Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Micrometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A micrometer sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers (opposing ends joined by a frame). The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

Method of risisting high-temp. oxidation and heat corrosion for high-temp. alloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

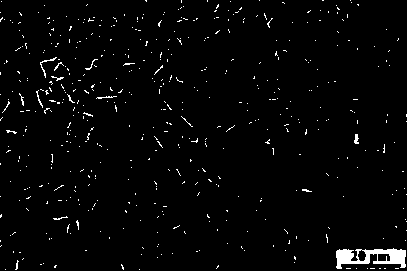

Method for metallizing ceramic surface and method for connecting ceramic with aluminum

ActiveUS20120121896A1Hot-dipping/immersion processesSoldering apparatusMicrometerAlloy thin film

A process for metalizing a ceramic surface or attaching a ceramic to a metal is provided. The process may comprise: immersing the ceramic into an aluminum or aluminum alloy melt, making the ceramic move or stay still relative to the melt to adhere the melt to the ceramic; and then removing the ceramic from the melt to unaffectedly cool the film adhered thereto. The process can attach an aluminum or aluminum alloy thin film having a thickness of several to tens of micrometers on a ceramic surface. The thin film is formed by solidification, and does not have microscopic faults such as oxide film inclusions or pores, therefore having proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.This invention discloses a process for metalizing the surface of a ceramic and a process for attaching a ceramic to a metal. A process for attaching an aluminum or aluminum alloy thin film to a ceramic surface comprises the steps of: immersing a ceramic surface to be metalized into a aluminum or aluminum alloy melt, and making the ceramic move or stay still relative to the melt to adhere the melt of the aluminum or aluminum alloy to the metalizing surface of the ceramic; and then removing the metalizing surface of the ceramic from the melt to unaffectedly cool the aluminum or aluminum alloy liquid film adhered thereto to obtain a ceramic having the aluminum or aluminum alloy thin film attached to the surface. The process to attaching aluminum or aluminum alloy thin film on the surface of a ceramic of the present invention can attach an aluminum or aluminum alloy thin film having a thickness of several micrometers to tens of micrometers on the surface of a ceramic. The thin film is formed by the solidification of the aluminum of aluminum alloy liquid film attached on the surface of a ceramic, and it does not have the microscopic faults such as oxide film inclusions or pores, therefore having the proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.

Owner:TSINGHUA UNIV

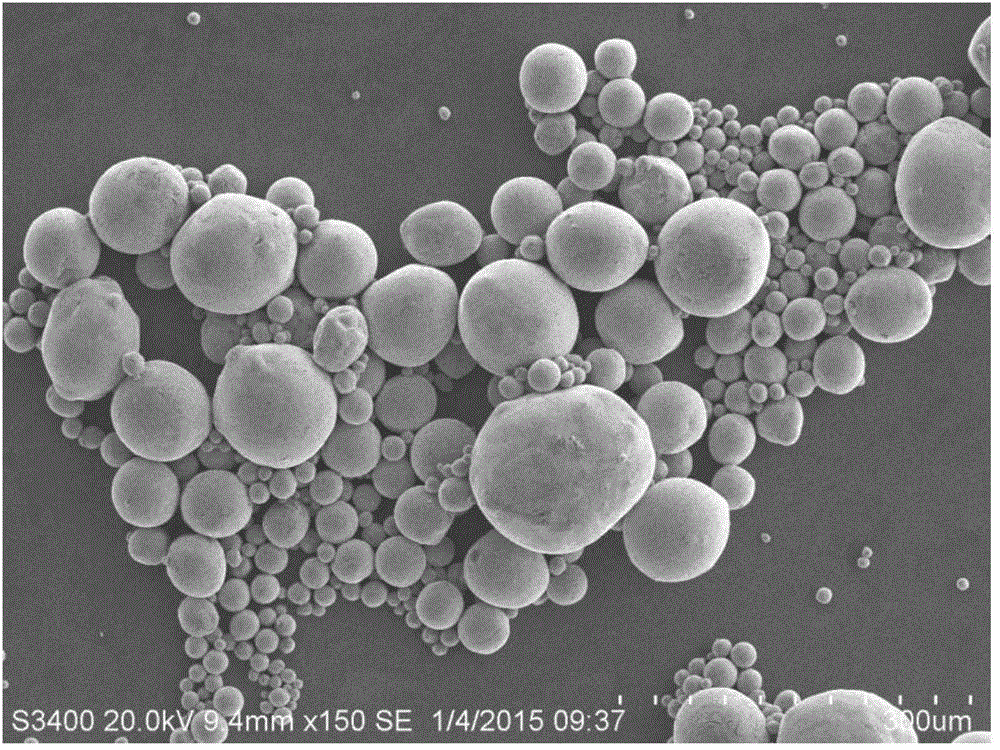

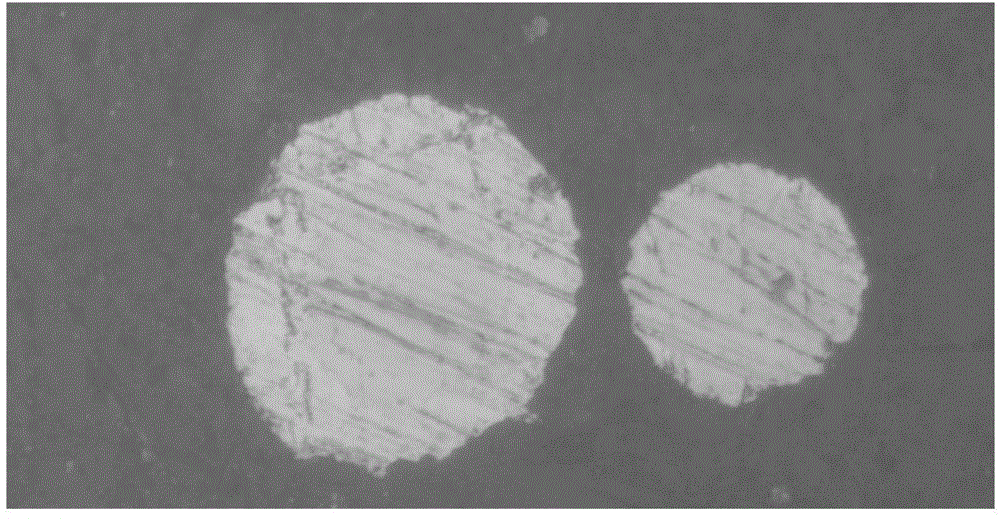

Manufacturing method of micrometer and nanometer composite spherical metal powder of core-shell structure

Owner:NANJING UNIV

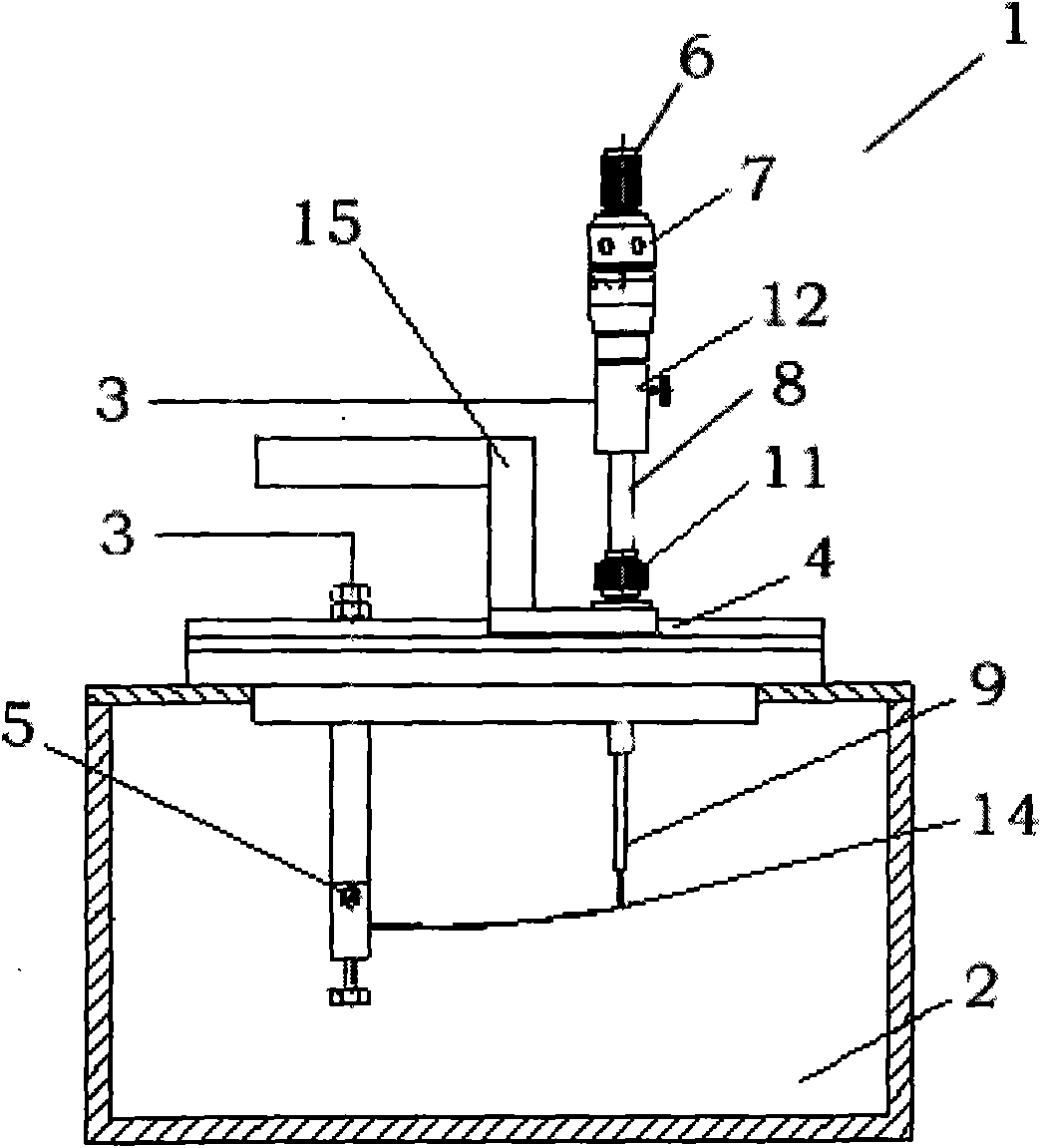

Device and method for detecting bimetallic thermo-sensitive property

InactiveCN101839872AMaterial thermal analysisMechanical solid deformation measurementsMicrometerEngineering

Owner:宝钢特钢有限公司

Composite carbon diaphragm with mesoporous and microporous gradient structure and preparation method for diaphragm

ActiveCN102580567ADecreased gas separation performanceHigh gas separation selectivitySemi-permeable membranesBreaking strengthMicrometer

The invention relates to a composite carbon diaphragm with a mesoporous and microporous gradient structure and a preparation method for the diaphragm. The composite carbon diaphragm with the mesoporous and microporous gradient structure consists of a porous support body, a mesoporous intermediate layer and a surface separation layer, and is characterized in that the pore diameter of the porous support body is 100 to 500 nanometers, the breaking strength is 2 to 15MPa, and the anti-explosion strength is 3 to 10MPa; the pore diameter of the mesoporous intermediate layer is 2 to 10 nanometers, the specific surface area is 400 to 1,000 m<2> / g, the porosity is 30 to 50 percent, and the thickness is 1 to 10 micrometers; and the pore diameter of the surface separation layer is 0.3 to 0.5 nanometer, the specific surface area is 300 to 600 m<2> / g, the porosity is 20 to 40 percent, and the thickness is 0.1 to 5 micrometers. By the composite carbon diaphragm with the mesoporous and microporous gradient structure, the phenomenon that the gas separation performance of the composite carbon diaphragm is greatly reduced due to the defect of the surface of the support body is avoided, and the permeability of the prepared composite carbon diaphragm is improved obviously on the basis of keeping high gas separation selectivity.

Owner:DALIAN UNIV OF TECH

Nano fluid sensor based on field effect tube

InactiveCN101130750AHigh sensitivityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsMicrometer

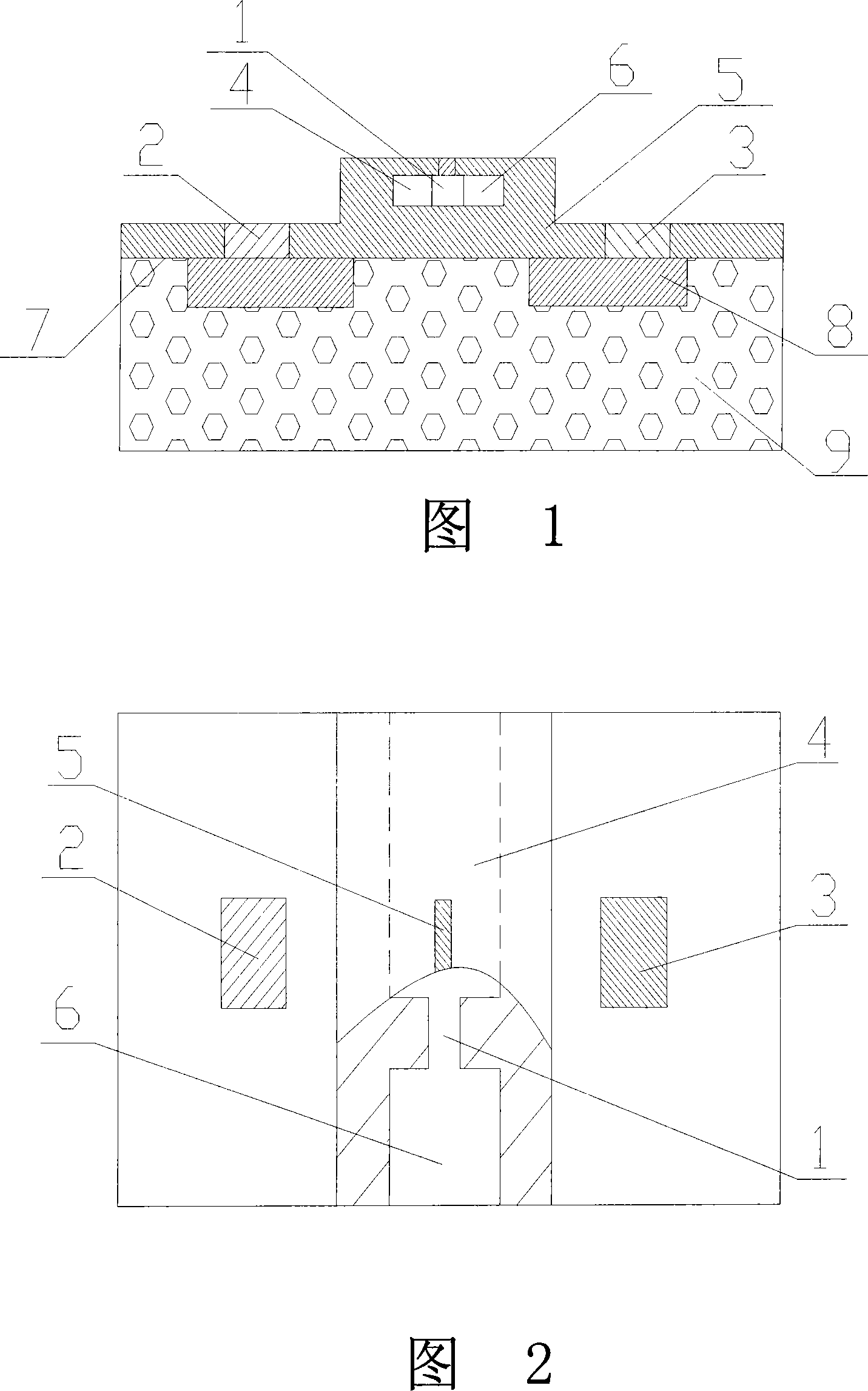

The invention relates to a nanometer flow sensor based on the field effect tube in particular to a nanometer flow sensor which can magnify the microscopic variations of conductivity of medium into the drain current fluctuation of the field effect tube. The invention comprises the field effect tube grid, wherein the nanometer channel is arranged on the field effect tube grid, two sides of the nanometer channel are connected with left and right micrometer channel, the grid control circuit comprises the medium in the micrometer channel, the medium in the nanometer channel and positive-negative electrode, and the electric resistance of the grid control circuit comprises the electric resistance R of medium in the nanometer channel and two electric resistances R1, R2 of medium in the micrometer channel. The aim of the invention is to provide a high fidelity nanometer flow sensor based on the field effect tube which can magnify the microscopic variations of conductivity of medium into the drain current fluctuation of the field effect tube.

Owner:SOUTHEAST UNIV

Detecting method and sensor for cracks of civil structure based on optical fiber long chirped grating frequency domain reflection technology

ActiveCN102175170ASimple structureLow costUsing optical meansConverting sensor output opticallyGratingStructure based

Owner:SOUTHEAST UNIV

Grind process for optical sapphire crystal substrate

InactiveCN1289261CReduce surface roughnessSize differenceMicrometer

Owner:SHANGHAI XINHUAXIA INDAL

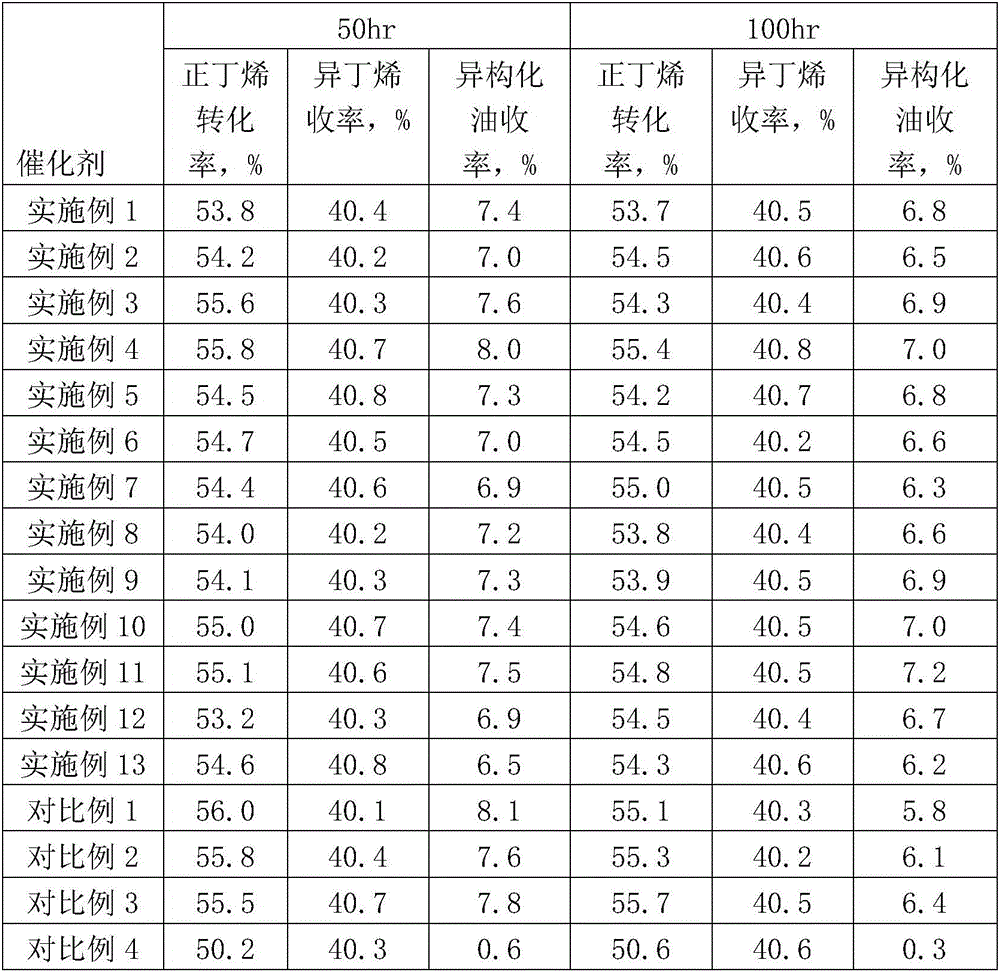

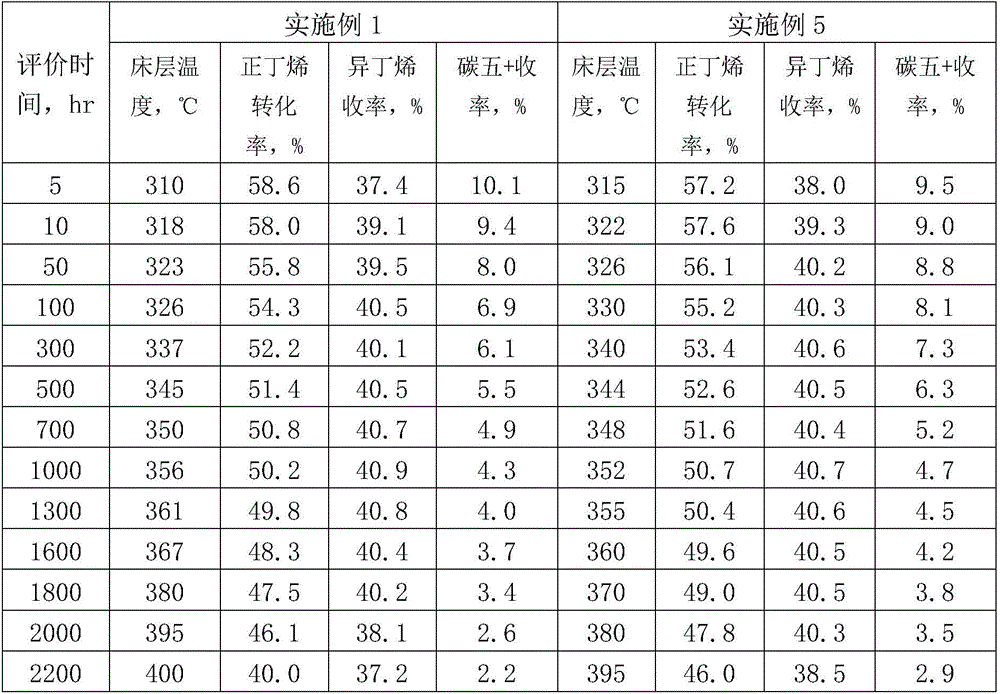

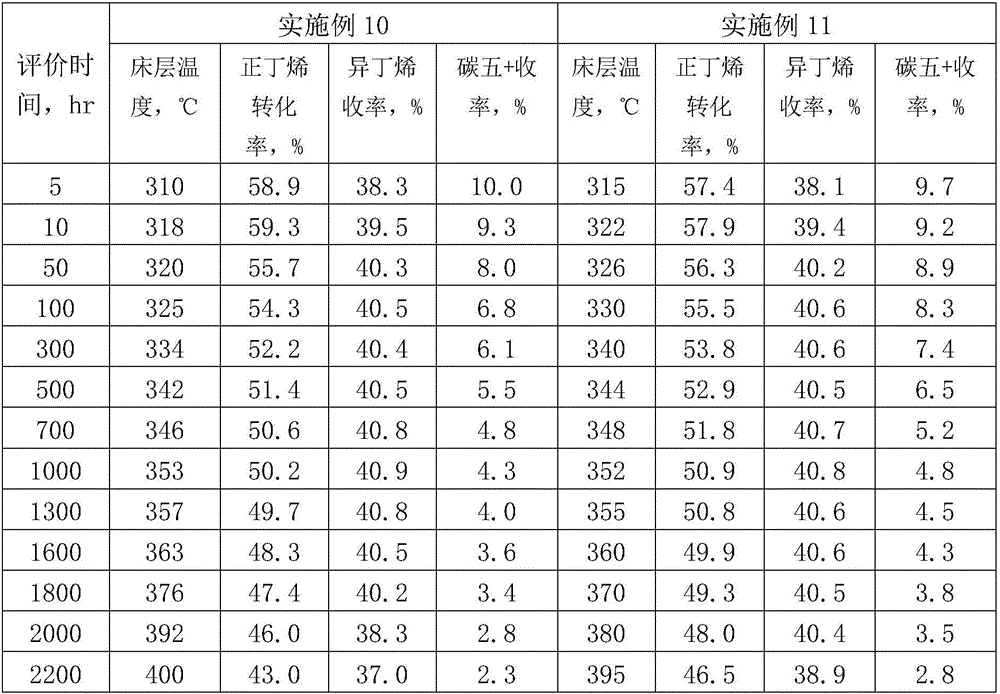

N-alkene isomerization catalyst and preparation method and application thereof

ActiveCN106076408AReduce in quantityReduce cokingHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

Owner:山东迅达化工集团有限公司

Method for measuring groove position of inner bearing ring

InactiveCN102052890AEasy to operateImprove pass rateMechanical clearance measurementsMicrometerMeasurement plane

Owner:浙江斯菱汽车轴承股份有限公司

Three-dimensional material based on copper sulfide lamellar structure, preparation method and application thereof

InactiveCN107597146ASimple processLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationSulfurMicrometer

Owner:YUNNAN MINZU UNIV

Clopidol controlled-release microparticle preparation and preparation method thereof

ActiveCN105168179AAvoid sudden releaseLess irritatingInorganic non-active ingredientsAntiparasitic agentsMicroparticleClopidol

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

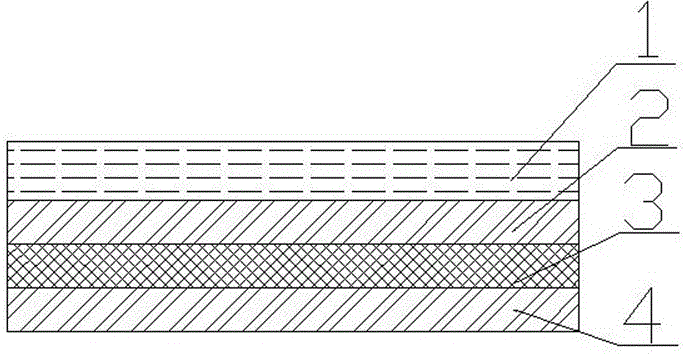

Thermal-dye-transfer receiver element with polylactic-acid-based sheet material

Disclosed is a thermal dye-transfer dye-image receiving element comprising a thermal dye-transfer receiver element comprising a dye-receiving layer 1; beneath layer 1, a substrate layer 2 containing a microvoided layer 2 comprising, in a continuous phase, a polylactic-acid-based material, wherein microvoids in said microvoided layer provide a void volume of at least 25% by volume, and wherein at least about half of the microvoids are formed from void initiating particles less than 1.5 micrometer in average diameter; and beneath layer 2, an optional support layer 3.

Owner:EASTMAN KODAK CO

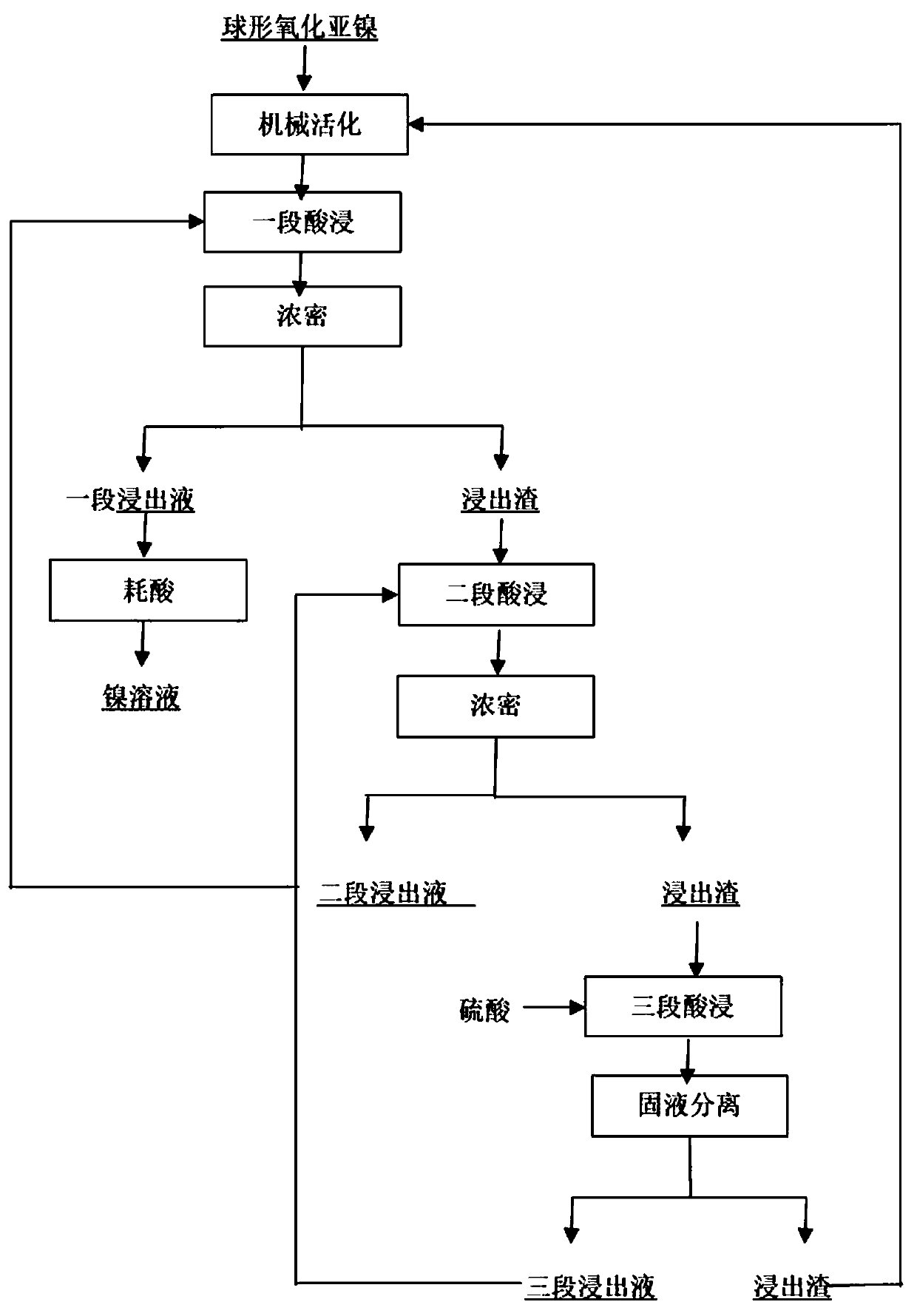

Method for recycling spherical nickel oxide after mechanical activation using three-section countercurrent acid leaching

InactiveCN110468289AGuaranteed leaching rateReduce solubilityNickel halidesNickel sulfatesSpherical shapedBiological activation

Owner:JINCHUAN GROUP LIMITED +1

High-barrier composite membrane applied to thermal baffle

Owner:SICHUAN HUILI IND

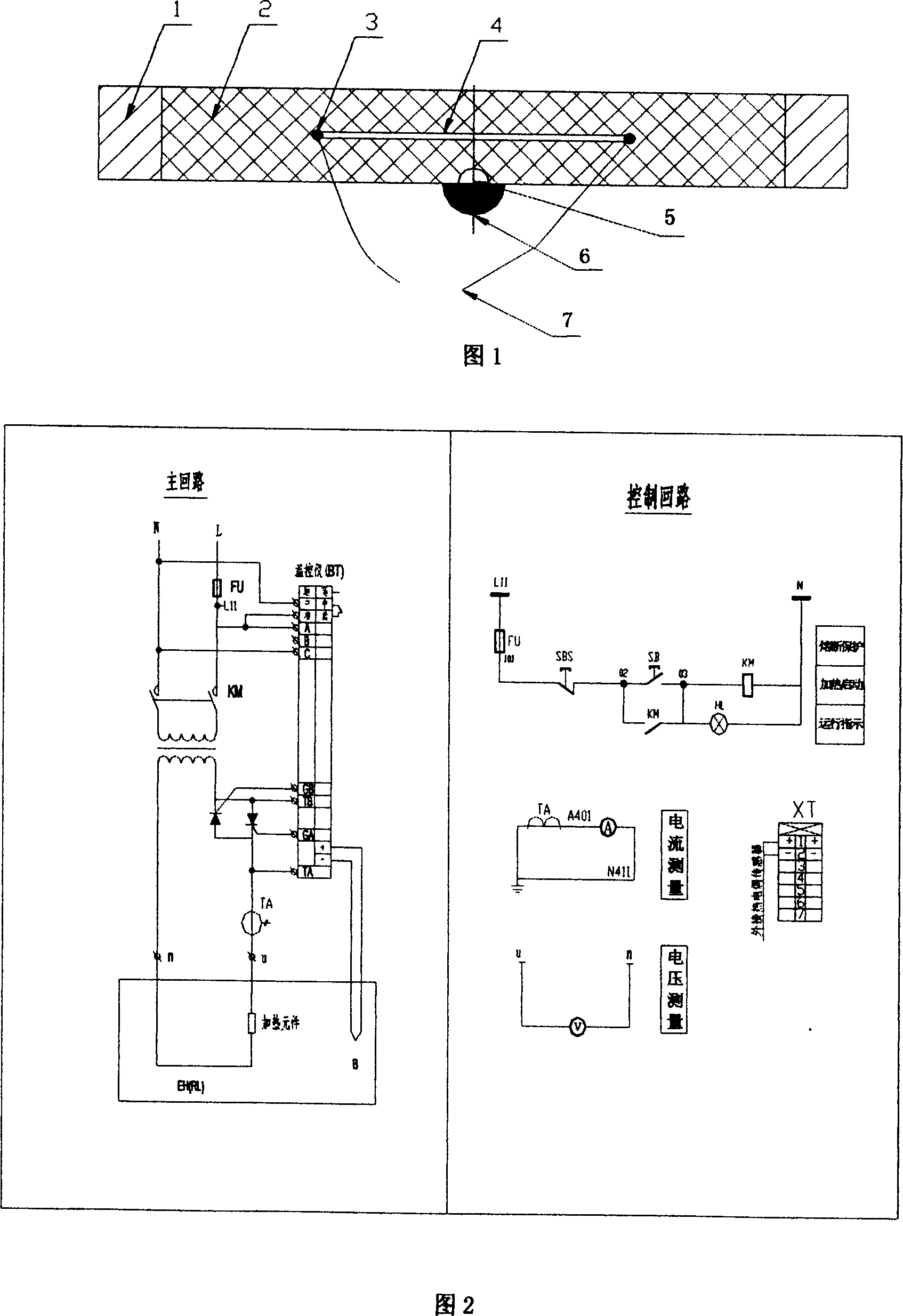

Preparation of the high-performance porcelain heating parts with automatic temperature-control

InactiveCN1997245AImprove pass rateNo pollution in the processHeater elementsHeating element materialsEpoxyTemperature control

Owner:范新宽

Application of cirsimaritin in preparing antiviral drug

ActiveCN106491583AInhibition of lesionsReduced expression levelOrganic active ingredientsAntiviralsCytopathic effectAmantadine

The invention relates to the technical field of medicines, in particular to application of cirsimaritin in preparing an antiviral drug. The invention for the first time proposes that the cirsimaritin has definite resistance to an influenza virus. The cirsimaritin can significantly inhibit a cytopathic effect caused by the influenza virus infection, and median inhibitory concentrations to an influenza virus A / FortMonmouth / 1 / 1947 and an influenza virus A / jinnan / 15 / 2009 are equivalent to that of an influenza virus Amantadine and an influenza virus Ribavirin; meanwhile, the cirsimaritin can significantly inhibit the expression of influenza virus specific protein M2 protein, and lower an expression level of influenza virus RNA; the intensities of inhibition functions of 40 microgrammes per milliliter of the cirsimaritin on expression of the influenza virus M2 protein and expression of the influenza virus RNA are equivalent to that of 10 micrometers of the Ribavirin, showing that intensity of the anti-influenza virus effect of the cirsimaritin is close to that of antiviral drugs currently commonly used in clinic, and application of the cirsimaritin in preparing anti-influenza drugs has a good prospect.

Owner:XINJIANG INST OF MATERIA MEDICA

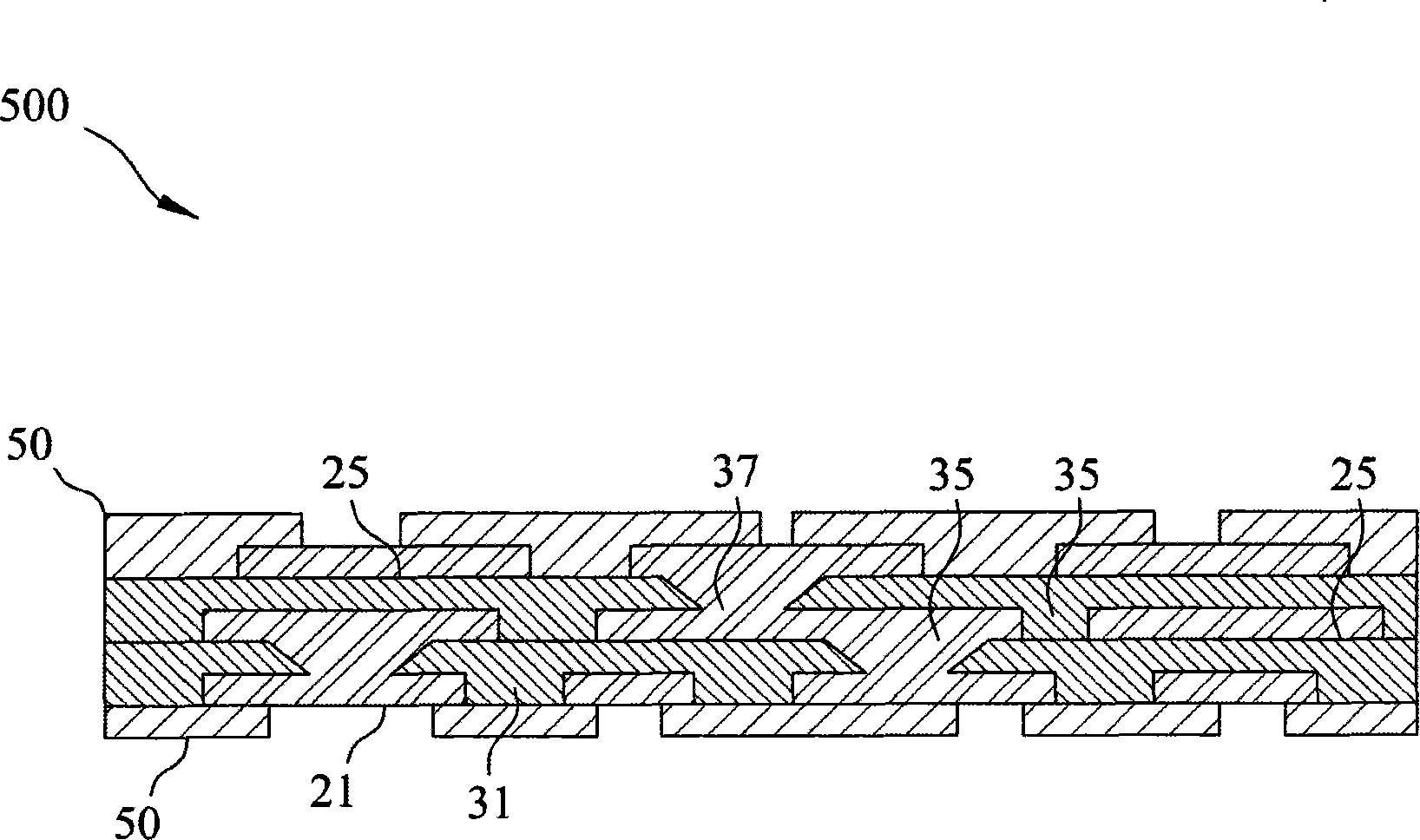

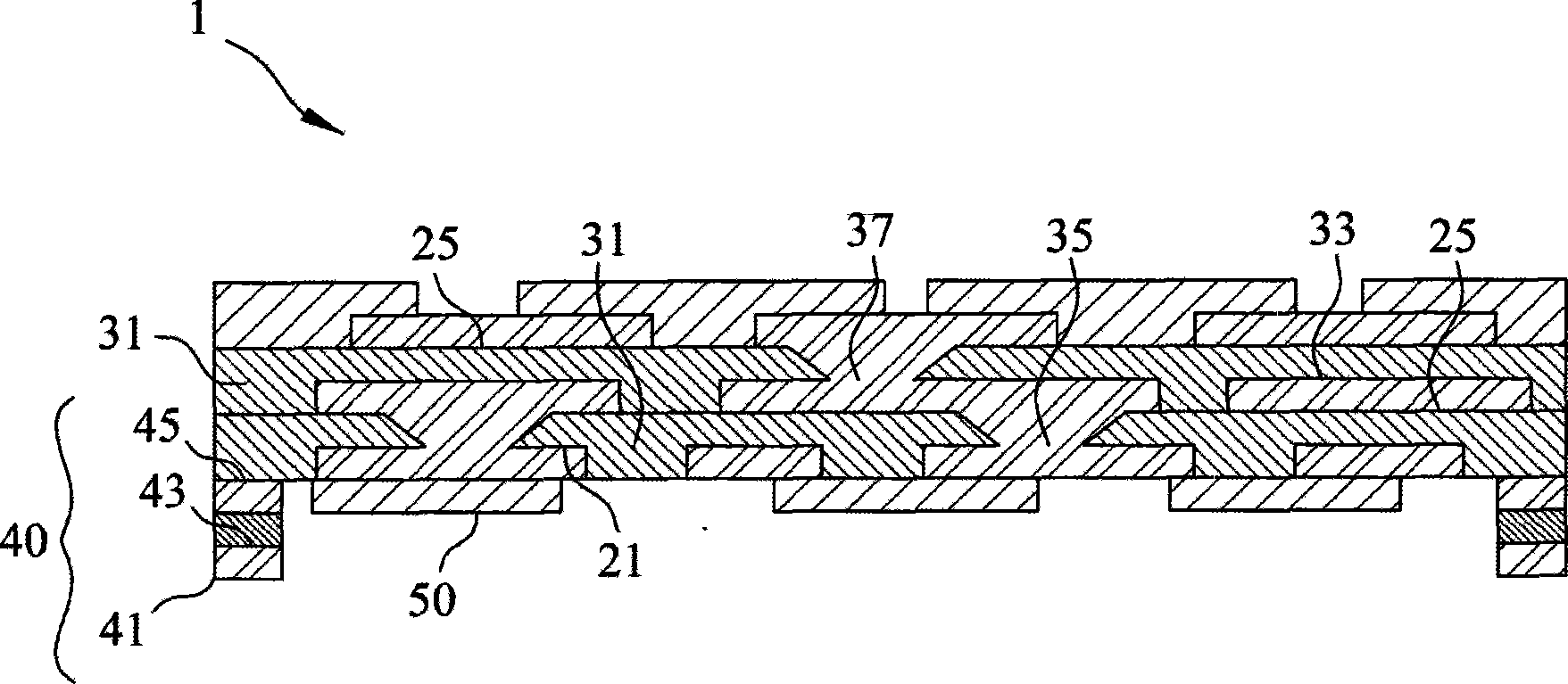

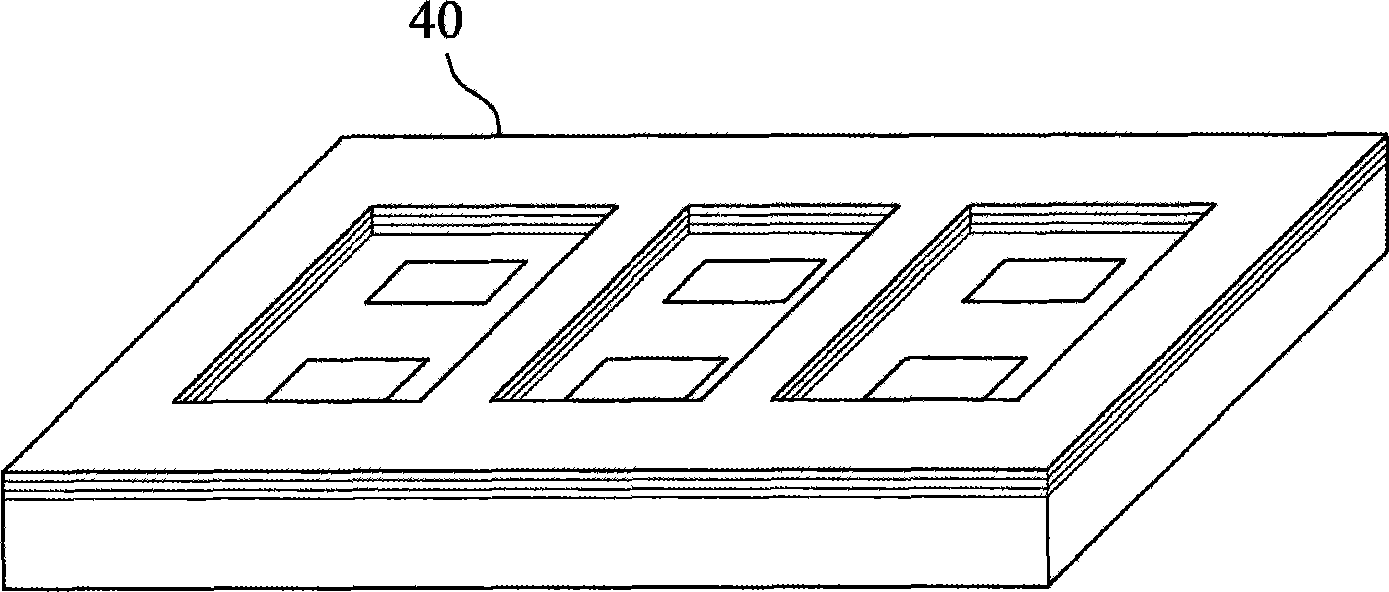

Circuit laminated board structure

ActiveCN103547057APrinted circuit detailsTotal thicknessMicrometer

Owner:KINSUS INTERCONNECT TECH

Method for removing tungsten carbide wear-resistant coating

Owner:HARBIN DONGAN ENGINE GRP

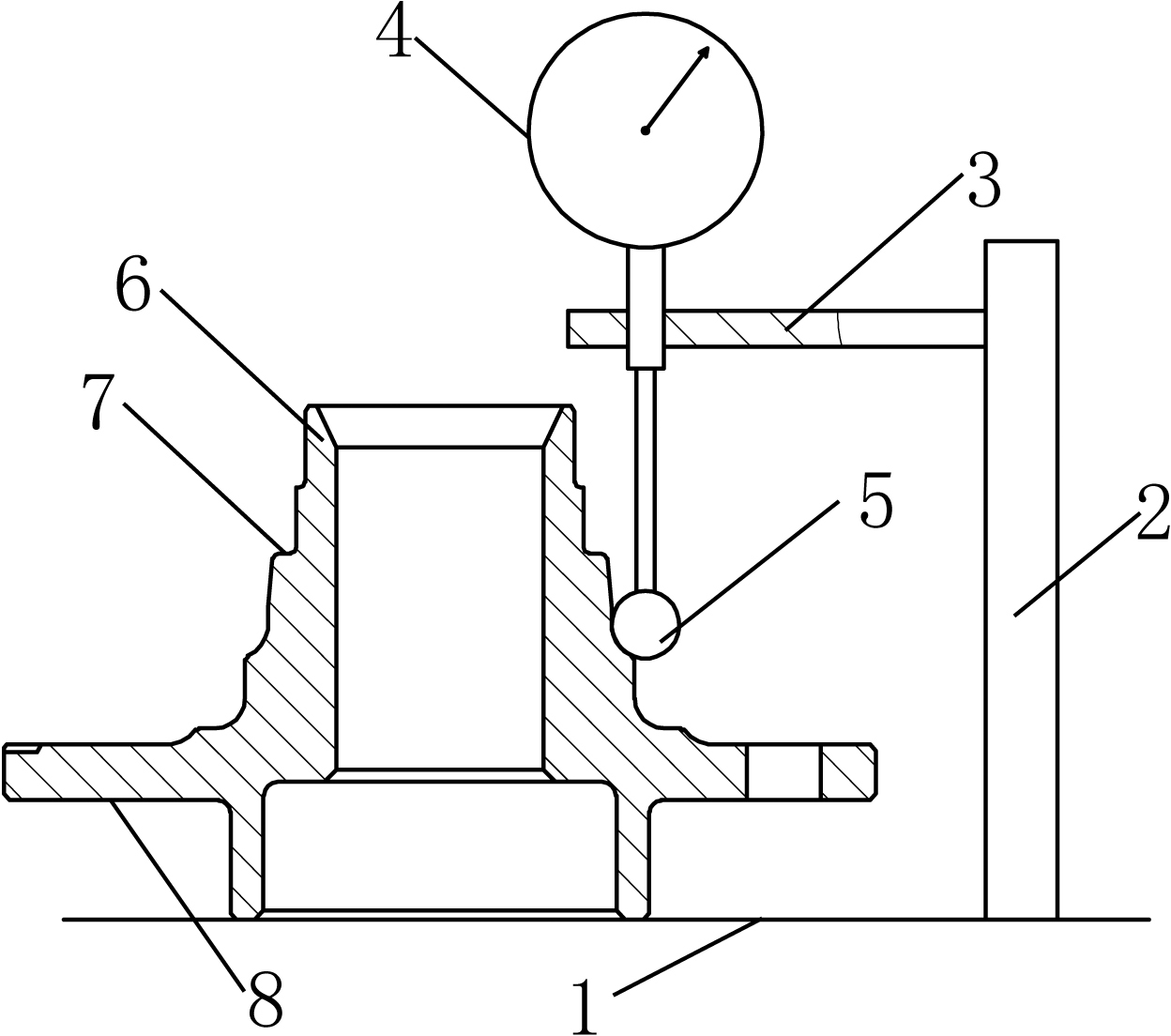

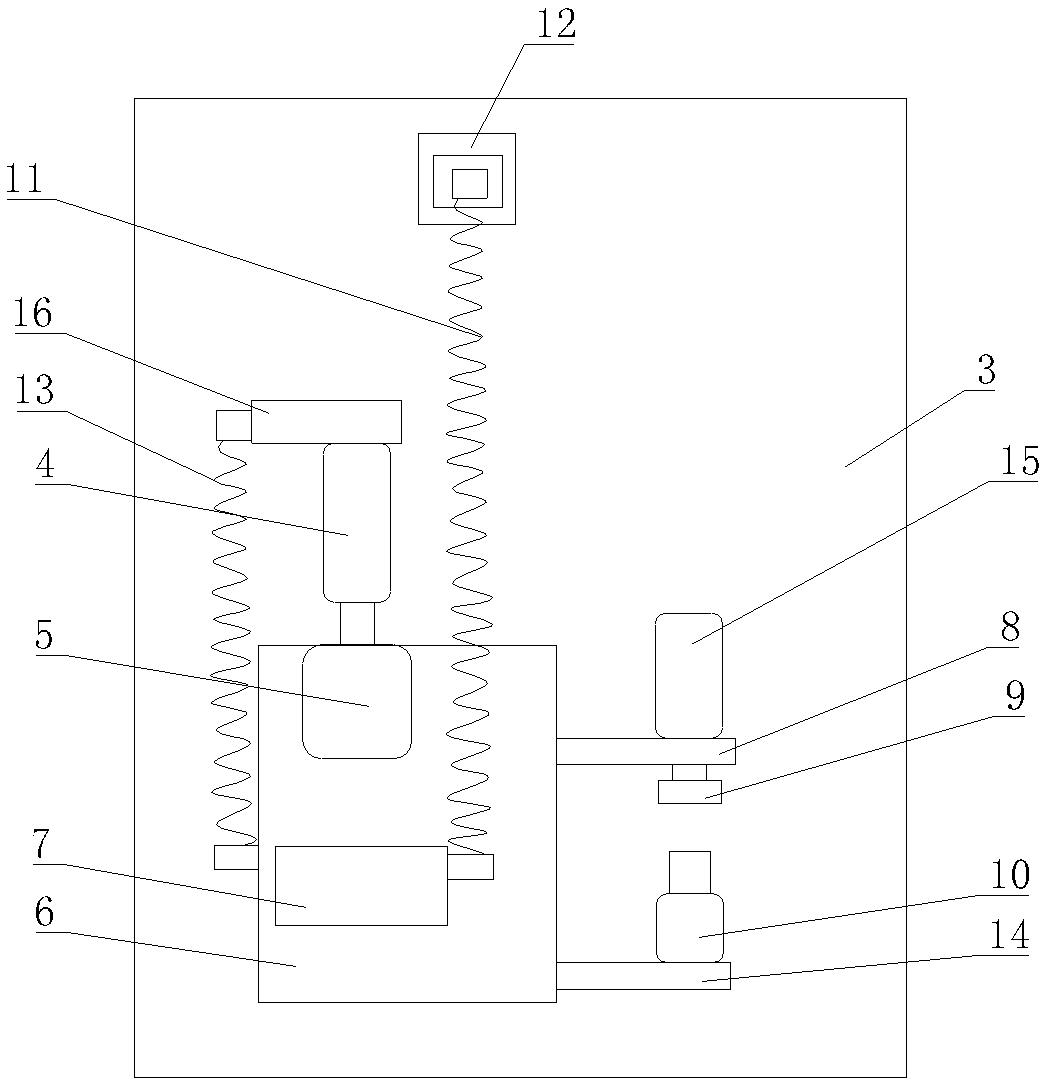

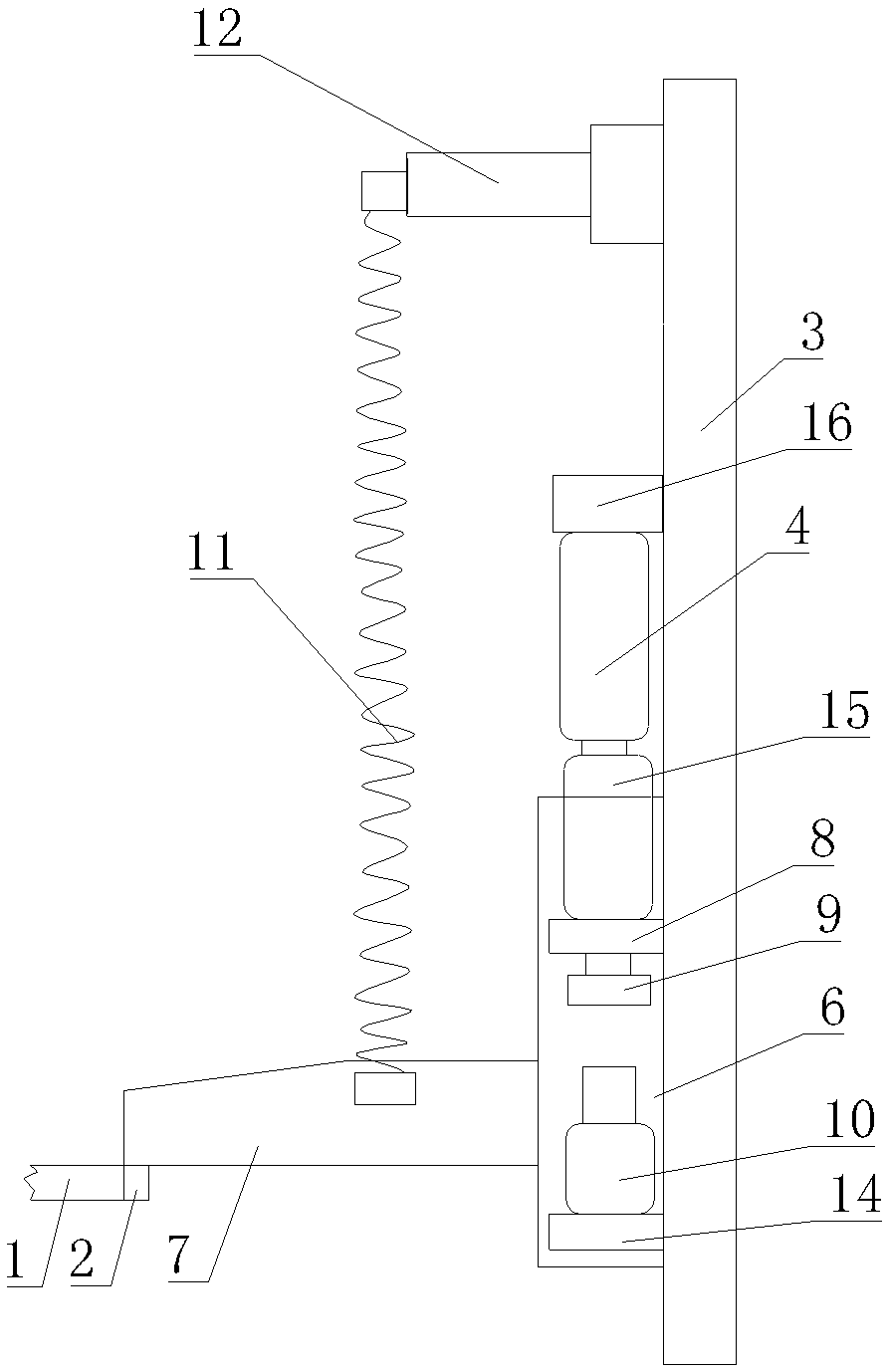

A height adjustment device for planting steel mesh

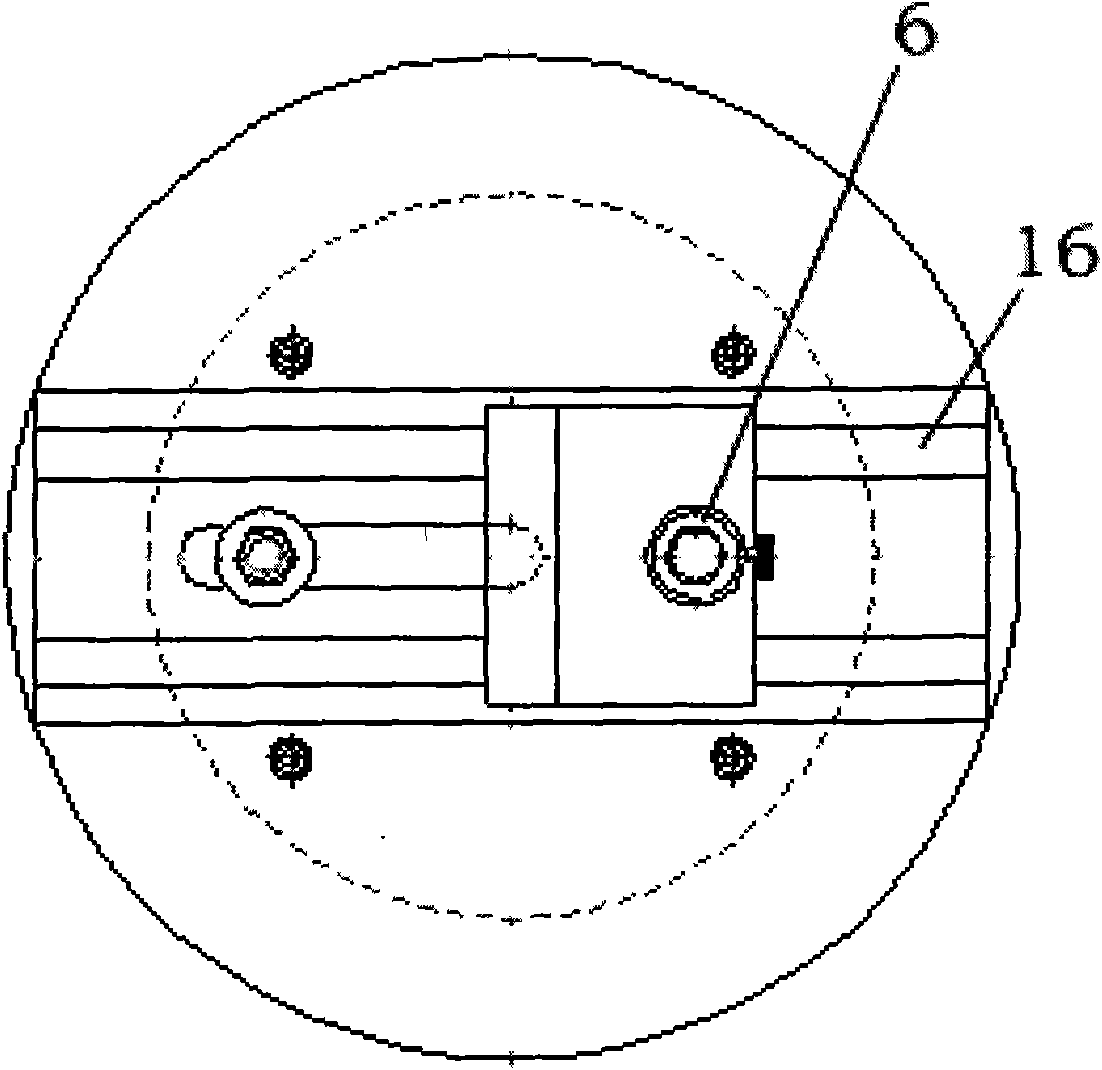

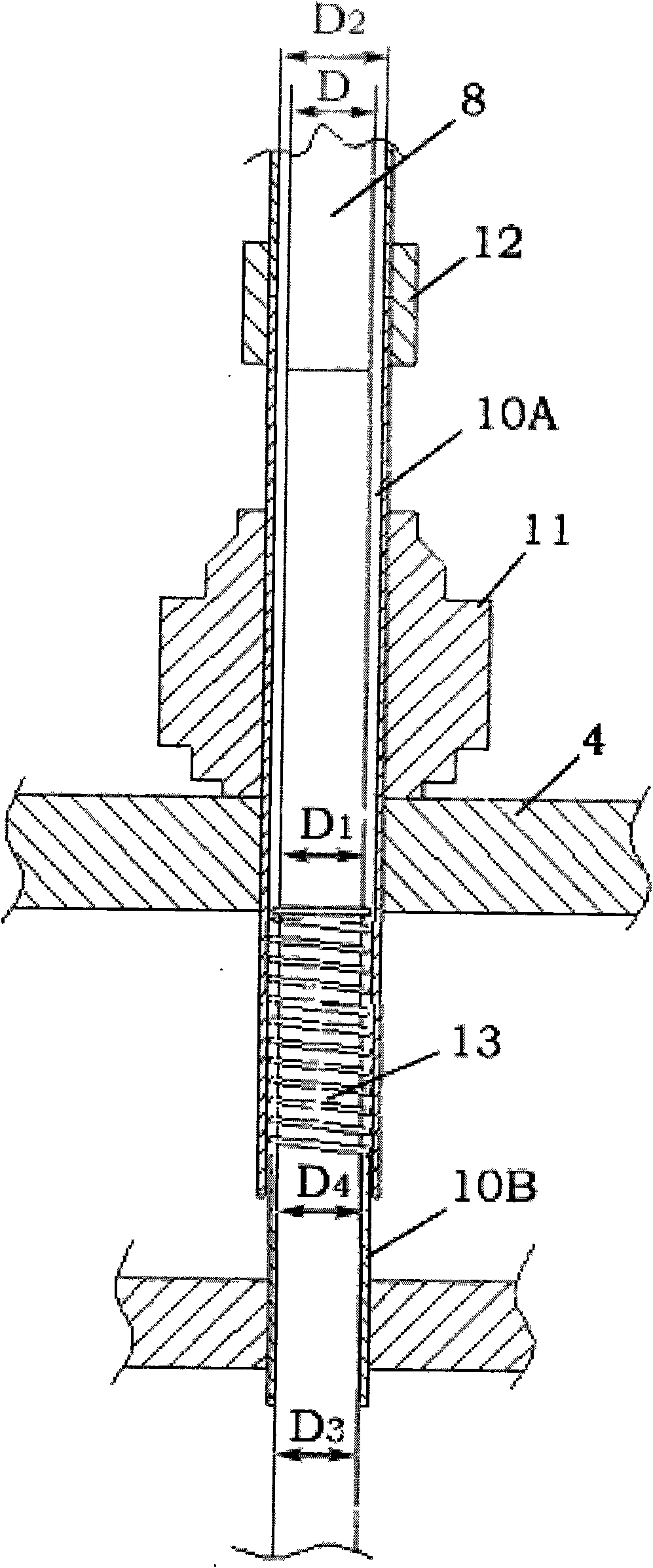

ActiveCN105873378BHigh altitude control accuracyGuaranteed levelnessPrinted circuit assemblingSolid-state devicesMicrometerPiston rod

Owner:RF360 TECH (WUXI) CO LTD

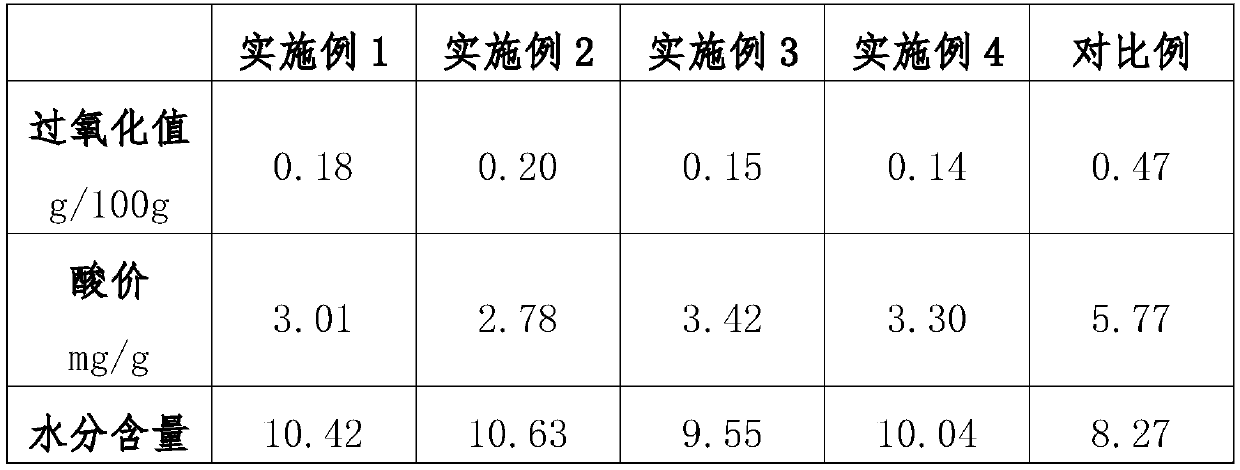

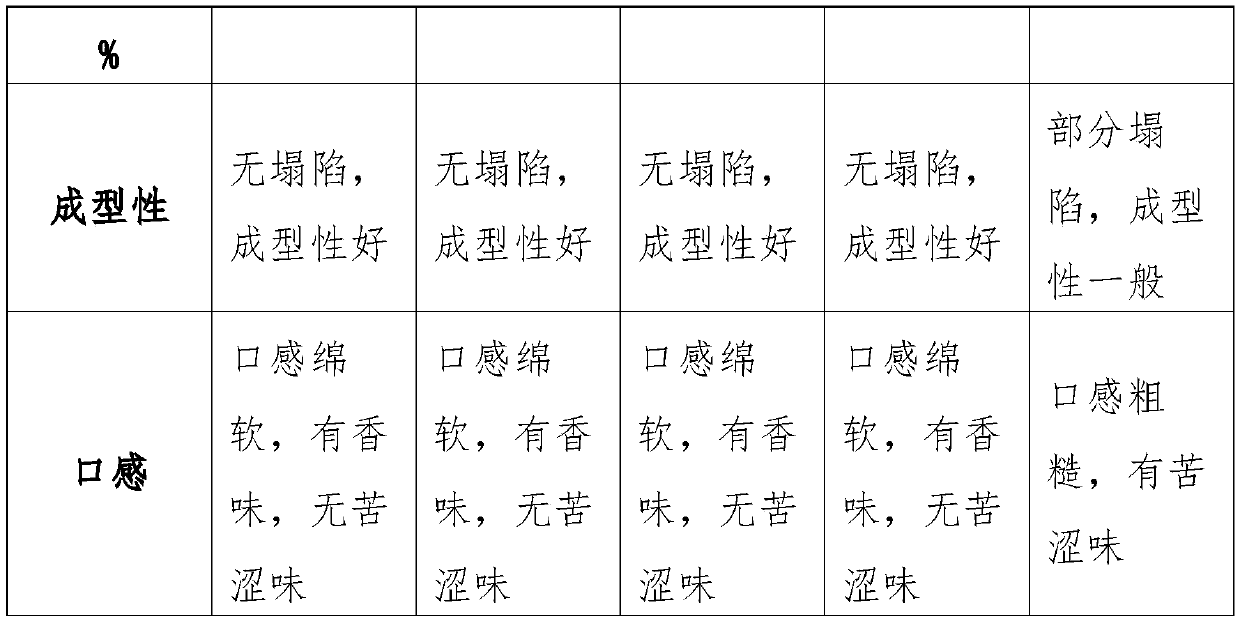

Pepper salt whole quinoa flour stuffing and preparation method thereof

InactiveCN109588456ALarge specific surface areaEnhanced water-holding and oil-holding propertiesBakery productsChemistryMicrometer

The invention discloses pepper salt whole quinoa flour stuffing and a preparation method of the stuffing. The preparation method comprises the steps of: (1) crushing and treating quinoa with an 80-mesh sieve and crushing bran till a particle size is less than 10 micrometers, (2) backfilling the bran into flour to prepare whole quinoa flour, (3) uniform stirring 950-1150 parts by weight of whole quinoa flour and 180-220 parts by weight of oat flour, (4) heating 650-750 parts by weight of salad oil, pouring the flour uniformly stirred in the step (3) into the oil, performing stir-frying until cooked, and pouring out for cooling to a room temperature, and (5) adding 18-23 parts by weight of D-mannitol, 860-950 parts by weight of white bean paste, 80-100 parts by weight of filiform meat floss,240-340 parts by weight of fructose syrup, 270-350 parts by weight of white granulated sugar, 18-24 parts by weight of salt, 90-160 parts by weight of orange dices, 60-85 parts by weight of raisins,80-100 parts by weight of cranberry, 40-60 parts by weight of wine soaked rose petals and 70-80 parts by weight of wine for soaking the rose petals for uniform stirring to form the stuffing. A quinoaprocessed product type is enriched, and a method is provided for an application of the quinoa in baked food.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap