Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove water resistanceImproves breakage resistanceFluid removalBreakage rateResin coating

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

Continuous noodle press and noodle pressing method

Owner:QINGDAO ZHENGYA MACHINERY TECH

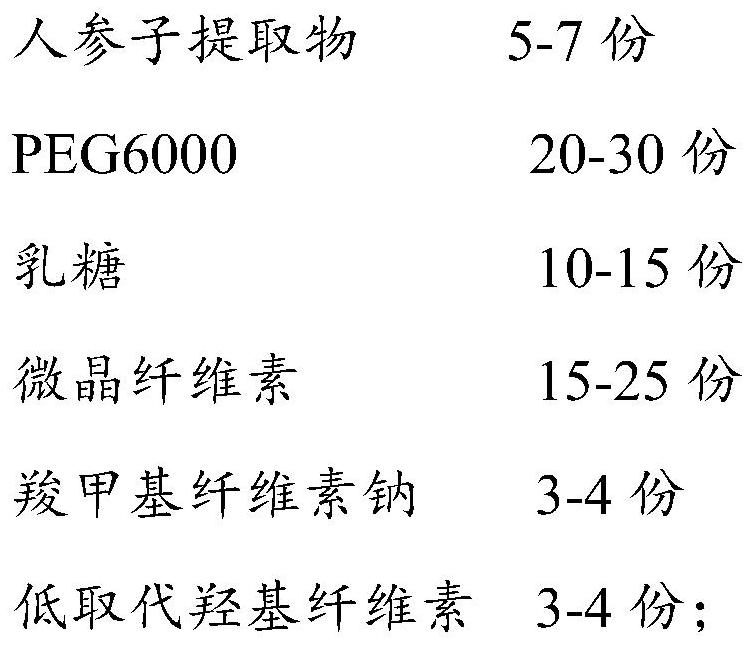

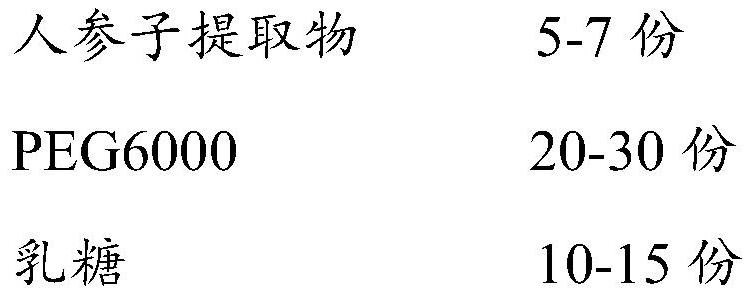

Ginseng seed quick-release pellet and preparation method thereof

PendingCN112999167AHigh yieldImprove pass rateAntineoplastic agentsAntinoxious agentsAqueous solubilityBiotechnology

Owner:深圳前海九华国际投资控股有限公司

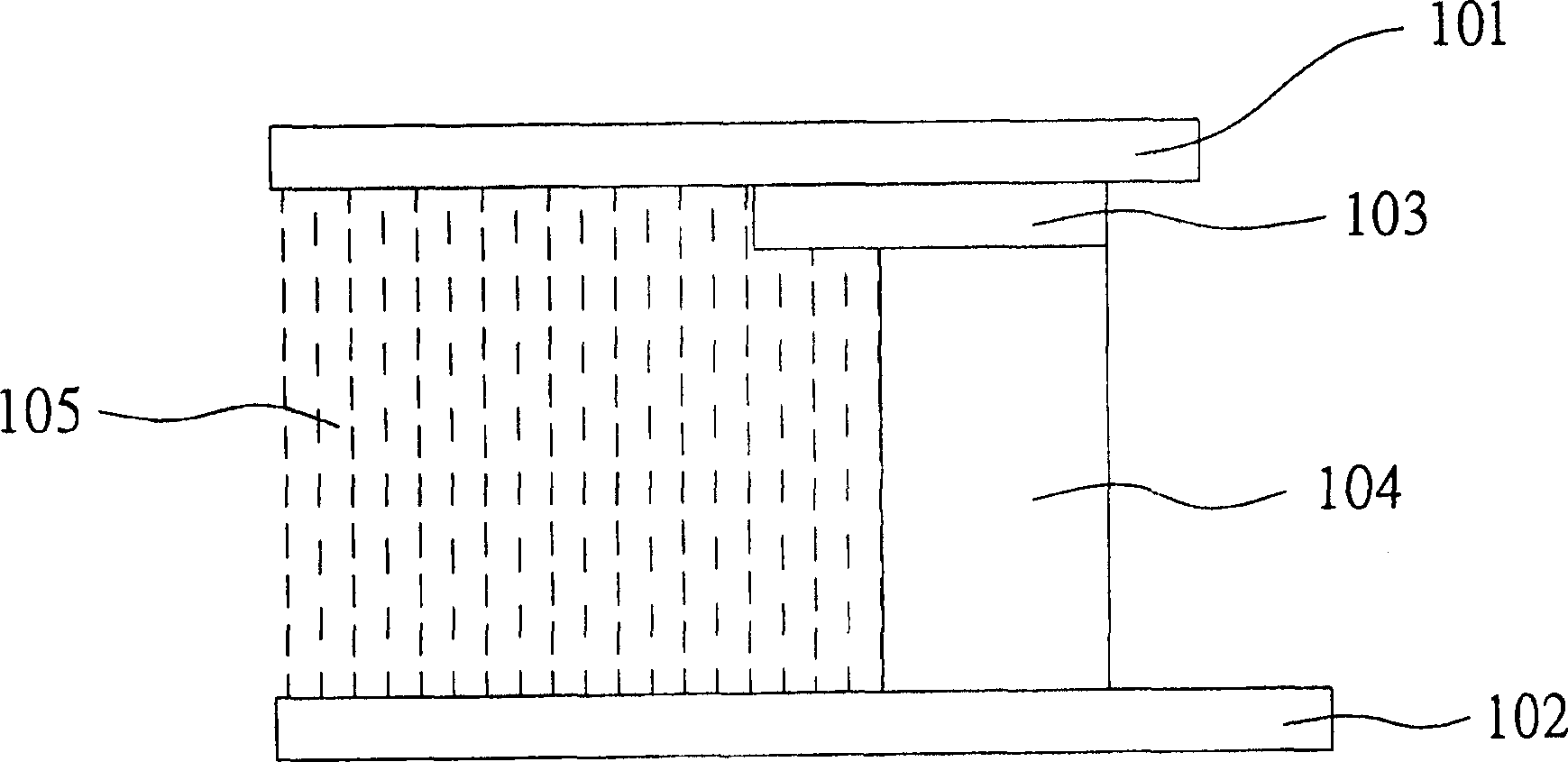

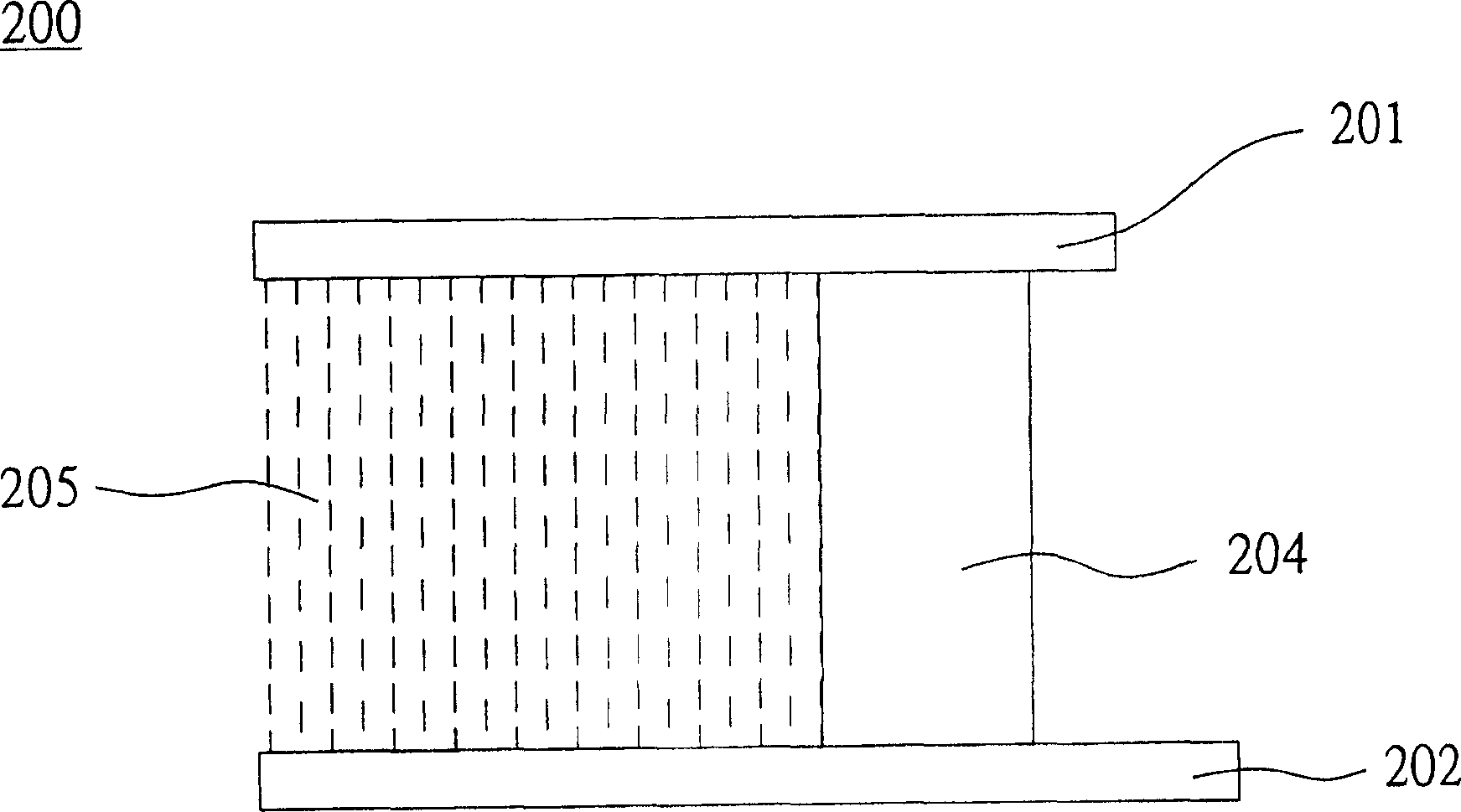

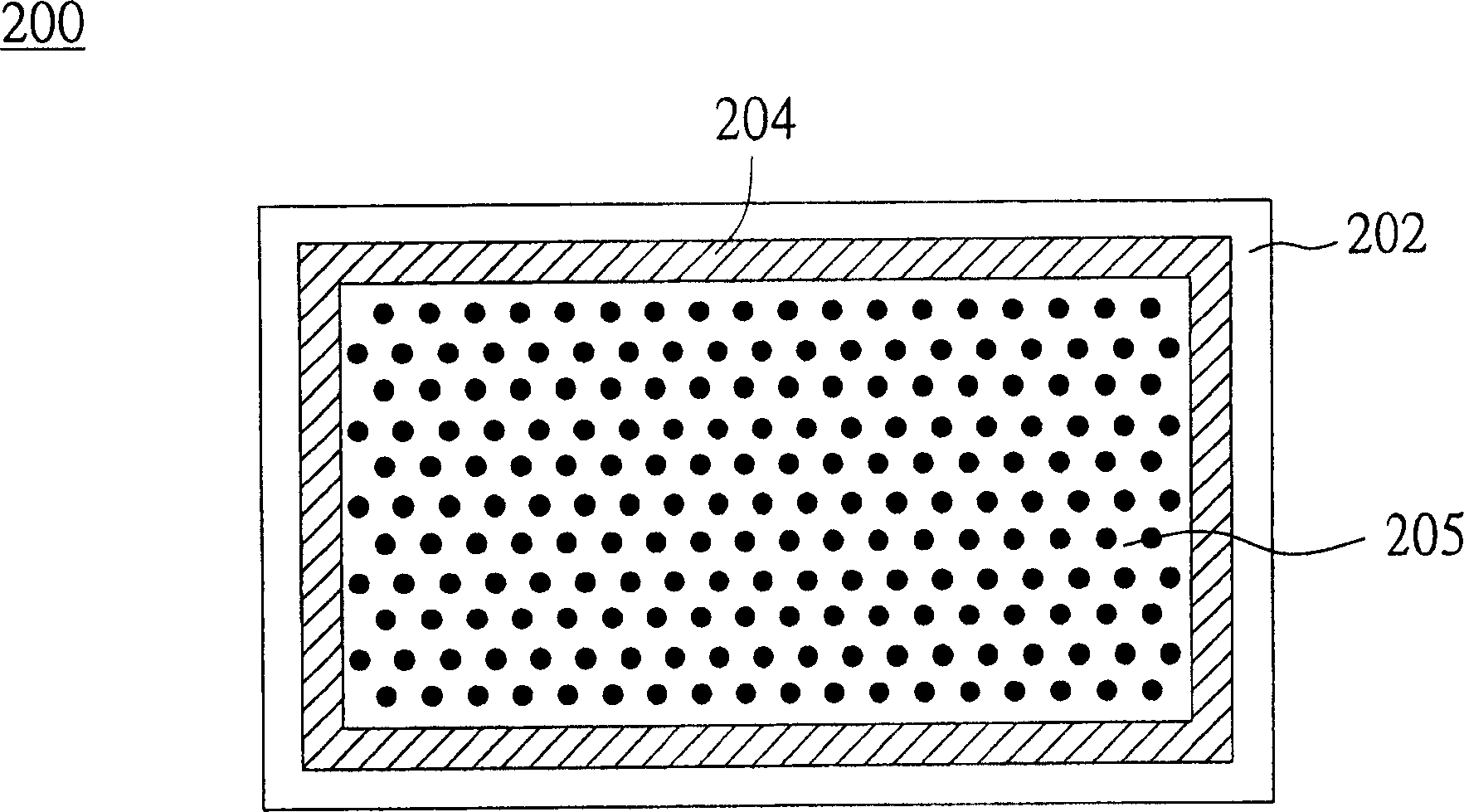

Display panel

ActiveCN1632646AEasy to distinguishReduces problems with cryogenic vacuum bubblesStatic indicating devicesSurface plateBiochemical engineering

Owner:AU OPTRONICS CORP

Welding repairing method for tin-based bearing alloy bearing bush

The invention relates to a welding repairing method for a tin-based bearing alloy bearing bush. The welding repairing method comprises the following steps that (1) a welding wire is prepared, specifically, a babbitt material matched with the tin-based bearing alloy bearing bush is selected to be smelted, and the welding wire is prepared; (2) the surface of the tin-based bearing alloy bearing bush is processed; and (3) TIG direct current welding is adopted, argon inert gas protecting is conducted, flat welding is adopted, wire filling welding repairing is conducted through a leftward welding method, the surface of the last layer of welding bead is higher than the original surface of the bearing bush, then protecting nozzle repairing welding is adopted, and the repaired bearing bush is obtained through machining. According to the welding repairing method for the tin-based bearing alloy bearing bush, operation is easy; the repairing result is ideal; the qualified rate is high; the reuse rate of the tin-based bearing alloy bearing bush is increased; and the recasting fund and time are reduced.

Owner:CSSC GUANGZHOU WENCHONG DOCKYARD CO LTD

Acidic double-color material electroplating peptizing solution and preparation method thereof

Owner:阿尔发埃德伟控汽车配件有限公司

Special high-strength modified phenolic resin adhesive for precoated sand and preparation method of special high-strength modified phenolic resin adhesive

InactiveCN105348461AImprove pass rateImprove toughnessFoundry mouldsFoundry coresPolymer sciencePtru catalyst

The invention provides a special high-strength modified phenolic resin adhesive for precoated sand and a preparation method of the special high-strength modified phenolic resin adhesive. The adhesive comprises phenol, formaldehyde, a catalyst, a modifier 1, a modifier 2 and silane, wherein the mole ratio of phenol to formaldehyde is 1:(0.7-0.8), the adding quantity of the modifier 1 accounts for 3%-30% of the mass of phenol, the adding quantity of the modifier 2 accounts for 0.5%-10% of the mass of phenol, and the adding quantity of silane accounts for 0.3%-0.8% of the mass of phenol. The preparation method is simple and convenient to operate, and reduction of the enterprise cost and promotion of energy saving and emission reduction are facilitated. The adhesive and the preparation method can be applied to the field of adhesives.

Owner:ZHUHAI DOUMEN FULIAN MOLDING MATERIALS IND CO LTD

Tool for gluing prisms

Owner:SHANGHAI ZHAOJIU OPTOELECTRONICS TECH CO LTD

Servo-motor-driven dual-hot-pressing plant fiber molding method and machine

The invention relates to a method and device to manufacture plant fiber products containing pulp by means of molding and is intended to provide a full-automatic manufacture method and device of plantfiber molded products, which have good operation stability and higher yield. According to the technical scheme, a servo-motor-driven dual-hot-pressing plant fiber molding method comprises the steps of1) allowing a suction filter forming device to manufacture a wet blank with slurry and transfer the wet blank to a left hot-pressing lower mold 3c or right hot-pressing lower mold 4c of a wet blank transfer station 7.1; 2) allowing the wet blank transfer station 7.1 to receive the wet blank to the left hot-pressing lower mold, and carrying the wet blank to horizontally move along a hot-pressing lower mold horizontal rail 8 to a left hot-pressing station 3.1; allowing a left hot-pressing upper mold 3a to move down and to be closed, and performing hot-pressing and drying on the wet blank to shape; 3) allowing the left hot-pressing upper mold 3a to move up and separate from the left hot-pressing lower mold, and taking out a dried product; allowing a right hot-pressing upper mold 4a to move up and separate from the right hot-pressing lower mold, and taking out the dried product.

Owner:郑天波

Method for drying ceramic green body in drying chamber

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Process for correcting deformation of ring piece through welding shrinkage

Owner:山东美陵美力达风机有限公司

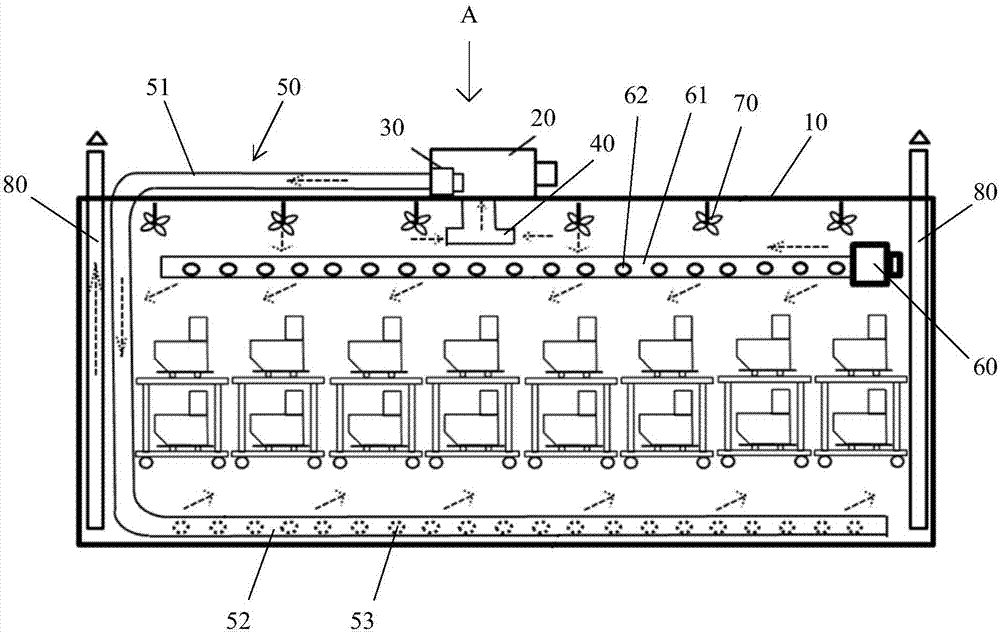

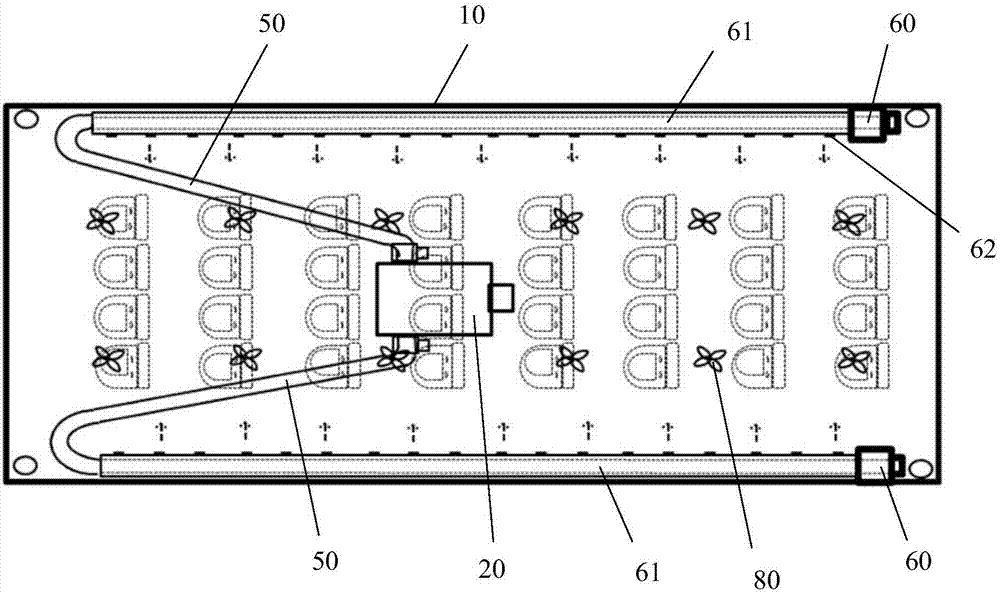

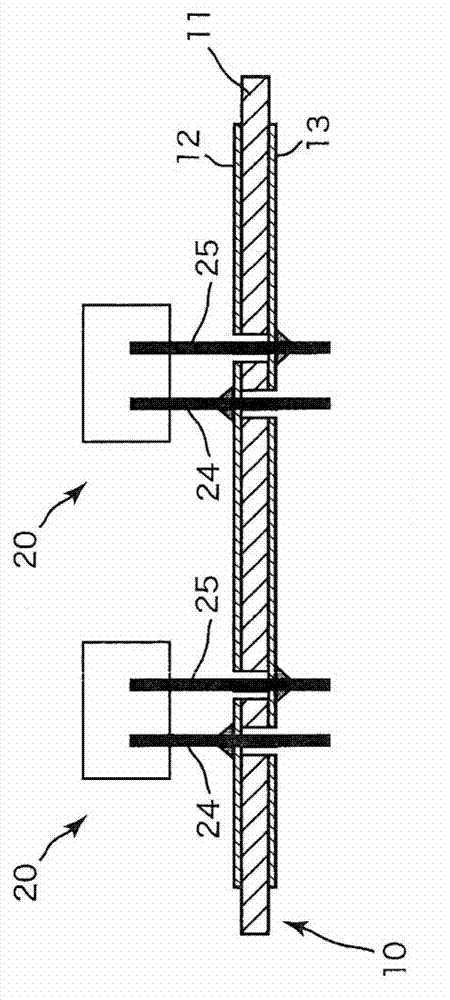

Laminating device and method applied to large-size battery assembly

PendingCN110370778ADistribute stressReduce shockLaminationLamination apparatusElectrical batteryThermal expansion

The invention relates to a laminating device and method applied to a large-size battery assembly. The laminating device comprises a laminating cavity, a curing cavity, pre-cooling cavities and a cooling cavity which are connected sequentially, and the temperature in the pre-cooling cavities is higher than the temperature in the cooling cavity; and in the laminating process, the assembly is sequentially subjected to the four steps of laminating, curing, pre-cooling and cooling, wherein in the pre-cooling process, the assembly is cooled from 130-160 DEG C to 50-80 DEG C firstly and then placed into the cooling cavity to be cooled to 20-50 DEG C. The laminating device and method have the beneficial effects that the laminating device including the one or more pre-cooling cavities is adopted, through a stepped cooling method, the influences of quick cooling on large-size battery pieces are reduced, stress, caused by thermal expansion and cold contraction phenomena in the cooling process, ofthe surface of a silicon wafer is dispersed, impact borne by the surfaces of the battery pieces is buffered, the phenomena of laminating fragments and subfissure of the battery pieces are obviously reduced, the efficiency of assembly preparation is improved, and the qualified rate of assembly preparation is increased.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

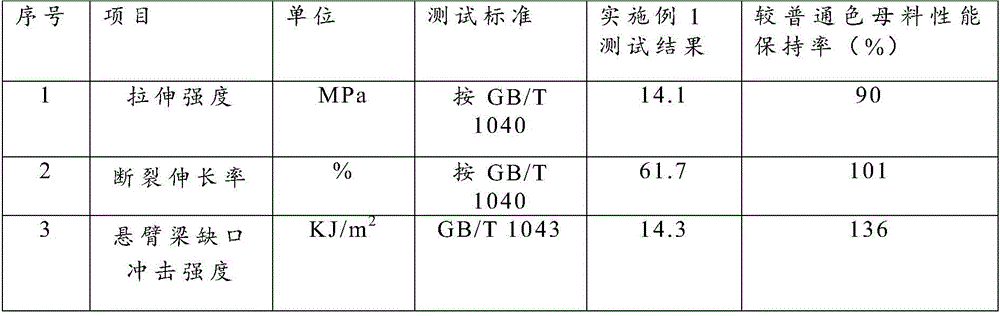

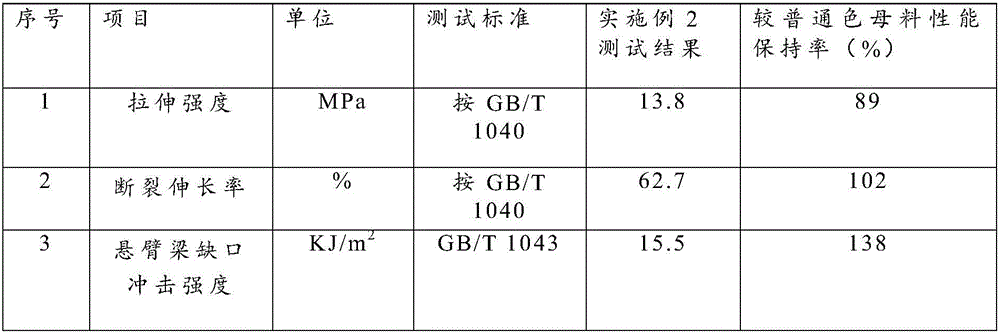

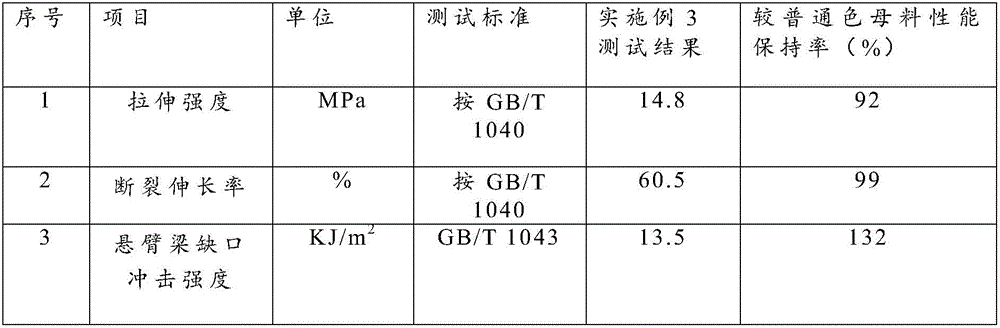

Special HIPS panel toughening color masterbatch for refrigerator, preparation method and application thereof

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

Method of adding auxiliary exposure graph

ActiveCN109407460AReduce defectsImprove stabilityOriginals for photomechanical treatmentGraphicsAlgorithm

The invention discloses a method of adding an auxiliary exposure graph. The method includes acquiring a complete design layout of an original layer; performing OPC (optical proximity correction) on alayout of the current layer according to an acquired original layout graph, and selecting a region of the treated layout graph spacing less than the provision of requirement I; in the selected region,adding an auxiliary exposure graph which has dimensions meeting the provision of requirement II, and no graph is exposed on a silicon wafer; upon adding of the auxiliary exposure graph, if the boundary of photoresist has indentation, allowing the width of the indentation to be less than the provision of requirement III, removing the convex portion of the corresponding original layout graph, and adding the auxiliary exposure graph to a new boundary generated by the removal of the convex portion. The method has the advantages that an ion injection layer process window can be effectively enlarged, graph defects can be decreased, and product yield can be increased.

Owner:SHANGHAI HUALI INTEGRATED CIRCUIT CORP

Hydraulic lifting system of toilet bowl lifting forming machine

ActiveCN105773830AEasy to useImprove pass rateAuxillary shaping apparatusSafety devices for lifting equipmentsMarine engineeringMaterial resources

Owner:TANGSHAN HEXIANG INDAL

Metal filing removal mechanism for production process of minced fillet

InactiveCN105077362AHigh degree of automationImprove pass rateFood mechanical treatmentFood preparationAutomationEngineering

Owner:ZHEJIANG OCEAN UNIV

Premixed high-performance concrete mixing device

InactiveCN113771218AAvoid problems with large aggregatesAvoid problems with reduced compressive strength valuesMixing operation control apparatusPretreatment controlElectric machineArchitectural engineering

The invention discloses a premixed high-performance concrete mixing device, and relates to the technical field of concrete processing. The device comprises a stirring device, a material guiding frame is fixed to the right side of the stirring device, a motor is fixed to the front face of the material guiding frame, a material mixing mechanism used for guiding aggregate is arranged in the material guiding frame, a crushing mechanism used for crushing large aggregate is arranged at the top of the right side of the material guiding frame, and an output shaft of the motor is in transmission connection with the crushing mechanism through a belt pulley group. Through the arrangement of a crushing roller set, aggregate is crushed by the crushing roller set, so that large aggregate is crushed into small aggregate, and under the action of a strip-shaped through groove, needle-sheet-shaped aggregate penetrates through the strip-shaped through groove to be screened to the bottom of the material guiding frame, so that the problems that the needle-sheet-shaped aggregate is mixed into concrete, the needle-sheet-shaped content of crushed stones is increased, and the compressive strength value of the concrete is reduced are avoided, and the quality of construction engineering is improved.

Owner:李向阳

Device for extrusion moulding of fertilizer stick

InactiveCN105859371AImprove pass rateLow cost of processing materialsFertiliser formsFertilizer mixturesElectrical and Electronics engineeringEngineering

Owner:吴青平

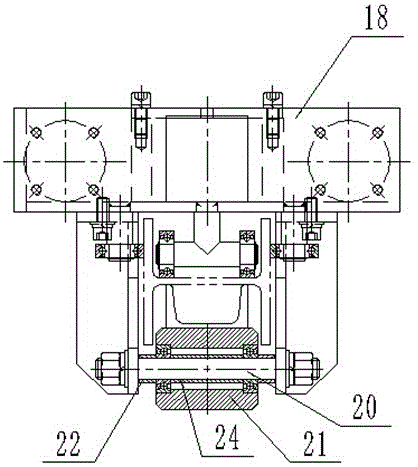

Automatic detection structure for water pipe nut

PendingCN111974697APrecise processingImprove pass rateSortingStructural engineeringMechanical engineering

The invention discloses an automatic detection structure for a water pipe nut. The automatic detection structure for the water pipe nut comprises an installation base, wherein a support is verticallyarranged on the front side of the installation base; an unaccepted product recycle bin is fixedly arranged at the lower end of the support; an installation plate is fixedly arranged at the upper end of the support; a left-and-right moving air cylinder is horizontally arranged on the surface of the installation plate; an up-and-down moving air cylinder is arranged at one end of the left-and-right moving air cylinder in a driving way; a front-and-back moving air cylinder is arranged at the bottom end of the up-and-down moving air cylinder in a driving way; a vertically downward automatic detection nut clamp is arranged at one end of the front-and-back moving air cylinder in a driving way; a loading station located below the automatic detection nut clamp is arranged on the installation base;a nut loading channel is arranged on one side of the loading station; and an unloading station is arranged on the other side of the loading station. According to the automatic detection structure forthe water pipe nut provided by the invention, each nut can be detected, unaccepted nuts can be directly rejected and cannot enter the follow-up processing link, and accepted nuts are fed to a next processing station so as to be screened, so that the product quality can be improved.

Owner:ZHONGSHAN DONGRUN INTELLIGENT EQUIP CO LTD

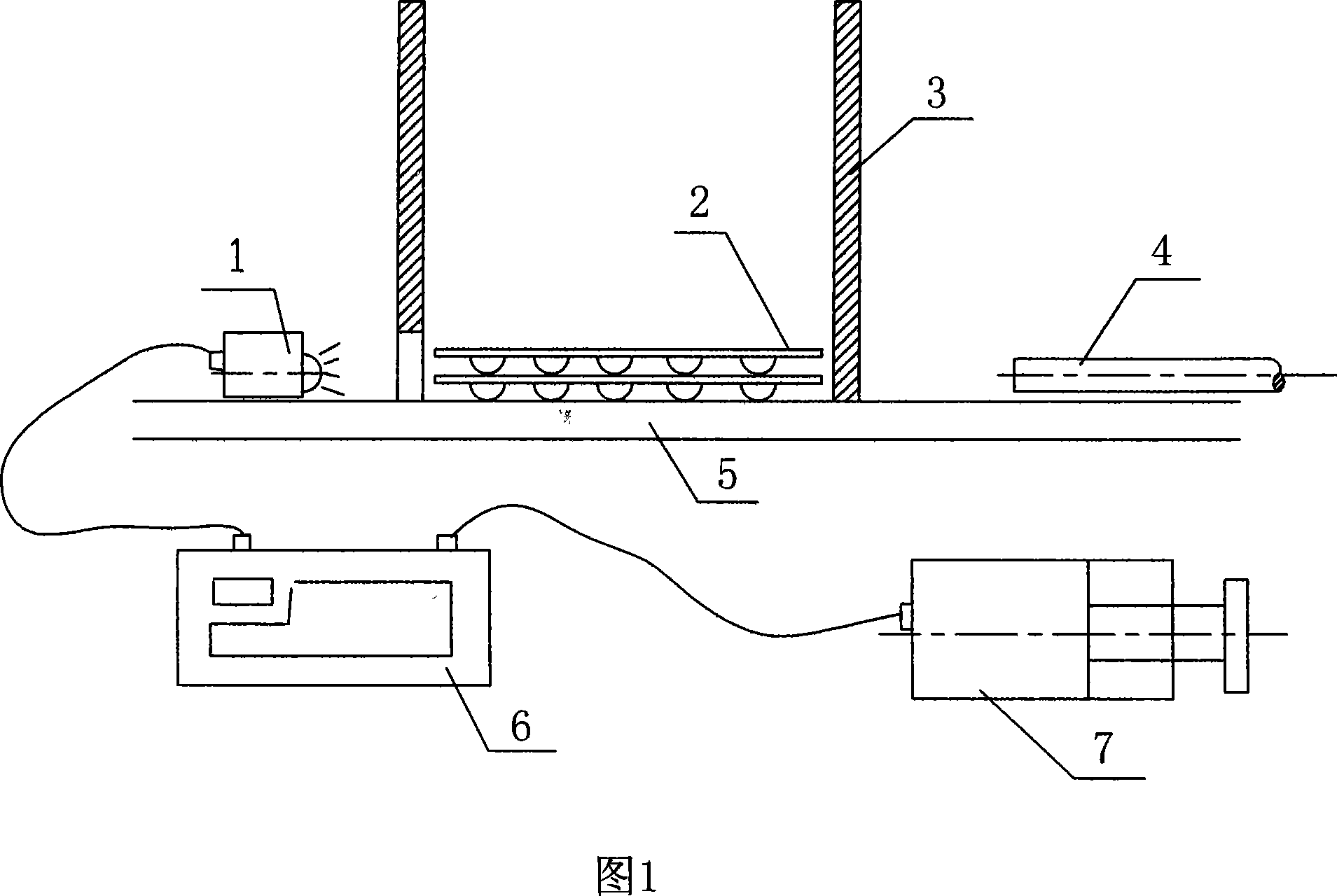

Article loading in case amount detecting and rejecting mechanism for package machinery

InactiveCN101168152AImprove product qualification rateReduce workloadPackaging automatic controlSortingOrifice plateVena contracta diameter

The invention relates to the technical field of packaging machinery, particularly to a mechanism for detecting and rejecting the article-boxing quantity of the packaging machinery. The invention comprises an orifice plate, a charging bottom-board, a control unit of the CPU and a pusher, which is characterized in that the invention also comprises a detecting mechanism of PUHs image of the CCD and an automatic rejecting mechanism, the detecting mechanism of PUHs image of the CCD is arranged nearby the pusher, the automatic rejecting mechanism is positioned on a transmission component position arranged for the output of packaging products, and the detecting mechanism of PUHs image of the CCD and the automatic rejecting mechanism are controlled by the control unit of the CPU. The invention has the advantages that the detecting mechanism of PUHs image of the CCD automatically detects the articles over pushed or less pushed into packaging boxes by the control of the control unit of the CPU, and the automatic rejecting mechanism automatically rejects the unqualified packaging products, excluding the unqualified packaging products from entering into the market, increasing the qualified rate of product, simultaneously reducing the workload of inspectors.

Owner:上海师明包装机械有限公司

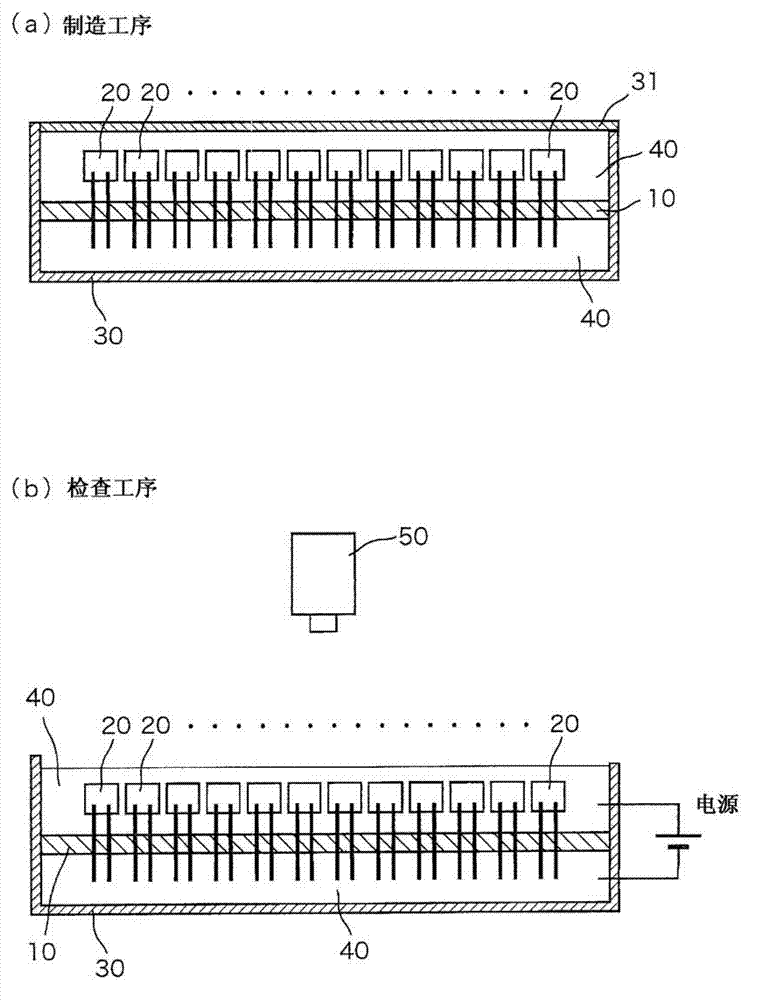

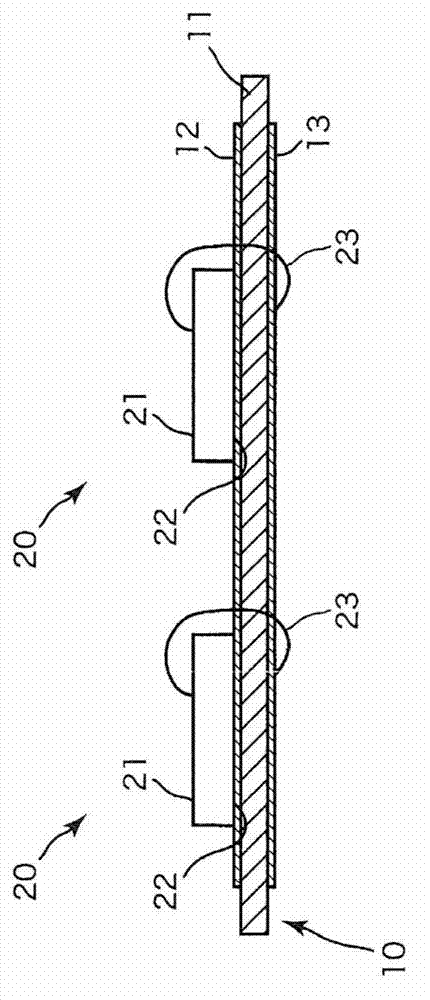

Method for manufacturing semiconductor device

InactiveCN102906563ASemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMicroscopeVoltage

Owner:SUMITOMO ELECTRIC IND LTD

Surface grinding method of high-grade stainless steel plates for automobiles

InactiveCN111558854AImprove pass rateMeet end-use requirementsStructural engineeringSS - Stainless steel

The invention discloses a surface grinding method of stainless steel plates. The method comprises steps as follows: (1), to-be-treated steel coils are fed into a scale breaker and subjected to scale breaking treatment, and steel plates with plate flatness smaller than or equal to 15 mm are obtained; (2), the steel plates are subjected to hot-rolled pickling, and then the hot-rolled plates are classified into light, moderate and severe according to the severity of surface defects; (3), the hot-rolled plates are fed into a grinder, abrasive belts of grinding heads of the grinder are configured according to the classification of surfaces of the hot-rolled plates, the surfaces of the hot-rolled plates are subjected to coarse grinding by adopting the abrasive belts with decay time of 20-60 min,and the surfaces of the hot-rolled plates are subjected to accurate grinding by adopting the abrasive belts with decay time of 300-1000 min; and (4), the steel plates output by the grinder are rolled, and the total deformation is larger than or equal to 60%. According to the method, defects of chromatic aberration and rough stripes on the surfaces of the hot-rolled plates can be overcome, the defect of small pits produced by grinding is overcome, the qualification rate of the steel plates for the automobile is increased, the use efficiency of the abrasive belts is improved, and the cost is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

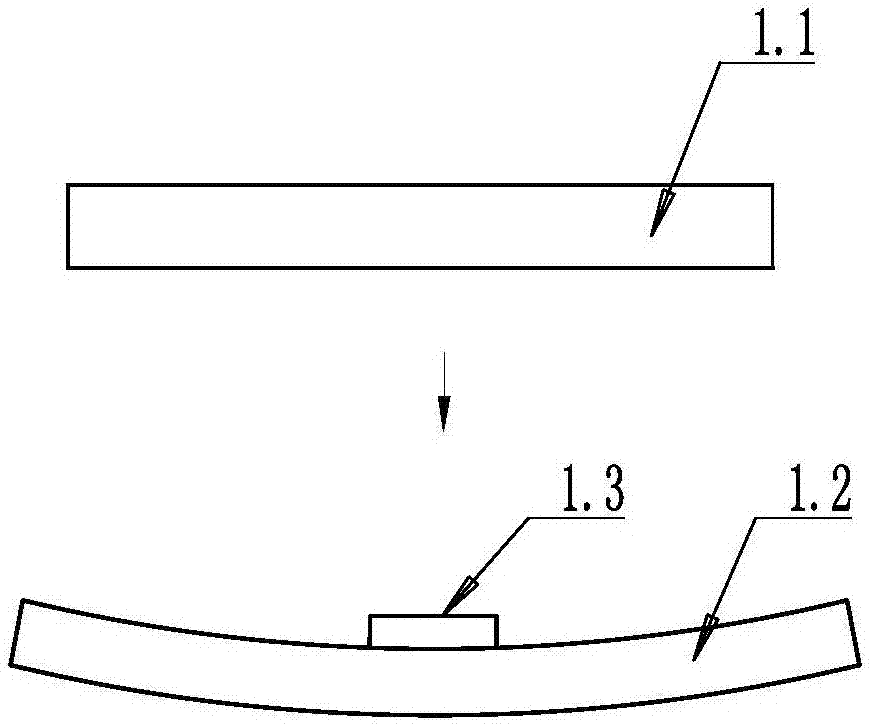

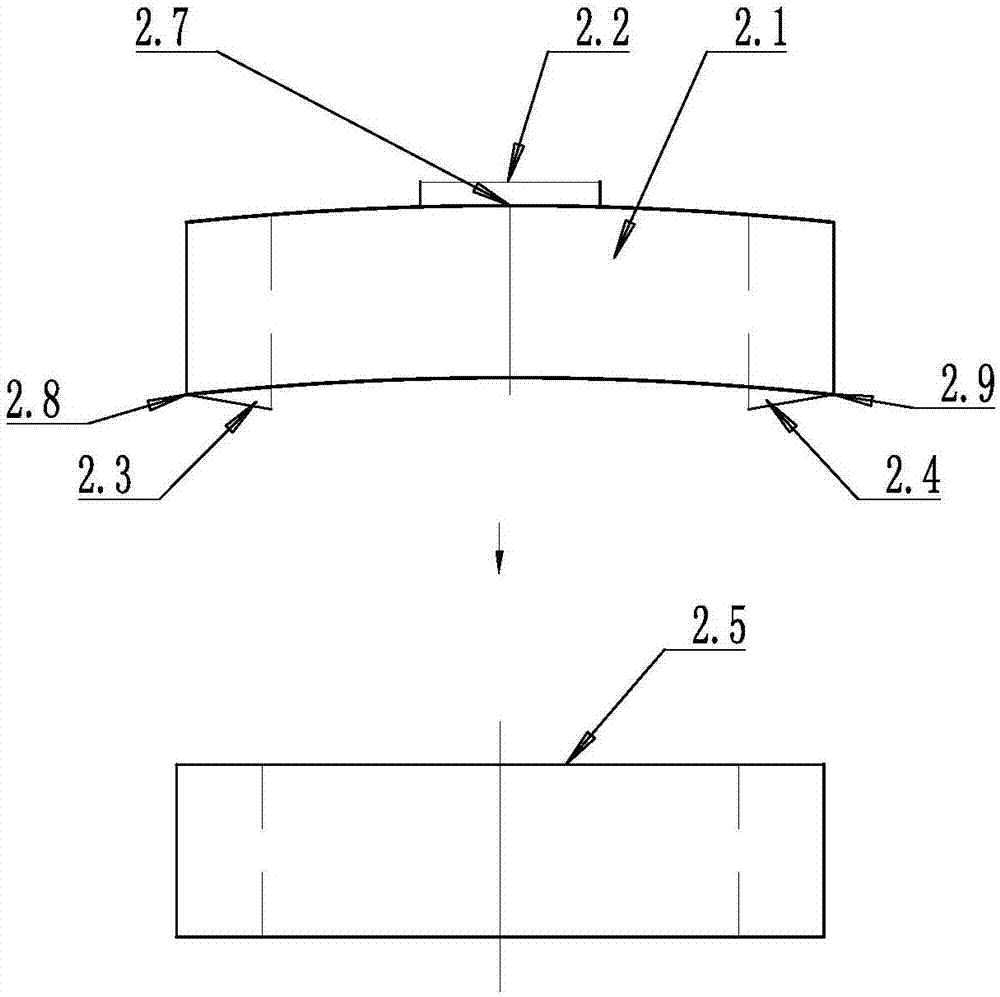

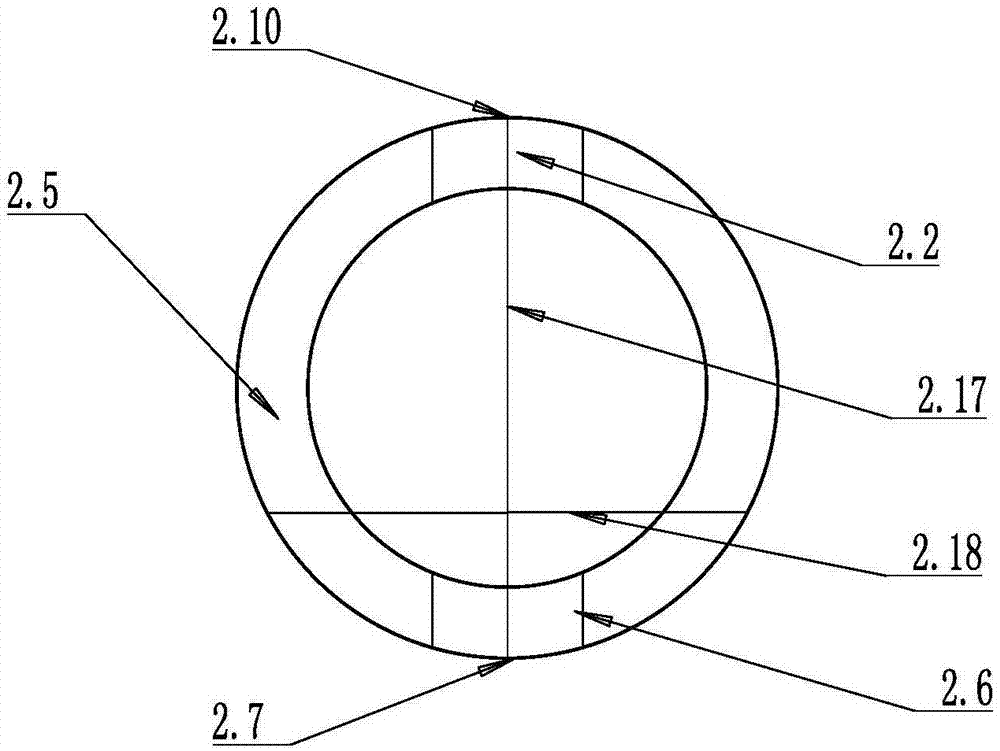

A base roller molding process

Owner:SUZHOU GOODTIME TECH DEV

Automatic curved surface coating apparatus

InactiveCN102424162ASufficient athletic abilityAccurate cloaking actionLabelling machinesManipulatorComputer control

The invention belongs to the technical field of curved surface coating, and especially relates to an automatic curved surface coating apparatus which can automatically complete a curved surface coating process. The automatic curved surface coating apparatus comprises a material conveying device and a film paper conveying device which are mounted on a frame; the material conveying device comprises a manipulator for clamping a material, and a manipulator motion mechanism for driving the motion of the manipulator; the film paper conveying device comprises a film paper frame for fixing the film paper, and a film paper horizontal motion mechanism for driving the motion of the film paper; a position measuring device is disposed on the motion tracks of the material conveying device and the film paper conveying device, and is fixed on the frame; the film paper conveying device is disposed in a water tank; the material conveying device, the film paper conveying device, and the measuring device are connected with a computer control device, and are controlled by the computer control device; an activator spraying device is disposed on the frame. The invention provides a curved surface coating apparatus which can perform material curved surface coating in an automatic production mode.

Owner:赖万明

Cylinder sleeve inner hole processing clamp

InactiveCN108747515ASimple structureReasonable designPositioning apparatusMetal-working holdersPlastic materialsArchitectural engineering

The invention relates to a cylinder sleeve inner hole processing clamp. The cylinder sleeve inner hole processing clamp comprises a clamp main body which is composed of a metal cylindrical housing andan ultrathin metal barrel, wherein two openings of the metal cylindrical housing are symmetrically equipped with circular ring baffle plates; the outer diameters of the circular ring baffle plates are fixedly connected with the metal cylindrical housing; the ultrathin metal barrel is fixedly connected to the inner diameters of the circular ring baffle plates; the inner cavity of the ultrathin metal barrel is equipped with a cylinder sleeve; the outer part of the ultrathin metal barrel is wound with a plastic material; the two ends of the plastic material are fixedly connected to sides of thecircular ring baffle plates; the bottom of the metal cylindrical housing is connected with a base; the bottom of the base is fixedly connected with a supporting plate through a screw; and piston barrels are symmetrically arranged at the two sides of the metal cylindrical housing. The cylinder sleeve inner hole processing clamp is simple in structure, is reasonable in design, can prevent the cylinder sleeve from being deformed and worn in a processing process, also can accurately position, reduces a rejection rate, improves production efficiency, can process cylinder sleeves of different specifications, can perform thick boring and fine boring, and reduces the cost.

Owner:JIANGSU ZIJIN POWER

Electrically-driven three-stage planetary speed reduction driver

PendingCN114552871AImprove assembly efficiencyImprove pass rateMechanical energy handlingStructural associationDrive motorElectric machine

Owner:TIANJIN SNEIJDER PRECISION MACHINERY

One-stage planetary reduction unit and three-stage planetary reduction driver

PendingCN114439887AImprove assembly efficiencyImprove pass rateGearing detailsToothed gearingsAssembly structureAstrophysics

Owner:TIANJIN SNEIJDER PRECISION MACHINERY

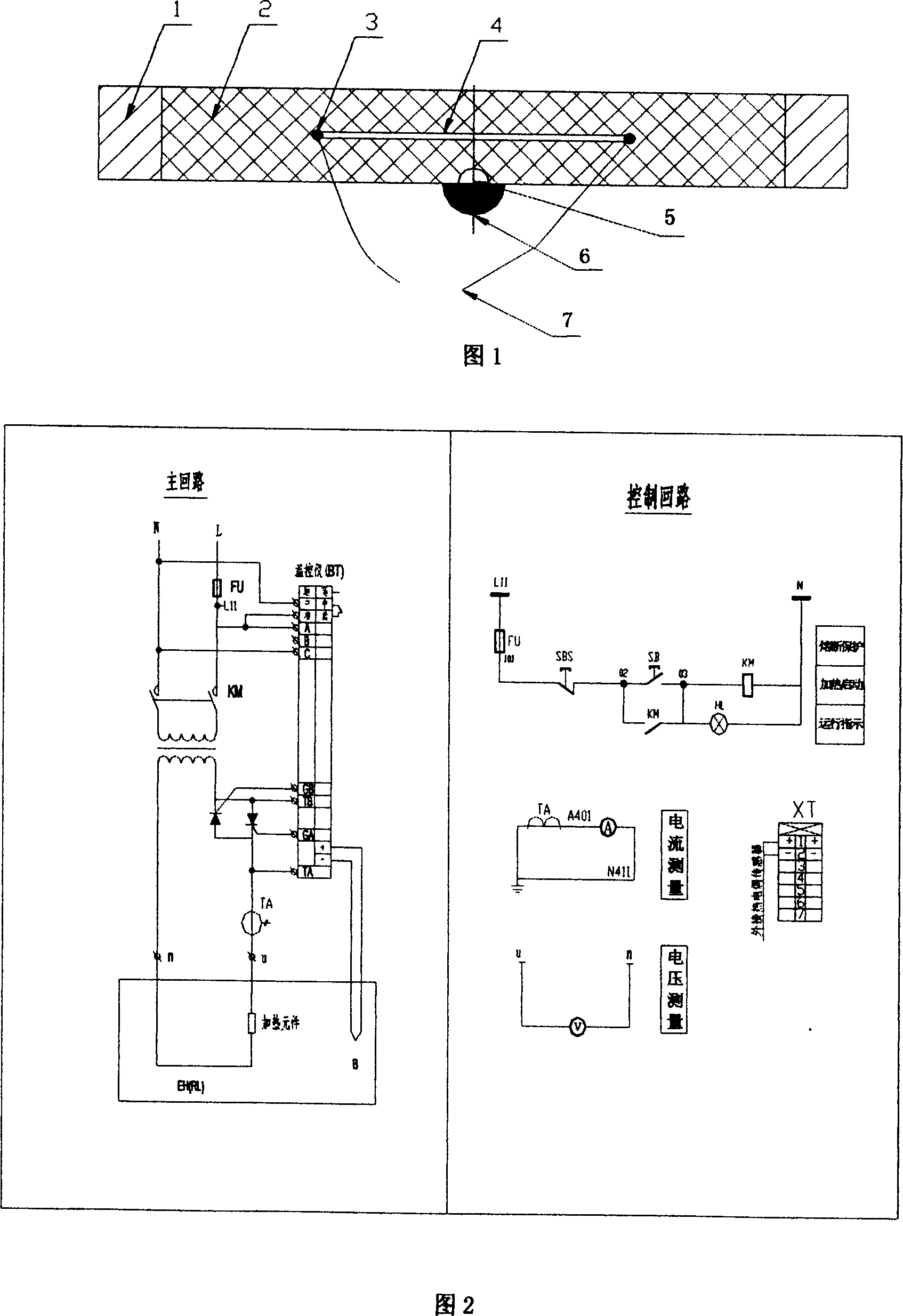

Bothway reactive voltage adjusting device

InactiveCN103762603AImprove voltage stabilityImprove pass rateAc network voltage adjustmentReactive power compensationDistribution power systemElectric network

The invention discloses a bothway voltage reactive adjusting device, and relates to a high voltage bus. The bothway reactive voltage adjusting device comprises a transformer, an on-load tap-changer, a first circuit breaker, a second circuit breaker, a capacitor bank, an electric reactor, a current transformer, a voltage transformer and a controller. A tap on the transformer is electrically connected with the on-load tap-changer which is electrically connected with the first circuit breaker and the second circuit breaker, the first circuit breaker is electrically connected with the electric reactor, the second circuit breaker is electrically connected with the capacitor bank, the controller is electrically connected with the on-load tap-changer, the first circuit breaker, the second circuit breaker, the current transformer and the voltage transformer, and the on-load tap-changer, the current transformer and the voltage transformer are electrically connected with the high voltage bus. The bothway reactive voltage adjusting device is simple in structure, capable of achieving bothway reactive voltage adjusting, free of flashy flow and current impact, accurate in voltage controlling, capable of effectively improving the voltage stability and the percent of pass of a partial electric network, and capable of enabling a power distribution system to be safer and more stable.

Owner:ANHUI HUAZHENG ELECTRIC

Preparation of the high-performance porcelain heating parts with automatic temperature-control

InactiveCN1997245AImprove pass rateNo pollution in the processHeater elementsHeating element materialsEpoxyTemperature control

Owner:范新宽

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap