Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244results about "Transportation and packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

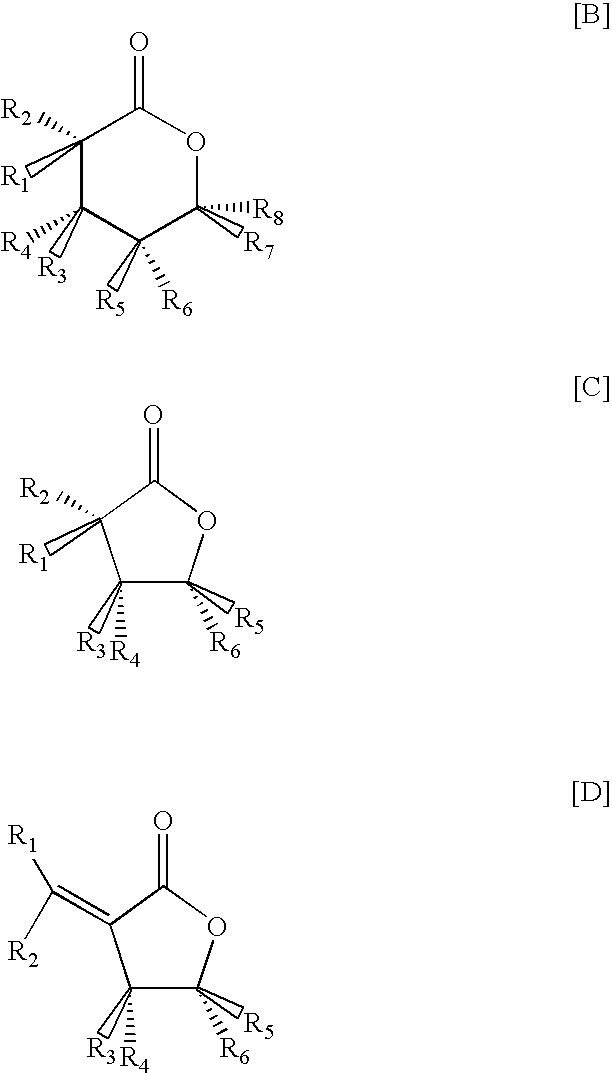

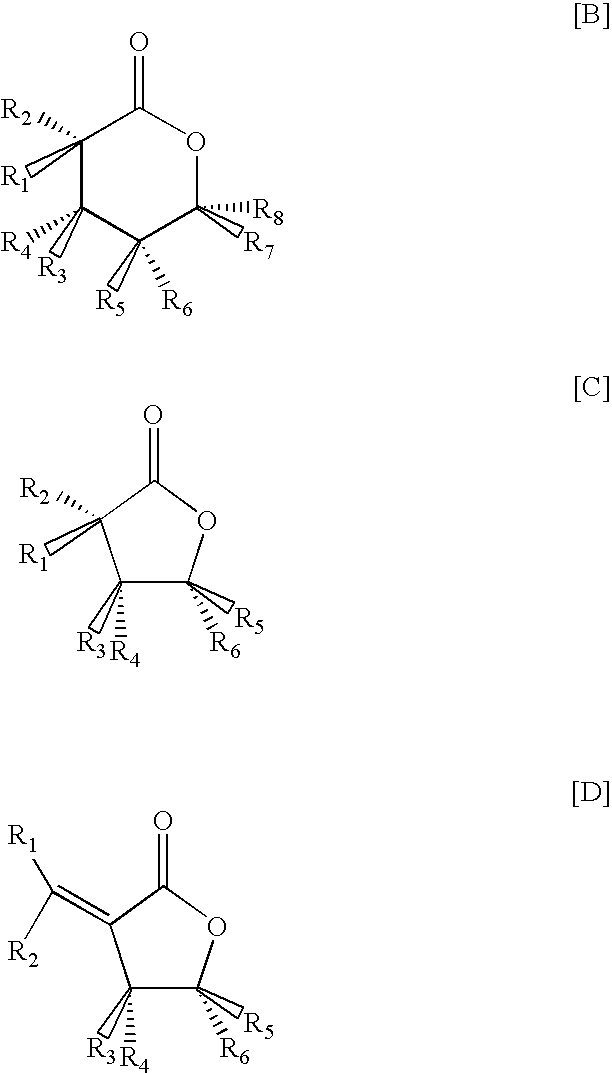

Compositions comprising a fluoroolefin

InactiveUS20060243944A1Reduce cooling capacityOther chemical processesTransportation and packagingPhysicsChemistry

Owner:EI DU PONT DE NEMOURS & CO

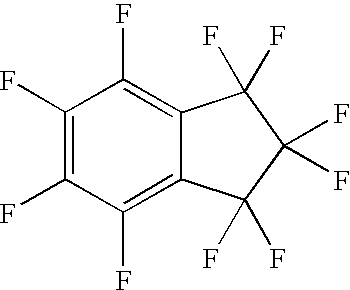

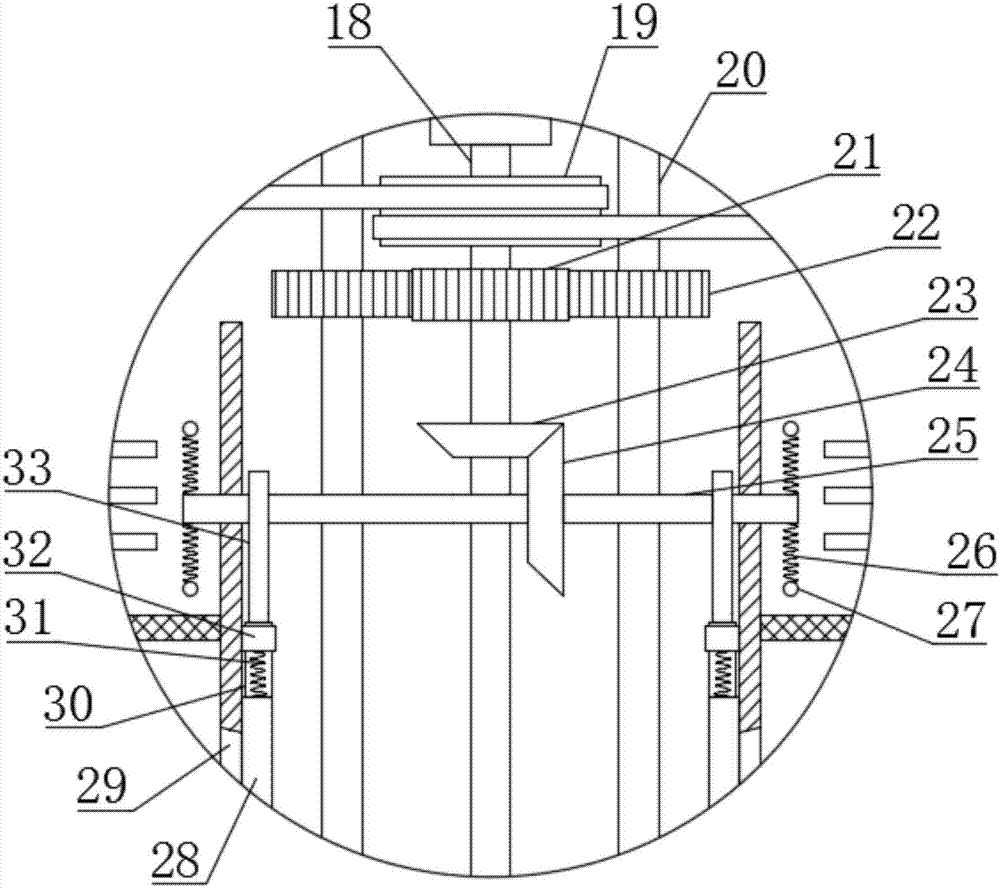

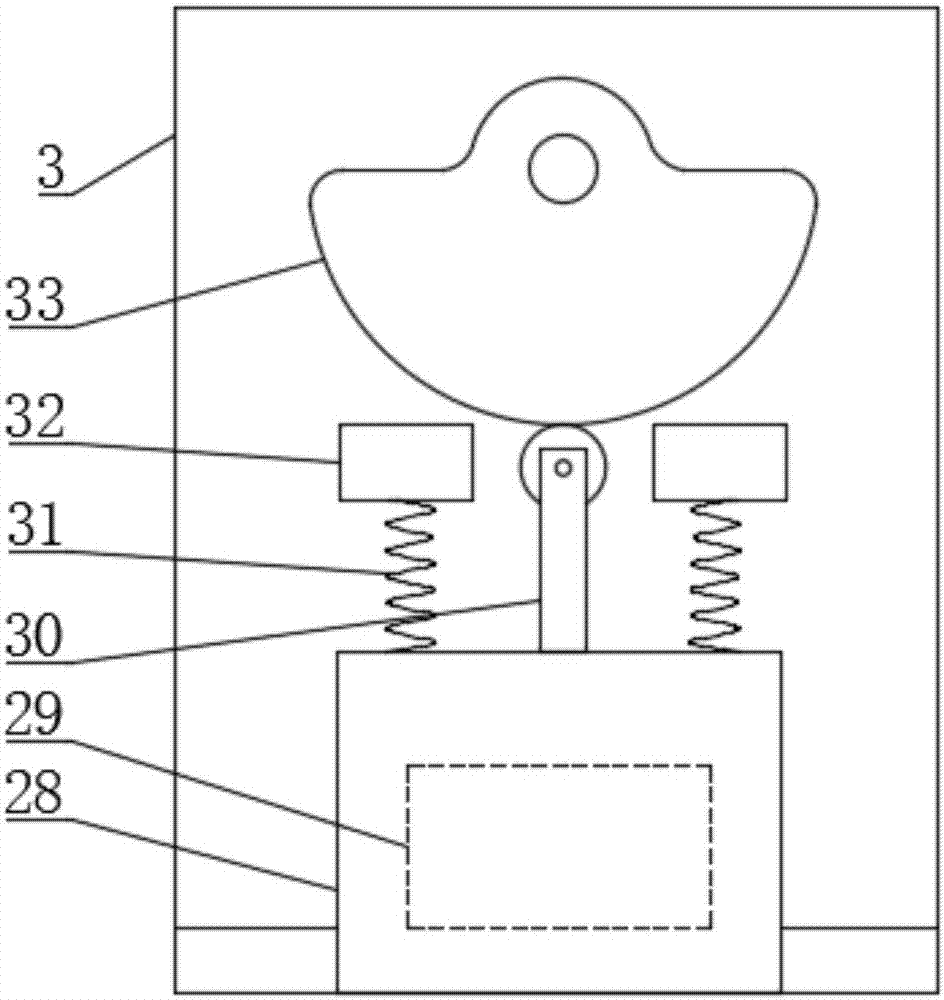

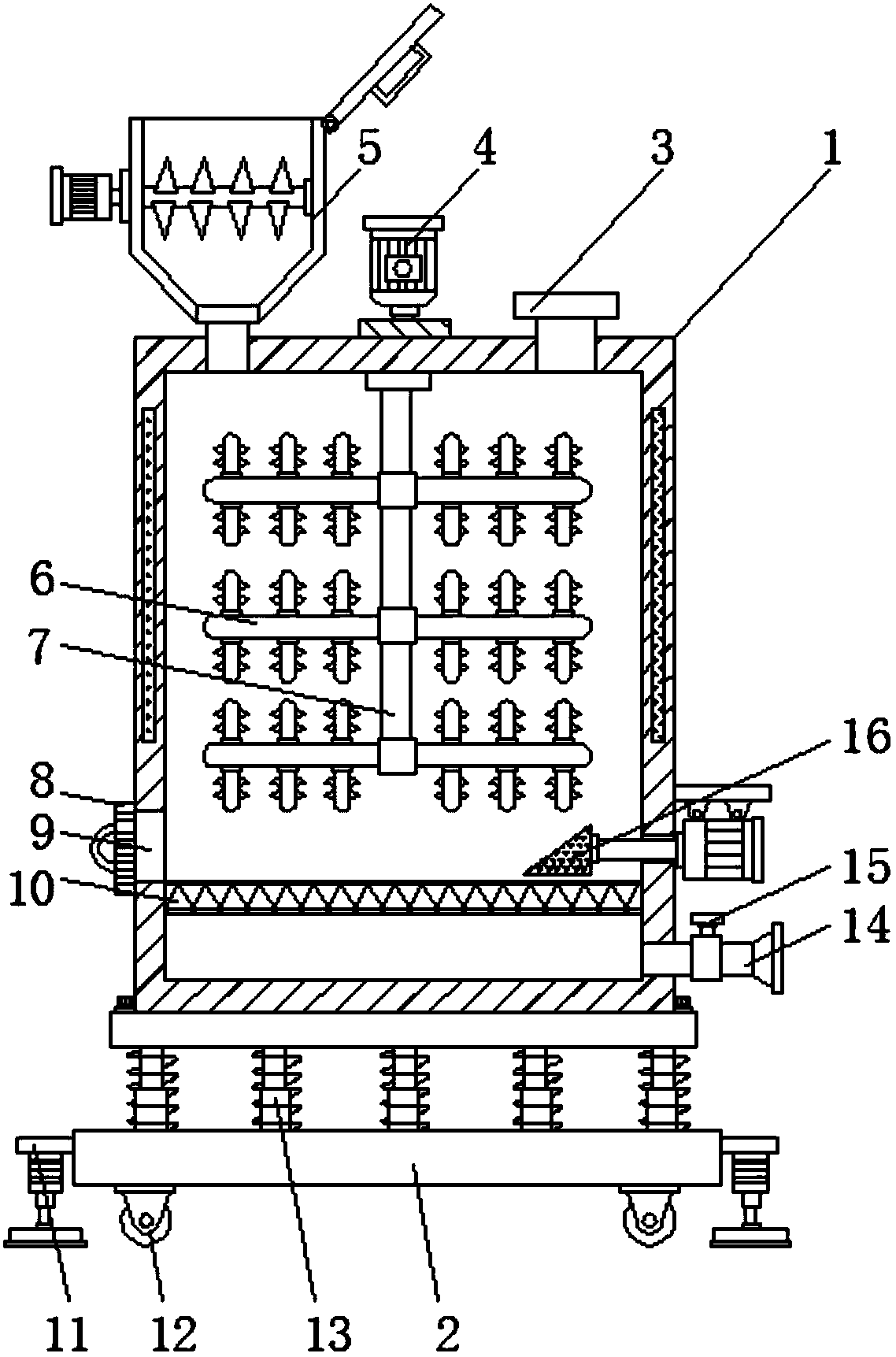

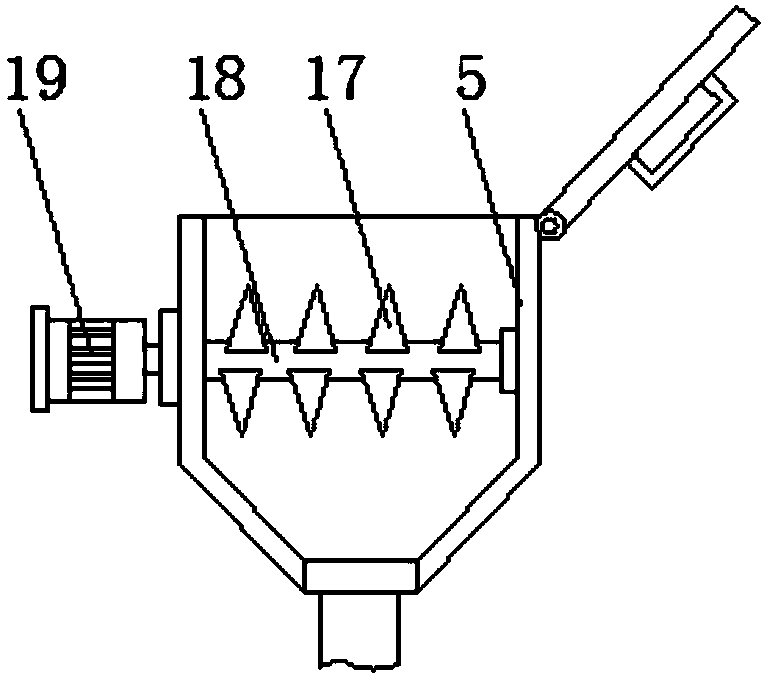

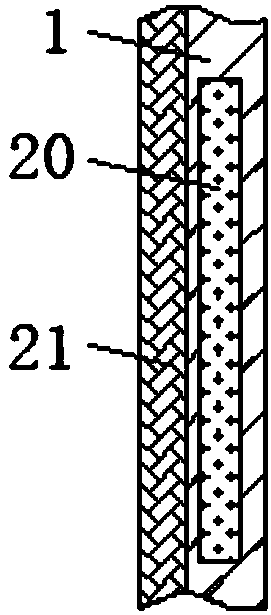

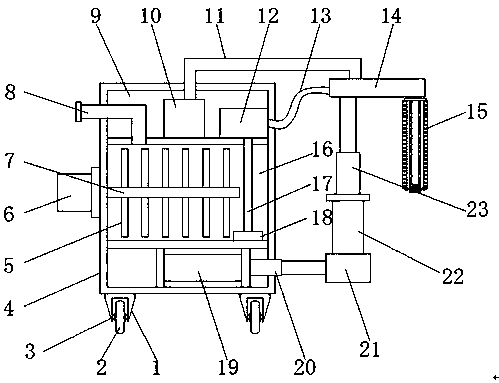

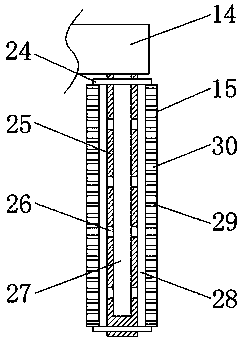

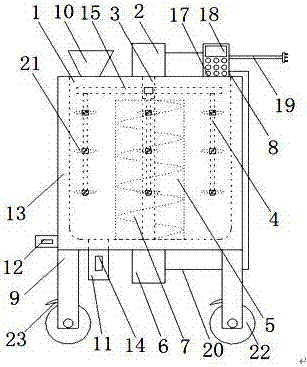

Crushing quantitative mixing pharmaceutical device for traditional Chinese medicinal material

Owner:邹铁梅

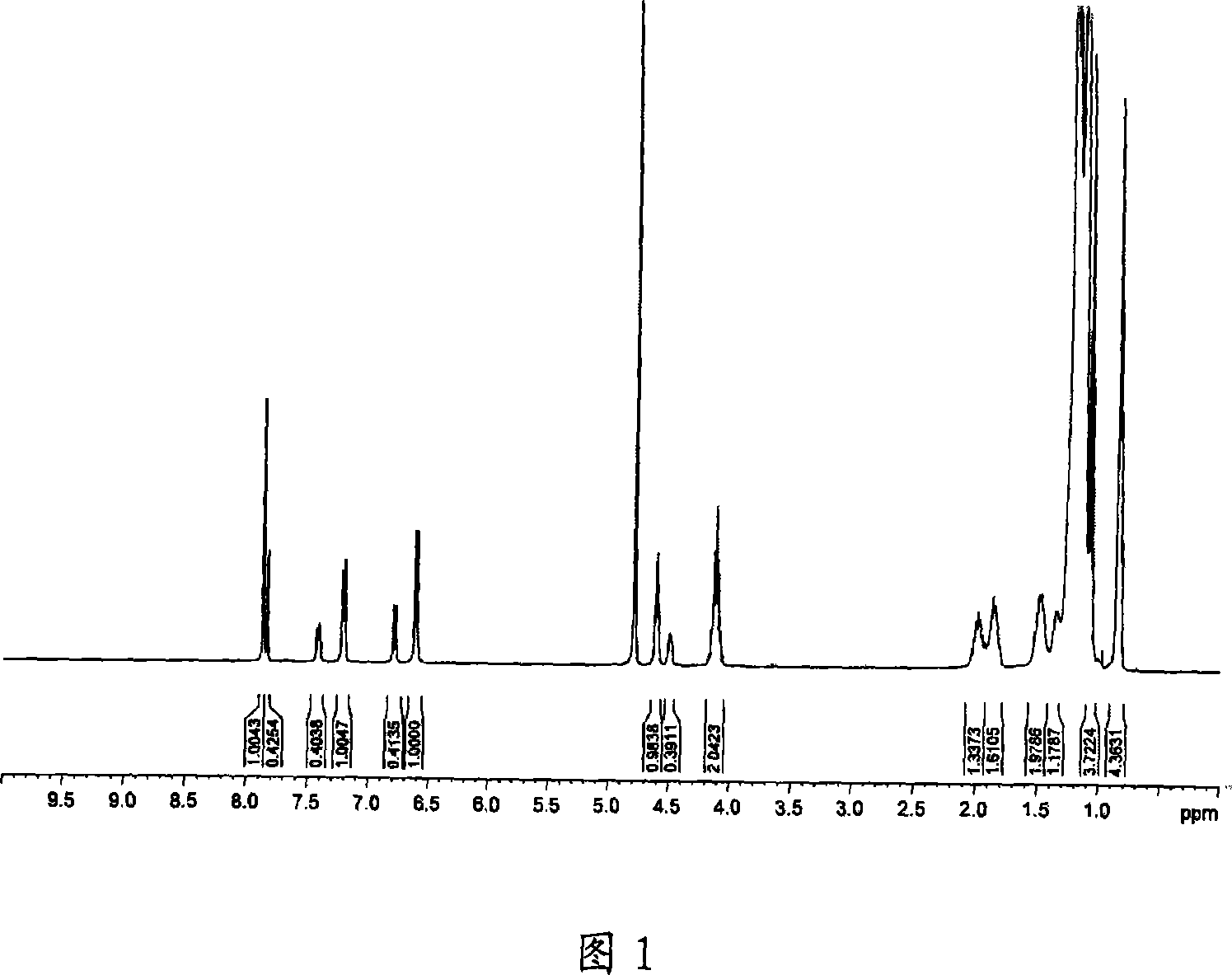

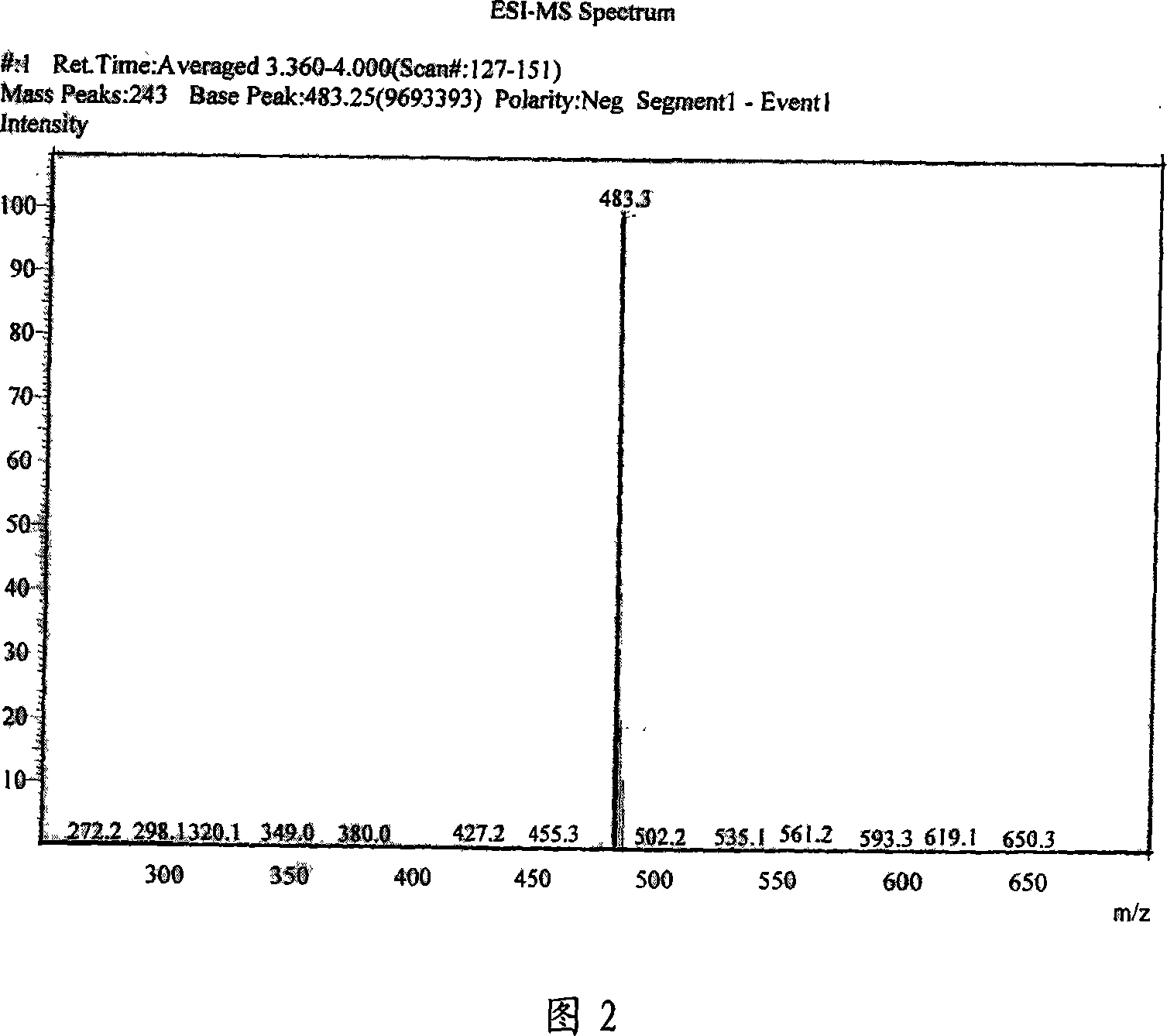

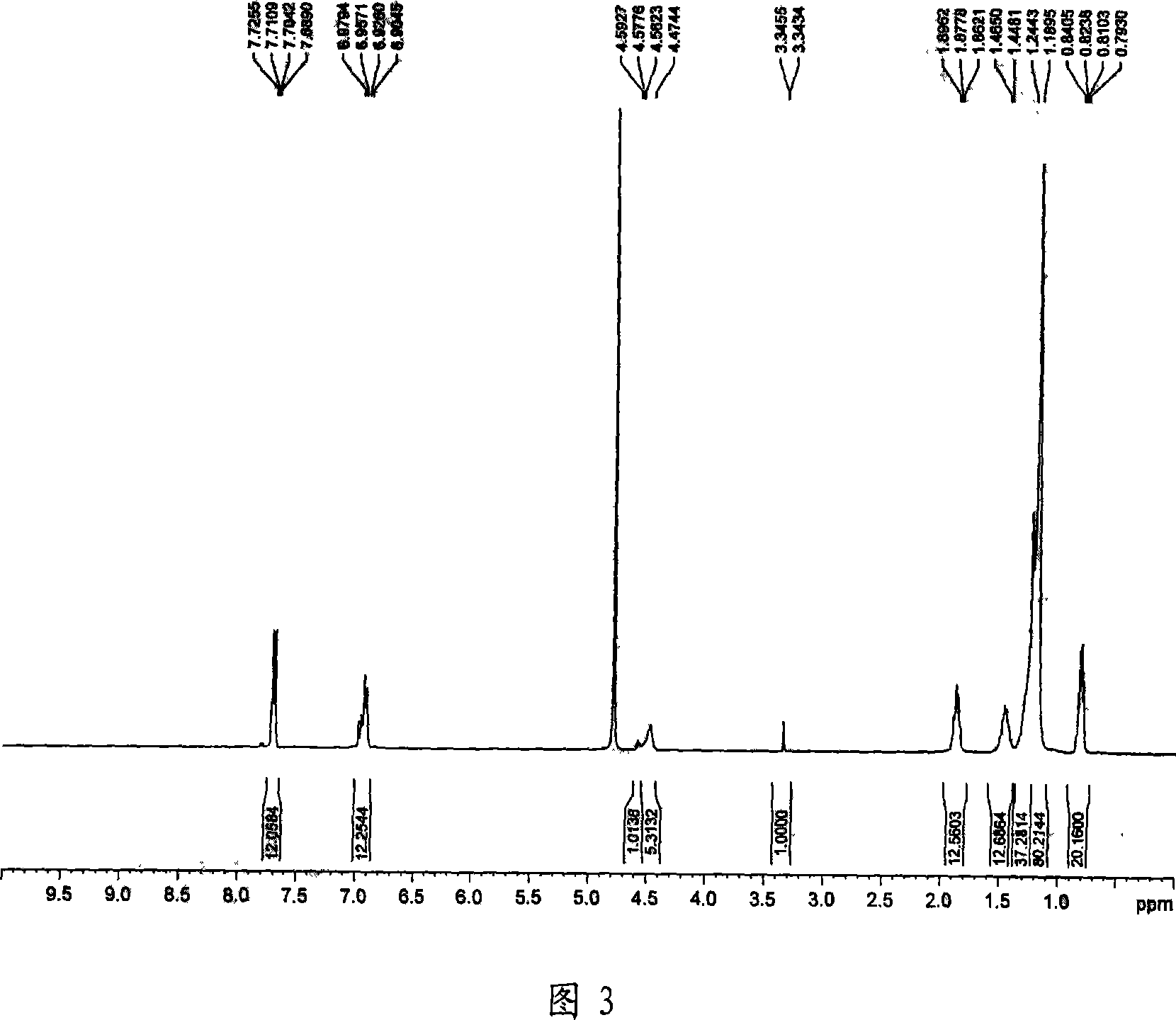

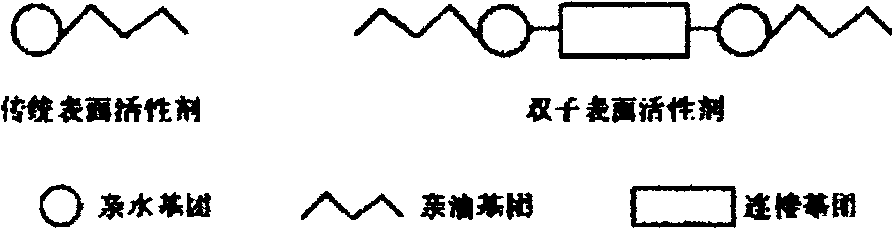

Asymmetric Gemini surface activator, its production and use

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

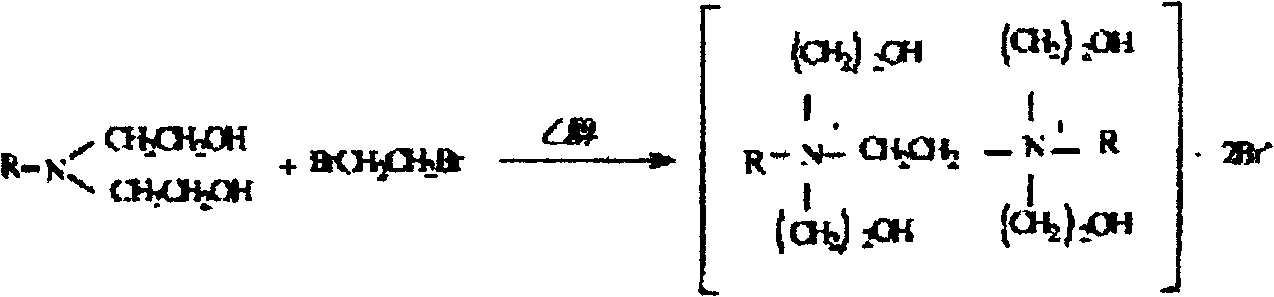

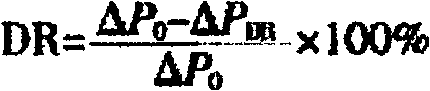

Synthetic method of gemini quaternary ammonium salt surfactant and application as drag reduction agent

Owner:TIANJIN VOCATIONAL INST

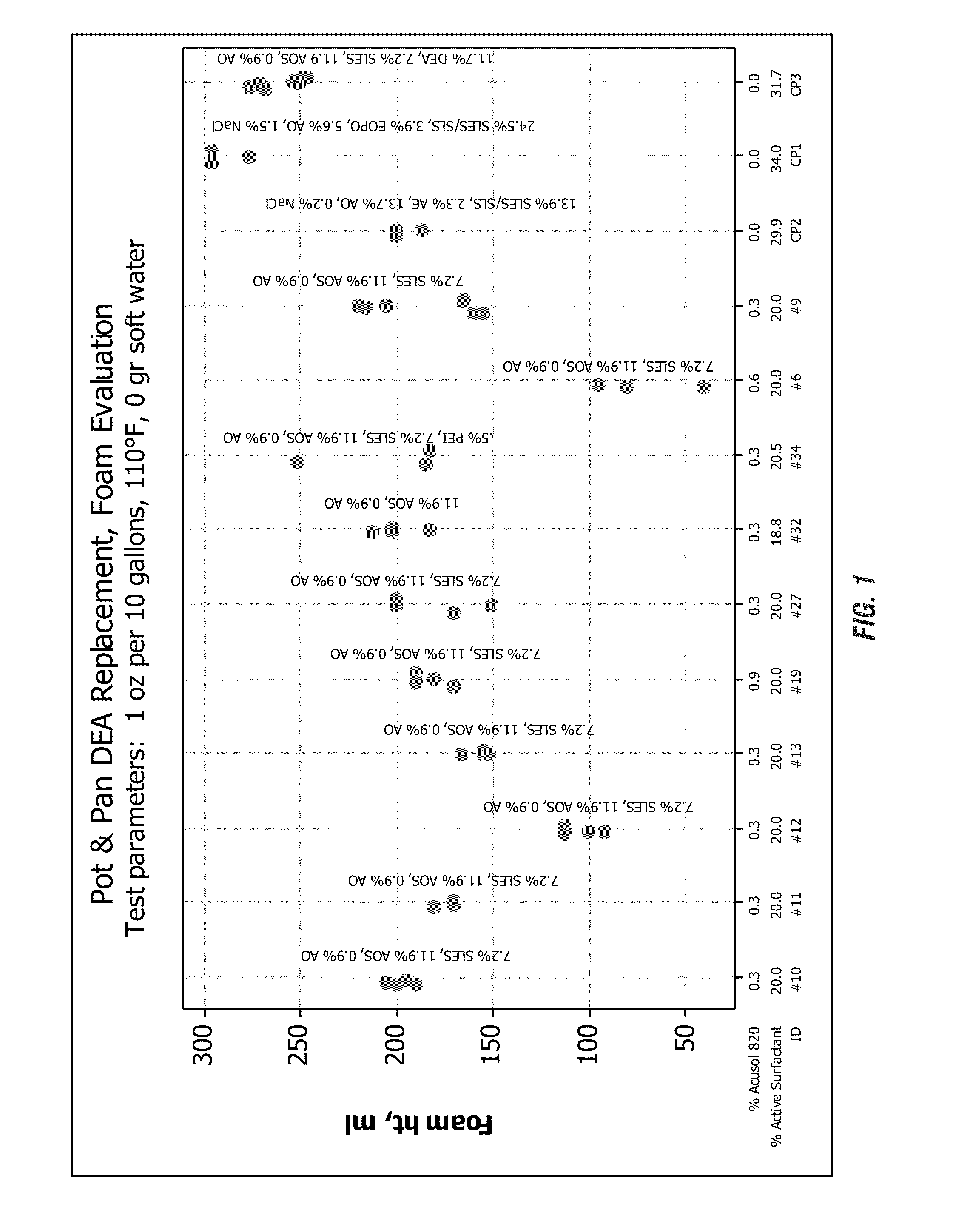

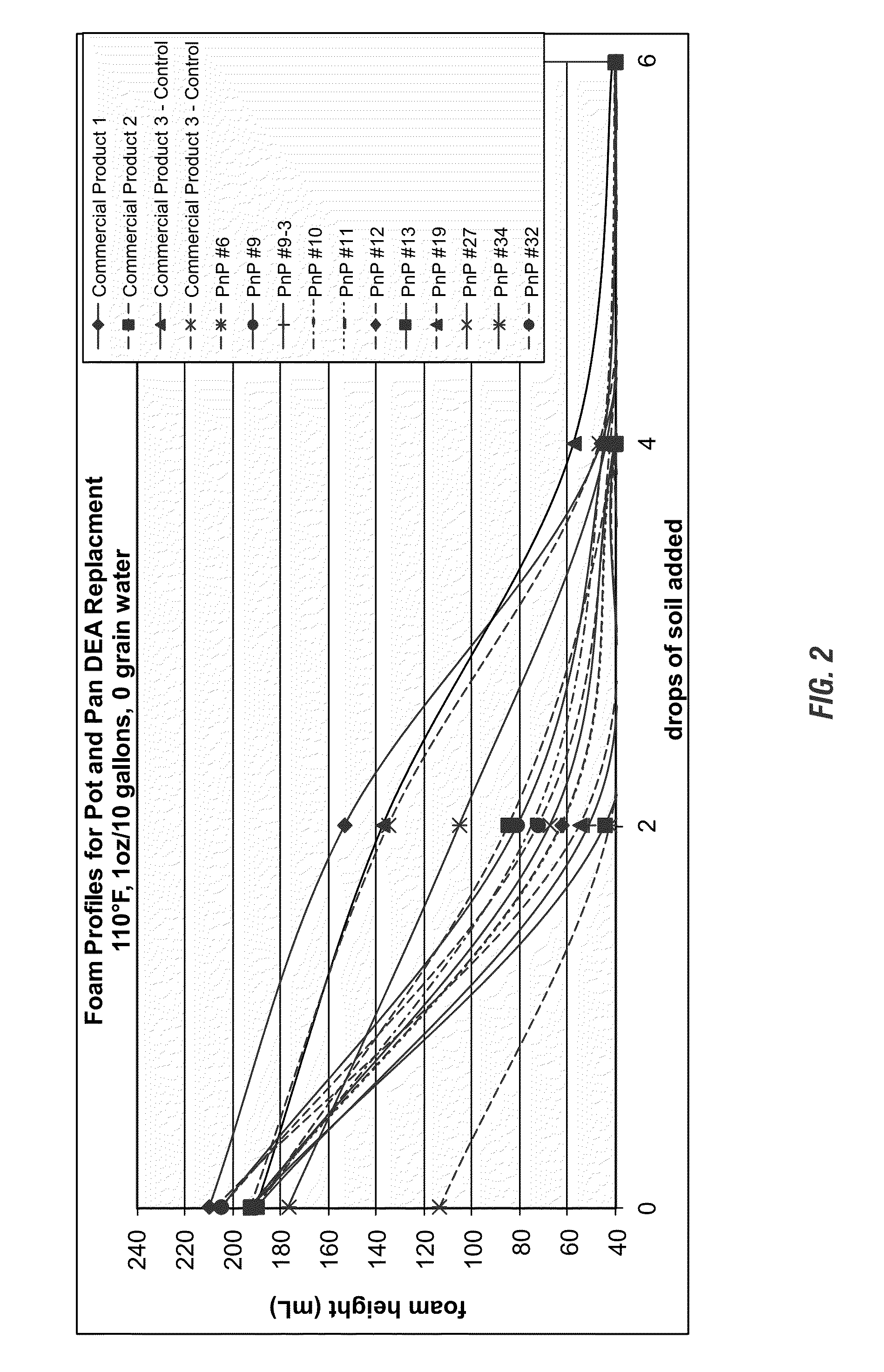

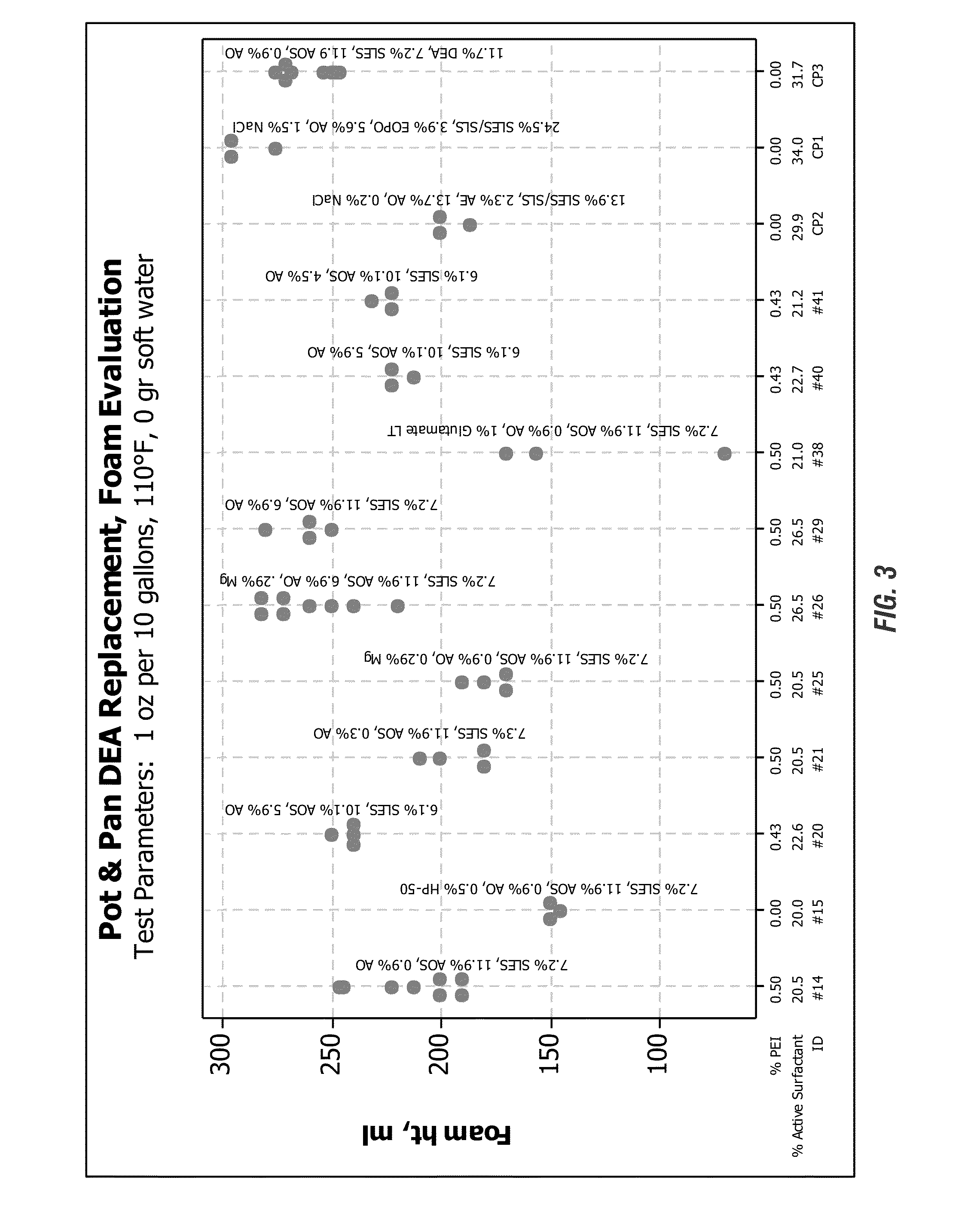

Foam stabilization with polyethyleneimine ethoxylates

ActiveUS20140148374A1Provide stabilityCosmetic preparationsOrganic detergent compounding agentsElectrostatic interactionCocamide DEA

Owner:ECOLAB USA INC

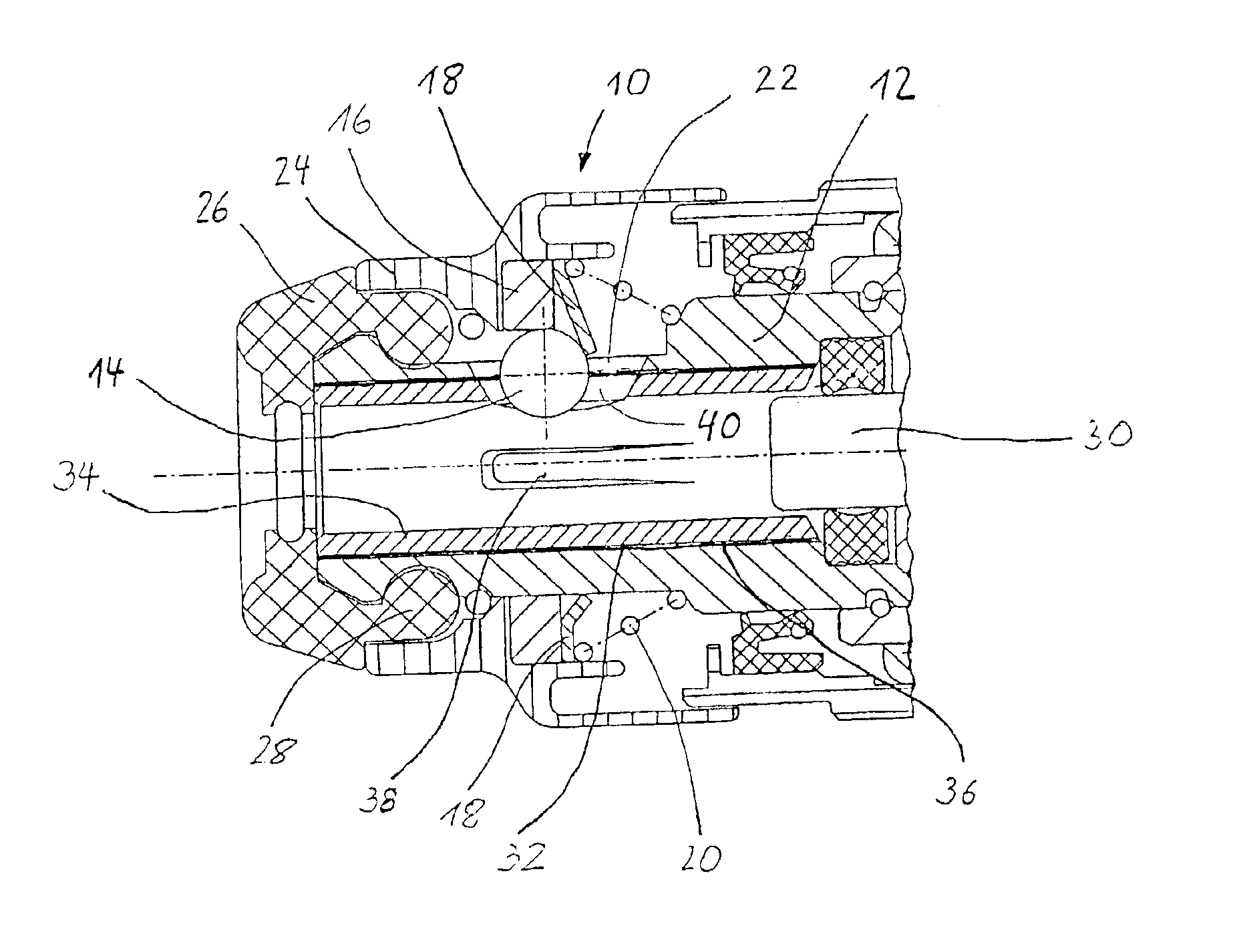

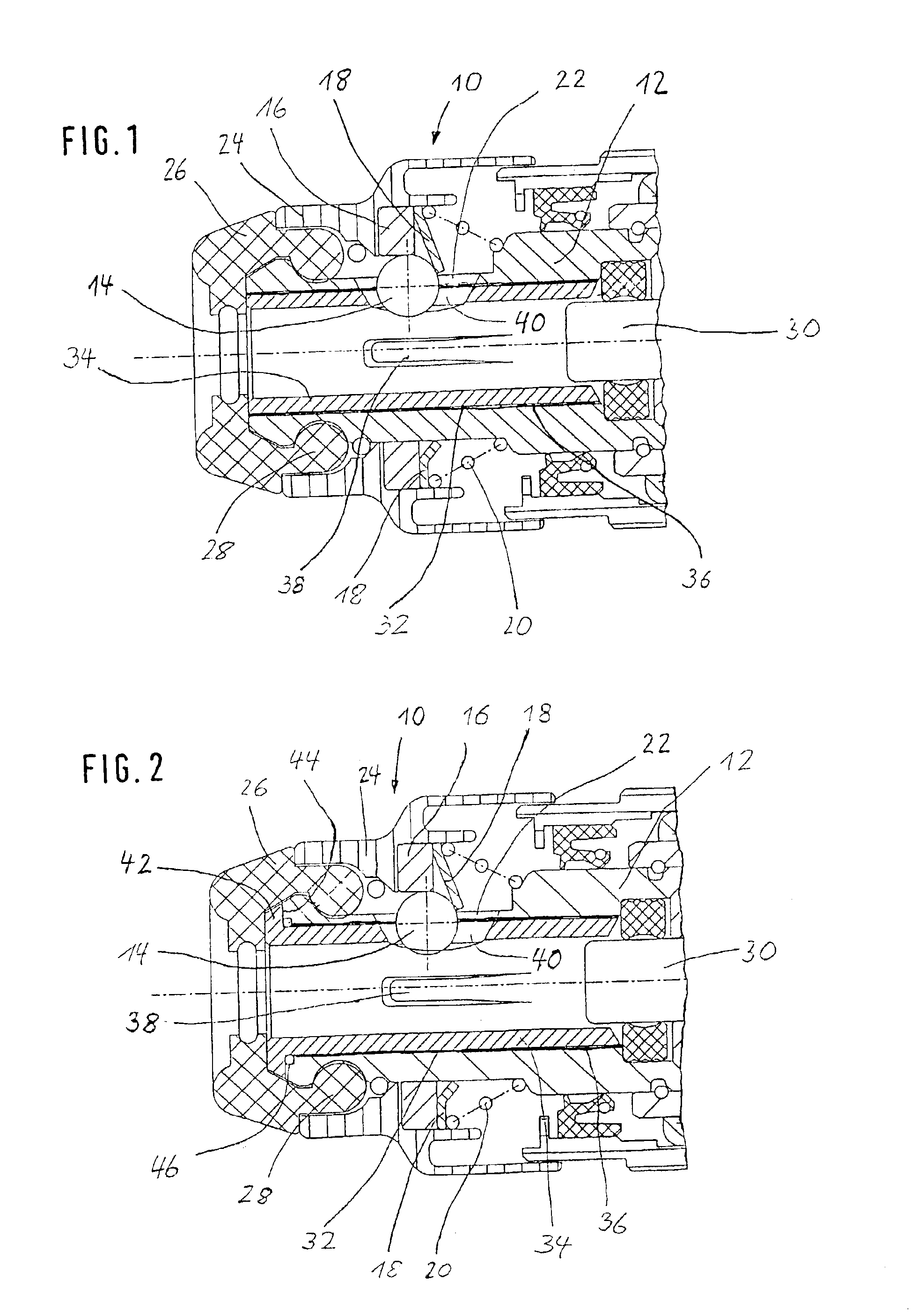

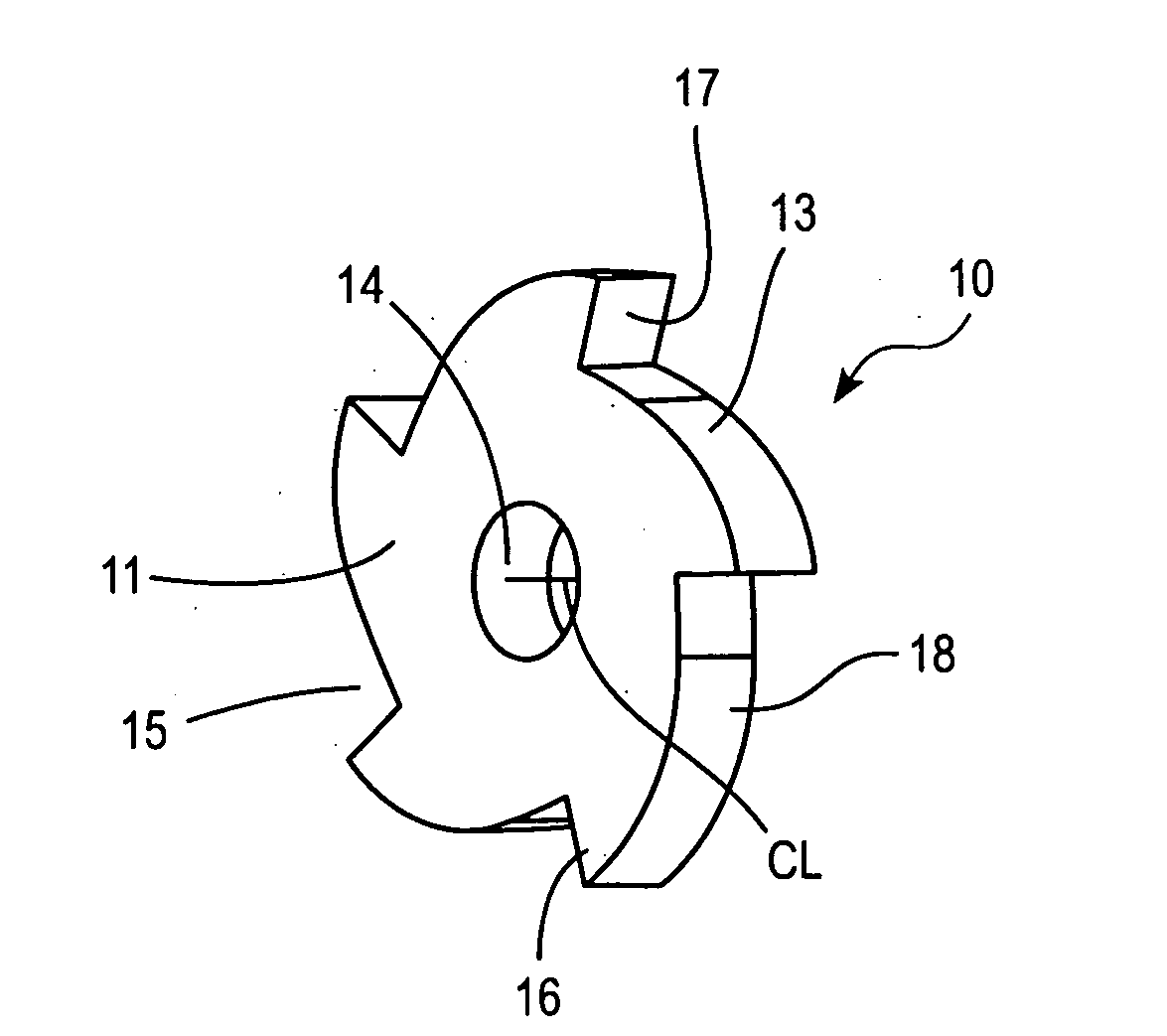

Tool mounting for a hand machine tool

Owner:ROBERT BOSCH GMBH

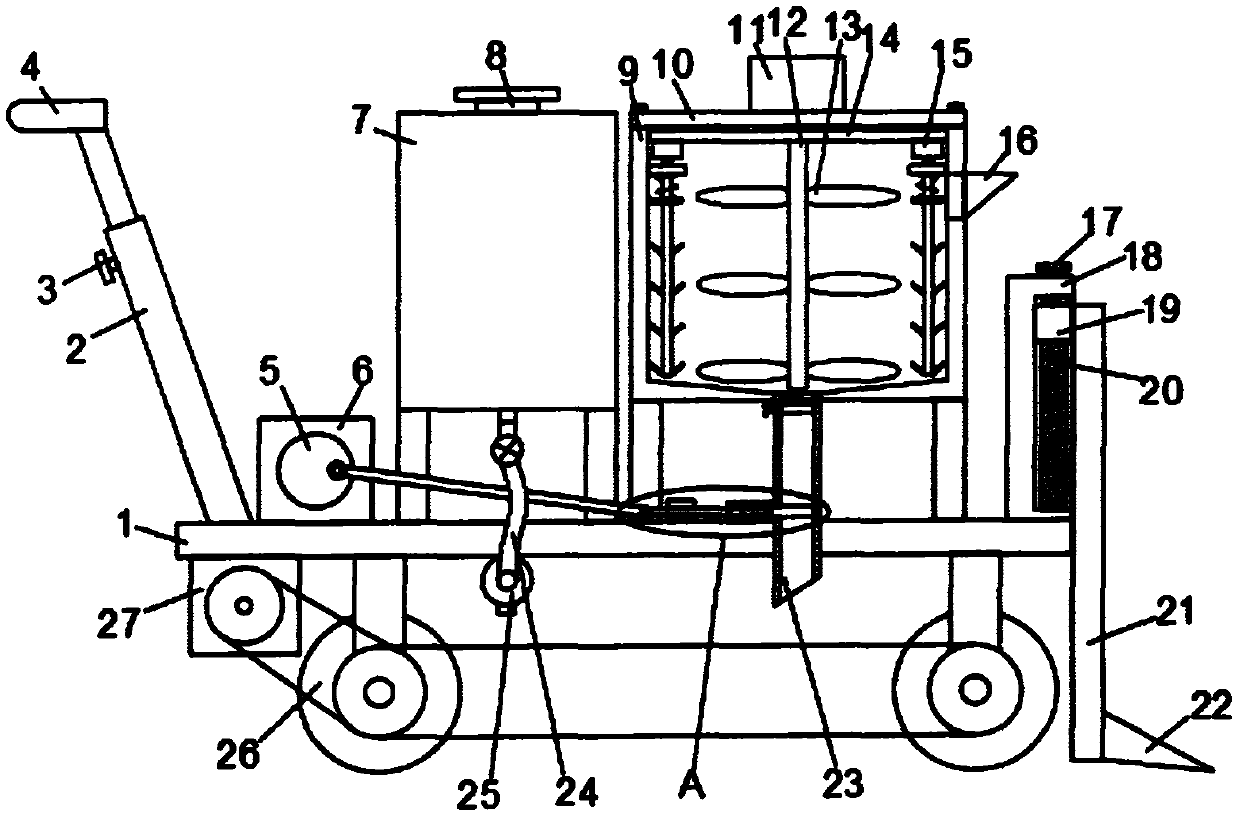

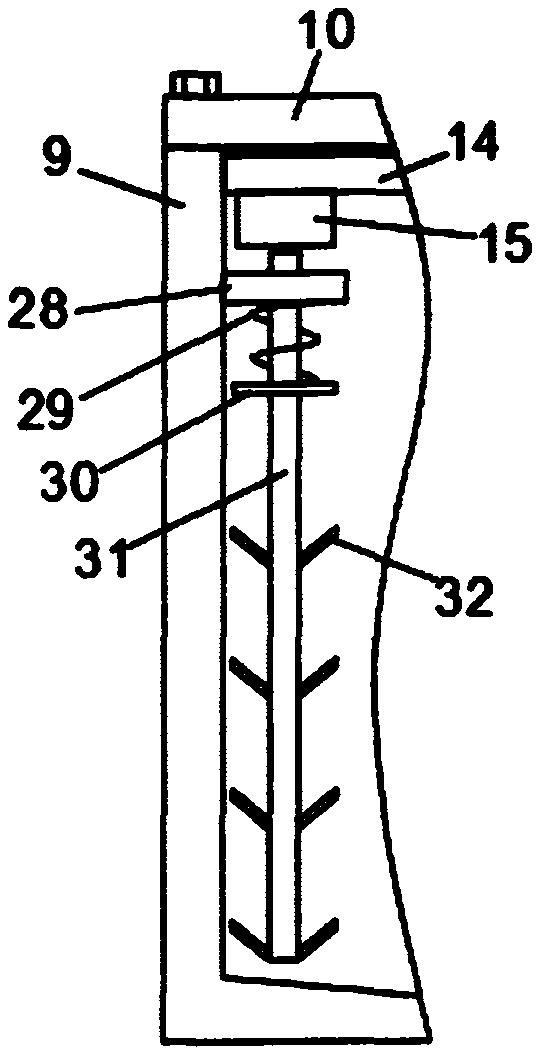

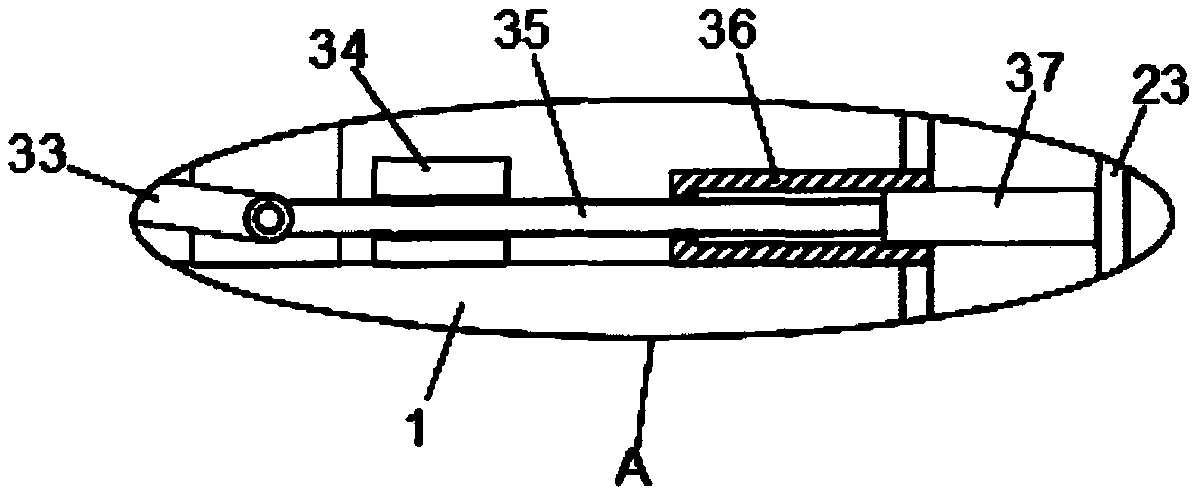

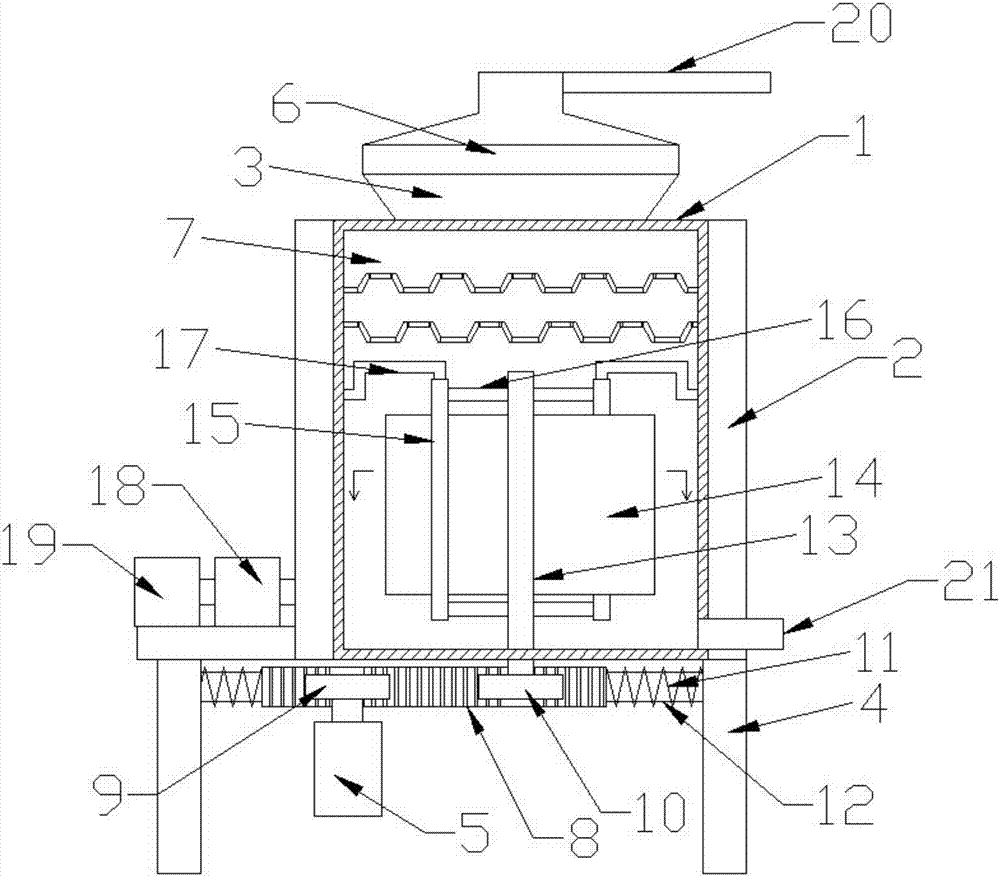

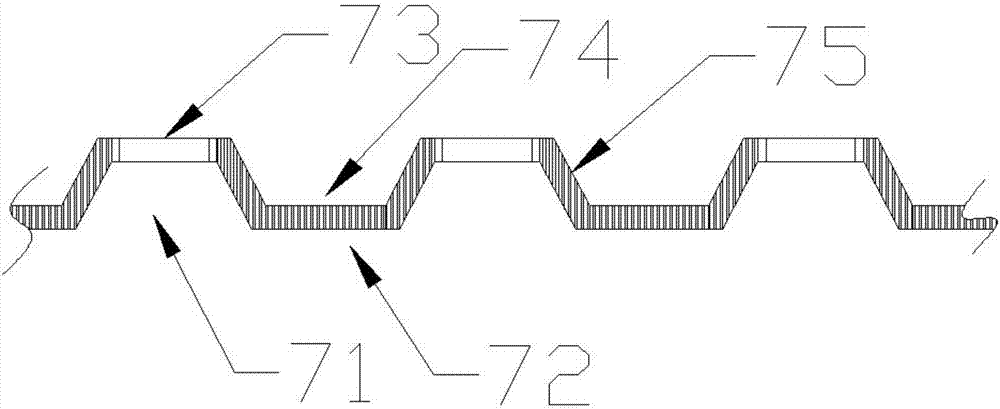

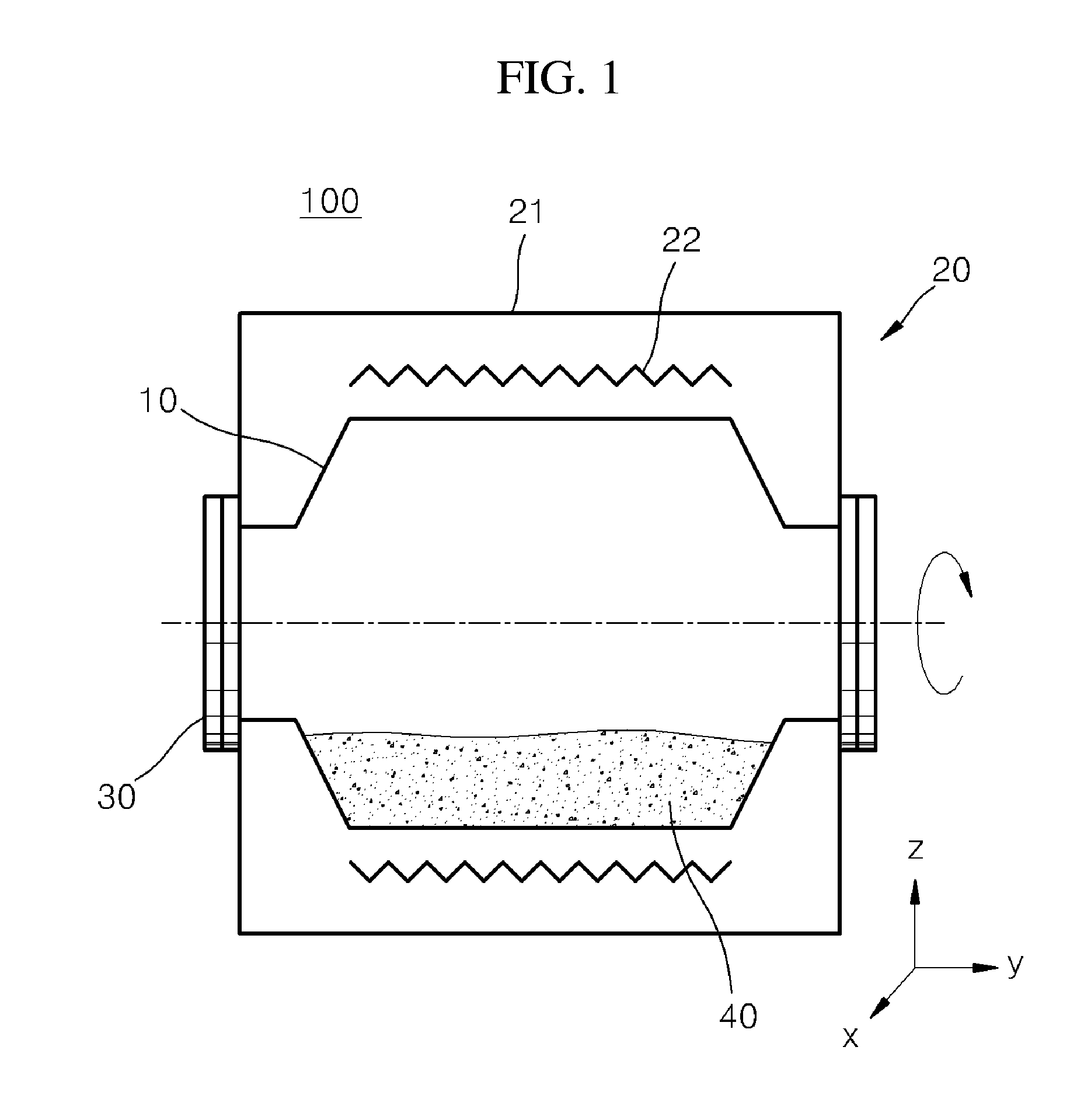

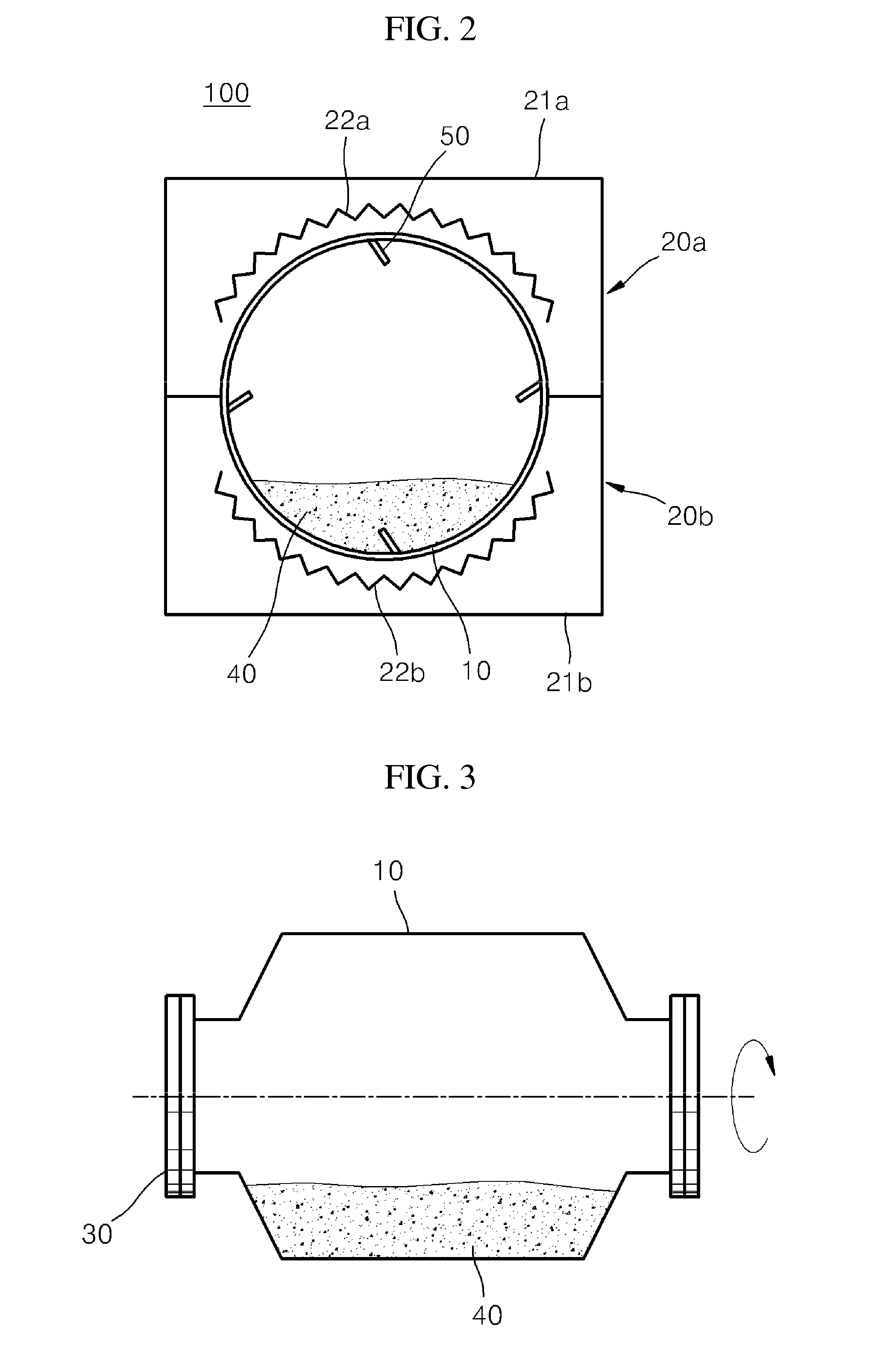

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High energyEfficient mixingMixing/kneading structural elementsFlow mixersSpray nozzleImpact area

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE GMBH & CO KG

Automatic fertilization device for agriculture science and technology

InactiveCN110178509AImprove mixing uniformityImprove stirring efficiencyRotary stirring mixersTransportation and packagingEngineeringMixing effect

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

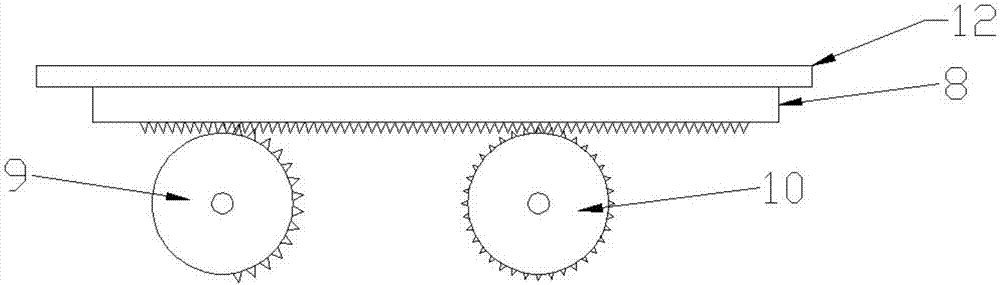

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

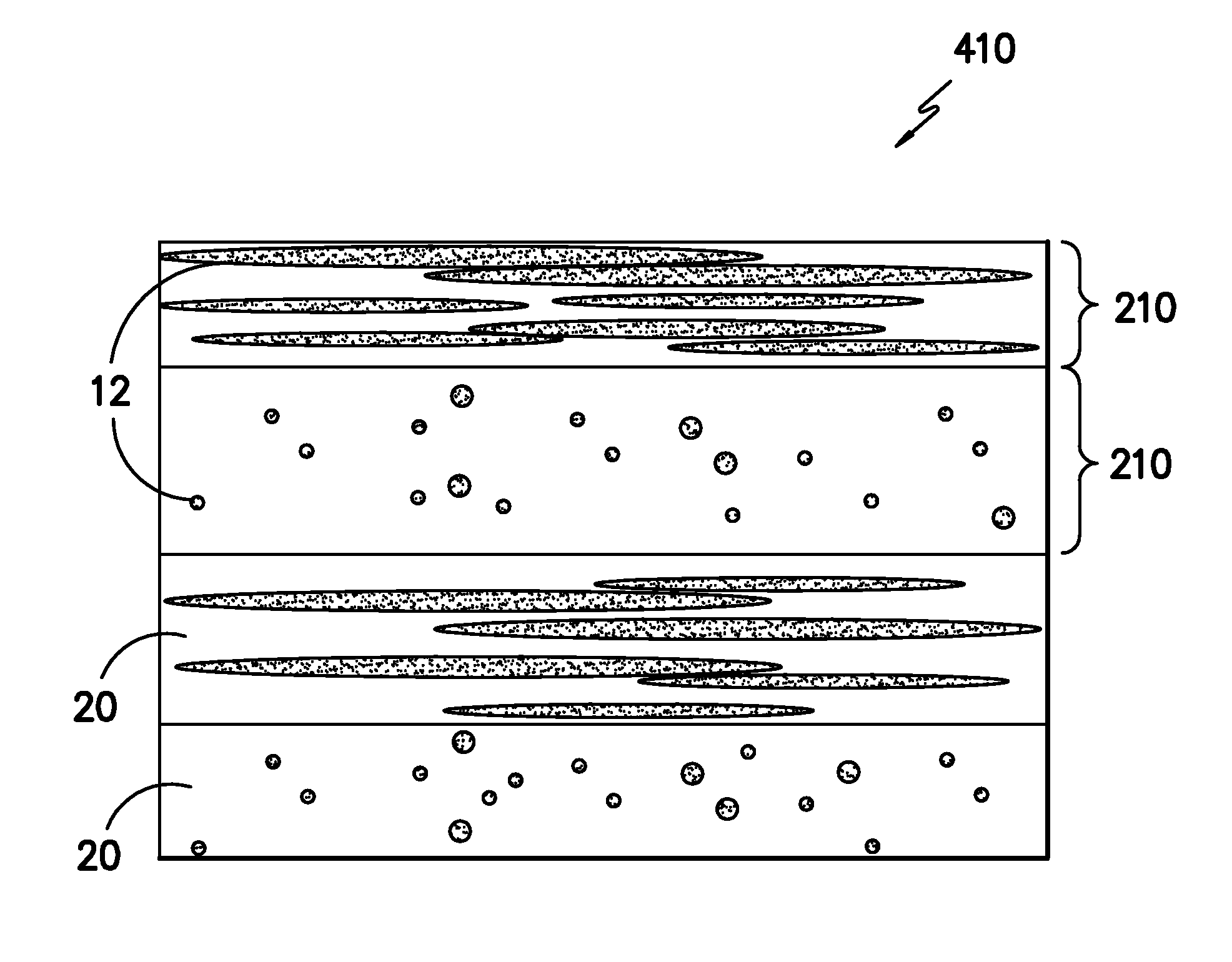

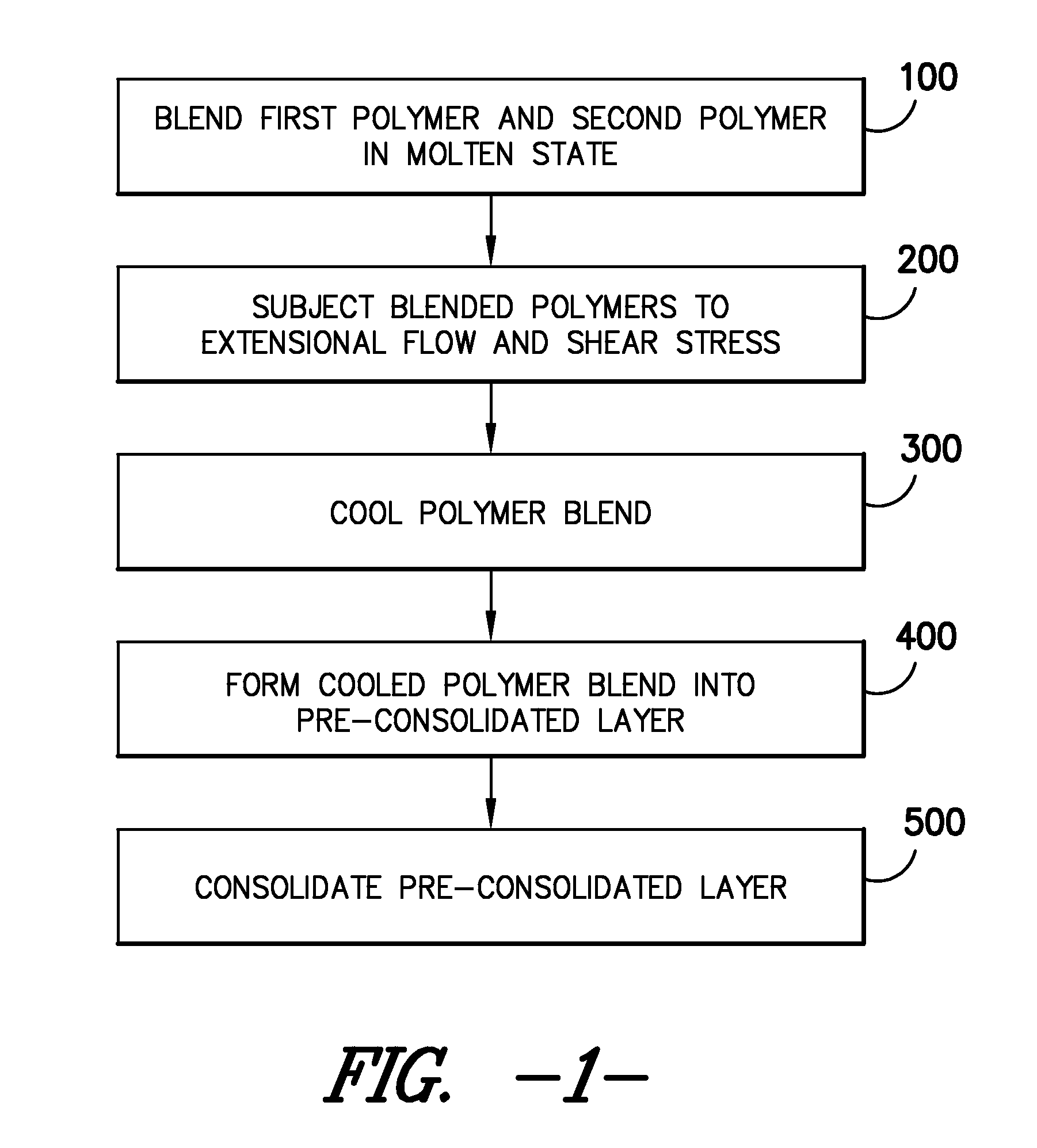

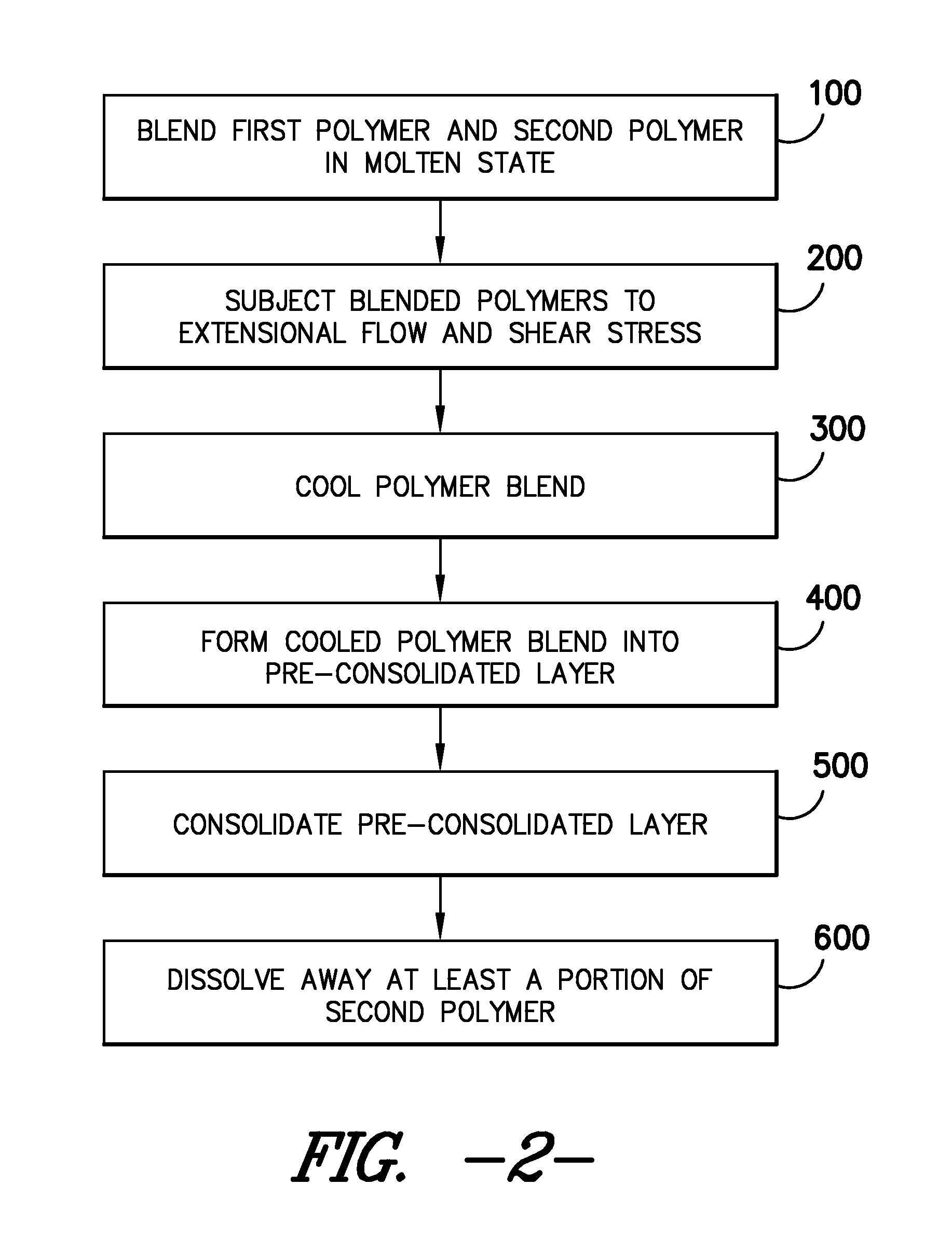

Process of Forming Nano-Composites and Nano-Porous Non-Wovens

Owner:MILLIKEN & CO

Metal powder for powder metallurgy, compound, granulated powder, and sintered body

InactiveUS20150252459A1High densityImprove expectationsTransportation and packagingMetal-working apparatusCrystal structureMetal powder

Owner:SEIKO EPSON CORP

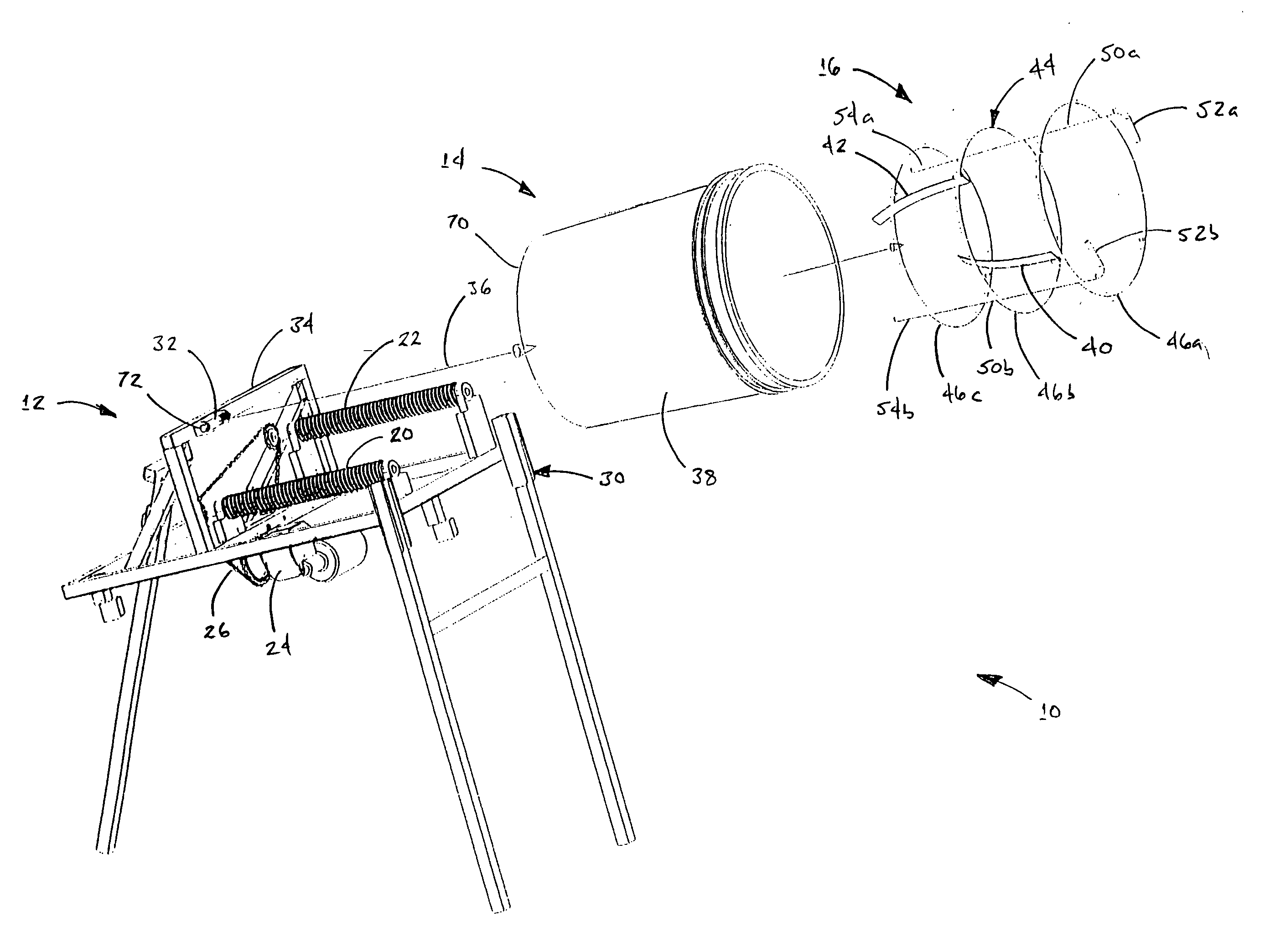

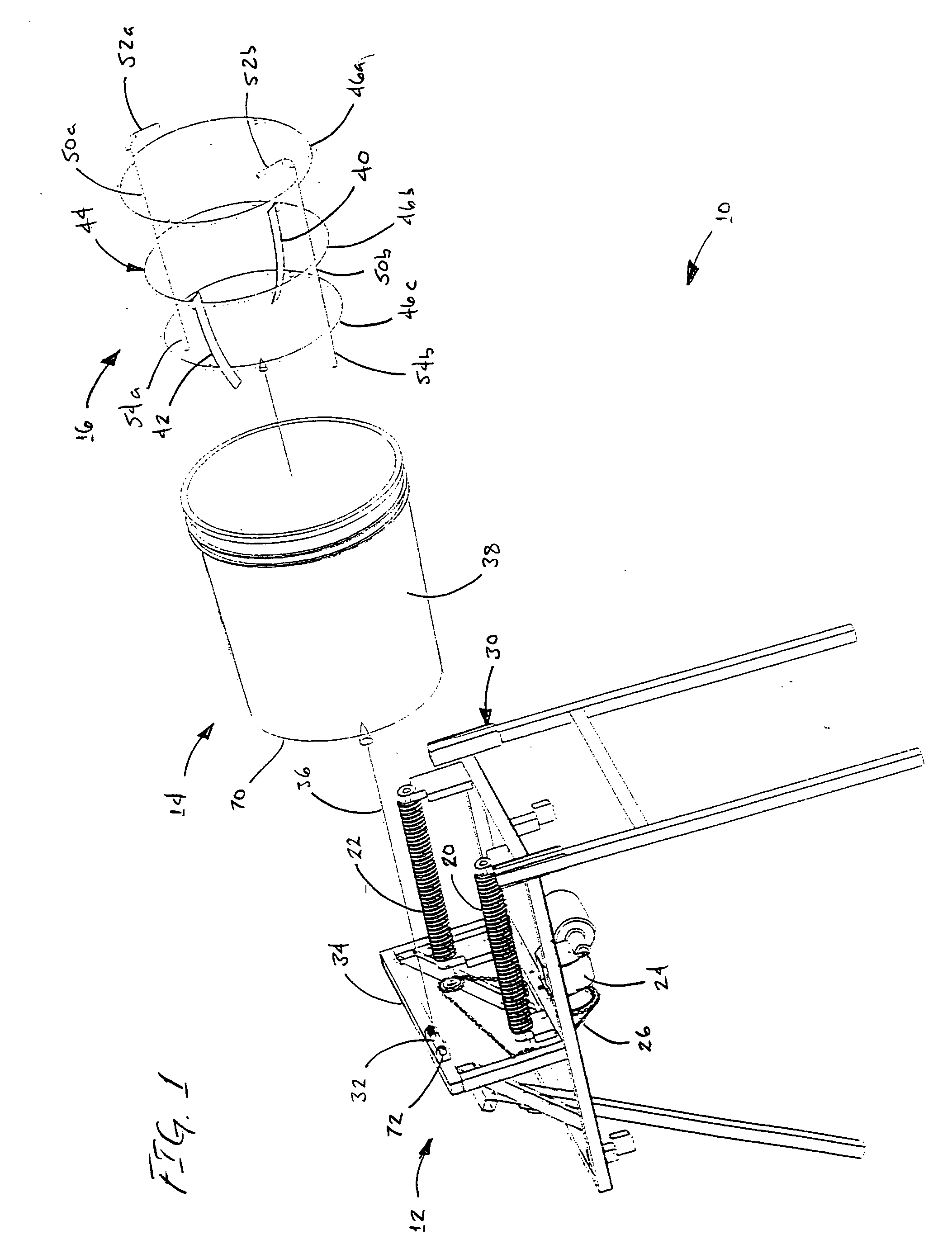

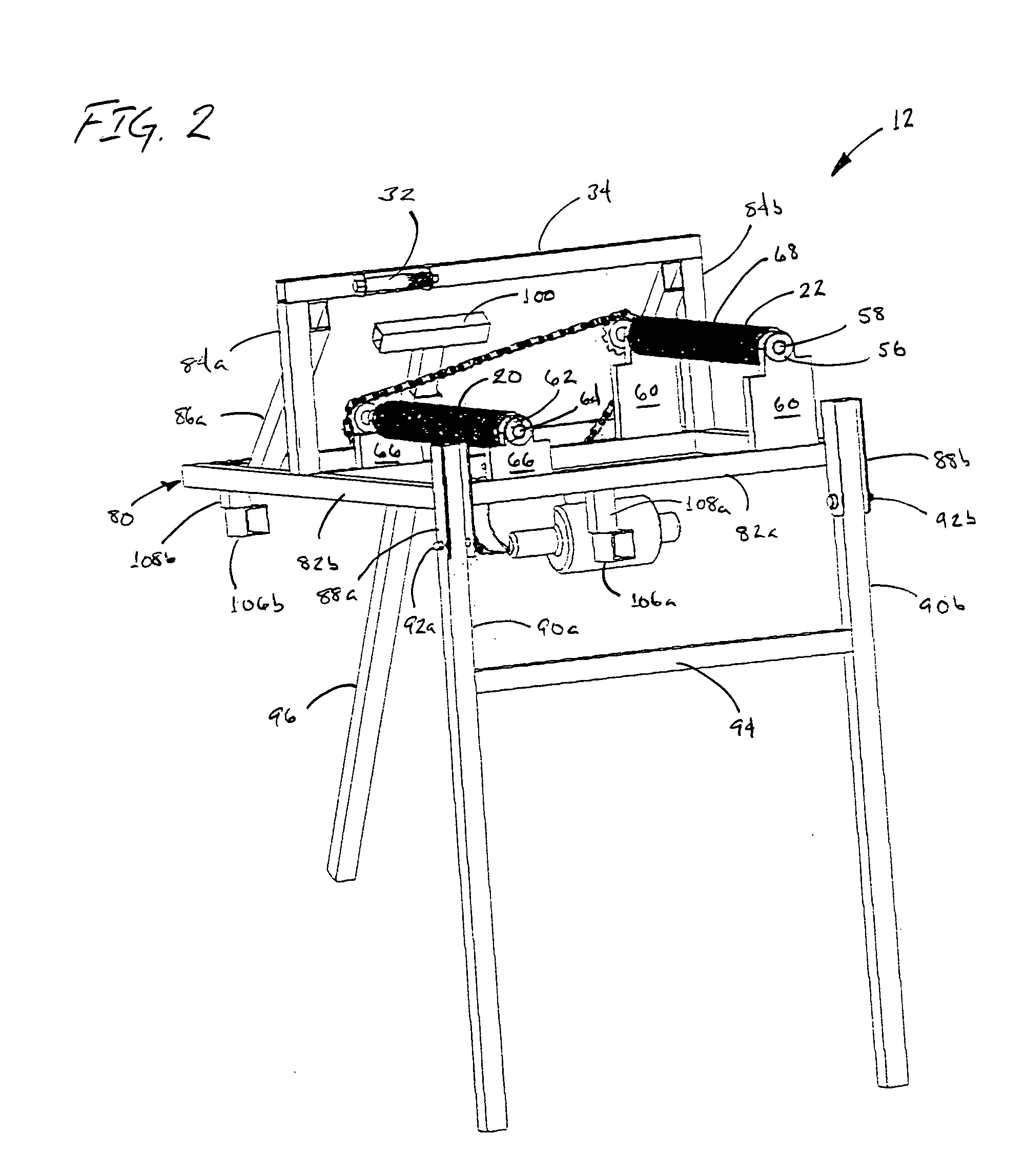

Portable mixing apparatus

InactiveUS20060028913A1Easy to transportRotating receptacle mixersTransportation and packagingMotor driveSlope angle

Owner:HASKELL GEORGE L

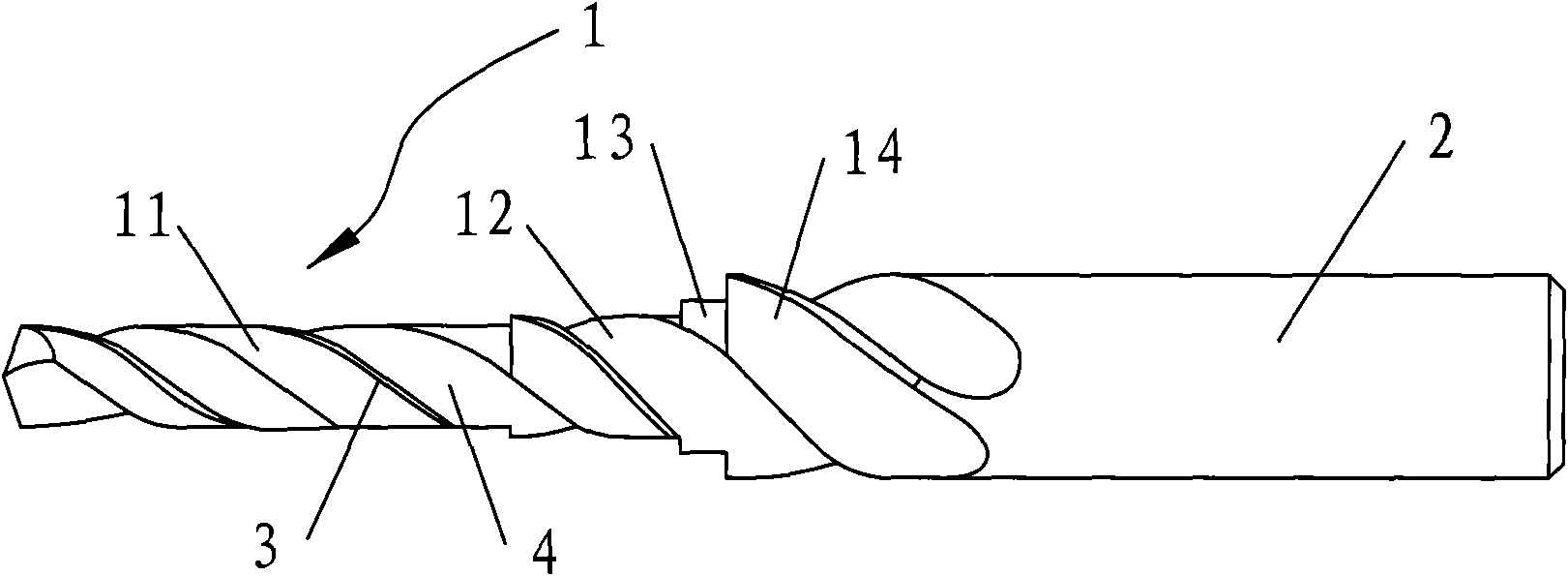

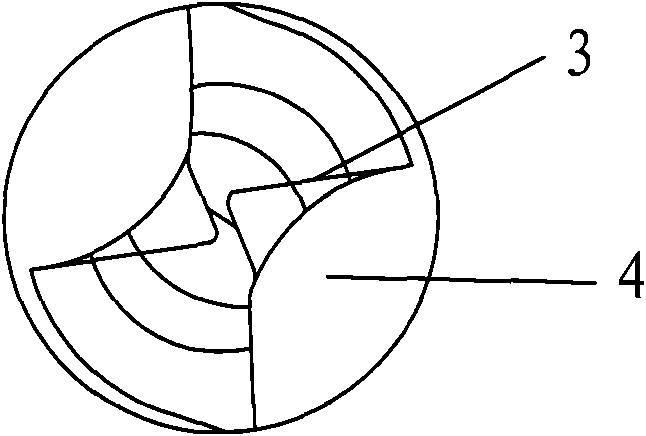

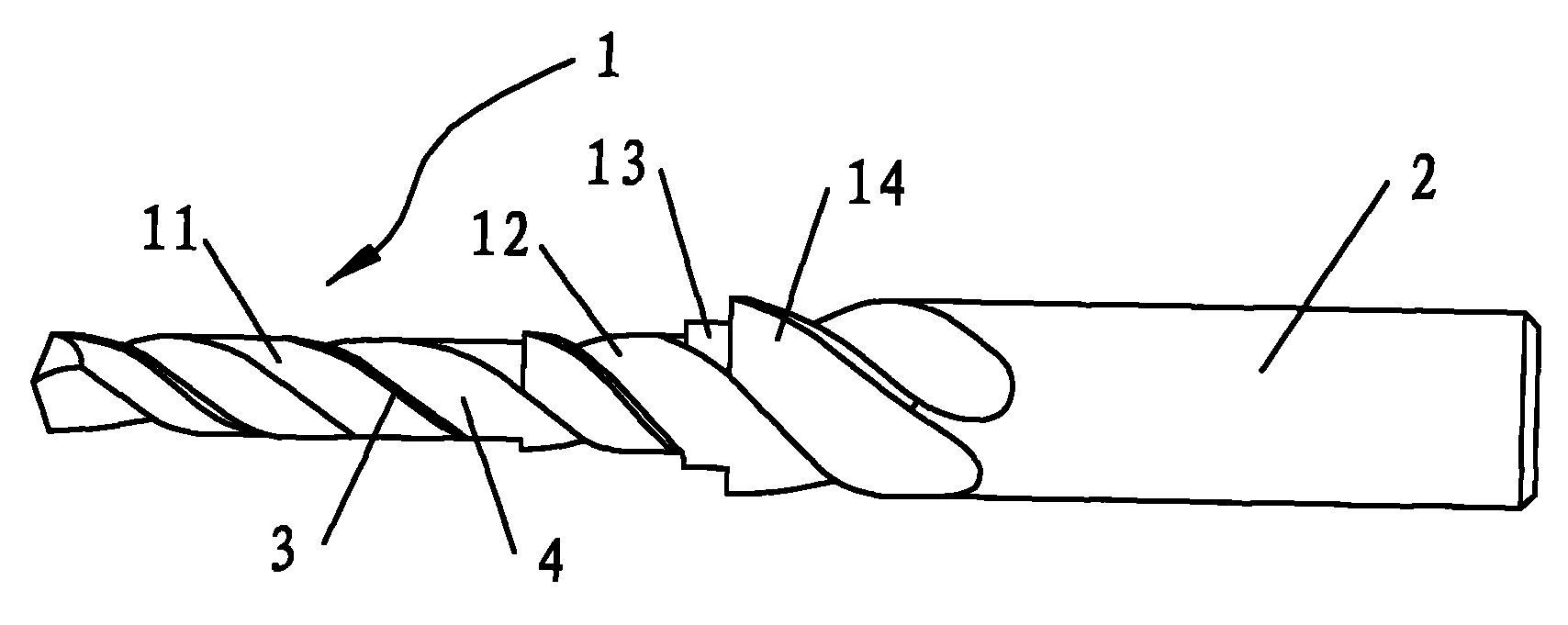

Step drill

InactiveCN101780555AImprove machining accuracyAvoid errorsTransportation and packagingTrepanning drillsEngineeringDrill bit

Owner:苏州富莱克精密工具有限公司

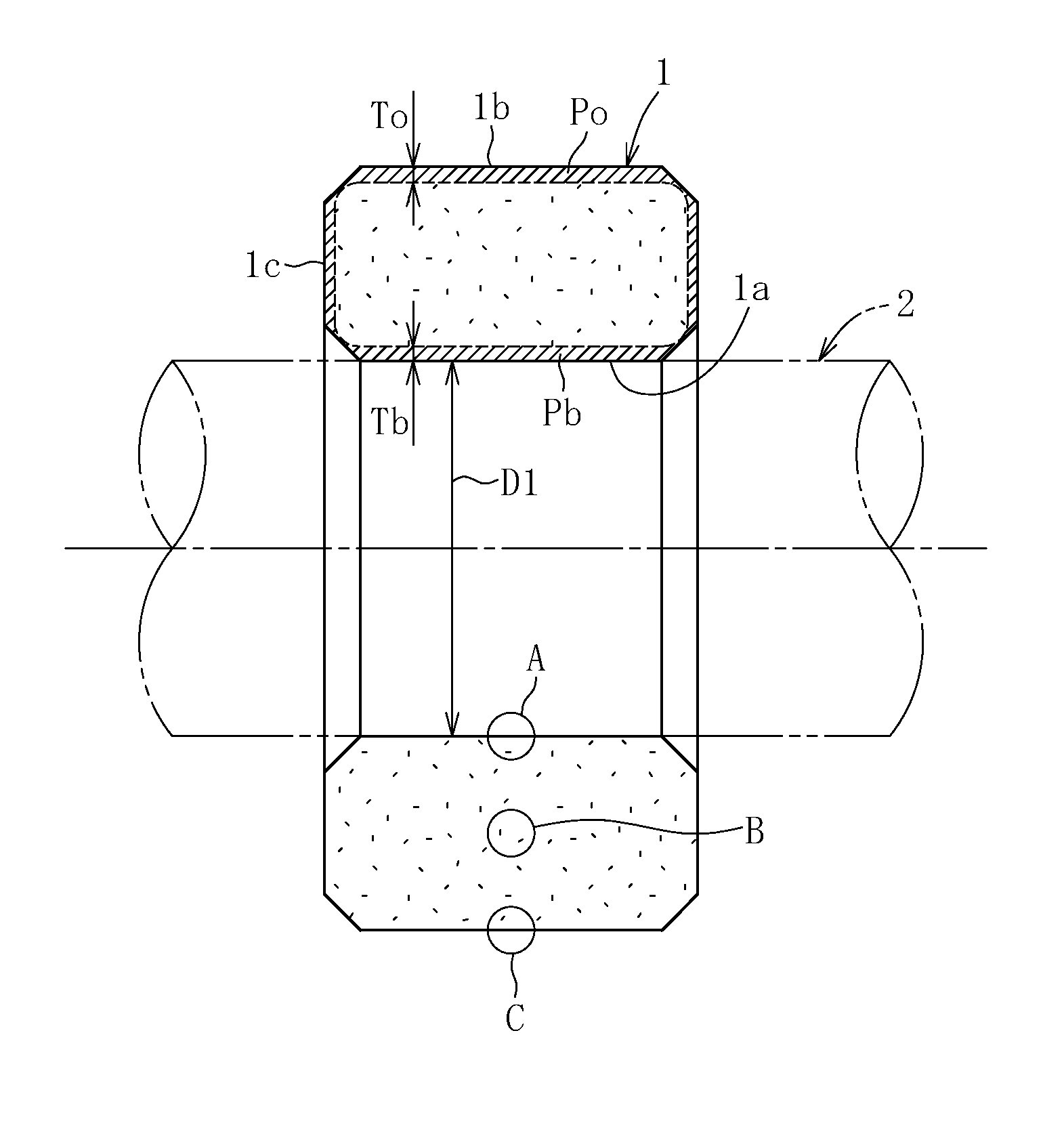

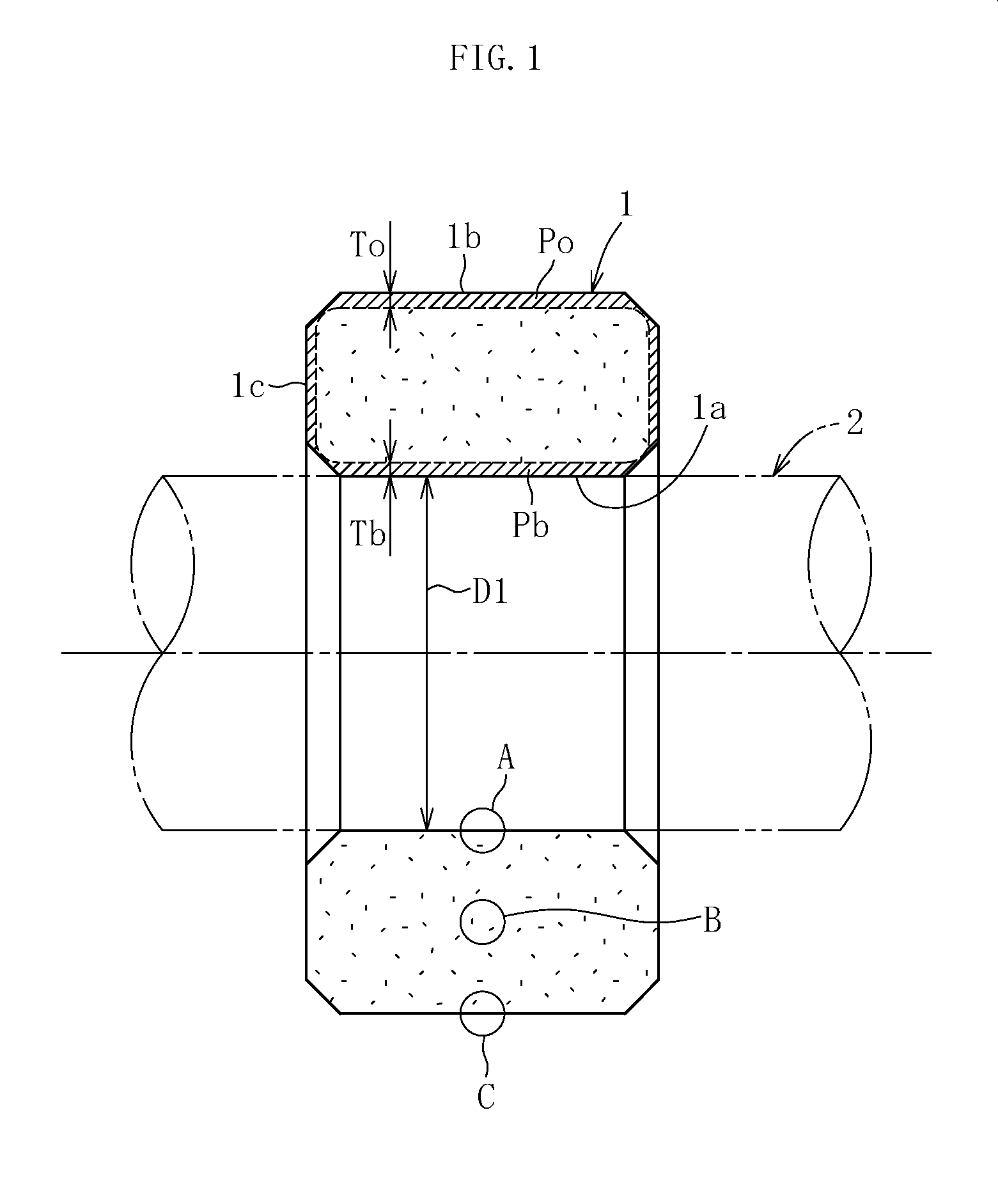

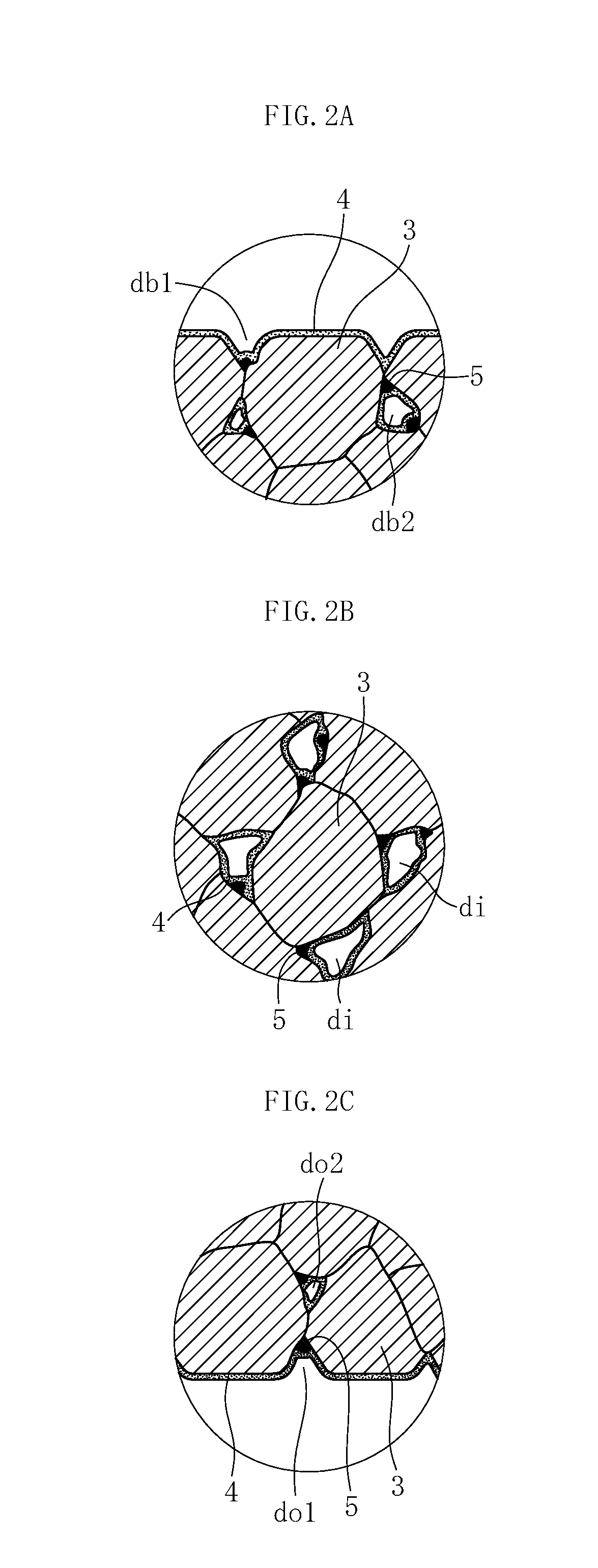

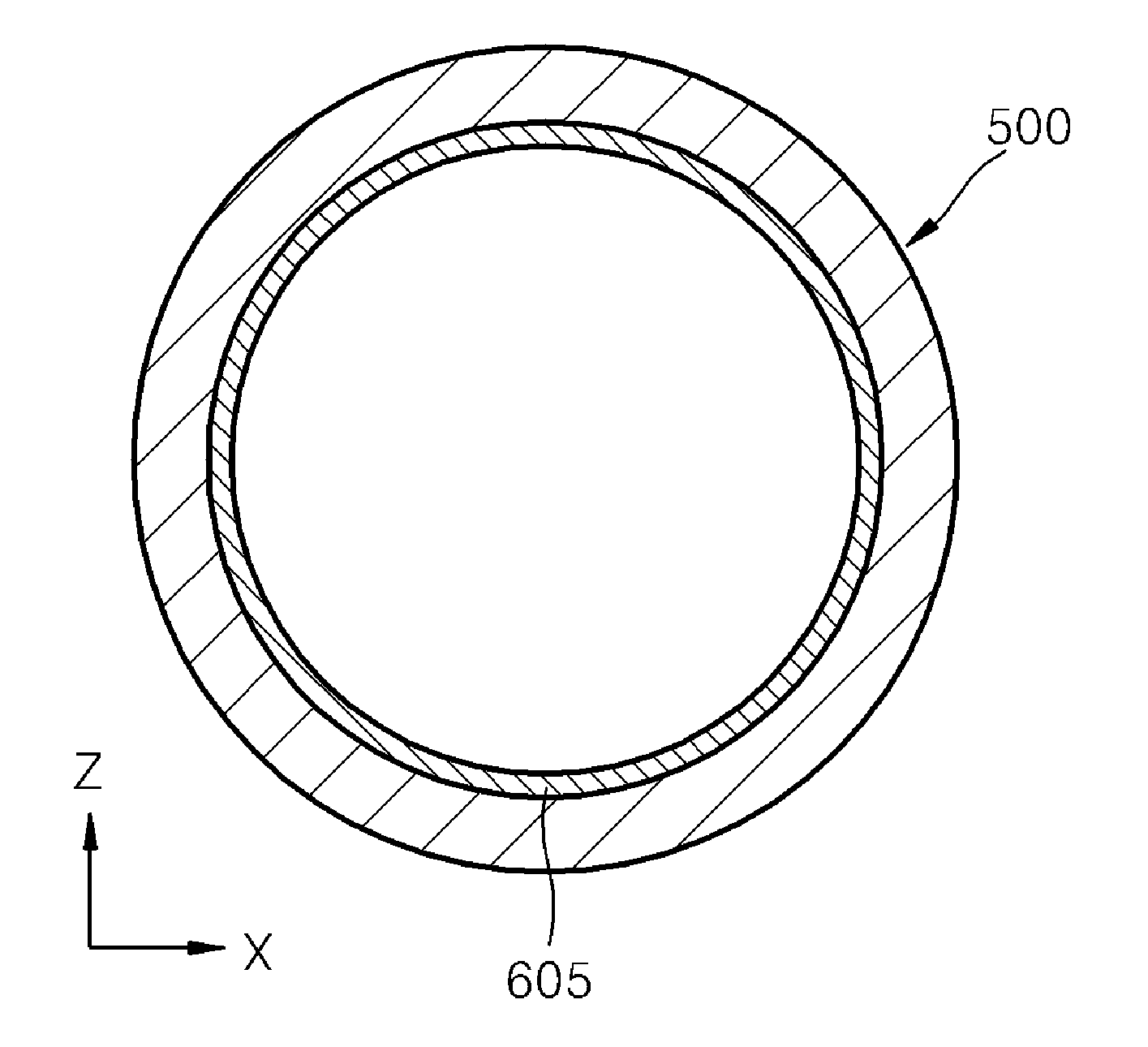

Compact, method for producing compact, reactor, converter, and power conversion device

InactiveUS20130322135A1Efficient productionTotal current dropTransportation and packagingInorganic material magnetismMetallurgyIrradiation

A low-loss compact and a method for producing the compact are provided.A method for producing a compact by using coated soft magnetic powder that includes coated soft magnetic particles constituted by soft magnetic particles and insulating coatings coating outer peripheries of the soft magnetic particles includes a raw material preparation step and an irradiation step. In the raw material preparation step, a raw compact is prepared by press-forming coated soft magnetic powder. In the irradiation step, part of a surface of the raw compact is irradiated with a laser. Irradiating a part of a surface of a raw compact with laser increases the number of disrupted portions of conductive portions where constituent materials of the soft magnetic particles at the surface of the raw compact have become conductive to each other, and the loss of the compact can be decreased.

Owner:SUMITOMO ELECTRIC IND LTD +1

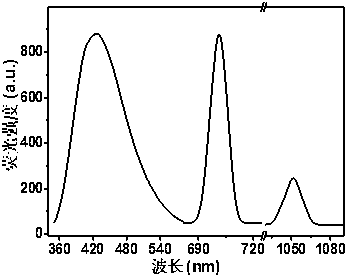

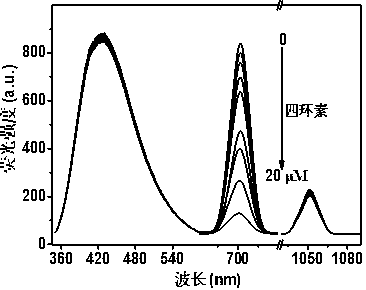

Preparation of fluorogold nano-clusters and application of fluorogold nano-clusters to tetracycline and copper fluorescent probes

PendingCN108760700AFluorescence intensity does not affectReduce distractionsMaterial nanotechnologyTransportation and packagingUltravioletQuenching

Owner:云南健牛环境监测有限公司

Simple and convenient synthesis method and application of waste grease based polyhydric alcohol

InactiveCN104262561ALow costSolve pollutionFatty acid esterificationPolyureas/polyurethane adhesivesTransesterification reactionAlcohol products

Owner:ZHEJIANG HENGFENG NEW MATERIAL

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

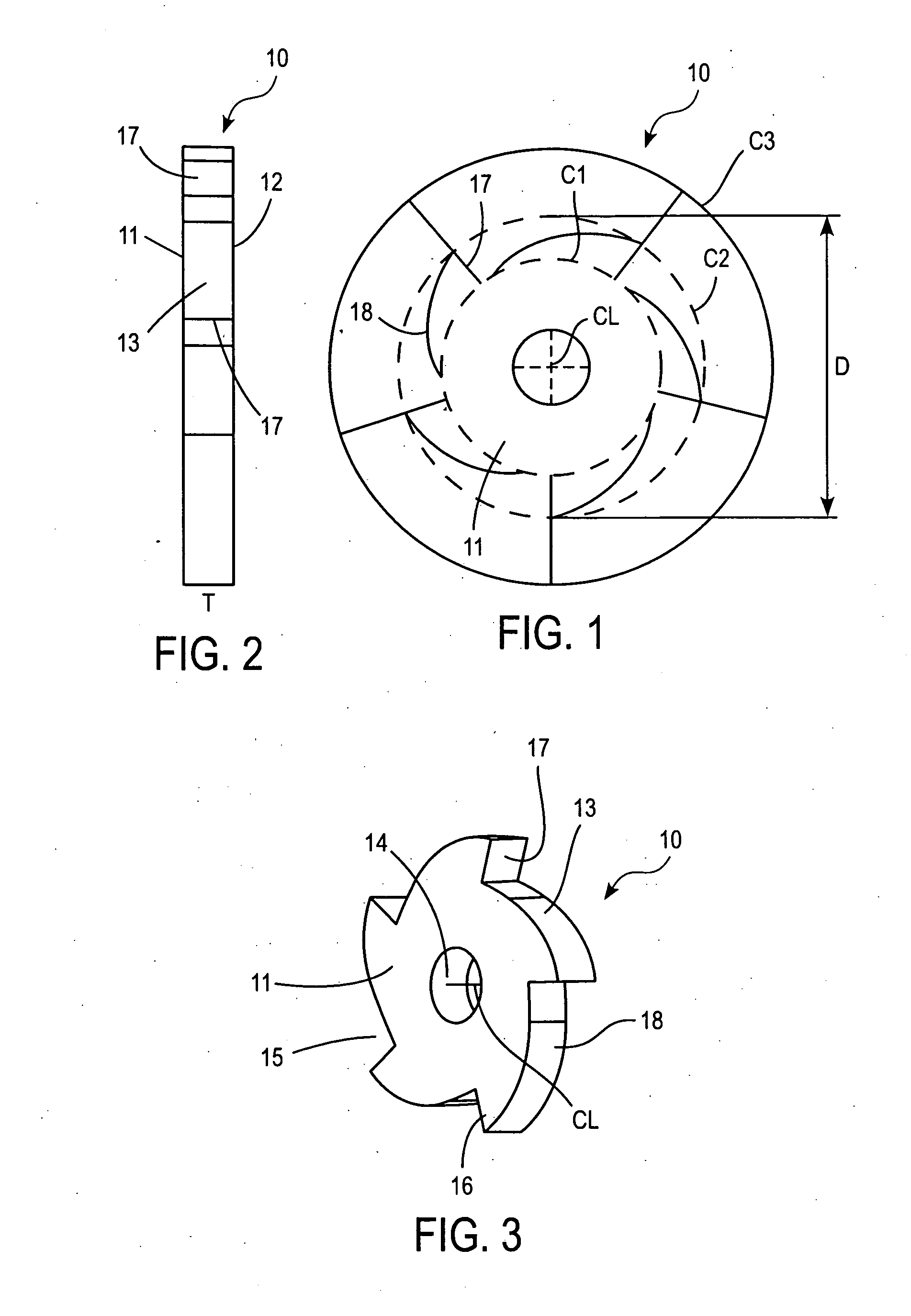

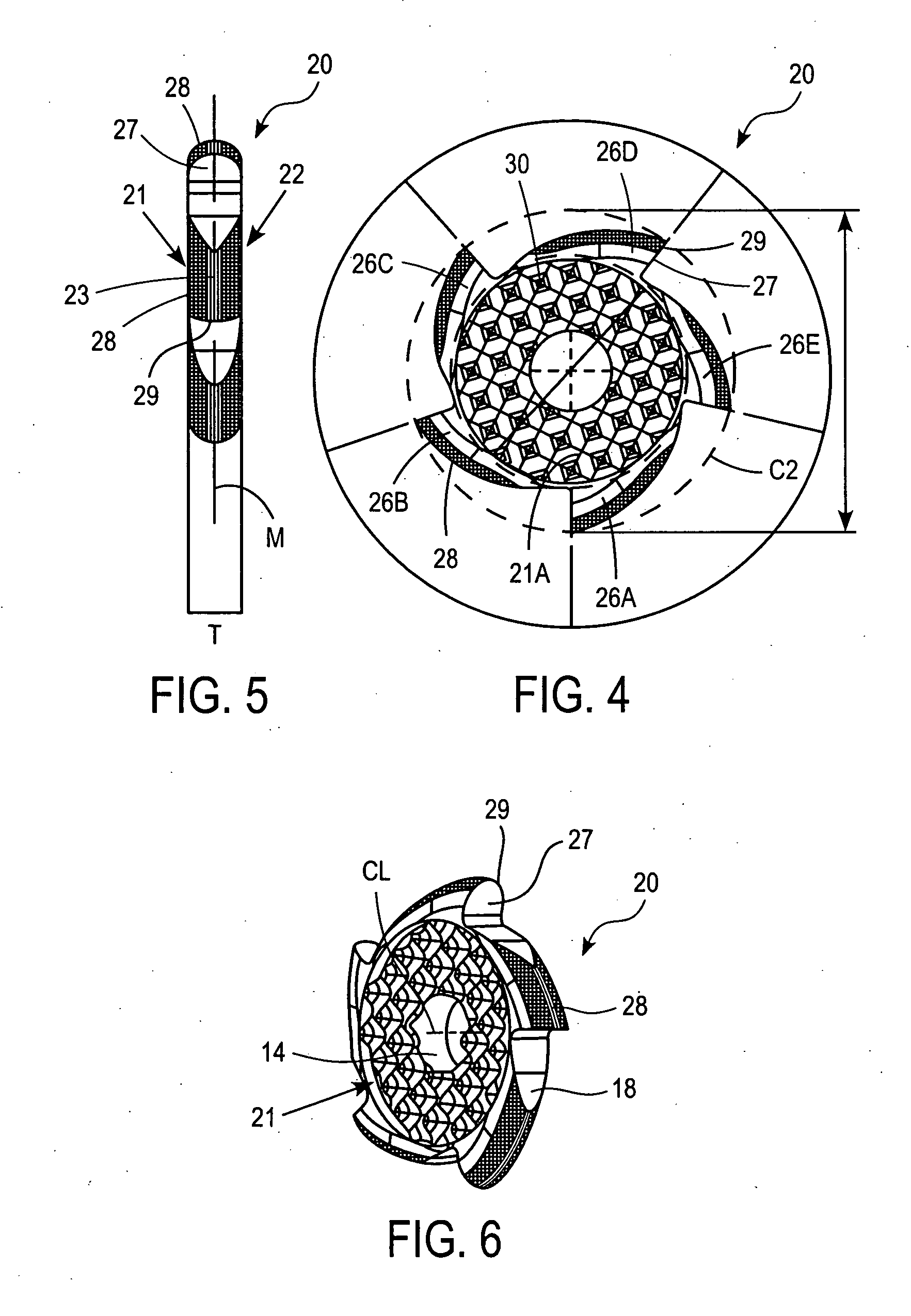

Milling insert and a milling insert tool for chip removing machining

InactiveUS20080118313A1Avoid problemsThread cutting toolsThread cutting machinesEngineeringBoron nitride

Owner:SECO TOOLS AB

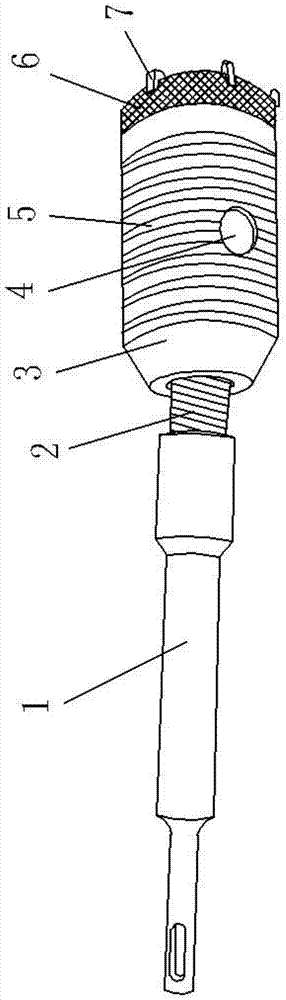

Drill bit of hollow drill and manufacturing method thereof

InactiveCN103752907AAnti-corrosionWith cleanTransportation and packagingTool adaptersWear resistantDrill bit

Owner:宁波神钻工具有限公司

Sintered bearing and manufacturing method for same

InactiveUS20150064045A1Increase production capacityLow costTransportation and packagingShaftsAluminiumSurface layer

Owner:NTN CORP

Disposable cutting insert for boring cutter

A disposable cutting insert for a boring cutter can reduce the roughness of a cut surface and achieve a mirror-like surface effect. The disposable cutting insert has a long curved blade edge, and the radius vertex of the long blade edge is deviated slightly from an external side of a vertex of the radius of cutting edge. A short curved blade edge is formed between the radius arc vertex and the radius arc vertex of the cutting edge. The vertical distance of the short curved blade edge is greater than the feed rate. The cutting edge cuts the work piece and the short curved blade edge can scrape a small size of material precisely for scraping the peak cut by the cutting edge and lower the height of the peak, so as to lower the surface roughness, and produce a mirror-like surface for an internal periphery of a bored hole.

Owner:CHANG SC

Feed processing dryer capable of stirring in positive and negative rotation mode

InactiveCN107280051AEasy to storeSmooth and safe deliveryFeeding-stuffRotary stirring mixersDrive shaftEngineering

Owner:王淑兰

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS20140096858A1High hardnessLow melting pointHeat treatmentsLiquid surface applicatorsPowder mixtureAlloy

Owner:KMT CO LTD

Movable type wall coating spraying device

InactiveCN107842183AAvoid layeringPrevent precipitationRotary stirring mixersTransportation and packagingAgricultural engineeringMovable type

Owner:蒋丹丹

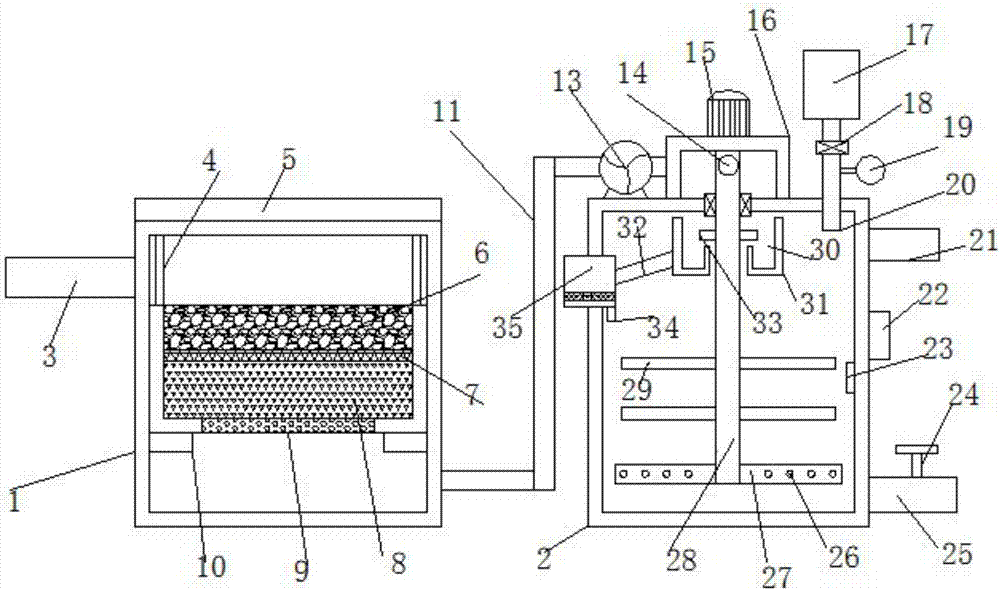

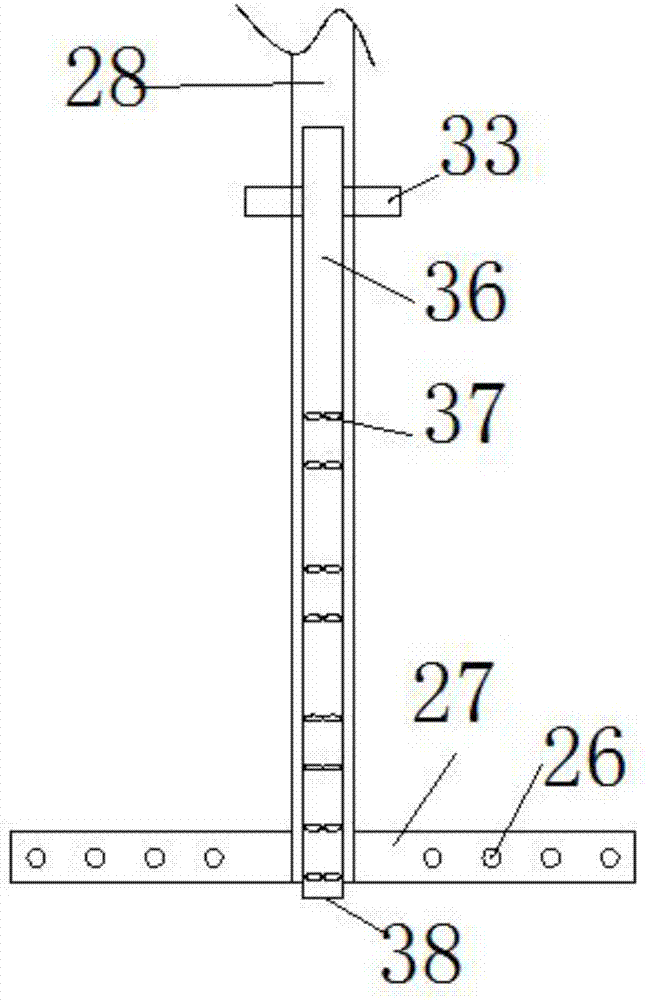

Compound filter element capable of being repeatedly used under microwave conditions and preparing method and activating method of compound filter element

ActiveCN110203993ADispersed particle filtrationSpecific water treatment objectivesActivated carbonMicrowave

The invention discloses a compound filter element capable of being repeatedly used under microwave conditions and a preparing method and activating method of the compound filter element. The compoundfilter element comprises an element body shell, an element body inner wall, activated carbon filler and element body partition plates. The element body partition plates are arranged at the two ends ofeach section of activated carbon filler respectively. The element body shell and the element body inner wall are each of a micro-pore structure. The element body partition plates are each of a porousstructure. The material of the element body shell has the ceramic-level strength and sealing performance and has the characteristics of high temperature resistance and corrosion resistance; meanwhile, microwaves can penetrate through the element body shell and can act on the element body inner wall and the element body partition plates; the element body inner wall can reach the process temperature required for microwave-activation of the filter element; the material of the element body partition plates is rapidly heated under the microwave conditions and has the advantages of being resistantto high temperature, thermal shock and corrosion and having the micro-pore structure; the compound filter element has the advantages of being repeatedly used, high in element body strength, high in thermal shock resistance, resistant to acid and alkali corrosion and resistant to high temperature.

Owner:WUHU YIYI PRECISION MASCH CO LTD

Magnetic Suspension Type Water Adding Device and Air Humidifier

ActiveUS20180195747A1Reasonable structureEasy to useOperating means/releasing devices for valvesLighting and heating apparatusPower flowElectric generator

Owner:AIRPPLE ELECTRONICS TECH XIAMEN

Ship waste gas desulfuration device and method

ActiveCN107998761AImprove the mixing effectFully purifiedGas treatmentDispersed particle filtrationActivated carbonMixing effect

Owner:唐山伟德船用设备有限公司

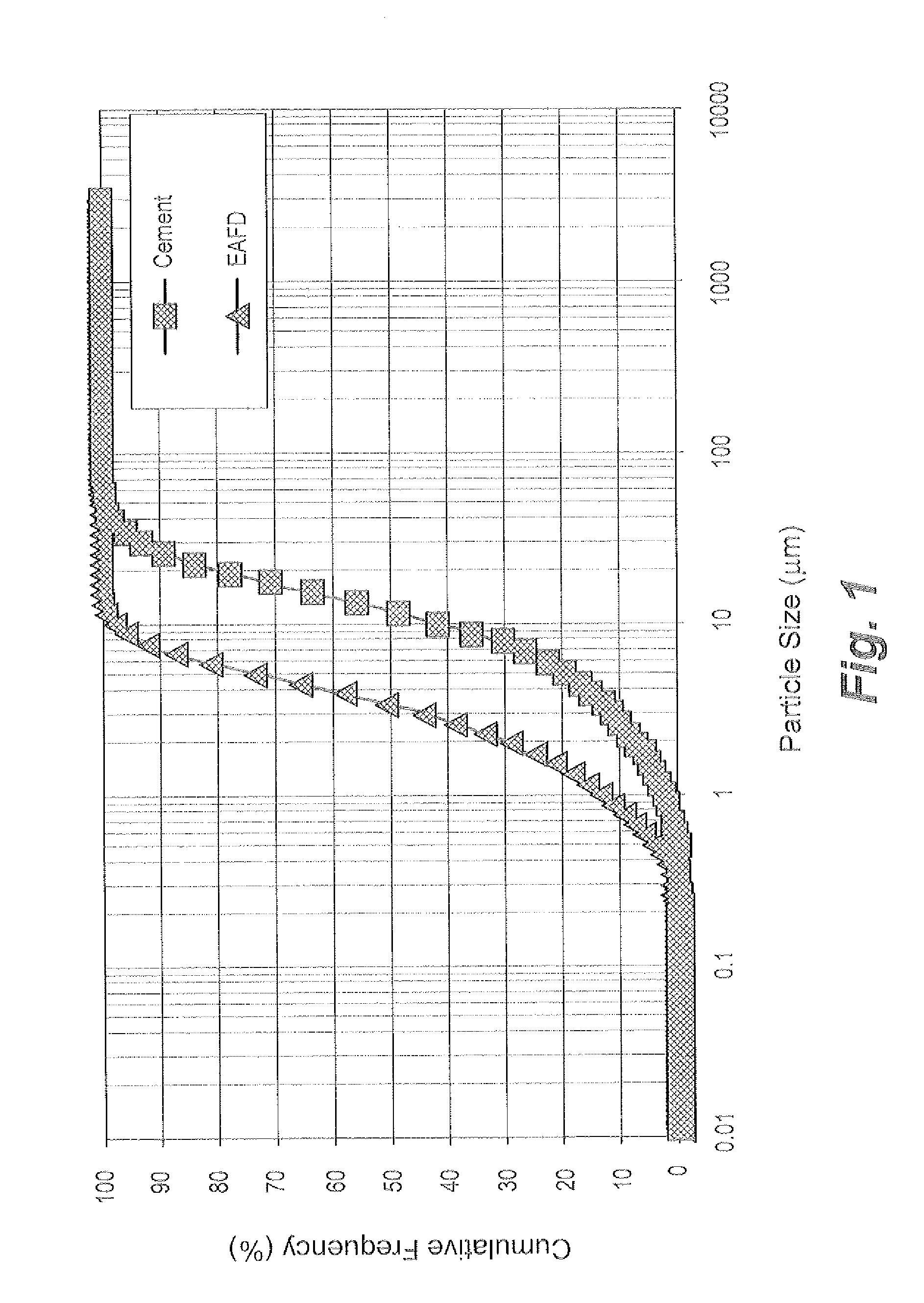

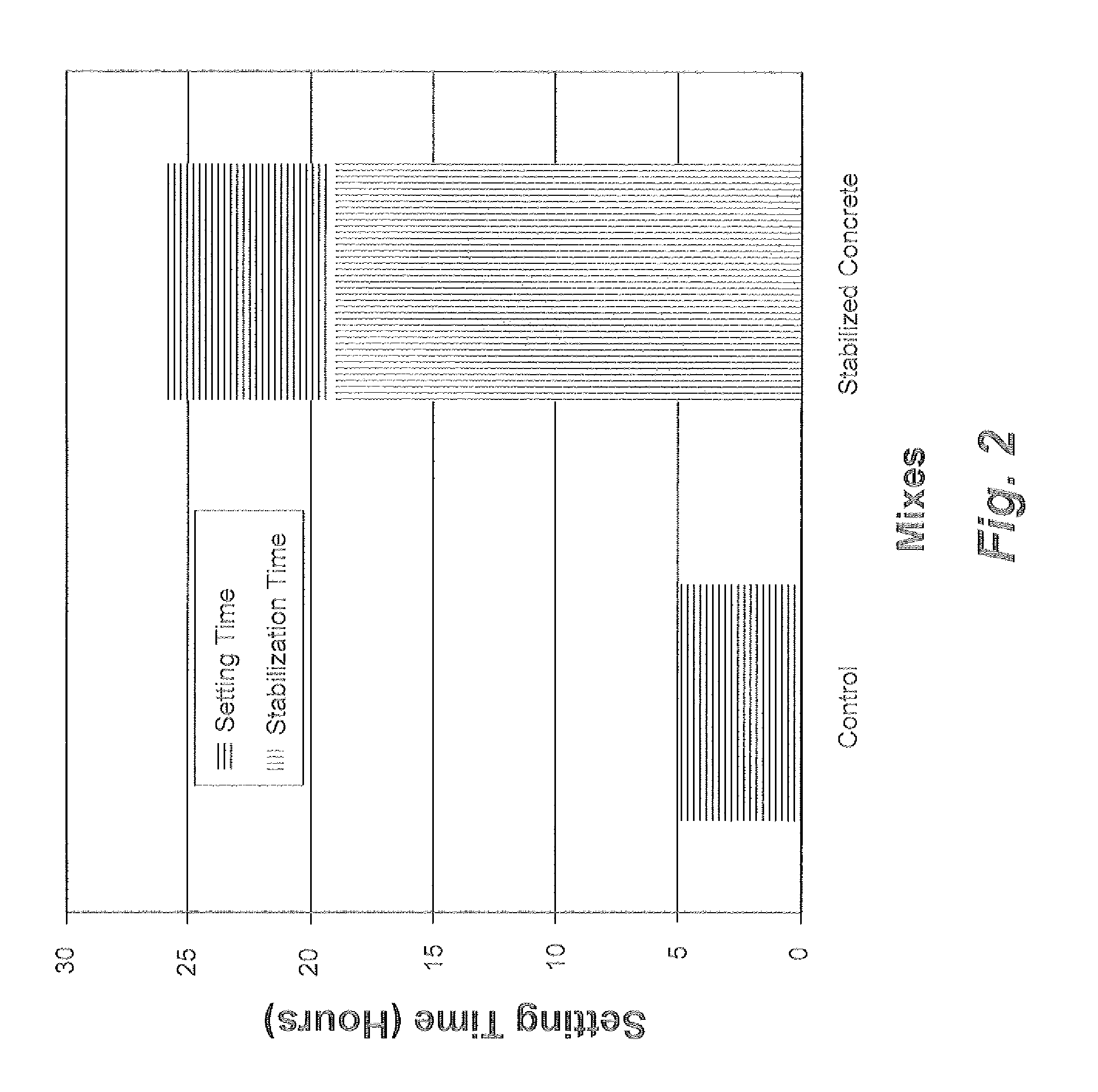

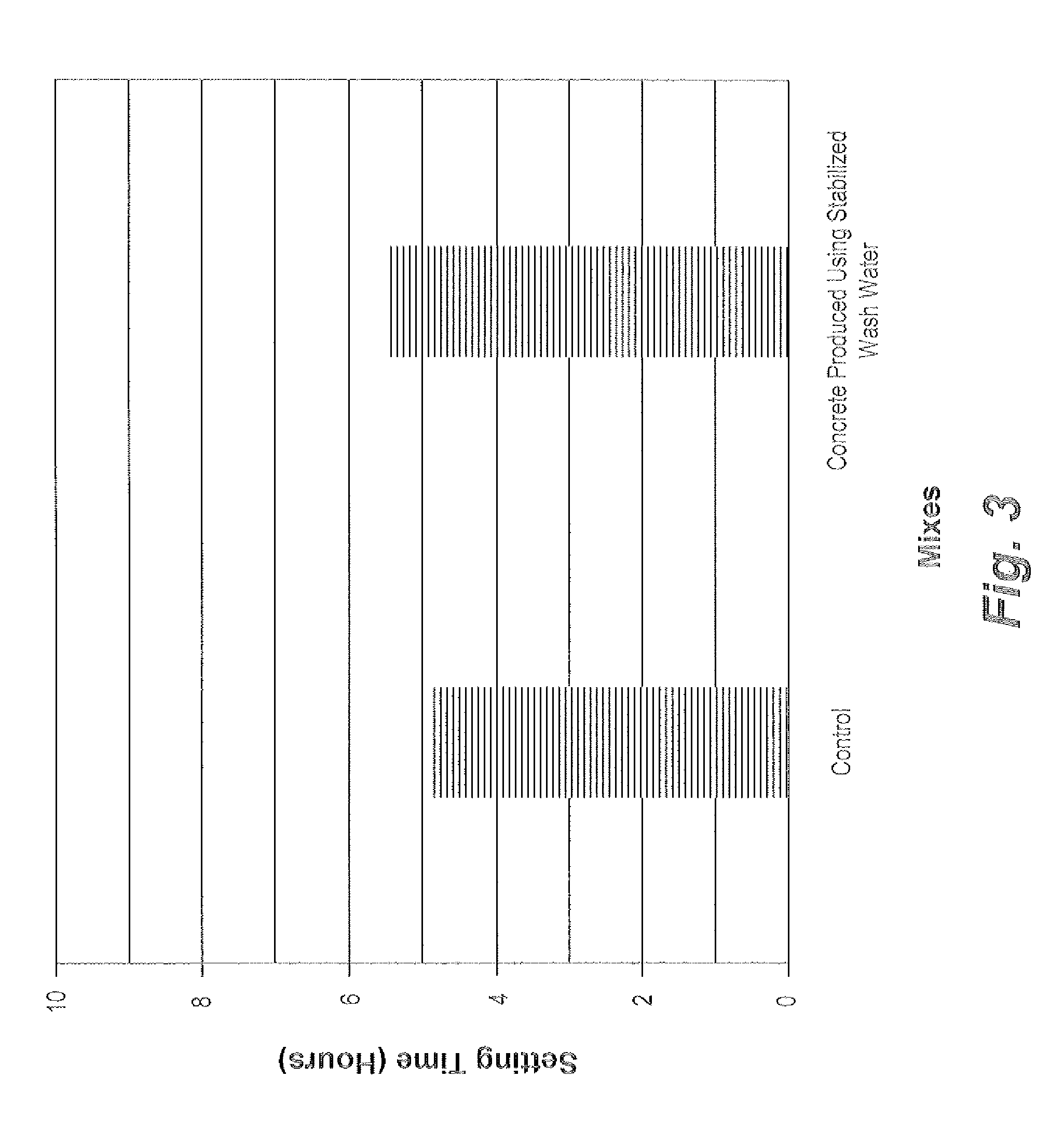

Eafd stabilizer for returned concrete and mixer drum wash water

ActiveUS20120049399A1Readily apparentSolid waste managementTransportation and packagingStabilizing AgentsMaterials science

Owner:KING SAUD UNIVERSITY

Mixing equipment for coating preparation and use method of mixing equipment

InactiveCN107413233AImprove processing speedImprove mix qualityRotary stirring mixersTransportation and packagingDrive shaftProcess engineering

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap