Molding pressing device of hemispherical rice crust molding machine

A material pressing device and forming machine technology, which is applied in the field of food machinery, can solve the problems of material splashing and spillage, and rice crusts cannot be made, and achieve the effects of smooth operation, simple structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

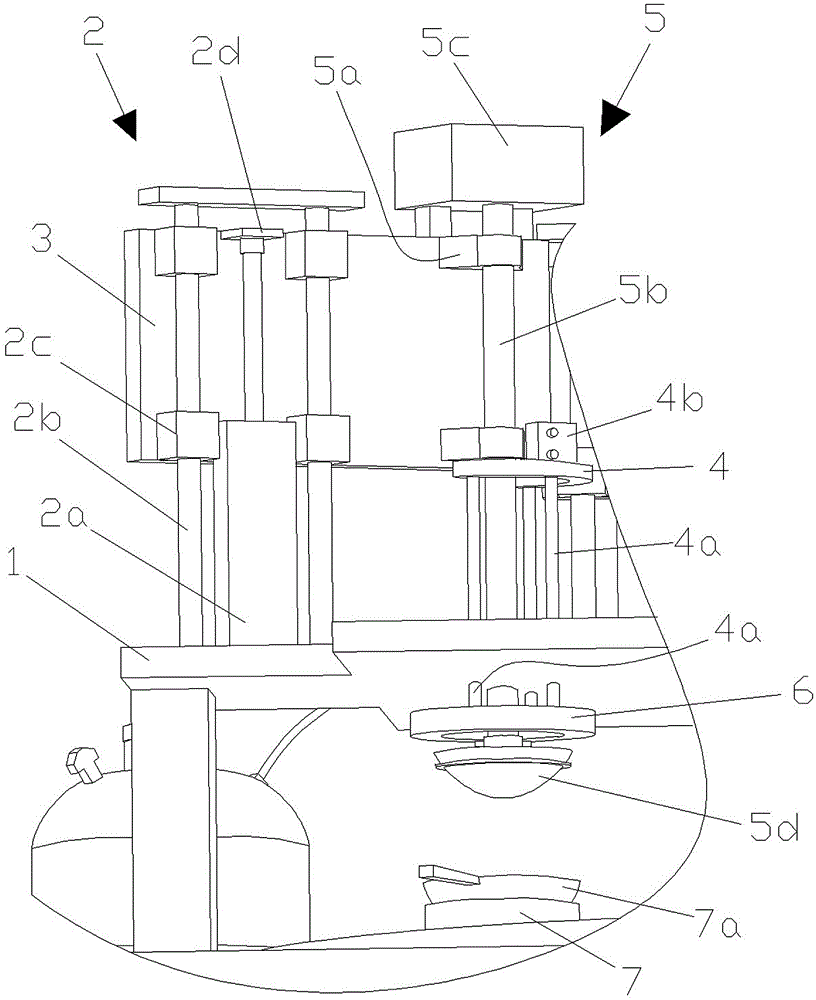

[0012] Such as figure 1 Shown, a kind of forming pressing device of hemispherical rice crust forming machine, it comprises and is provided with driving device 2 on upper frame 1. Described driving device 2 comprises, is provided with a cylinder 2a on the upper frame 1, is respectively provided with a vertical guide post 2b on the upper frame 1 on the left and right sides of the cylinder 2a, on each guide post 2b A set of sliders 2c is provided, and a mounting plate 3 is connected to one side of the sliders 2c.

[0013] The output shaft of the cylinder 2a protrudes vertically upwards, and a connecting plate 2d connected to the mounting plate 3 is provided at its upper end, so that the cylinder 2a can drive the mounting plate 3 to move up and down in the vertical direction.

[0014] A forming head driving mechanism 5 is also provided on the mounting plate 3 on one side of the guide post 2b. The forming head driving mechanism 5 includes a pair of longitudinally distributed bearing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap