Collet for quick connect tube coupling and a mold apparatus for making the same

a quick-connect tube and mold technology, applied in the field of quick-connect tube coupling and mold apparatus for making the same, can solve the problem of short lifespan and achieve the effect of long lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

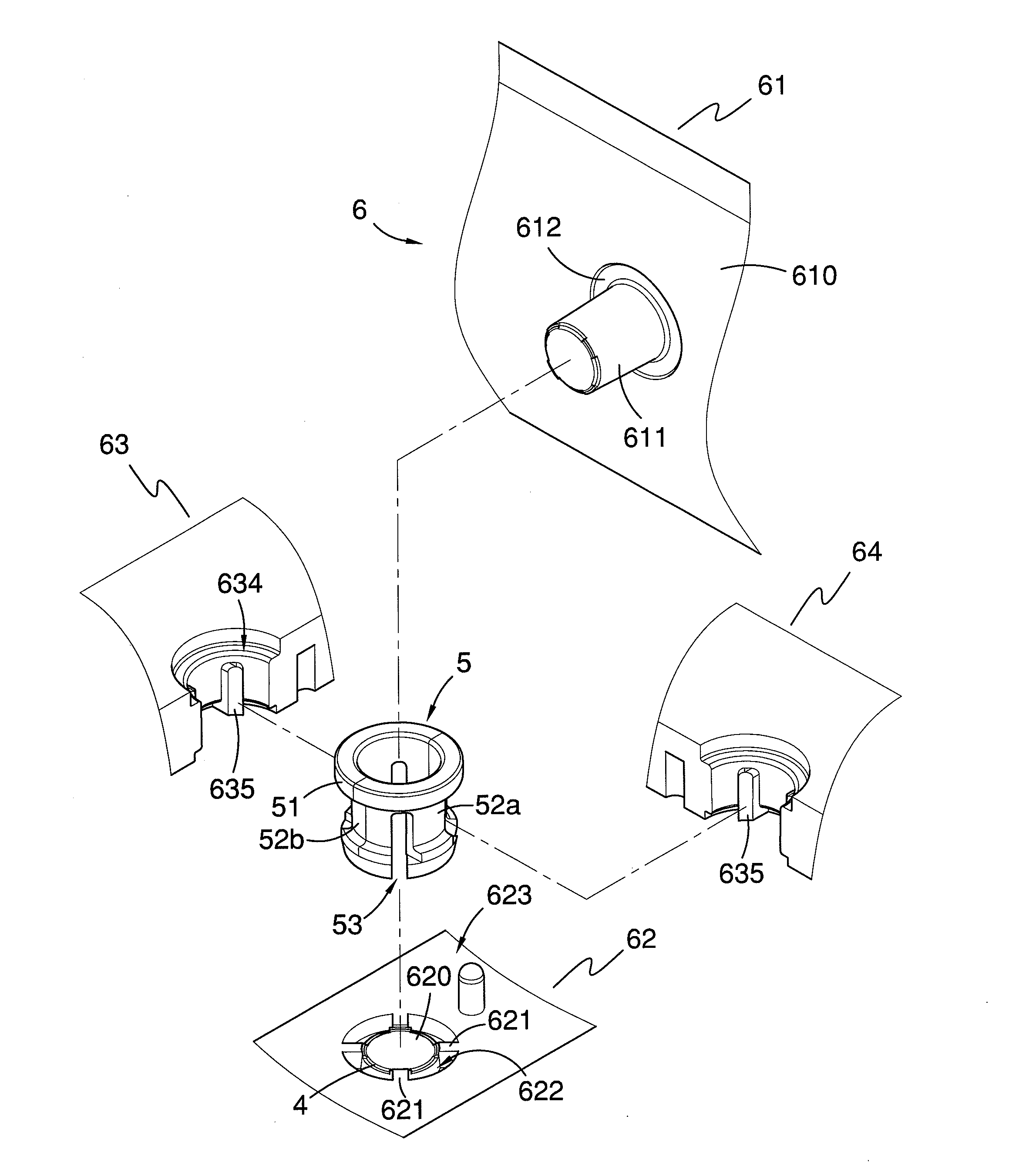

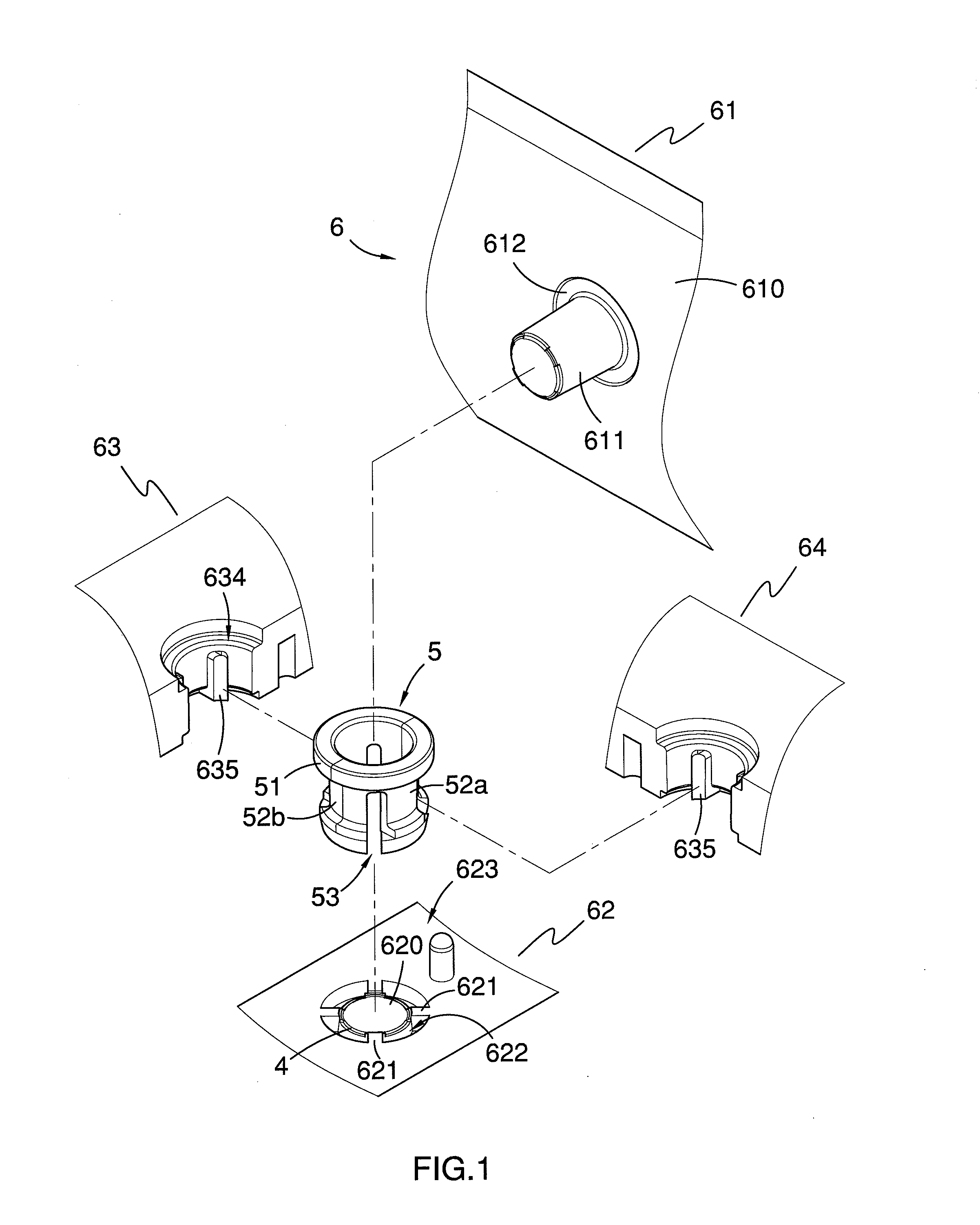

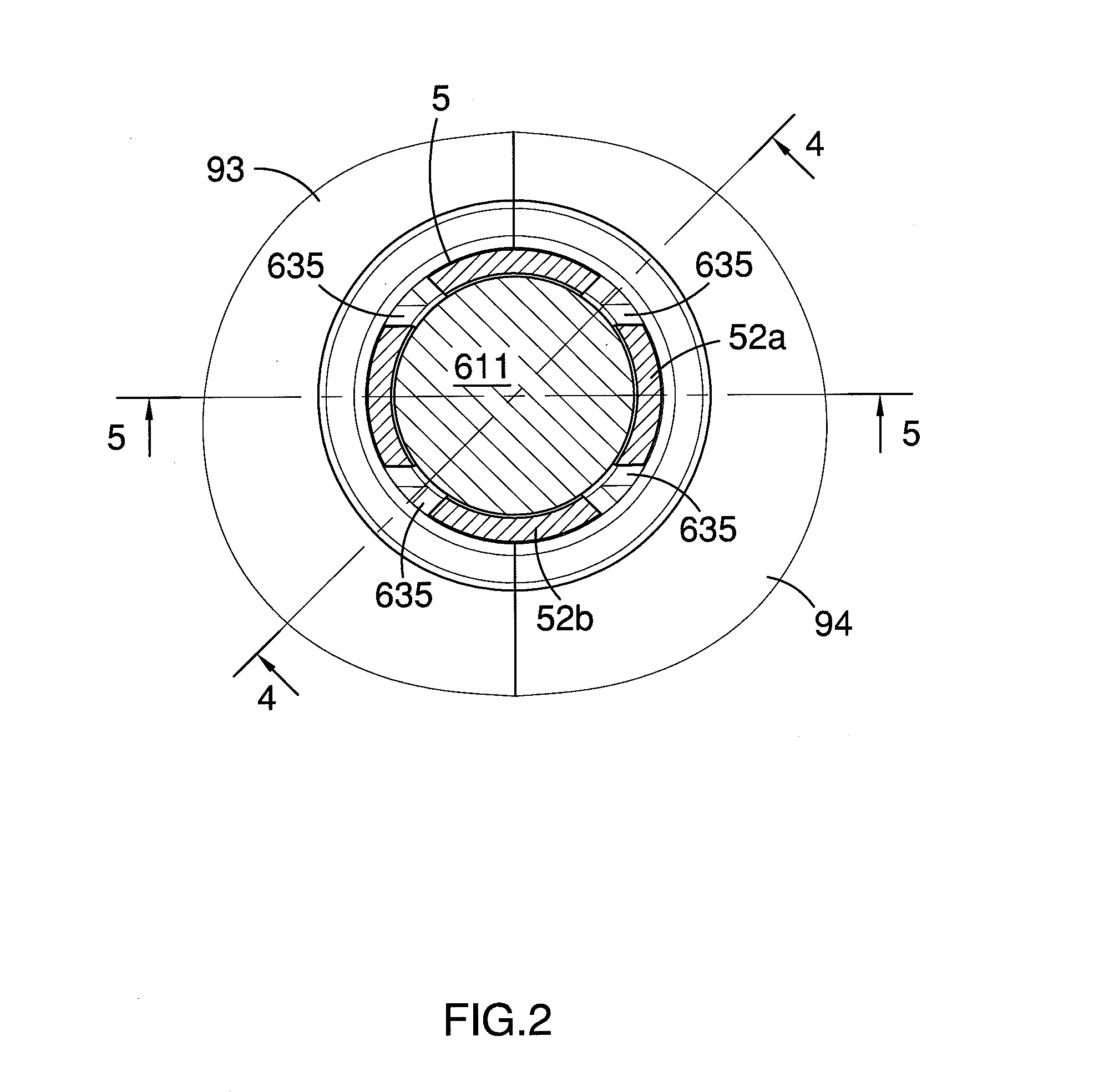

[0042]Referring now to FIGS. 1 through 10 of the drawings, there are shown a collet 5 and a mold apparatus 6 in accordance with the preferred embodiment of the invention. The collet 5 is molded in one piece from plastic for locking a tube in a tube coupling body (not shown) and generally includes an annular collar 51 and four arms 52a, 52b extending from the collar 51 in a direction generally parallel to the axis of the collar 51. The four arms 52a, 52b are arranged in a circle and spaced a distance apart from one another by slots 53 for encircling the tube. The four arms 52a, 52b are composed of two pairs of arms 52a, 52b that are quite different from each other, as will be discussed later in detail.

[0043]To shape this type of collet 5, the mold apparatus 6 generally includes an upper male mold segment 61, a lower female mold segment 62 and two side opposing mold segments 63, 64. As shown in FIGS. 1 and 3, the upper male mold segment 61 has a base 610 and a mold core 611 extending fro

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap