LED lamp bead tinning mechanism

A technology of LED lamp bead and rotating mechanism, which is applied in the direction of assembling printed circuit with electrical components, glass production, etc. It can solve the problems of time-consuming and laborious tinning operation, large manual labor force, and incomplete tinning on circuit boards, etc., to reduce inconsistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

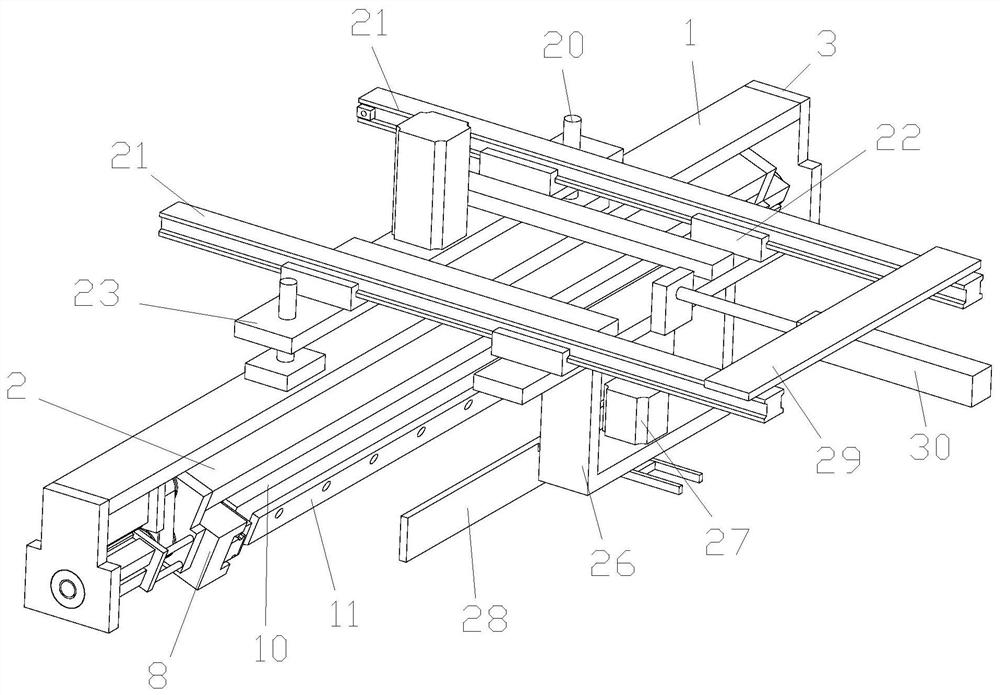

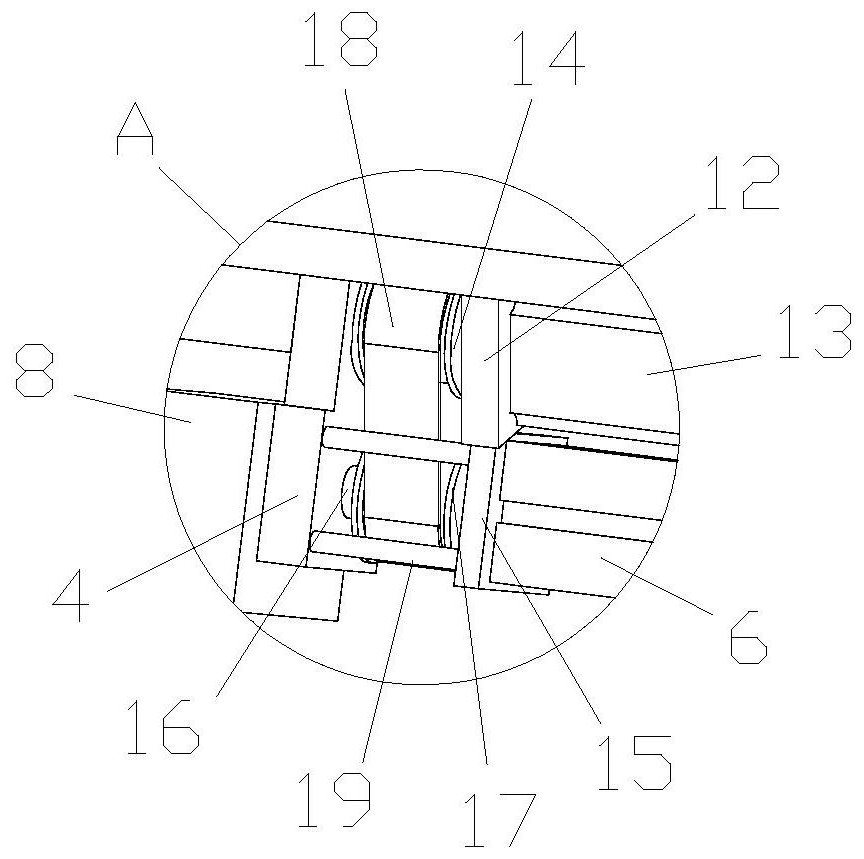

[0017] Embodiment: A tinning mechanism for LED lamp beads, such as Figure 1-Figure 3 As shown, it includes a rotating mechanism and a moving mechanism. The rotating mechanism includes an upper shelf plate 1 and a lower shelf plate 2. An outer mounting plate 3 is respectively connected to two ends of the upper shelf plate 1, and the two ends of the lower shelf plate 2 Each is connected with an inner mounting plate 4, and the inner surfaces of the two outer mounting plates 3 are rotatably connected with a rotating shaft 5 through a bearing. It is fixedly connected with the inner end of the rotating connecting column 6 on the left side, a left clamping cylinder 7 is provided on the inner side of the inner mounting plate 4 on the left side, and a right clamping cylinder 7 is arranged on the inner side of the inner mounting plate 4 on the right side. The cylinder 8, the left clamping cylinder 7 and the right clamping cylinder 8 can achieve the closing and opening of the mounting fram

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap