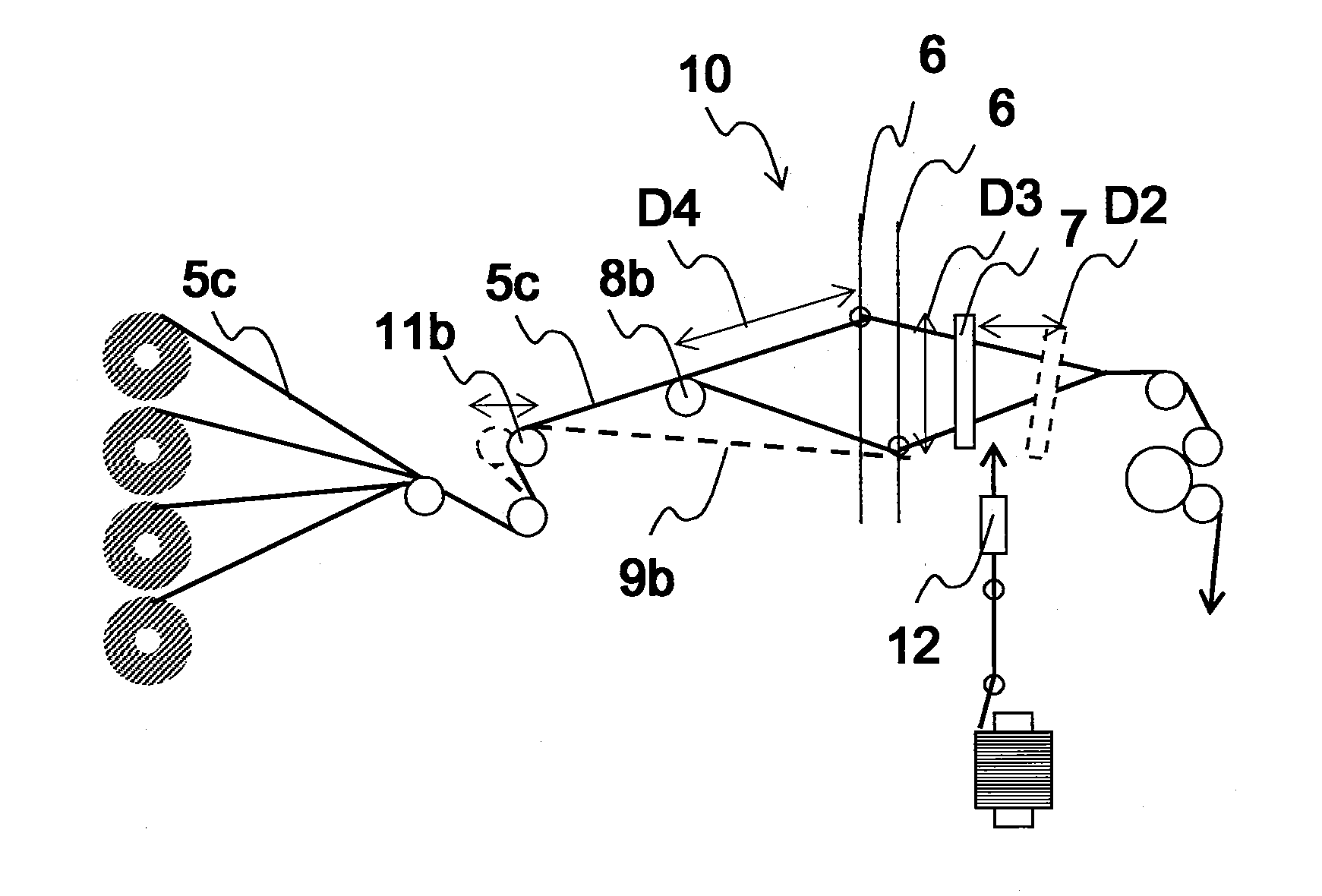

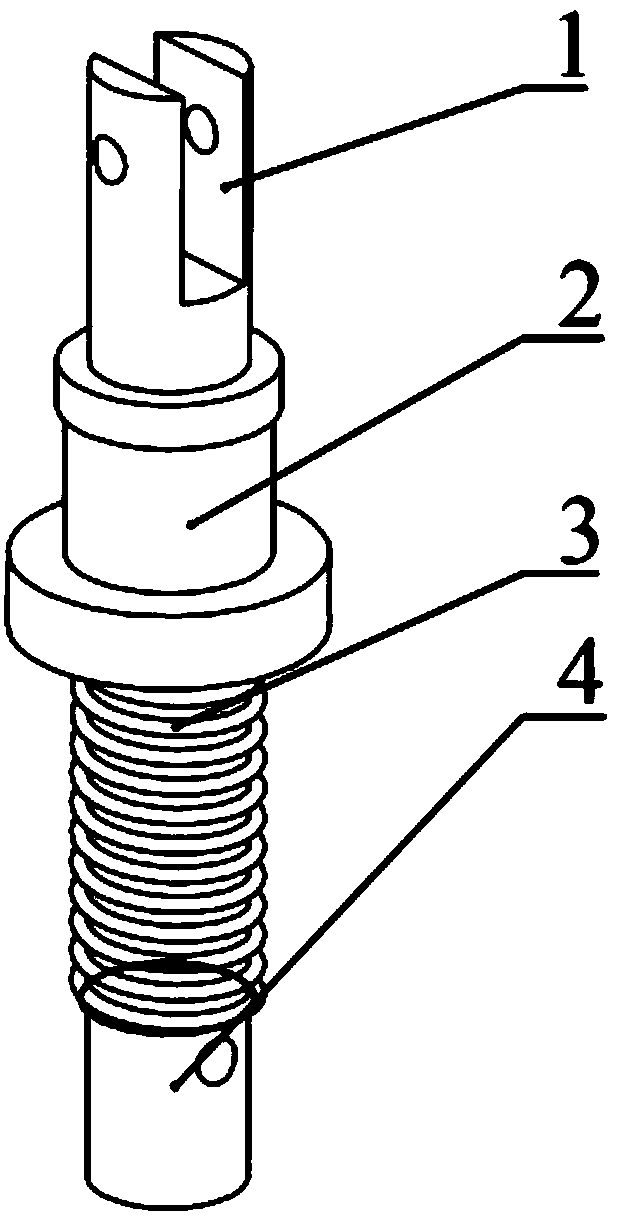

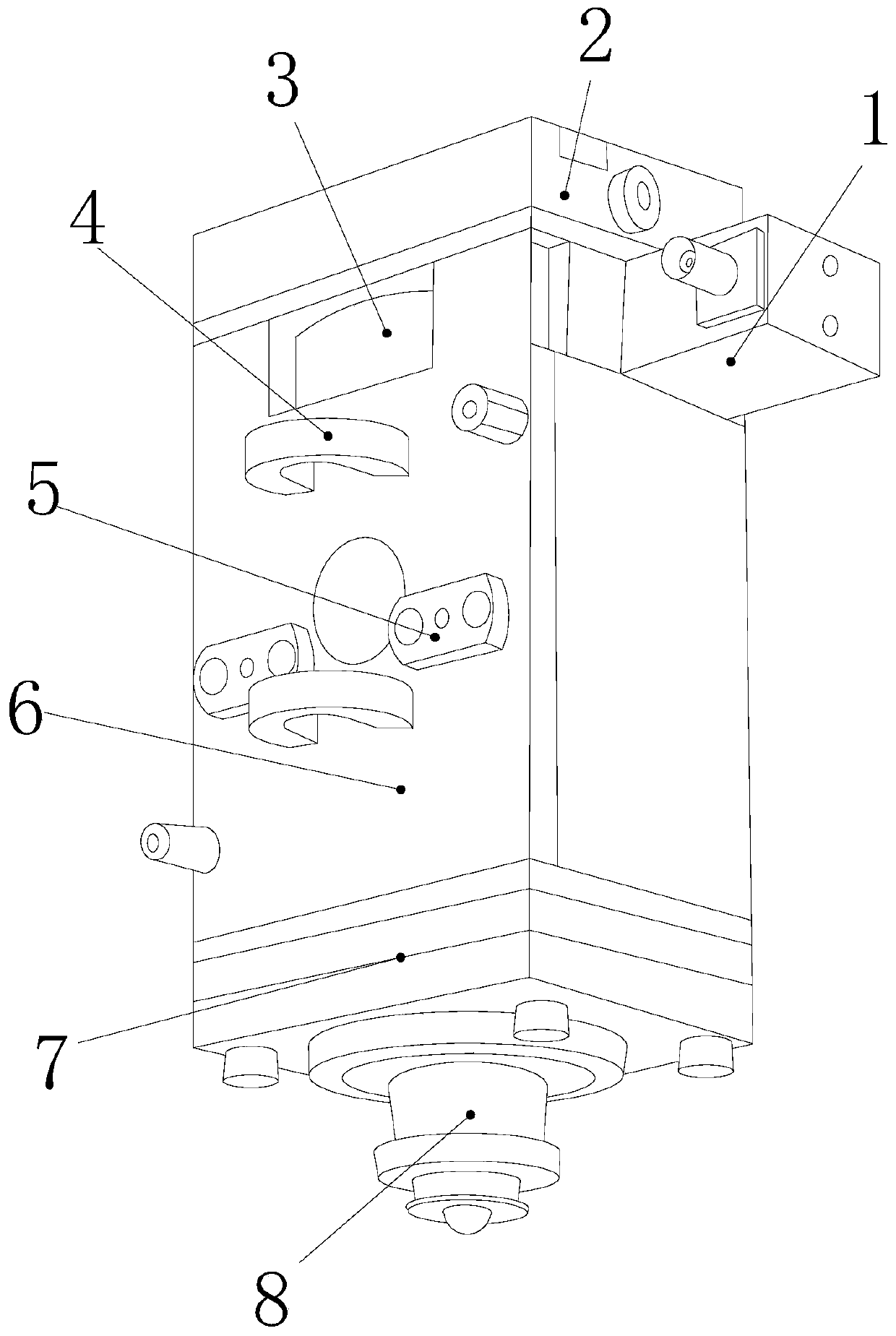

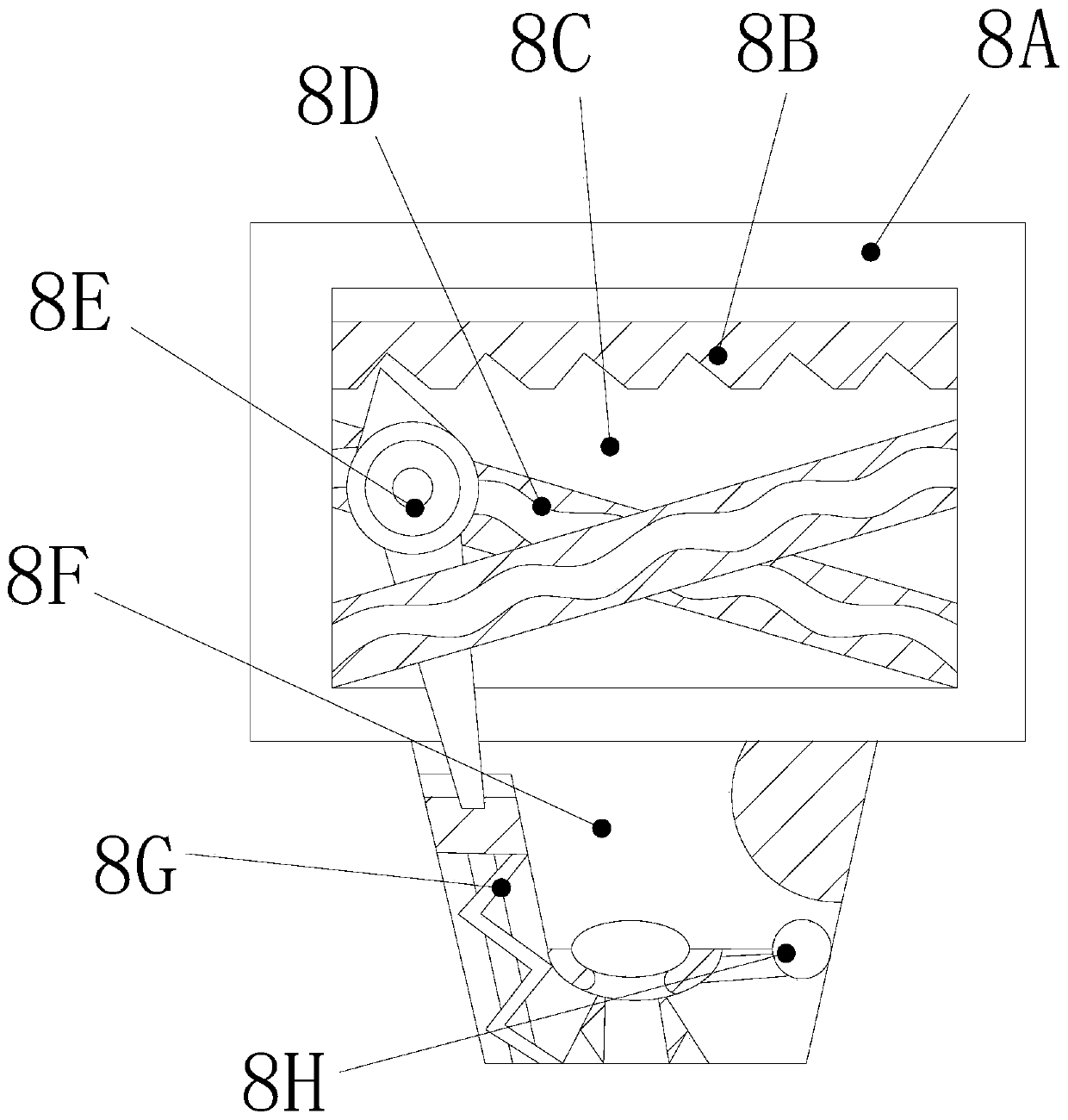

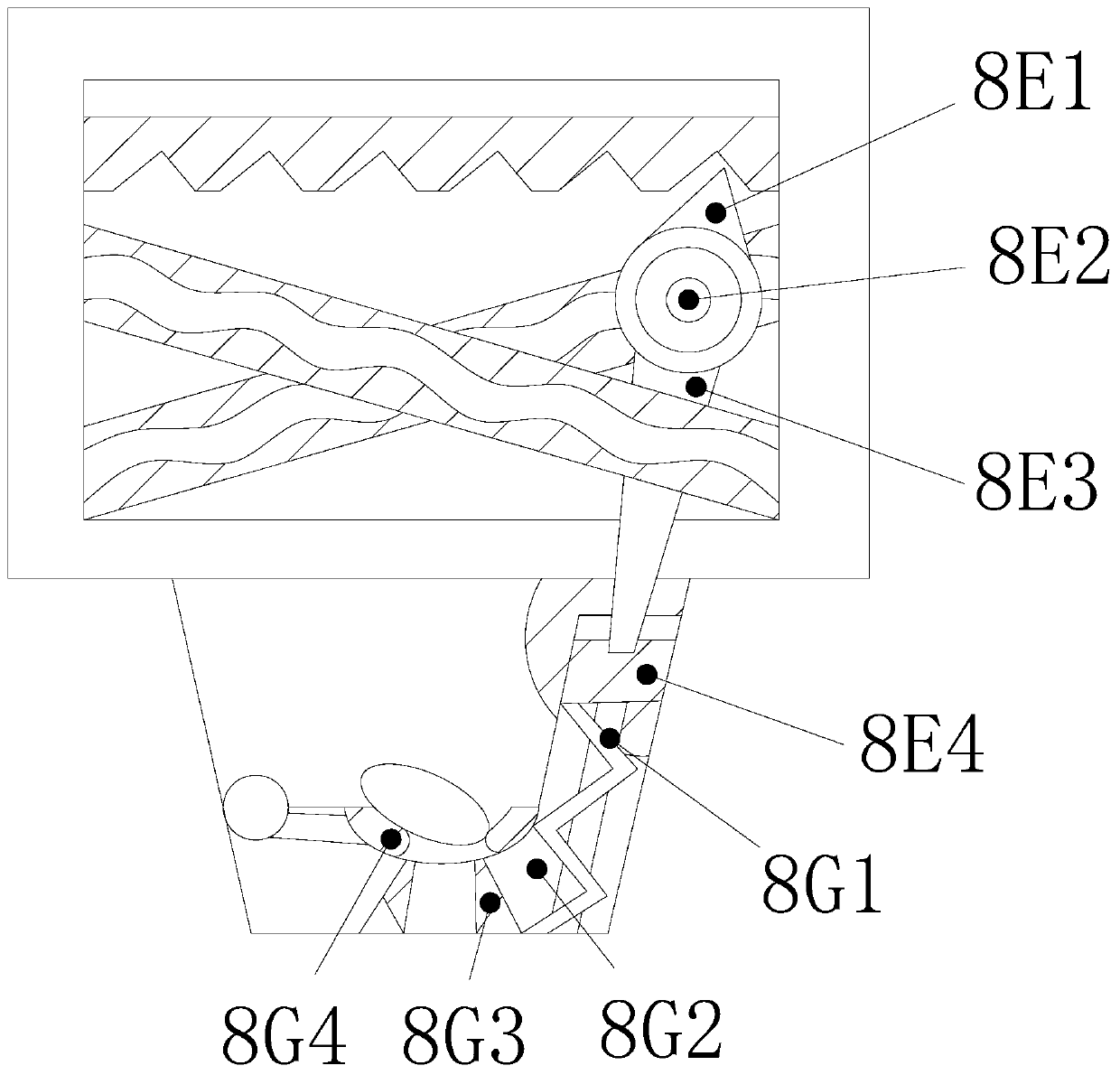

Laser material processing system capable of finely adjusting warping distance through striker for laser marking

InactiveCN110605480AGuarantee high-quality qualified outputAvoid wastingLaser beam welding apparatusEngineeringMaterials processing

Owner:NANAN QUANJIAN MACHINERY TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap