Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about "Printed circuit assembling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

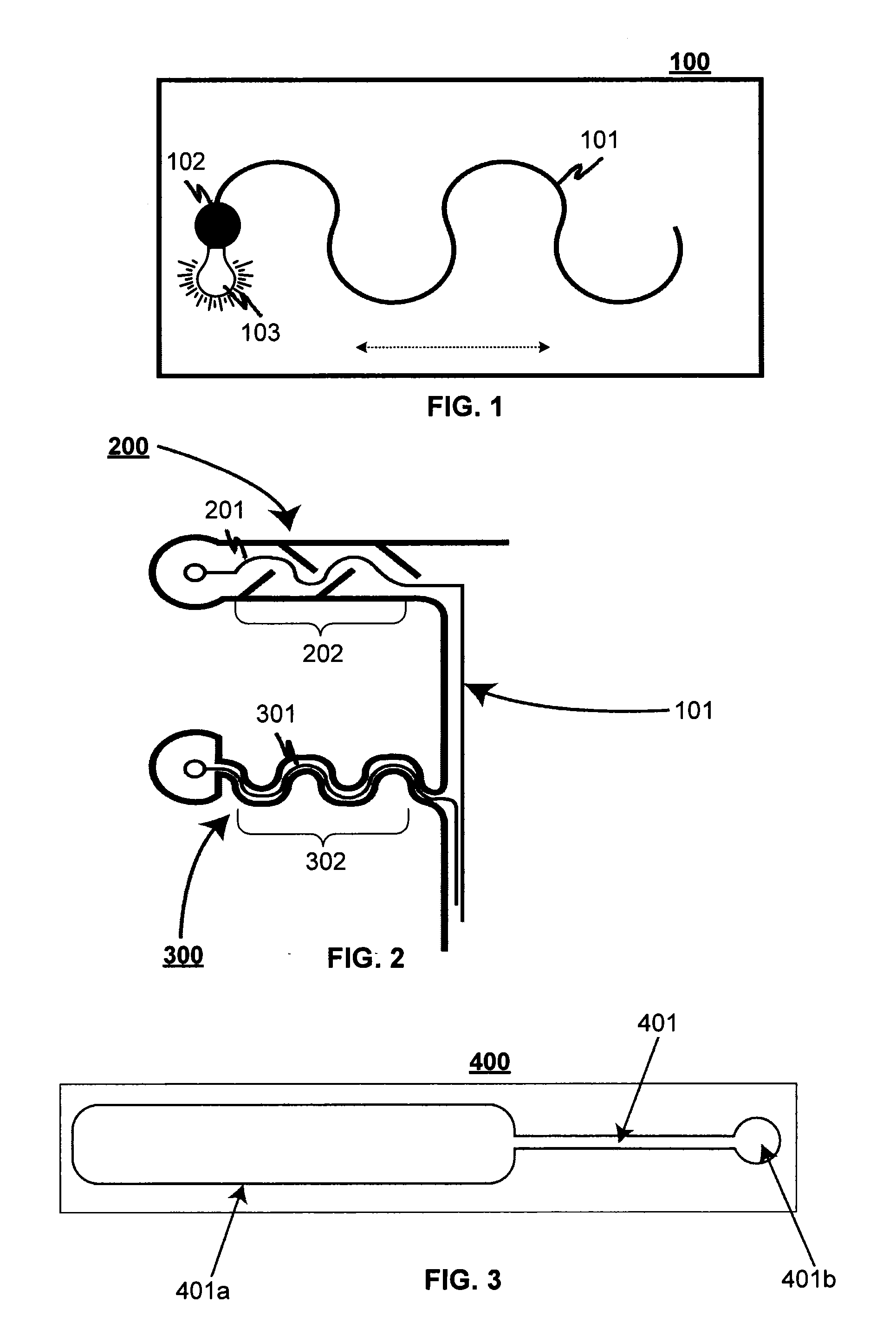

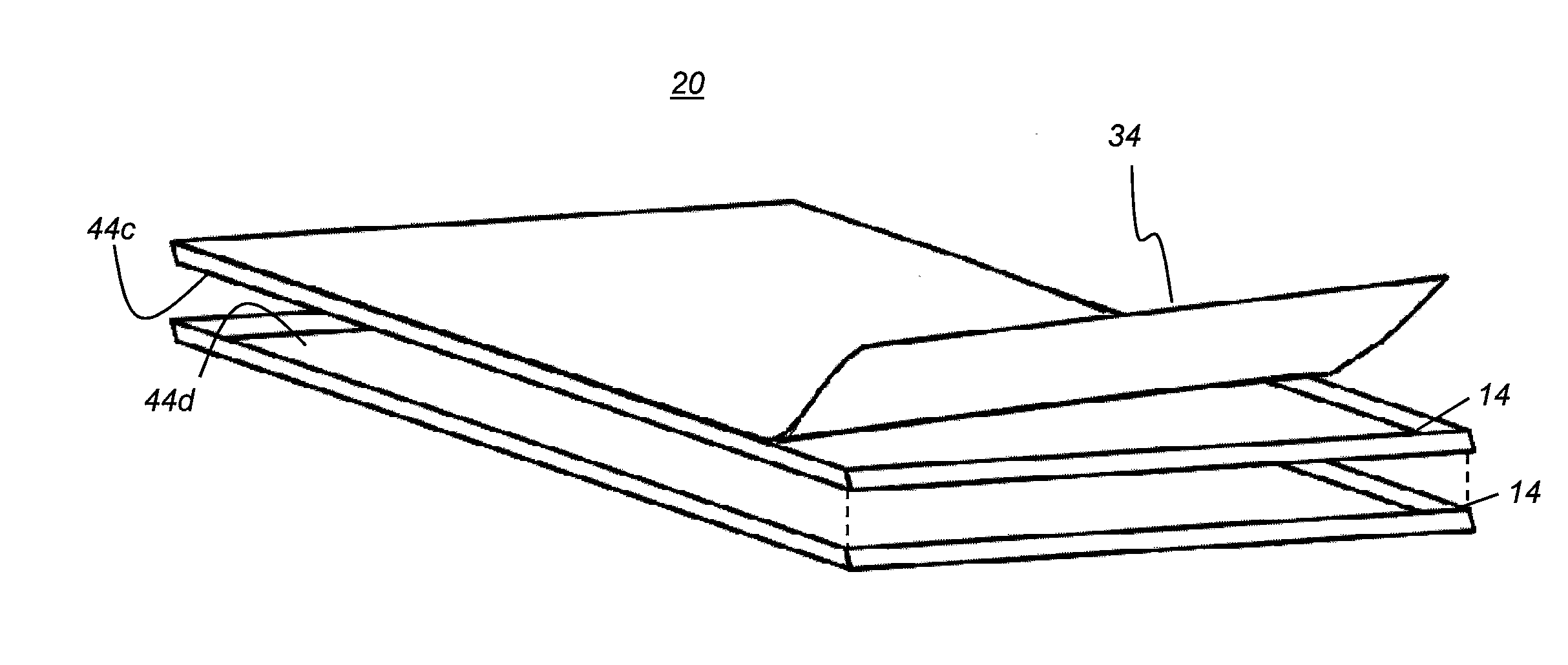

Textile arrangement and method for manufacturing

InactiveUS20130160183A1The process is simple and fastCost-effective manufacturingGlovesLaminating printed circuit boardsFlexible circuitsEngineering

Owner:CLOTHING PLUS MBU

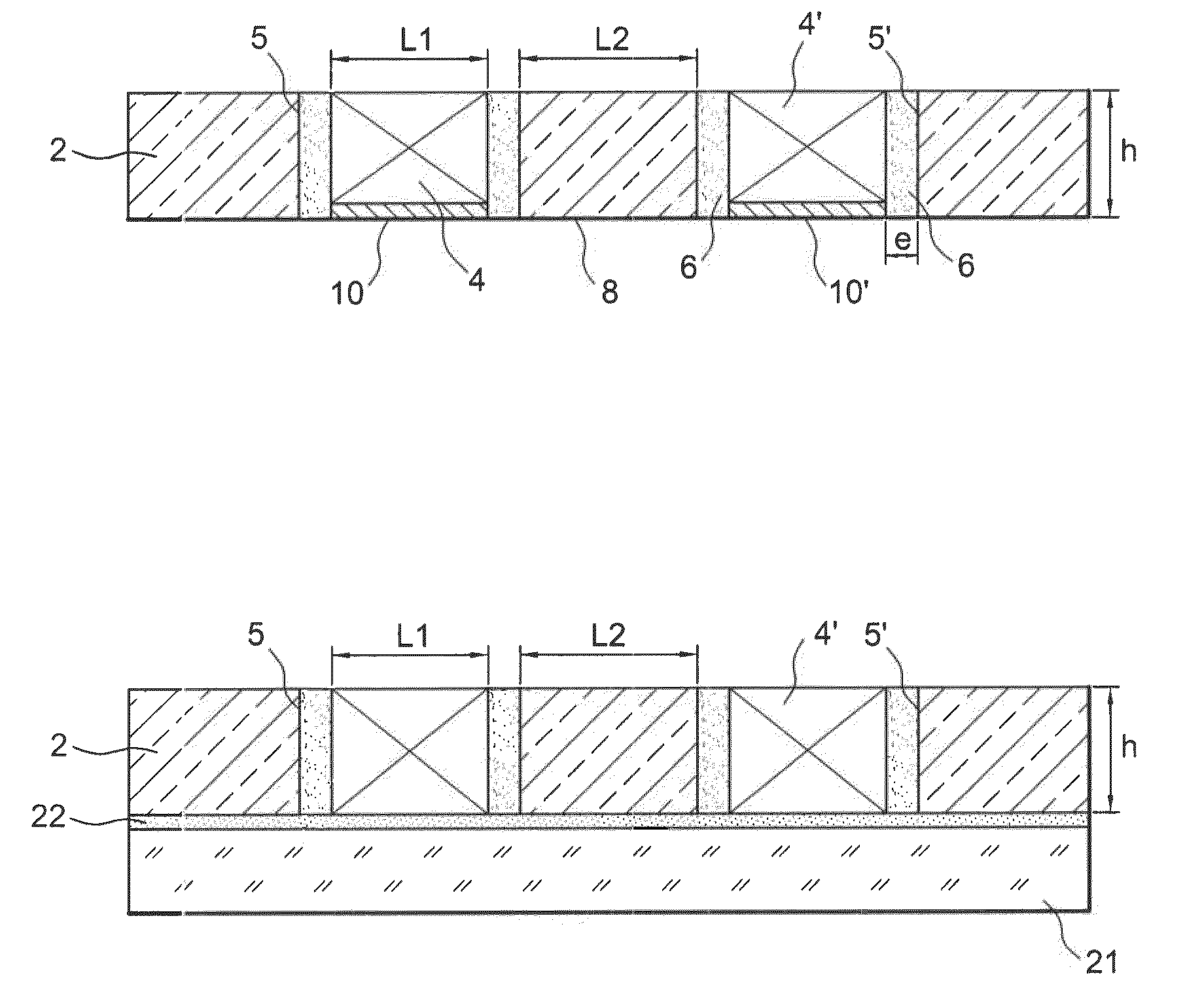

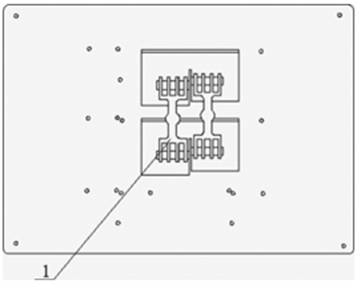

Integrated multicomponent device in a semiconducting die

ActiveUS20100195299A1Known techniquePrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

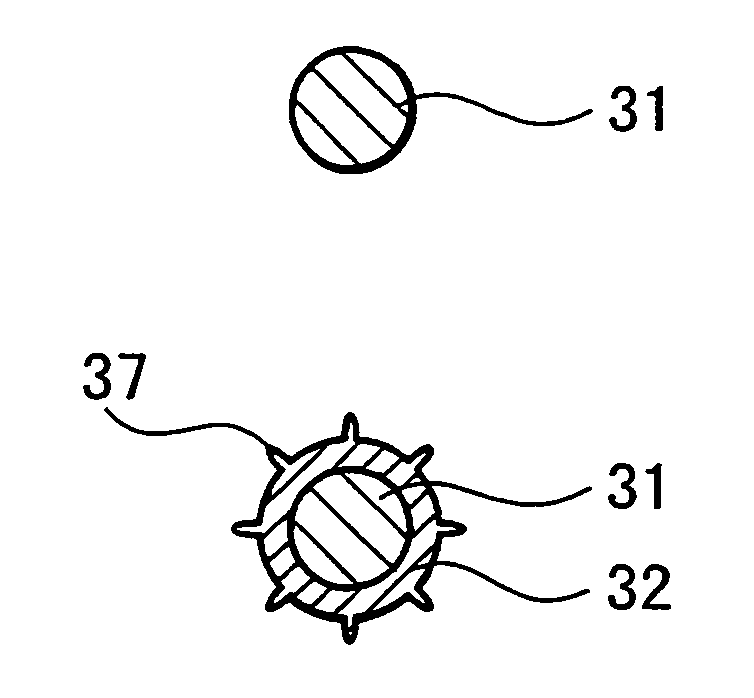

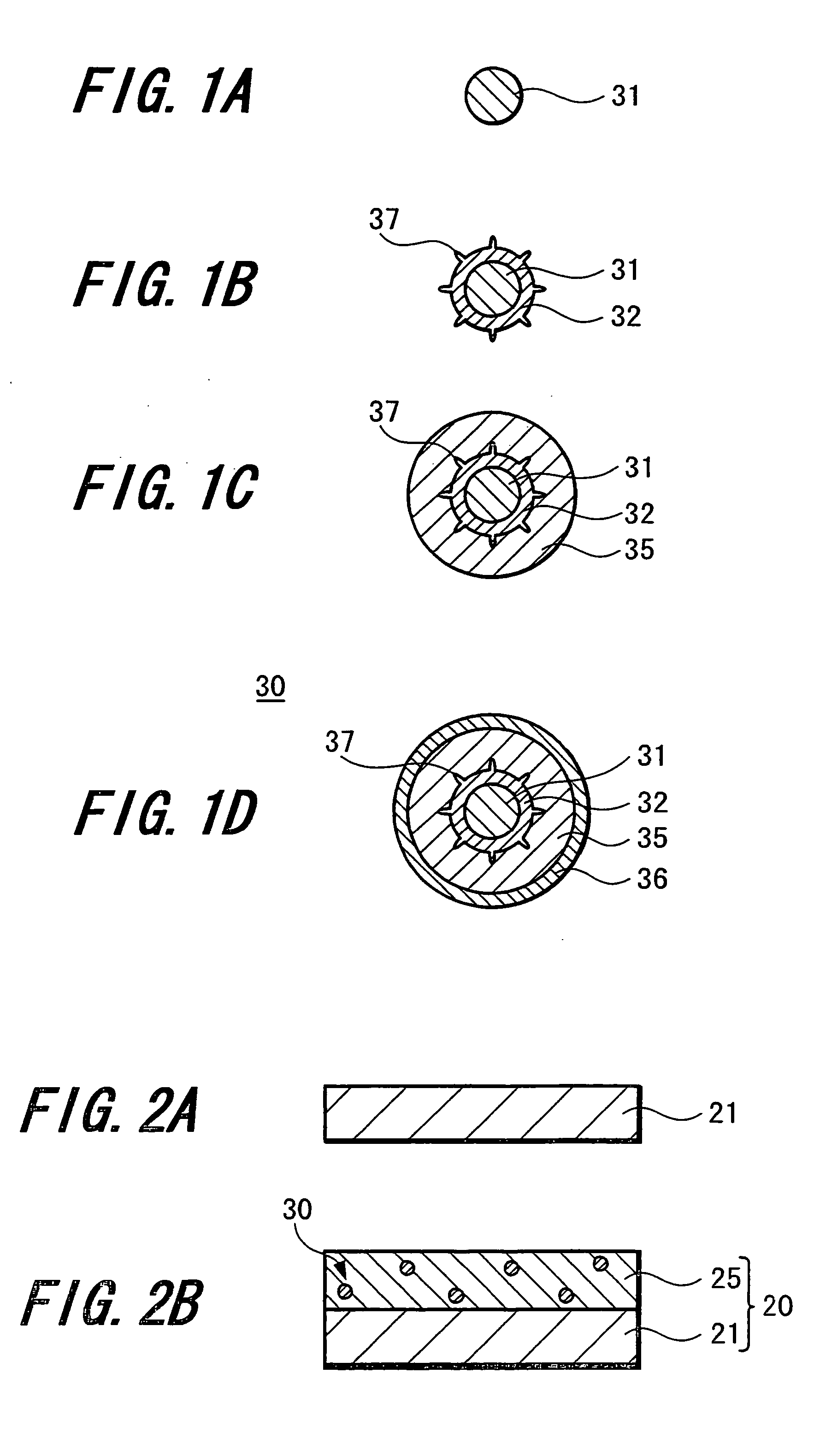

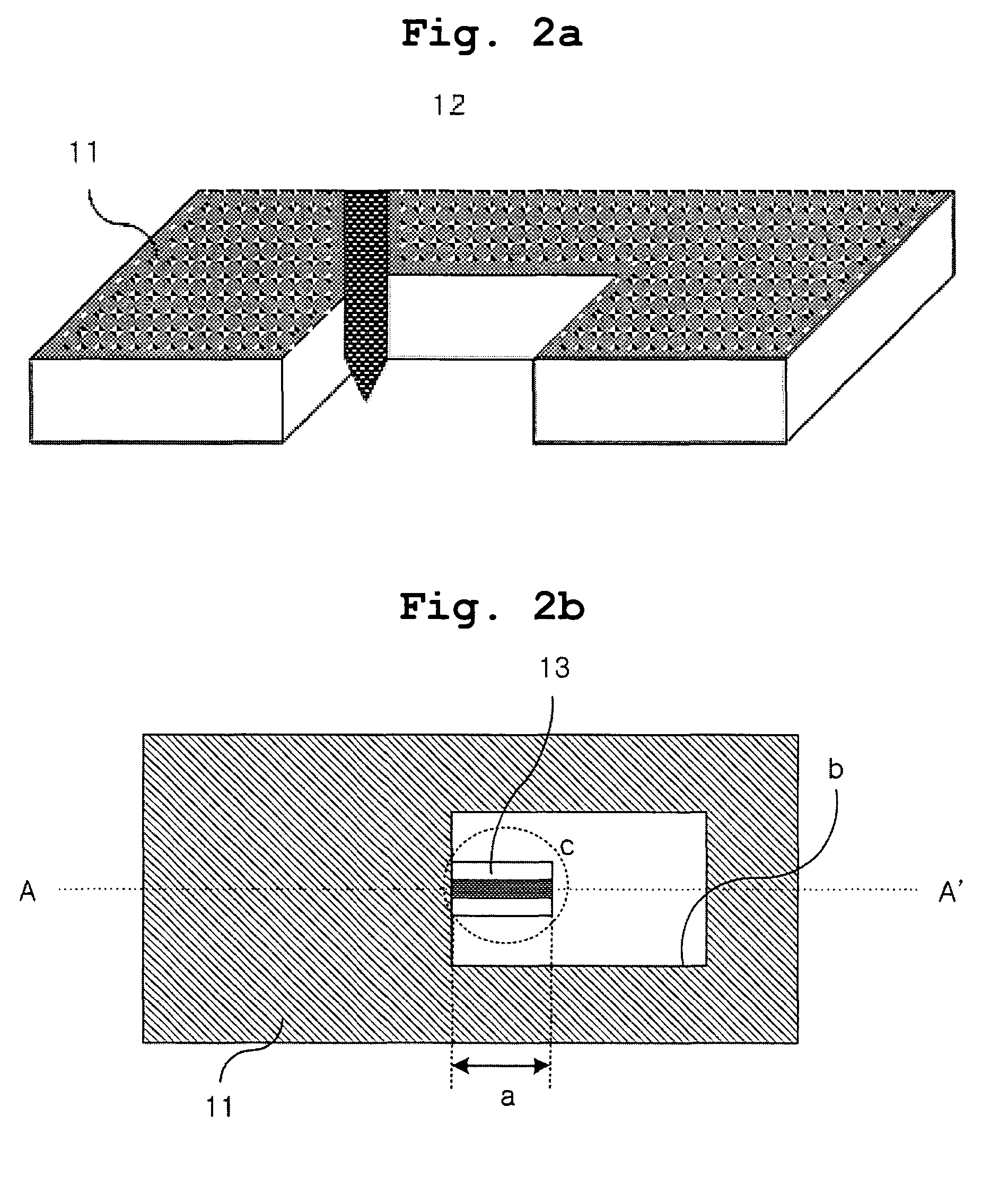

Conductive particle and adhesive agent

ActiveUS20060054867A1Avoid deformationReliable electrical connectionNon-insulated conductorsSolid-state devicesResin coatingMaterials science

Owner:SONY CORP +1

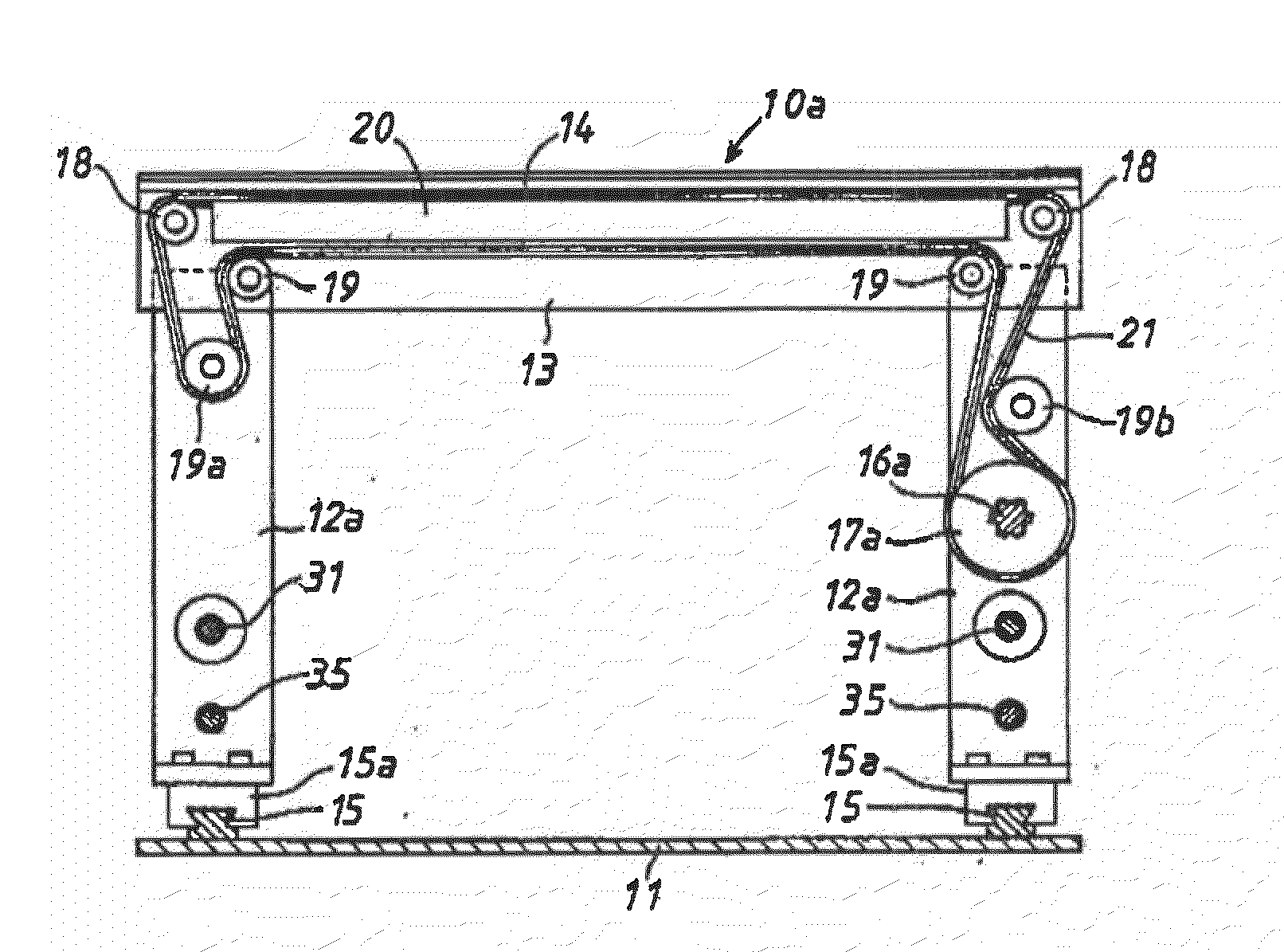

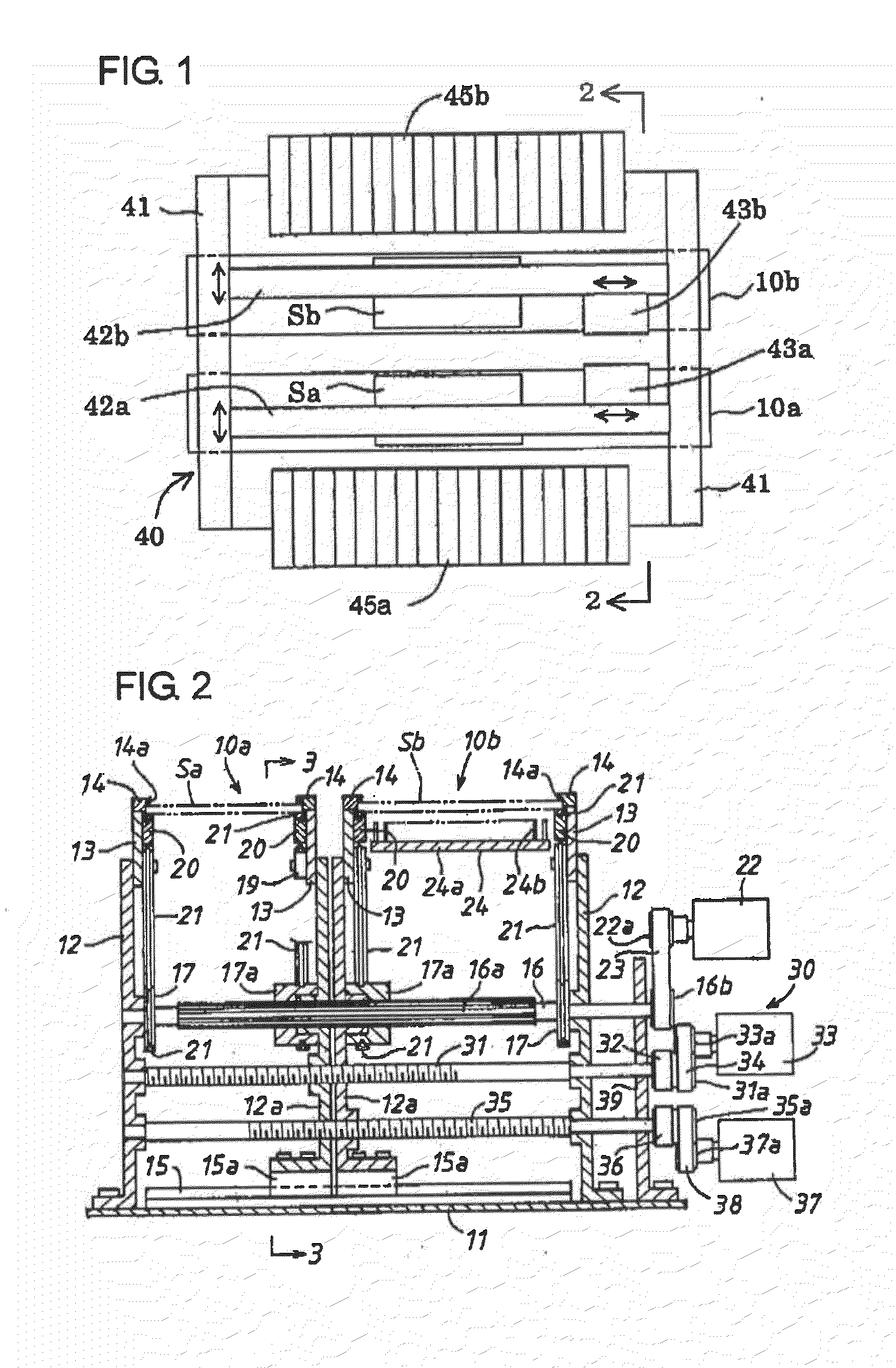

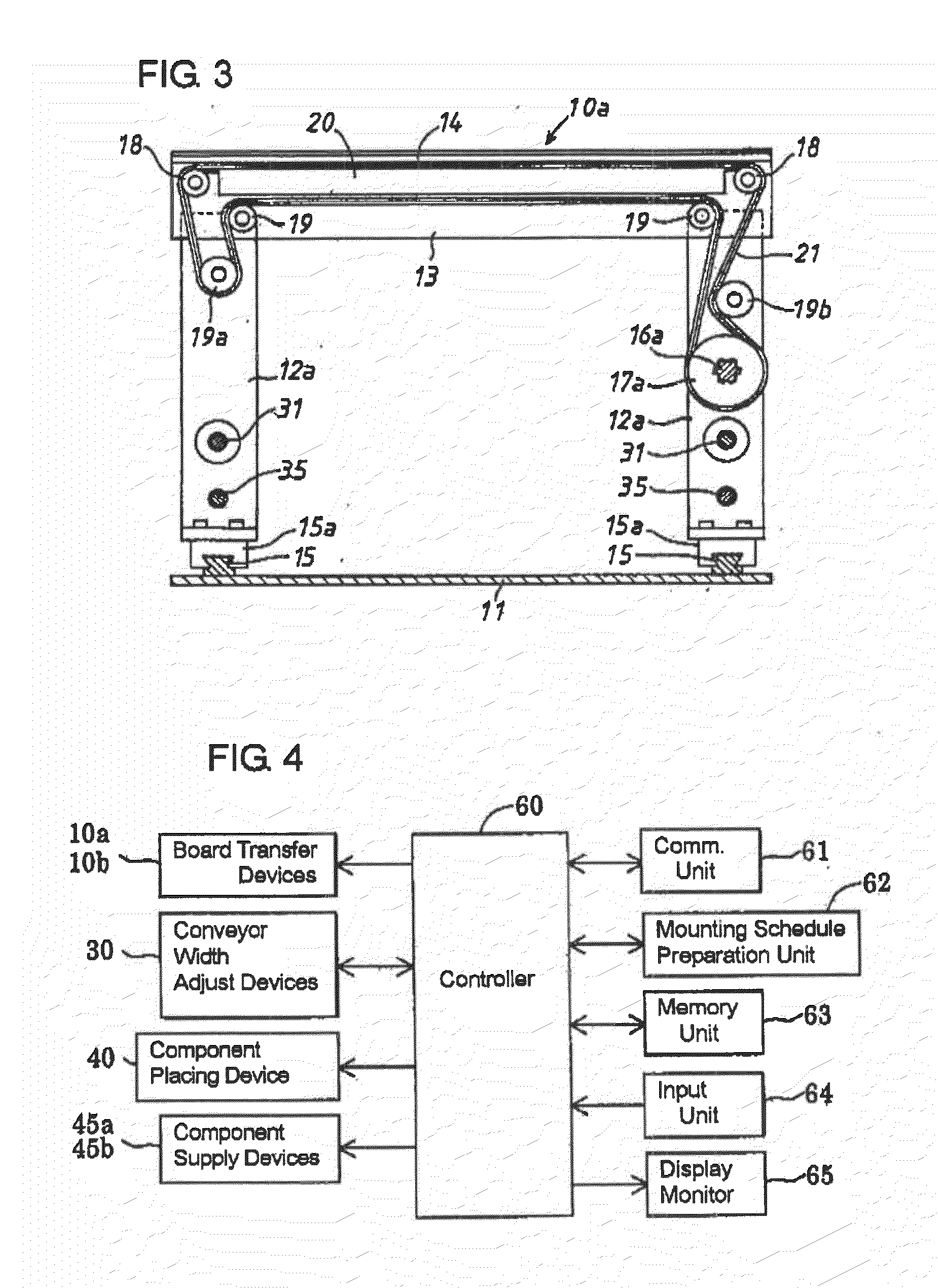

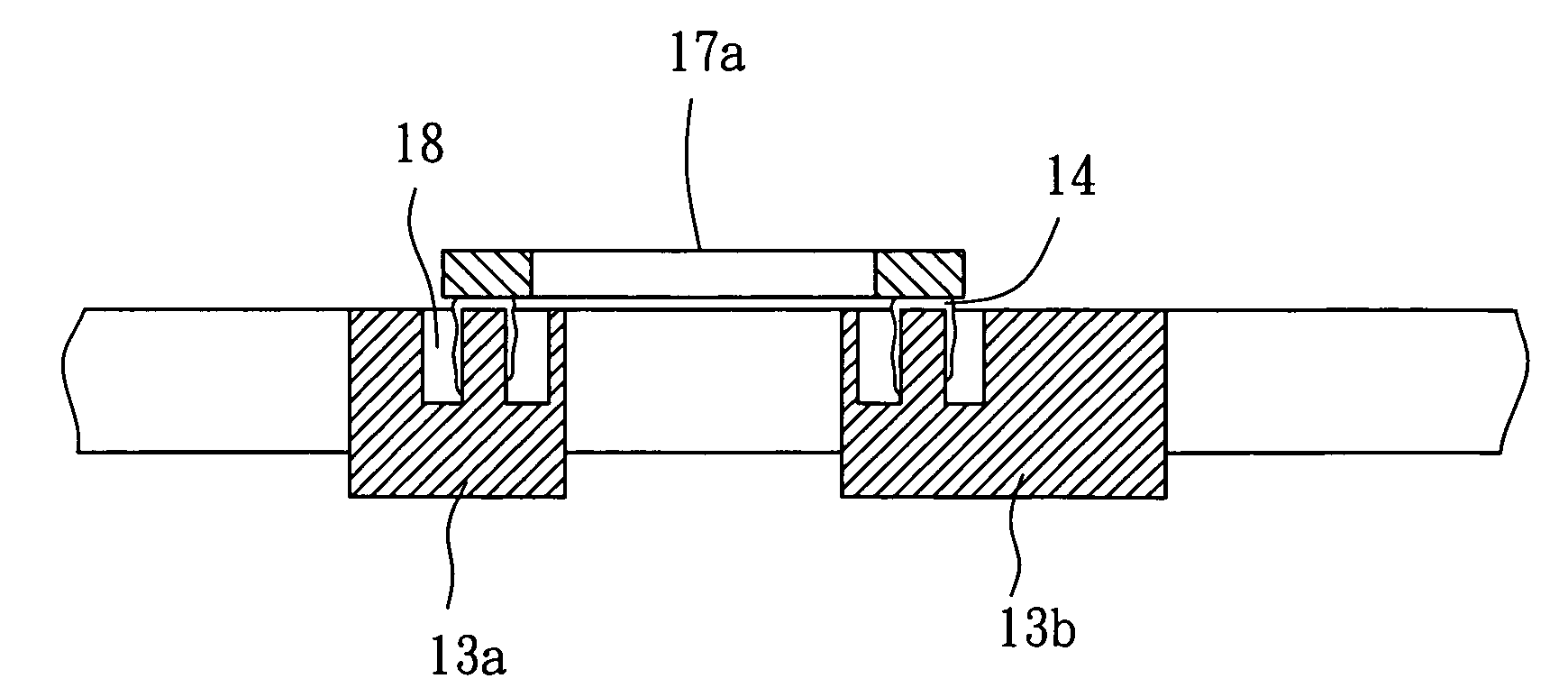

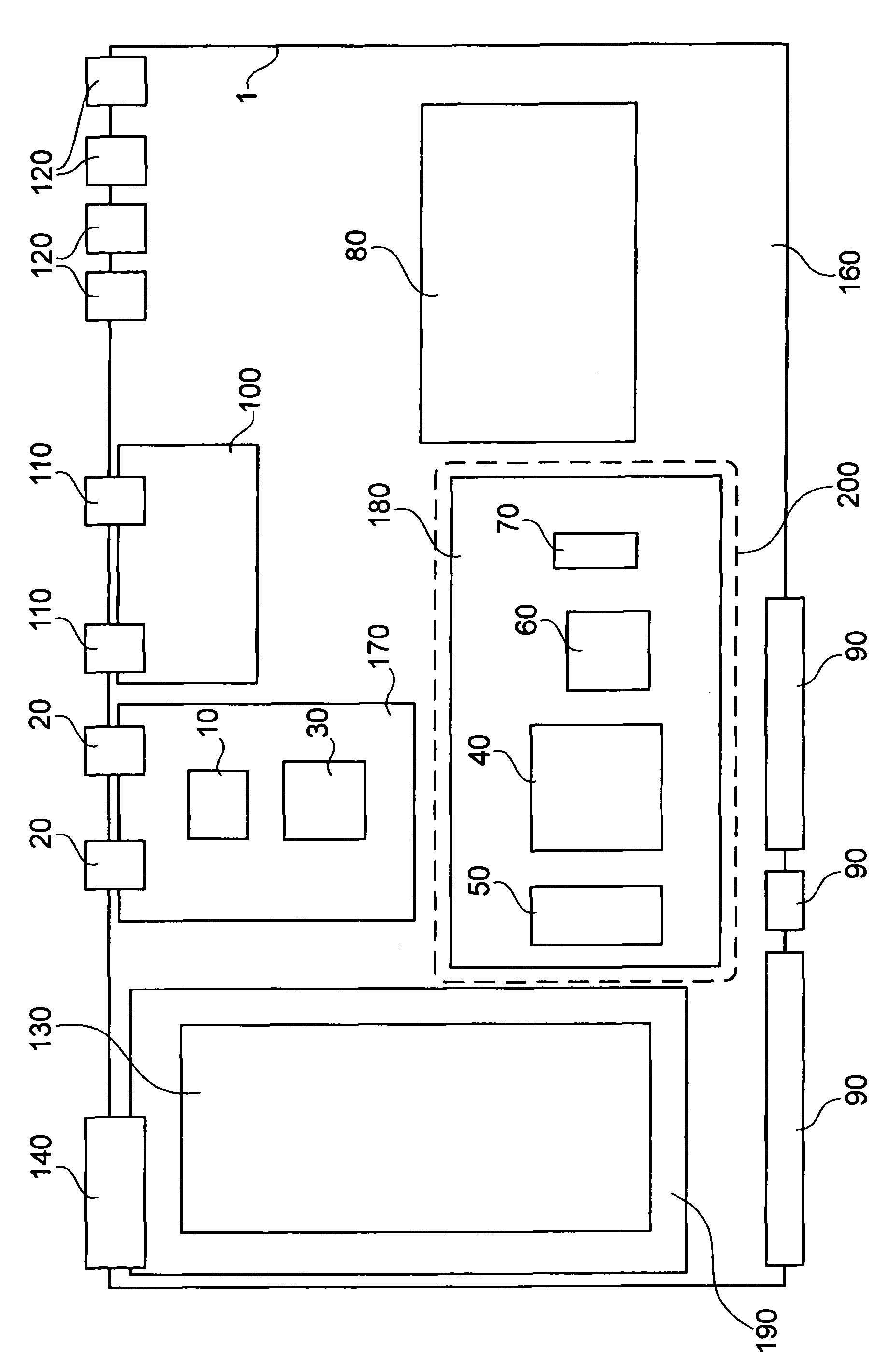

System for mounting components on boards

Owner:FUJI MASCH MFG CO LTD

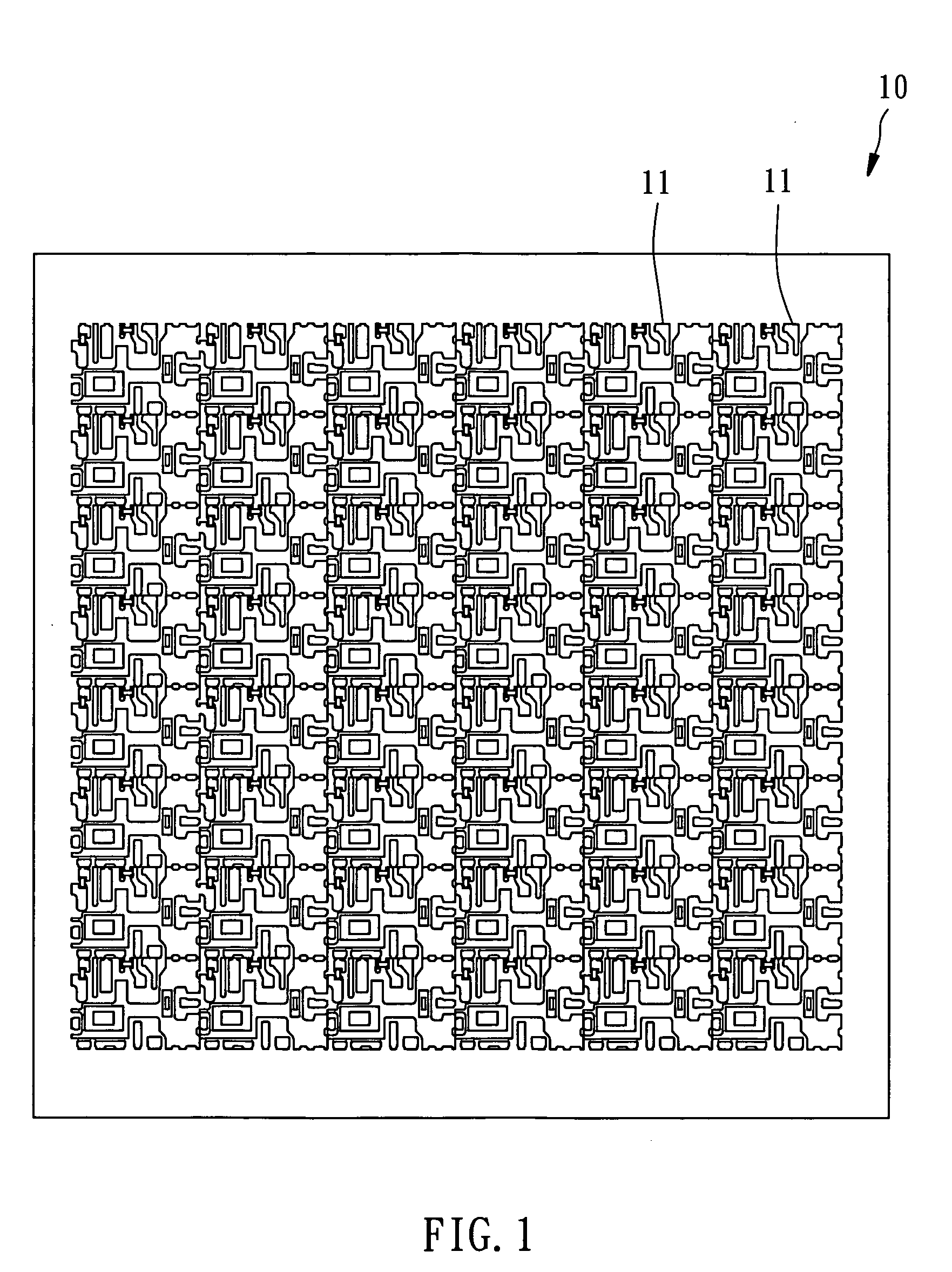

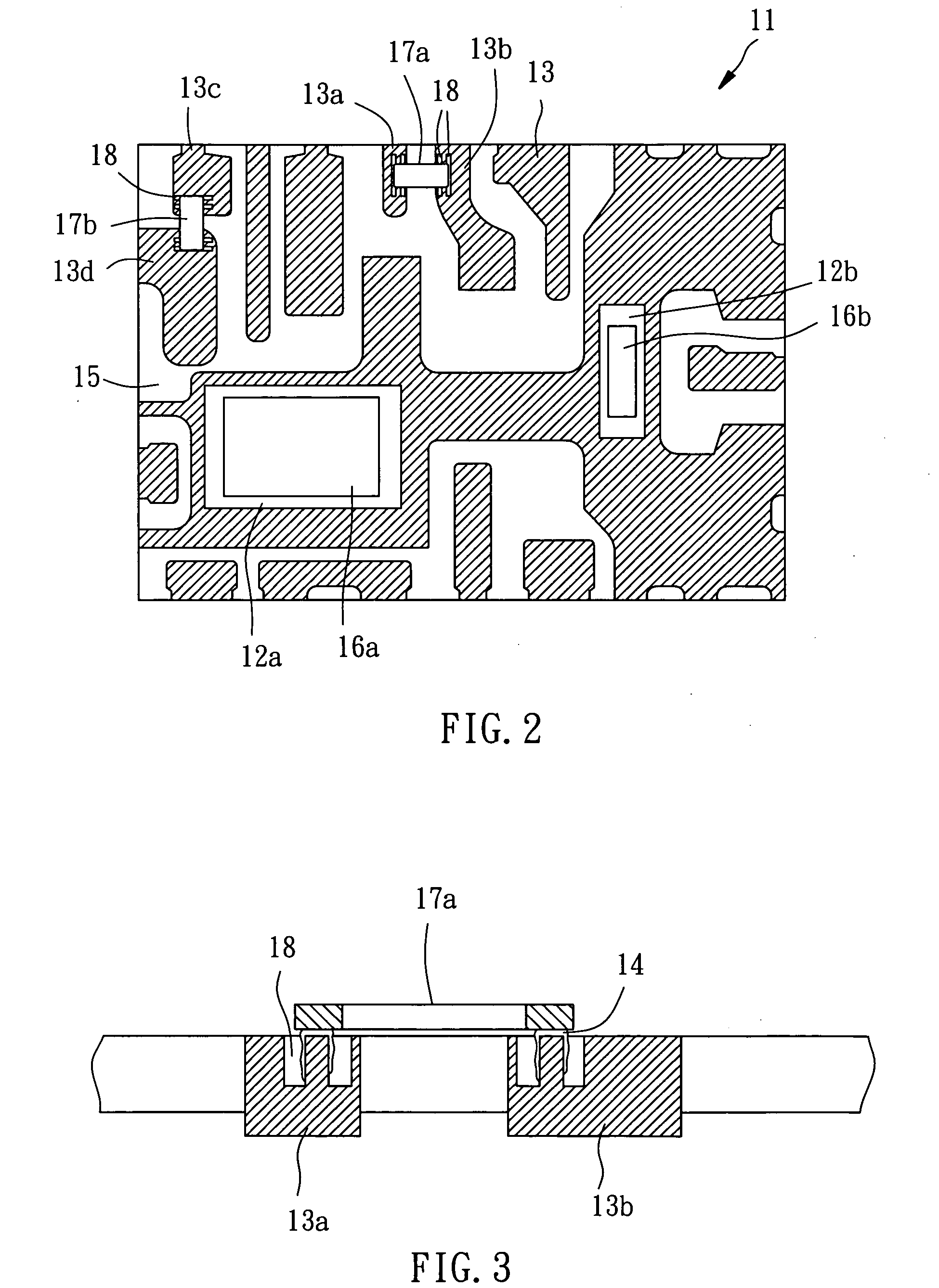

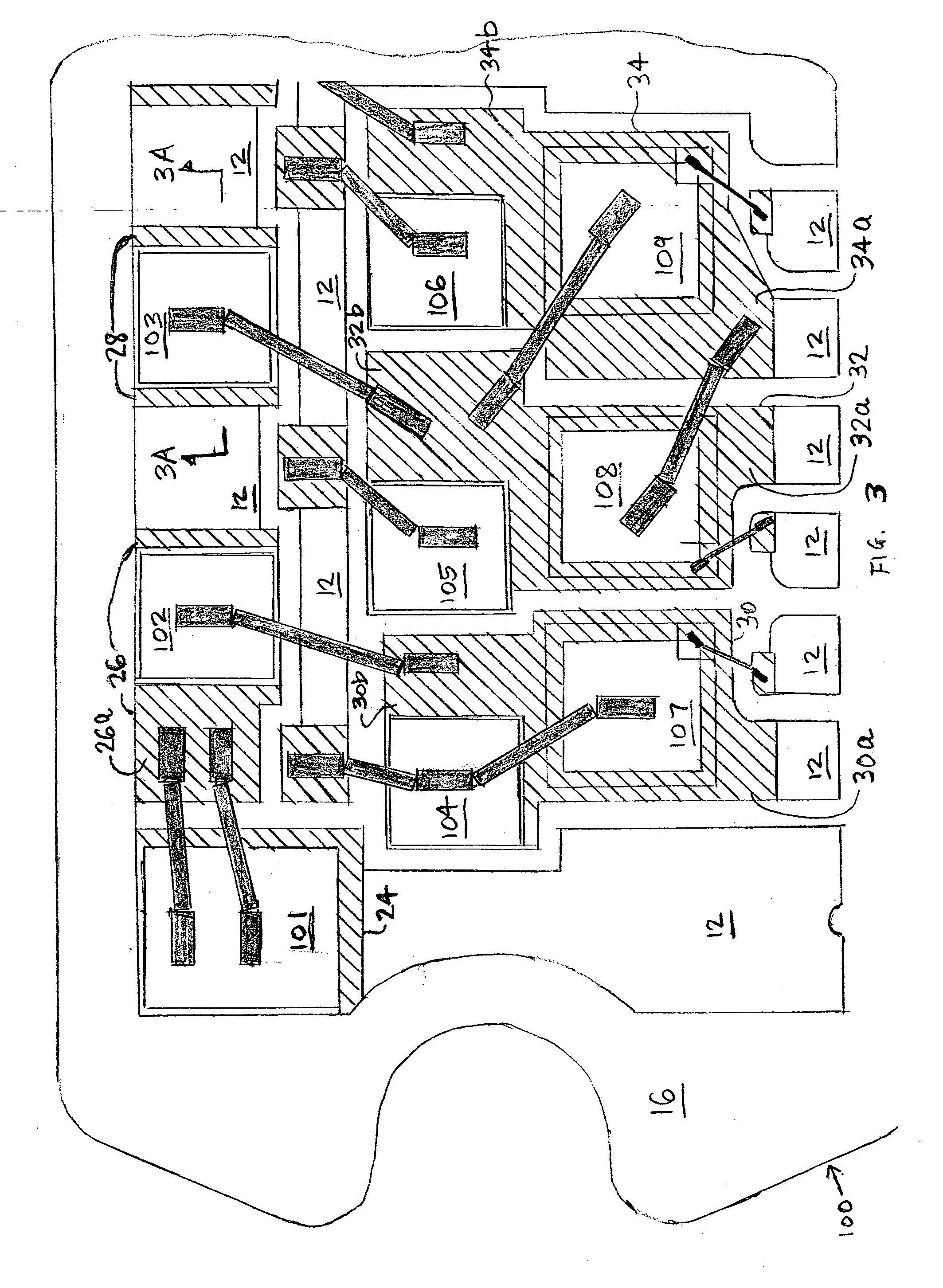

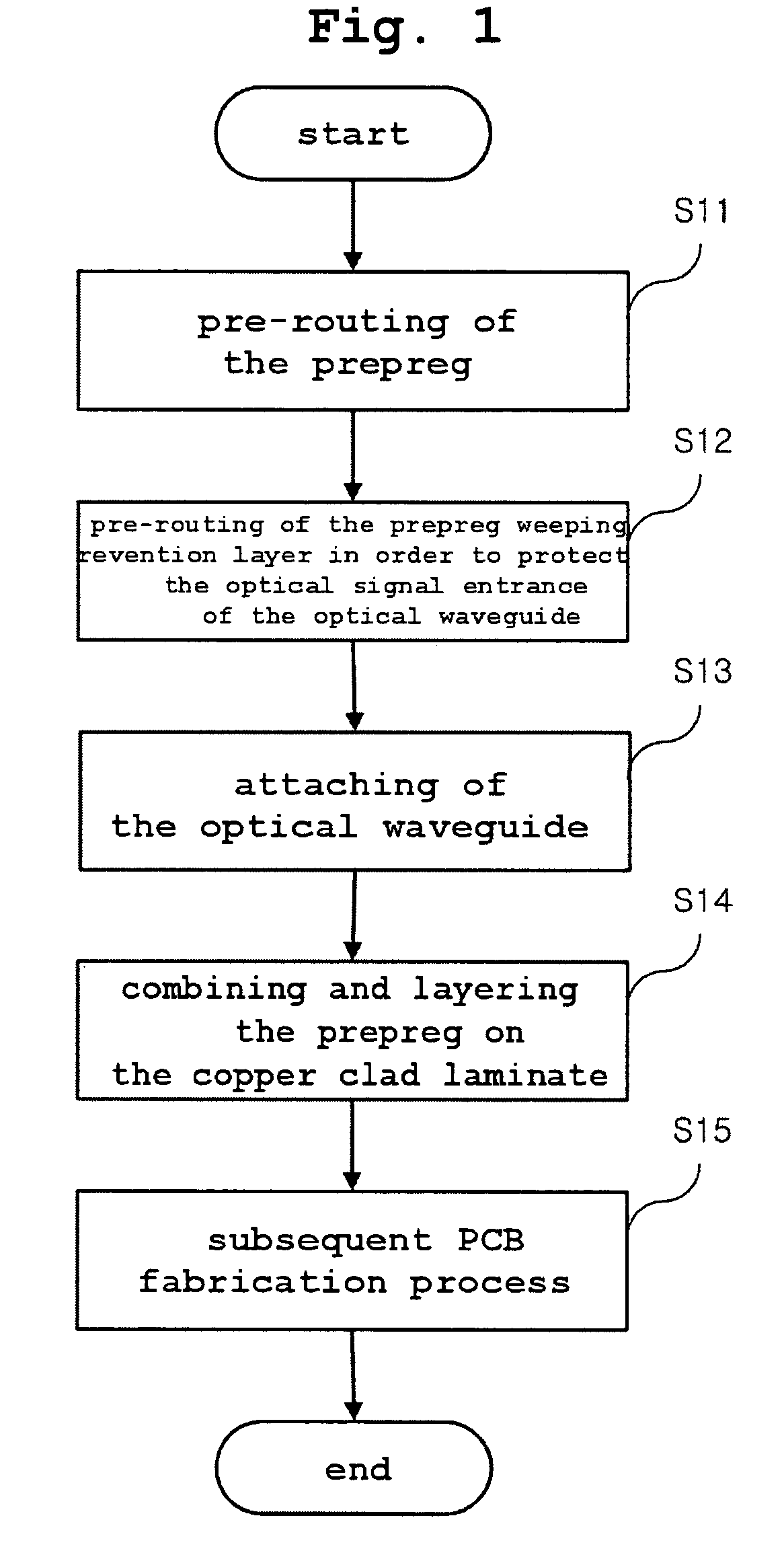

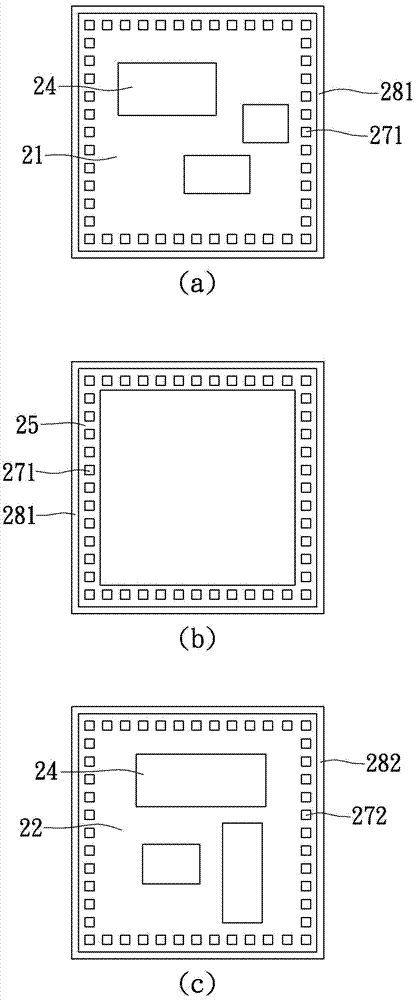

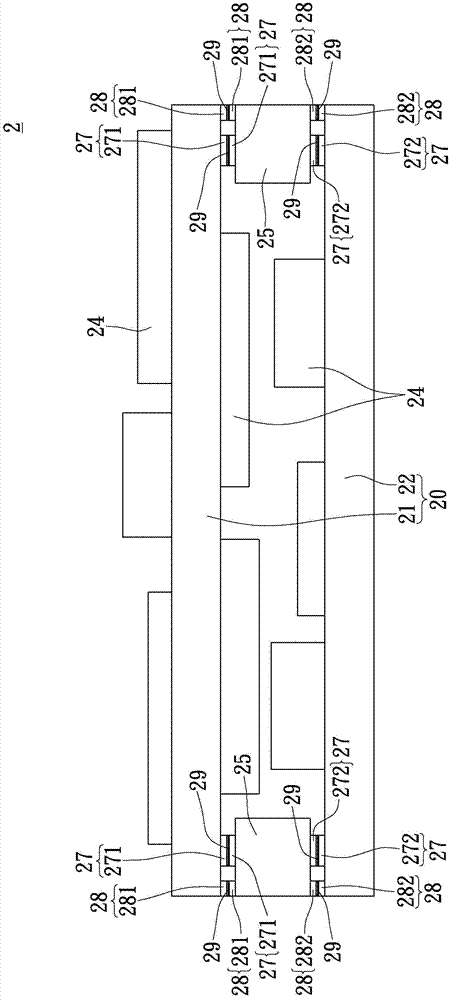

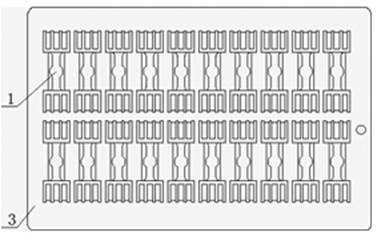

Packaging substrate having adhesive-overflowing prevention structure

InactiveUS20060221586A1Prevent a short circuit happenedPrevent overflowPrinted circuit assemblingPrinted electric component incorporationEngineeringAdhesive

A packaging substrate includes an array of packaging units. Each packaging unit has a chip pad carrying a chip, a plurality of pins arranged around the chip pad and spaced from one another and the chip pad by an open space, an insulative member filling up the open space, passive components each connected between two pins, a bonding adhesive applied to the pins to which the passive components is connected to affix the connection between the passive components and the respective pins, and a plurality of overflow-preventive grooves respectively provided around the bonding adhesive at each of the pins to which the passive components are connected to prevent overflow of the bonding adhesive.

Owner:LINGSEN PRECISION INDS

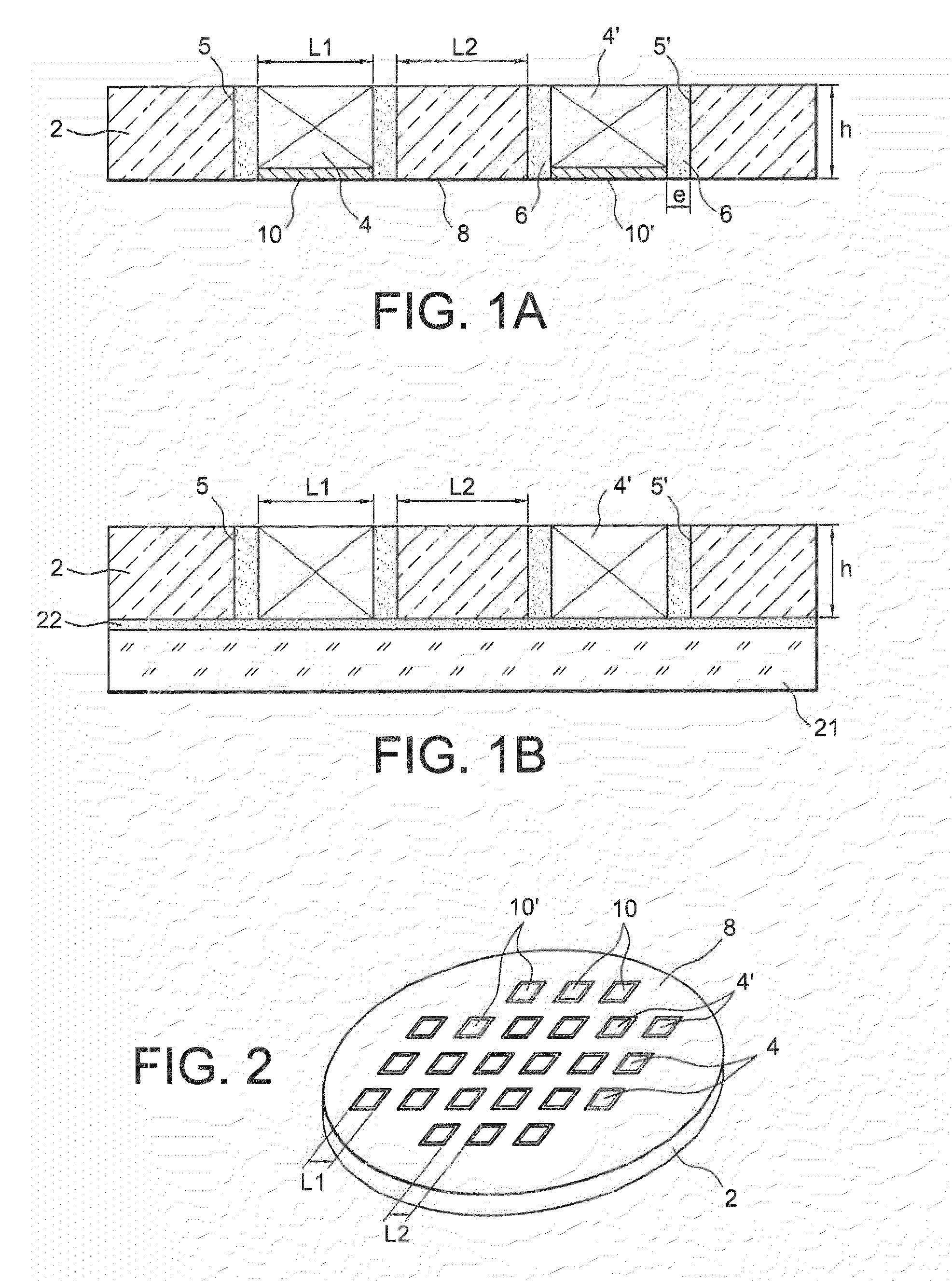

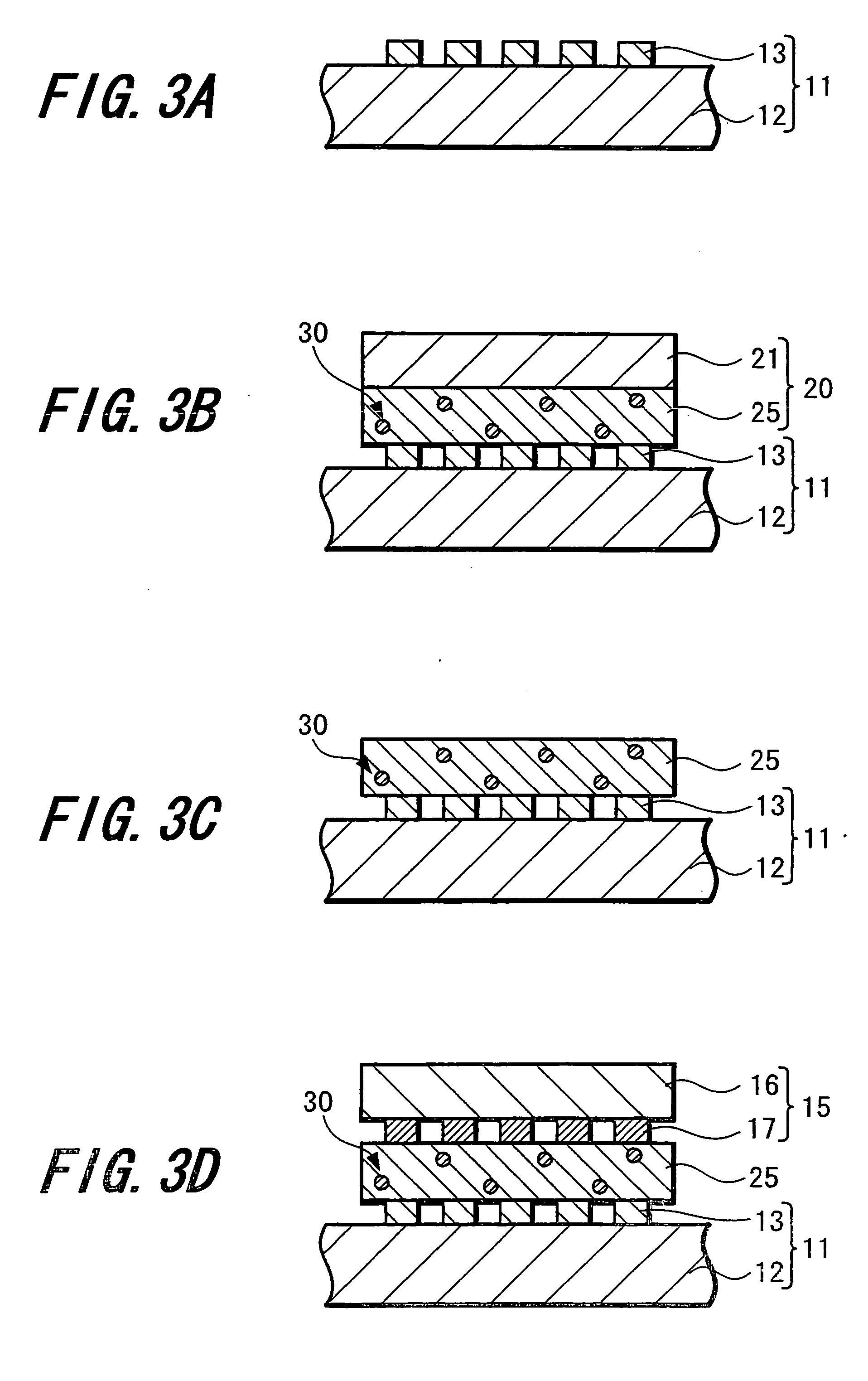

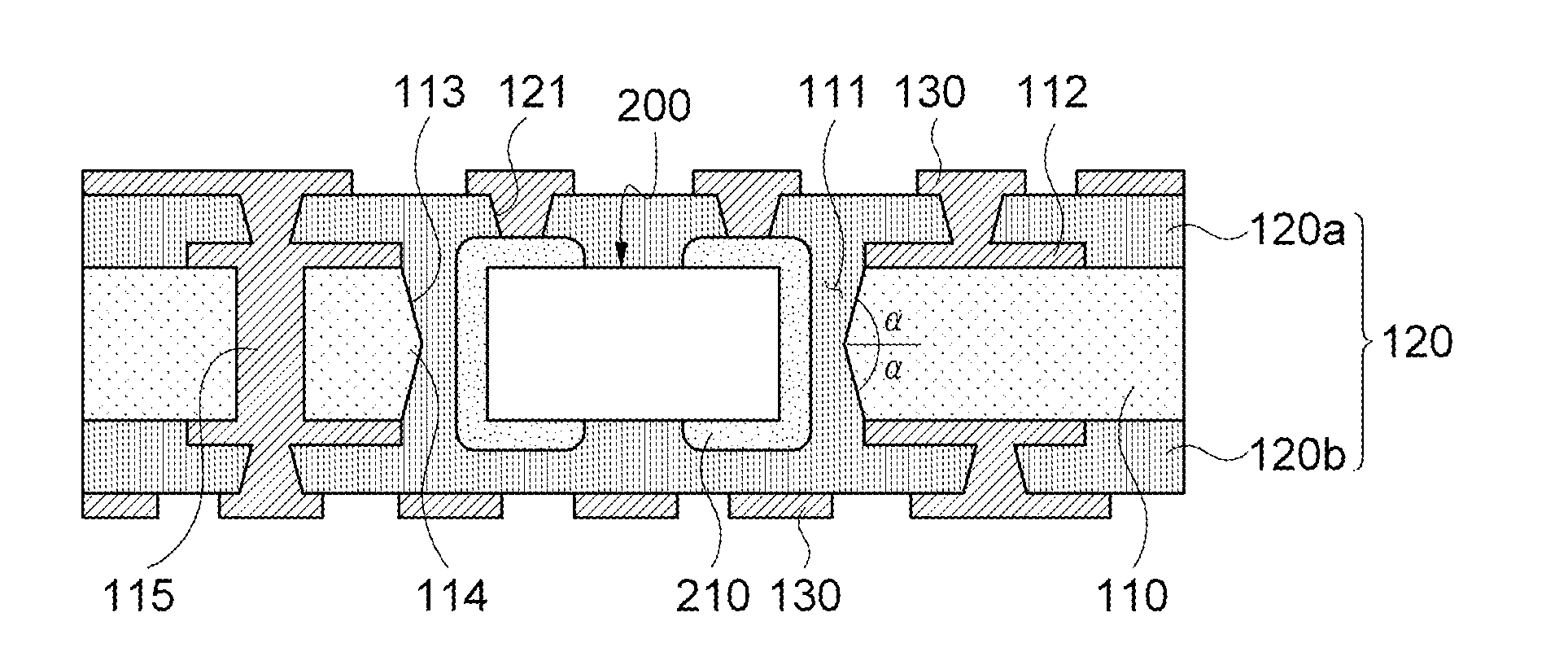

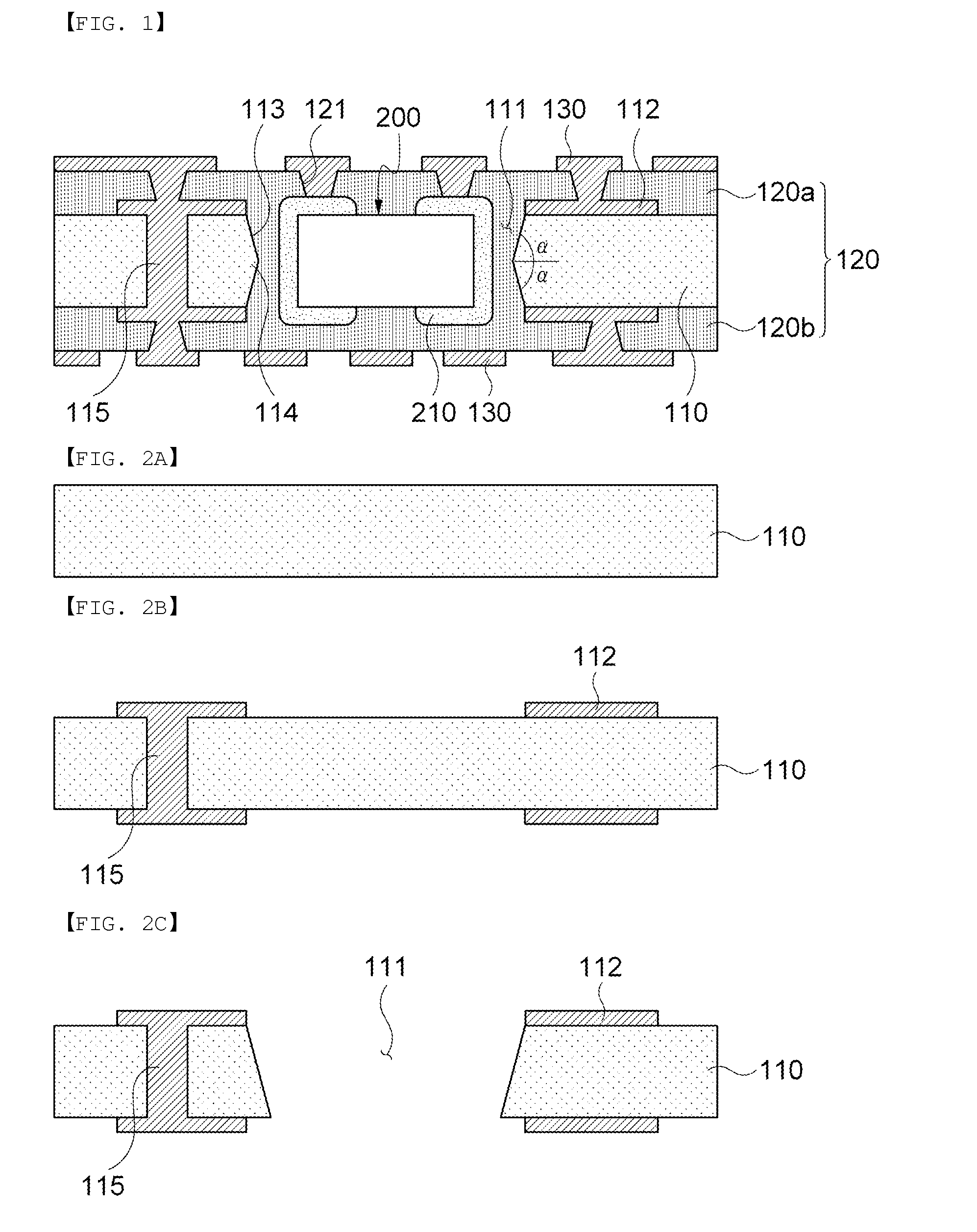

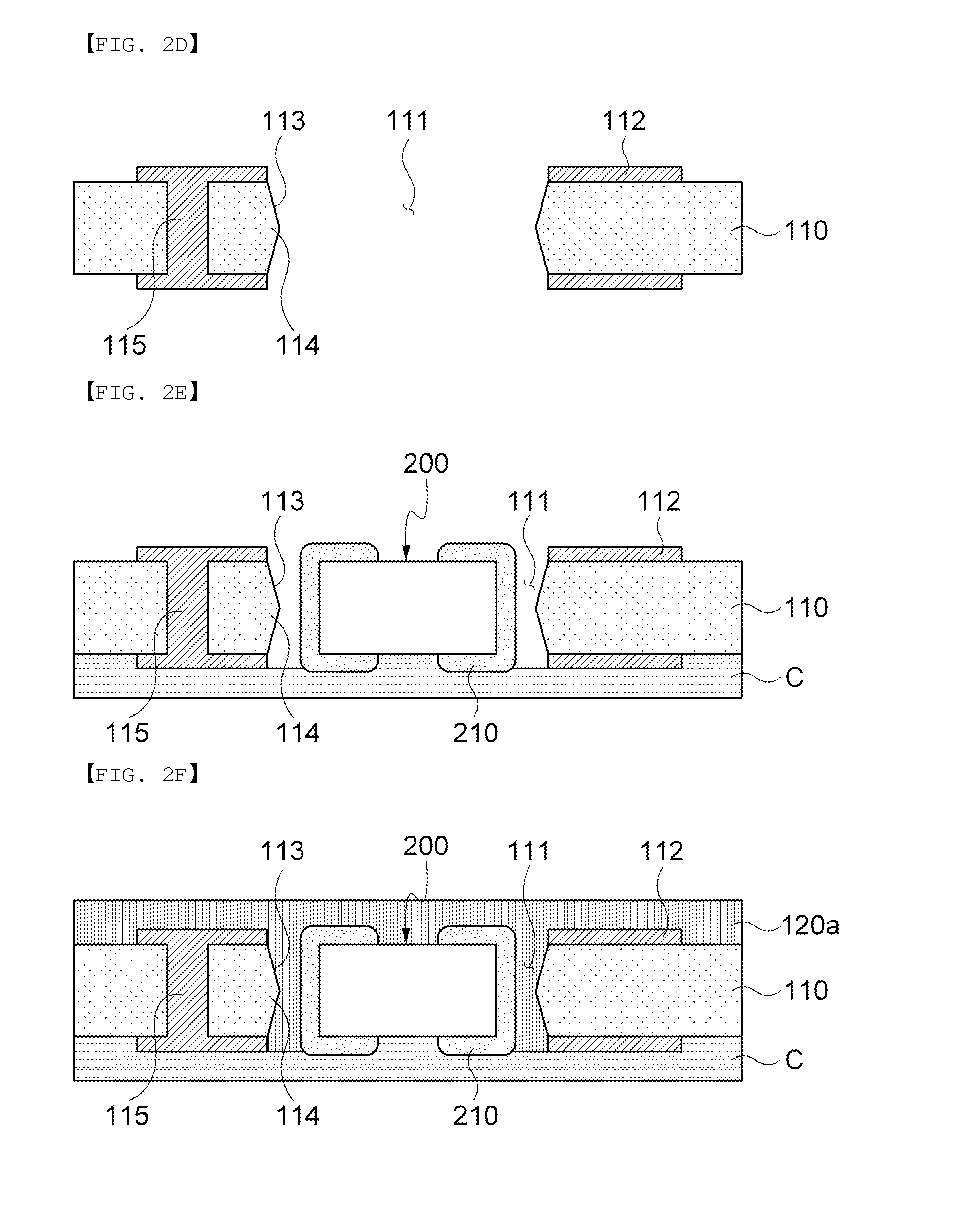

Printed circuit board including electronic component embedded therein and method for manufacturing the same

ActiveUS20140321084A1Improve reliabilityHigh yieldPrinted circuit assemblingPrinted electric component incorporationEngineeringElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Electronic device

ActiveUS20140328036A1Printed circuit assemblingPrinted circuit aspectsDielectric substrateInterposer

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

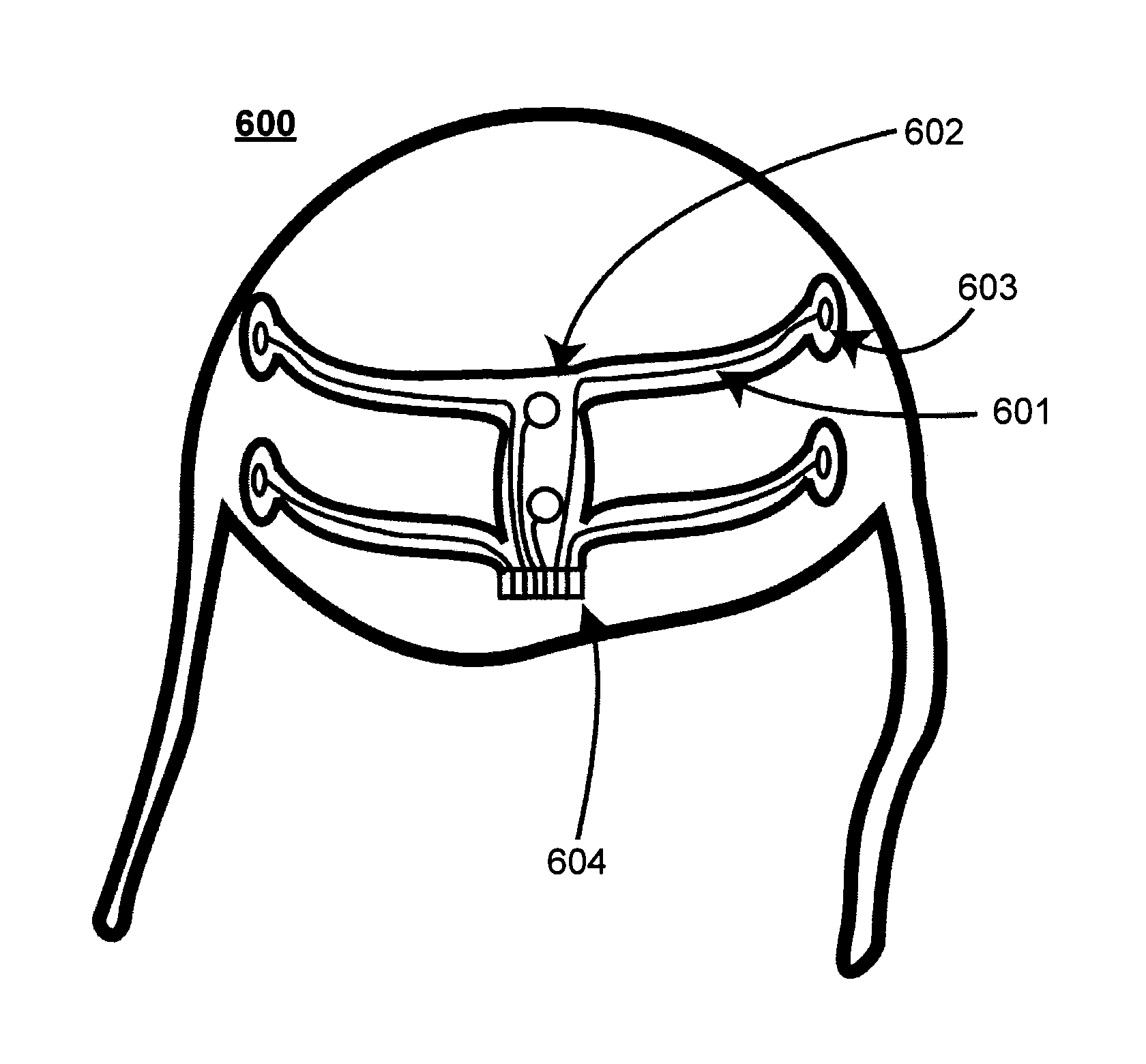

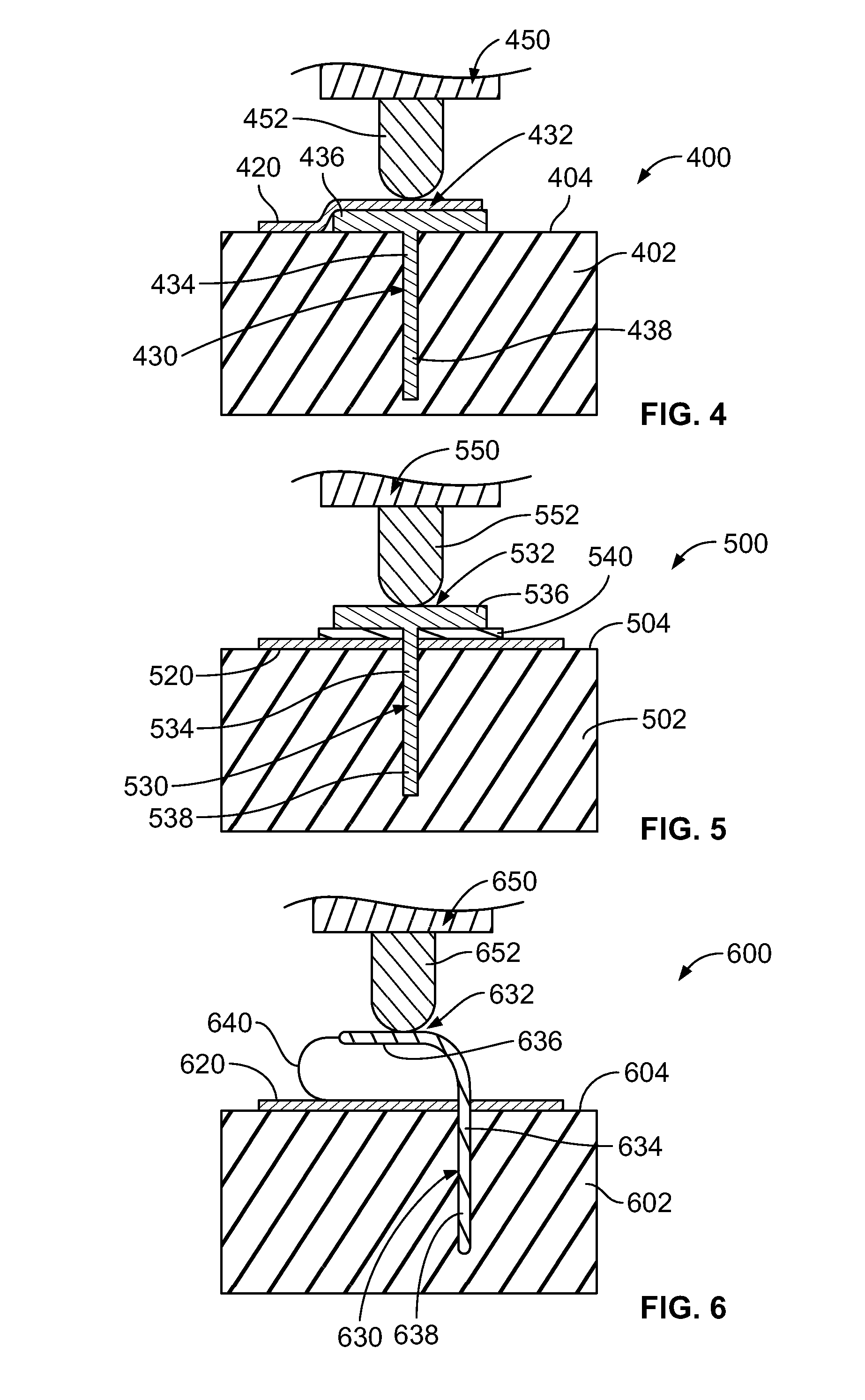

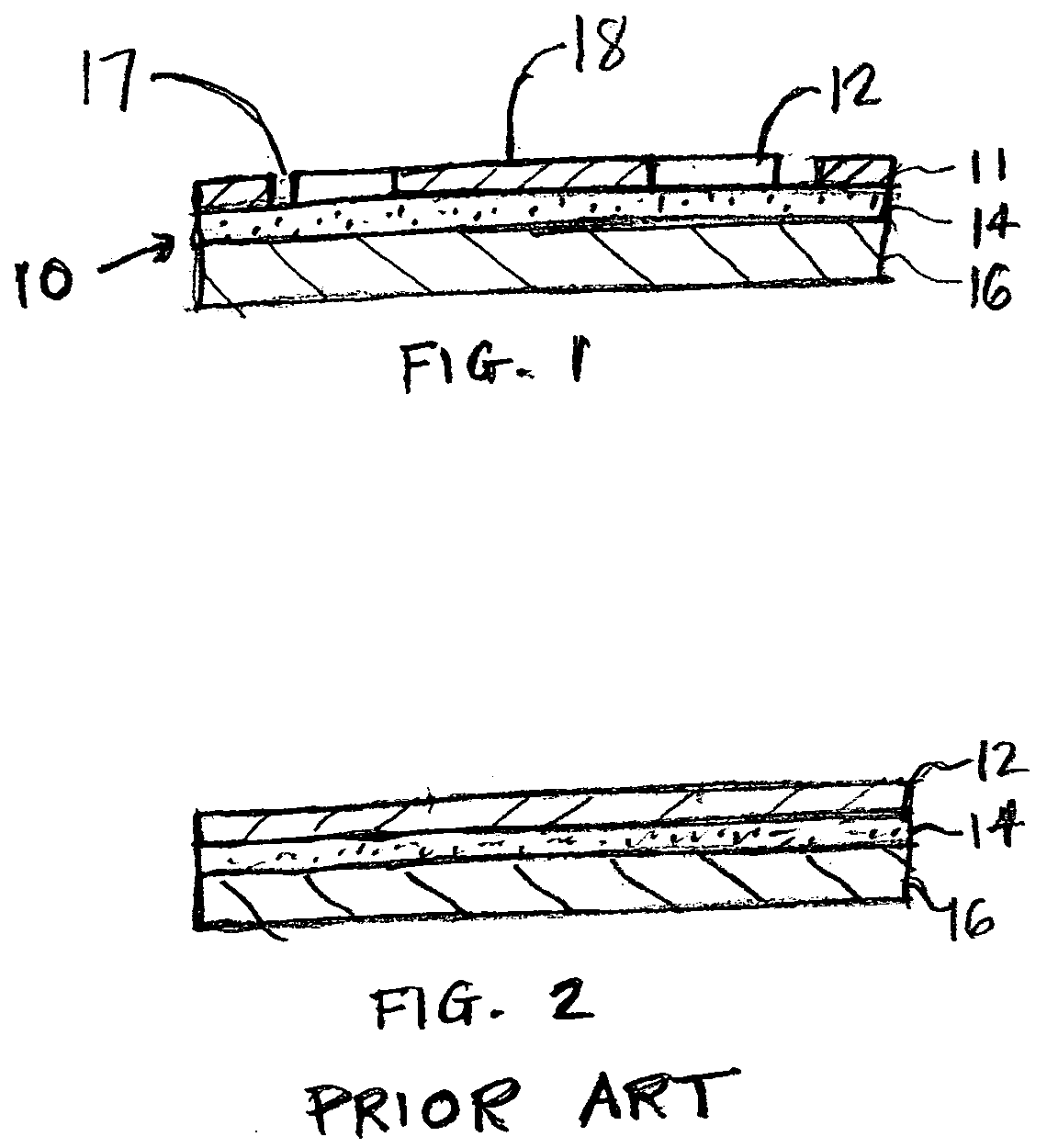

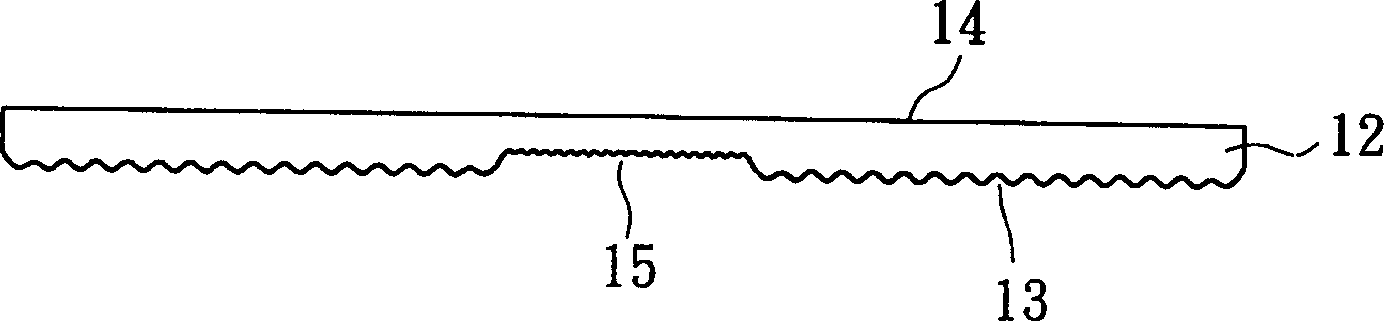

Substrate layer adapted to carry sensors, actuators or electrical components

ActiveUS20110069459A1Improve throughputImprove reliabilityThermometer detailsPrinted circuit assemblingEngineeringActuator

This invention relates to a substrate layer structure adapted to carry electronic device, or components, or electro-mechanical, or electro-chemical sensors, or a combination thereof, and adapted to be attached to a surface of a human or animal body or biological species. The surface of the flexible substrate layer structure is a patterned structure of pre-fixed geometry-formed by one or more slits, but this geometry being selected such that the stretchability of the substrate layer structure becomes adapted to the geometry of the body surface under it.

Owner:KONINK PHILIPS ELECTRONICS NV

Method for conductively connecting a component on a transparent substrate

InactiveUS20120266461A1Avoid cleaningFast solderingPrinted circuit assemblingLight absorption dielectricsEnergy supplyLength wave

The invention relates to a method to conductively connect an electrical component with at least one conductive layer, whereby the conductive layer is applied to a substrate which is essentially transparent in the visible wavelength zone of light, comprising the following steps: the electrical component or the conductive layer is provided with a soldering material in the area where the component is to be connected to the conductive layer; the soldering material is provided with energy supplied by an energy source, such that the soldering material melts and a non-detachable, material-bonded conductive connection between the electrical component and the conductive layer is established.

Owner:SCHOTT AG

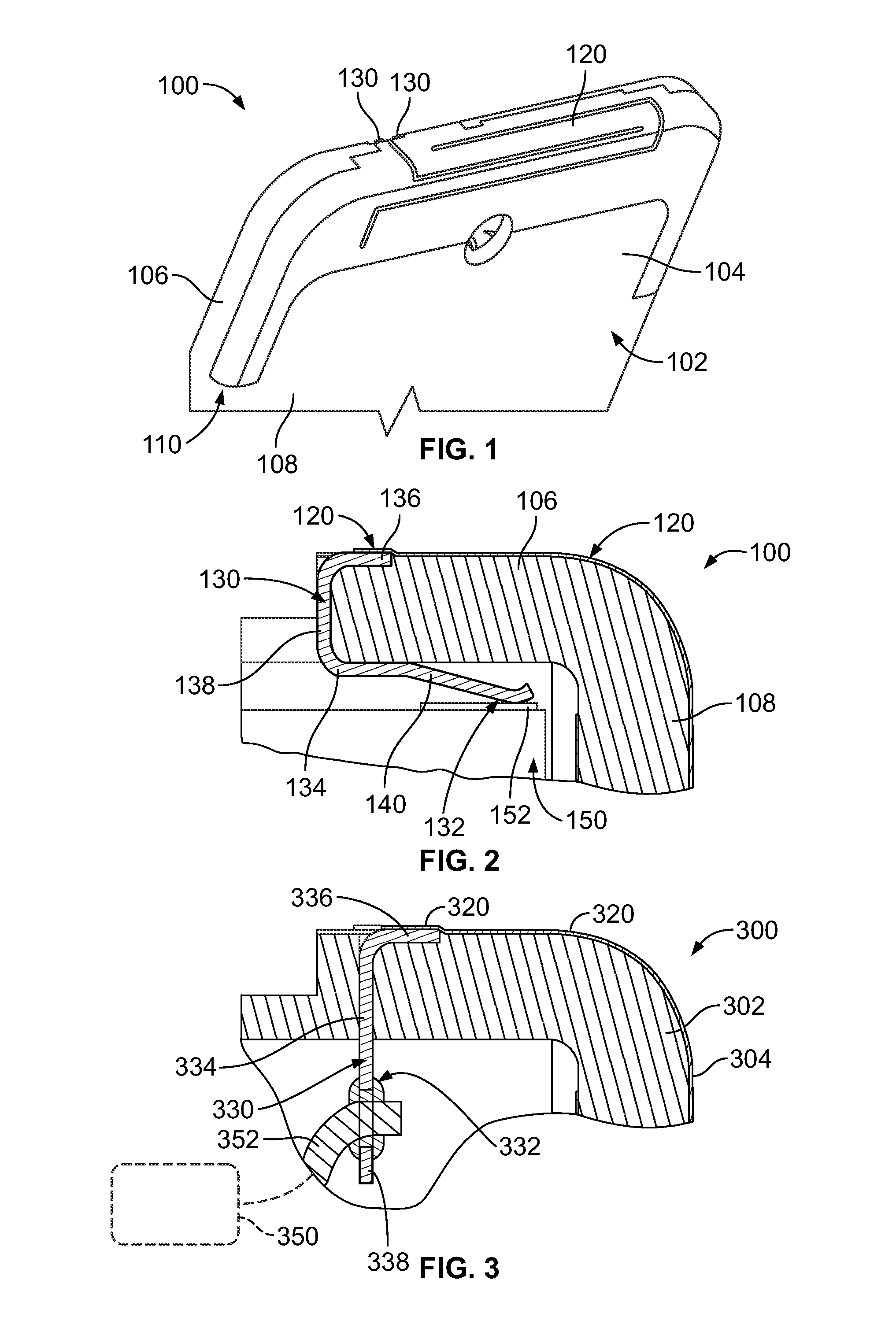

Solder flow stops for semiconductor die substrates

InactiveUS20050253258A1Prevent rotationAvoid flowPrinted circuit assemblingSemiconductor/solid-state device detailsNon wettingMetallurgy

Owner:INTERNATIONAL RECTIFIER COEP

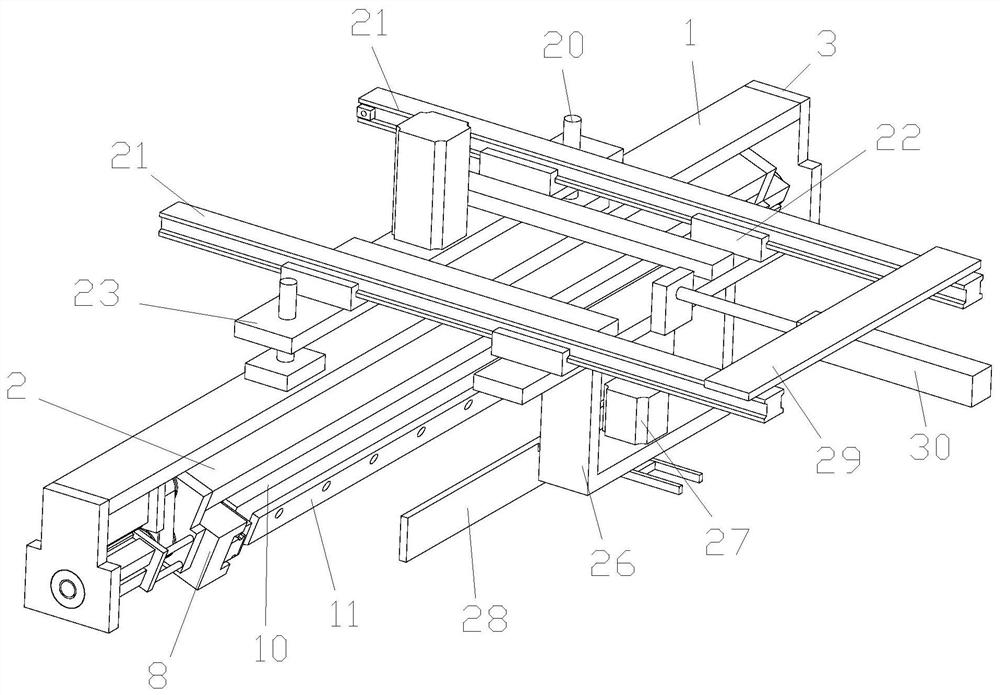

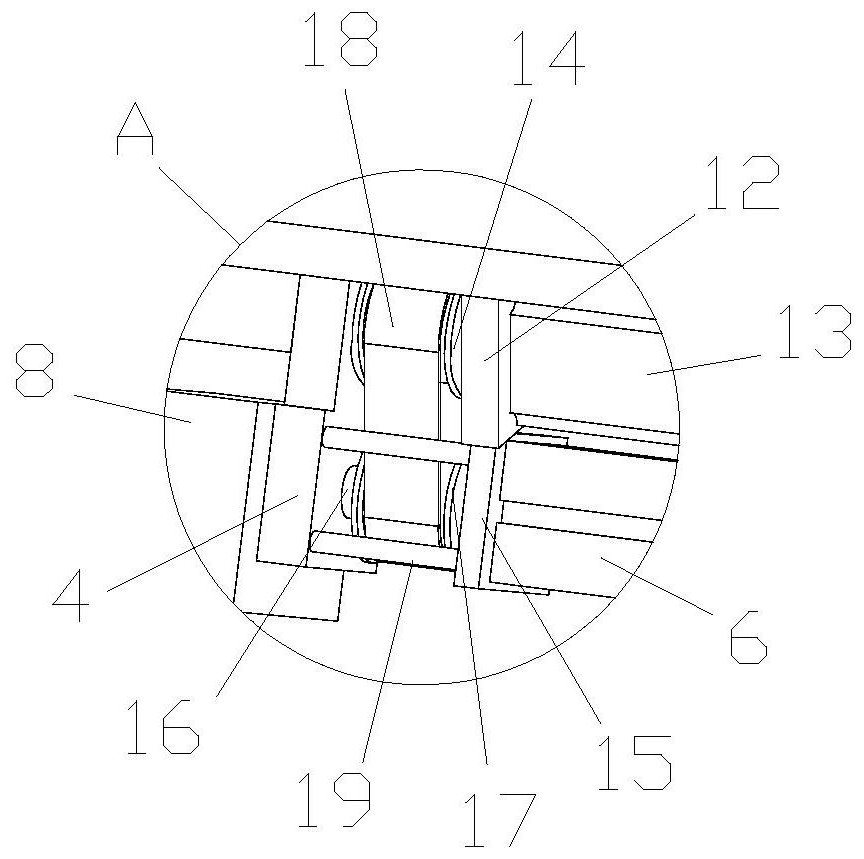

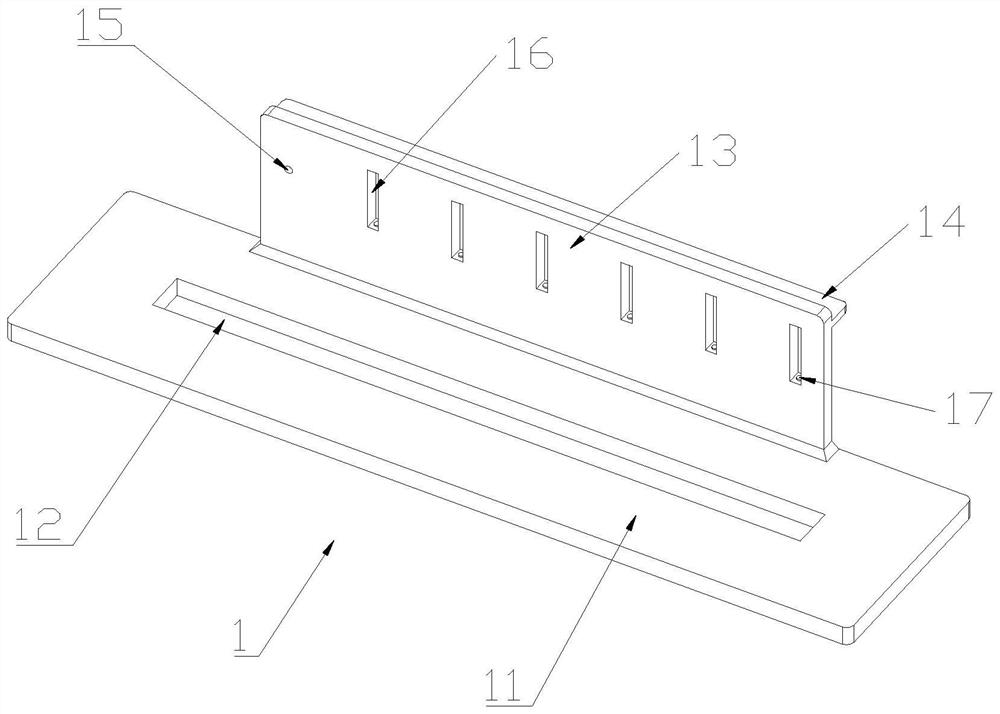

Supporting and adsorbing jig for PCB

InactiveCN103406848AMove doesn't happenImprove versatilityPrinted circuit assemblingWork holdersEngineeringMachining process

Owner:KUSN MAIZHI FIXTURE TECH

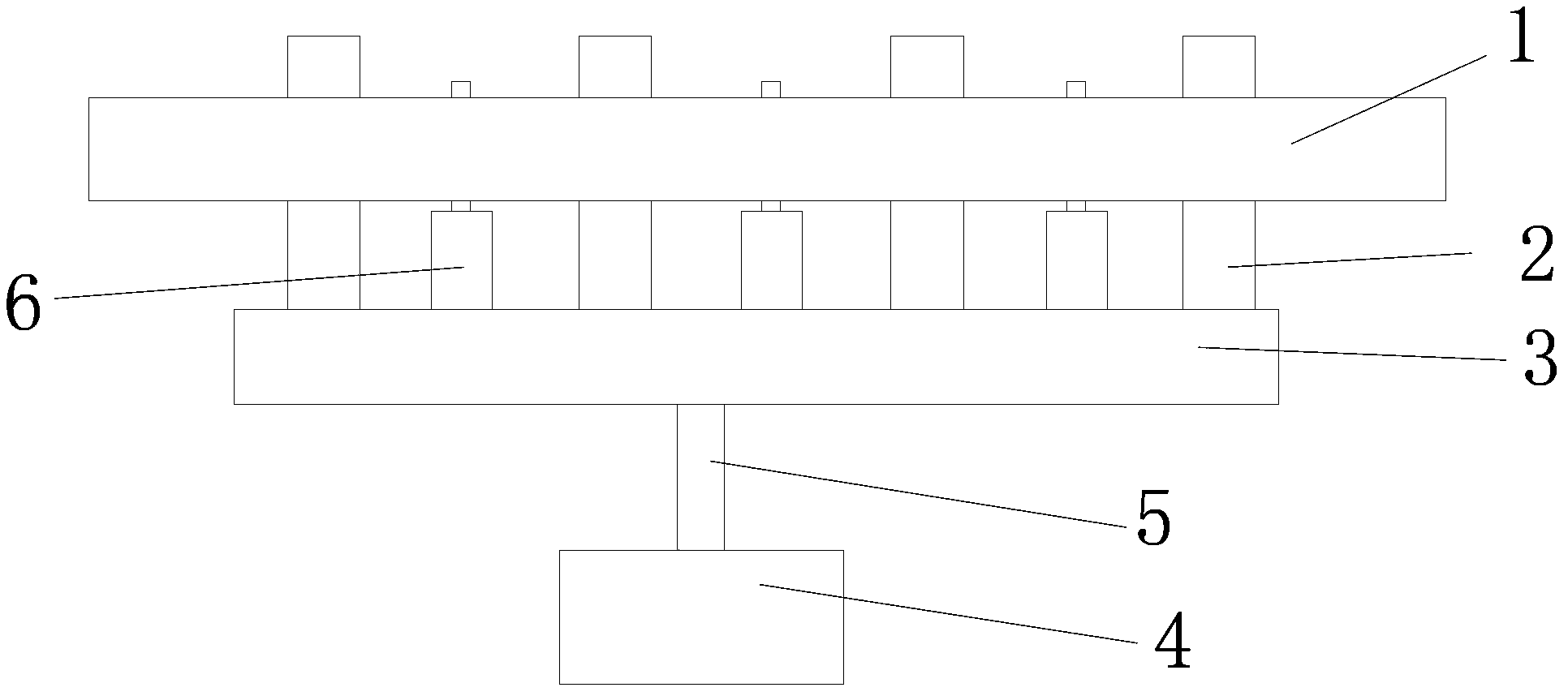

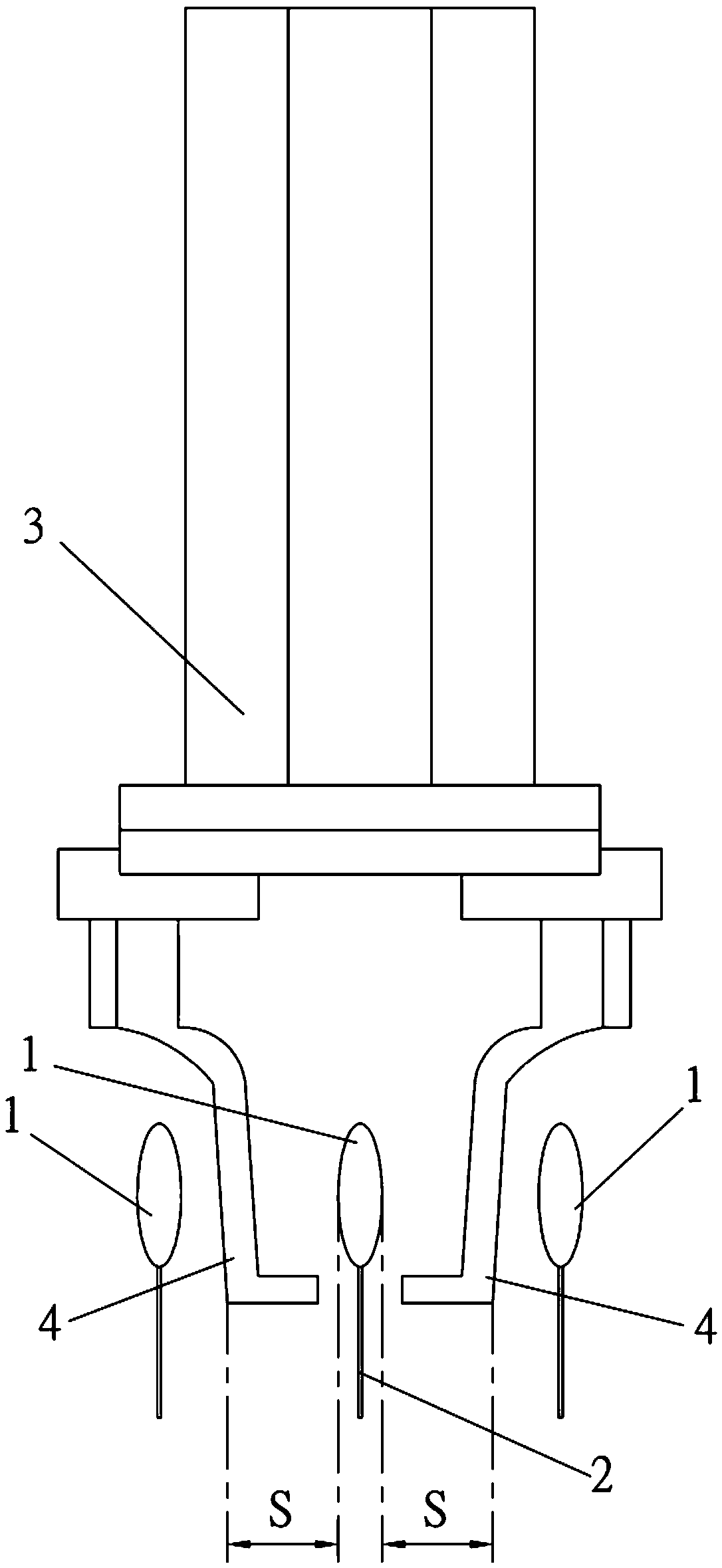

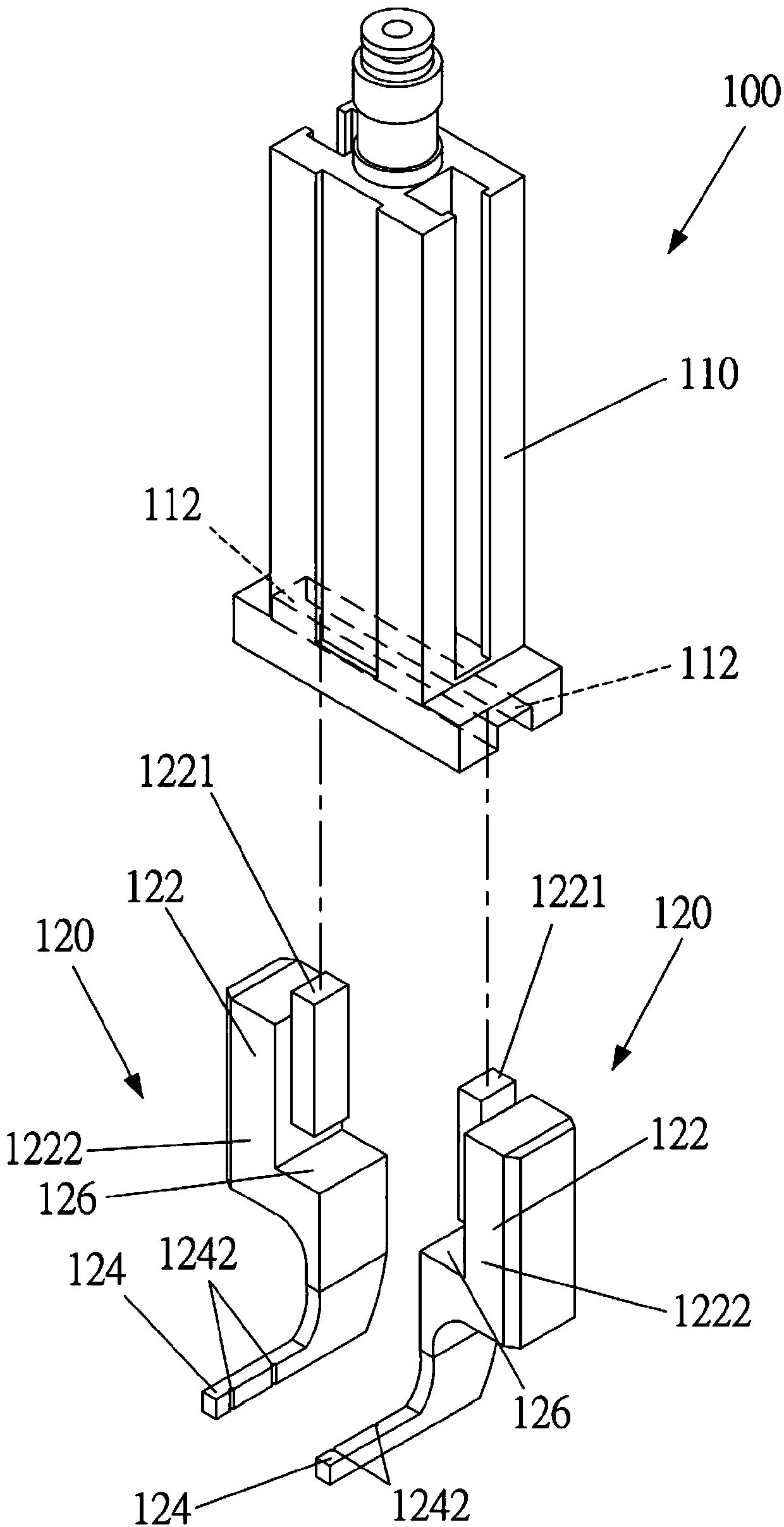

Clamping device for plug-in unit

ActiveCN110831425AIncrease profitShorten the separation distancePrinted circuit assemblingElectrical componentsPhysicsElectronic component

The invention provides a clamping device for a plug-in unit. The device comprises a driving assembly and two clamping jaws, wherein the two clamping jaws are connected with the driving assembly, the driving assembly drives at least one of the two clamping jaws to move in the horizontal driving direction to get close to each other, the two clamping jaws are respectively provided with a vertical part and a clamping part, the vertical part is provided with a first end and a second end, the first end is connected with the driving assembly, and the clamping part is connected with the second end, the clamping parts of the two clamping jaws are arranged in parallel and are perpendicular to the horizontal driving direction. The clamping device for the plug-in unit is advantaged in that the operation space reserved for the clamping jaws by the front side face and the rear side face of a body of an electronic element can be effectively reduced.

Owner:CHICONY POWER TECH CO LTD

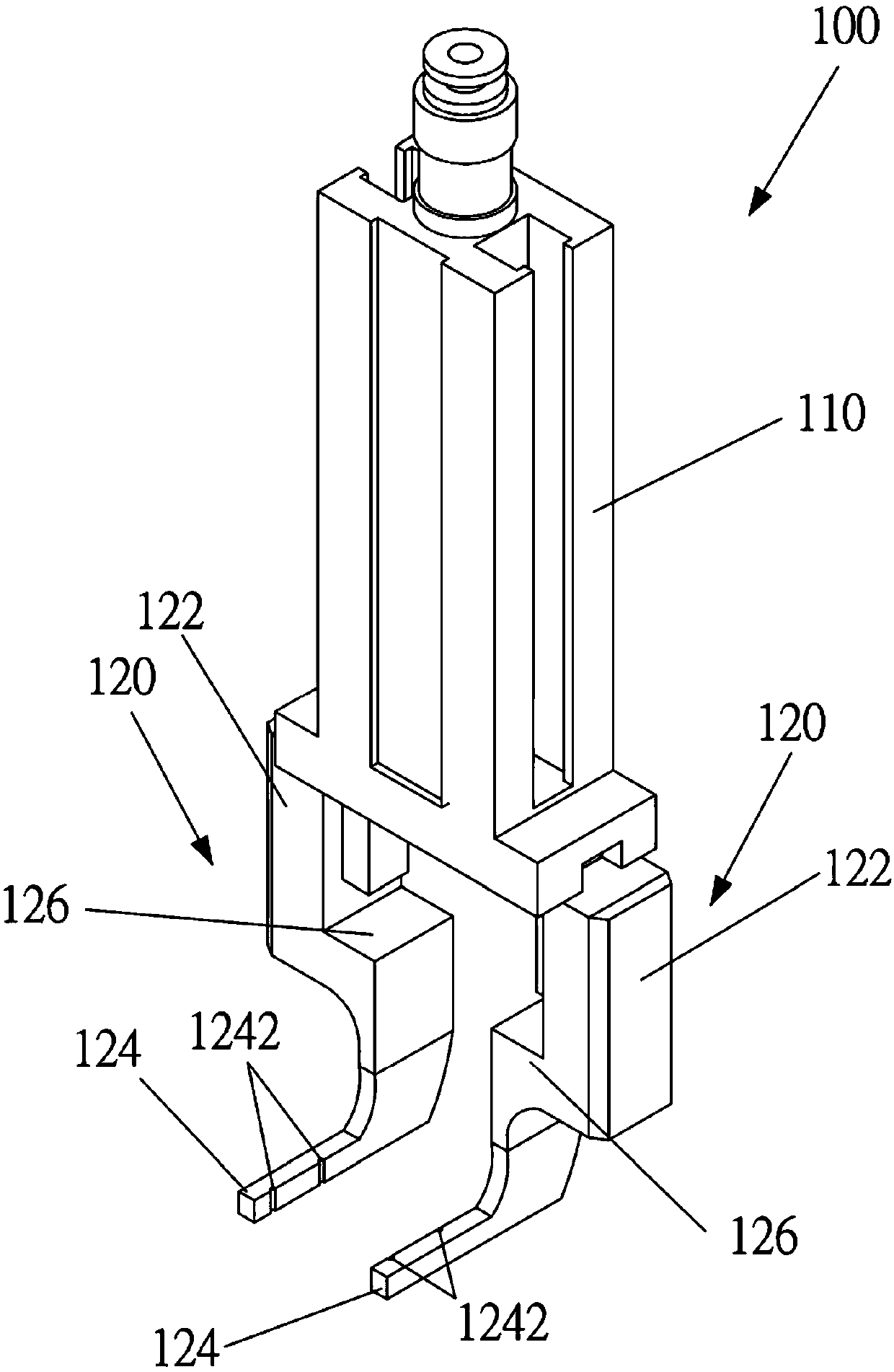

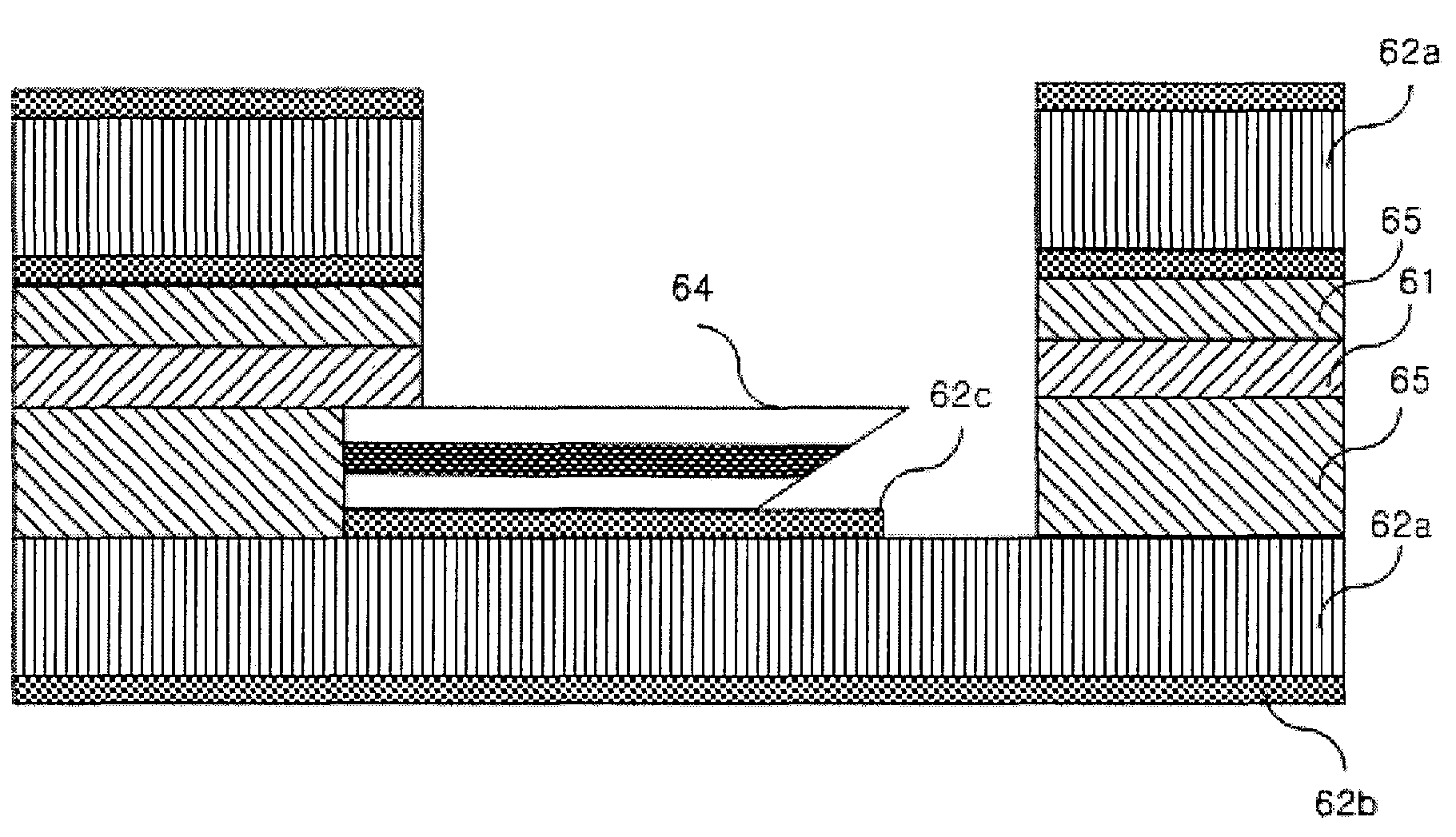

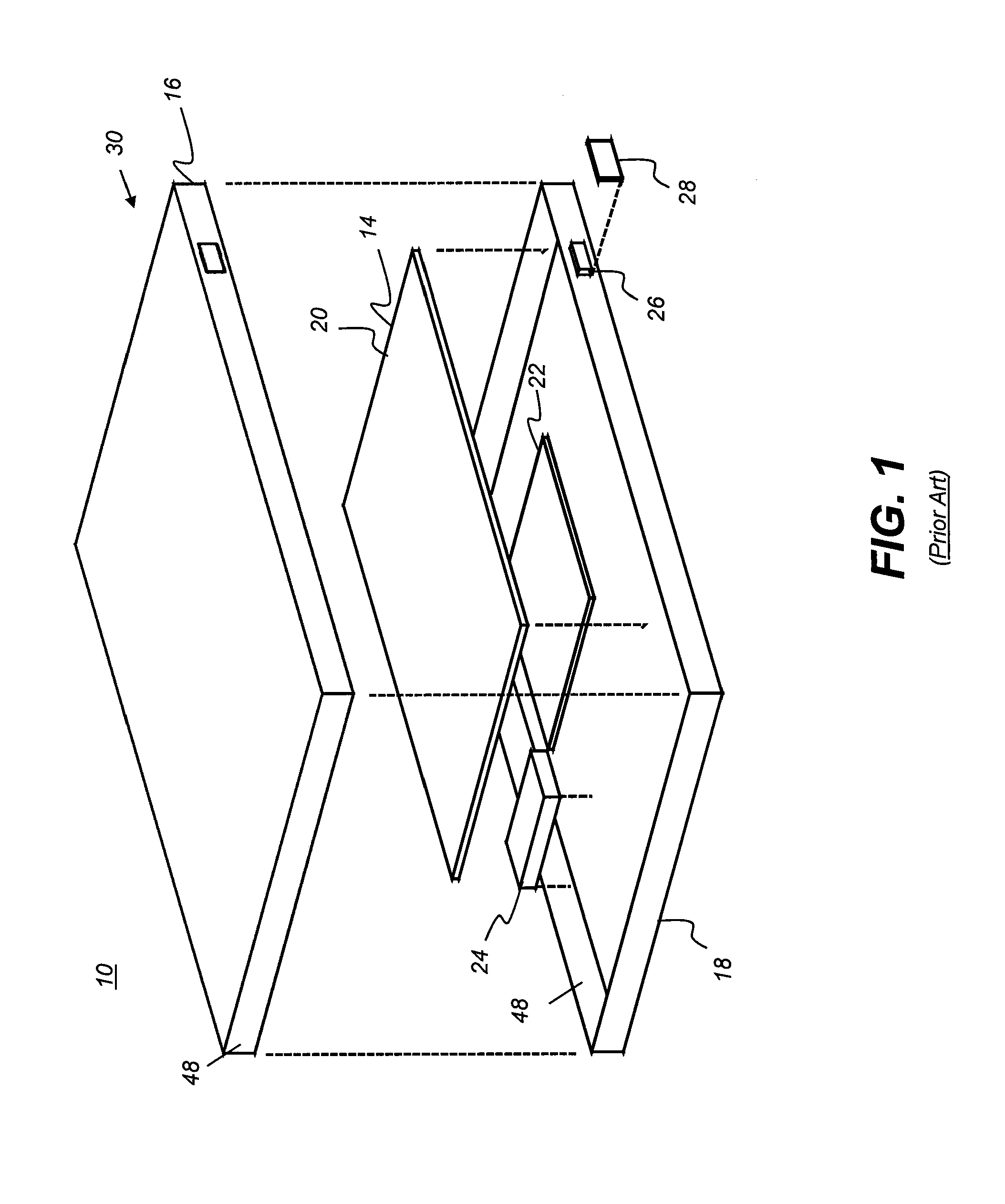

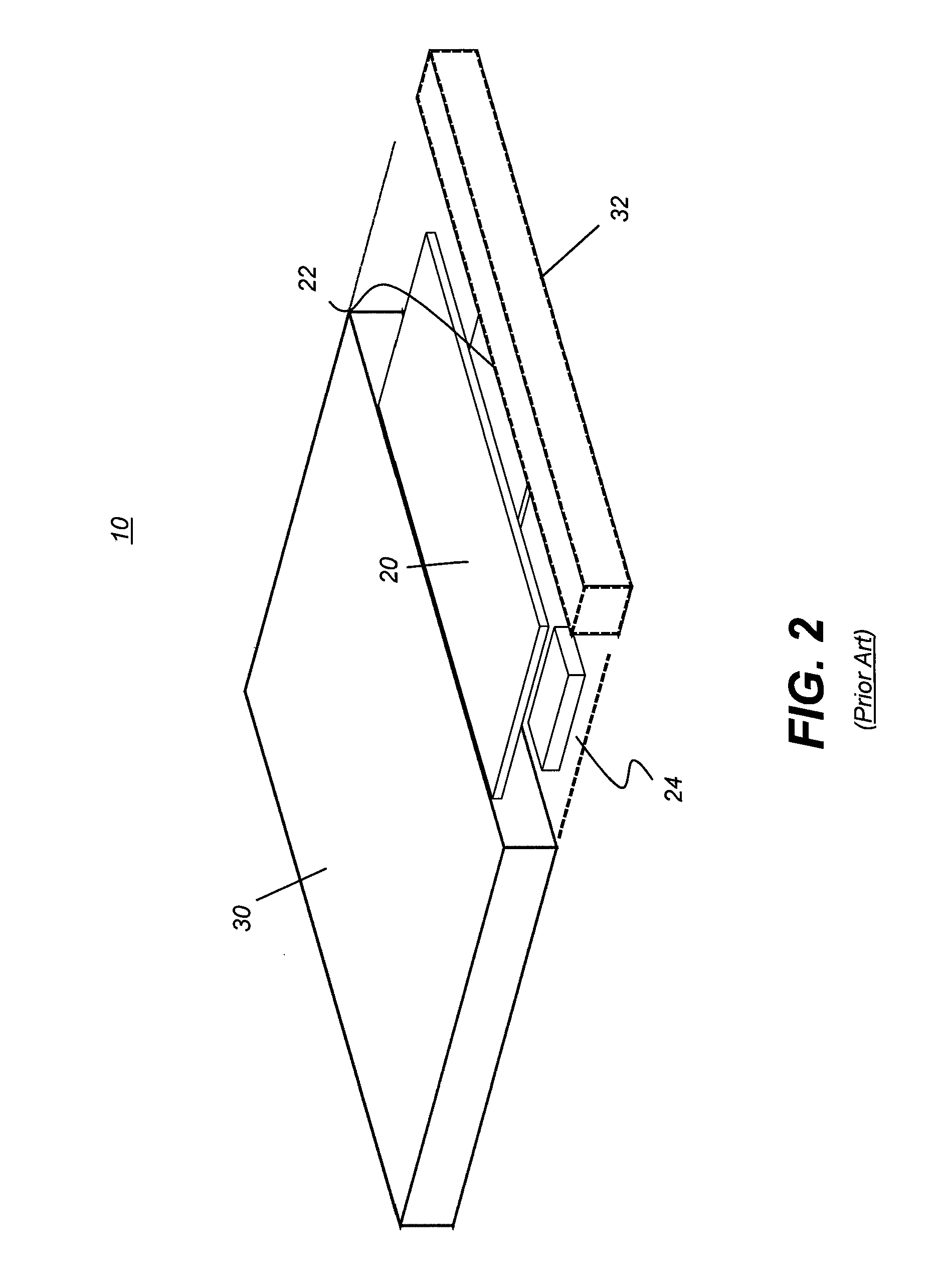

Method of fabricating multi-layered printed circuit board for optical waveguides

InactiveUS7046870B2Facilitating precise interfacing of optical signalPrinted circuit assemblingLine/current collector detailsAdhesiveCopper foil

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

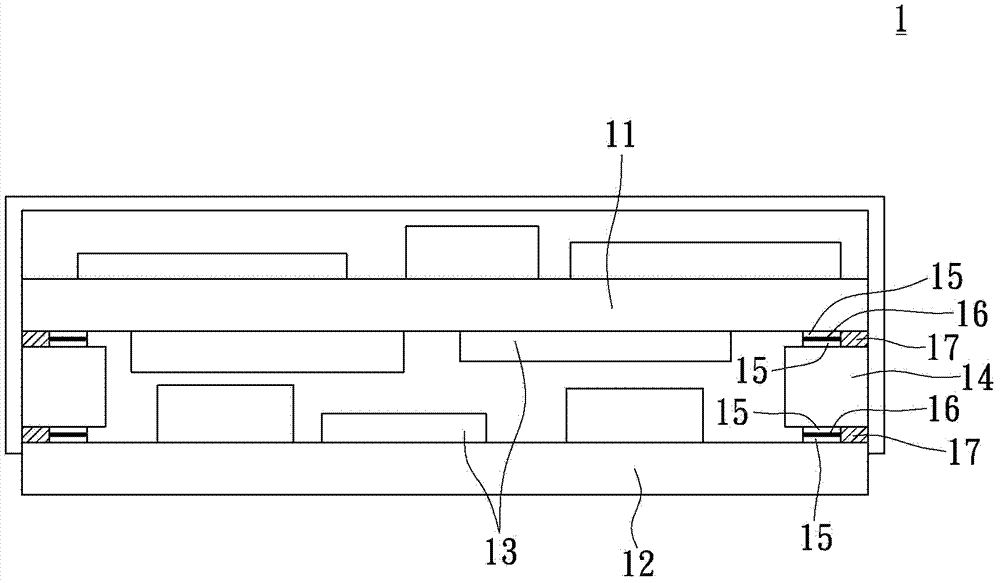

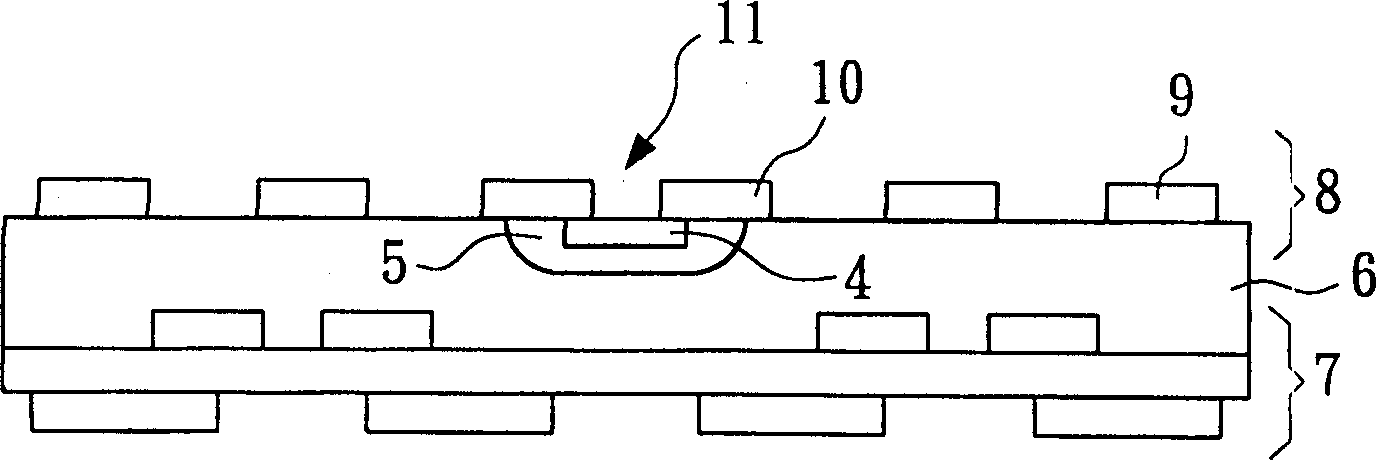

Stack type baseplate structure

ActiveCN103249273APrinted circuit assemblingMagnetic/electric field screeningEngineeringElectrical conductor

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD +1

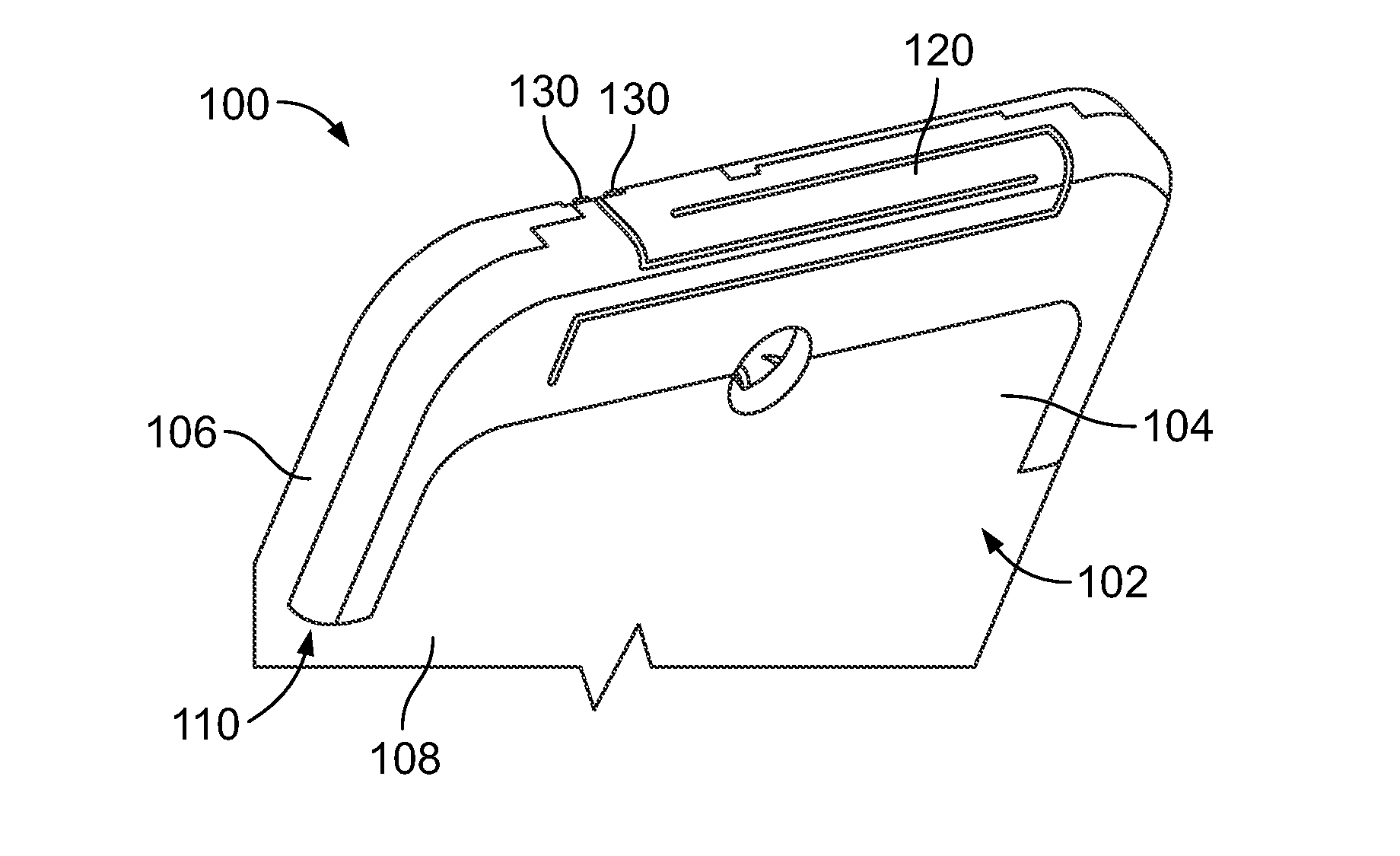

Impact protection for wireless digital detector glass panel

InactiveUS20160169714A1Improved crash protectionImpact resistancePrinted circuit assemblingCathode ray tubes/electron beam tubesEngineeringIonizing radiation

Owner:CARESTREAM HEALTH INC

Cooling-assisted, heat-generating electrical component and method of manufacturing same

InactiveUS20050284607A1Long useful lifeCost-effective to buildPrinted circuit assemblingFinal product manufactureElectricityEngineering

A cooling-assisted, heat-generating electrical component reduces heat generated during operation. The electrical component, typically a resistor, has a least one heat-removing element electrically associated therewith. Heat-removing element comprises a plurality of thermal vias therein and is fixedly attached to an end portion of the electrical component, typically on opposed end portions. Heat absorbed by the heat-removing element can be transported away from the electrical component during service.

Owner:EASTMAN KODAK CO

Method for making multi-layer circuit board with internal inserted passive component

InactiveCN1429065AEasy to manufactureImprove reliabilityPrinted circuit assemblingPrinted electric component incorporationCapacitanceEngineering

Owner:PHOENIX PRECISION TECH CORP

Reflow soldering auxiliary tool and reflow soldering method for flexible circuit board

Owner:SHANGHAI FPC ELECTRONICS

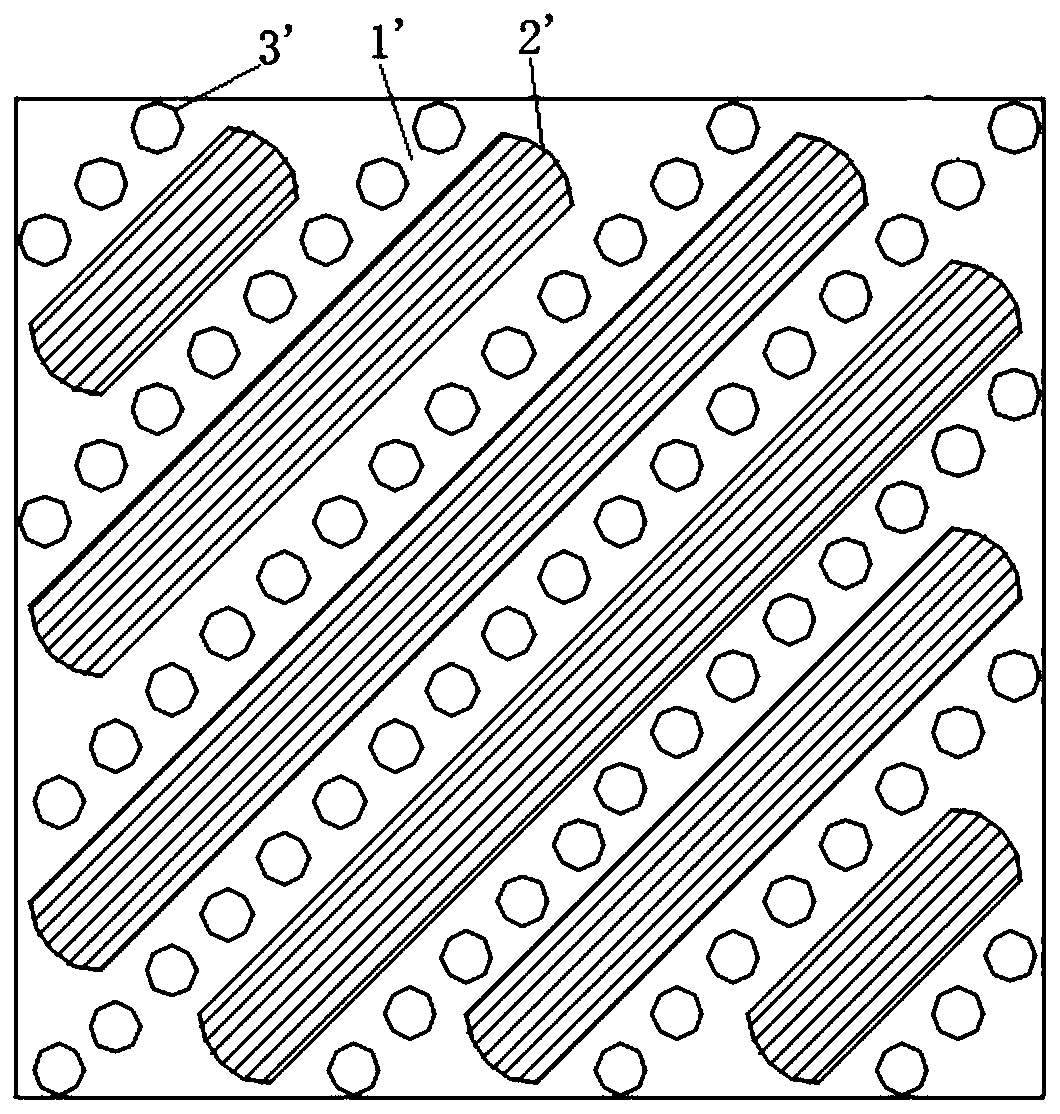

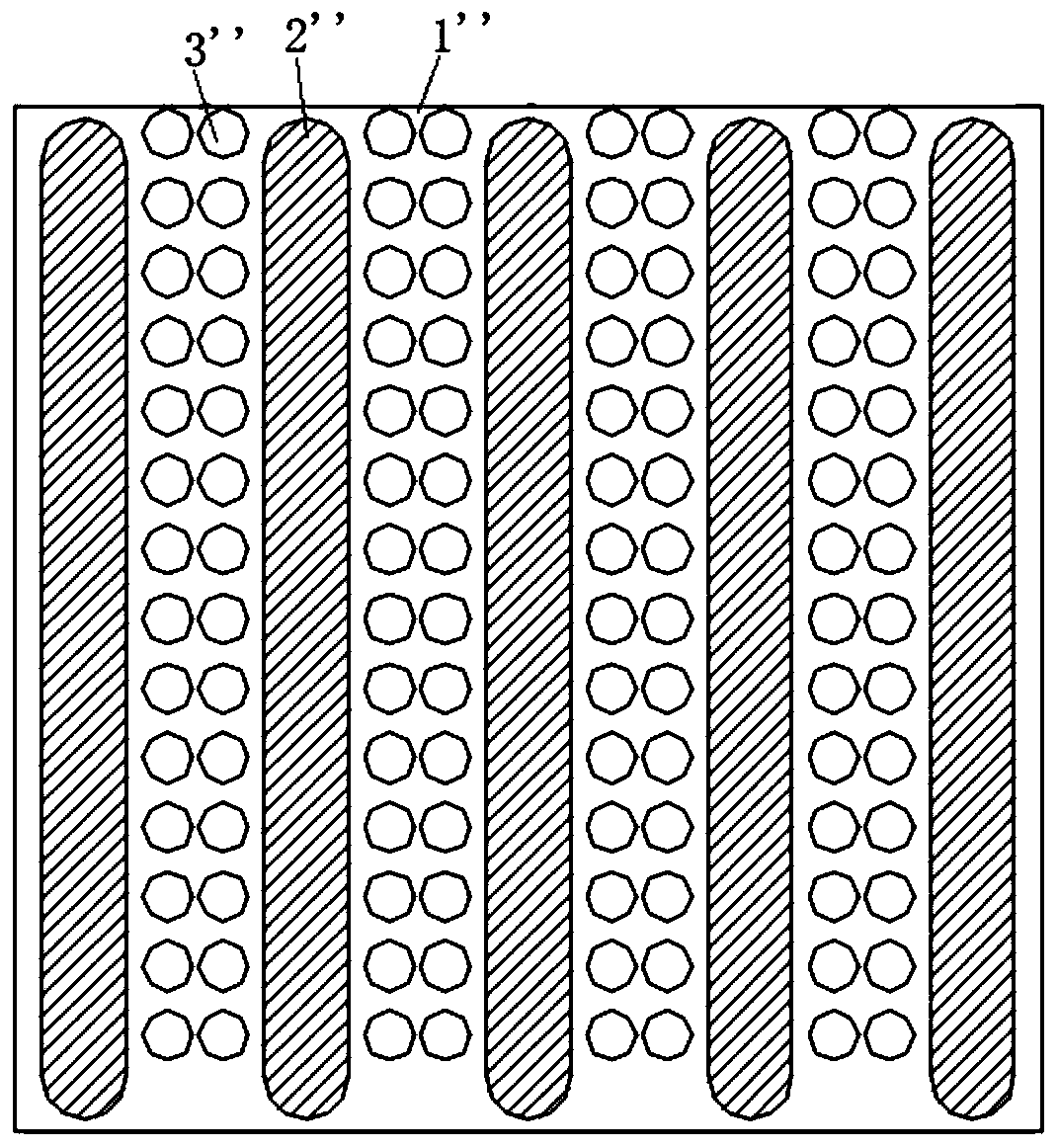

Surface mounting technology print stencil net frame

ActiveCN101301808AImprove flexural strengthQuality improvementPrinted circuit assemblingScreen printersYarnSurface mounting

The invention discloses a printing template screen frame of a surface sticking technology; the middle width of the section of the proximate matter of the screen frame is larger than the width of the lower side; as the middle width of the section of the proximate matter of the screen frame is designed to be larger than the width of the lower side, the invention can improve the anti-bending intensity of the screen frame under the situation of being capable of preserving net yarn with a certain width needed by the tension of a steel sheet, thereby improving the quality of the printing solder paste. The invention also relates to a method for manufacturing the section of the proximate matter of the screen frame.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

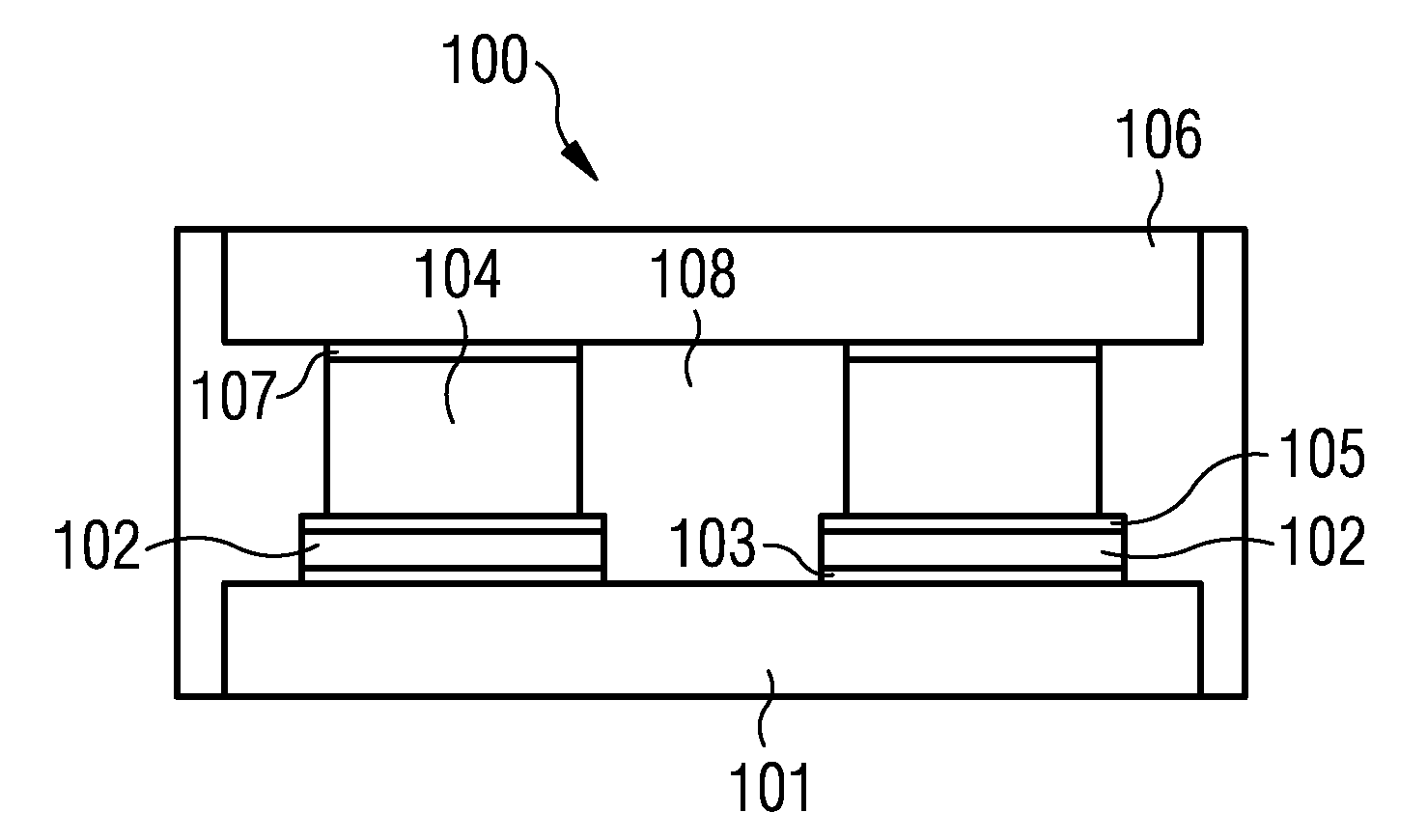

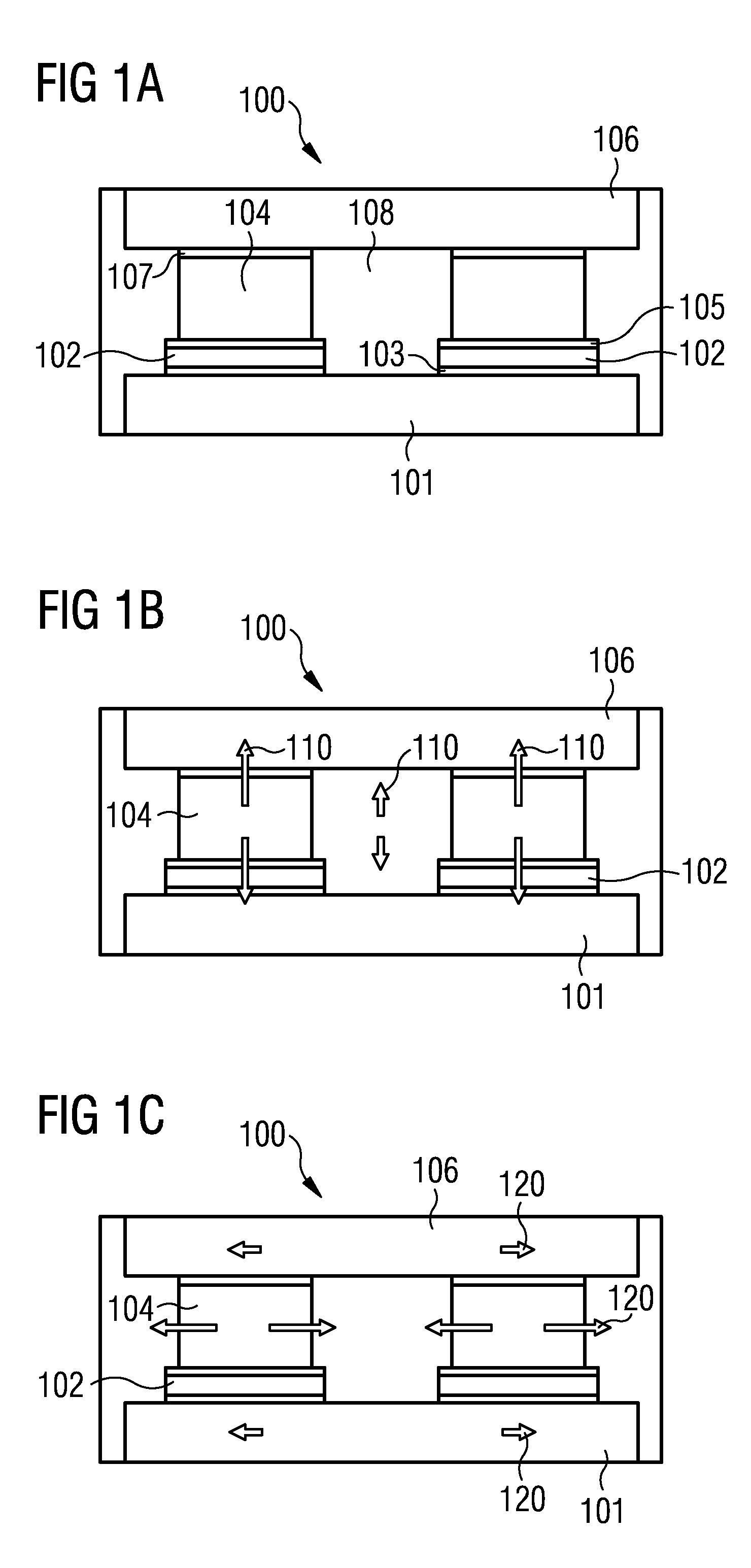

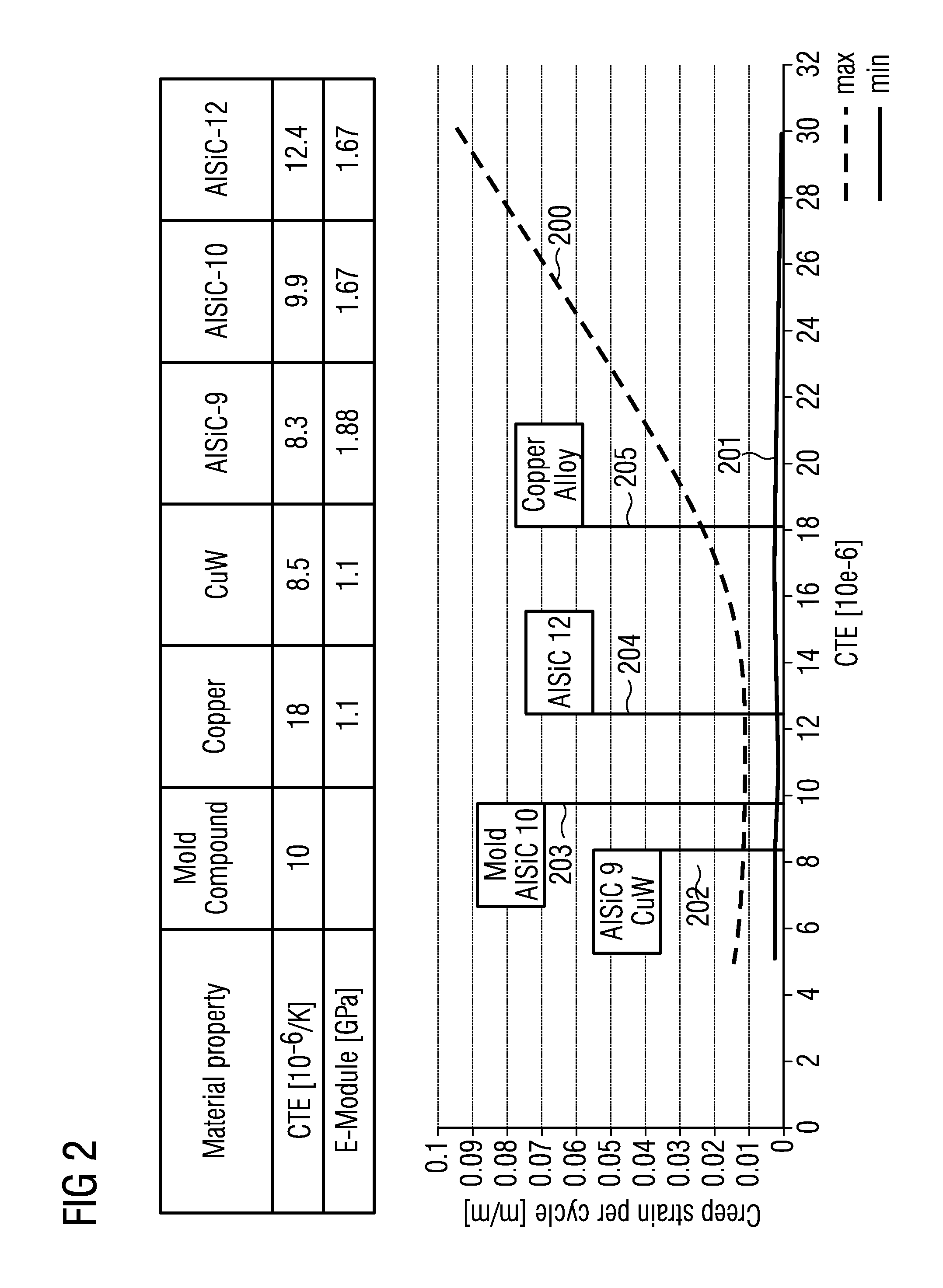

Electronic module and method of manufacturing the same

ActiveUS20150264796A1Easy to operateLow failure ratePrinted circuit assemblingSemiconductor/solid-state device detailsComputer moduleElectronic component

Owner:INFINEON TECH AG

Method for determining tin-soldering paste amount of glue dispenser on pads

ActiveCN102006731BReduce welding defectsGood welding reliabilityPrinted circuit assemblingCapacitanceElectrical resistance and conductance

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

Digital television receiver

Owner:NOVABASE DIGITAL TV TECH

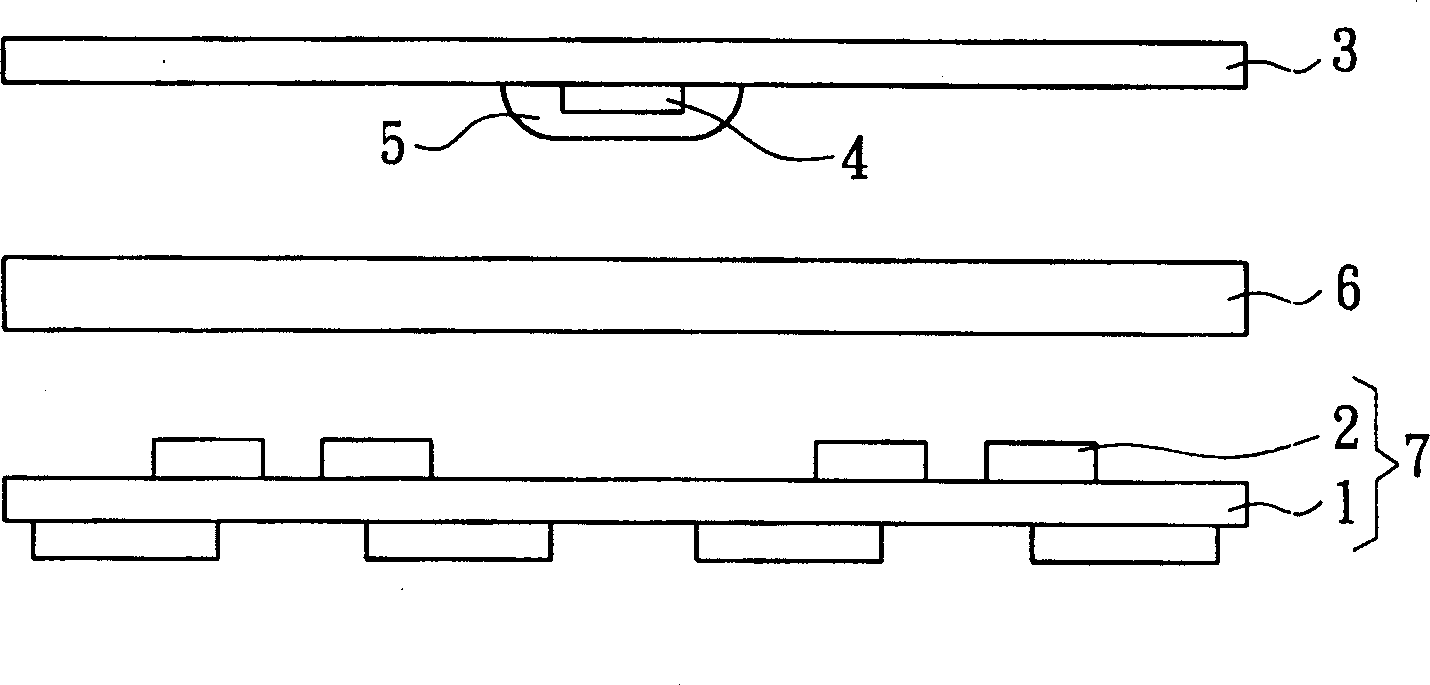

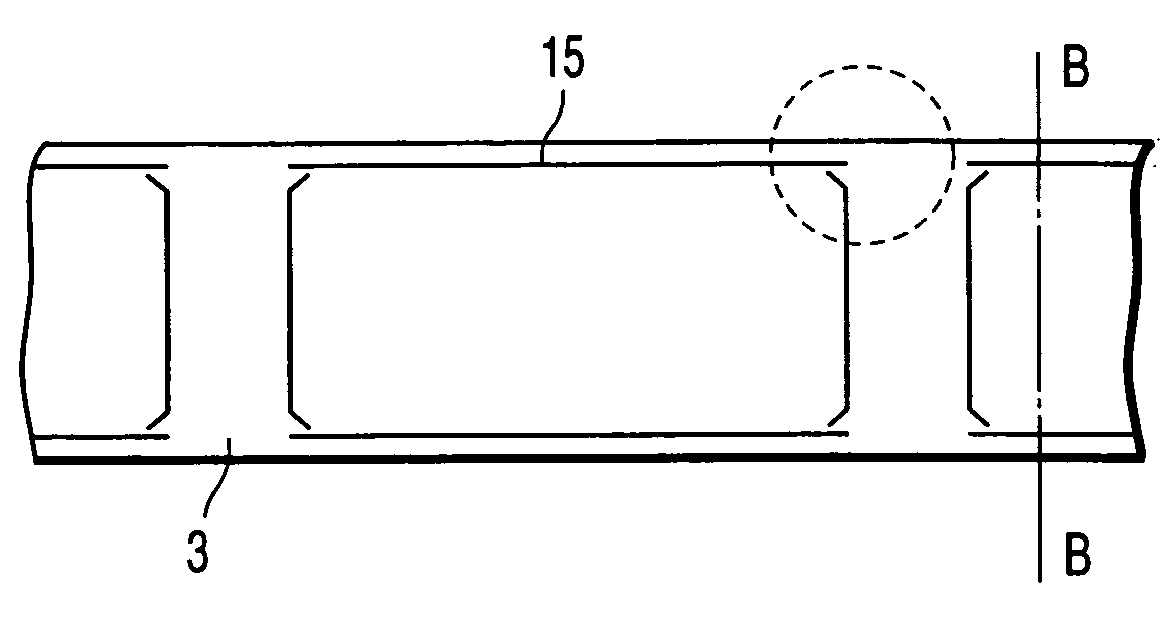

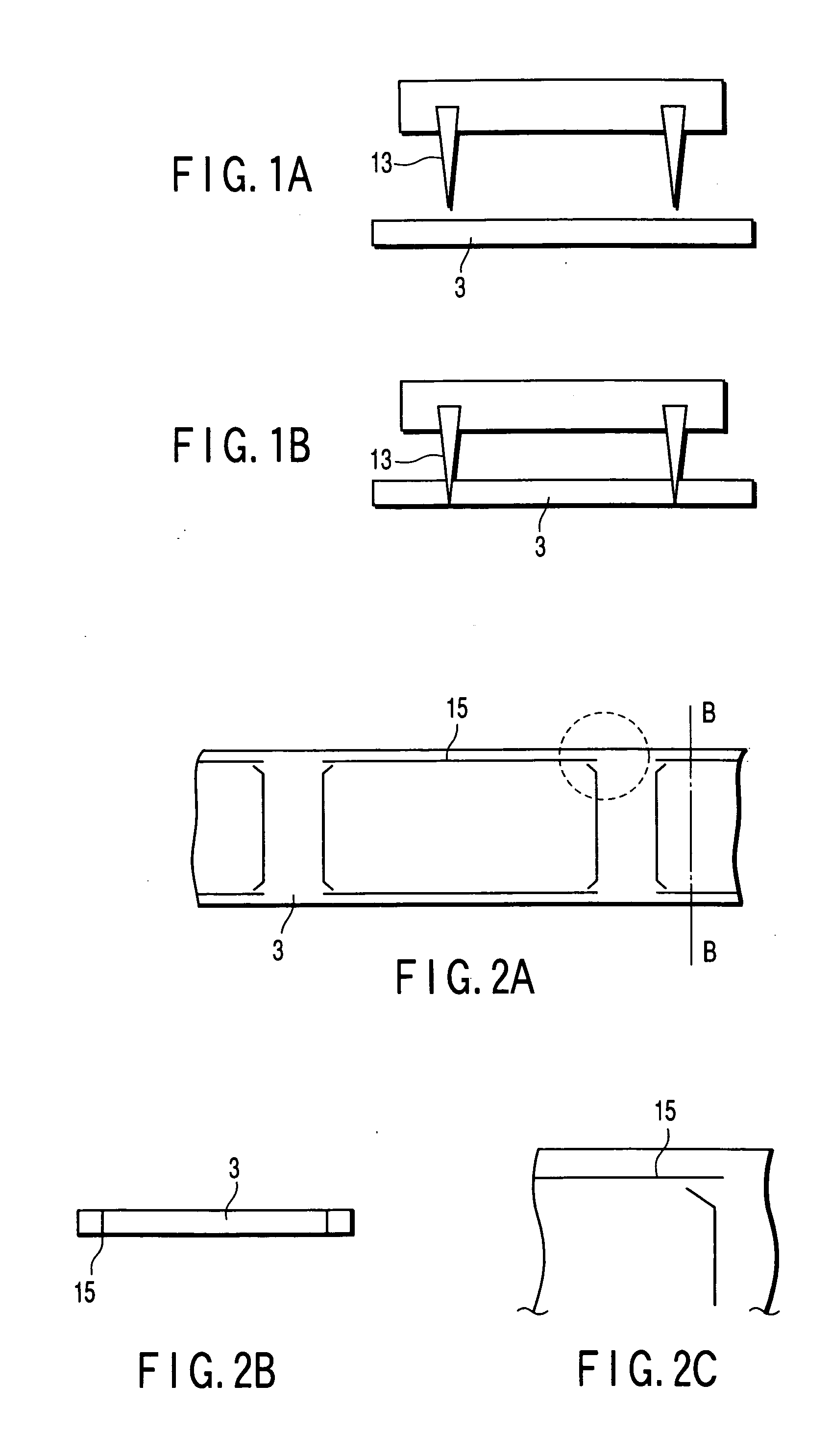

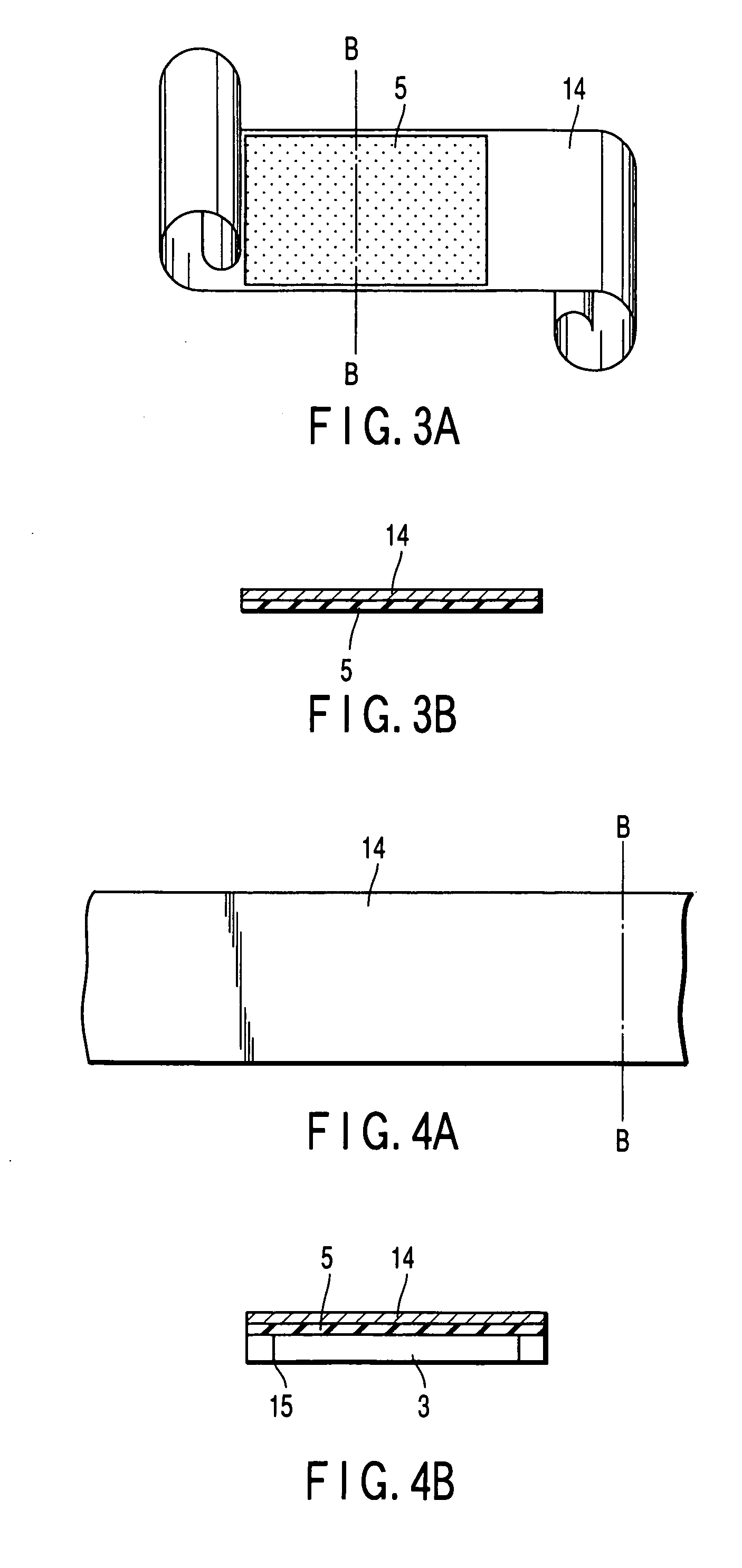

Film substrate, semiconductor device, method of manufacturing film substrate, method of manufacturing semiconductor device and method of manufacturing circuit board with semiconductor device

InactiveUS20050029635A1Printed circuit assemblingSemiconductor/solid-state device detailsDevice materialEngineering

Owner:KK TOSHIBA

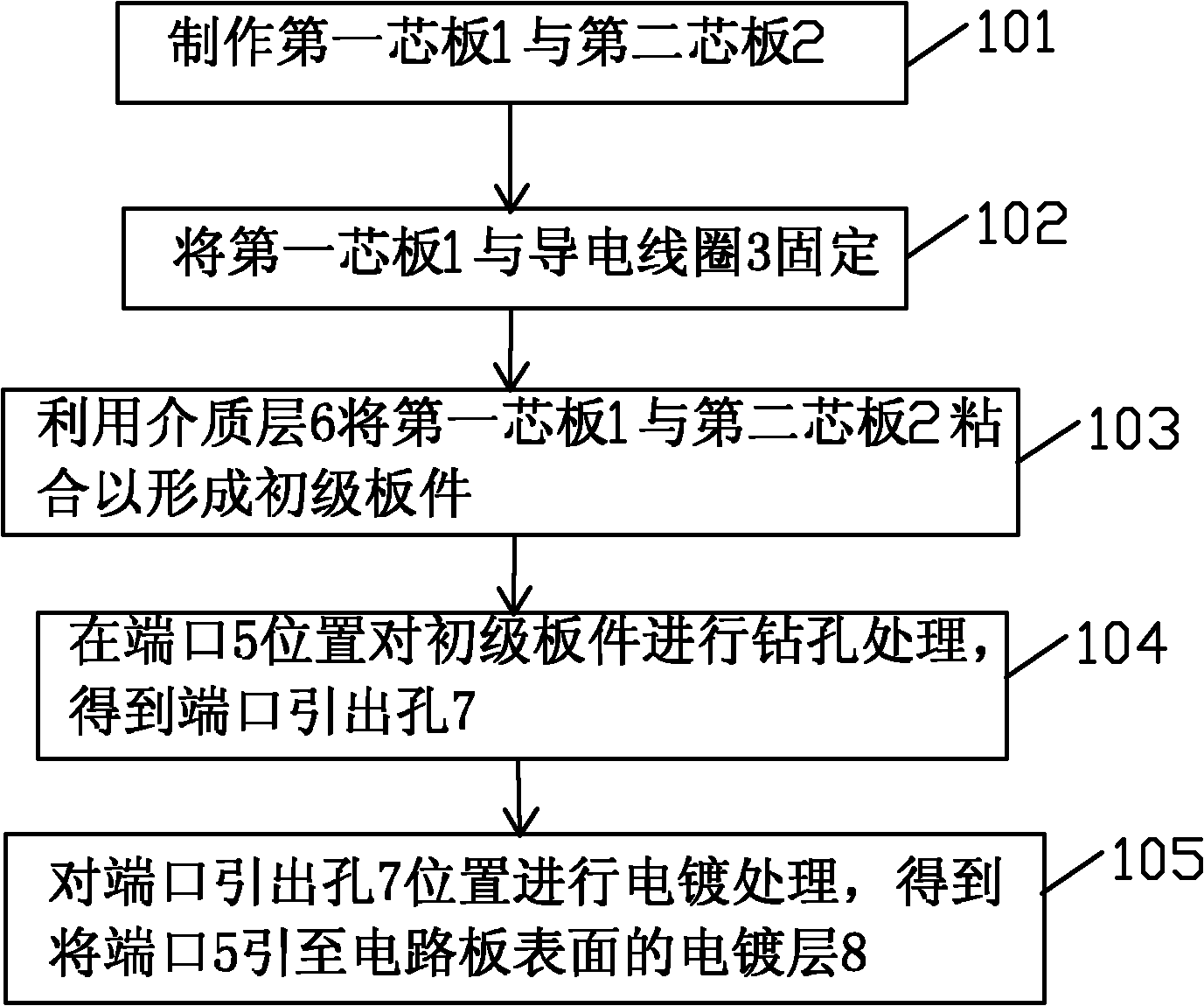

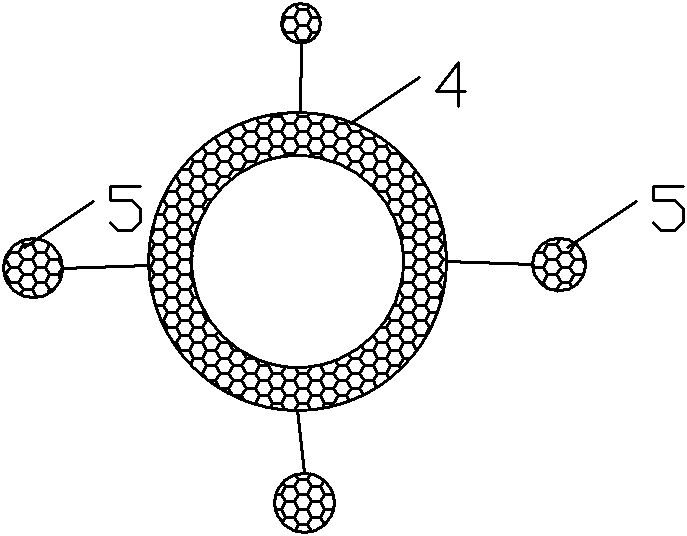

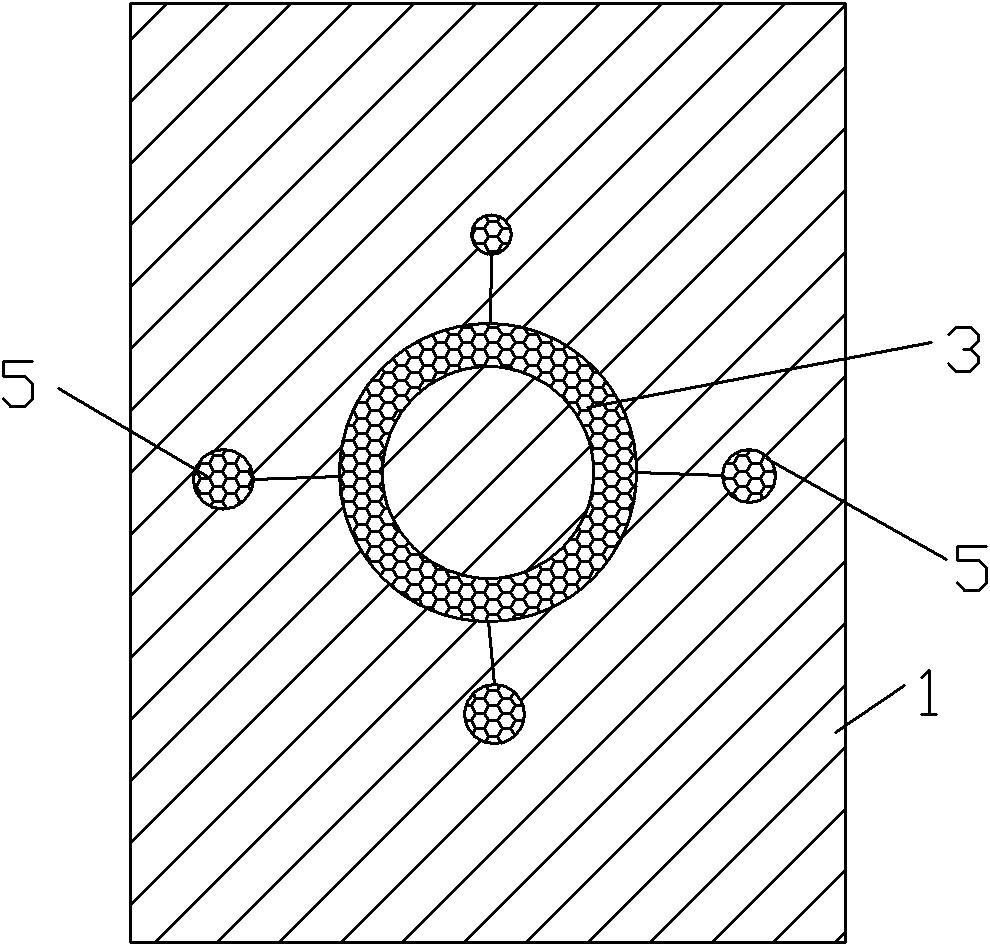

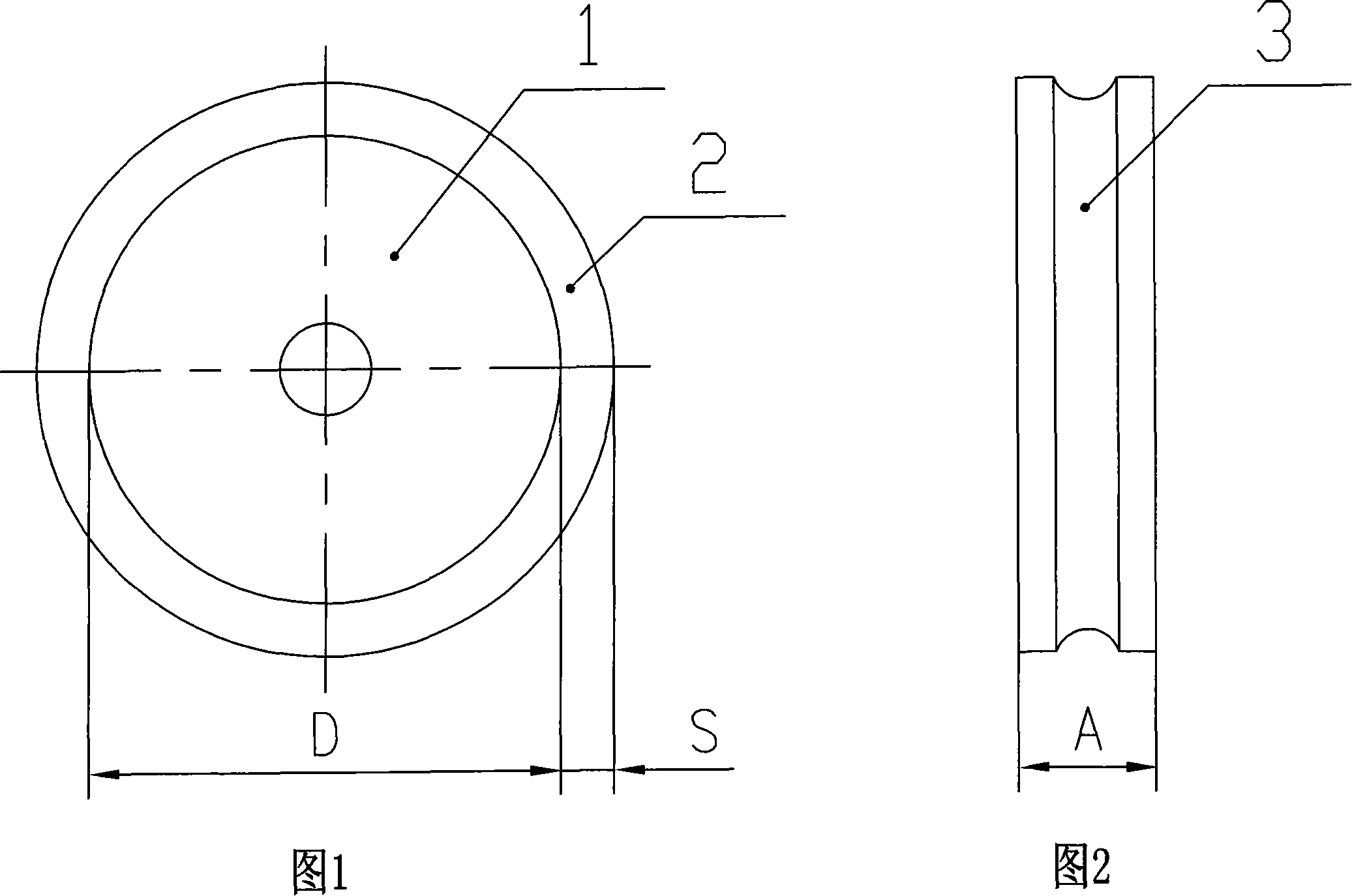

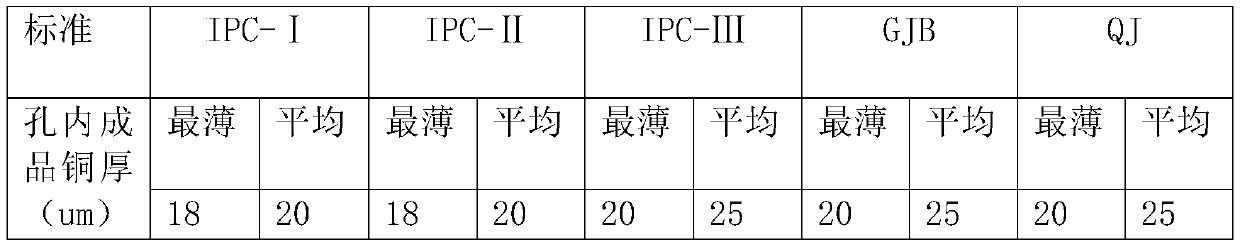

Circuit board and processing method thereof

ActiveCN102186311AGuaranteed electromagnetic performancePrinted circuit assemblingPrinted circuit non-printed electric components associationPower flowEngineering

Owner:SHENNAN CIRCUITS

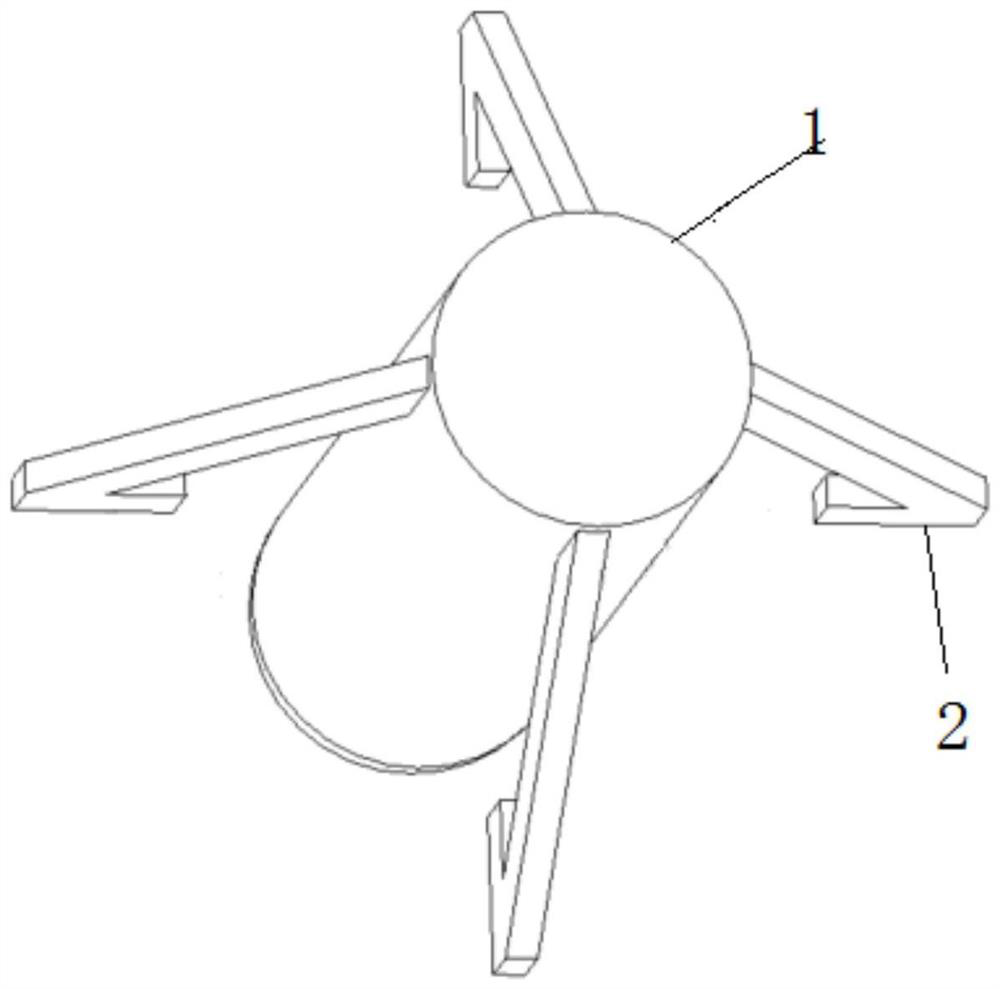

Wave generator belt wheel

Owner:苏州明杰自动化科技有限公司

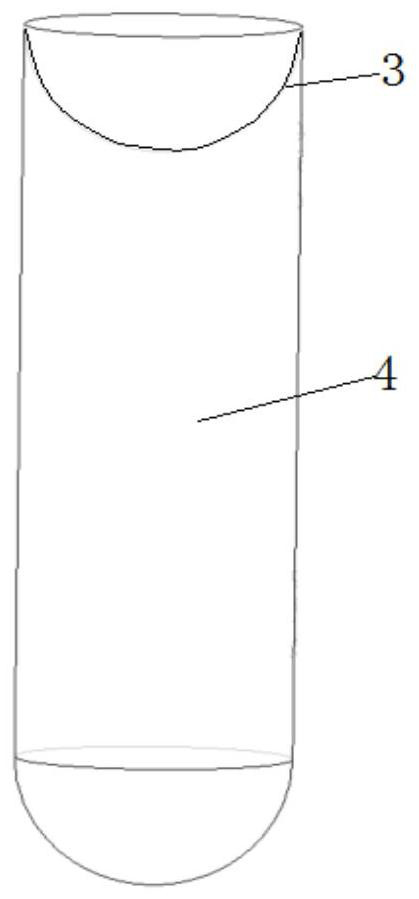

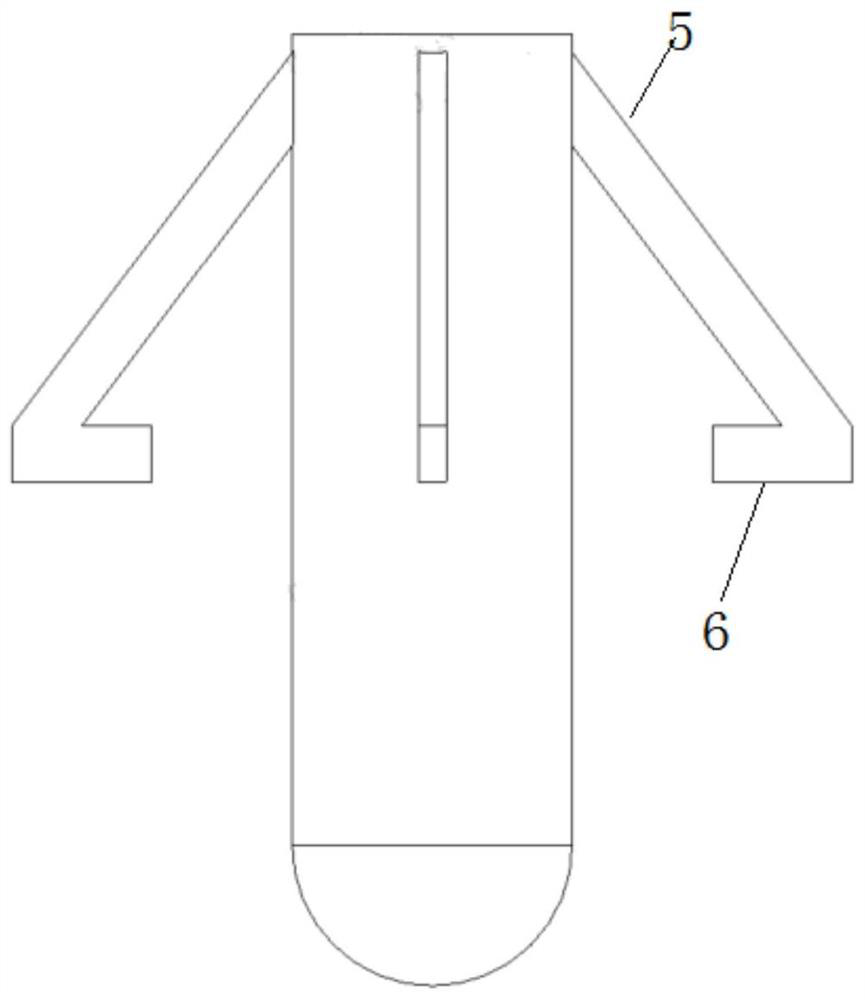

LED lamp bead tinning mechanism

ActiveCN112911828AAchieve grippingReduce inconsistencyPrinted circuit assemblingGlass productionTransmission beltElectric machinery

Owner:绍兴微创电子科技有限公司

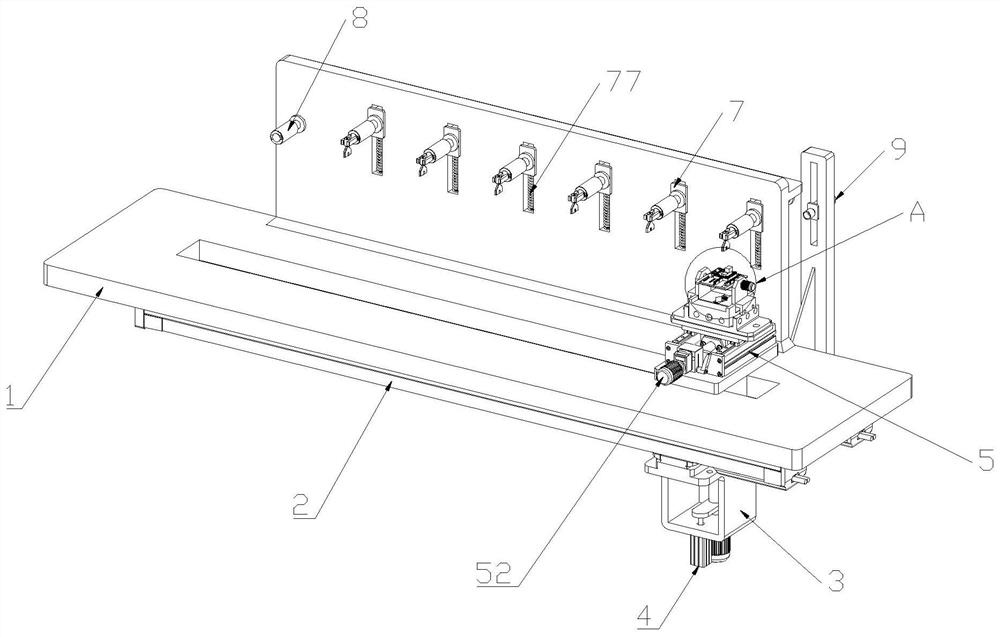

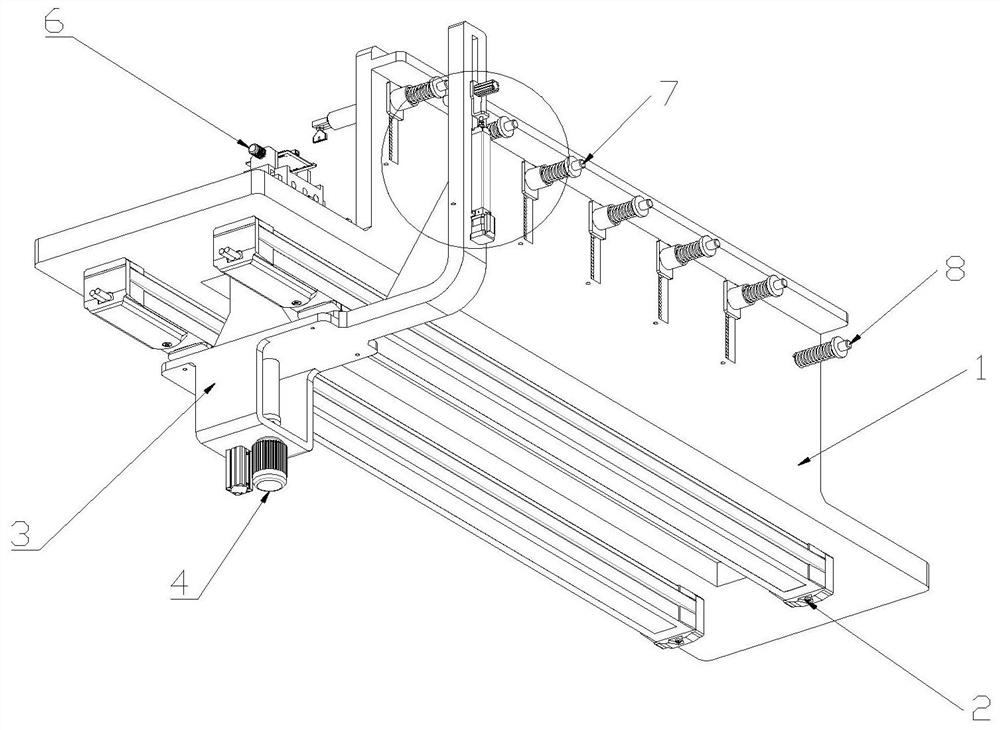

Automatic control processing device for electronic element

ActiveCN113973490ASatisfy plug-in operationRealize multi-directional adjustmentPrinted circuit assemblingMeasurement instrument housingAutomatic controlEngineering

The invention discloses an automatic control processing device for an electronic element. The automatic control processing device comprises a base, a first sliding groove is formed in the base, linear electric cylinders are arranged on the two sides of the first sliding groove and located below the base, a first support is arranged between the linear electric cylinders, the first support is fixed to sliding blocks of the linear electric cylinders, an adjusting part is arranged on the first support, a sliding base is arranged on the adjusting part, a clamping part with a turnover function is arranged on the sliding base, and the clamping part is used for clamping an electronic element; and a first connecting piece and a second connecting piece are arranged on the base, a driving piece is arranged on one side of the first support, and the driving piece drives the first connecting piece or the second connecting piece to move and be inserted. The machining device replaces a traditional mode of manually detecting a plug connector to detect the electronic element, the production and machining efficiency of the electronic element is improved, and the labor intensity of workers is reduced.

Owner:深圳市本致科技有限公司

PCB and manufacturing method thereof

ActiveCN110446328AAvoid WeldingImprove thermal efficiencyPrinted circuit assemblingPrinted circuit aspectsResistEngineering

Owner:WUHAN JINGLI ELECTRONICS TECH +1

Flexible circuit board, manufacturing method thereof and display device

ActiveCN113645758AImprove welding qualityImprove welding yieldPrinted circuit assemblingElectrical connection printed elementsFlexible circuitsDisplay device

The invention provides a flexible circuit board, a manufacturing method thereof and a display device. The flexible circuit board comprises a main board and a small board, the main board is provided with at least one first welding area for exposing a part of a first conductive layer, the small board is provided with at least one second welding area for exposing a part of a second conductive layer, the second welding area comprises a welding hole, the orthographic projection of the second welding area on the mainboard is at least partially overlapped with the first welding area, and the first conductive layer and the second conductive layer are connected through a welding structure. The welding structure comprises: a first layer of welding flux which is located on the first conductive layer part exposed by the first welding area; a second layer of welding flux which is located on the part, exposed out of the second welding area, of the second conducting layer, wherein at least part of the second layer of welding flux is welded and fixed to the first layer of welding flux through the welding hole; and a high-melting-point connecting piece, wherein one end of the high-melting-point connecting piece is located in the first layer of welding flux, the other end of the high-melting-point connecting piece is located in the second layer of welding flux in the welding hole, and the melting point of the high-melting-point connecting piece is higher than that of the first layer of welding flux and that of the second layer of welding flux. According to the flexible circuit board, the manufacturing method thereof and the display device, the welding quality and the welding yield of the circuit board can be improved.

Owner:BOE TECH GRP CO LTD +1

Device and method for lengthening pins of original device

InactiveCN112672499APrinted circuit assemblingPrinted circuit non-printed electric components associationPhysicsWave soldering

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap