Device and method for detecting bimetallic thermo-sensitive property

A detection device and detection method technology, which is applied in the direction of measuring device, material thermal analysis, mechanical solid deformation measurement, etc., can solve the problems of instruments without bimetallic thermal performance, and meet the requirements of specific bending performance detection and high measurement accuracy , Measuring the effect of good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-48

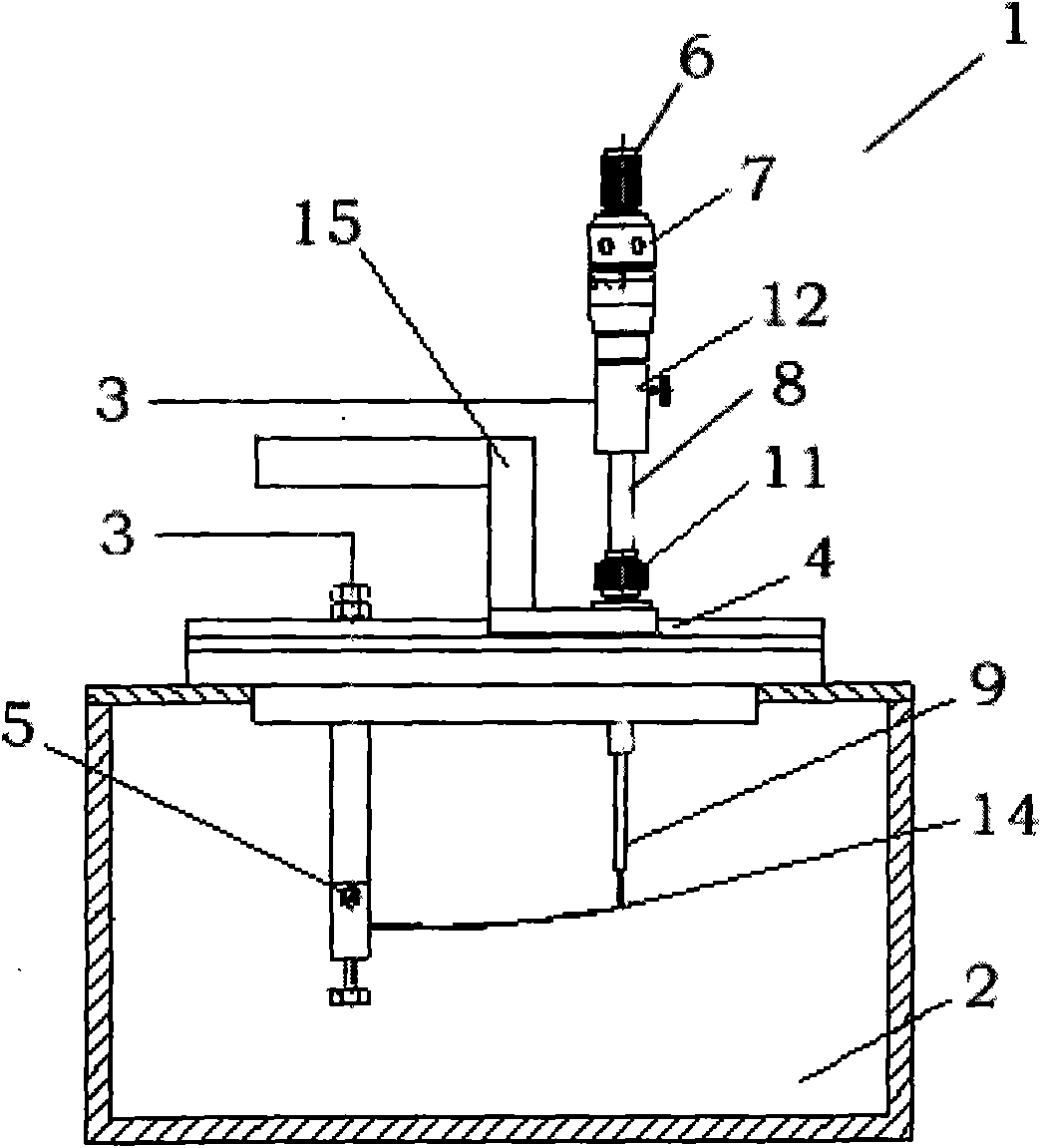

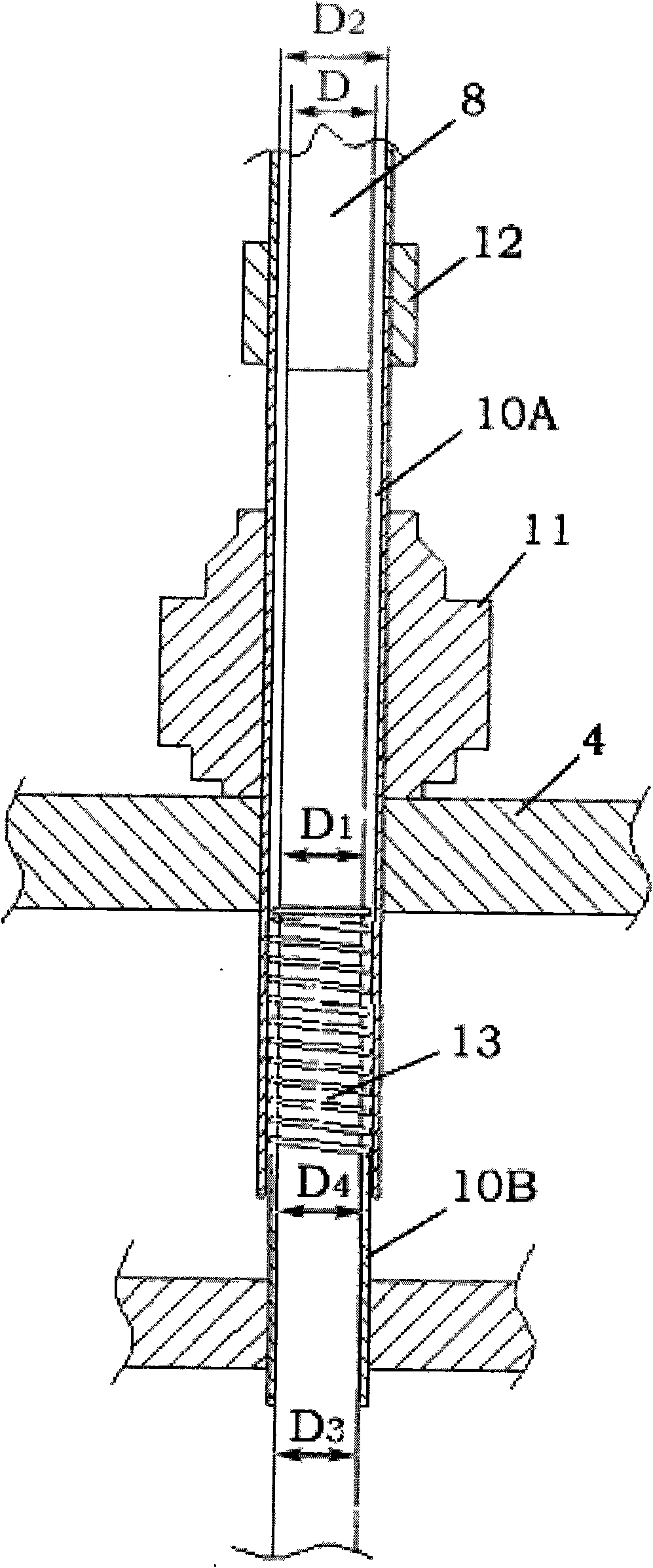

[0055] A bimetal thermal performance detection device includes a flexometer 1, a temperature control oil tank 2 placed under the flexometer, and an electronic contact indicator 3 connected with the flexometer. The flexometer includes: a support platform 4, a sample holding rod (rack) 5 arranged on the support platform and submerged in the temperature control oil tank 2, and a measuring pen 6 that can move on the support platform. The measuring pen It includes a micrometer head 7 and a measuring rod 8 connected to the micrometer head 7 via a connecting block 12, submerged in the temperature control oil tank 2 and in contact with the sample.

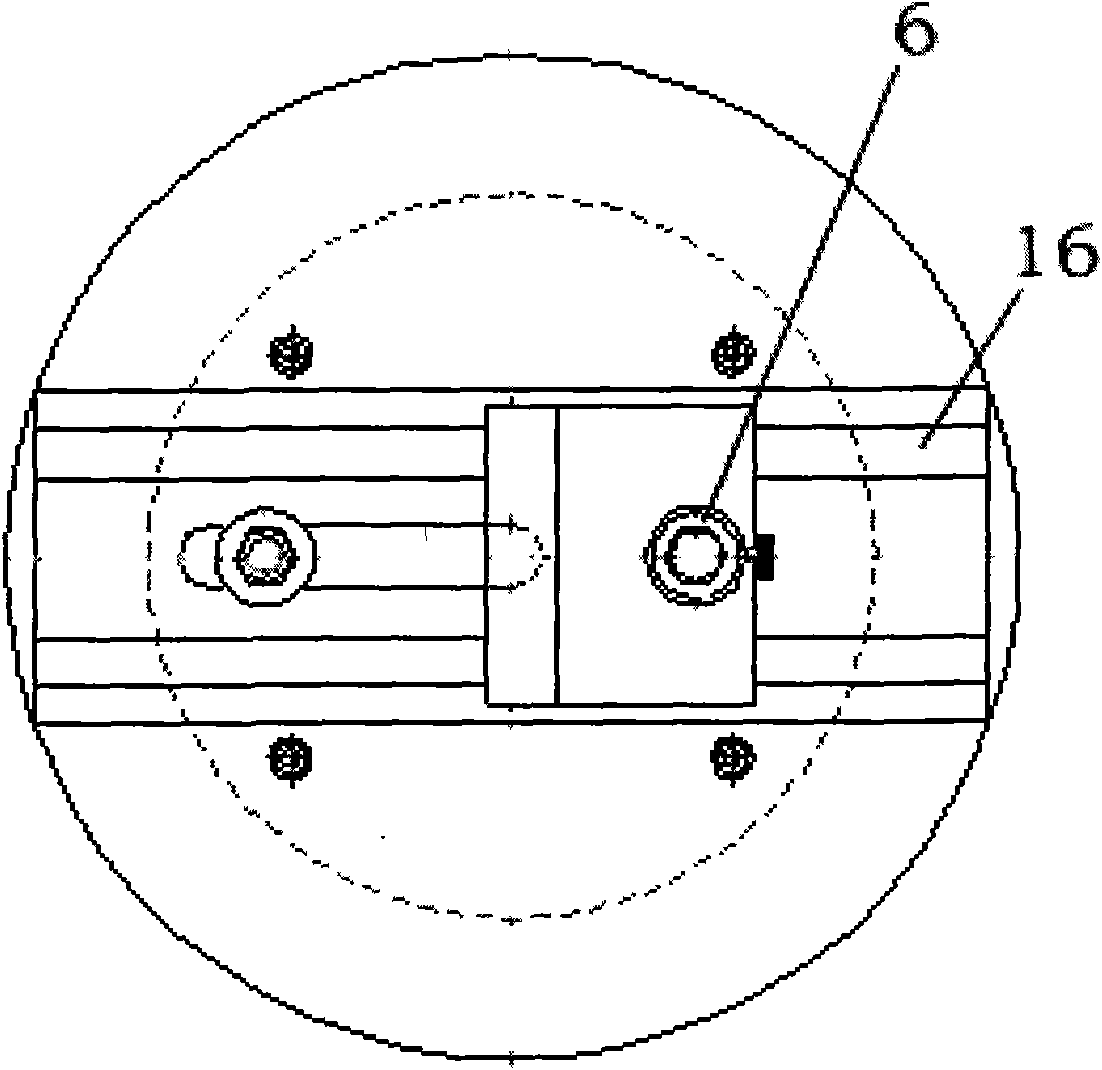

[0056] The measuring pen can be moved on the support platform through the moving slide on the top of the support platform. A handle 16 is designed on the flat plate on the top of the support platform and fixed on the moving slide, so that the above-mentioned flexometer can be moved conveniently.

[0057] The measuring rod has the same cross-sectio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap