Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Pickling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from ferrous metals, copper, precious metals and aluminum alloys. A solution called pickle liquor, which usually contains acid, is used to remove the surface impurities. It is commonly used to descale or clean steel in various steelmaking processes.

Manufacturing process of high-carbon tool steel SK85 cold-rolled wide steel strip

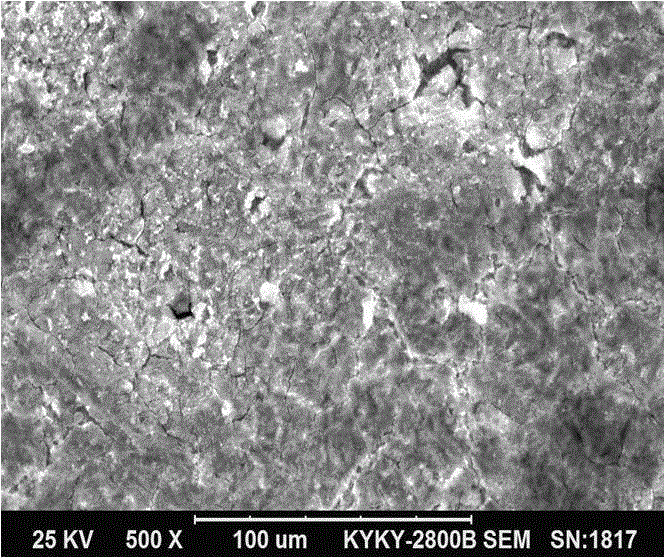

The invention discloses a manufacturing process of a high-carbon tool steel SK85 cold-rolled wide steel strip. The process is characterized in that steel is subjected to converter smelting, LF furnacerefining and slab continuous casting to obtain continuous casting slabs with the thickness ranging from 210 mm to 230 mm, the continuous casting slabs are heated and subjected to hot continuous rolling and laminar cooling to reach the coiling temperature, a hot-rolled wide steel strip with the thickness ranging from 2.5 mm to 6.0 mm is obtained, the coiled hot-rolled wide steel strip is put in storage and slowly cooled to the room temperature, and the obtained metallographic structure is thin-sheet-shaped pearlite; the total reduction of first cold rolling is controlled to be 20%-50% after acid pickling of the hot-rolled wide steel strip, then spheroidizing annealing is conducted, the Vickers hardness HV5 is 180 or below, and the spheroidizing rate is 92% or above; after the steel strip is subjected to primary spheroidizing annealing, secondary cold rolling is conducted, the total reduction of cold rolling is controlled to be 30%-85%, and a cold-rolled wide steel strip with the finished product specification being 0.70-3.00 mm thick is obtained; the steel strip subjected to secondary cold rolling is further spheroidized and annealed, the Vickers hardness HV5 is 175 or below, and the spheroidizing rate is 94% or above; and then third cold rolling is conducted, the total reduction of cold rolling is controlled to be 50%-85%, and the cold-rolled wide steel strip with the finishedproduct specification being 0.10-0.70 mm thick is obtained.

Owner:新余钢铁股份有限公司

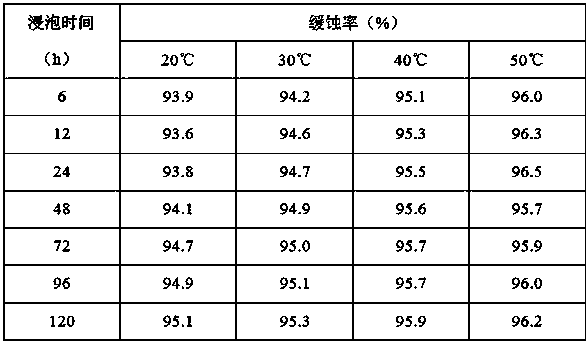

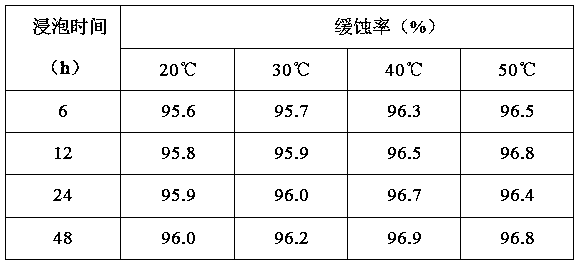

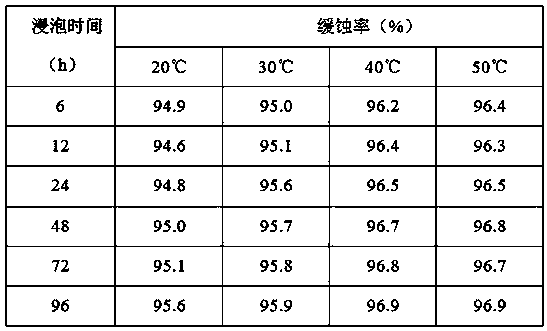

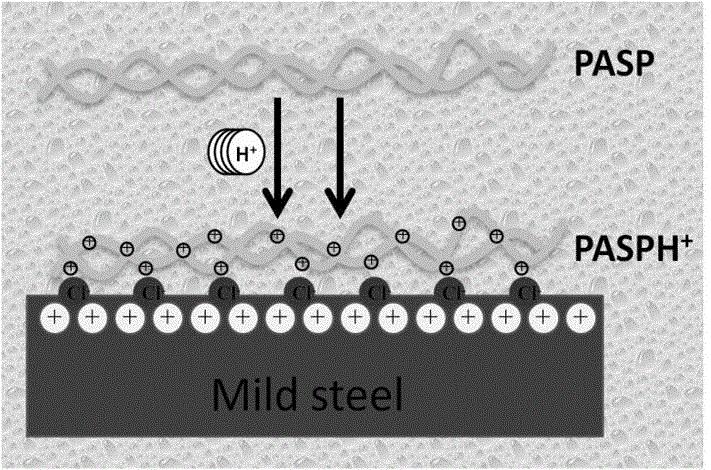

Camellia oleifera abel shell compound corrosion inhibitor and preparation method and application thereof

Owner:SOUTHWEST FORESTRY UNIVERSITY

Environment-friendly carbon steel pickling inhibitor and application thereof

Owner:QINGDAO AGRI UNIV

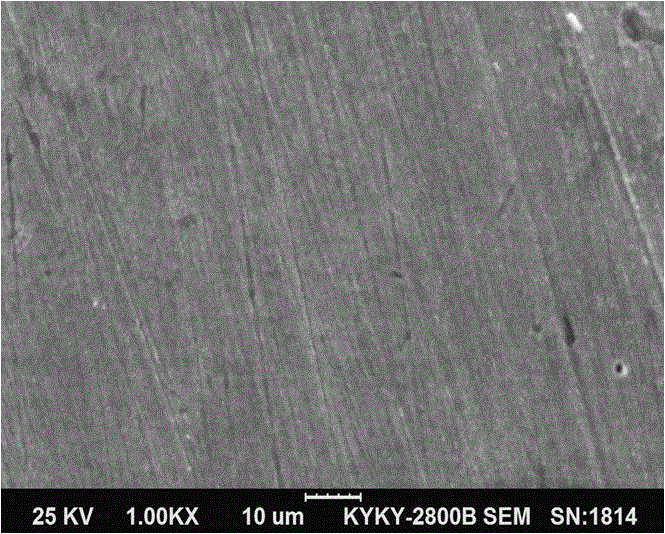

Surface grinding method of high-grade stainless steel plates for automobiles

InactiveCN111558854AImprove pass rateMeet end-use requirementsStructural engineeringSS - Stainless steel

The invention discloses a surface grinding method of stainless steel plates. The method comprises steps as follows: (1), to-be-treated steel coils are fed into a scale breaker and subjected to scale breaking treatment, and steel plates with plate flatness smaller than or equal to 15 mm are obtained; (2), the steel plates are subjected to hot-rolled pickling, and then the hot-rolled plates are classified into light, moderate and severe according to the severity of surface defects; (3), the hot-rolled plates are fed into a grinder, abrasive belts of grinding heads of the grinder are configured according to the classification of surfaces of the hot-rolled plates, the surfaces of the hot-rolled plates are subjected to coarse grinding by adopting the abrasive belts with decay time of 20-60 min,and the surfaces of the hot-rolled plates are subjected to accurate grinding by adopting the abrasive belts with decay time of 300-1000 min; and (4), the steel plates output by the grinder are rolled, and the total deformation is larger than or equal to 60%. According to the method, defects of chromatic aberration and rough stripes on the surfaces of the hot-rolled plates can be overcome, the defect of small pits produced by grinding is overcome, the qualification rate of the steel plates for the automobile is increased, the use efficiency of the abrasive belts is improved, and the cost is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

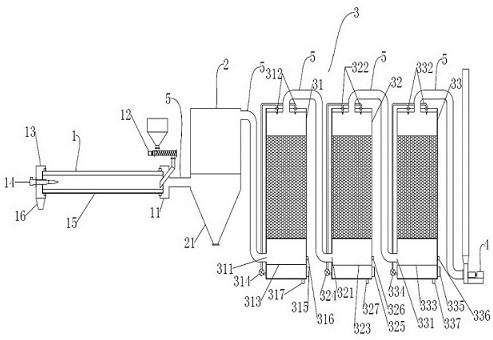

System and method for preparing sulfuric acid by recycling waste crude ferric sulfate salt in iron and steel industry through pickling

PendingCN113511634ASuppress generationEfficient use of resourcesSulfur compoundsIron sulfateSteelmaking

Owner:佛山市景嘉机电设备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap