Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Mixing chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High energyEfficient mixingMixing/kneading structural elementsFlow mixersSpray nozzleImpact area

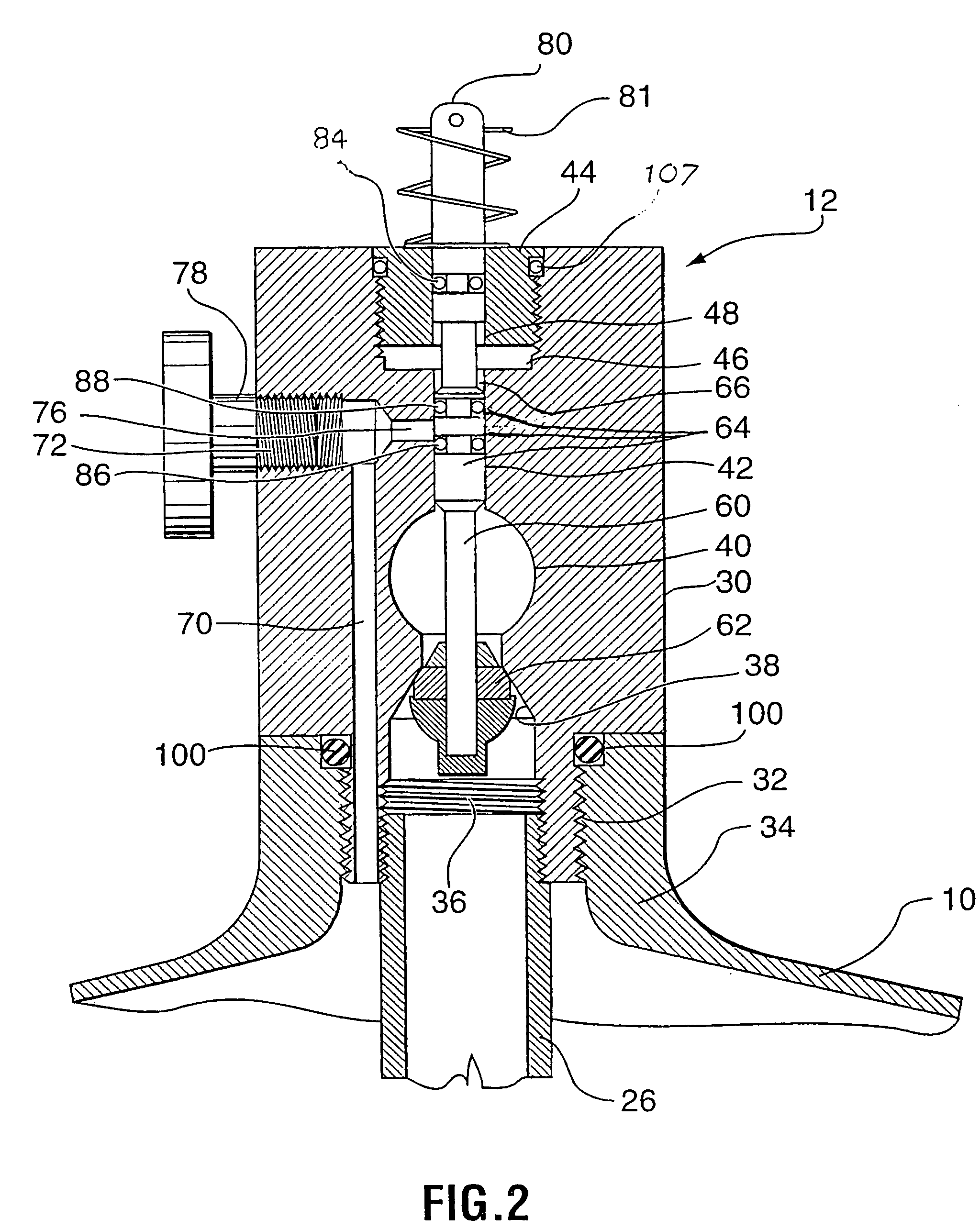

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE GMBH & CO KG

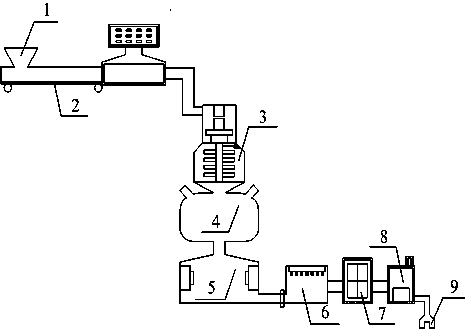

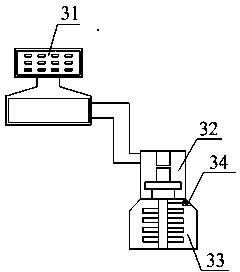

Production equipment of autoclaved aerated concrete blocks

InactiveCN104842446AHigh precisionHigh viscosityMixing operation control apparatusCeramic shaping plantsSlurryMechanical engineering

Owner:HANCHUAN XINXIN TECH

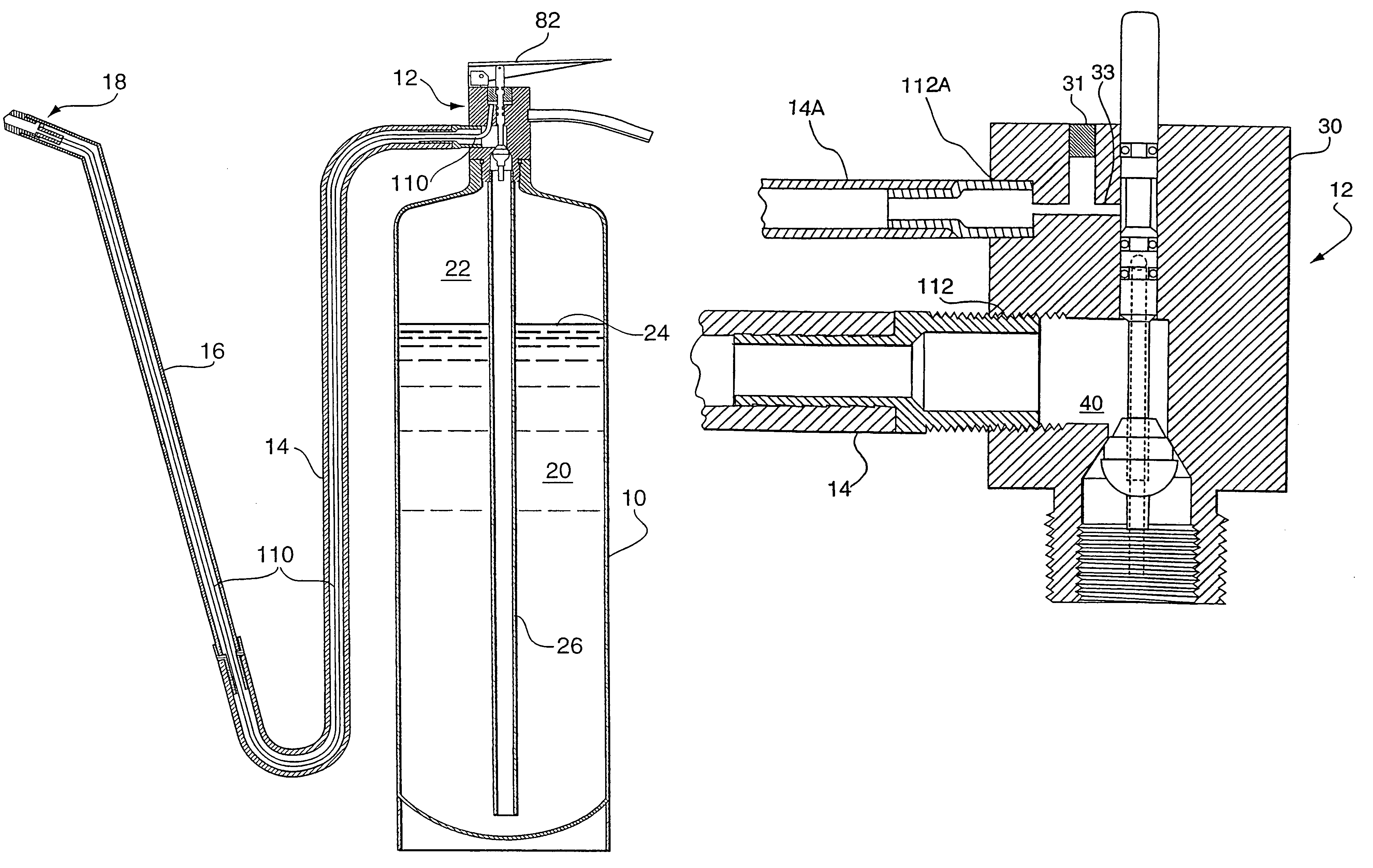

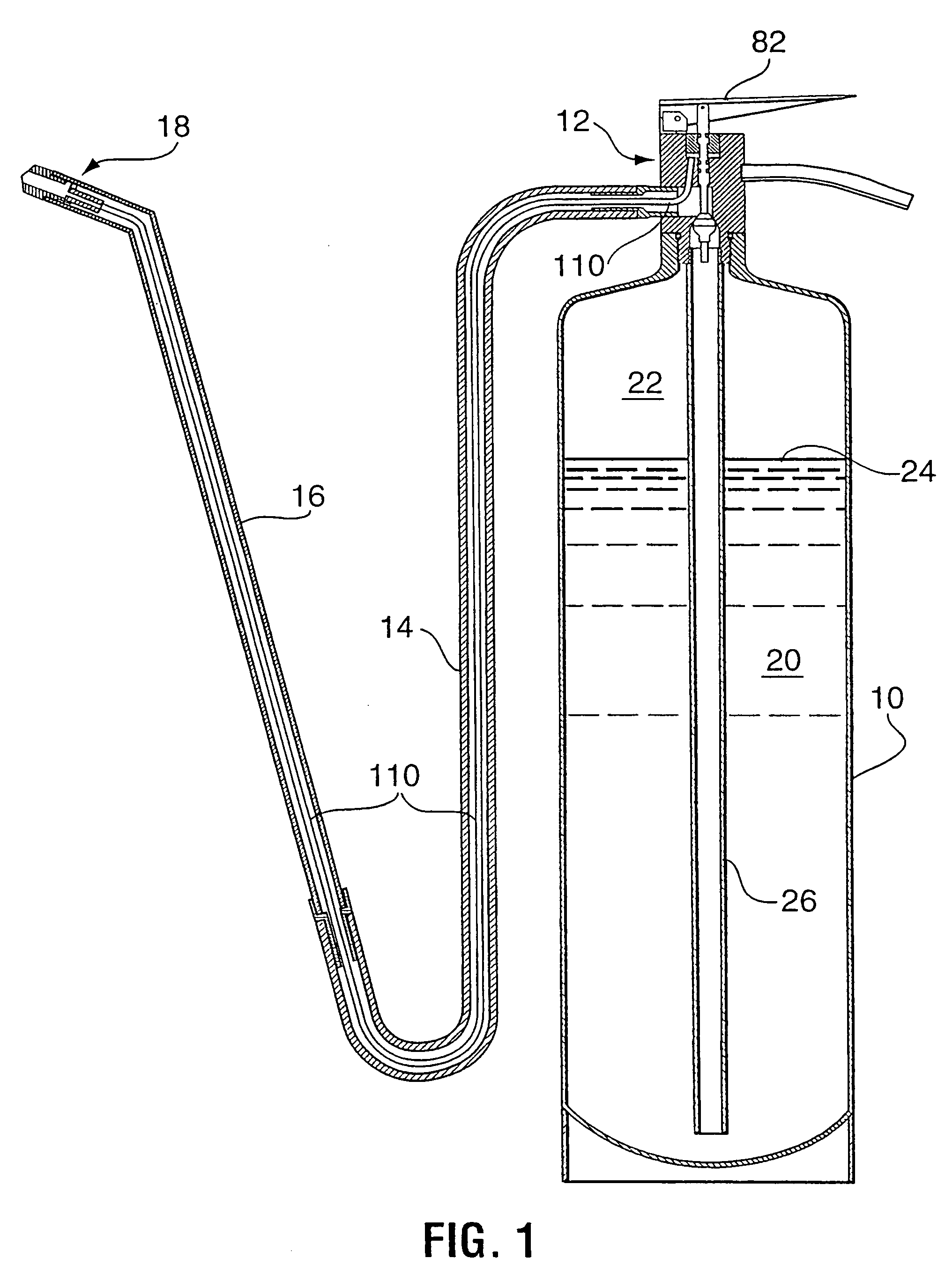

Liquid mist fire extinguisher

Owner:HOPKINS GORDON DUANE

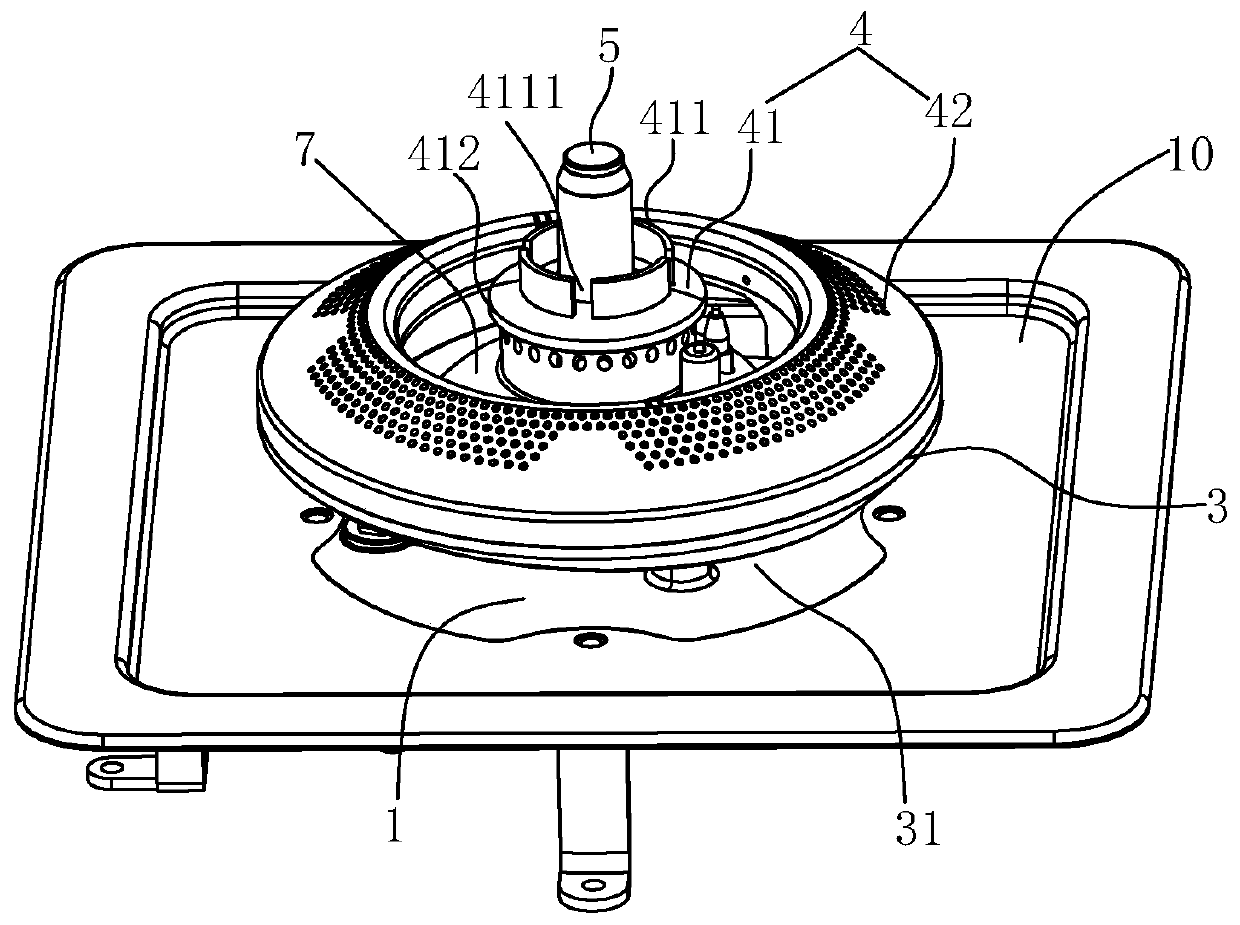

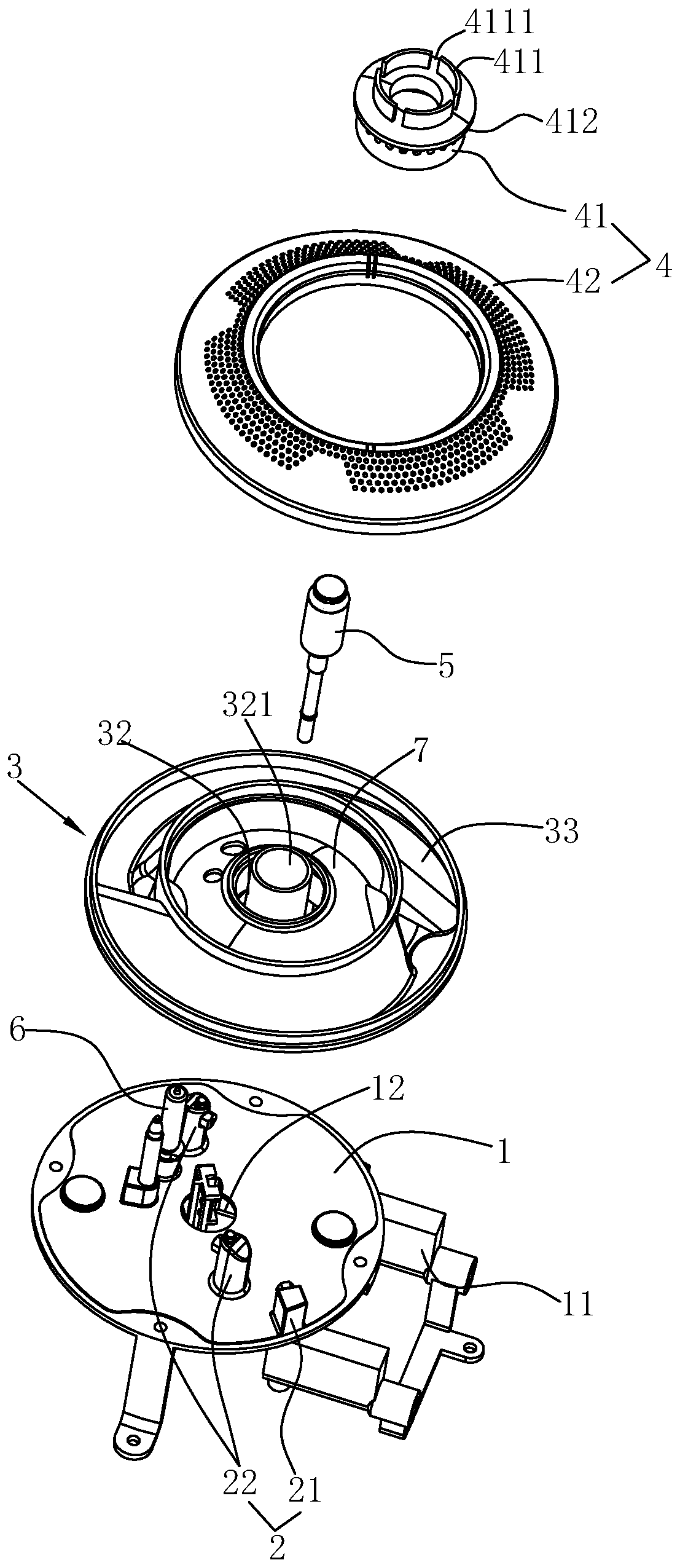

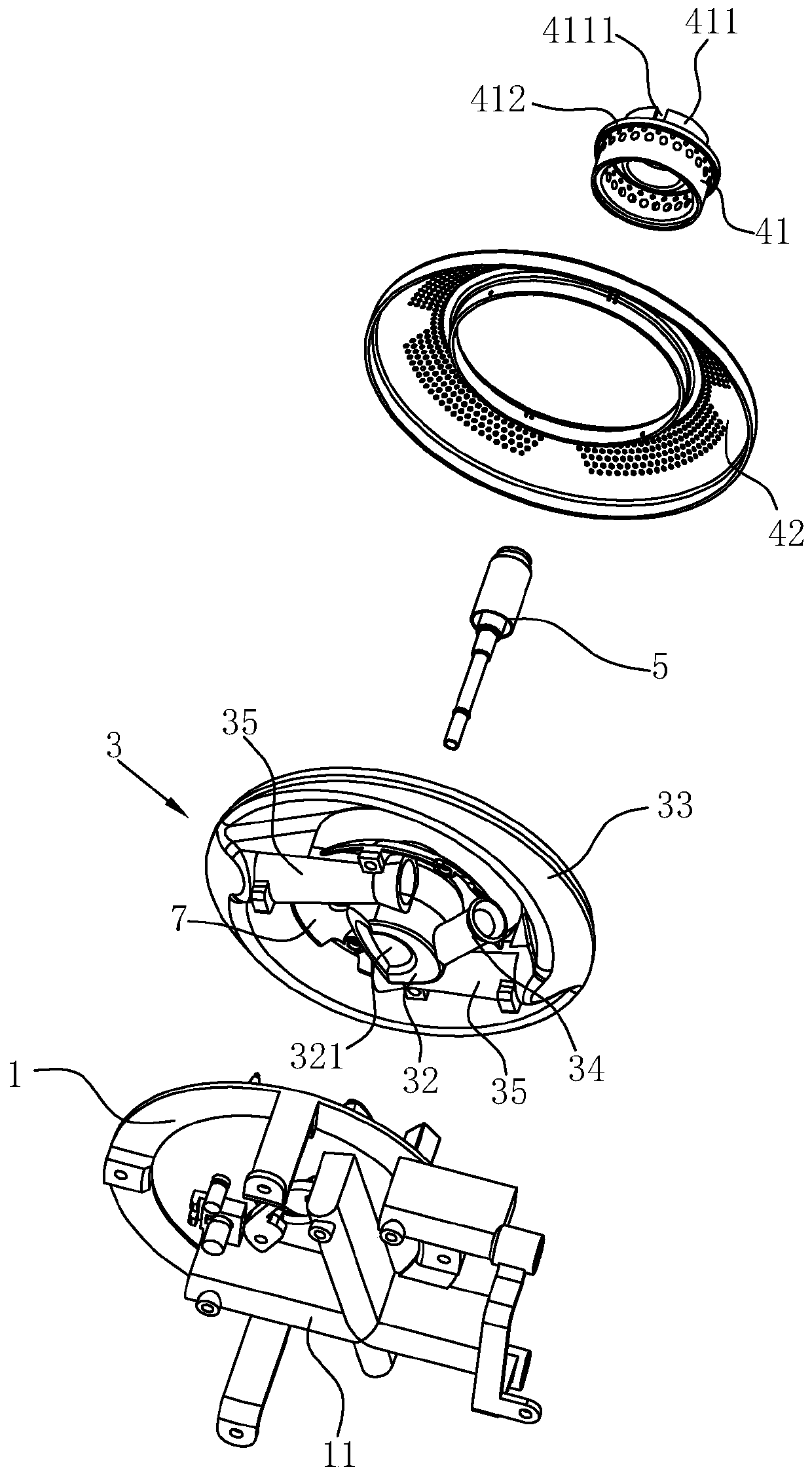

Upper-air-intake dual-ring combustor

PendingCN111486456AReduce the effect of temperature riseImprove temperature measurement accuracyDomestic stoves or rangesCooking fumes removalCombustorEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

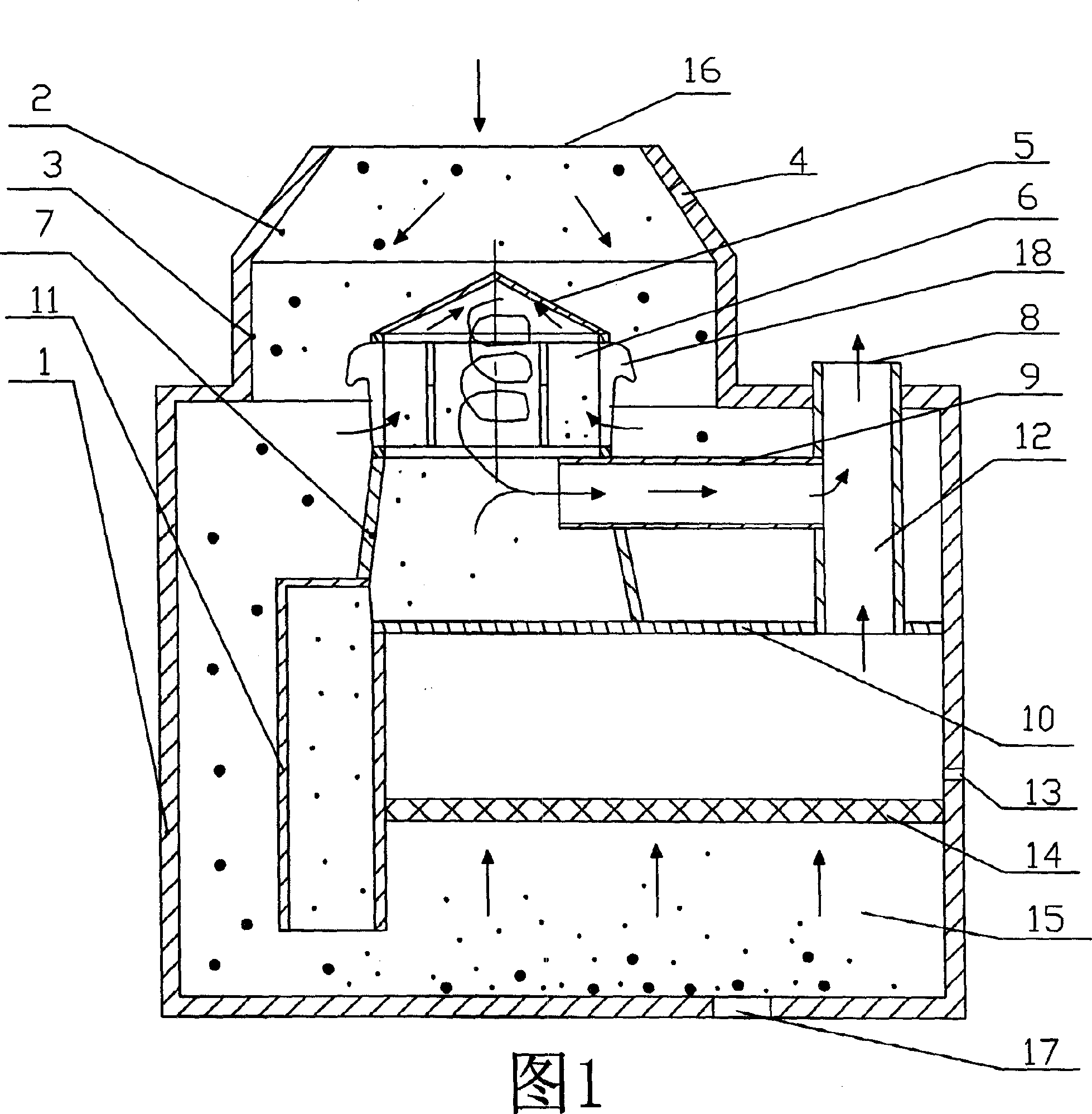

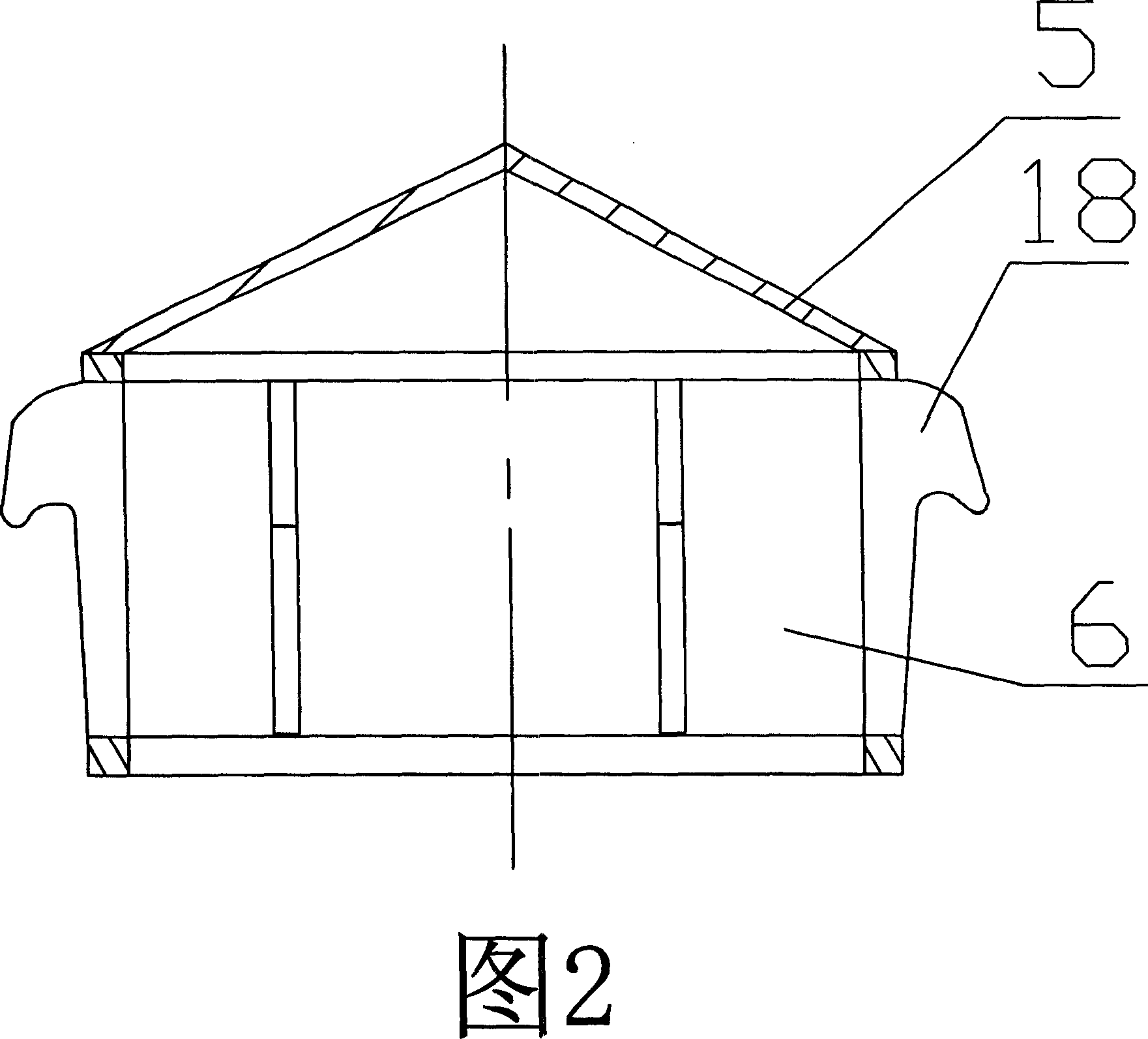

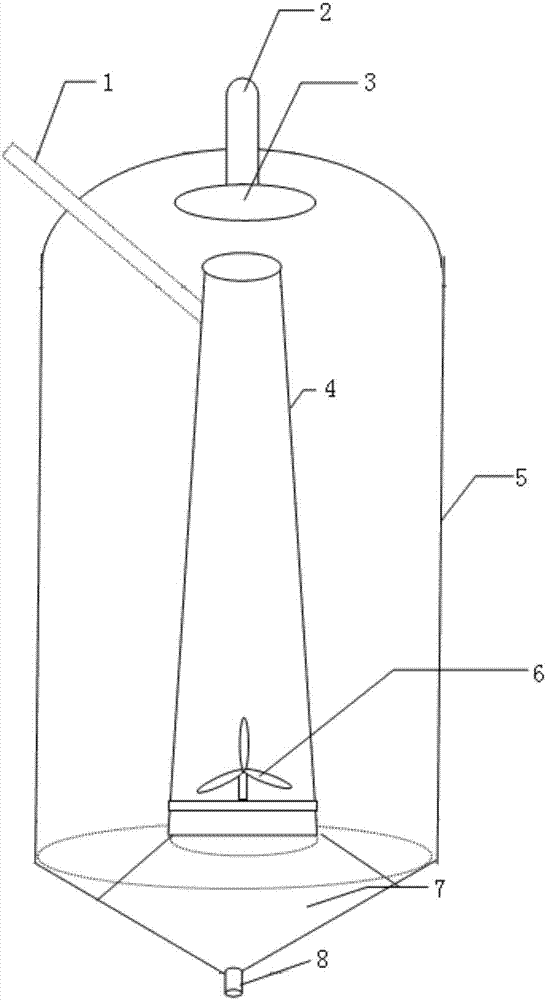

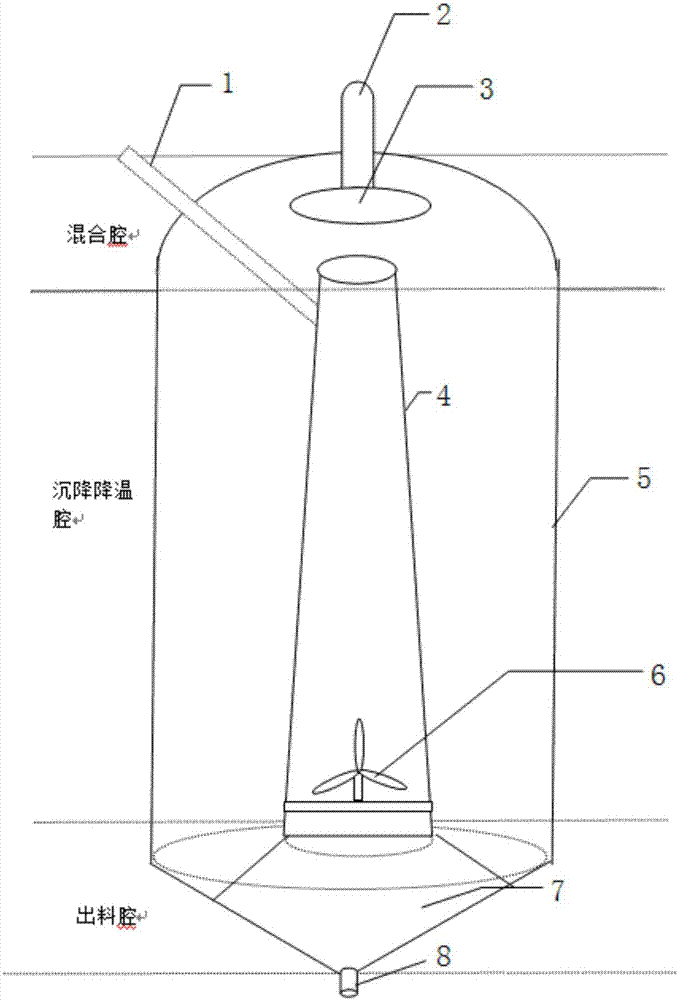

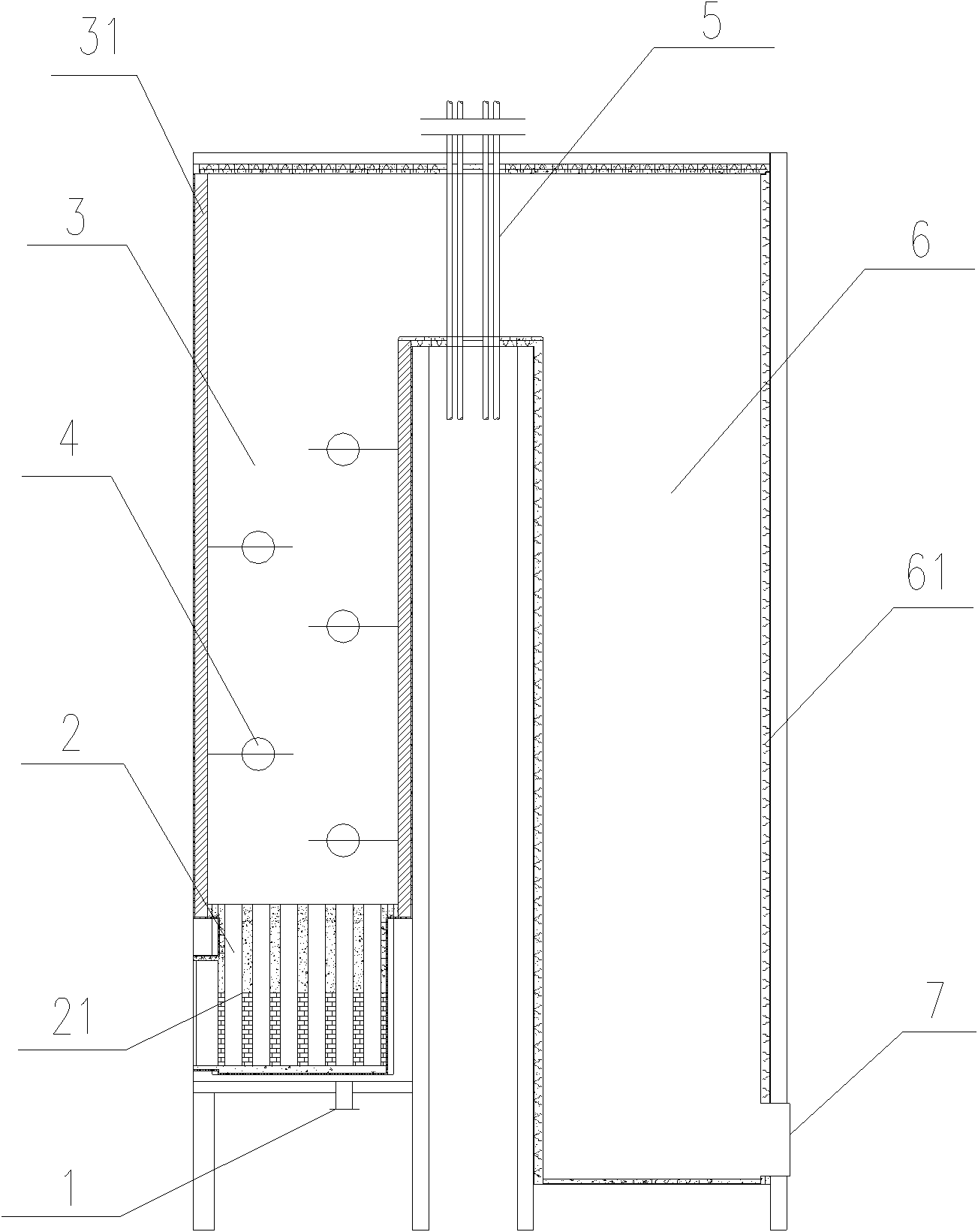

High-efficiency and low-energy-consumption sewage treatment equipment

InactiveCN105502685ASimple structureImprove processing efficiencyEnergy based wastewater treatmentWater/sewage treatment by heatingReaction layerSolar light

The invention discloses high-efficiency and low-energy-consumption sewage treatment equipment. The high-efficiency and low-energy-consumption sewage treatment equipment comprises an inlet, a mixing chamber, a reaction tank and an outlet which are communicated in sequence. The mixing chamber is inclined by a certain angle, and the included angle formed between the horizontal edge and the vertical edge of the mixing chamber is 20-30 degrees. A plurality of baffle plates arranged in a staggered mode are arranged inside the mixing chamber to form a bent channel. A reaction layer is arranged inside the reaction tank. A lens layer is arranged at the lower portion of the reaction tank. The height of the lens layer is one tenth that of the reaction tank. Reflection layers are arranged on the outer surface of a tank cover and the outer surfaces of four tank walls of the reaction tank. A black light absorbing layer is arranged on the inner surface of the tank bottom. The lens layer is located above the tank bottom. The high-efficiency and low-energy-consumption sewage treatment equipment is simple and reasonable in structure, and the reaction tank absorbs solar light by means of the special structure, so that the liquid inside the reaction tank achieves circulative convection, the sewage processing efficiency of the high-efficiency and low-energy-consumption sewage treatment equipment is improved, and energy consumption of the high-efficiency and low-energy-consumption sewage treatment equipment is lowered.

Owner:NANJING ZHONGDE ENVIRONMENTAL PROTECTION EQUIP MFG

Device for removing free sulfur trioxide gas in fuming sulfuric acid

InactiveCN106219498AEffective absorptionReduce pollutionSulfur-trioxide/sulfuric-acidOleumSulfur trioxide

The invention relates to the technical field of chemical environmental protection, in particular to a device for removing free sulfur trioxide gas in fuming sulfuric acid. The device is characterized by comprising a suction chamber, a mixing chamber, a diffusion chamber and a fuming sulfuric acid absorption tower which are sequentially connected from top to bottom, wherein the upper end of the suction chamber is respectively connected with a fuming sulfuric acid storage tank and the top of an acid trailer of the fuming sulfuric acid; a sulfuric acid nozzle is arranged in the suction chamber. The device is capable of effectively absorbing the free SO3 gas, is simple in operation, improves the absorption efficiency, saves investment and reduces environmental pollution.

Owner:JINCHUAN GRP CO LTD

Wet nanometer grade vortex dust-removing device and dust removing method

InactiveCN101007233AAchieve the ideal effect of dust removal and gas purificationGood dust removalHuman health protectionCombination devicesLiquid smokeUltra fine

Owner:董俊 +1

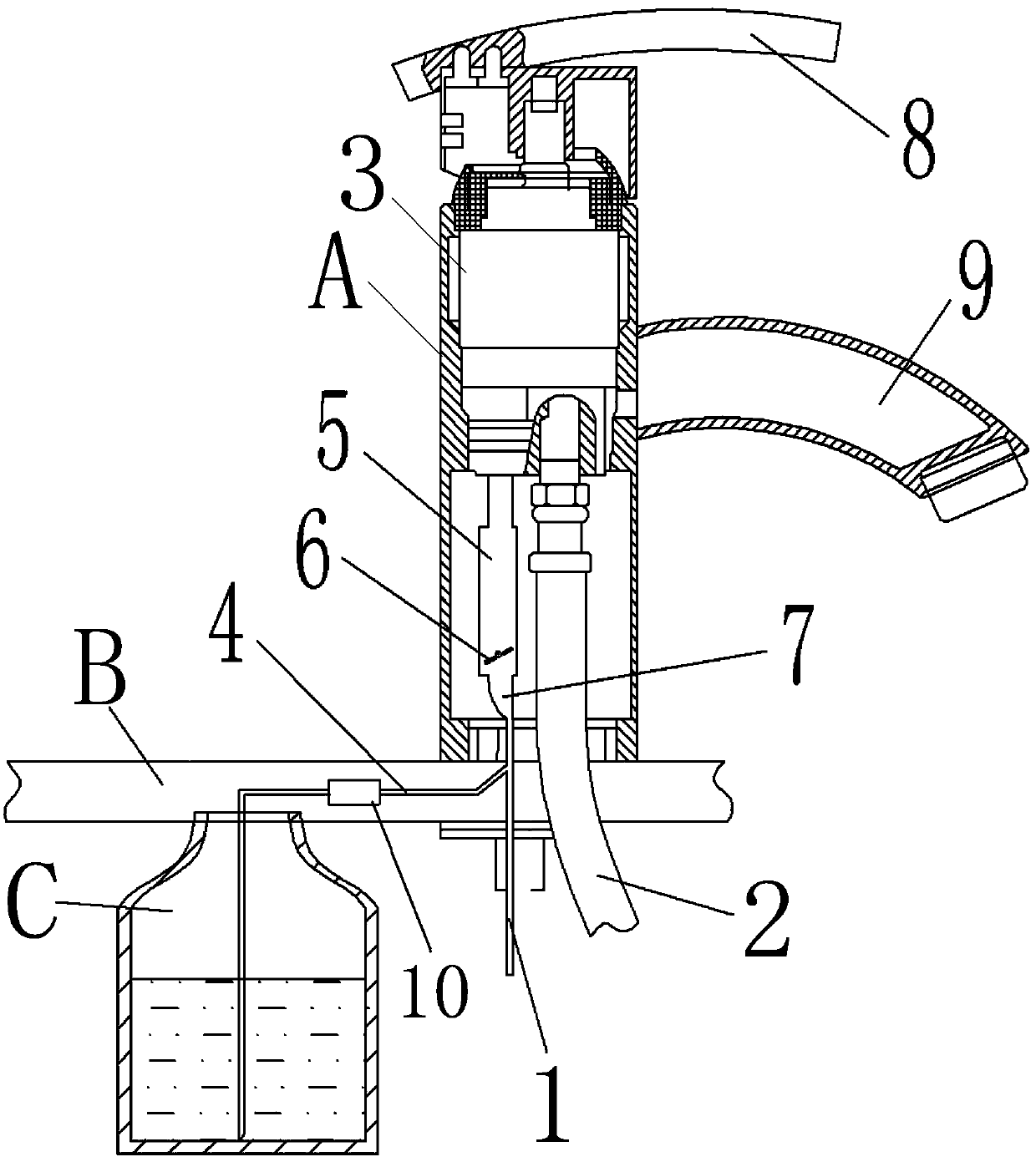

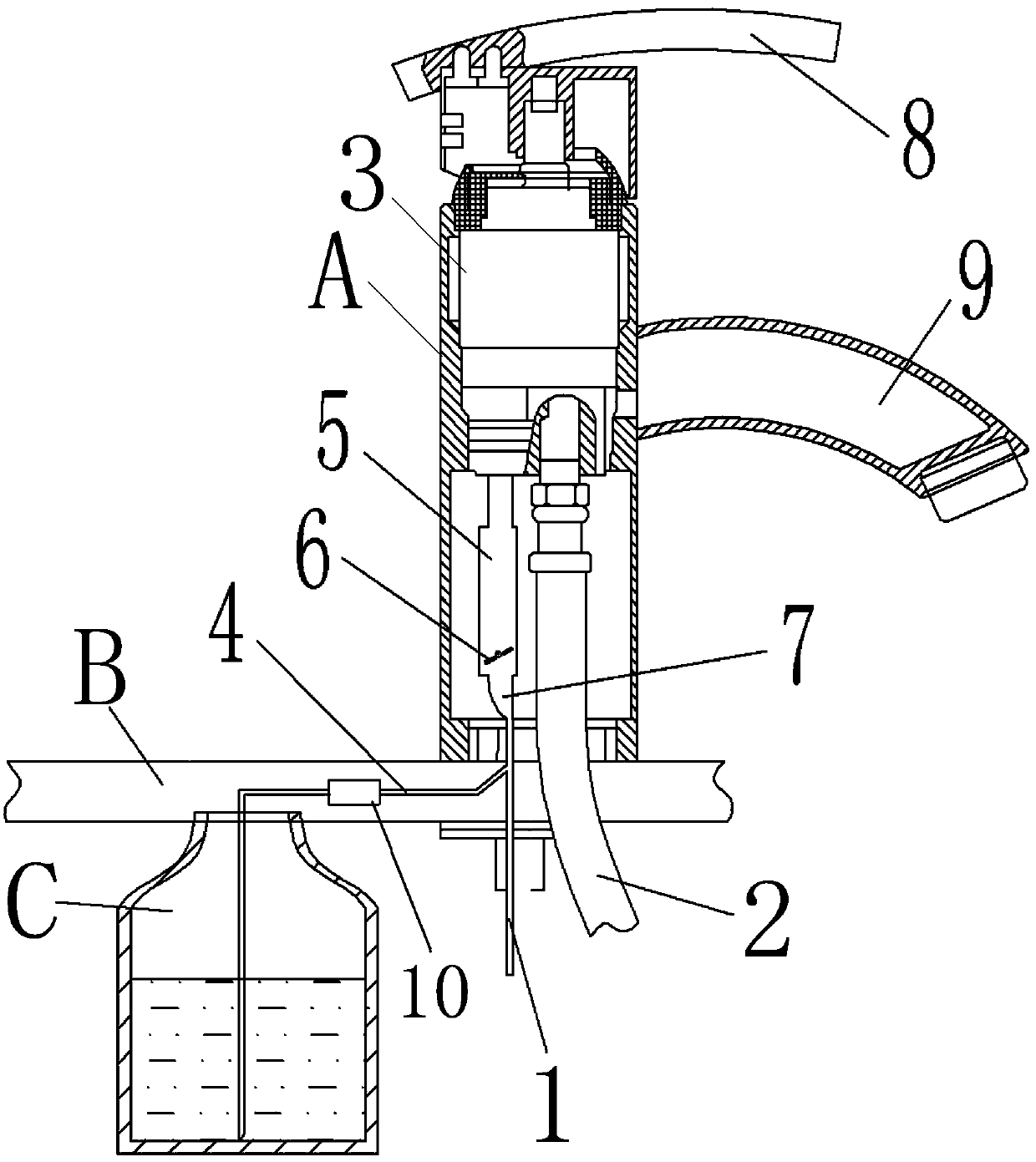

Liquid mixing faucet

ActiveCN109973680ANormal cleaningReduce concentrationDomestic plumbingMultiple way valvesWater flowEngineering

Owner:TAIZHOU SANYANG TAI SANITARY WARE CO LTD

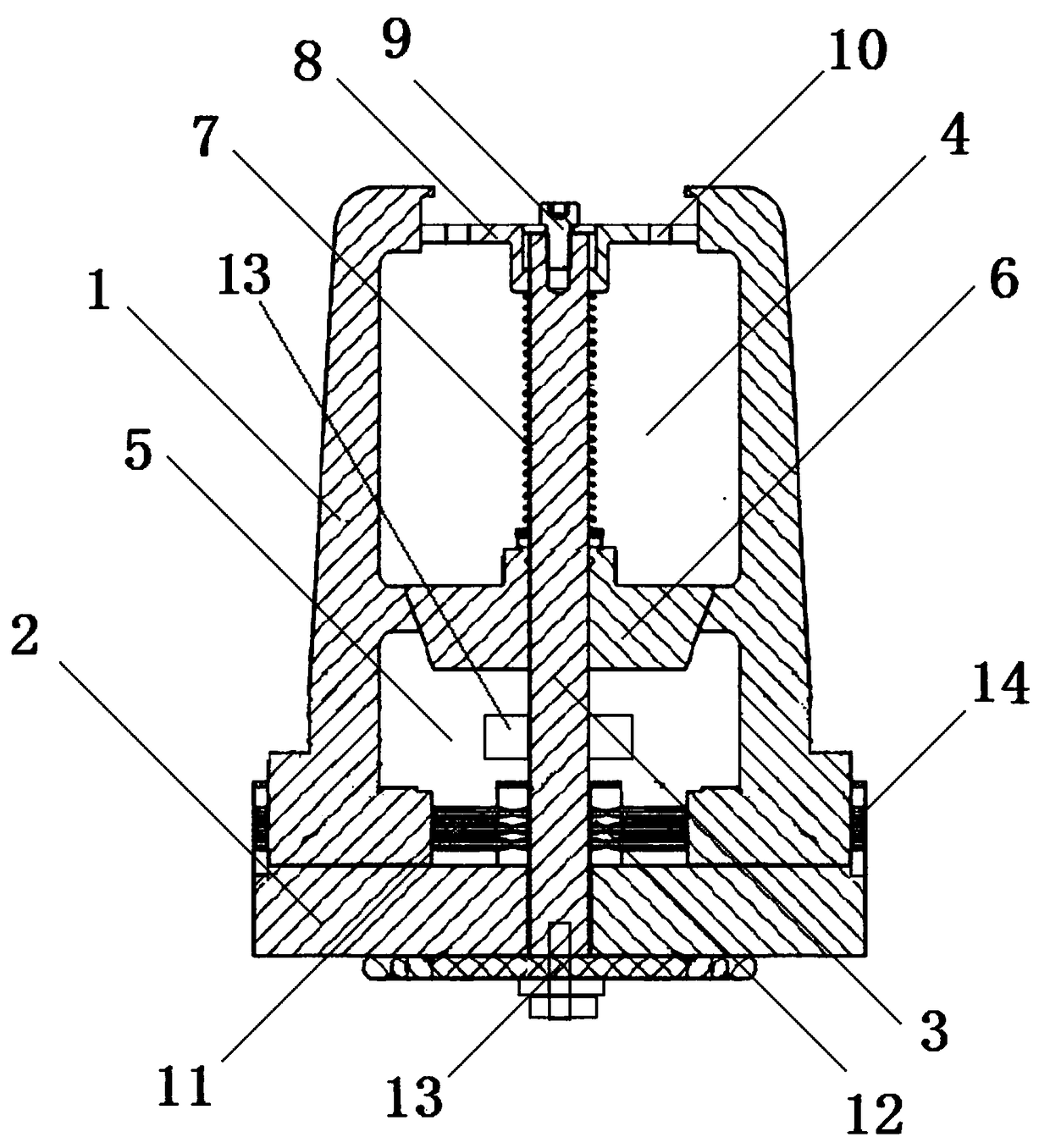

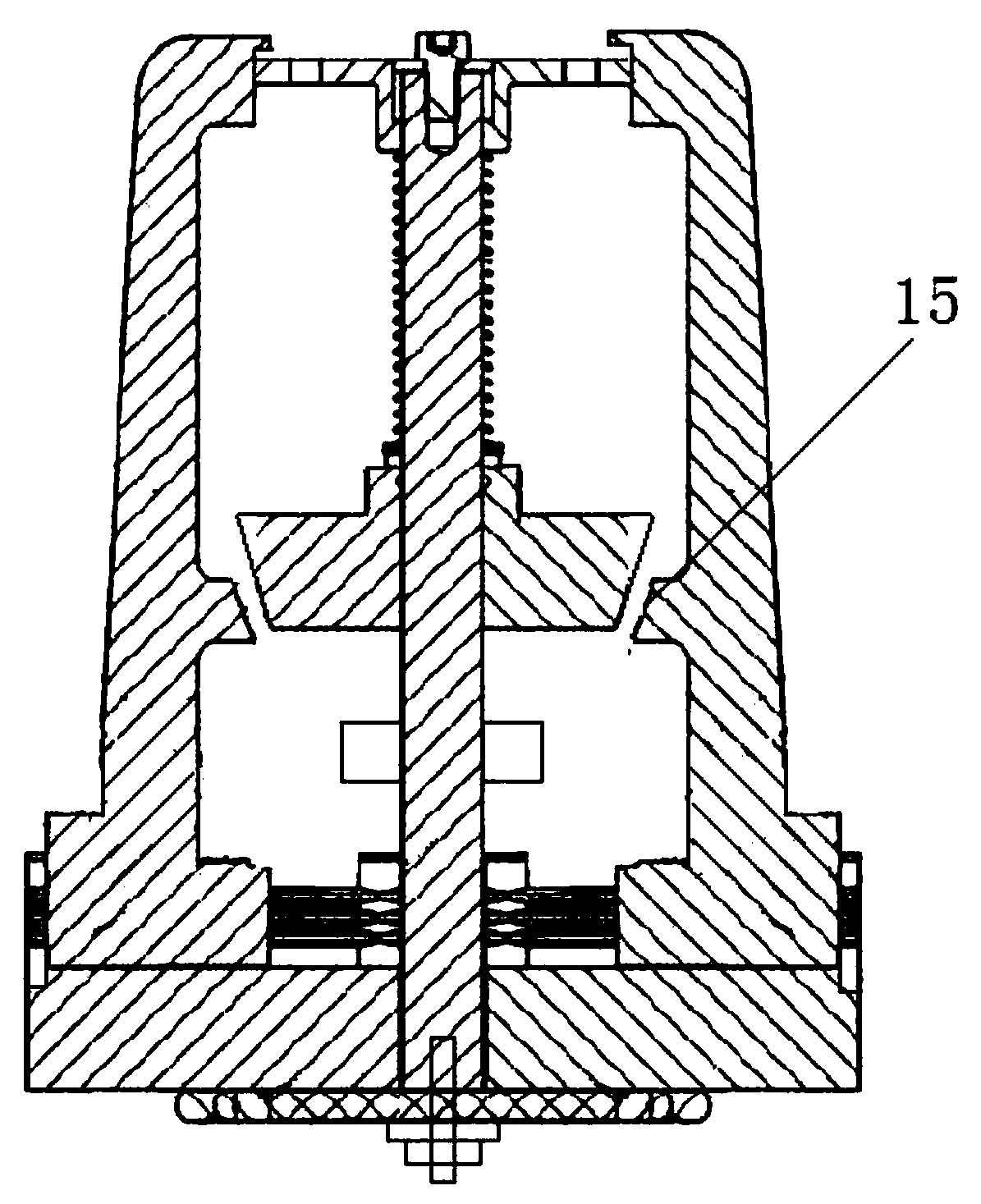

Anti-shock internal mixer

InactiveCN107160577AImprove working environmentAvoid wear and tearNon-rotating vibration suppressionEngine lubricationFixed bearingEngineering

The invention discloses an anti-seismic internal mixer, which comprises a working table, a mixing room, a material storage room and a discharge plate. The two ends of the working table are provided with a left fixing seat and a right fixing seat, and the left fixing seat and the right fixing seat There is a mixing room between the seats, and a mixing shaft passes through the mixing room, and the mixing shaft is rotatably connected with the mixing room through a bearing fixed on the mixing room; the two ends of the mixing shaft are respectively arranged on In the sealing block on the left fixed seat and the right fixed seat, the sealing blocks are respectively embedded in the left fixed seat and the right fixed seat, and the material of the sealing block is copper; a lubricating cavity is opened in the sealing block, and the cross section of the lubricating cavity is a circle shape, and the radius is greater than the diameter of the mixing shaft, and the two ends of the mixing shaft extend into the lubricating chamber; the invention ensures the working stability of the device, effectively reduces the noise caused by vibration, and improves the work of the operator. Environmental protection, fast operation, simple structure, convenient and practical, saving production cost and easy maintenance.

Owner:ZHUJI LEADING MANAGEMENT CONSULTING FIRM

Granulated arabinose preparation method and device

PendingCN107987109AHigh hardnessHigh densitySugar derivativesSugar derivatives preparationMolten stateCooling chamber

Owner:山东绿健生物技术有限公司

Feed additive mixing equipment

InactiveCN107694402AWell mixedStirring speed is fastRotary stirring mixersTransportation and packagingEngineeringFeed additive

The invention relates to feed additive mixing equipment, which comprises a mixing drum, wherein a mixing chamber is arranged in the mixing drum, a material inlet groove communicated to the mixing chamber is arranged in the top wall of the mixing drum, an chute is arranged in the bottom wall of the mixing chamber, the upper end of the chute is rotatably provided with a flipping plate through a pinshaft, a drive assembly for driving the flipping plate to rotate is arranged in the mixing drum, a rotation groove is arranged in the top wall of the mixing chamber, a rotation shaft is rotatably arranged in the rotation groove, and is fixedly provided with a drive gear, the upper end of the rotation shaft is connected to a rotation motor fixedly arranged at the upper end of the mixing drum in a power manner, the center position of the top wall of the mixing chamber is fixedly provided with a reinforcing bush, a rotation bush is rotatably arranged in the reinforcing bush, the upper end of therotation bush extends into the rotation groove and is fixedly provided with a driven gear engaged with the drive gear, the lower end of the rotation bush is fixedly provided with a connection arm, andlongitudinal stirring arms are symmetrically and fixedly arranged at the lower end of the connection arm in a left-and-right manner. The feed additive mixing equipment of the present invention has advantages of good stirring effect and high stirring efficiency.

Owner:GUANGZHOU YALONG AUTOMATION EQUIP CO LTD

Isolation drainage heating stirrer

InactiveCN108905840ASolve the function of isolation, drainage, mixing and stirringFeeding-stuffTransportation and packagingAgricultural engineeringMixing chamber

Owner:江苏众众电热科技有限公司

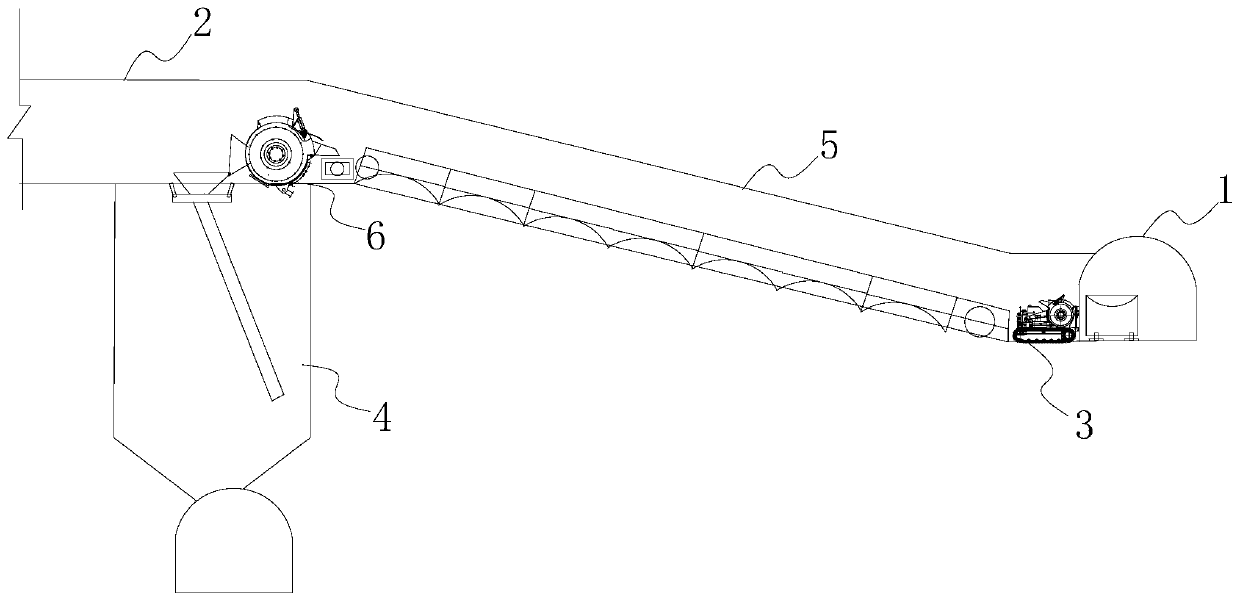

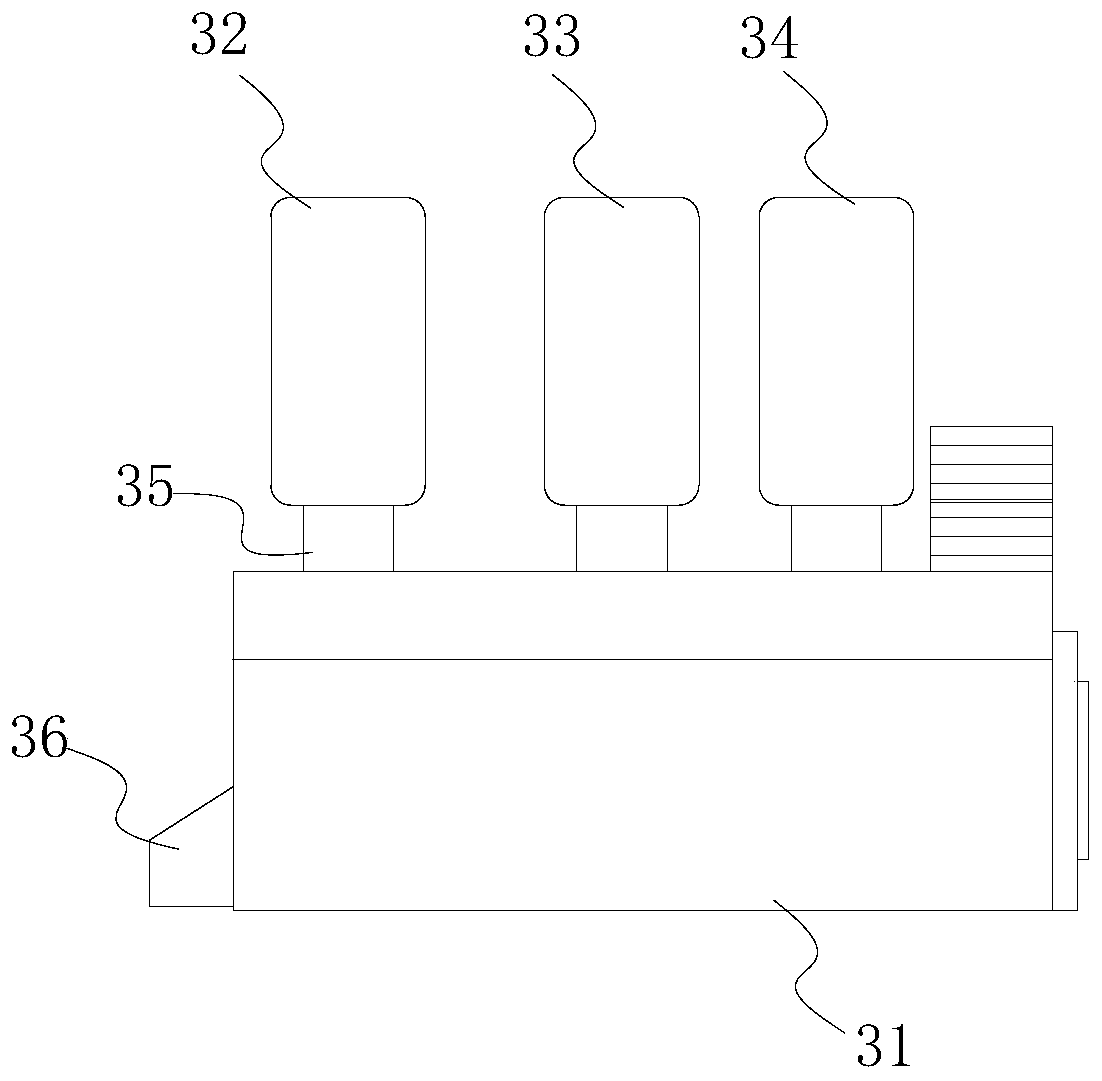

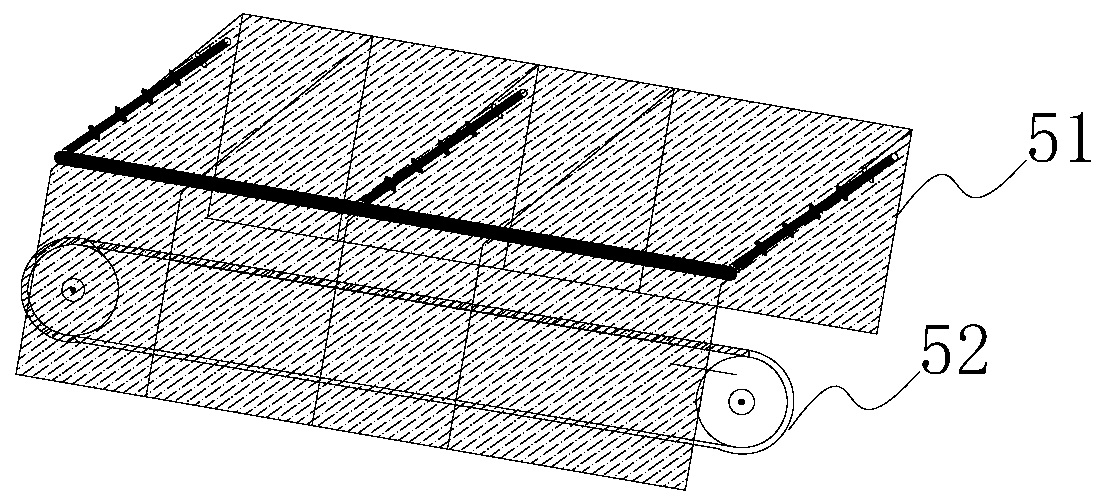

Mining area coal bunker concrete preparing system and coal bunker building method

PendingCN110293628AGuaranteed continuityContinuous realizationDischarging apparatusCement mixing apparatusEngineeringCoal

Owner:临沂矿业集团菏泽煤电有限公司

Compound plant skin-care essential oil and preparation method and application thereof

InactiveCN108926498AImprove mixing efficiencyImprove mixing uniformityCosmetic preparationsRotary stirring mixersAgricultural engineeringMixing chamber

The invention discloses compound plant skin-care essential oil and a preparation method and application thereof. The equipment comprises a base frame, inside which a mixing chamber is arranged. Adapter disks are in running fit at left and right sidewalls of the mixing chamber. A first adapter spindle is fixedly arranged at the dead center between the adapter disks at the left and right sides. A first mixing rod is fixedly arranged on the first adapter spindle. A mixing shaft is in running fit on the first mixing rod. Multiple second mixing rods are fixedly disposed on the external surface of the mixing shaft. The mixing shaft is respectively in running fit with the adapter disks at the left and right sides. A first adapter chamber is arranged at the right side of the mixing chamber and inside the base frame. An arc-shaped chute is communicated between the first adapter chamber and the adapter disks. A dog ring is fixedly arranged inside the first adapter chamber. The mixing shaft is inclearance fit with the arc-shaped chute and extends into the first adapter chamber, and the tail end of the mixing shaft is fixedly provided with a transmitting gear.

Owner:GUANGZHOU YIDE INTELLIGENT TECH CO LTD

Residual heat absorbing boiler for CO

InactiveCN102734810AEvenly distributedPromotes full combustionIncreasing energy efficiencyIncinerator apparatusCombustion chamberCombustor

Owner:无锡市晨光耐火材料有限公司

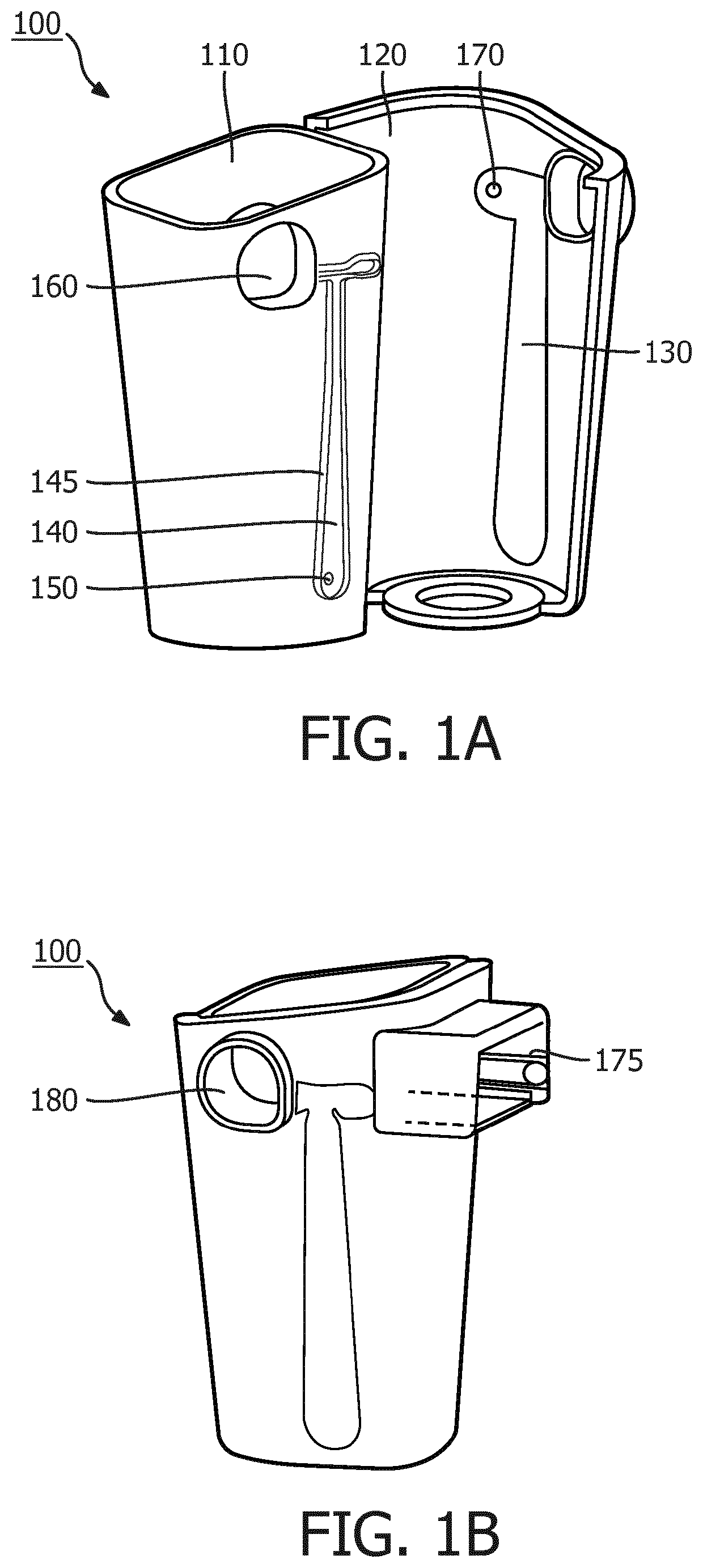

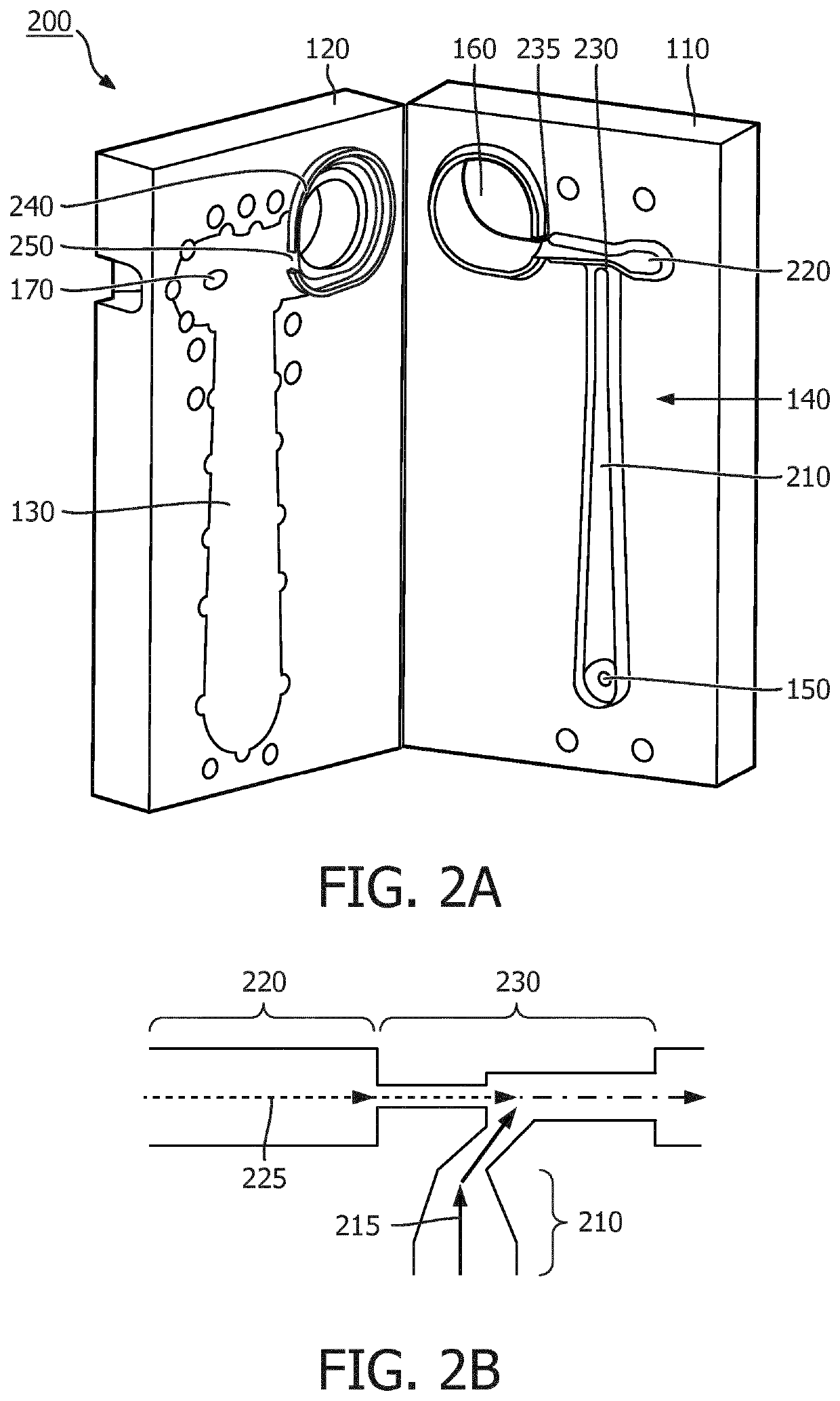

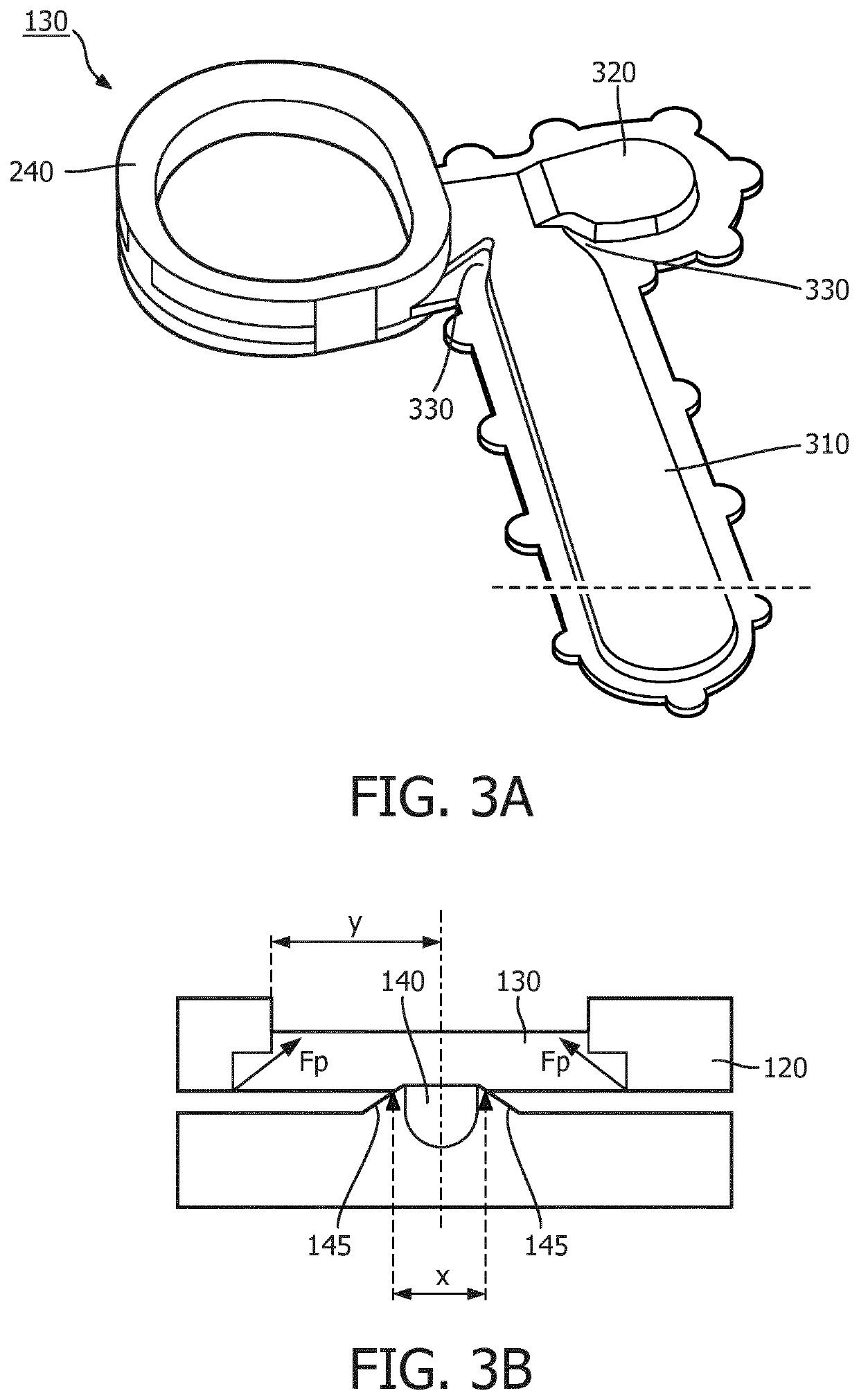

A mixing apparatus having a seal

Owner:KONINKLJIJKE PHILIPS NV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap