Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Corrosion inhibitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corrosion inhibitor is a chemical compound that, when added to a liquid or gas, decreases the corrosion rate of a material, typically a metal or an alloy. The effectiveness of a corrosion inhibitor depends on fluid composition, quantity of water, and flow regime. A common mechanism for inhibiting corrosion involves formation of a coating, often a passivation layer, which prevents access of the corrosive substance to the metal. Permanent treatments such as chrome plating are not generally considered inhibitors, however. Instead corrosion inhibitors are additives to the fluids that surround the metal or related object.

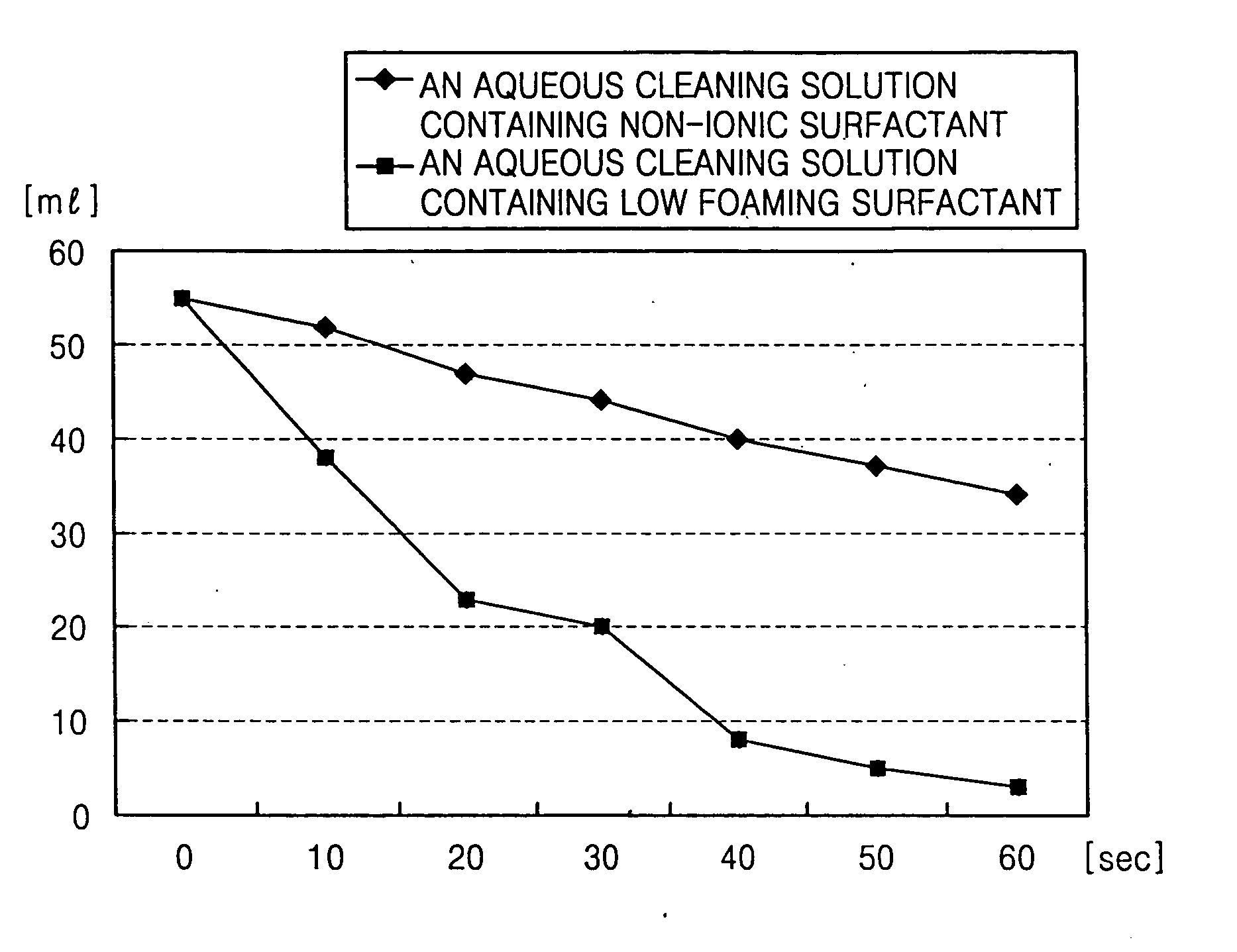

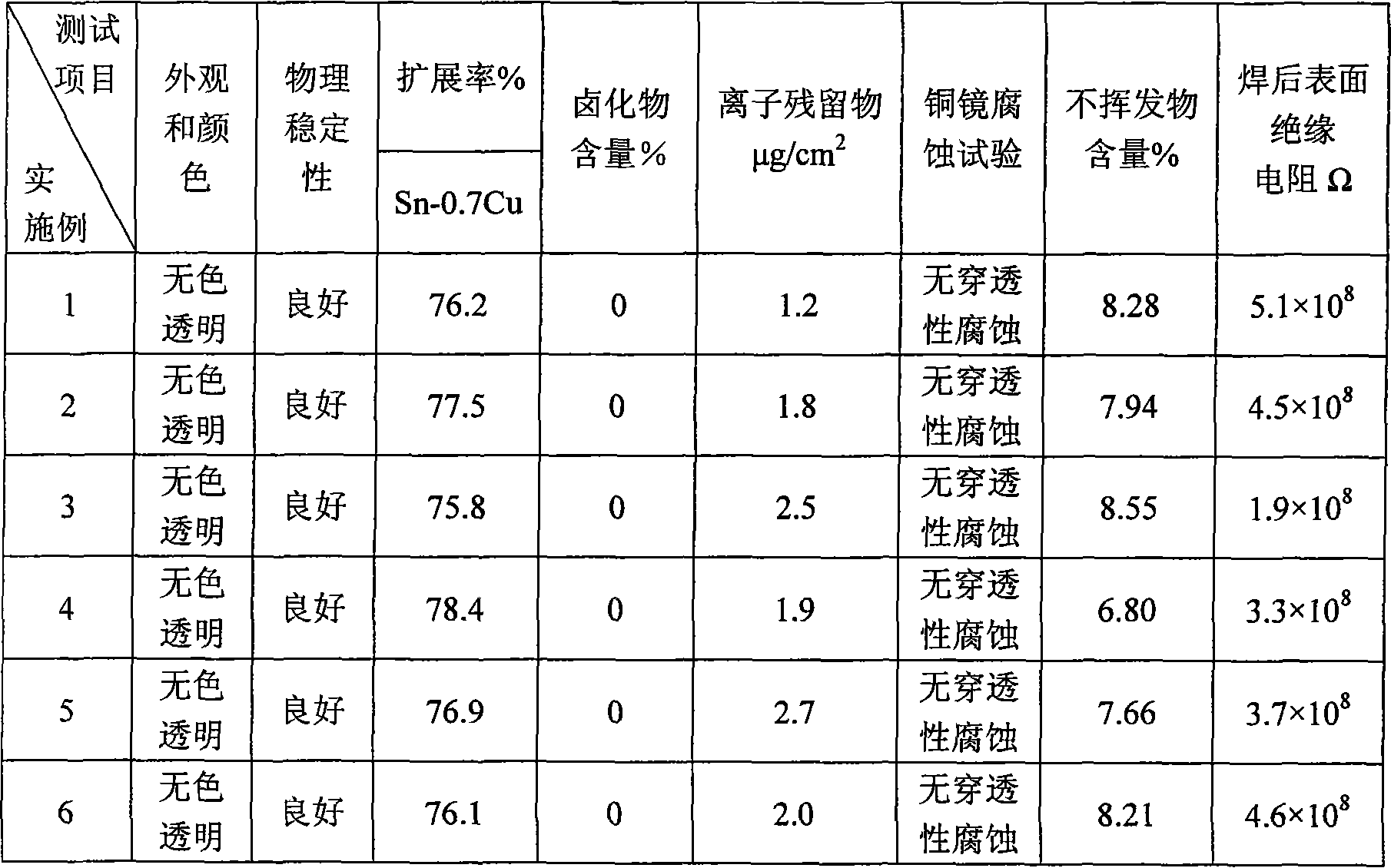

Aqueous cleaning solution for integrated circuit device and method of cleaning using the cleaning solution

InactiveUS20050159322A1Suitable for cleaningPrevent overflowInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDevice formPh control

Owner:SAMSUNG ELECTRONICS CO LTD

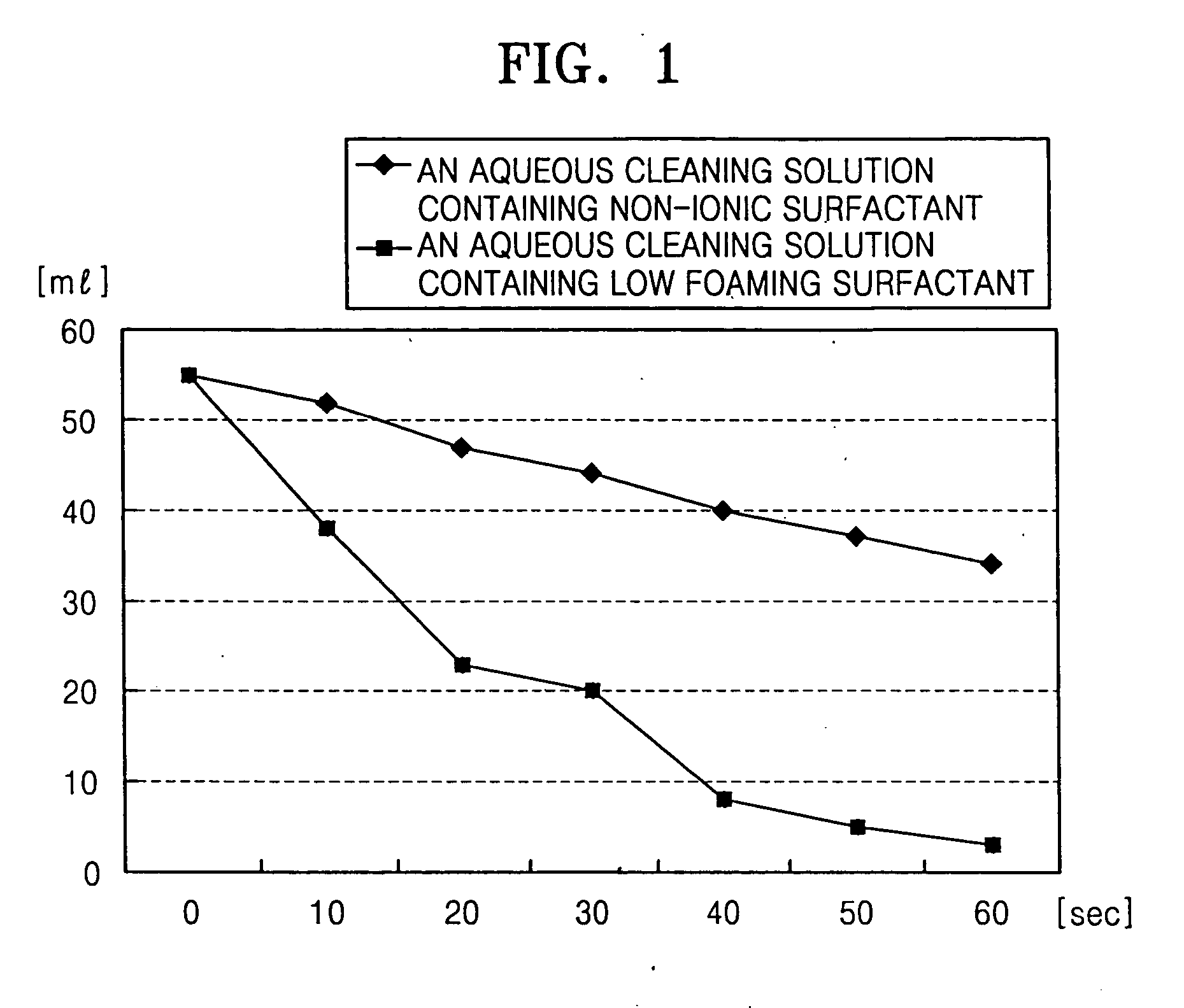

Free from cleaning soldering flux without halogen and rosin in use for solder without lead

InactiveCN101049661AImprove solderabilitySolderability is sufficientWelding/cutting media/materialsSoldering mediaHalogenSoldering

Owner:BEIJING UNIV OF TECH

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareImprove performanceLiquid carbonaceous fuelsFuel additivesNew energyOil additive

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:YONGZHOU JINZHEN NEW ENERGY DEV CO LTD

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AThe formula is scientific and reasonableSimple production processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSurface cleaning

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:BEIJING KAILAN AVIATION TECH CO LTD

Green total organic carbon steel scale and corrosion inhibitor for circulating cooling water system

InactiveCN102351328AEasy to makeEasy to useScale removal and water softeningEutrophicationCarboxylic acid

The invention discloses a green total organic carbon steel scale and corrosion inhibitor for a circulating cooling water system, which comprises a scale inhibitor and a corrosion inhibitor, wherein the scale inhibitor comprises one or more of hydrolyzed polymaleic anhydride, polyacrylic acid, polymethacrylic acid, acrylic acid / hydroxypropyl acrylate copolymer, acrylic acid / hydroxypropyl acrylate / methyl acrylate terpolymer and acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid copolymer; and the corrosion inhibitor comprises oxalic acid or oxalate, alpha-hydroxycarboxylic acid or salt thereof and silicate. The scale and corrosion inhibitor has excellent scale inhibition and corrosion inhibition performance, and belongs to a completely phosphorus-free metal-free environment-friendly total organic composition. Discharged waste water treated by the composition can not cause eutrophication pollution to the environment.

Owner:TIANJIN HEGUANG ELECTRICAL & MECHANICAL EQUIP CO LTD

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

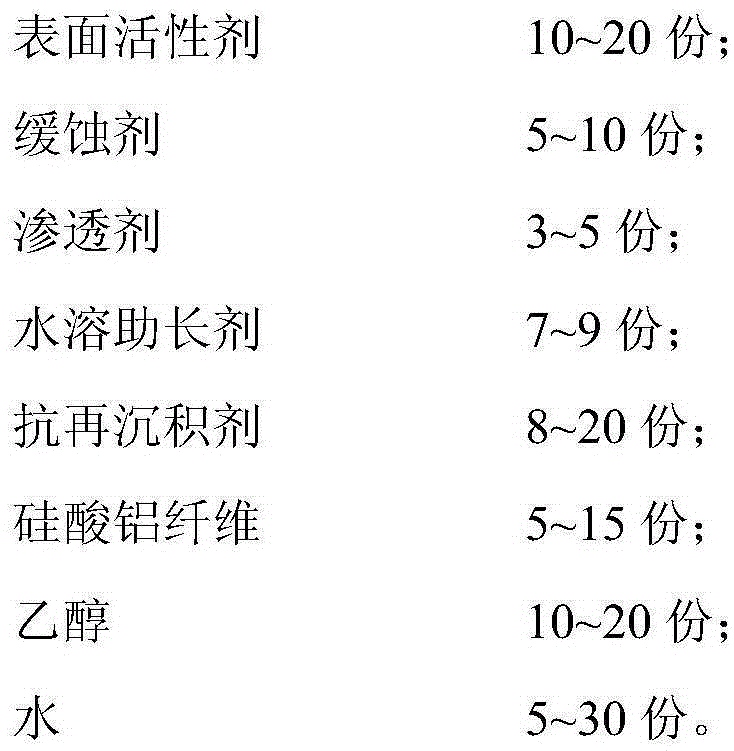

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

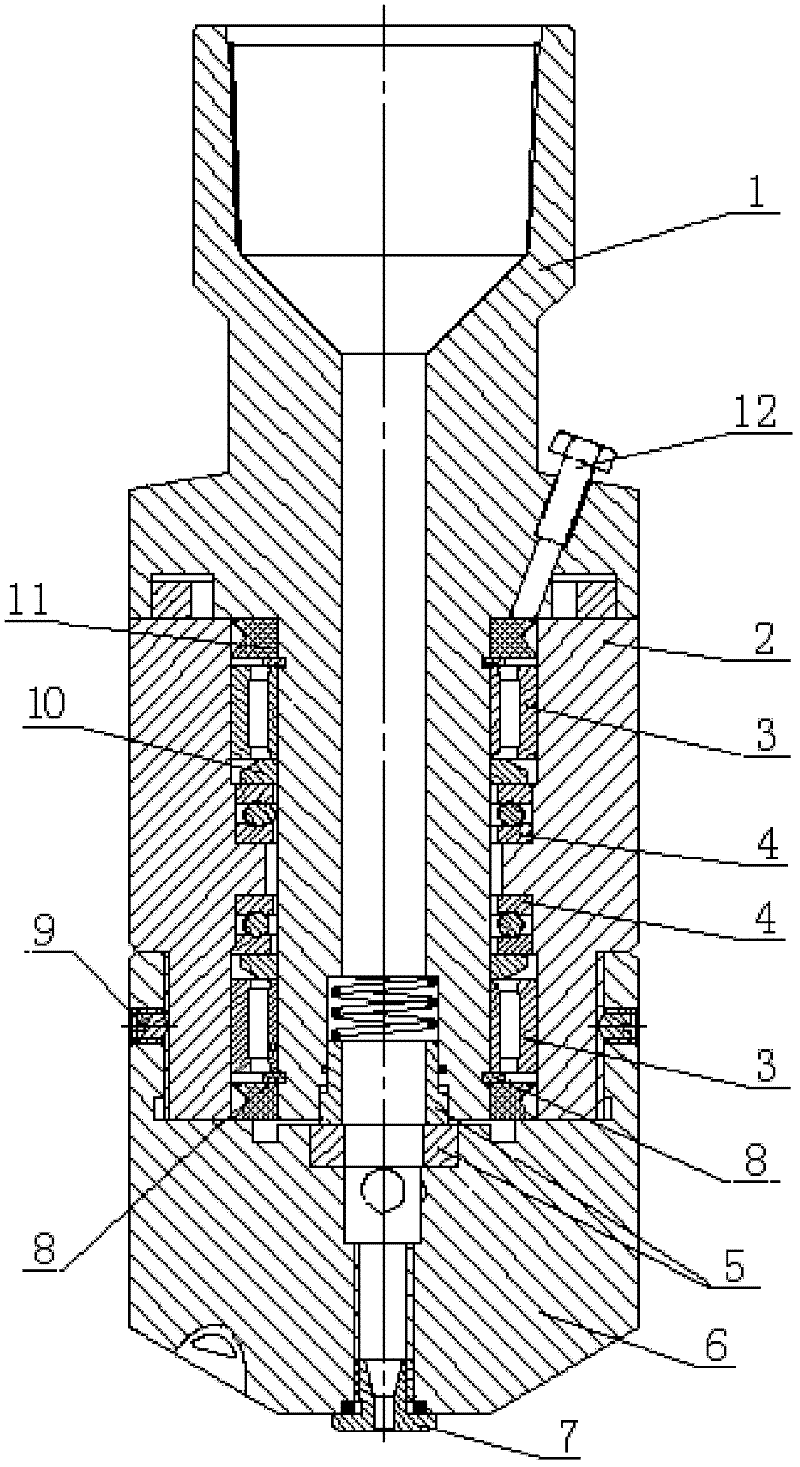

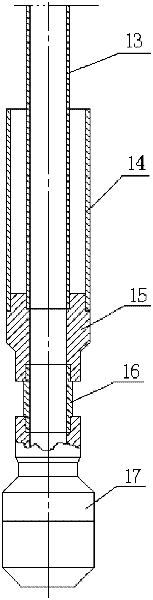

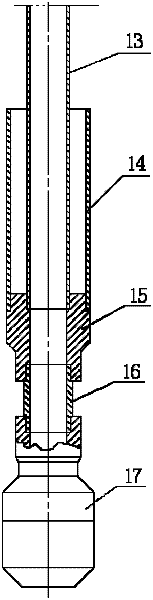

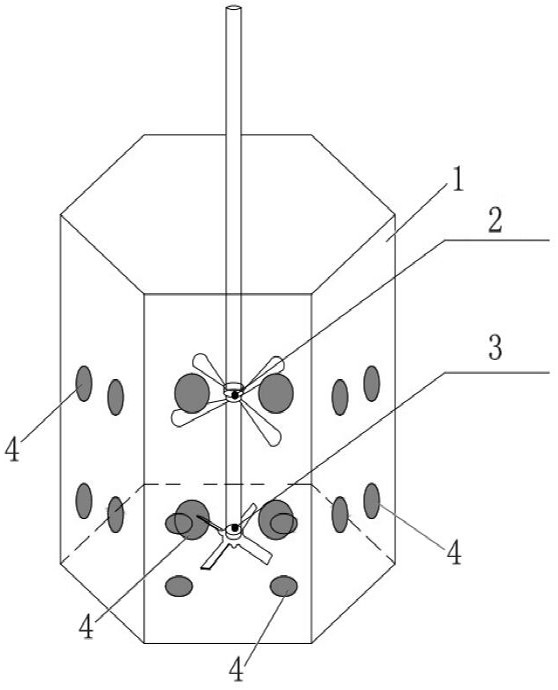

A kind of rotary jet sand cleaning method

ActiveCN102287152ASimple structureEasy to disassembleMovable spraying apparatusFlushingAdhesiveWellbore

Owner:PETROCHINA CO LTD

Photoresist cleaning fluid

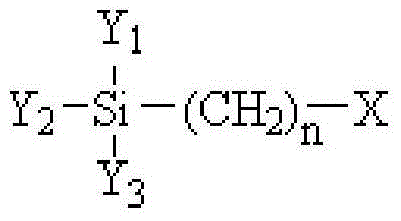

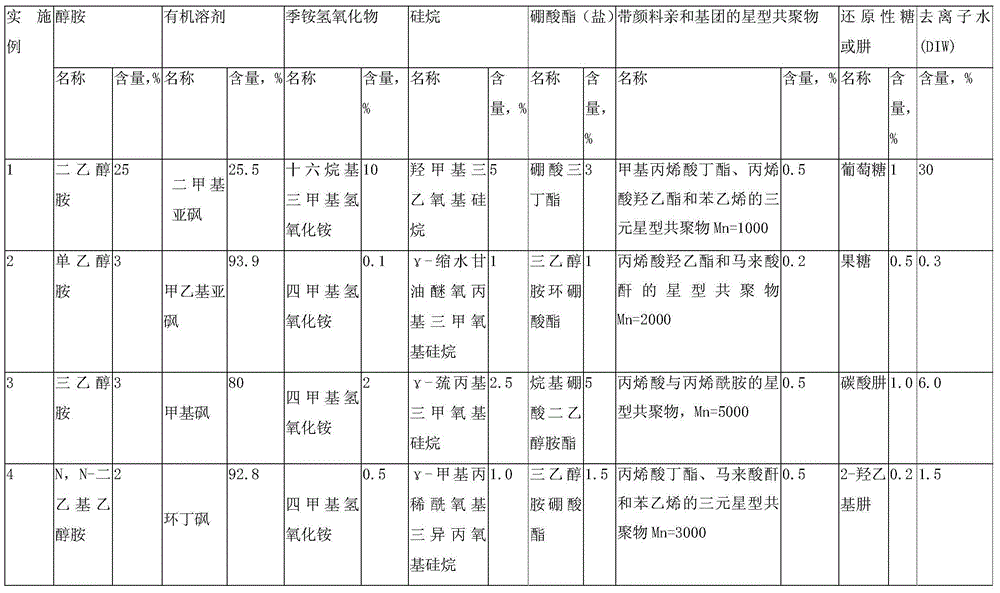

InactiveCN105527802AEfficient removalLarge operating windowPhotosensitive material processingSilanesSolvent

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

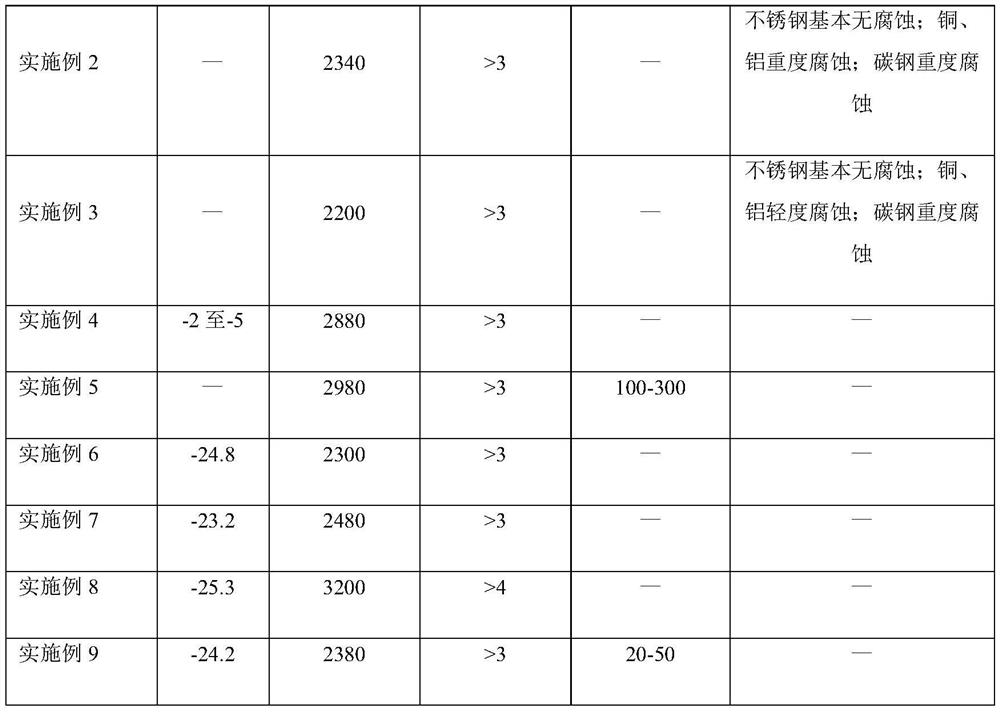

Low-temperature peracetic acid disinfectant and preparation method thereof

InactiveCN112790191AReduce the use temperatureReduce corrosionBiocideFungicidesCold chainEnvironmental engineering

Owner:海韵一剑大卫生科技有限公司

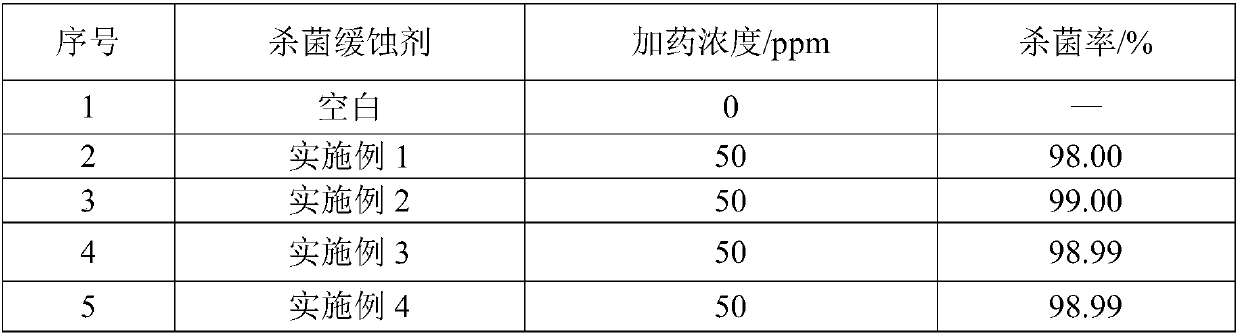

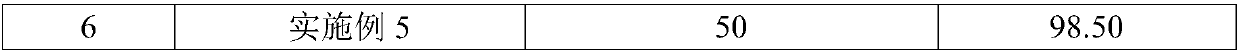

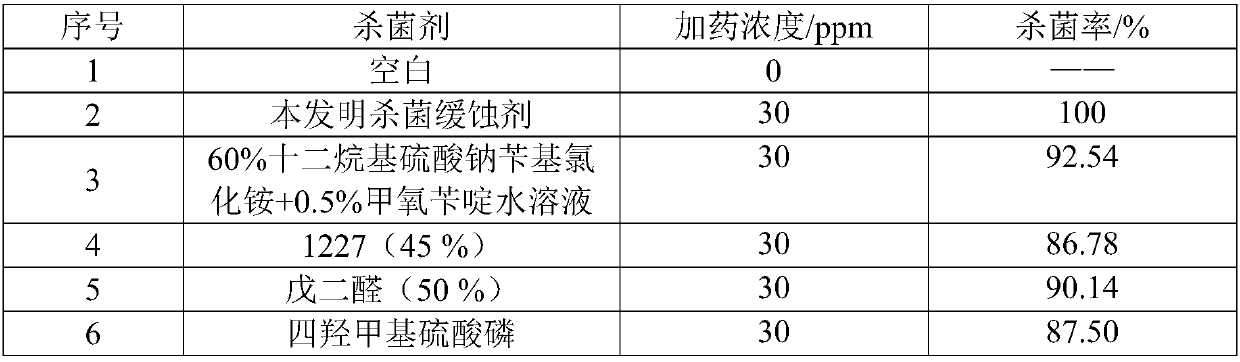

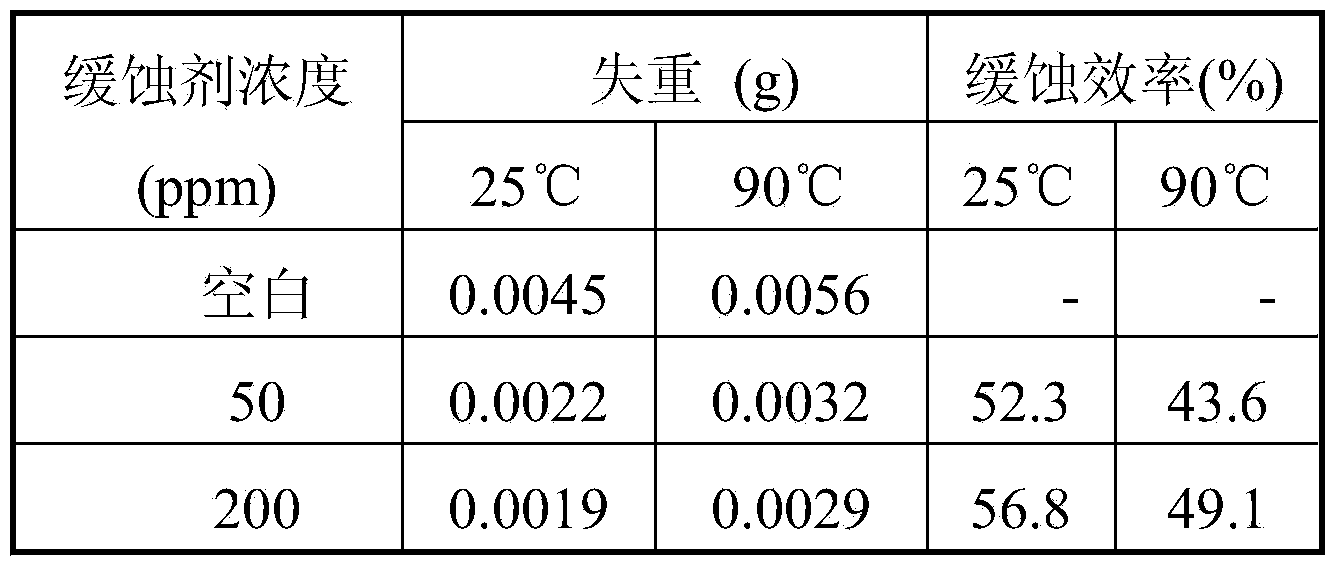

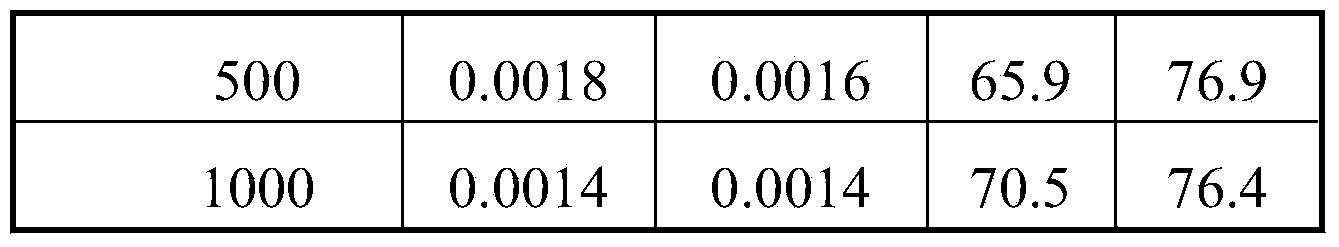

Sterilization corrosion inhibitor for oil field water treatment system as well as preparation method and application thereof

ActiveCN107760290ABoth bactericidalBoth corrosion inhibitionBiocideWaste water treatment from quariesWater treatment systemSulfate-reducing bacteria

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Iron and steel product surface treating agent and preparation method thereof

InactiveCN105256321AReduce productionReduce wasteMetallic material coating processesIndustrial waste waterO-Phosphoric Acid

The invention provides an iron and steel product surface treating agent and a preparation method thereof, and relates to the technical field of metal surface treating agents. The surface treating agent comprises, by weight, 12%-17% of phosphoric acid with the concentration of 85%, 3%-8% of composite phosphate, 7%-12% of nitric acid with the concentration of 65%, 5%-10% of corrosion inhibitor(s), 1%-3% of aqueous surface active agent(s), 3%-6% of zinc chrome, 4%-7% of polyol ester, and the balance water. The iron and steel product surface treating agent can be used for carrying out derusting, deoiling and phosphating on iron and steel products at the same time, and the generation amount of industrial waste water in the production process can be greatly reduced; the iron and steel product surface treating agent can be stored for a long time without lowering of the effectiveness, and uniform and compact phosphating films still can be formed on the surfaces of the iron and steel products even if the iron and steel product surface treating agent is stored for a long time; in addition, when the iron and steel product surface treating agent is used for carrying out comprehensive surface treating on the iron and steel products, the replacement frequency of bath solutions is low, the utilization rate of acid liquor is high, and the production cost of enterprises is low.

Owner:NANHUA UNIV +1

Cation emulsified asphalt for reducing corrosivity during production process and preparation method thereof

InactiveCN107722656AChange state of chargeGood corrosion inhibition effectBuilding insulationsOrganic acidAsphalt

The invention relates to cation emulsified asphalt for reducing the corrosivity during a production process and a preparation method thereof. The cation emulsified asphalt is prepared from the following raw materials in percentage by weight: 53 to 70 percent of asphalt, 0.8 to 3.0 percent of an emulsifier, 3.0 to 5.0 percent of a modifier, and the balance of water. The cation emulsified asphalt has the innovation point of a difunctional asphalt emulsifier required for producing the cation emulsified asphalt; a basic component is prepared from organic polyamine and organic acid which serve as raw materials; then the basic component, an acidic component and organic aldehyde with the molar ratio being 1: (1-1.3): (1-1.3) are reacted, so that the difunctional asphalt emulsifier is formed; themolecular structure of the difunctional asphalt emulsifier comprises a plurality of adsorption centers which can form an adsorption protective film and have emulsification and corrosion inhibition double functions. The emulsified asphalt has low corrosivity during a preparation process, and the hidden danger of corrosion during emulsification, storage and conveying process can be greatly reduced without a corrosion inhibitor. The emulsified asphalt is simple in production technology, wide in source of raw materials and excellent in performance, and can be applied to micro-surfacing and slurrysurfacing.

Owner:WEIFANG UNIVERSITY

Treatment method of circulating water with leaking wax oil

ActiveCN102730866AEasy to controlAvoid re-adhesionFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWaxCarboxylic acid

The invention provides a treatment method of circulating water with leaking wax oil. The method comprises the following steps: a) adding an oxidation-type bactericide; b) adding a corrosion and scale inhibitor containing at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor agent and an optional zinc salt; and c) adding at least one polysorbate as a wax oil emulsifier; and d ) adding at least one polyoxyethylene nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Viscous acid and preparation method thereof

InactiveCN105713594AImprove solubilityEasy to prepareDrilling compositionWater blockCorrosion inhibitor

Owner:XI'AN PETROLEUM UNIVERSITY

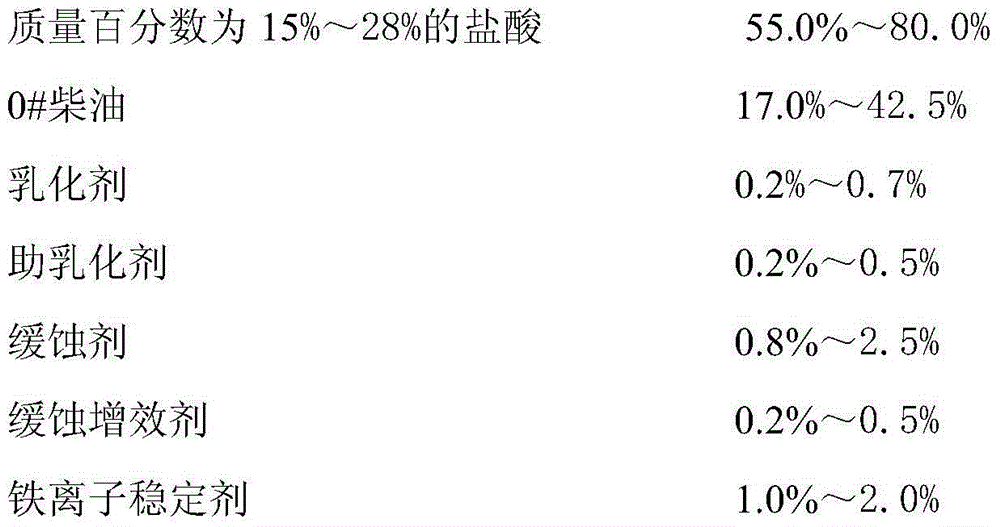

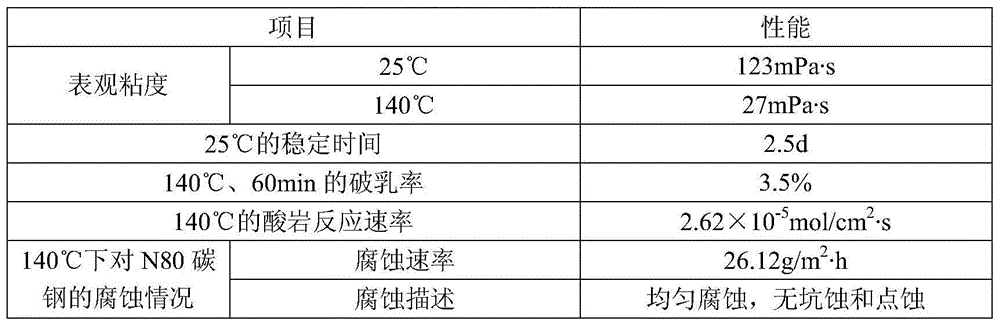

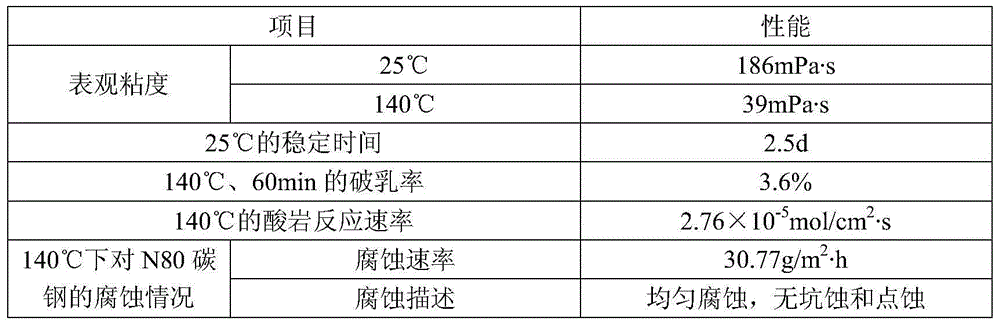

Formula and preparation method of high temperature emulsified acid

Owner:PETROCHINA CO LTD

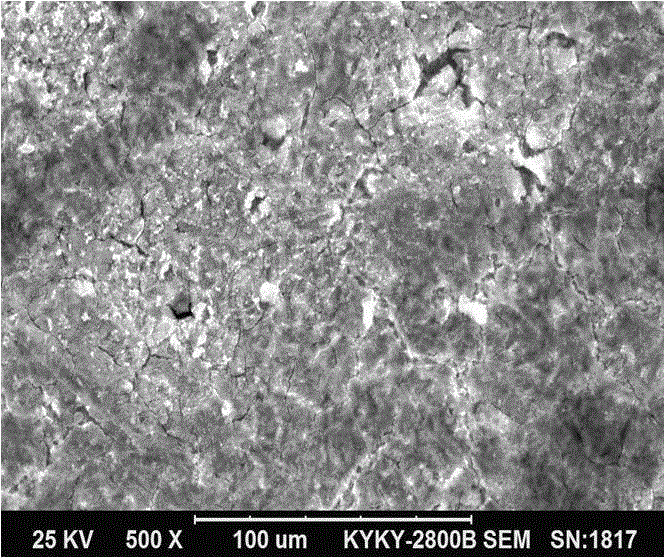

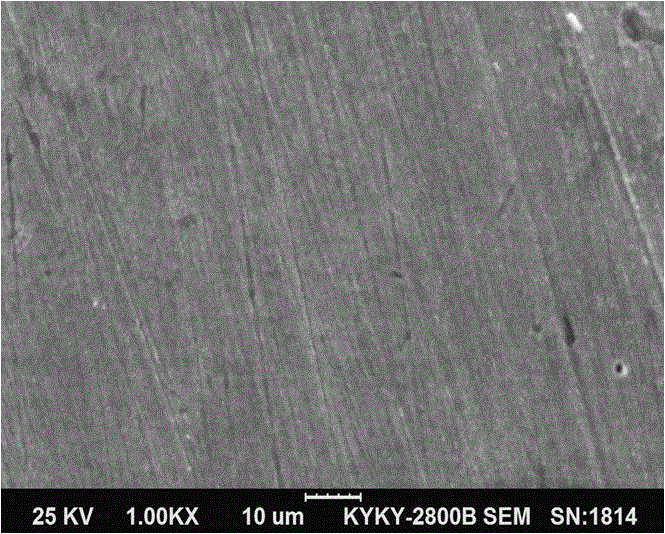

Diamond wire cutting fluid, and preparation method, application and use method thereof

ActiveCN111647453APromote degradationReduce pollutionWorking accessoriesFine working devicesDiethylene glycolPolyethylene glycol

The invention relates to a diamond wire cutting fluid, and a preparation method, application and a use method thereof. The diamond wire cutting fluid is prepared from, by weight, 10 to 30 parts of polyethylene glycol, 5 to 25 parts of diethylene glycol, 0.5 to 15 parts of a solubilizer, 0.5 to 15 parts of an acid-base balance agent, 0.1 to 1.5 parts of a penetrating agent, 0.1 to 1.5 parts of a dispersing agent, 0.1 to 5 parts of a corrosion inhibitor and 40 to 85 parts of water. The diamond wire cutting liquid is low in surface tension value, abrasion of a fretsaw can be reduced, the wire breaking rate is reduced, and the cutting yield of products is increased; foam generated in the cutting process can be reduced, so the problem of cylinder overflowing is solved; and the COD value is low,so microbial degradation is facilitated, and environmental pollution is reduced.

Owner:BYD CO LTD

Methanol gasoline

InactiveCN106957697ALow costImprove performanceLiquid carbonaceous fuelsFuel additivesGasoline fuelAntioxidant

Owner:泸州清大能源股份有限公司

Camellia oleifera abel shell compound corrosion inhibitor and preparation method and application thereof

Owner:SOUTHWEST FORESTRY UNIVERSITY

Copper material surface detergent

InactiveCN105018946AGood decontamination effectSystem stabilitySodium bicarbonateSulfamic acid

Owner:JIANGYIN SHENGYUAN COPPER MATERIAL

Copper-containing laminated etching solution, etching method and application thereof

ActiveCN112342548ALow costReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentOrganic base

The invention relates to the field of metal surface chemical treatment, in particular to a copper-containing laminated etching solution, an etching method and application thereof. The etching solutioncomprises a main agent, and by weight, the main agent comprises, 1-20 parts of an oxidizing agent, 0.01-1 part of a fluorine ion source, 0.01-5 parts of inorganic acid, 1-15 parts of organic acid, 1-15 parts of organic alkali, 0.01-5 parts of a hydrogen peroxide stabilizer, 0.01-1 part of a metal corrosion inhibitor and the balance solvent, wherein the total weight parts are 100. The etching solution is low in cost, free of phosphorus, environmentally friendly and low in waste liquid treatment cost; cracks at different metal interfaces can be effectively inhibited; the copper-containing laminated etching solution has high copper ion loading capacity, and has excellent etching characteristics, wherein the unilateral CD-Loss is smaller than 0.9 micrometer, and the taper is 35-45 degrees; and the chamfering problem can be solved, bubbles of an insulating layer are effectively avoided, and meanwhile the step of copper pre-dissolving can be omitted.

Owner:JIANGSU HEDA ELECTRONIC TECH CO LTD +1

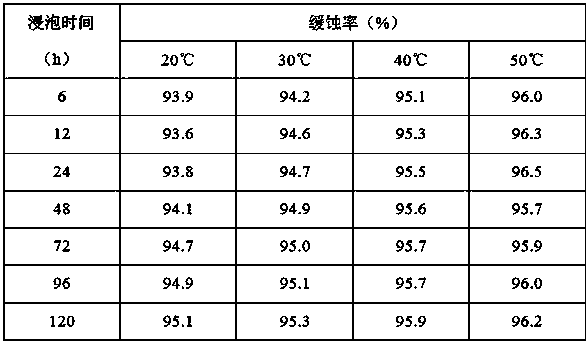

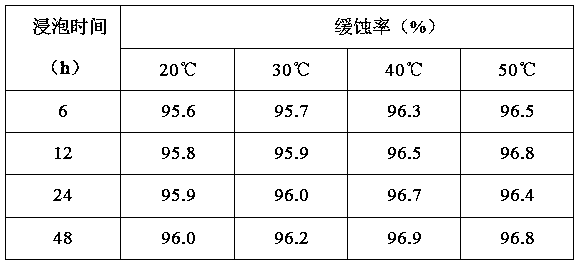

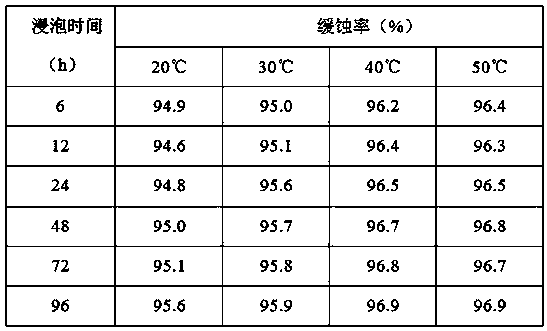

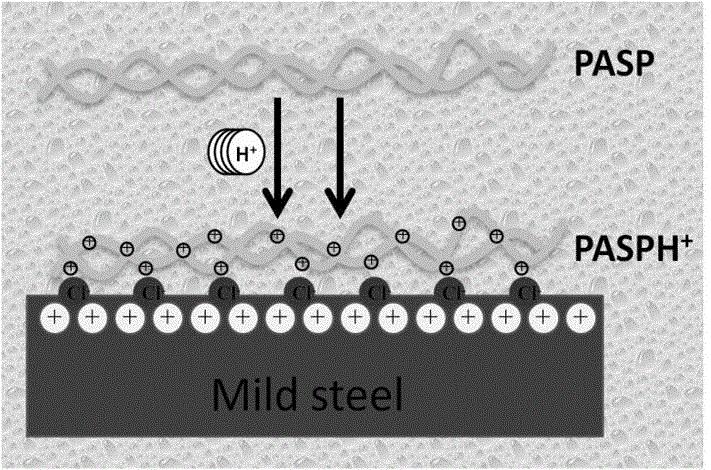

Environment-friendly carbon steel pickling inhibitor and application thereof

Owner:QINGDAO AGRI UNIV

Anti-scaling agent for metal equipment

Owner:NANJING JINGYUN SHIP FITTINGS

Preparation method of silver-coated copper conductive powder

PendingCN114101665AFully dispersedFully moistenedTransportation and packagingMetal-working apparatusCeric sulfateActive agent

Owner:深圳市绚图新材科技有限公司 +1

Gel type annulus protection liquid and preparation method thereof

PendingCN111378422AProductsWaste water treatment from quariesEnvironmental geologyCorrosion inhibitor

Owner:PETROCHINA CO LTD

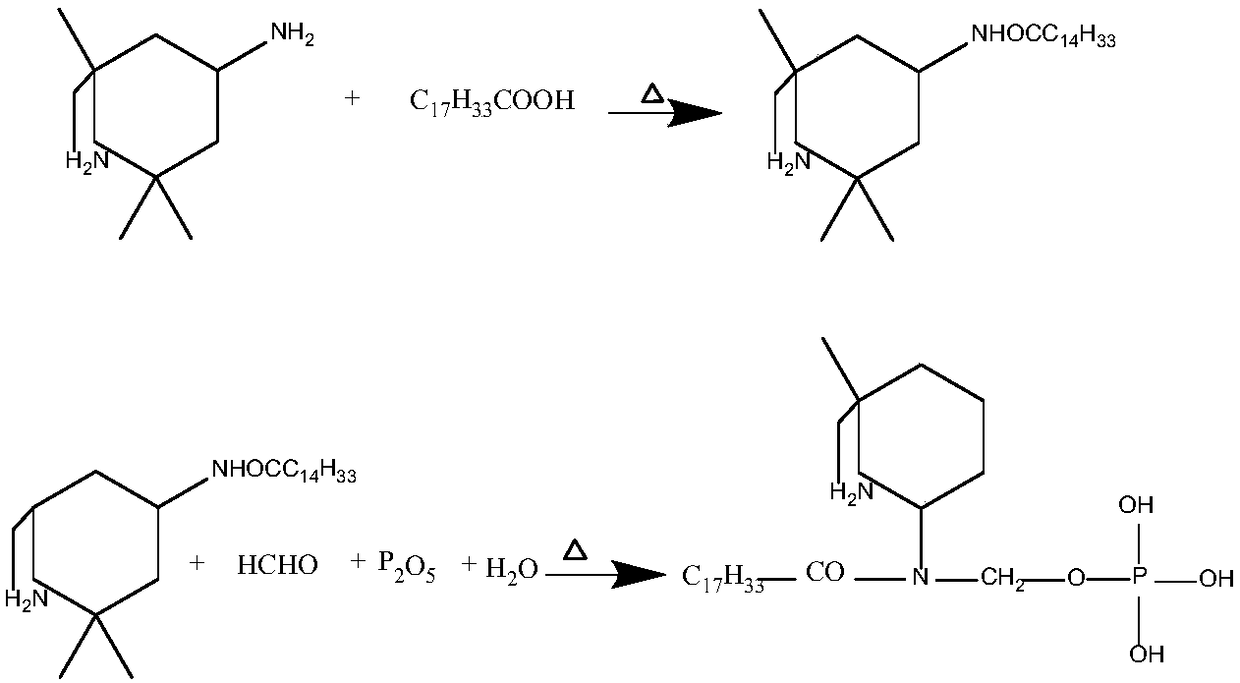

Amino phosphate water-soluble corrosion inhibitor and preparation method thereof

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Scale and corrosion inhibitor

InactiveCN105110490AAvoid badQuality is not affectedTreatment using complexing/solubilising chemicalsDodecaneTrimethyloxamine

Owner:江苏绿科生物技术有限公司

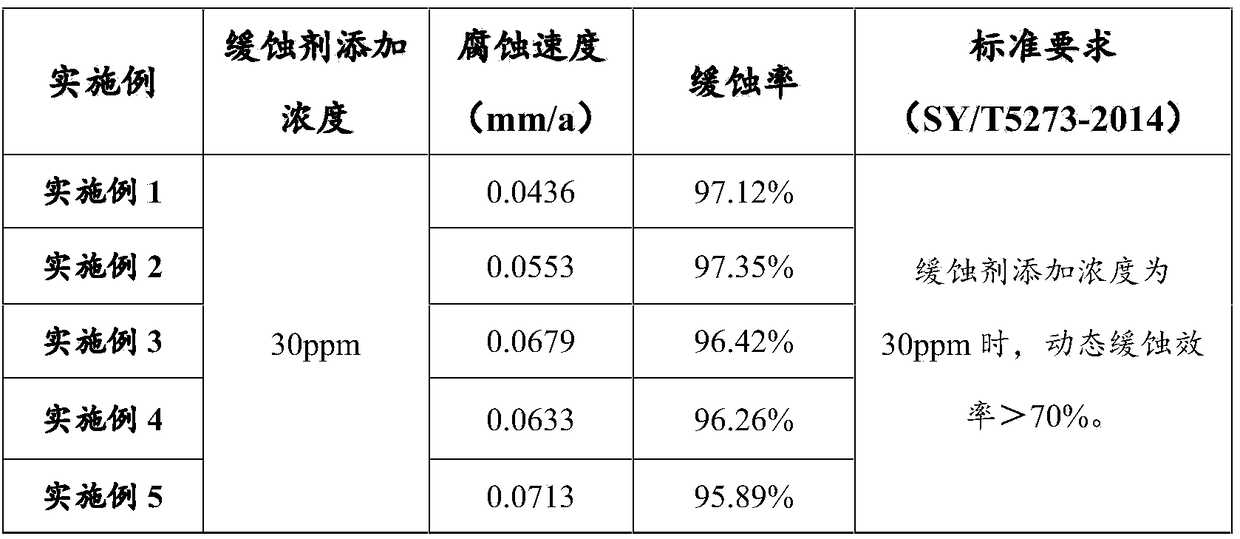

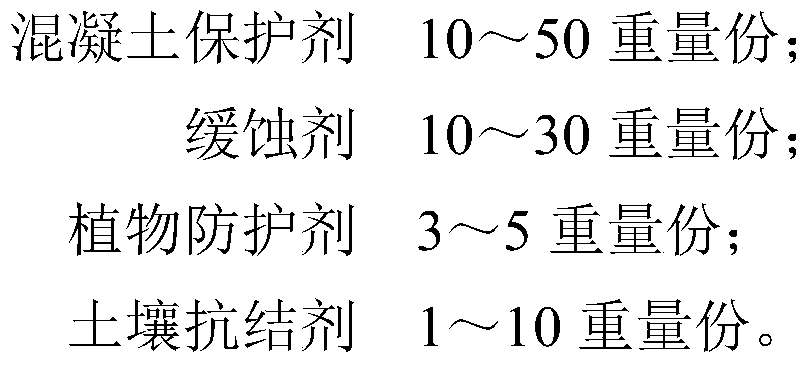

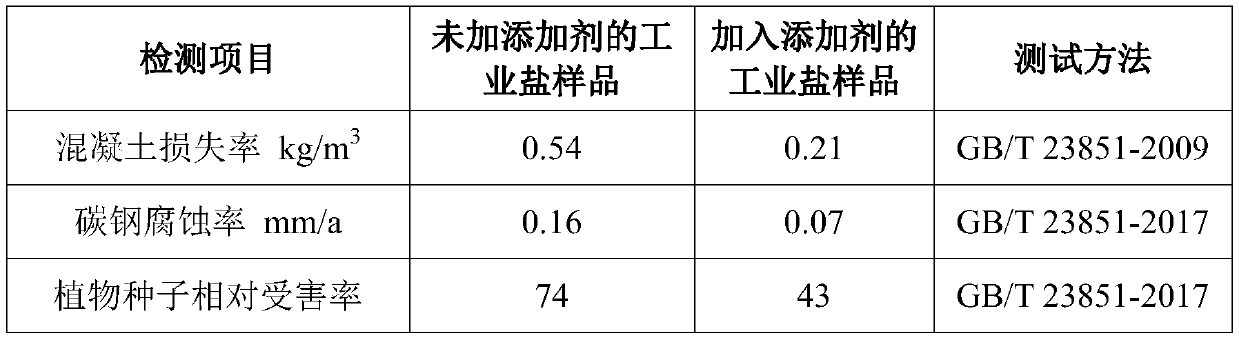

Industrial salt snow melting agent additive and using method thereof

ActiveCN110205098AHarm reductionImprove environmental performanceOther chemical processesAnticaking agentSnow melting

Owner:西安华泽道路材料有限公司

Metal spray cleaning agent

InactiveCN111041500AResidue reductionReduce alkalinityMeth-Sodium phosphates

Owner:南京明仁光电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap