Residual heat absorbing boiler for CO

A boiler and waste heat technology, which is applied in the field of refractory layer boilers, can solve the problems that the exhaust gas cannot be evenly distributed, the CO is difficult to be fully burned, and the CO is fully burned, so as to achieve the effect of convenient and full combustion, complete combustion of exhaust gas, and increased combustion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

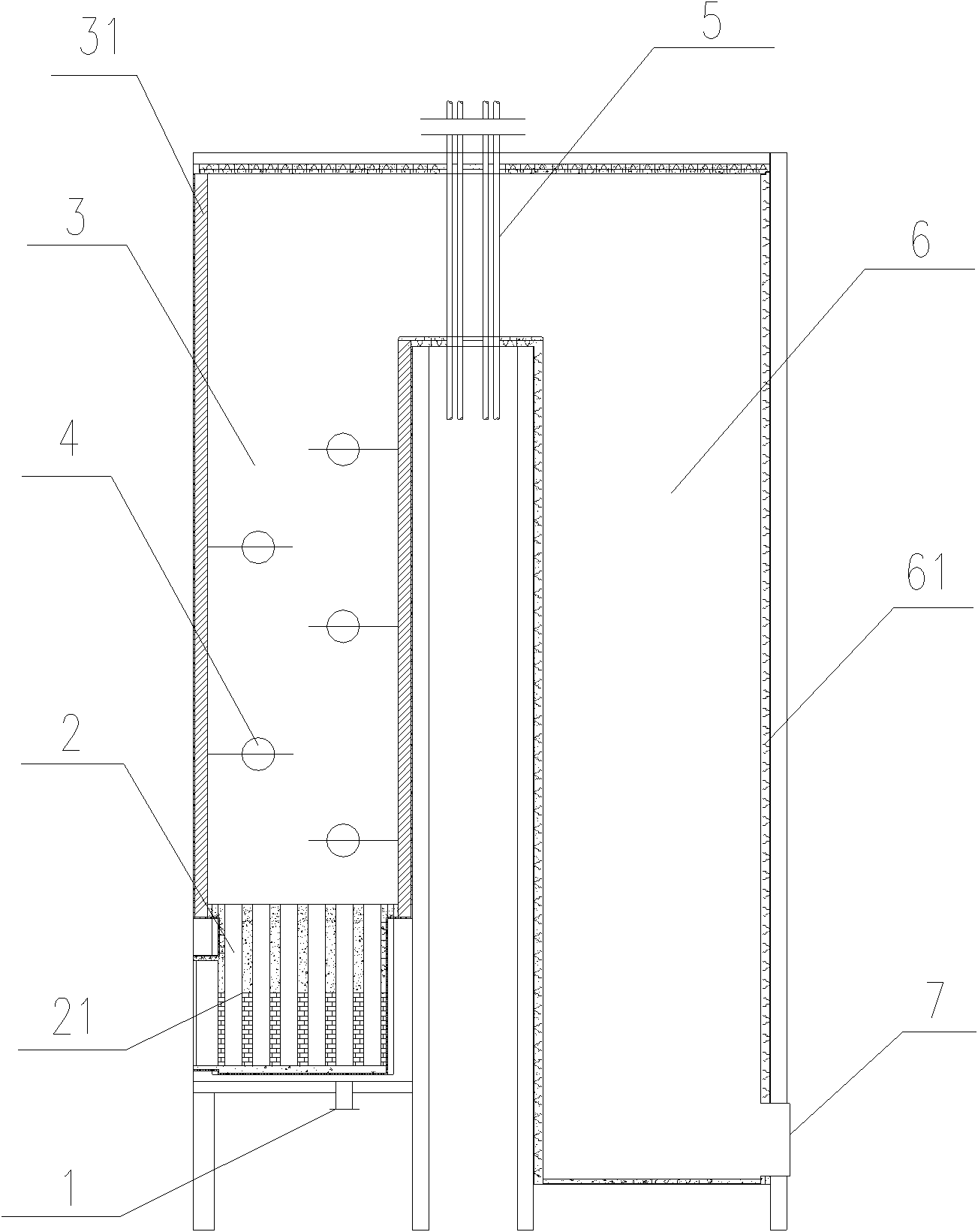

[0017] As shown in the figure, a CO waste heat absorption boiler provided by the present invention includes an inlet 1, a flue gas mixing chamber 2, a combustion chamber 3, a burner 4, a wall pipe 5, an evaporation chamber 6 and an outlet 7; the flue gas mixing chamber 2 is located above the entrance 1 and below the combustion chamber 3, and a grille 21 is provided in the flue gas mixing chamber 2 to make the flue gas mix uniformly and buffer the flow velocity of the flue gas; the combustion chamber 3 is equipped with 5 burners 4, crossed Distributed in the combustion chamber 3; in order to prevent high temperature, the side wall 31 of the combustion chamber is made of high-alumina lightweight bricks; there is a wall-through pipe 5 between the combustion chamber 4 and the evaporation chamber 6 to absorb the heat generated by CO combustion; the side wall of the evaporation chamber 61 is filled with refractory materials to facilitate waste heat absorption; the bottom of the evaporat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap