Sheet sending device for thermoplastic molding machine

A molding machine and sheet feeding technology, which is applied in the field of thermoplastic molding machine sheet feeding devices, can solve the problems of low product qualification rate, material waste, inaccurate positioning, etc., to facilitate the cutting process, prevent penetrating damage, The effect of reducing the occurrence of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

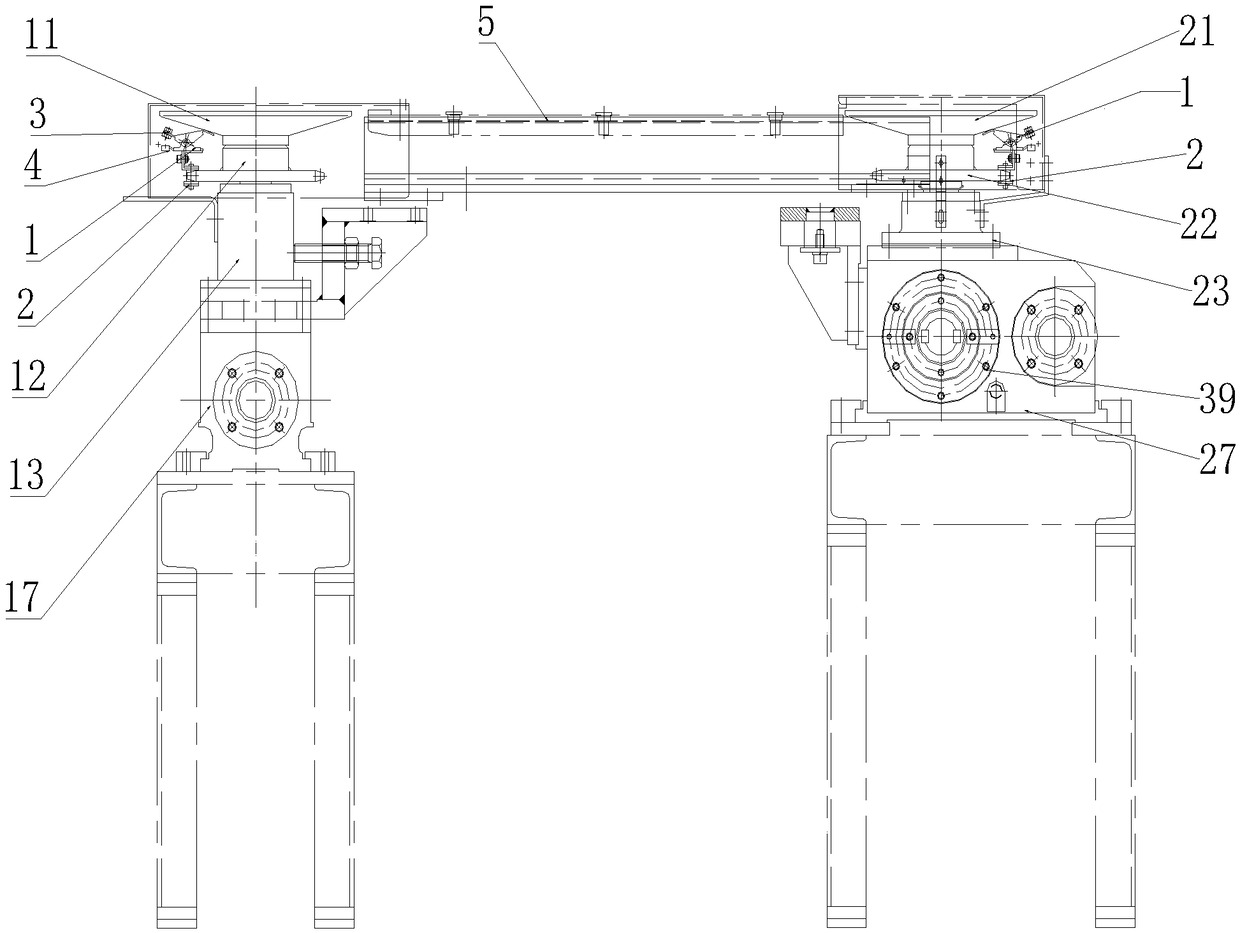

[0036] figure 1 Shows the planar structure of the sheet feeding device of the thermoplastic molding machine according to the embodiment of the present invention, as figure 1 Shown:

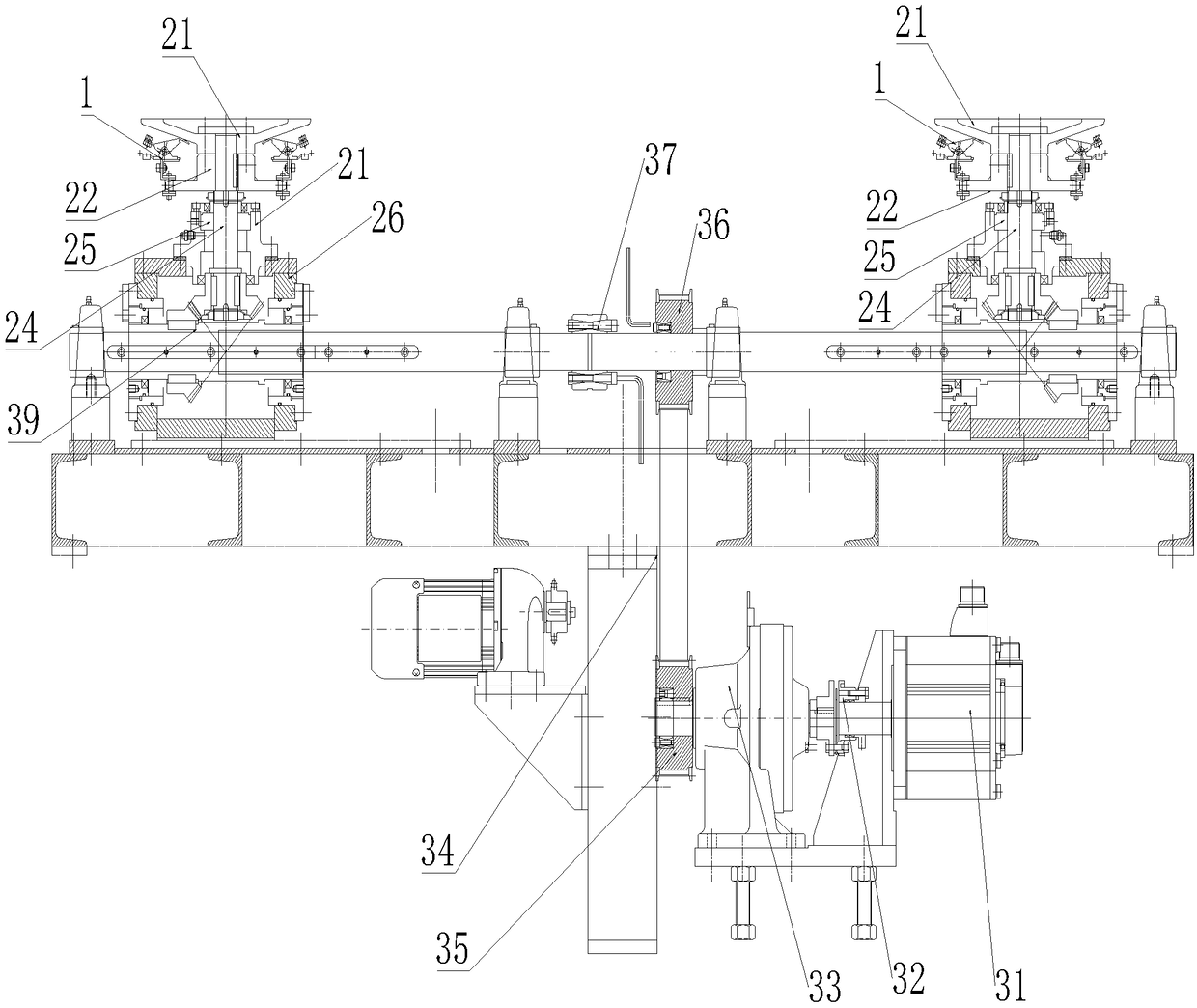

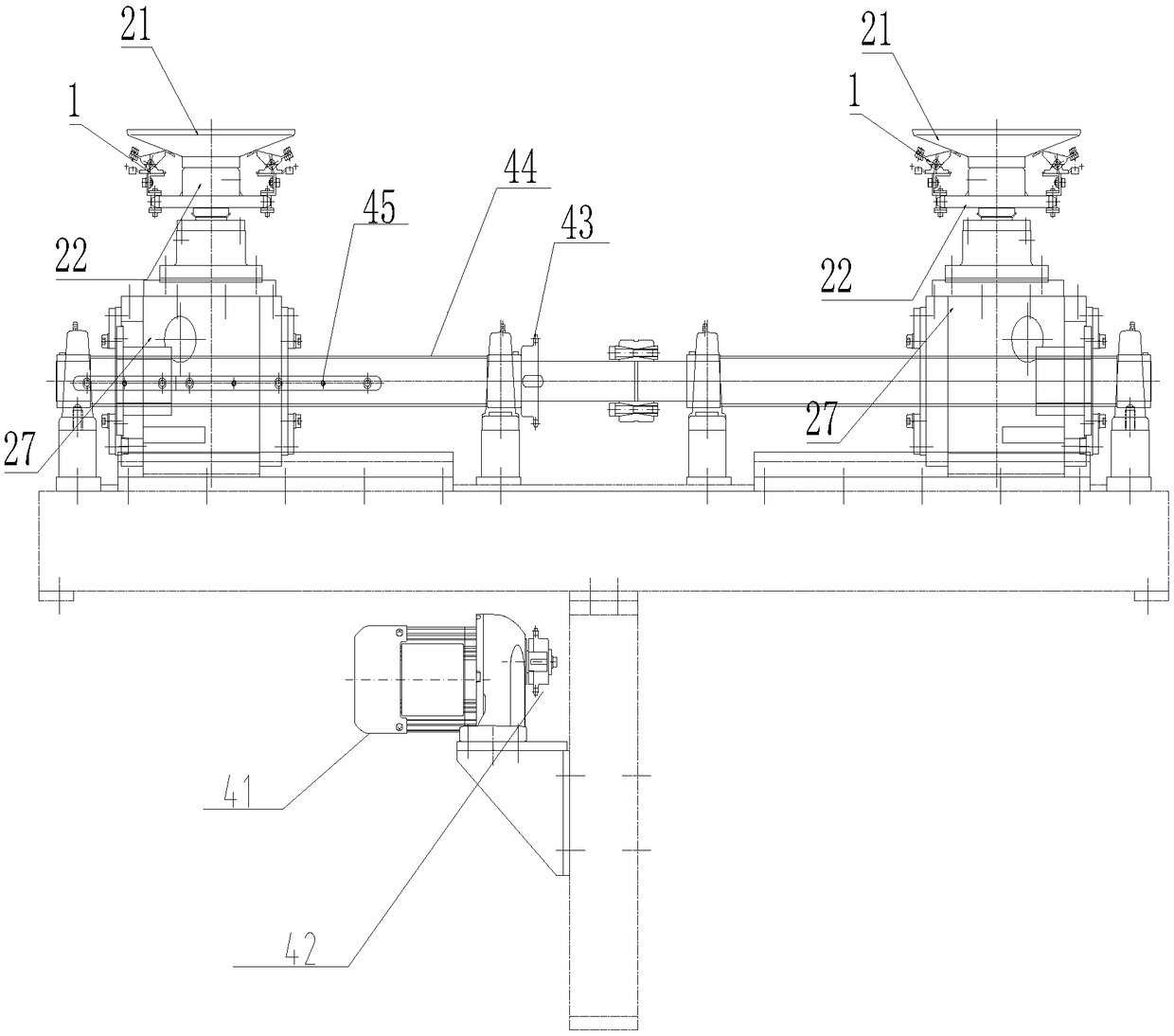

[0037] The thermoplastic molding machine sheet feeding device provided by the present invention is composed of a feeding mechanism, a discharging mechanism, a chain 2, a clip 1 and a driving mechanism; wherein, the feeding mechanism includes a feeding platen 11, a feeding sprocket 12 and a feeding mechanism Material carrying mechanism 17, feed platen 11 is fixed on the feed sprocket 12, and feed sprocket 12 is fixed on the feed carrying mechanism 17; The discharge mechanism includes discharge pressure plate 21, discharge sprocket 22 and discharge The material carrying mechanism 27, the discharge pressure plate 21 is fixed on the discharge sprocket 22, and the disch

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap