Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "Food shaping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

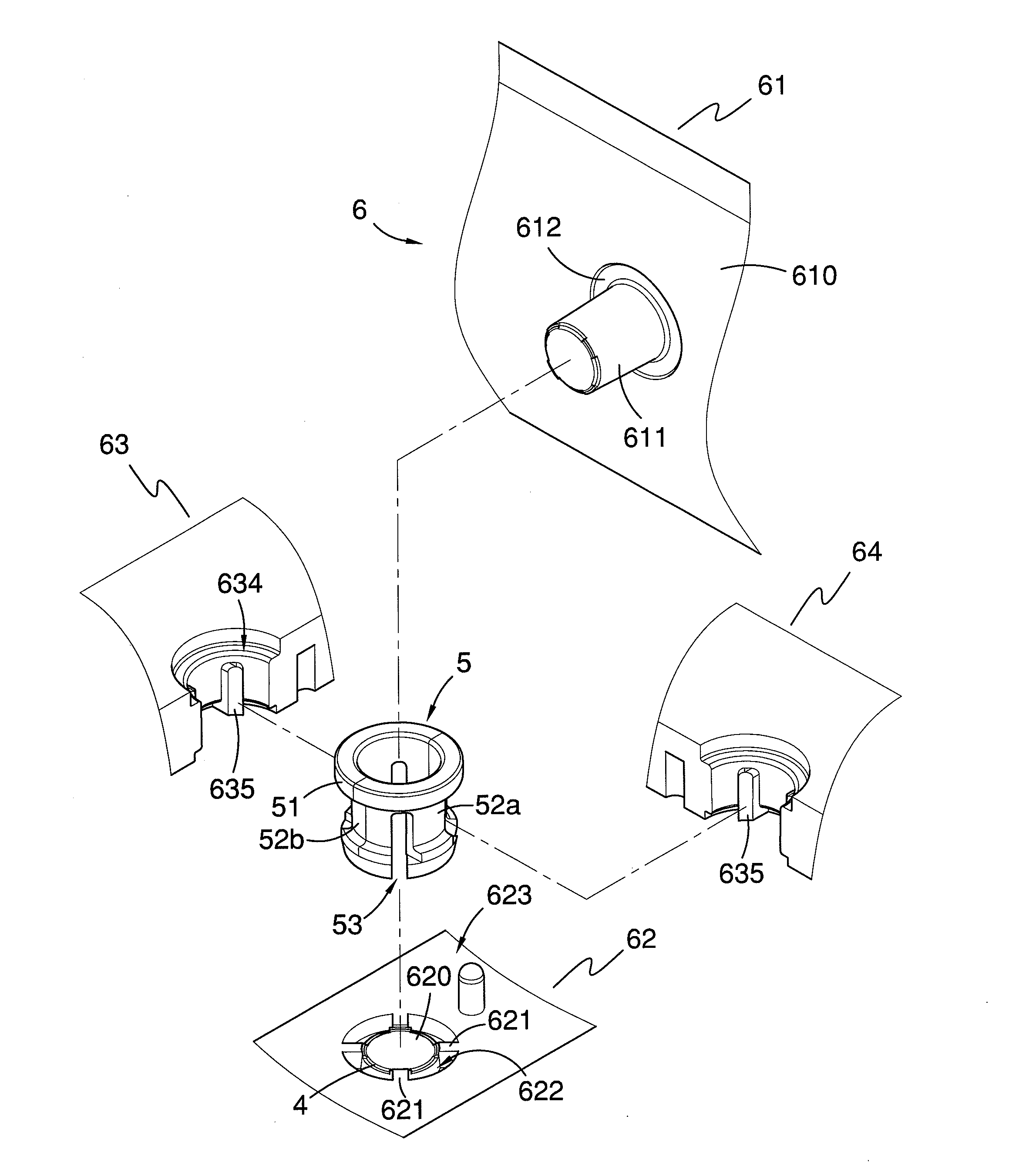

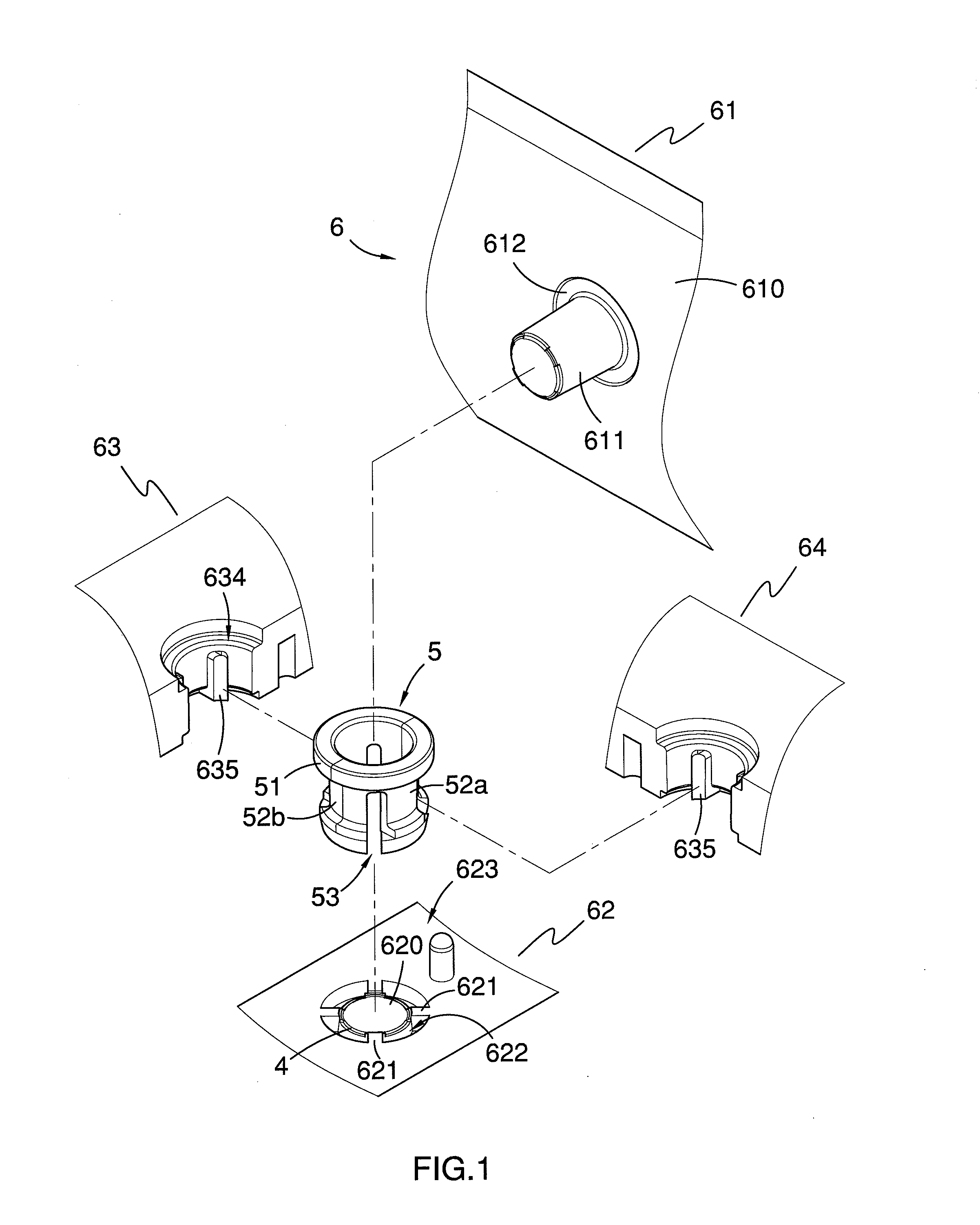

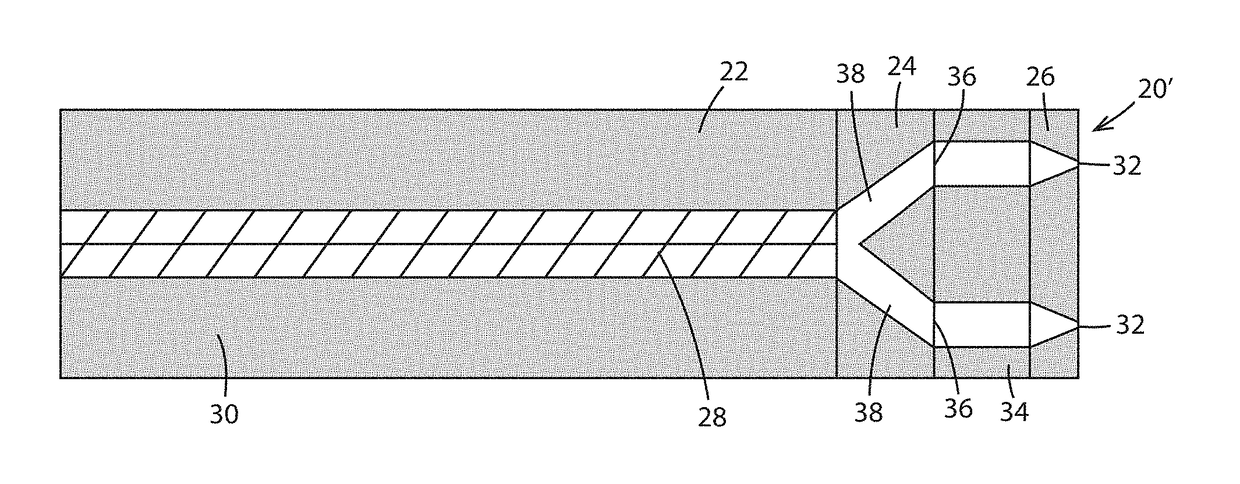

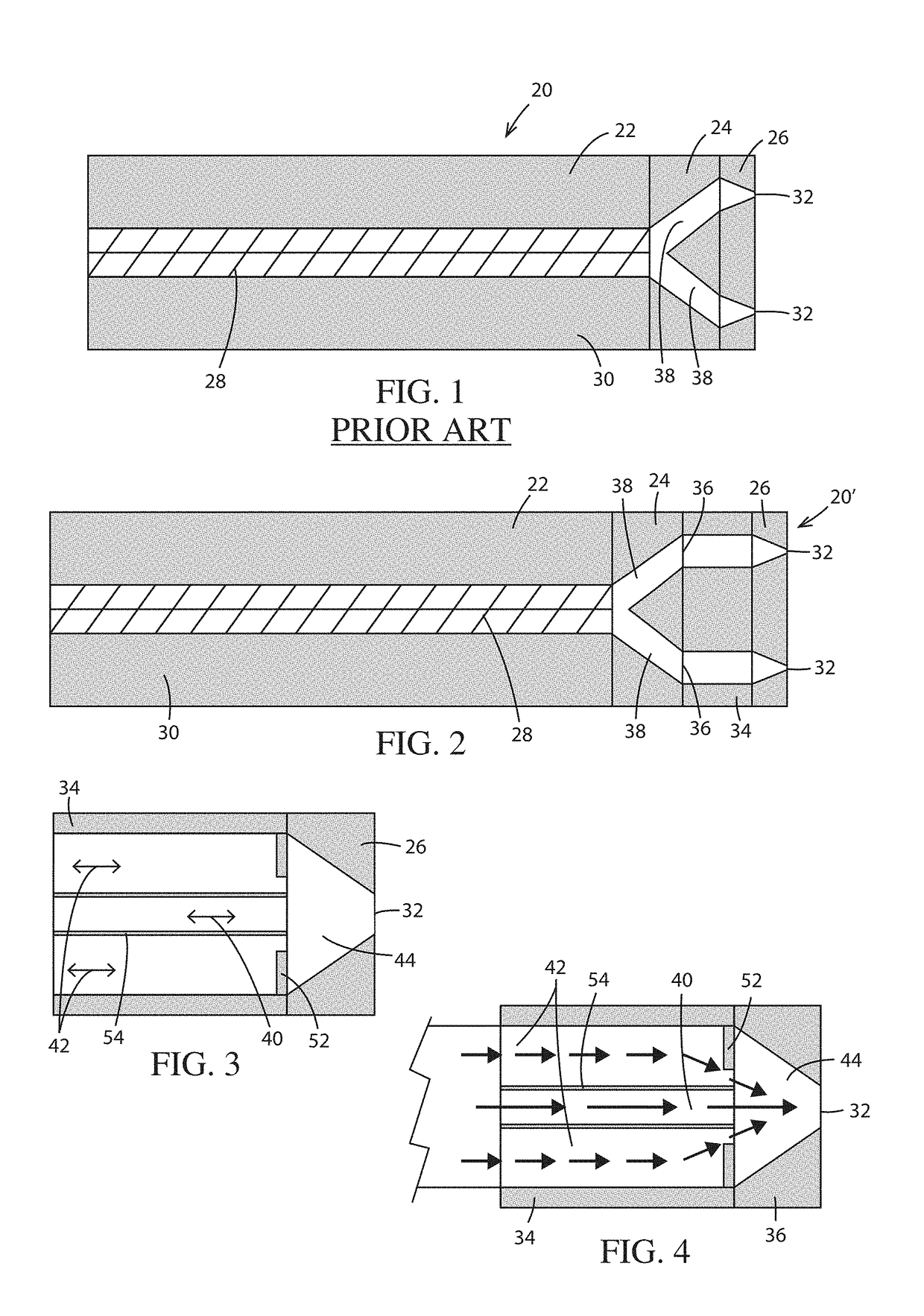

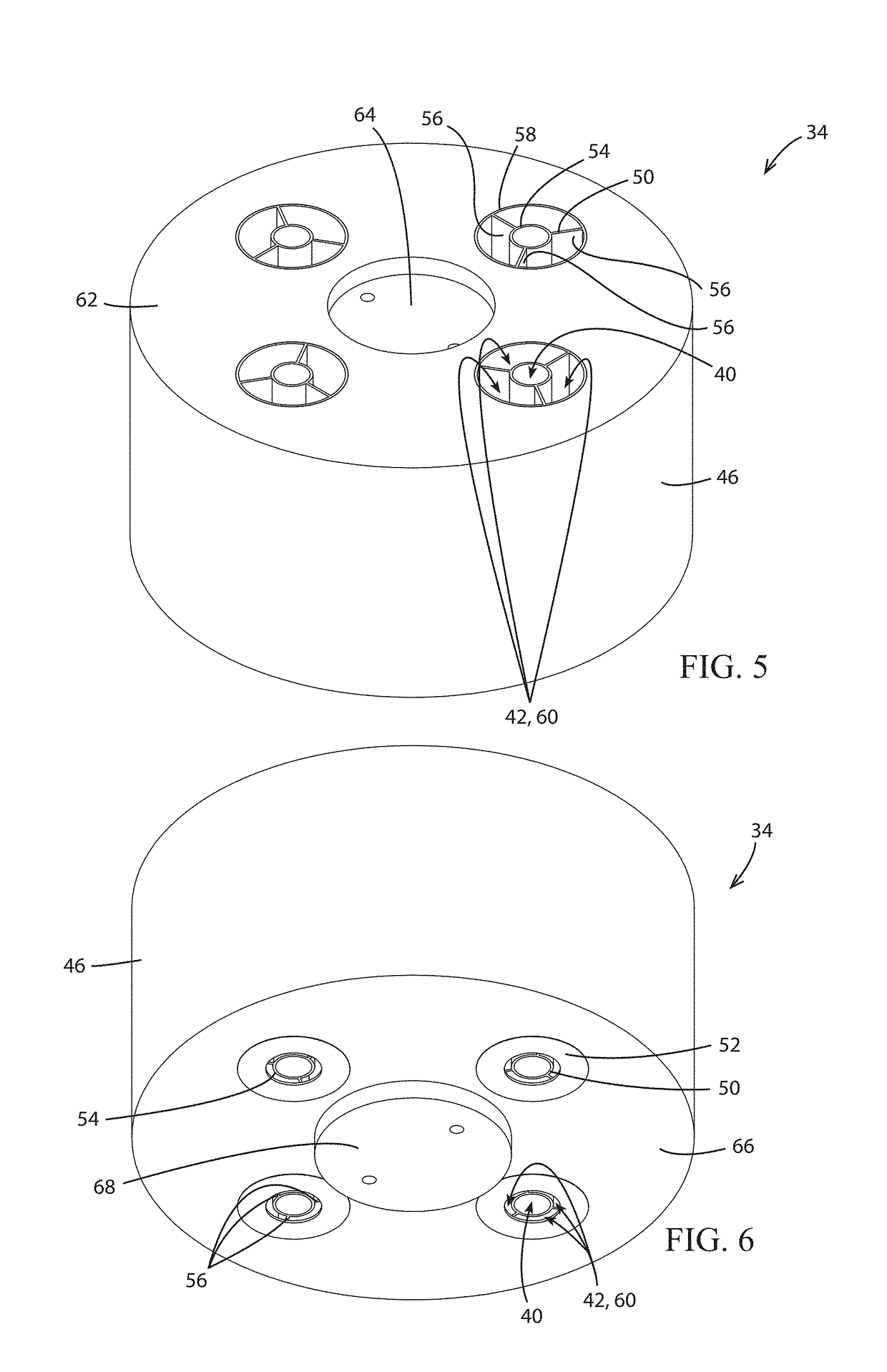

Spray head

InactiveUS7040554B2Eliminate the problemEasy to disassembleLiquid surface applicatorsDust removalLiquid productCoupling

Owner:ASEPT INT

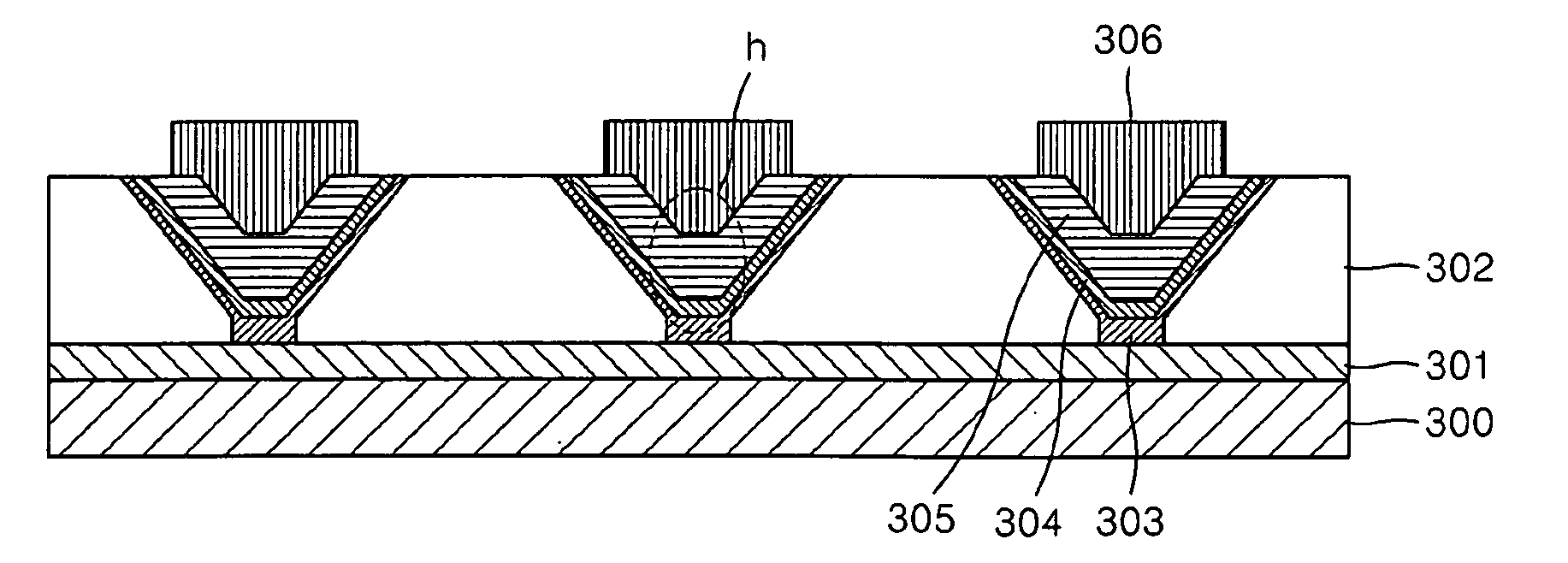

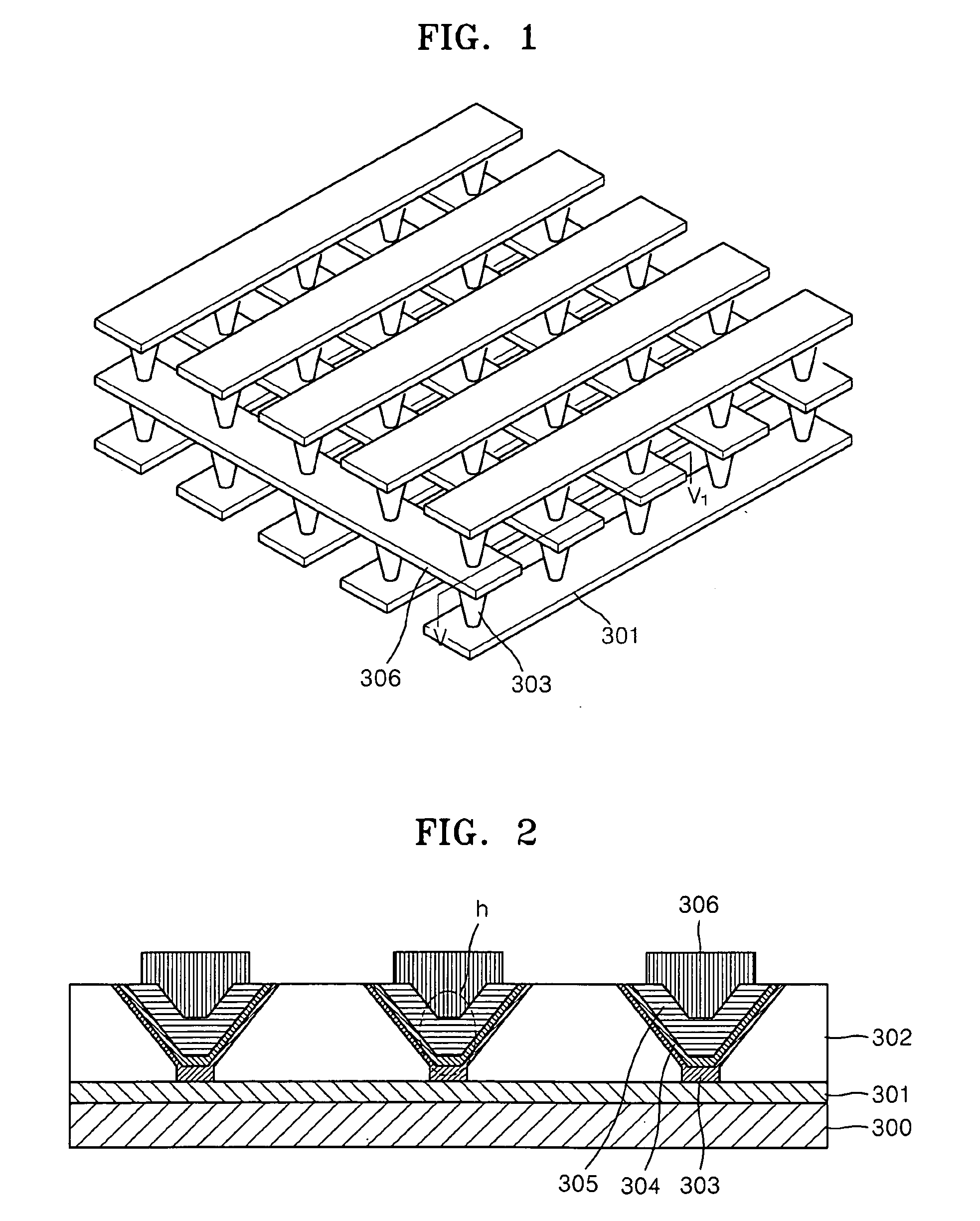

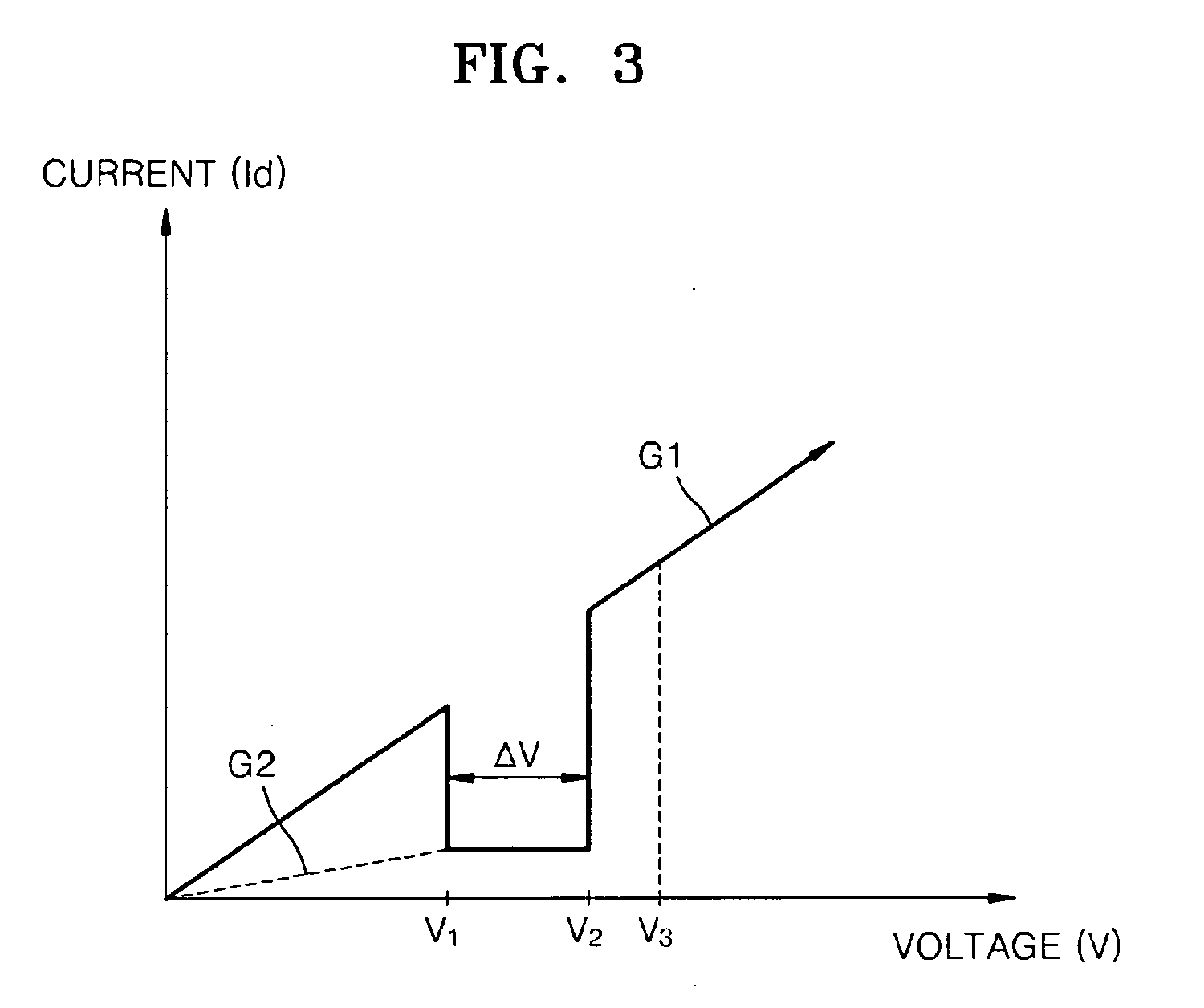

Cross point memory arrays, methods of manufacturing the same, masters for imprint processes, and methods of manufacturing masters

Owner:SAMSUNG ELECTRONICS CO LTD

Hard capsule

InactiveUS20060153909A1Impair stability of drugImpair propertyOrganic active ingredientsBiocideWater activityHard Capsule

Owner:WAKUNAGA PHARMA CO LTD

Health-care food with functions of improving immunocompetence and protecting damaged gastric mucosa and its preparing method

Owner:吉林云尚保健食品有限公司

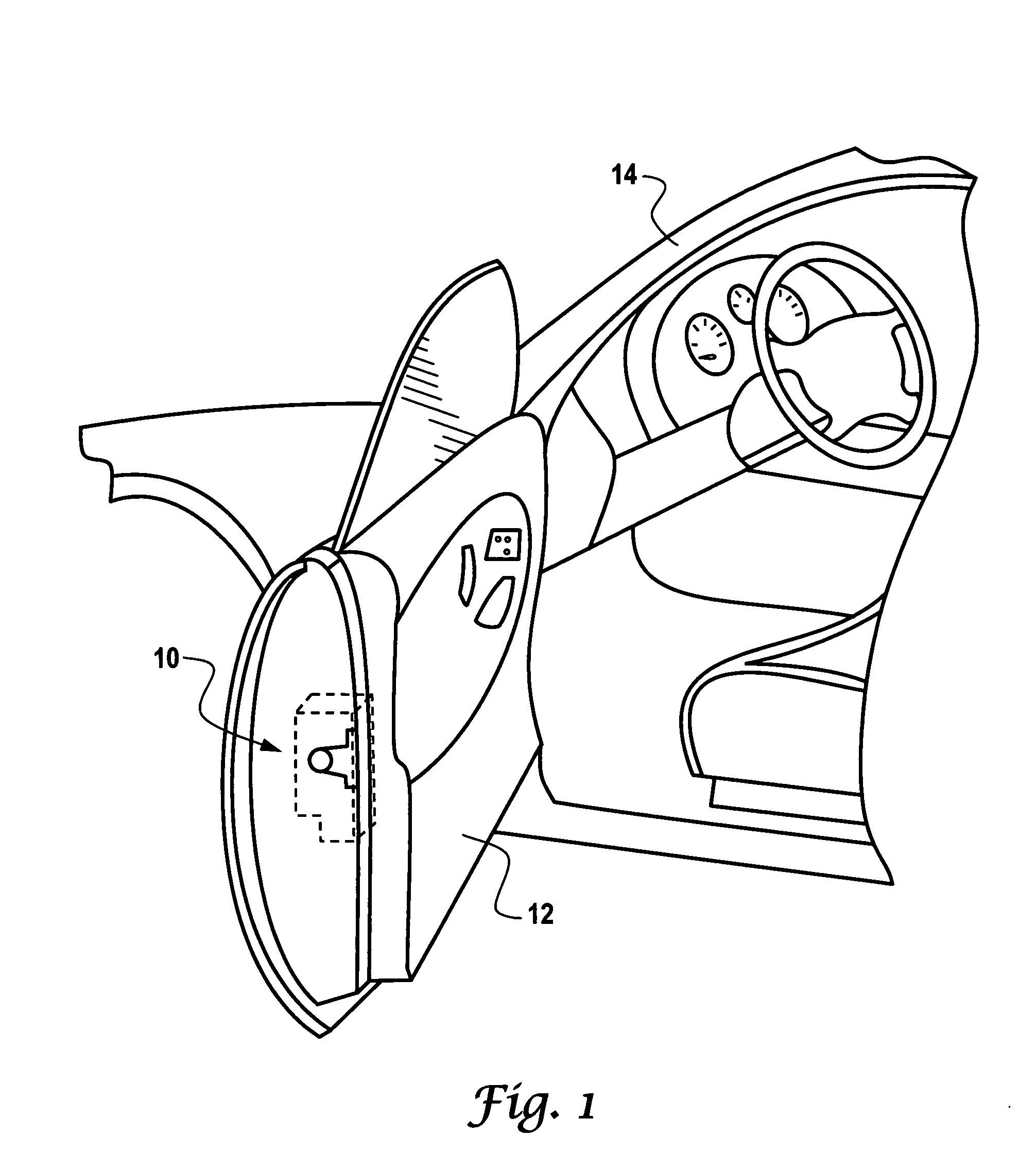

Circuit insulation methods and systems for vehicle door latches

Owner:HONEYWELL INT INC

Mushroom powder rich in vitamin D2, and preparation method and application thereof

InactiveCN109527530AMeet the process requirementsAvoid over dryingOrganic active ingredientsFruits/vegetable preservation by irradiation/electric treatmentUltraviolet lightsNitrogen gas

The invention relates to the field of domestic fungus processing, and discloses a mushroom powder rich in vitamin D2, and a preparation method and an application thereof. The preparation method comprises the following steps: slicing a mushroom raw material, and performing ultraviolet irradiation treatment in an environment having a temperature of 20-55 DEG C and a relative humidity of 50-85%, wherein the ultraviolet light irradiation is a combination of 280-315 nm UVB irradiation and 200-280 nm UVC irradiation, and the water content of the mushroom raw material is not less than 20%; drying theultraviolet-irradiated mushroom raw material under a nitrogen-filling condition; and crushing the dried mushroom raw material. The conversion rate of ergosterol into the vitamin D2 is improved by controlling the wavelength, temperature and humidity conditions during ultraviolet irradiation treatment, and a nitrogen-protected drying process is adopted to avoid the vitamin D2 from forming isomer impurities or from being degraded and lost in order to improve the quality of the mushroom powder product.

Owner:瞿瀚鹏

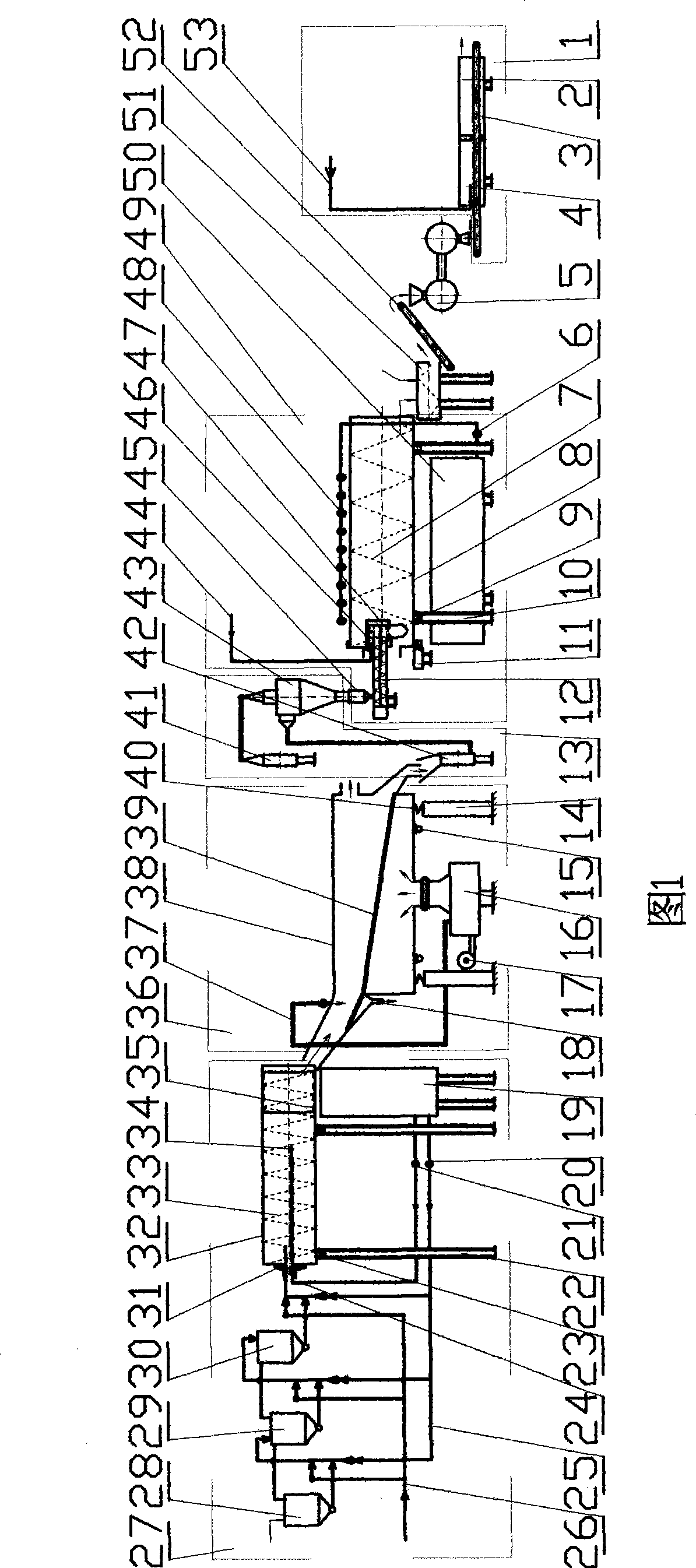

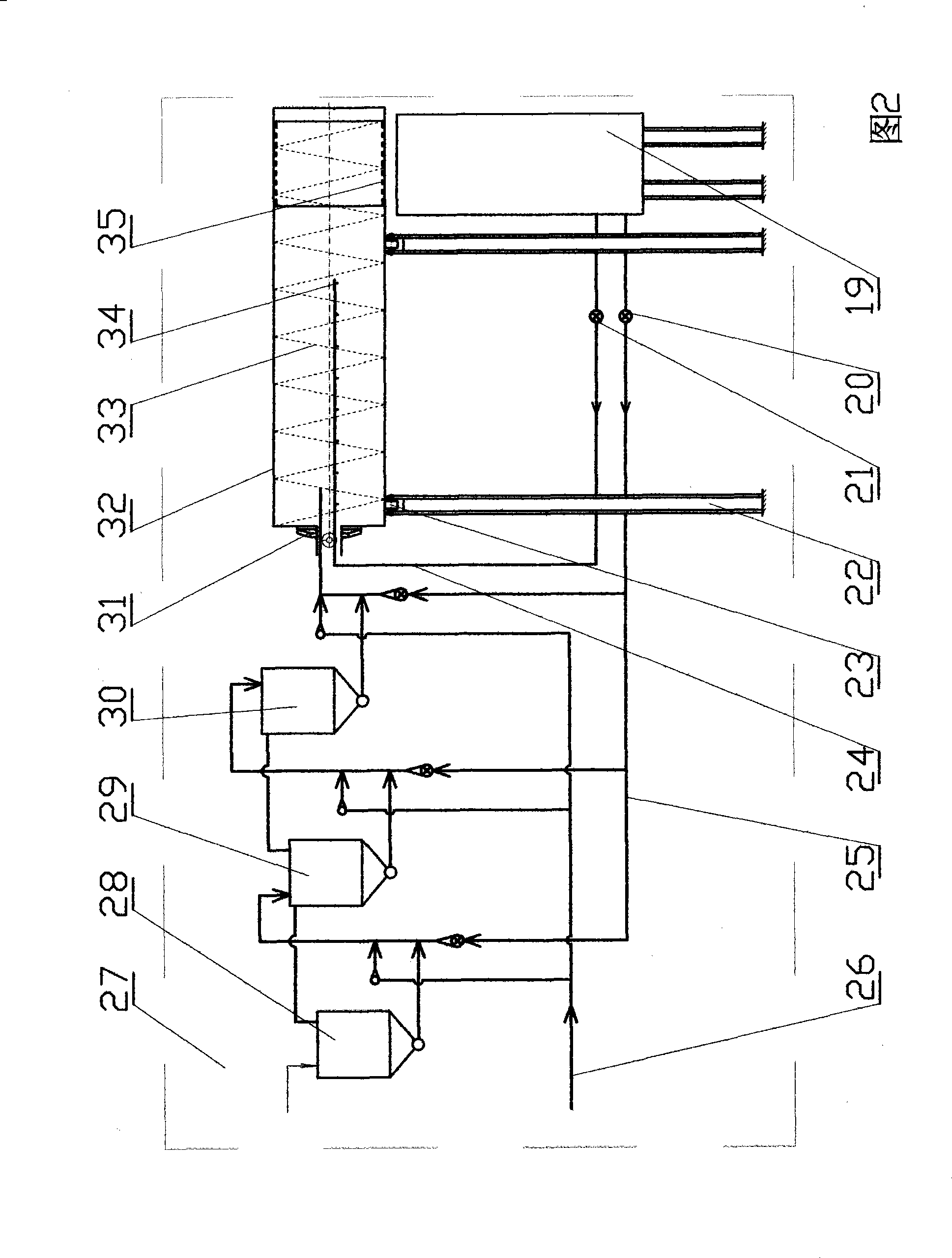

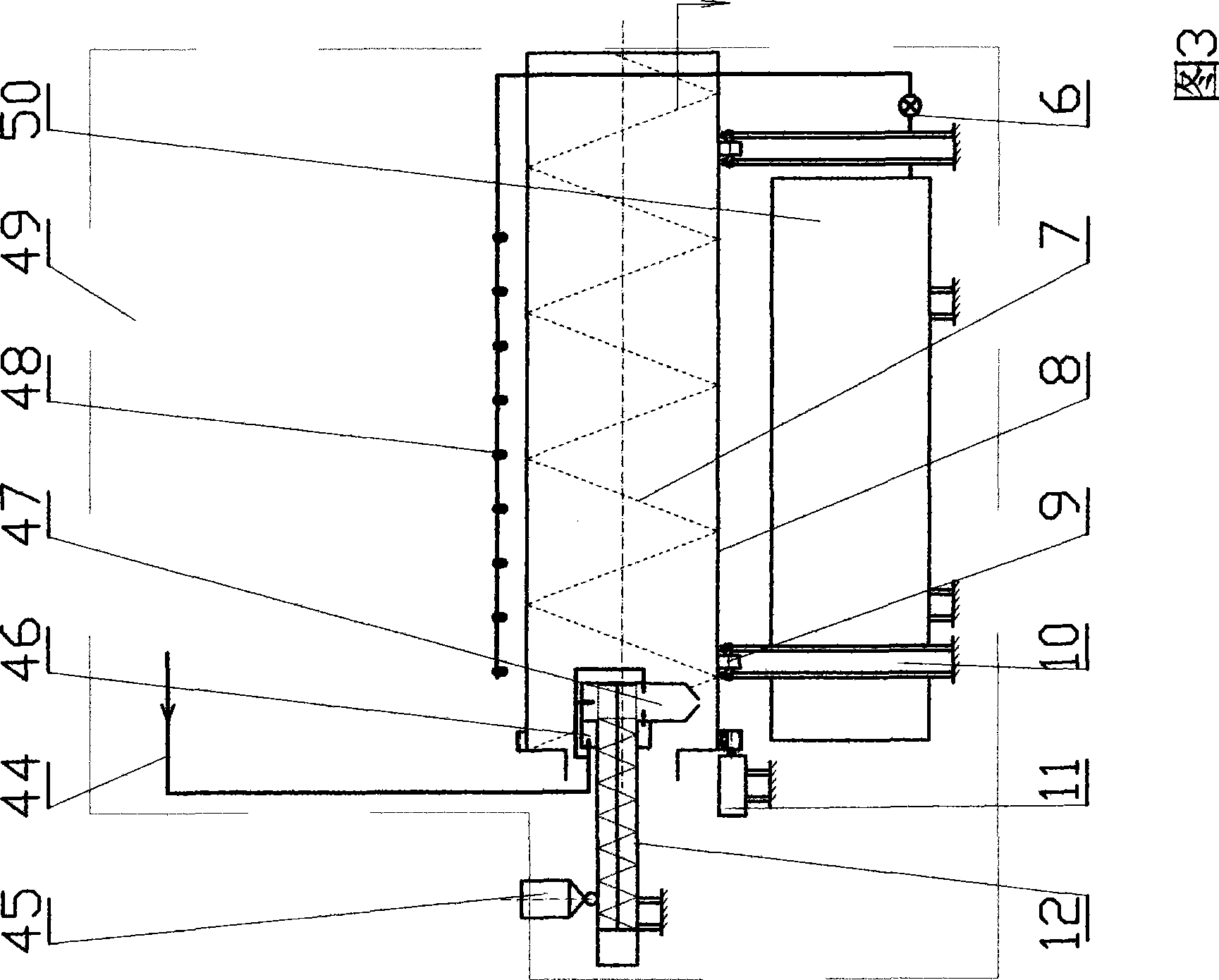

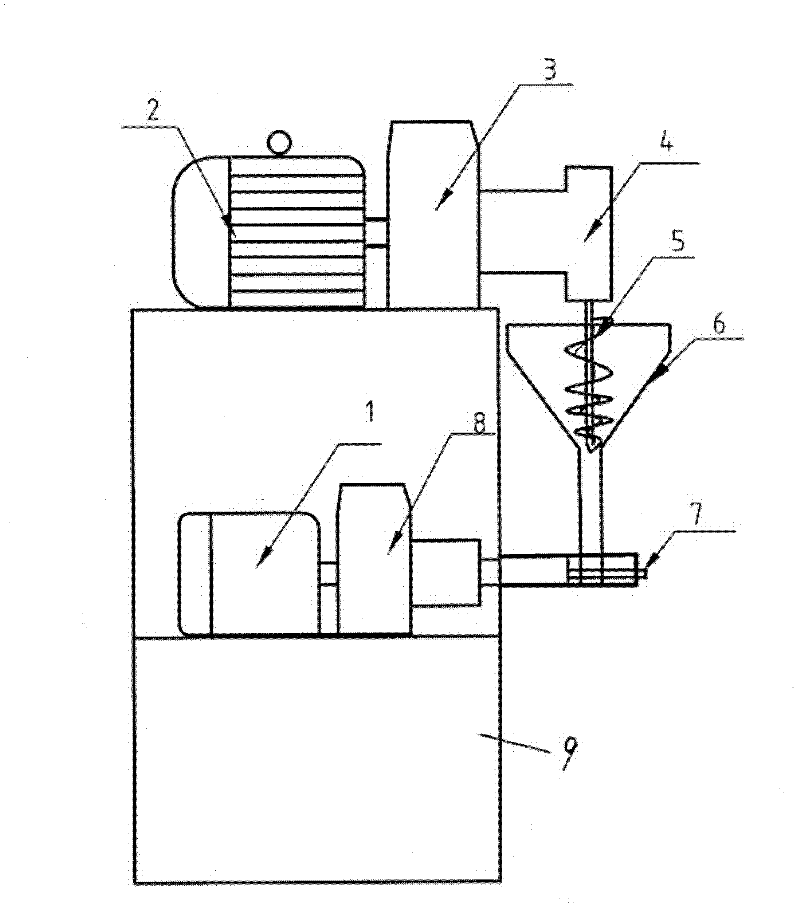

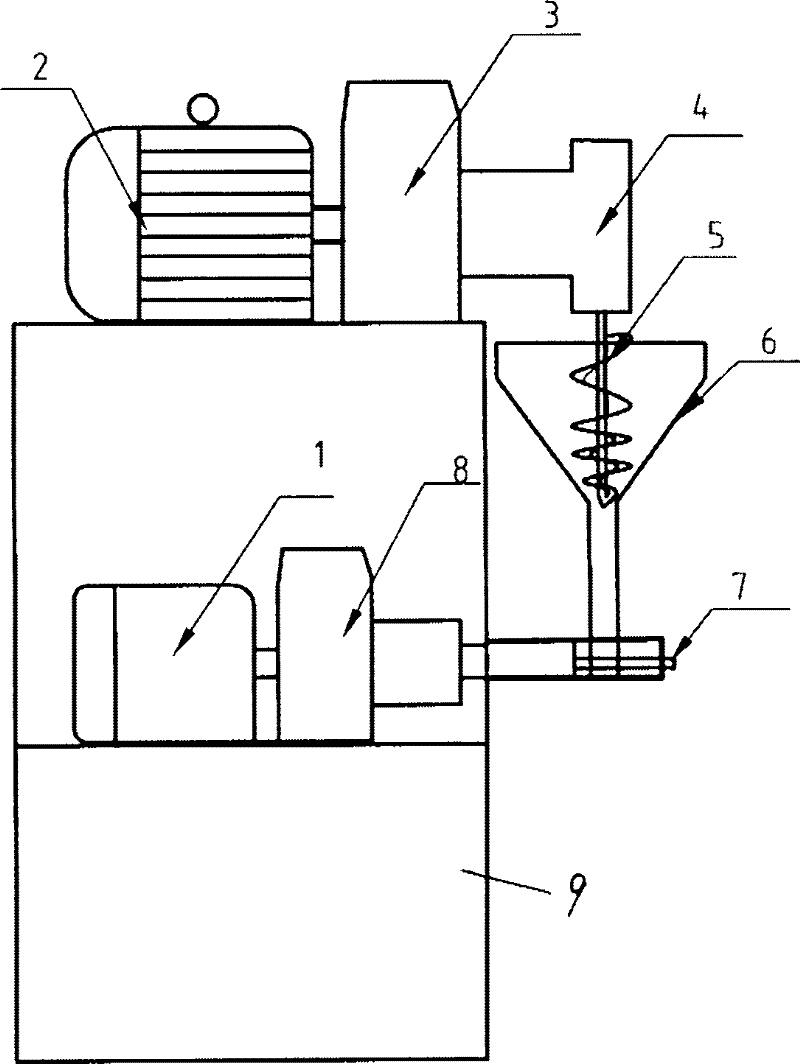

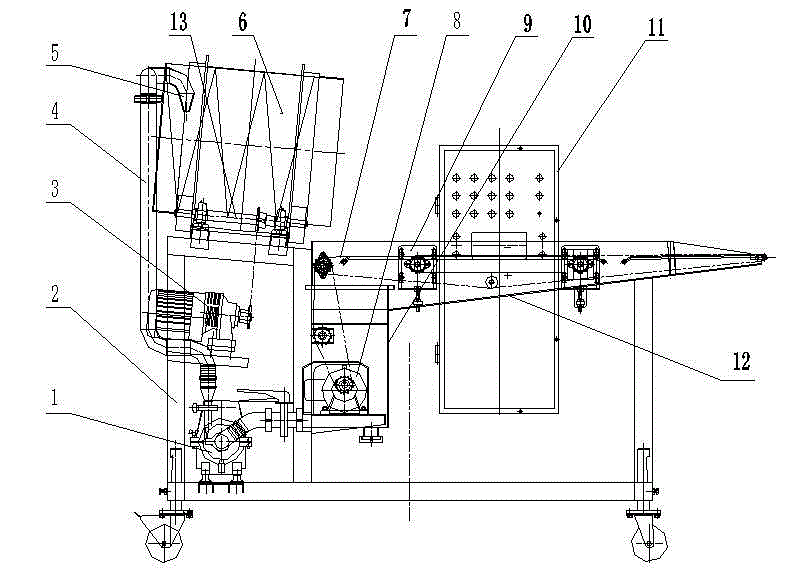

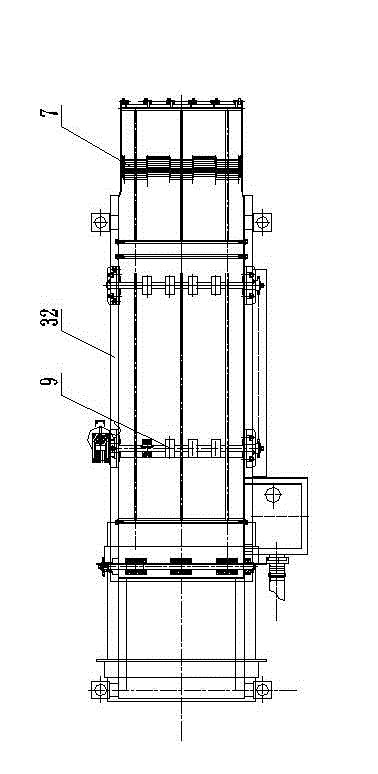

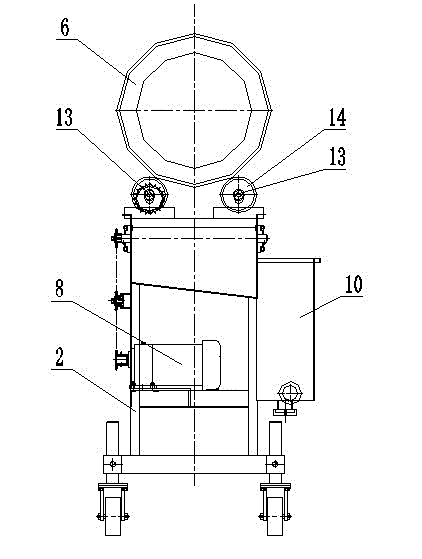

Dry-type three-segment mature-method rice powder set

InactiveCN101455295AReduce viscosityAvoid affecting product qualityFood shapingFood preparationAdditive ingredientEngineering

Owner:湖南省天龙米业有限公司

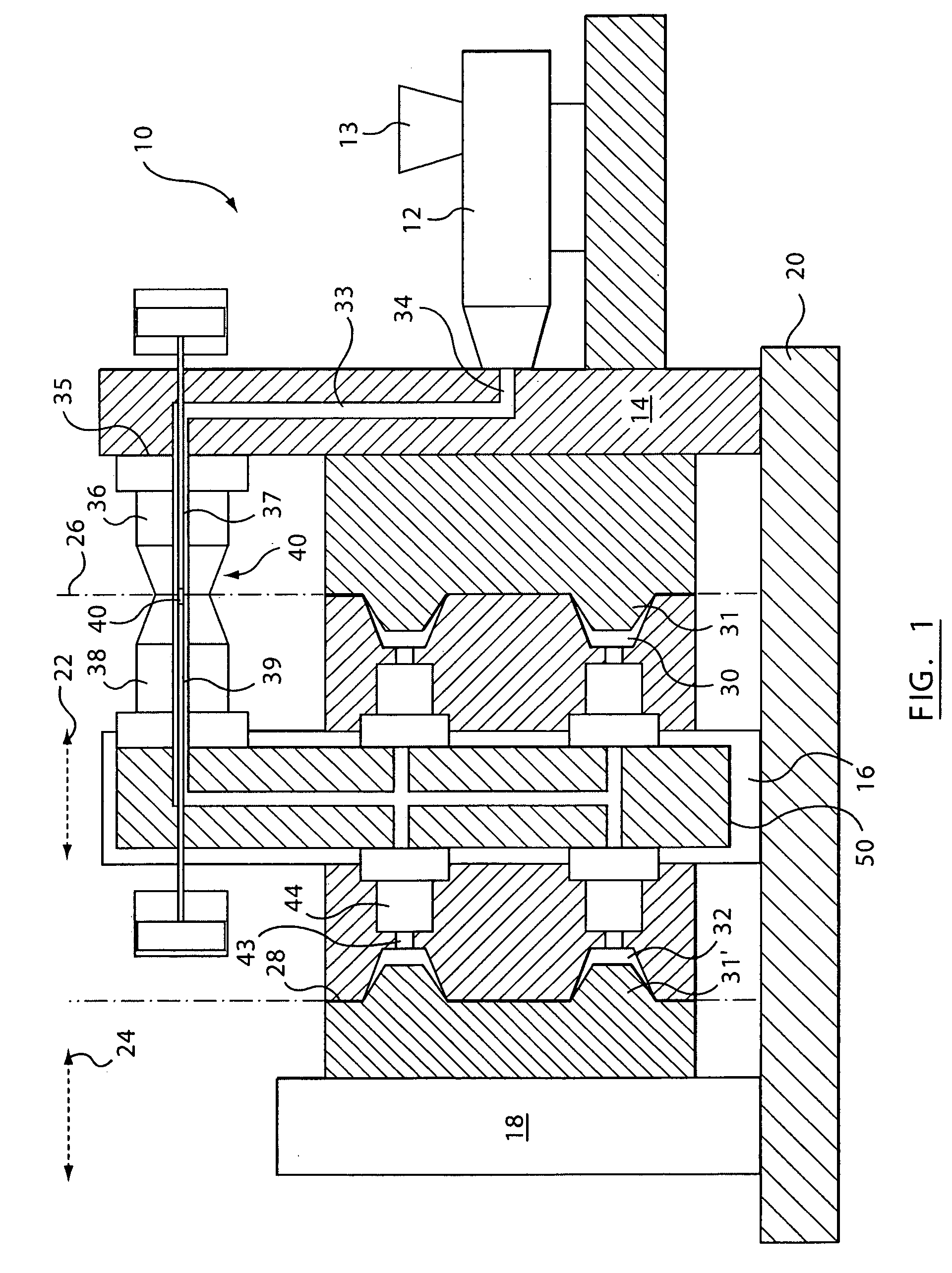

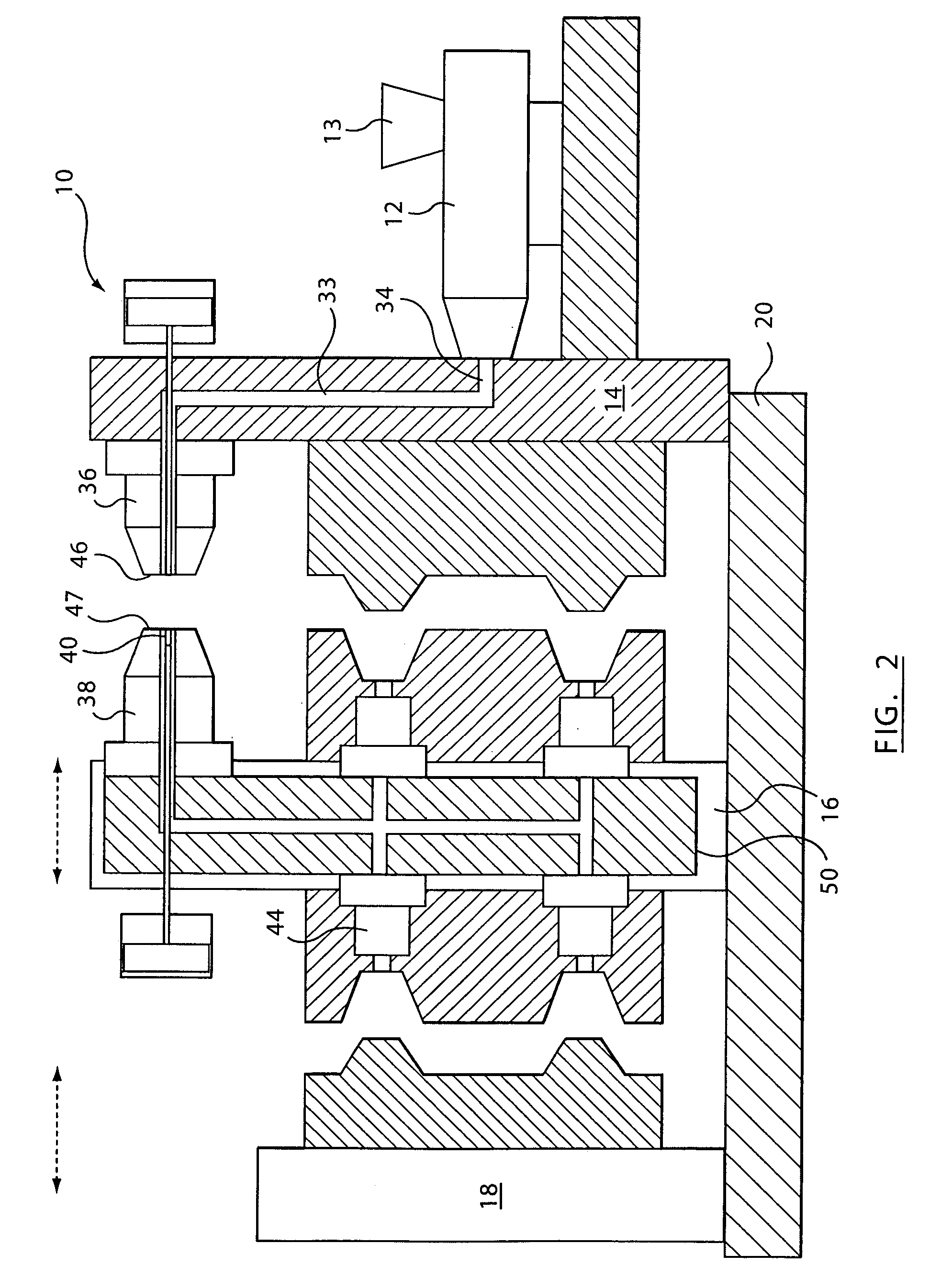

Stack mold having a melt homogenizing element

Owner:MOLD MASTERS 2007

Imprinting apparatus and imprinting method using the same

InactiveUS20110298159A1Easy to solveTailstocks/centresConfectioneryEngineeringMechanical engineering

Owner:LG DISPLAY CO LTD

High-protein high-fiber solid beverage

Owner:陕西中鸿科瑞再生医学研究院有限公司

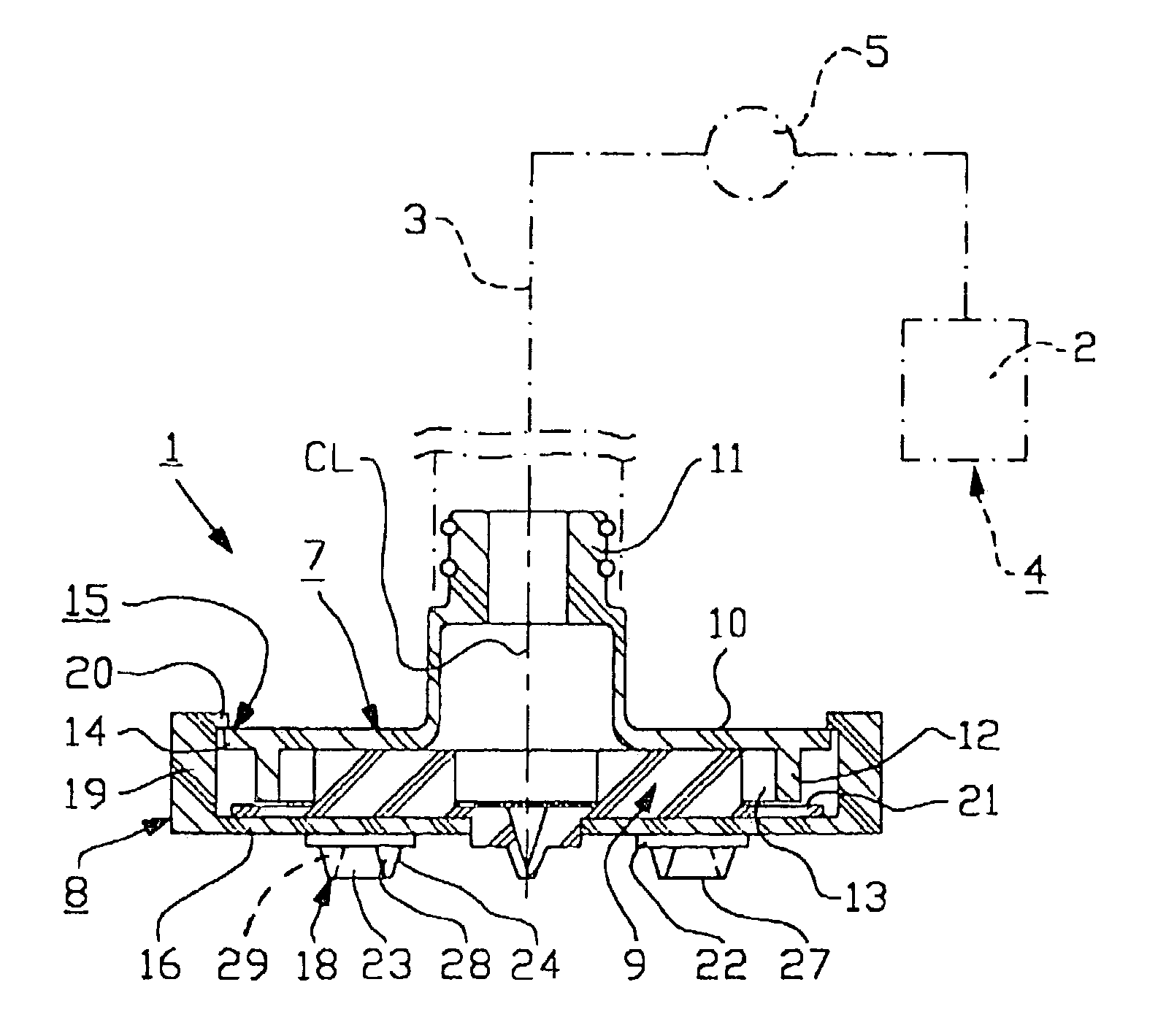

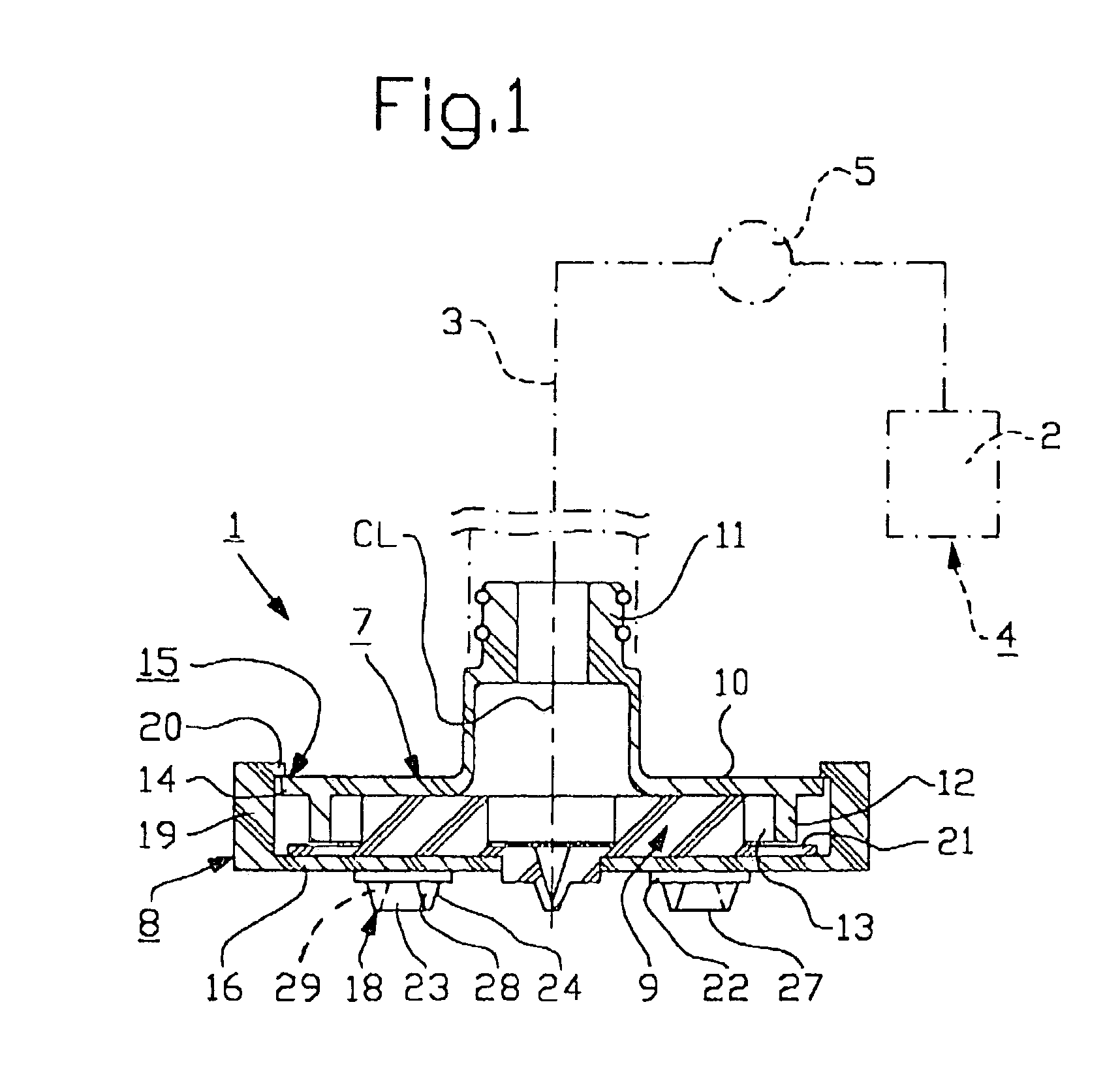

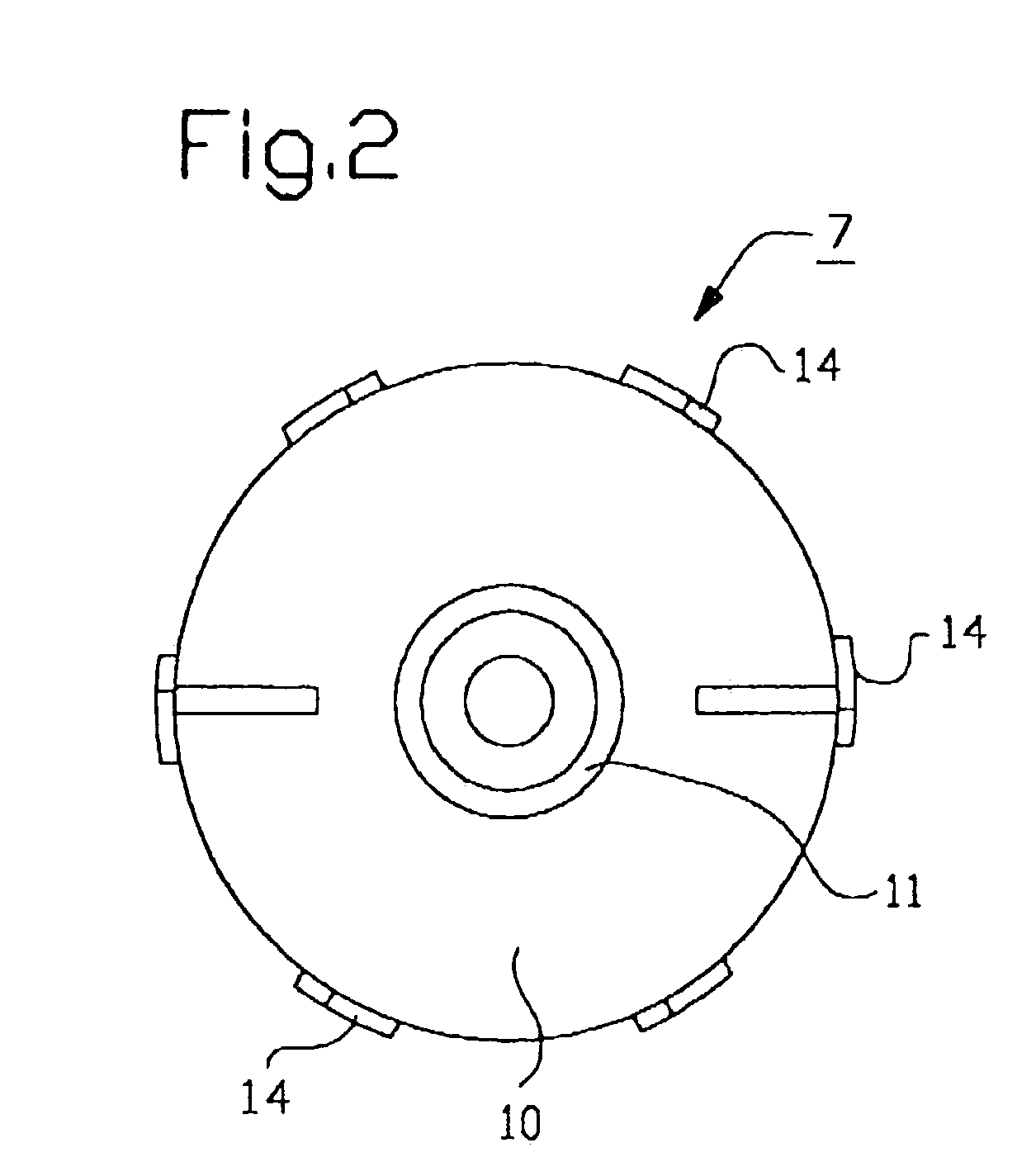

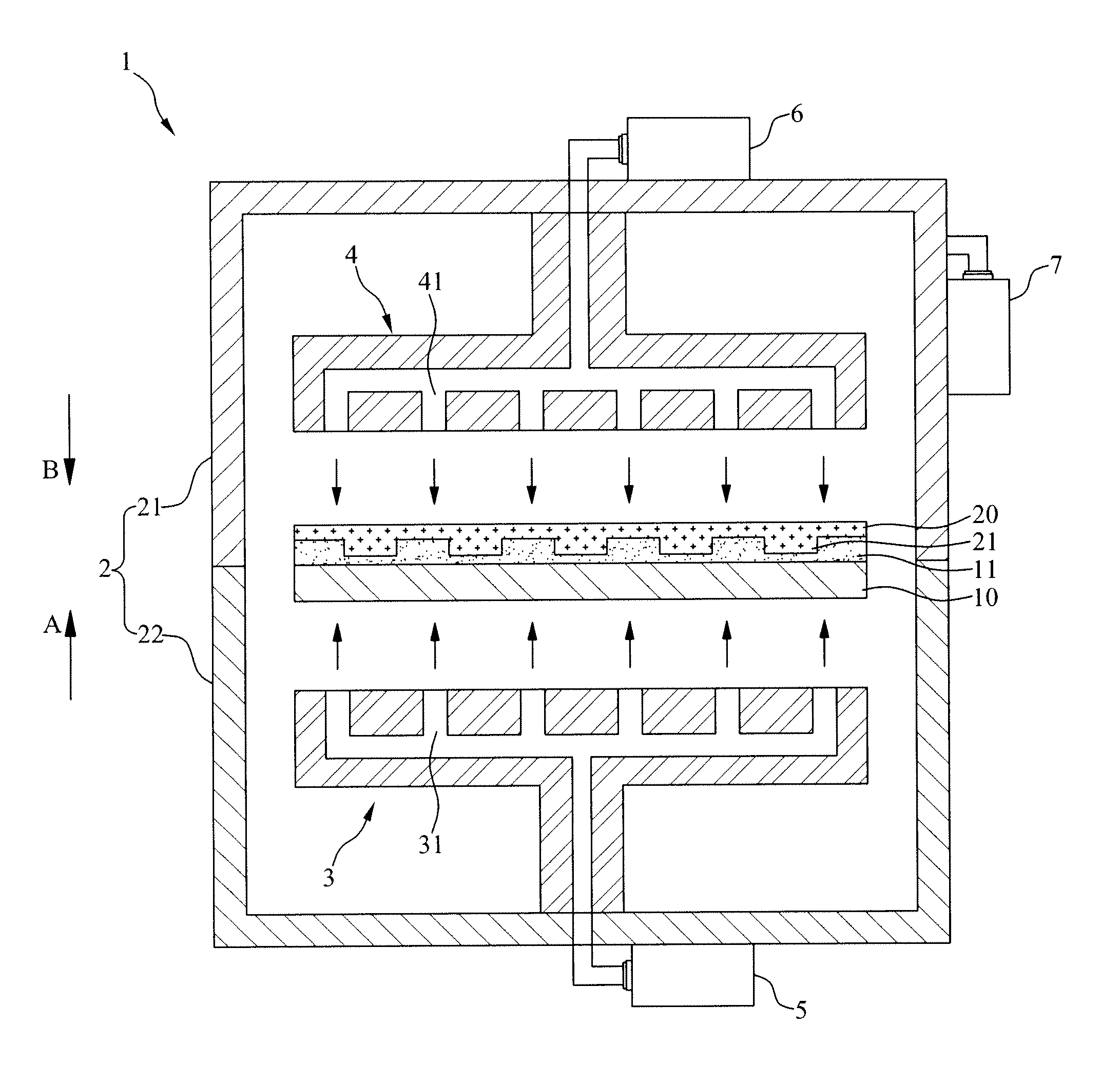

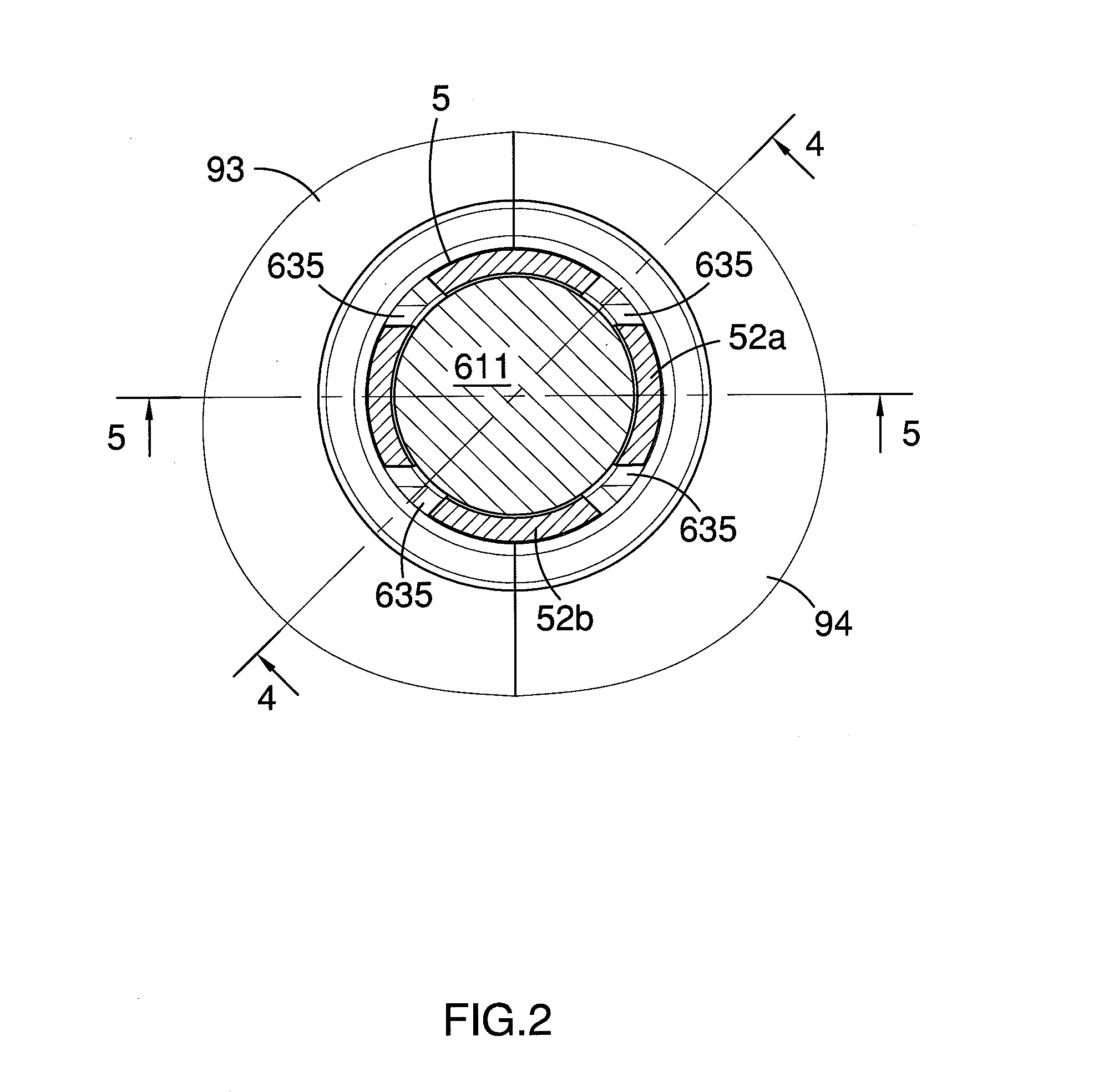

Substrate forming mold, and plate thickness adjusting method of formed substrate in substrate forming mold

A substrate forming mold for forming a substrate by filling a cavity formed between a pair of matching molds 1, 2 with resin, that is, this substrate forming mold has shims 9, 12 disposed at least between a mirror finished surface plate 6 for composing one mold 1 and a stable mold base 8, and in a region inside of a fixed abutting ring 13, depending on fluctuations of plate thickness of formed substrate. As a result, the plate thickness of formed substrate can be adjusted finely, and fluctuations occurring in the radial direction or peripheral direction of the formed substrate can be decreased.

Owner:PANASONIC CORP

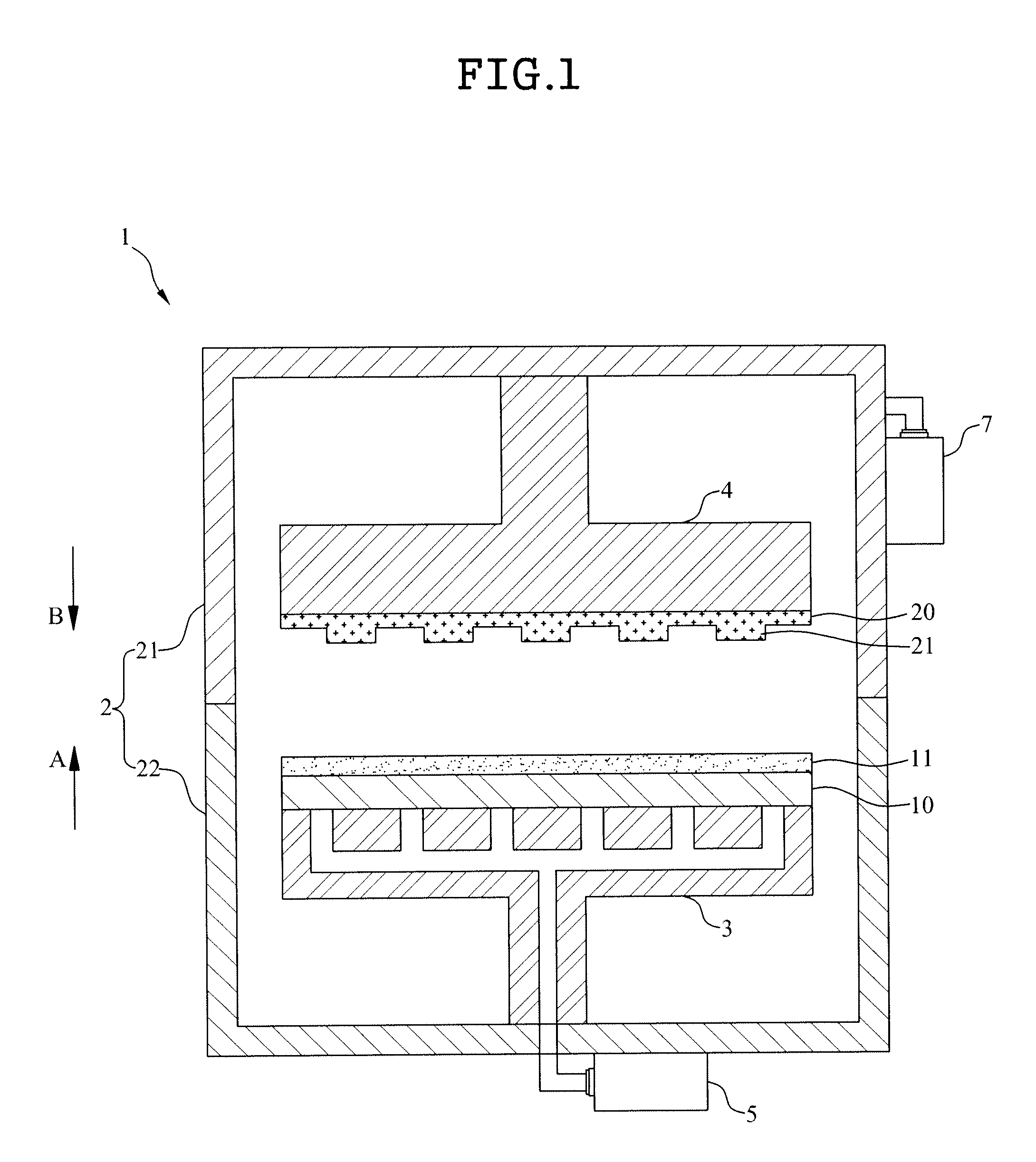

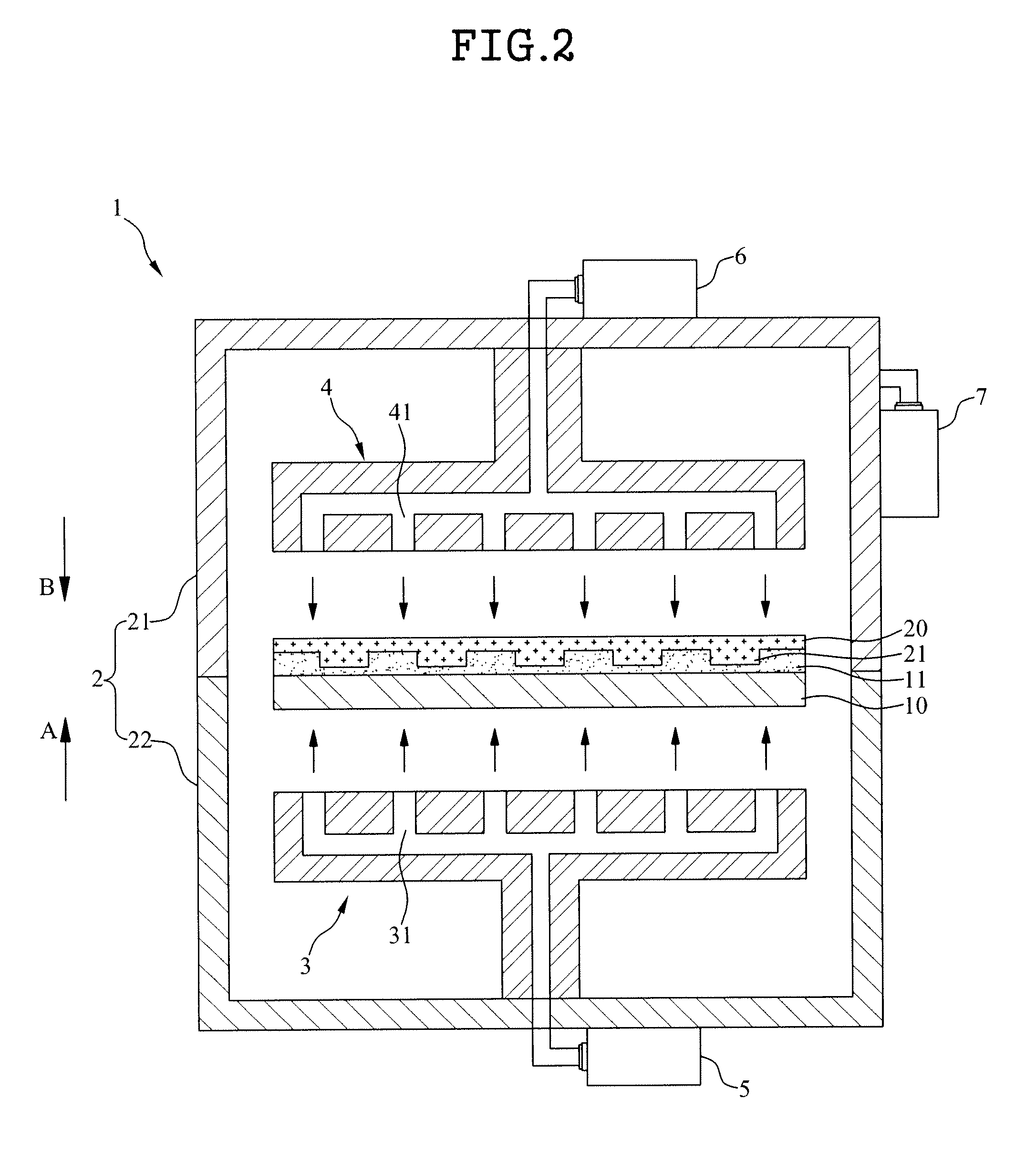

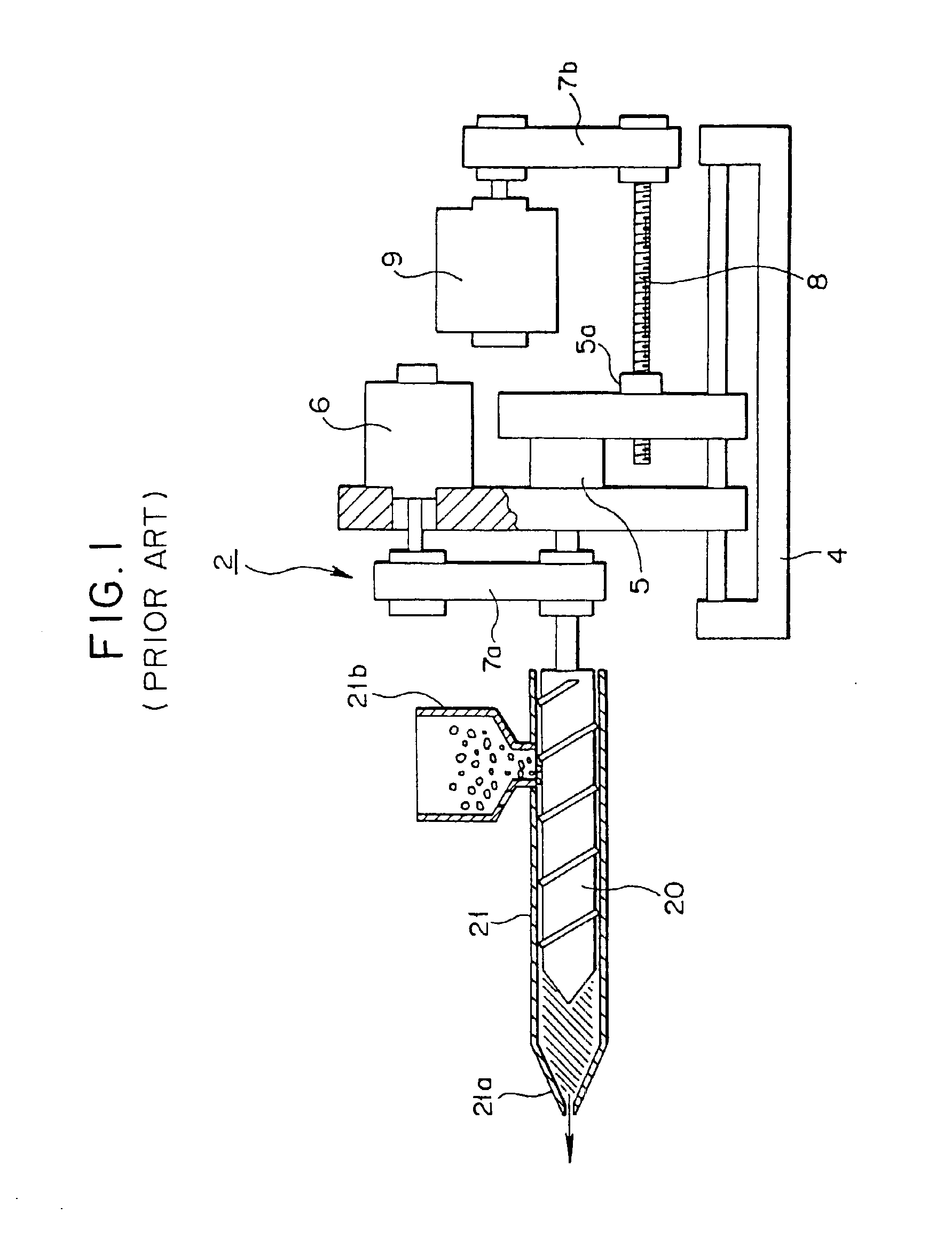

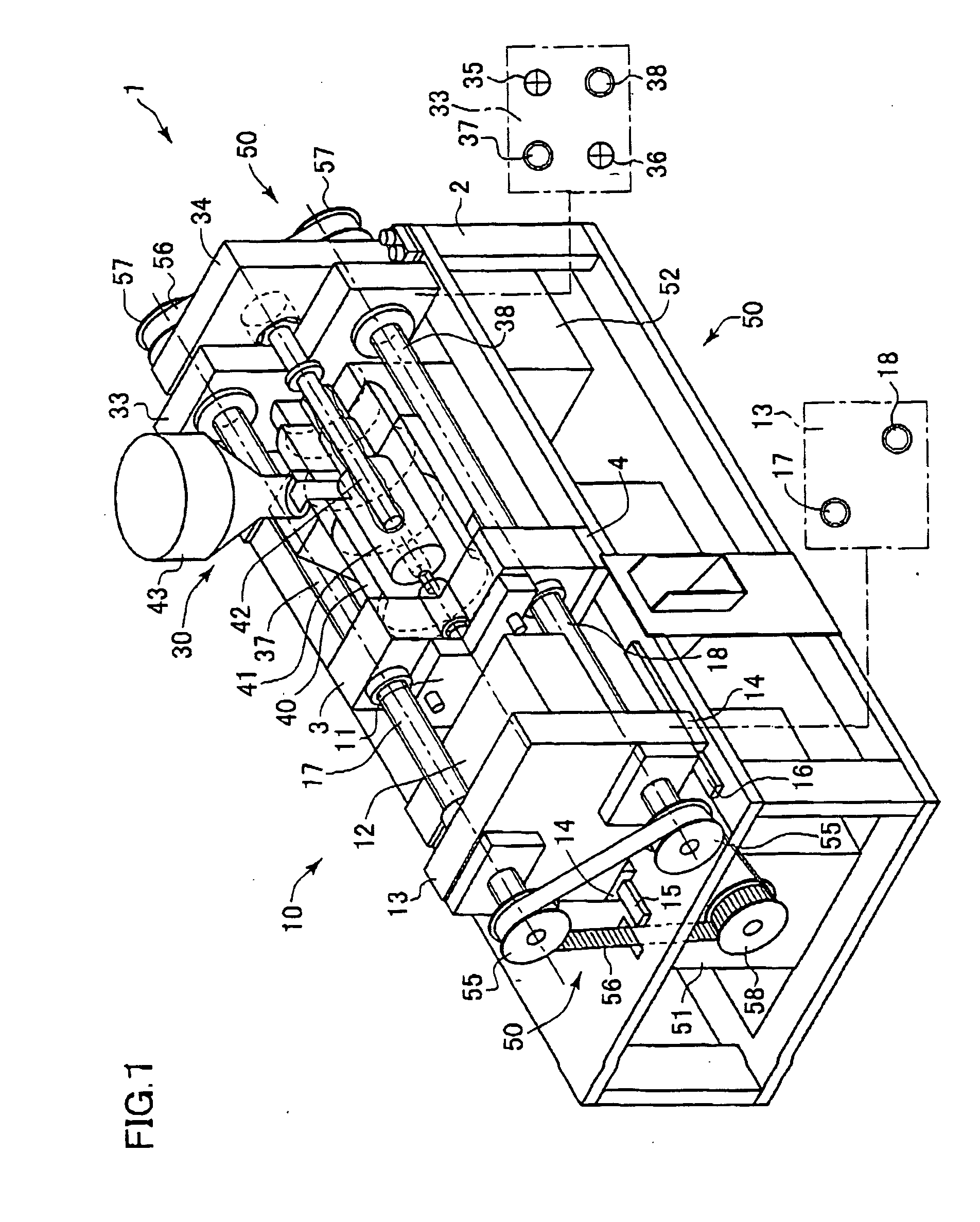

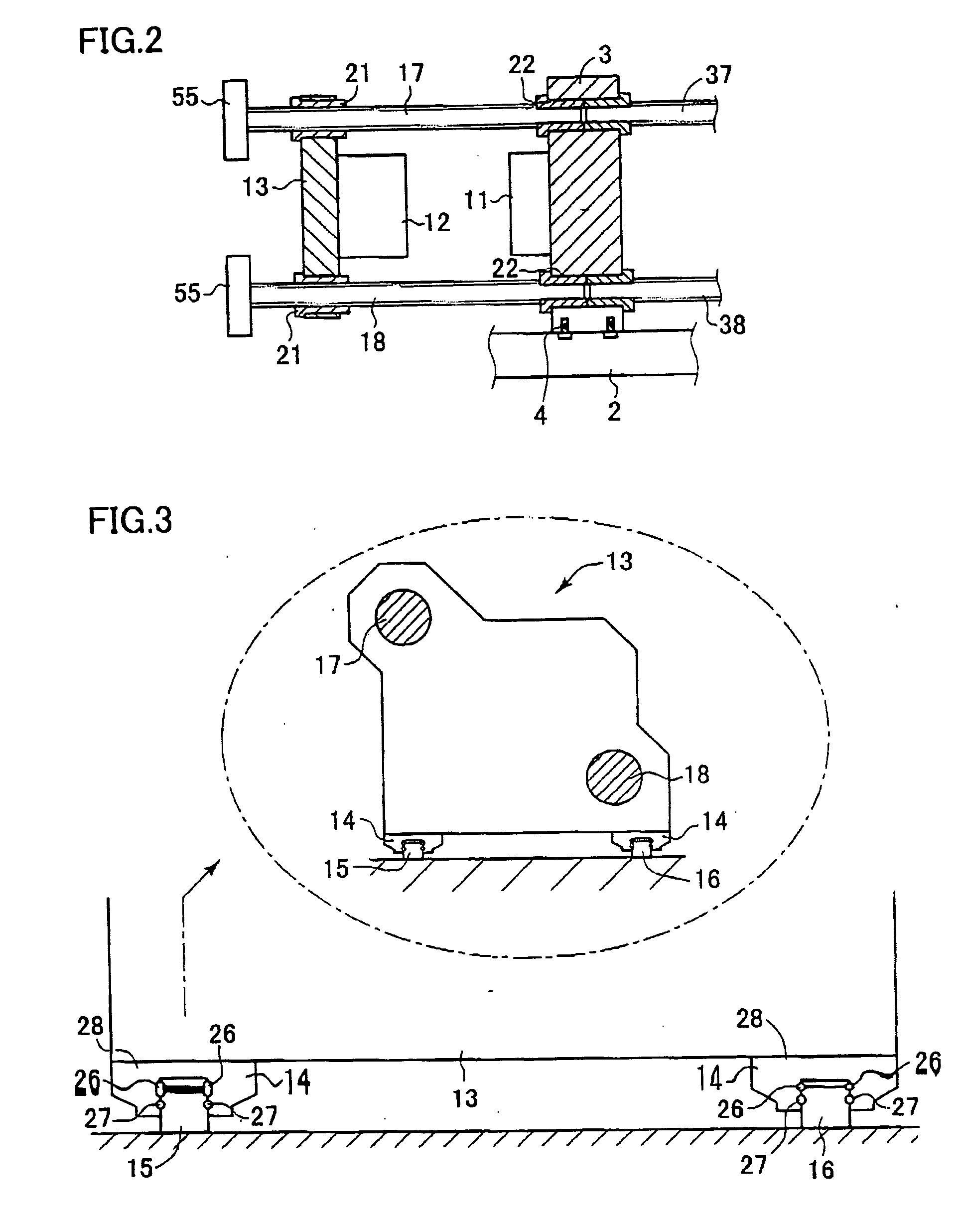

Injection molding machine

InactiveUS7234928B2Easy to assembleEasy maintenanceAuxillary shaping apparatusFood shapingLinear motionDrive shaft

Owner:SUMITOMO HEAVY IND LTD

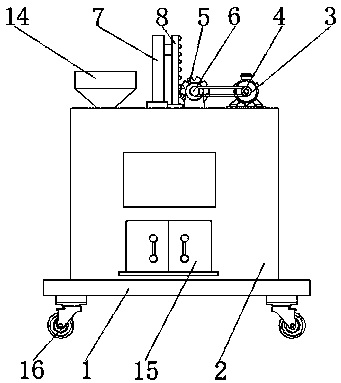

Novel environment-friendly and energy-saving vermicelli manufacturing device

Owner:佛山市天宇鸿图创新科技有限公司

Double-motor speed-adjusting ball making machine

Owner:SHANDONG HUIFA FOODS

Food starching machine

Owner:JINAN HIWELL MACHINERY

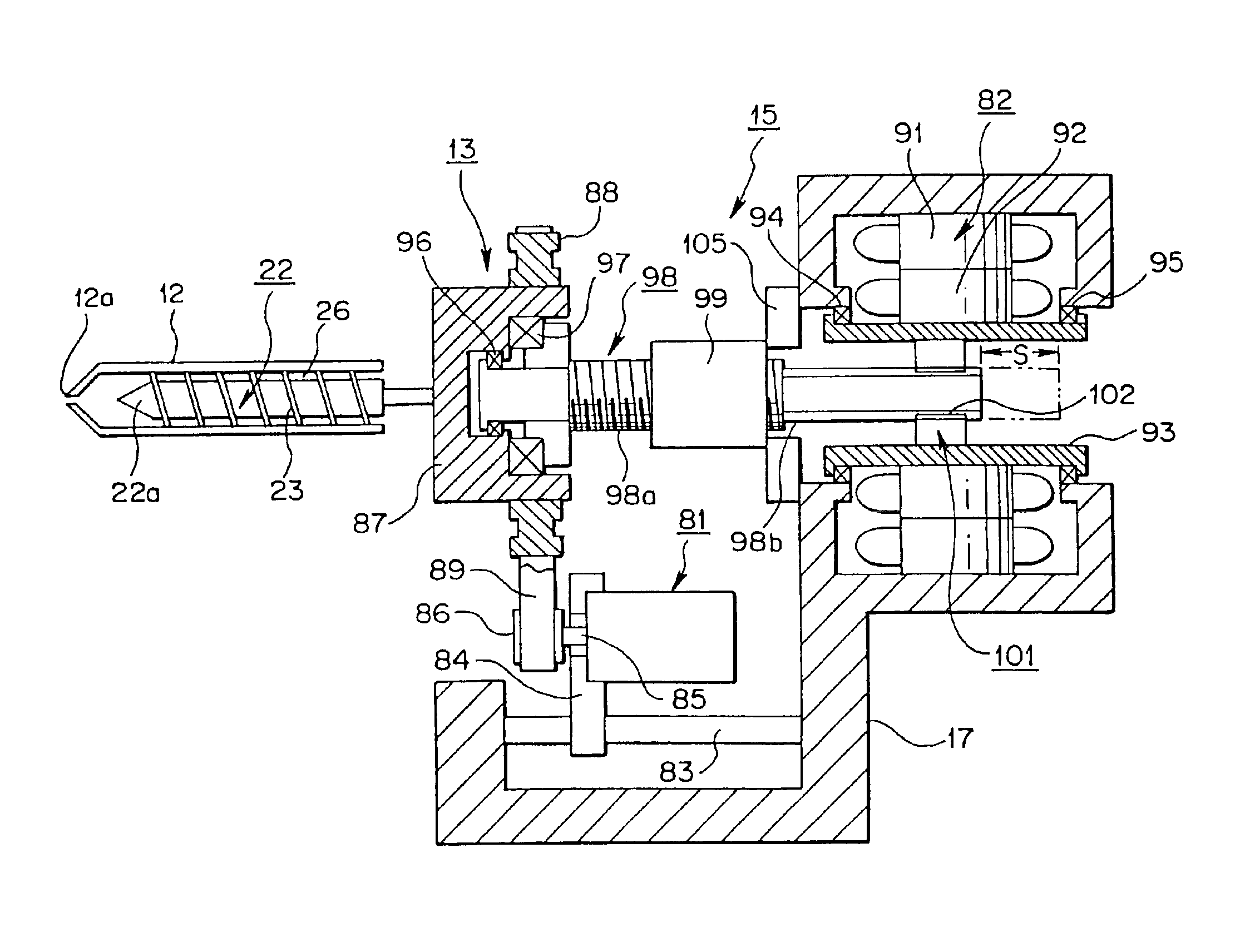

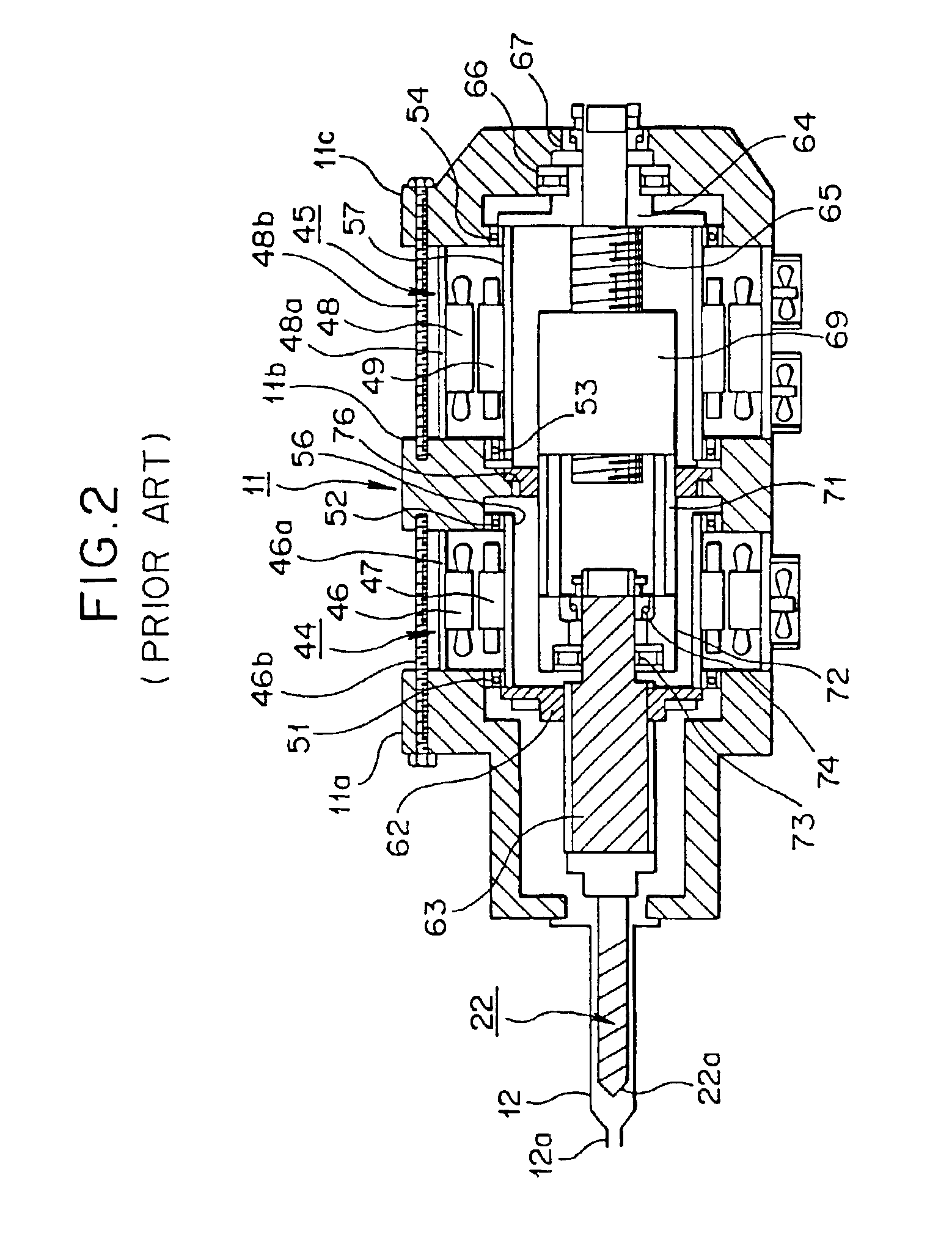

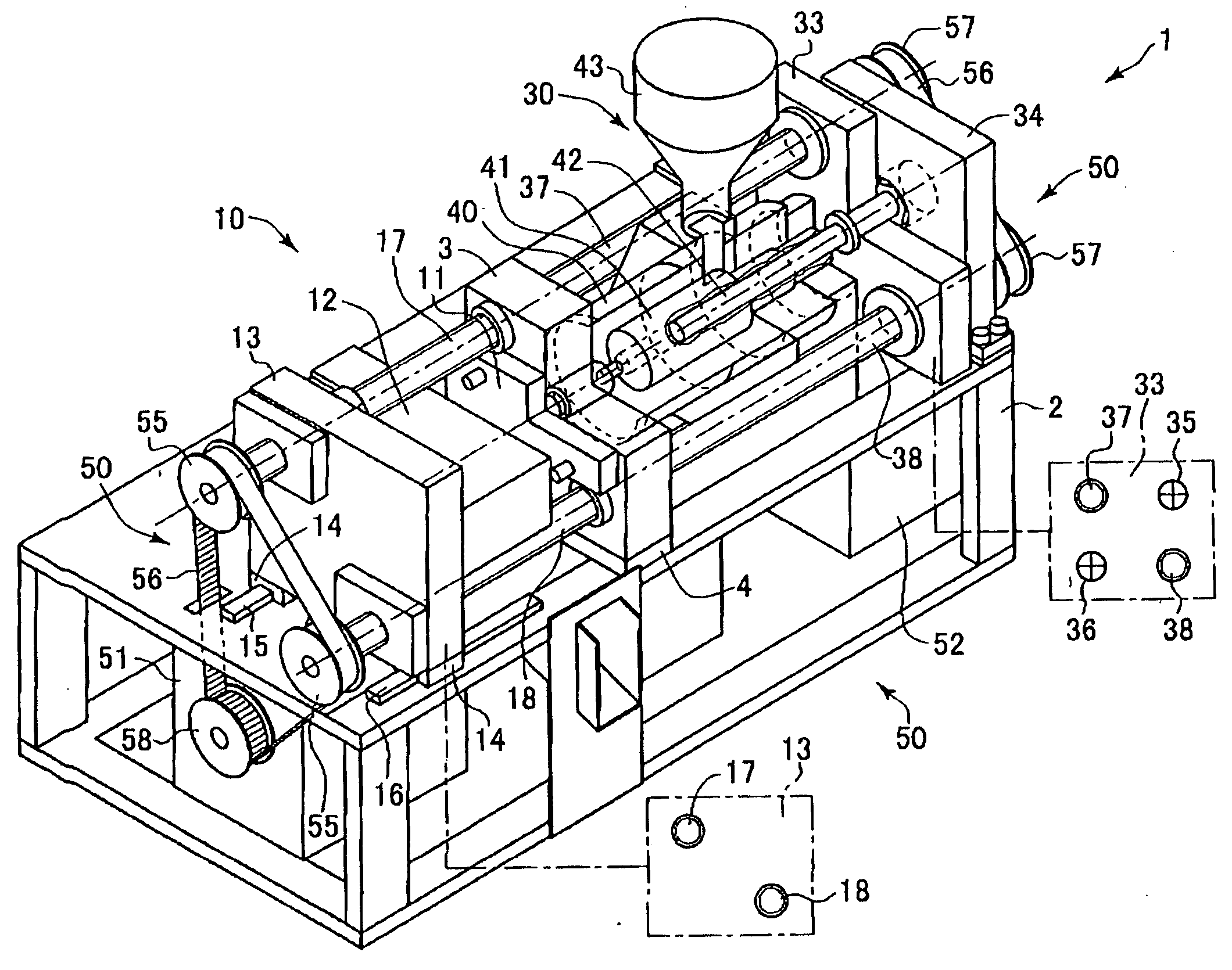

Motor-driven injection molding apparatus

InactiveUS20050074517A1Reduce the number of partsSimple structureCeramic shaping apparatusFood shapingTiming beltBall screw

Owner:DAIWA KASEI IND CO LTD

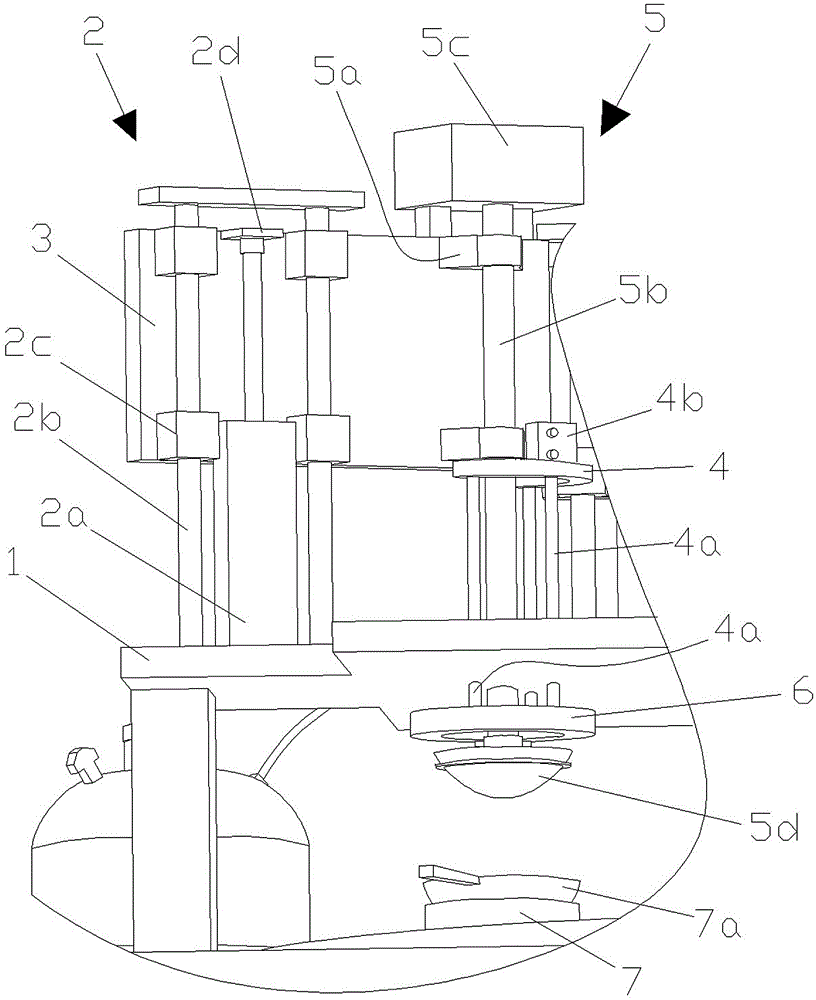

Continuous food 3D printer

The invention relates to the technical field of agricultural product processing equipment, and provides a continuous food 3D printer, which comprises a rotating platform, a clamping extrusion mechanism, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism and a plurality of raw material extrusion heads; the plurality of raw material extrusion heads are detachably connected to the rotating platform; the Z-axis motion mechanism drives the Y-axis motion mechanism to move in the Z-axis direction, the Y-axis motion mechanism drives the X-axis motion mechanism to move inthe Y-axis direction, and the X-axis motion mechanism drives the clamping extrusion mechanism to move in the X-axis direction; the clamping extrusion mechanism is used for clamping the raw material extrusion heads and extruding the raw material from the raw material extrusion heads. The continuous food 3D printer is provided with the plurality of raw material extrusion heads, so that raw materialswith various tastes can be added to the printed food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

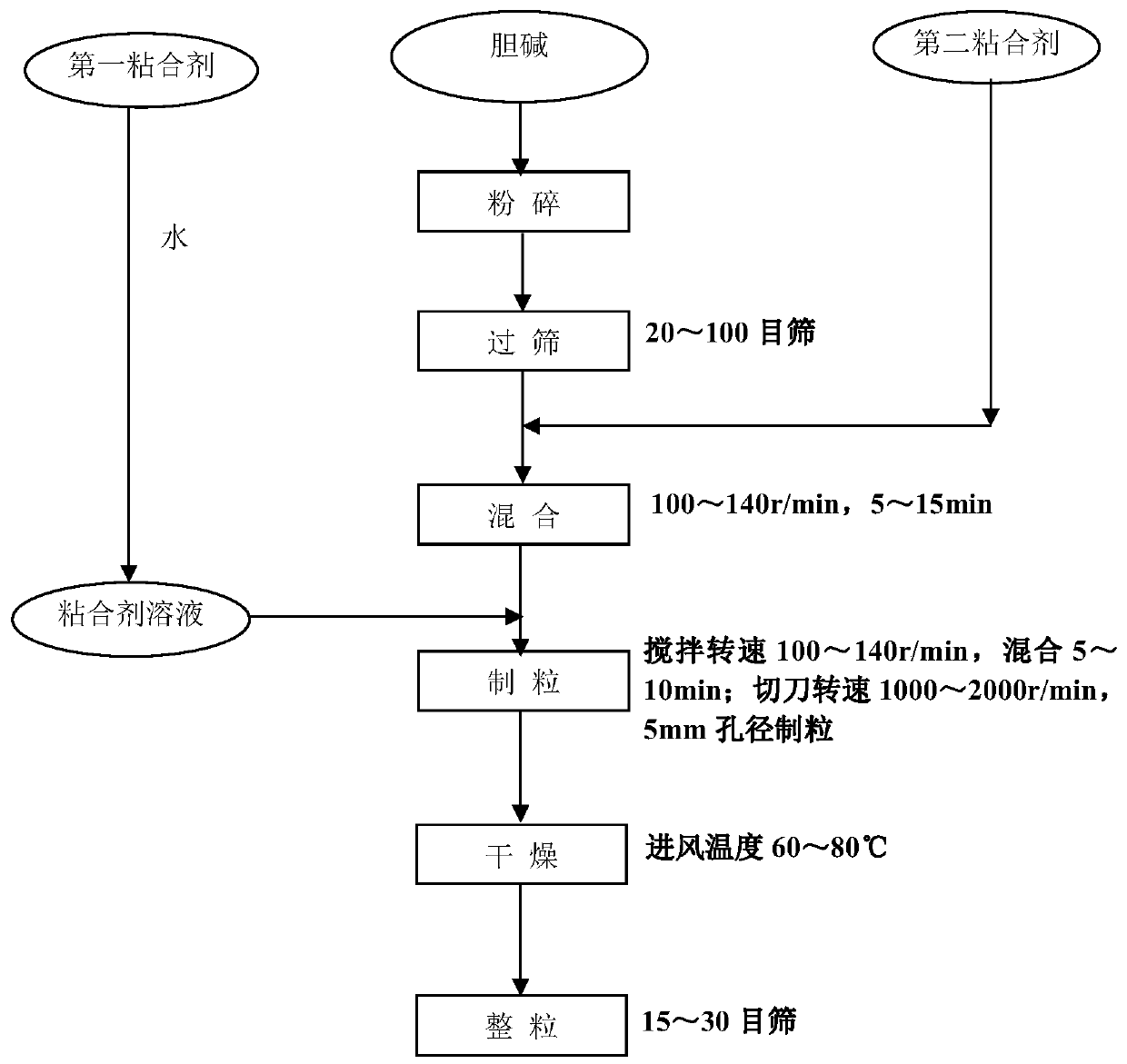

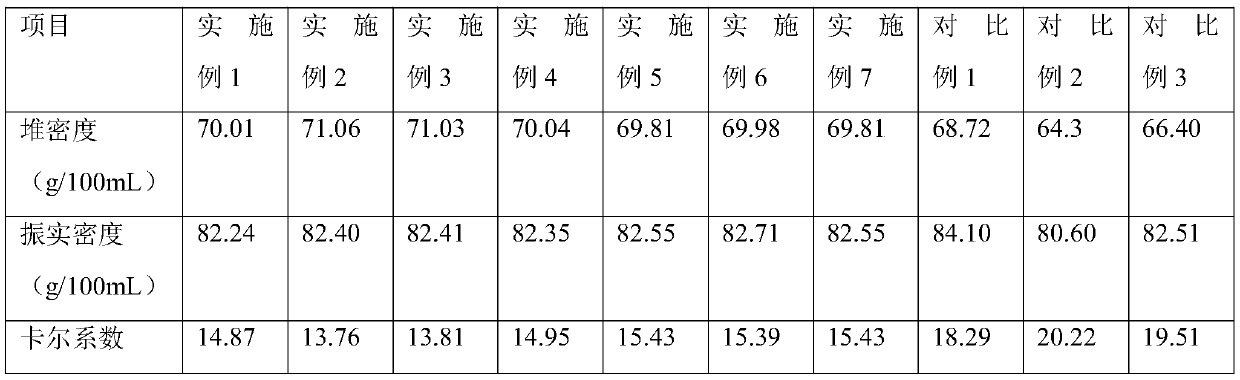

Choline particle and preparation method and application thereof

Owner:HANGZHOU MINSHENG HEALTHCARE CO LTD

Molding pressing device of hemispherical rice crust molding machine

Owner:安徽宏锦包装设备有限公司

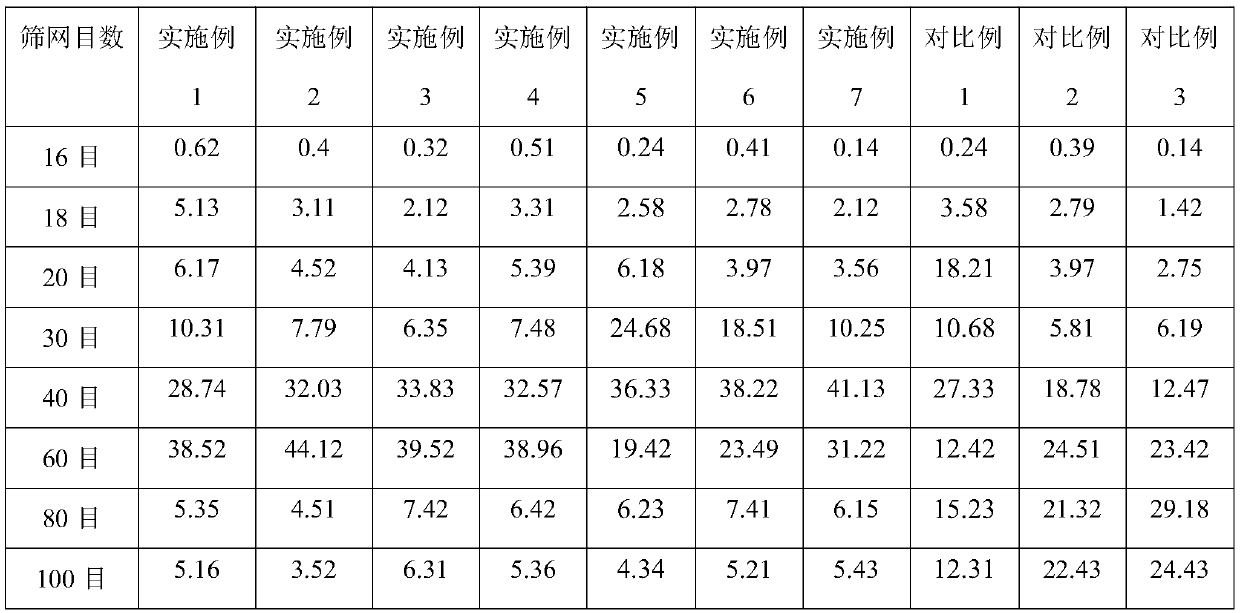

Processing technology of maca superfine powder

InactiveCN106509709AImprove dissolution rateHigh dissolution rateFood freezingFood shapingFreeze thawingBULK ACTIVE INGREDIENT

Owner:北京桔色控股集团股份有限公司 +1

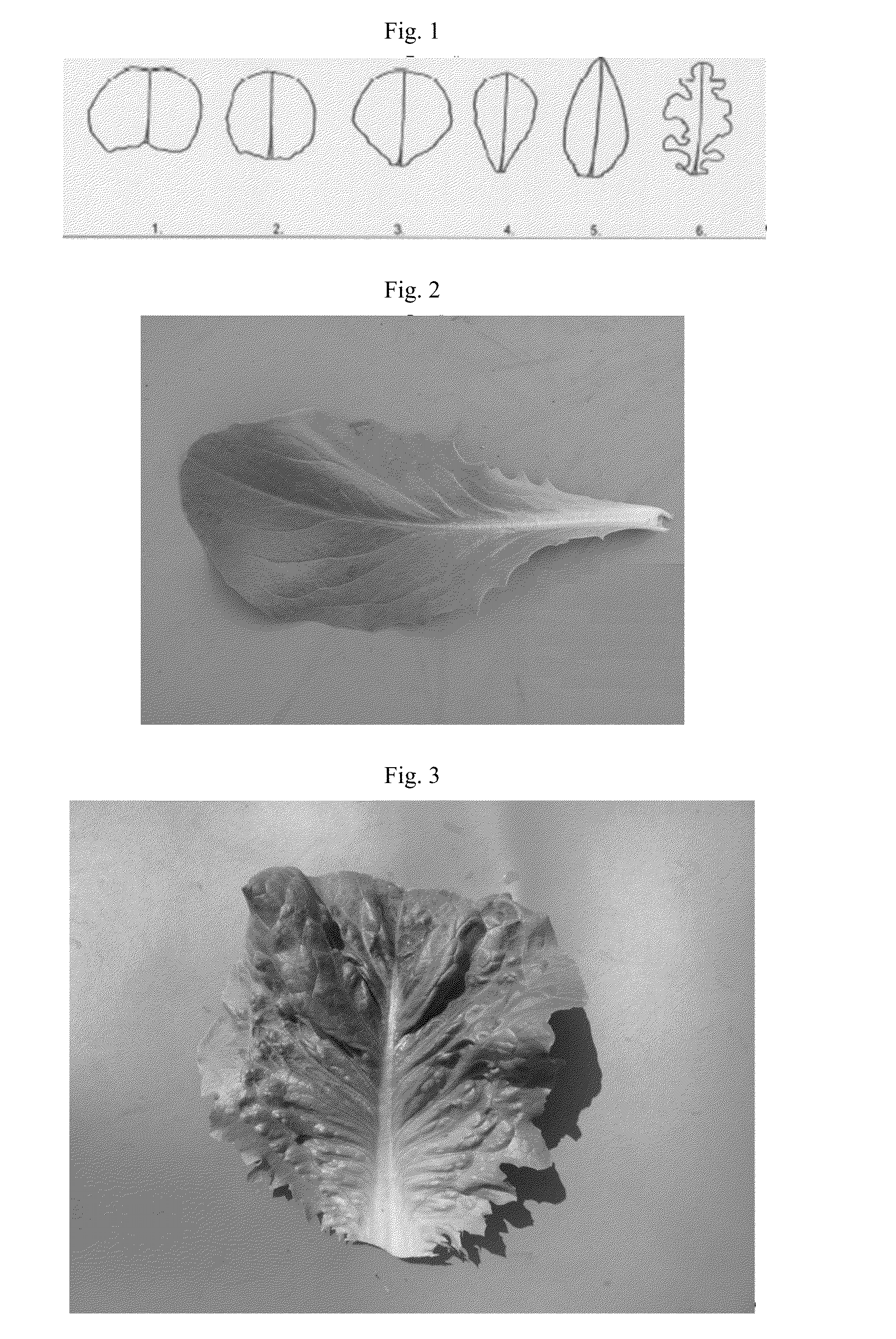

Lettuce variety 41-137 rz, "delibes rz"

InactiveUS20140020129A1Microbiological testing/measurementFood preservationBremia lactucaePemphigus bursarius

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

Ribbon cutter apparatus and method for making sandwich baked goods

A method for the continuous production of sandwich baked goods having a high volume of filler includes conveying a bottom base cake, detecting the position of the base cake, and extruding a filler through a die aperture to form a ribbon in response to the detection of the position of the bottom base cake. In response to detection of the base cake, a signal or timing mechanism may activate a guillotine knife or blade to open the die aperture to allow filler to be deposited on the bottom base cake and to close the die aperture to sever or cut the ribbon to a predetermined dimension. The severing prevents further flow of the filler through the die aperture until the next bottom base cake is detected and the die aperture is again opened to allow filler to be deposited on the next bottom base cake.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

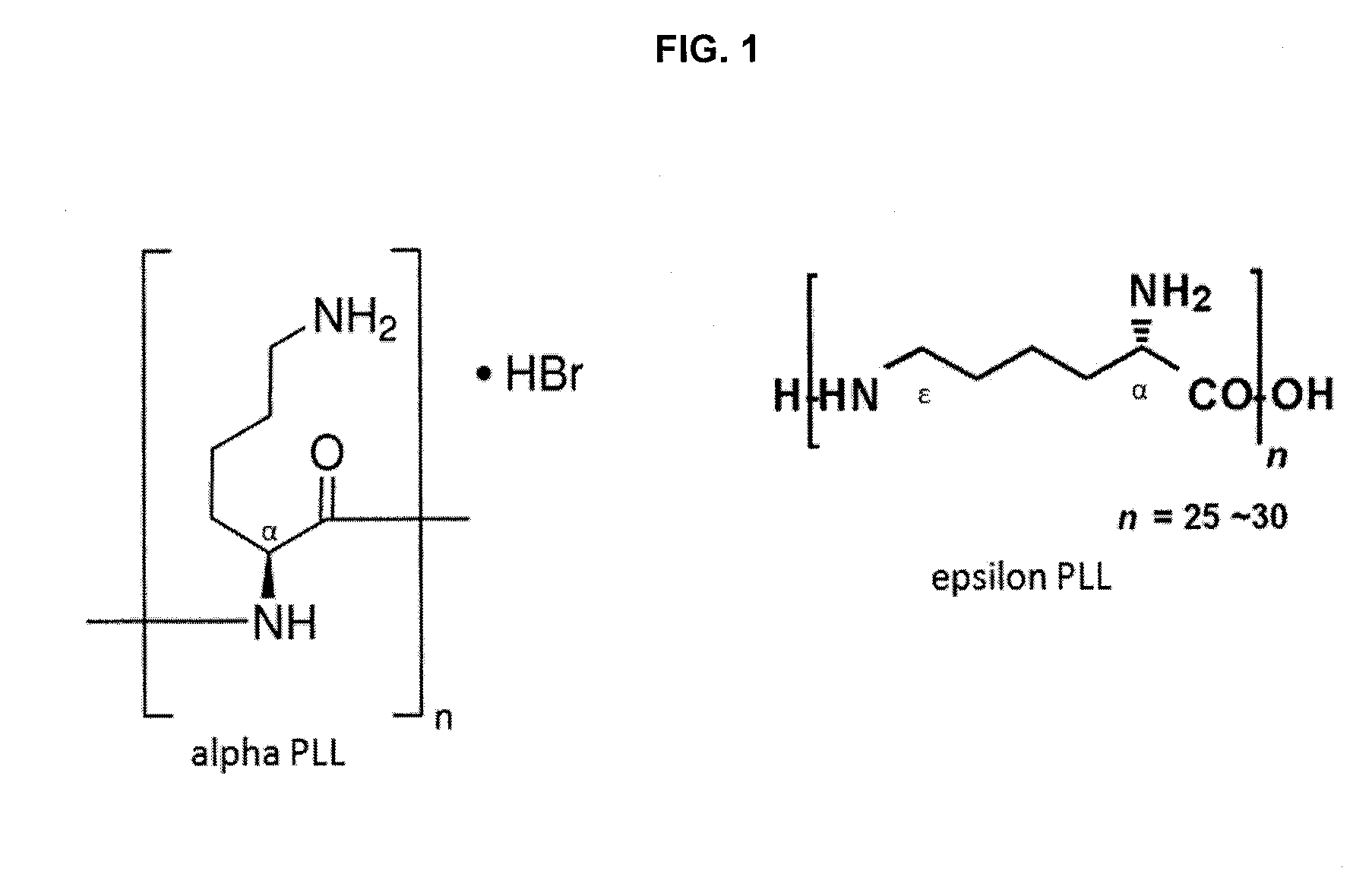

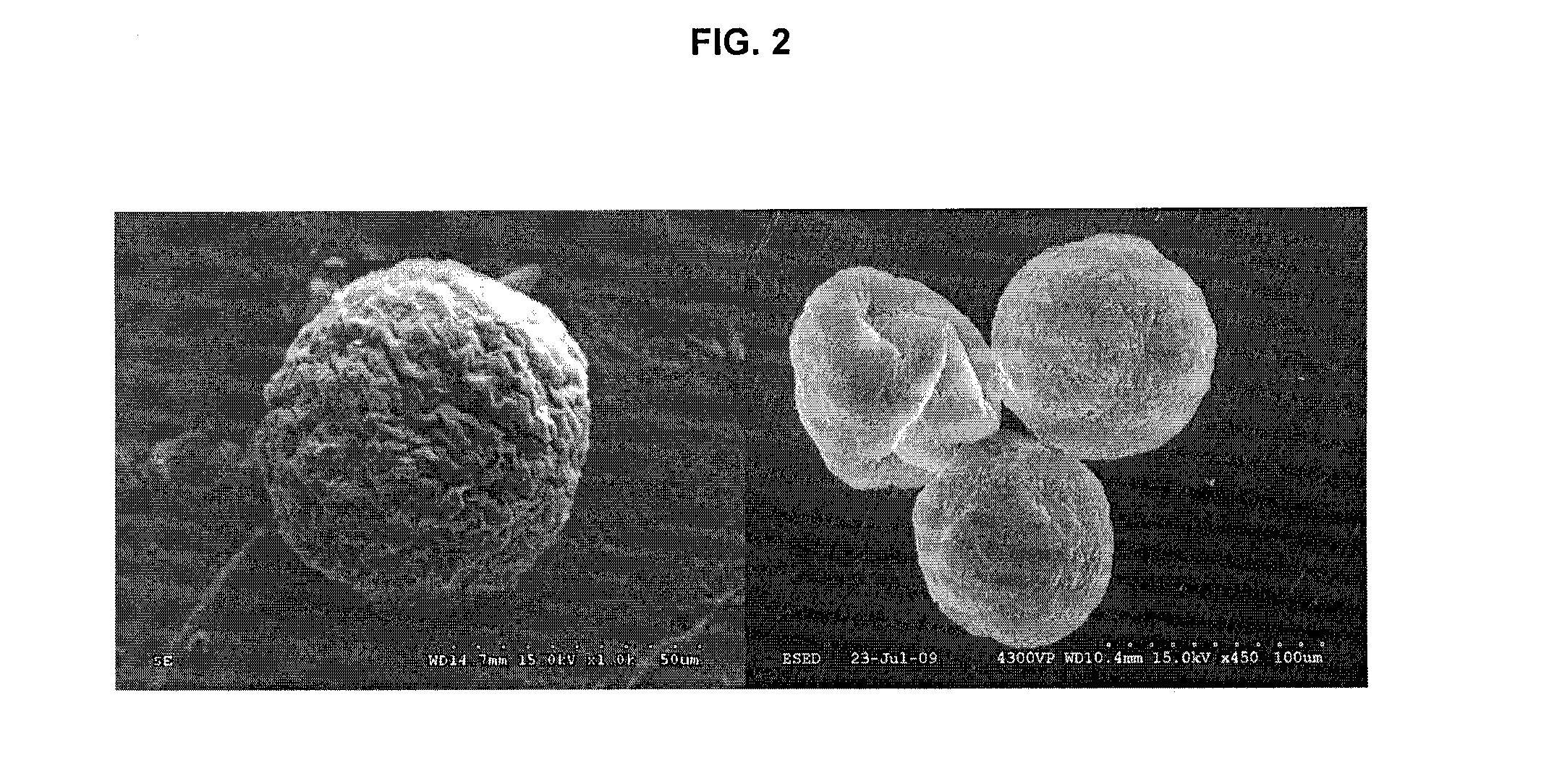

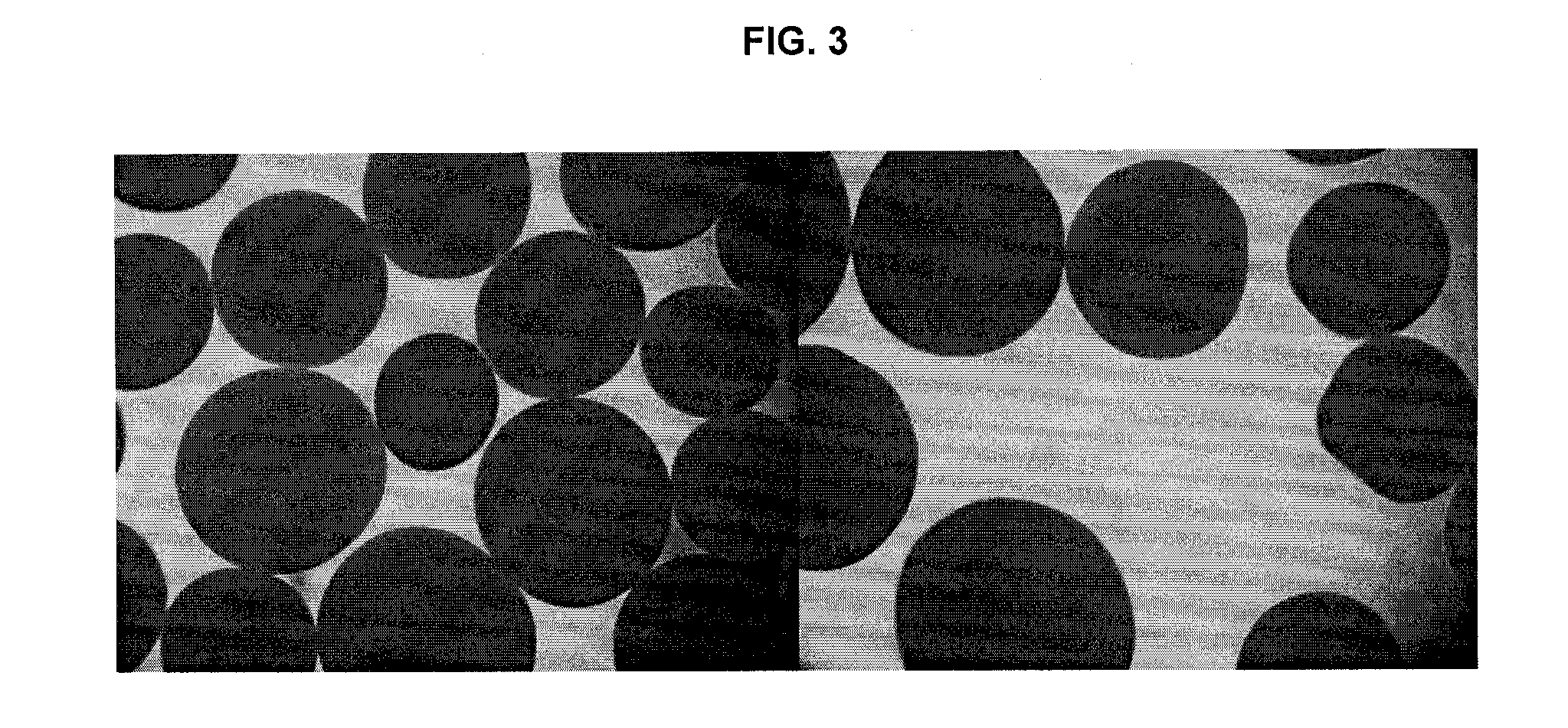

Epsilon-poly-lysine capsules

InactiveUS20120258047A1Protection attackIncrease buoyancyPowder deliveryBiocideMedicineGreek letter epsilon

Owner:MICROPHARMA

Collet for quick connect tube coupling and a mold apparatus for making the same

Owner:KOUW PINNQ ENTERPRISE

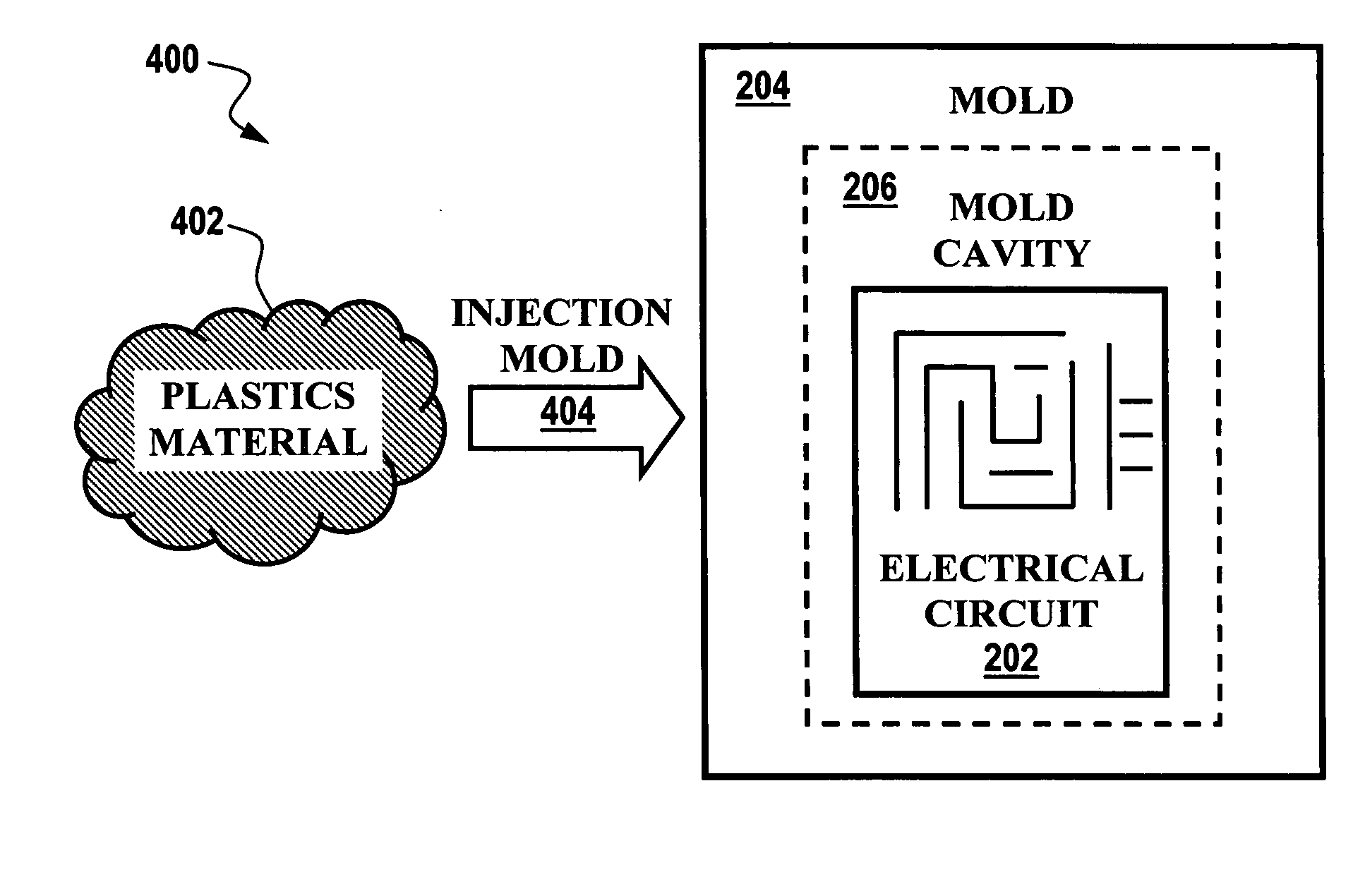

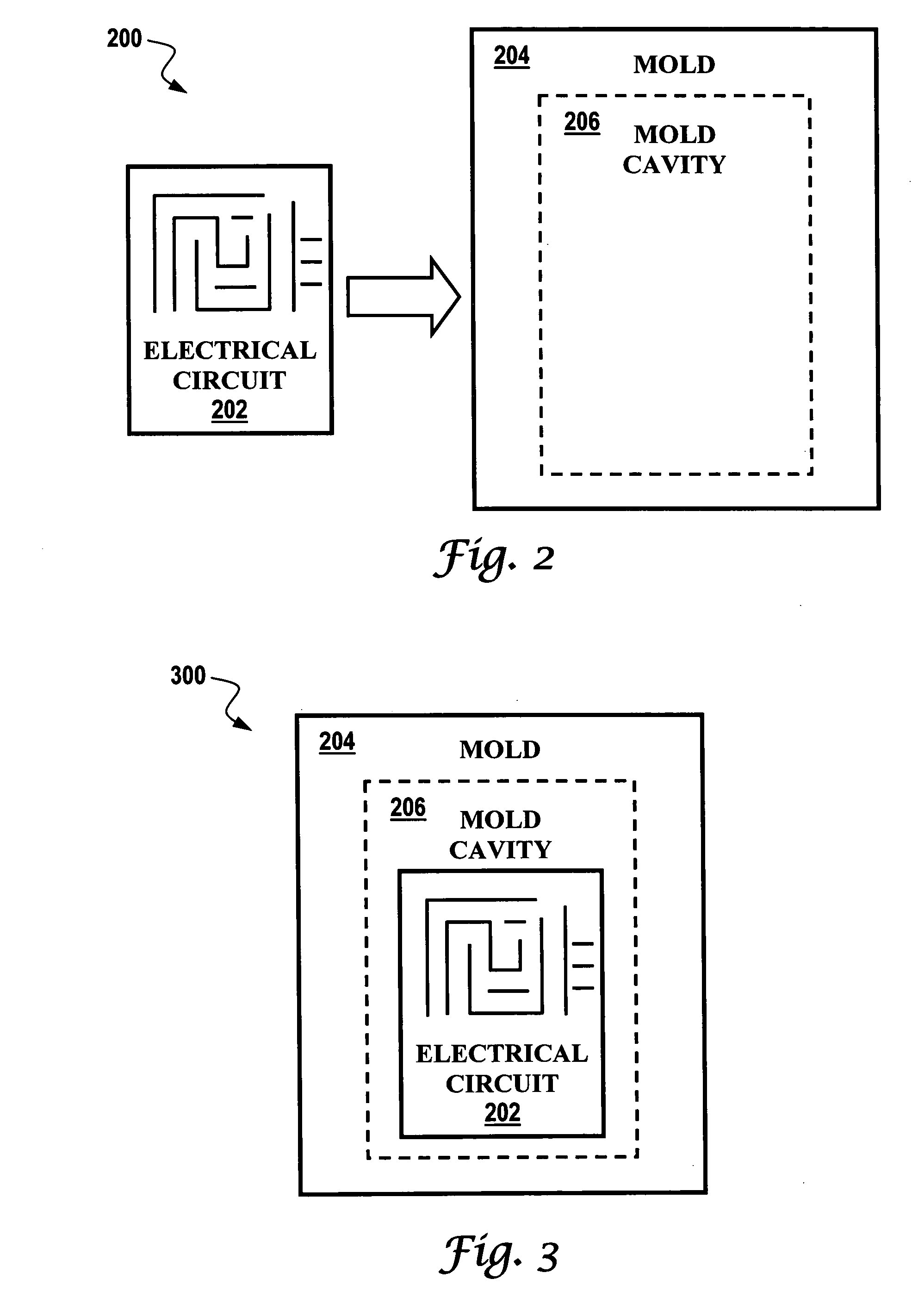

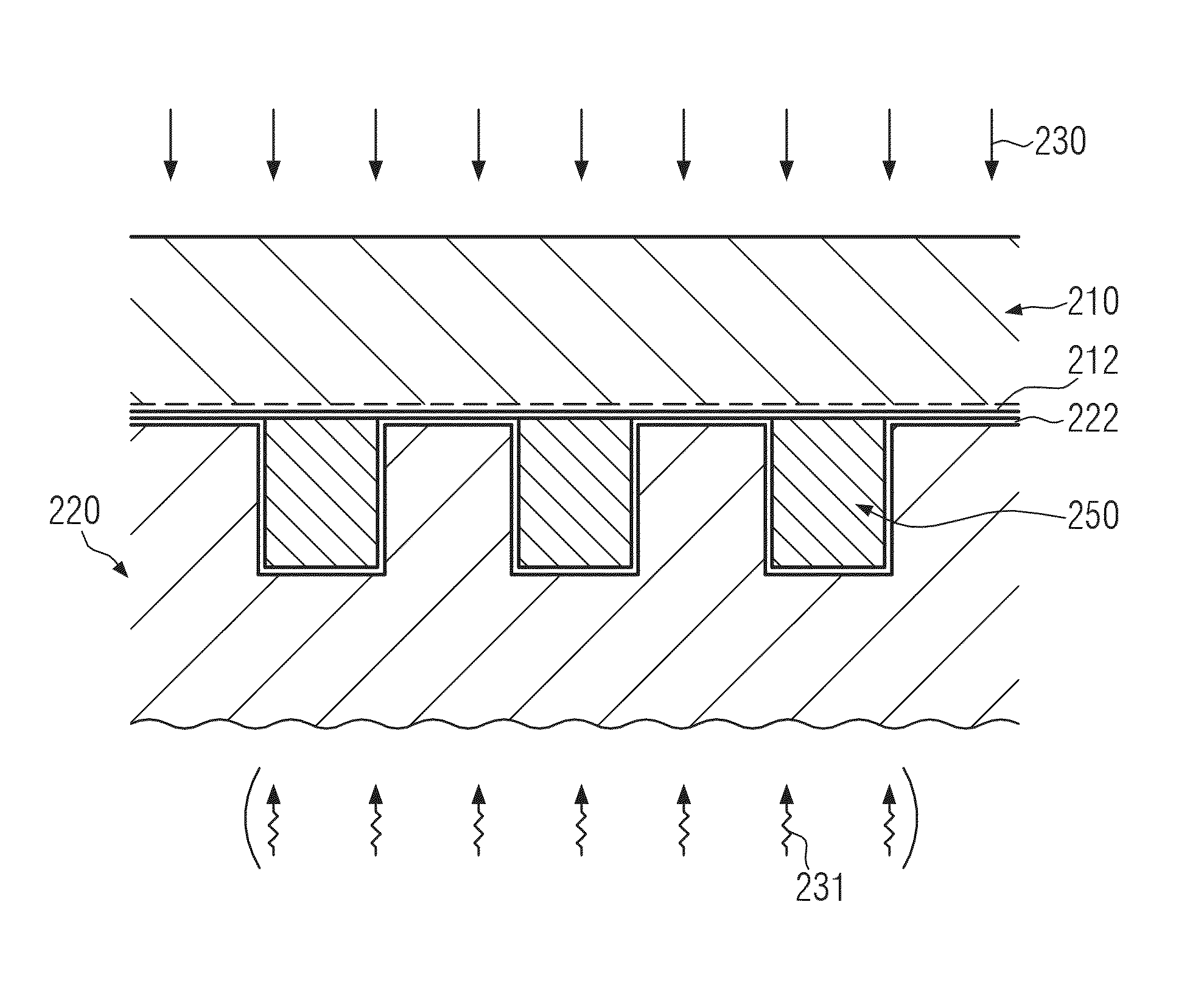

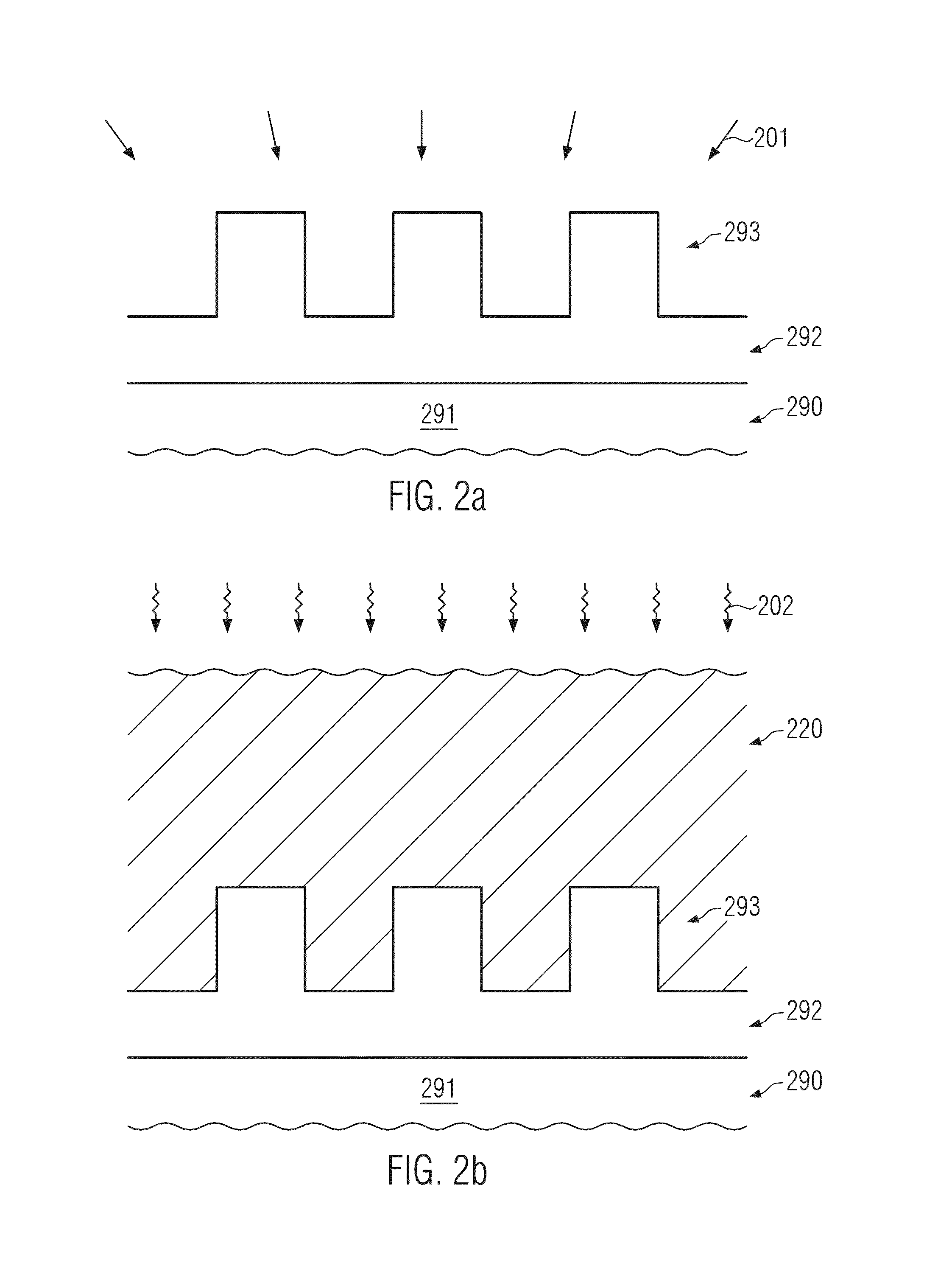

Methods and a mold assembly for fabricating polymer structures by imprint techniques

InactiveUS20140084519A1Highly hydrophobic surfaceReduced surface wettabilityConfectioneryPhotomechanical apparatusLithography processMaterials science

Owner:STMICROELECTRONICS SRL +1

Highly stable aerated oil-in-water emulsion

InactiveUS20180035691A1Improve rigidityIncrease viscosity of fluidEdible oils/fats ingredientsFrozen sweetsAlcohol sugarsOil phase

Owner:CSM BAKERY SOLUTIONS EURO HLDG BV

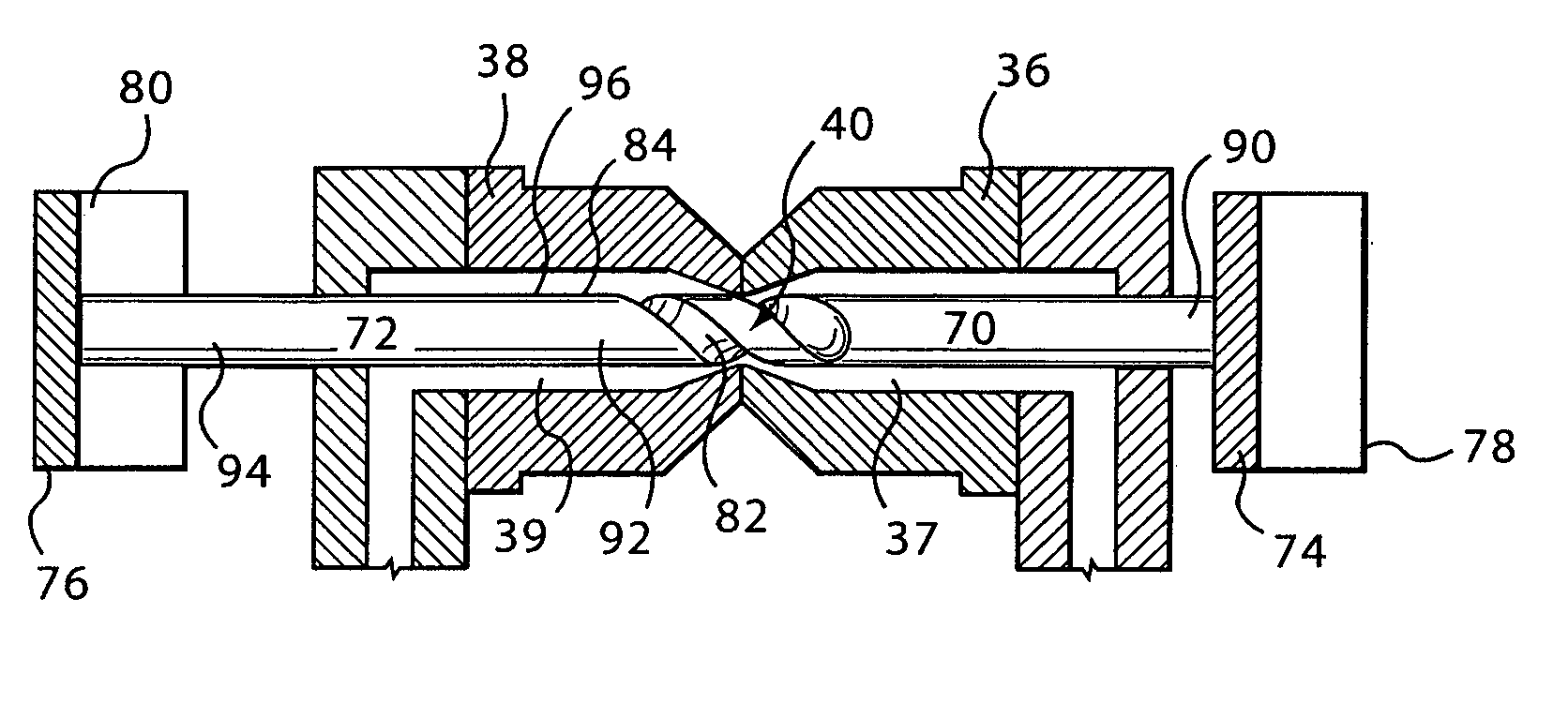

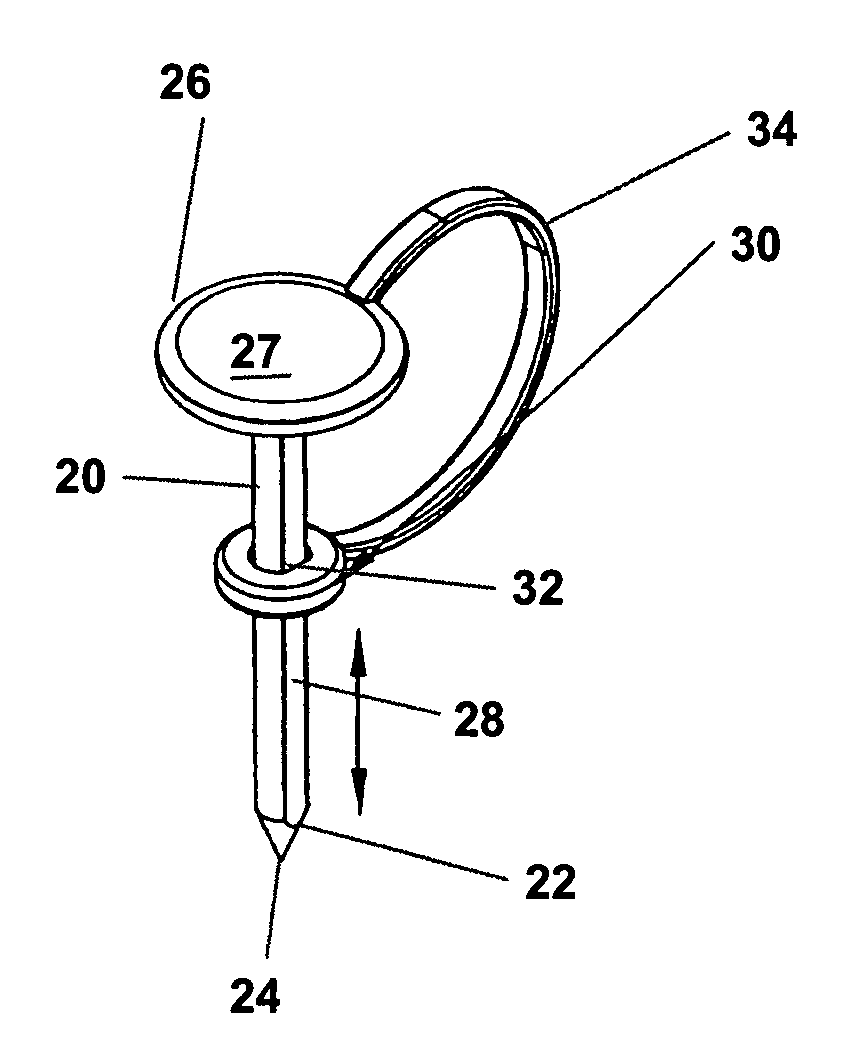

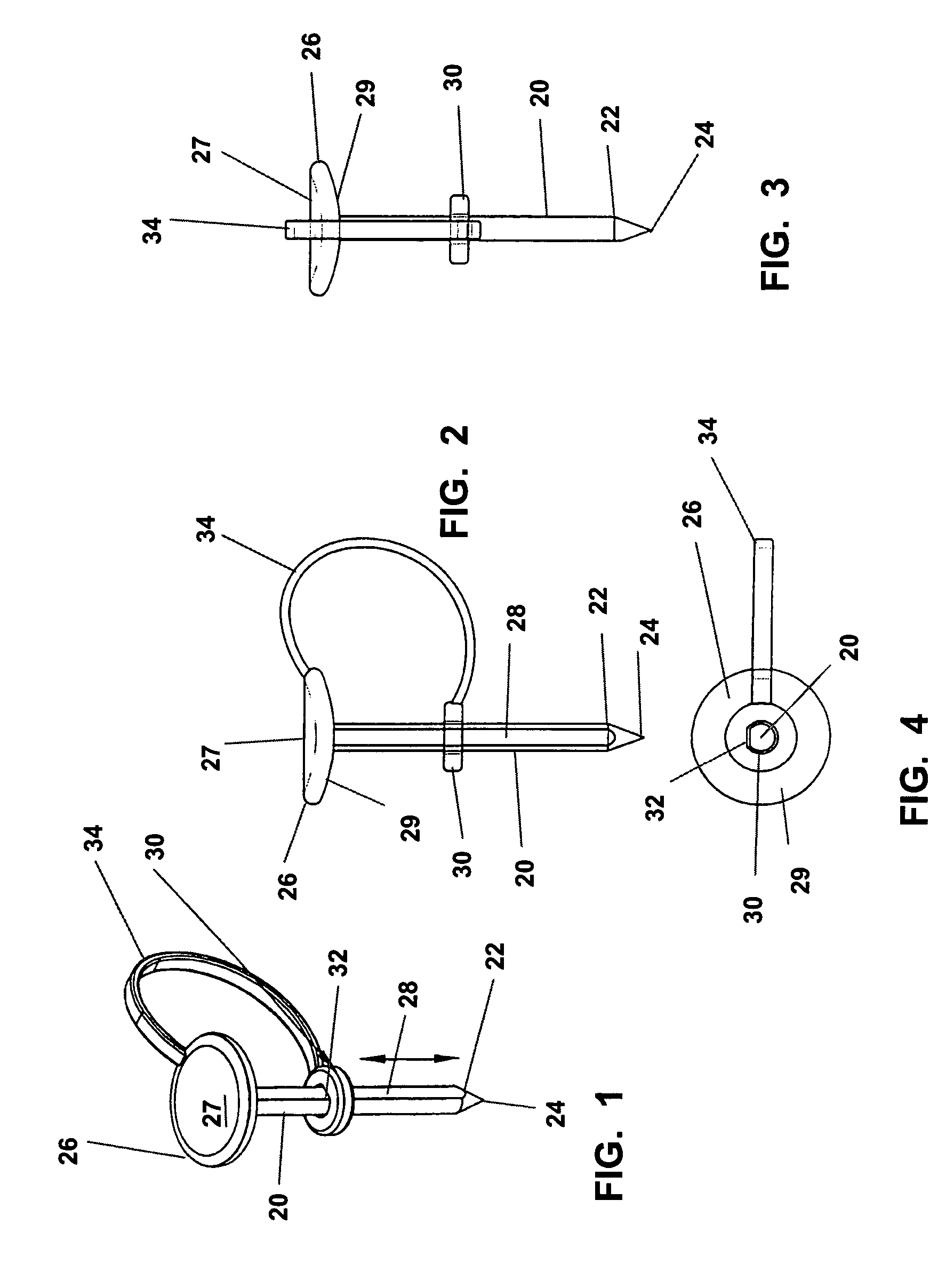

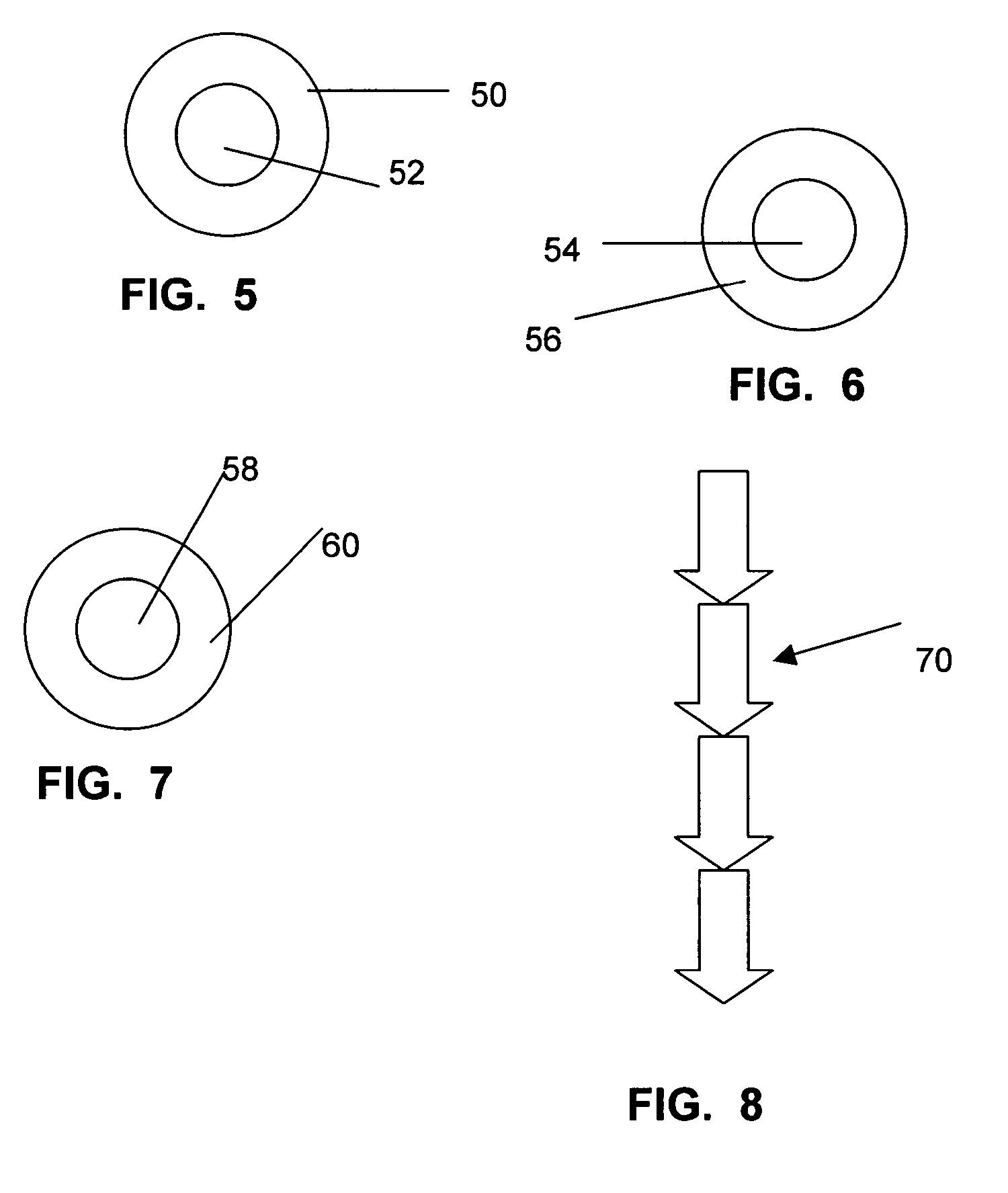

Seasoning stick and method and apparatus for preparing foods

InactiveUS7169433B2Improve applicabilitySmall sectionMilk preparationConfectioneryParticulatesFood products

Owner:SEASONING STICKS

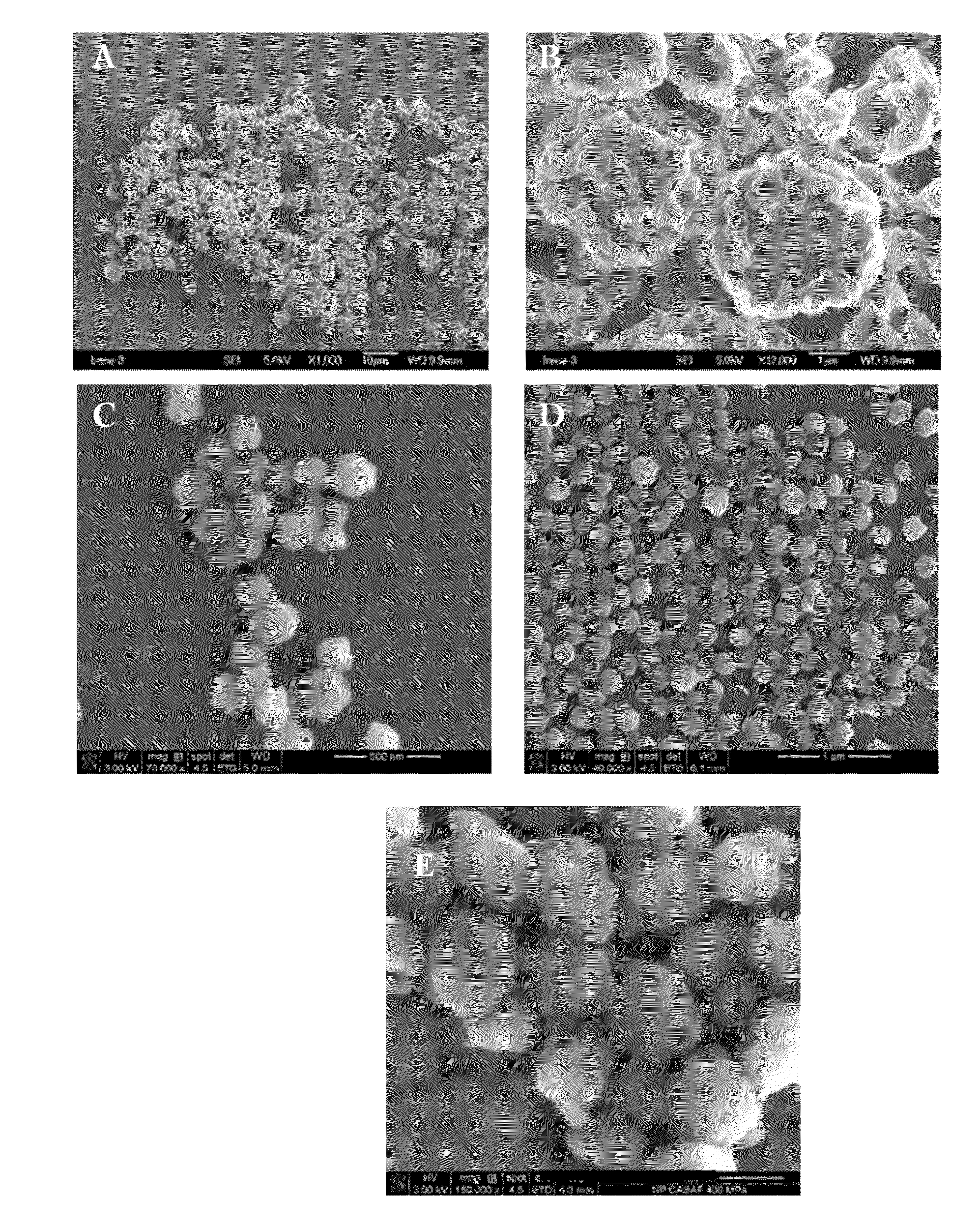

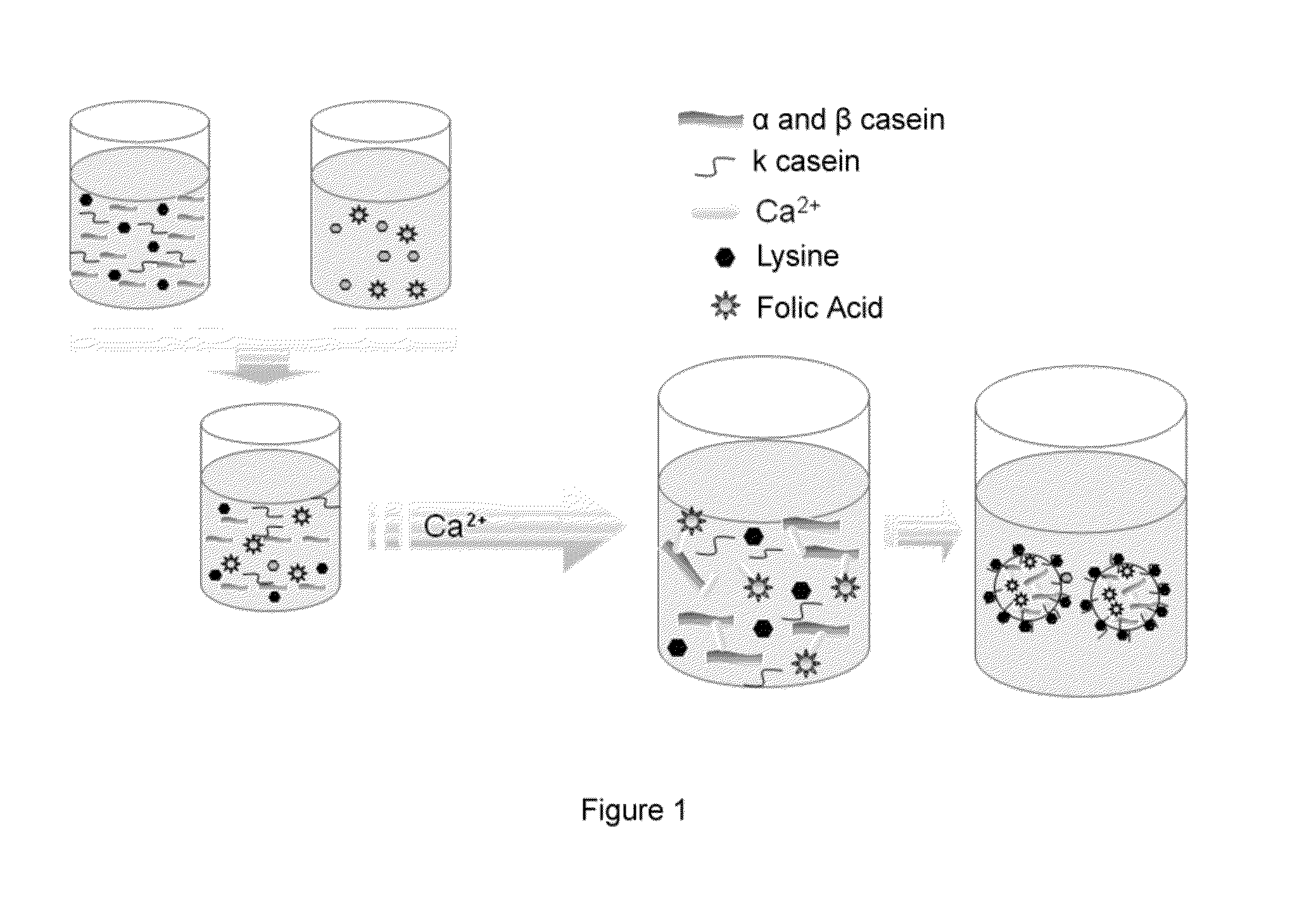

"nanoparticles for the encapsulation of compounds, preparation thereof and use of same"

ActiveUS20130209530A1Improve bioavailabilityReduced bioavailabilityPowder deliveryBiocideNanoparticleDivalent metal

Owner:CENT NACIONAL DE TECHA Y SEGURIDAD ALIMENTARIA LAB DEL EBRO +1

Food Extruder and Method of Using the Same

Owner:POST CONSUMER BRANDS LLC

Device for injection molding

The present disclosure relates to a device for the injection molding of an item including at least one face, a protruding peripheral part provided with an edge for the connection with another face, said device including mold elements movable with respect to each other and jointly cooperating by delimiting therebetween joint planes as well as a cavity intended to be filled with liquid plastic material through injection channels to form said item after the ejection from the mold, characterized in that it includes a mold element to form the protruding part of the item, whose joint plane with the immediately adjacent front mold element is angularly oriented from said edge and on at least a portion of the length thereof, according to the direction of ejection.

Owner:AURAY PLAST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap