Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about "Anti-corrosive paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyaniline-graphene composite based anticorrosive paint and preparation method thereof

Owner:HARBIN ENG UNIV

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

Owner:EI DU PONT DE NEMOURS & CO

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

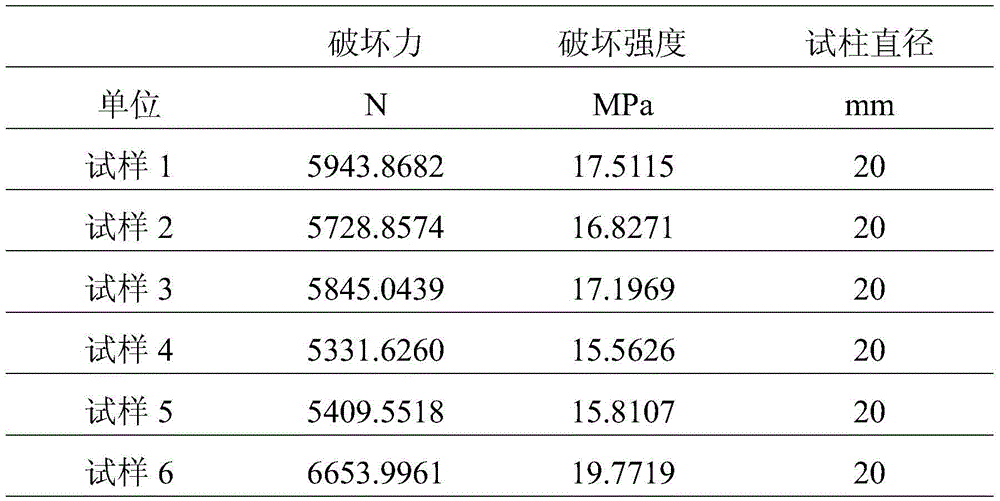

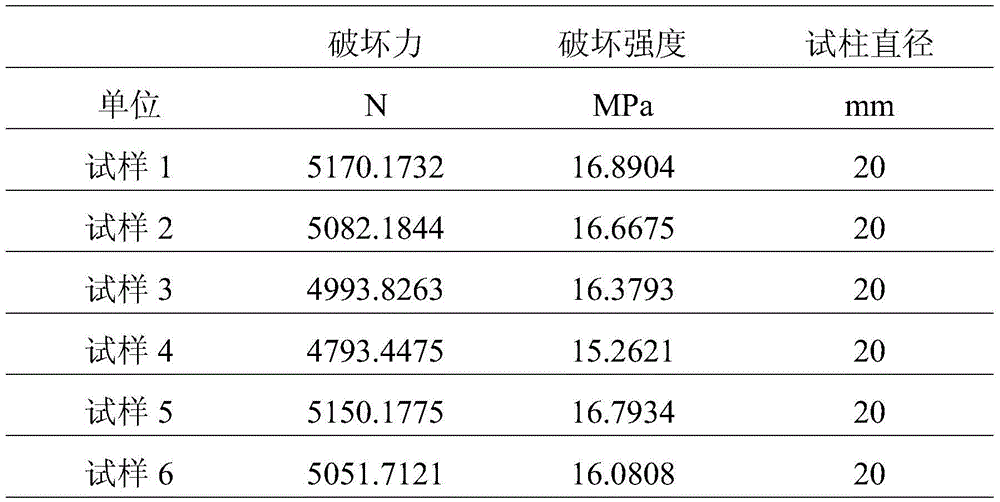

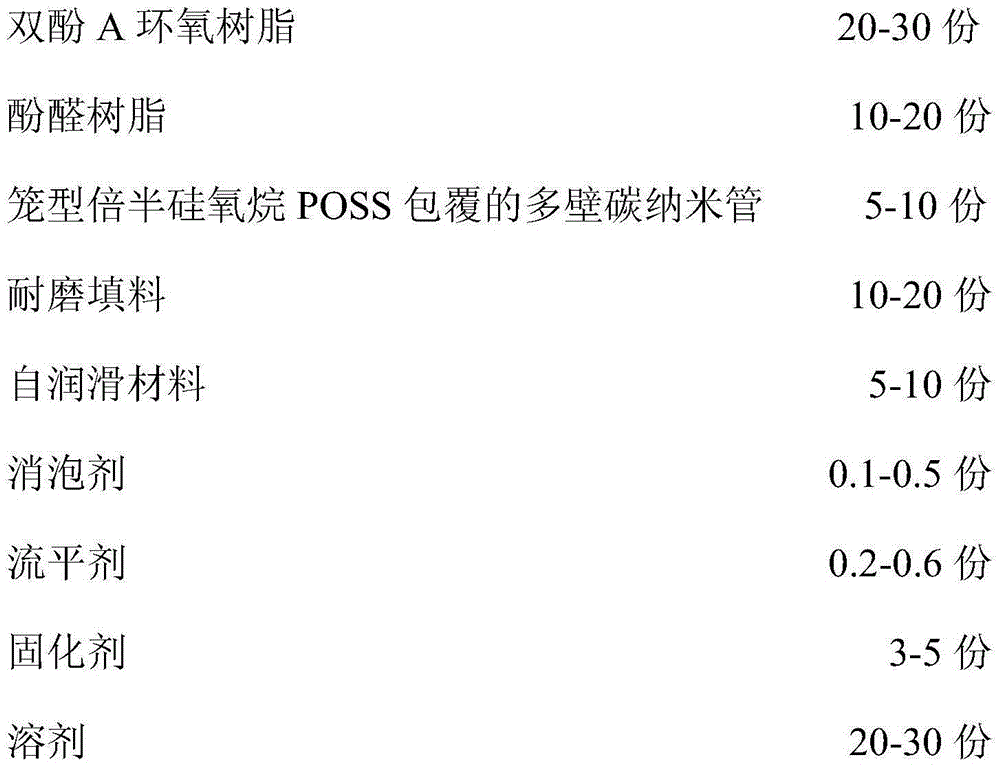

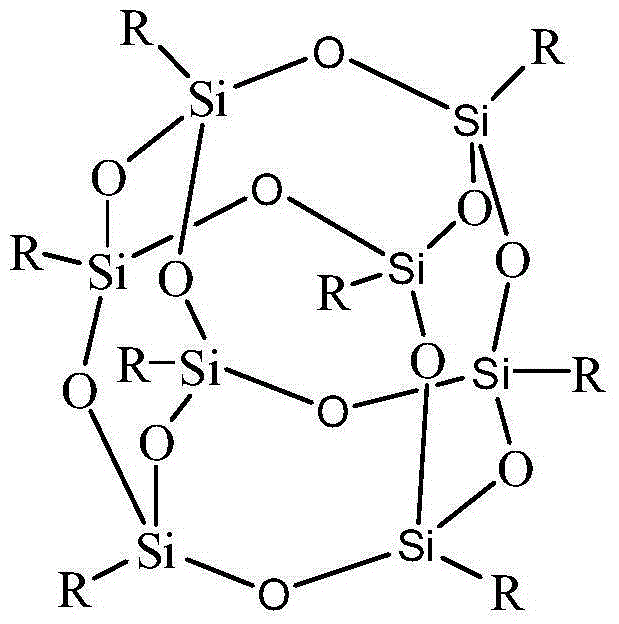

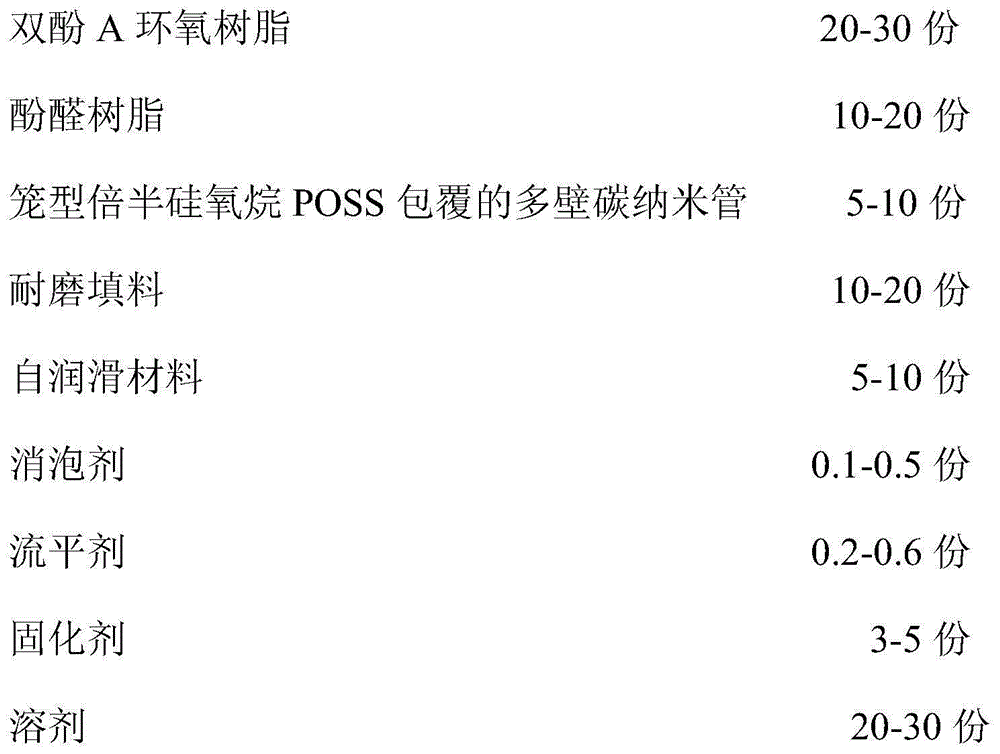

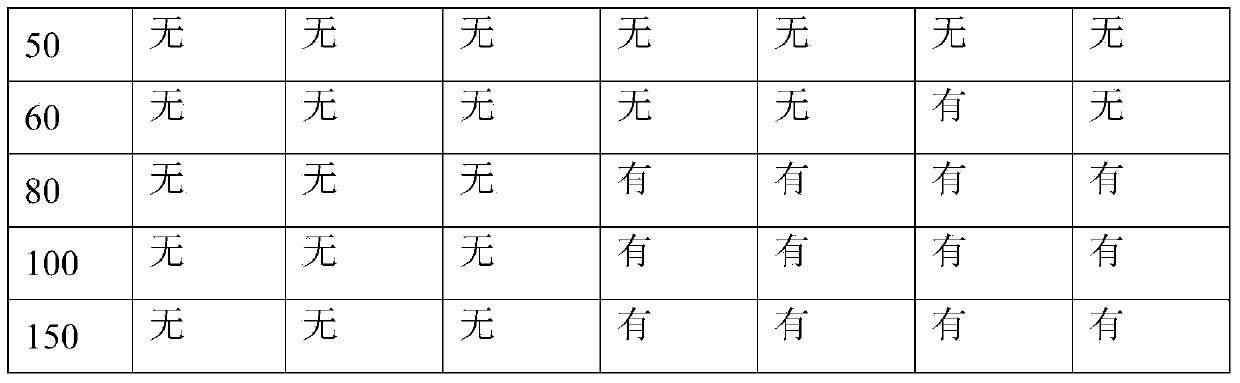

Anti-corrosion and wear-resisting coating for throwing disc of pneumatic type feeder and preparation method of coating

InactiveCN105062300AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsMultiwalled carbonRoom temperature

Owner:JINHU JIEDA MACHINERY MFR

High-performance water-based bicomponent epoxy zinc rich primer and preparation method thereof

ActiveCN107573816AReduce usageImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyCollocation

The invention relates to a high-performance water-based bicomponent epoxy zinc rich primer and a preparation method thereof. A water-based bicomponent epoxy zinc rich coating A in the high-performancewater-based bicomponent epoxy zinc rich primer comprises a water-based epoxy curing agent, an additive A, a complex solubilizer, zinc powder, zinc and an anti-settling agent; a water-based bicomponent epoxy zinc rich coating B comprises a water-based epoxy emulsion and an additive B; the weight ratio of the coating A to the coating B is at 100 to (10-30). The preparation method comprises the following steps: (1) uniformly mixing the components in the coating A at ratio and using a 100-mesh screen for filtering; (2) uniformly mixing the components in the coating B at ratio; and uniformly mixing the coating A with the coating B at the weight ratio in a use process and regulating the construction viscosity. When the high-performance water-based bicomponent epoxy zinc rich primer is used, water is taken as a solvent, so that the use of the organic solvent is greatly reduced and the environmental protection is benefited. The collocation of the anti-settling agent is utilized to solve the problems of storage and construction.

Owner:SHANDONG QIWEI NEW MATERIALS CO LTD

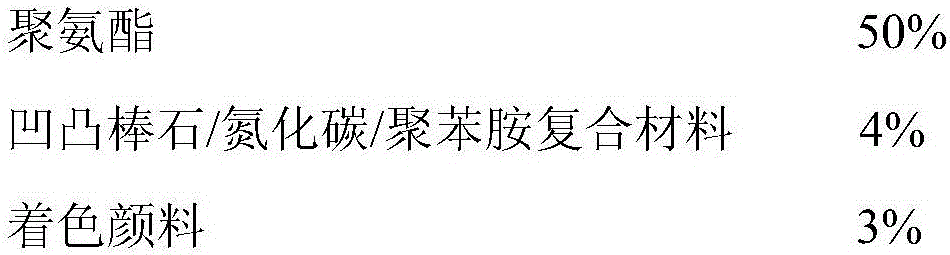

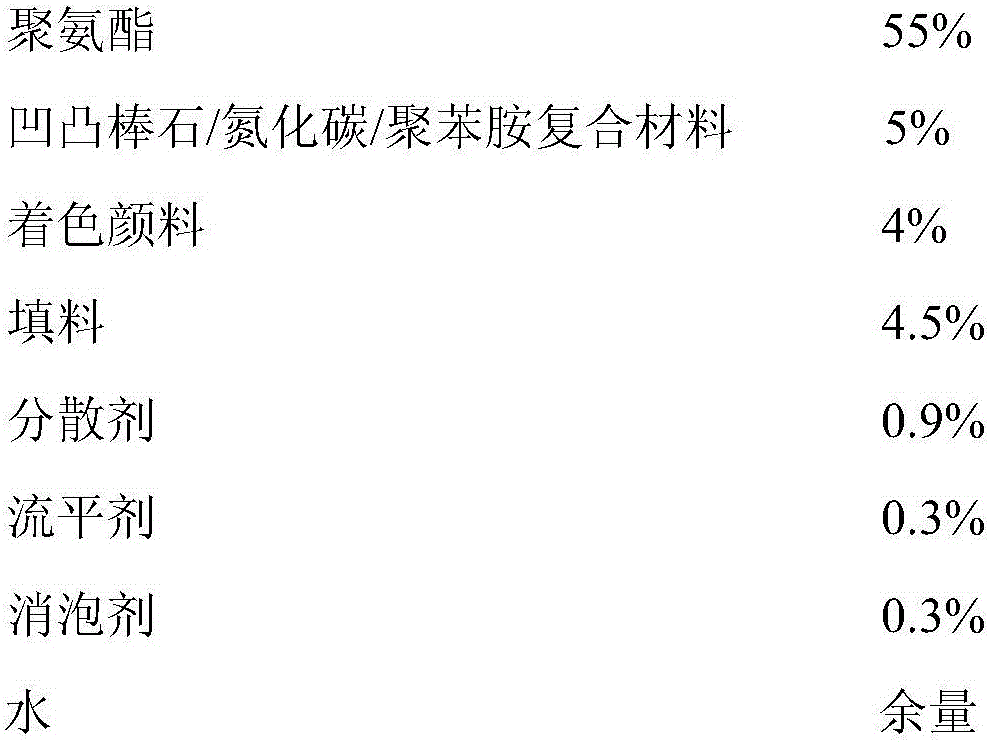

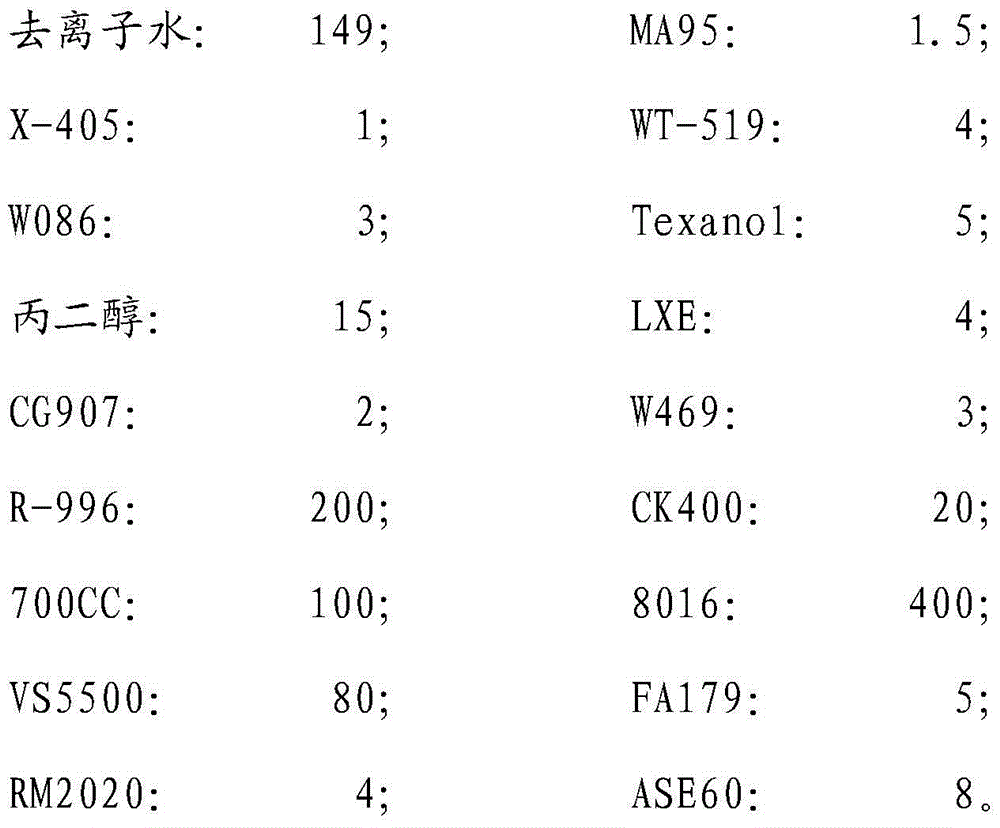

Preparation method of attapulgite-carbon nitride-polyaniline composite material and application thereof in anticorrosive paint

InactiveCN105754092AAvoid reunionReduce manufacturing costAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nitrideGraphite

Owner:CHANGZHOU UNIV

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

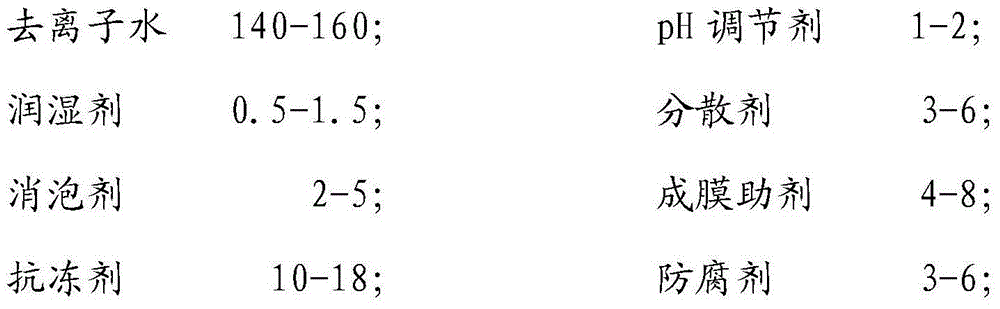

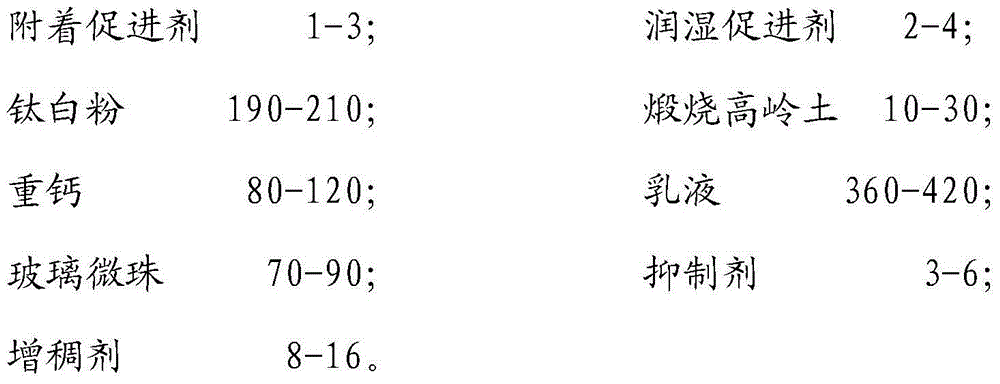

Metal roof coating and preparation method thereof

Owner:厦门防水博士新材料有限公司

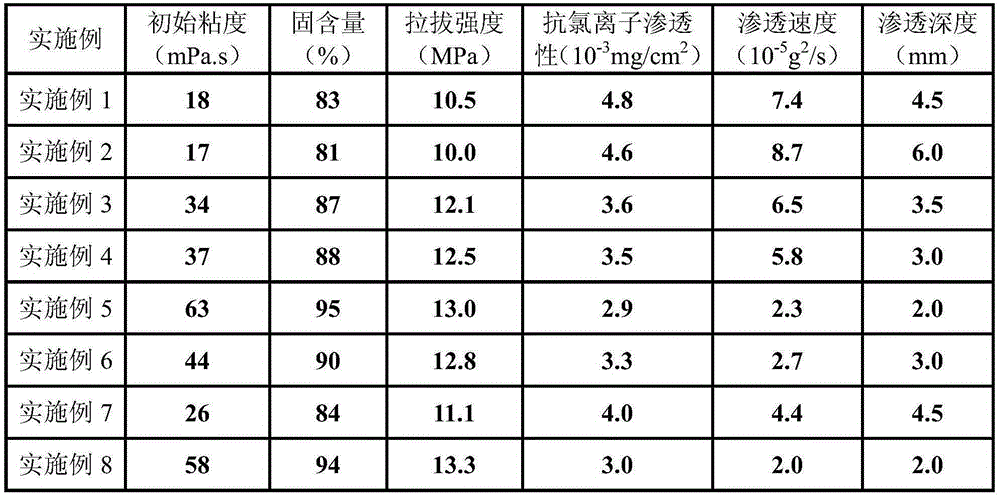

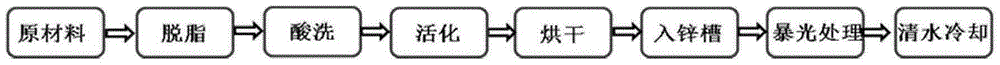

Permeation consolidation type solvent-free epoxy anticorrosive coating, and preparation method and application thereof

ActiveCN105238217AImprove wetting abilityImprove bonding abilityAnti-corrosive paintsEpoxy resin coatingsSolventSurface corrosion

The invention belongs to the technical field of anticorrosive coatings, and discloses a permeation consolidation type solvent-free epoxy anticorrosive coating, and a preparation method and an application thereof. The anticorrosive coating consists of a component A and a component B. The component A consists of the following components in parts by weight: 18-89 parts of epoxy resin, 5-50 parts of enhanced type reactive solvents, 5-60 parts of permeation type reactive solvents, 0-5 parts of interfacial modifiers and 0-3 parts of permeation enhancers. The component B consists of the following components in parts by weight: 5-95 parts of functional curing agents, 0-30 parts of curing regulators, 0-50 parts of double-function regulators, 0-40 parts of curing accelerators and 0-5 parts of condensation catalysts. The coating is low in viscosity and excellent in permeability, and has an excellent mechanical property after being cured. In addition, the permeation consolidation type solvent-free epoxy anticorrosive coating disclosed by the present invention has good wettability and viscocity with concrete, and strength of the concrete can be improved, water on the surface of the concrete can be removed, and surface corrosion factors of the concrete are reduced.

Owner:SOUTH CHINA UNIV OF TECH

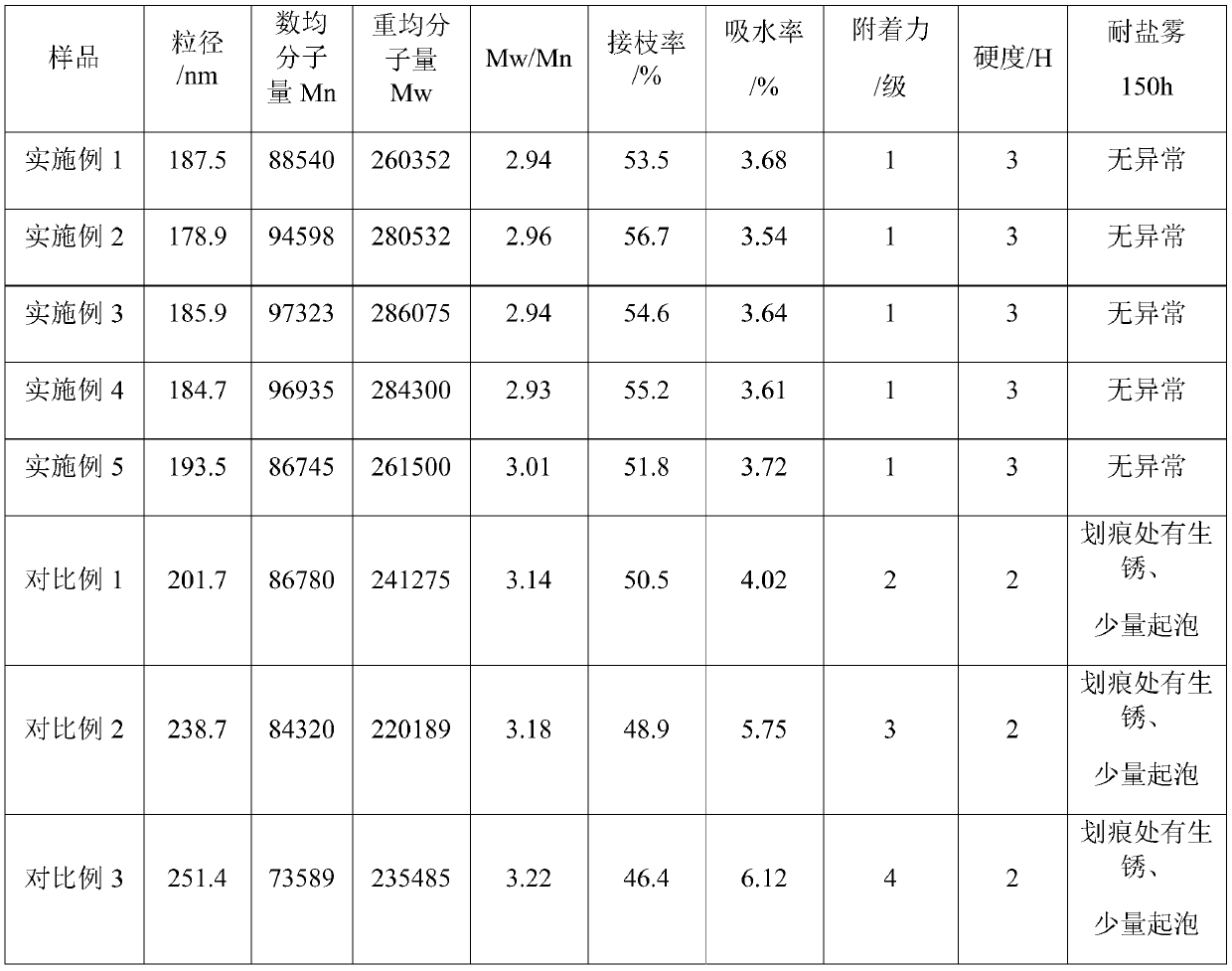

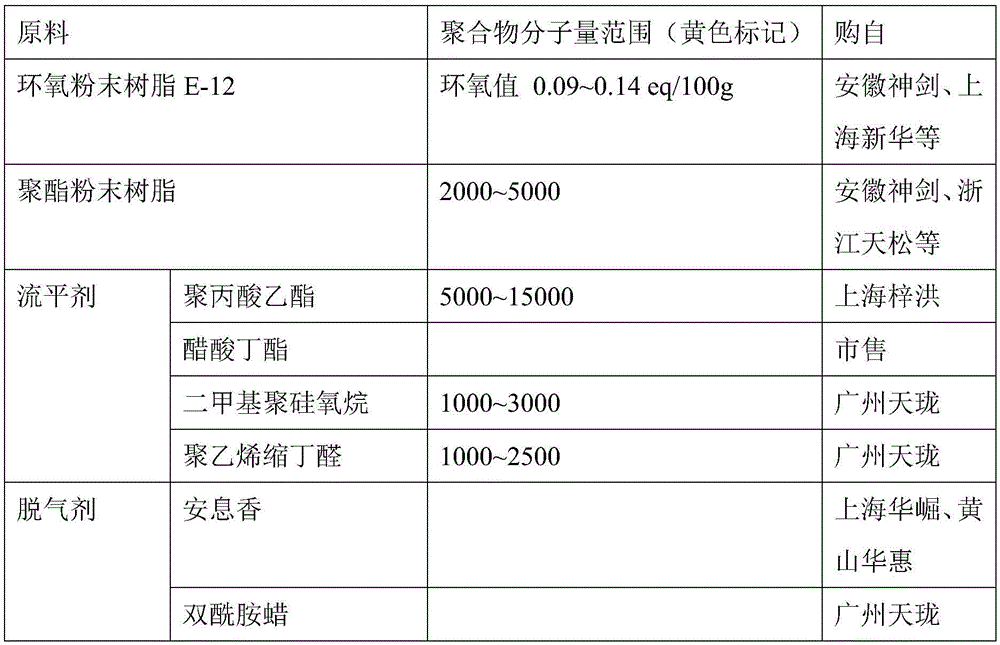

Water-based alkyd-acrylate dispersion as well as preparation method and application thereof

ActiveCN111138603AImprove compactnessImprove the level ofAnti-corrosive paintsPolymer sciencePtru catalyst

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

VCI powder zinc-rich paint for protecting surface of steel structure and preparation method thereof

Owner:JIANGSU AVIC BAIMU NEW MATERIAL TECH +1

Water-based epoxy thick slurry anticorrosive paint as well as preparation method and application thereof

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Static-conducting and anti-corrosive coating on inner wall of oil tank, and preparation method of static-conducting and anti-corrosive coating

InactiveCN104098989ALight colorEasy for visual inspectionAnti-corrosive paintsEpoxy resin coatingsPetrochemicalReactive diluent

The invention discloses a static-conducting and anti-corrosive coating and a preparation method thereof. The static-conducting and anti-corrosive coating comprises bisphenol A epoxy resin, a reactive diluent, rutile titanium dioxide, conductive mica powder, a coupling agent and a flexibilizer. The bisphenol A epoxy resin is ground; the reactive diluent, the flexibilizer, the coupling agent and a light-colored static-conducting material are added; and the coating free of an inertial and volatile solvent is prepared. The coating has the characteristics of high cohesion, good closure and stable static conductivity, is suitable for internal anti-corrosive and static-conducting protection of oil storage and transport equipment such as an oil storage tank, an oil transport pipeline and an oil transport tank in the petrochemical industry, and is also suitable for anti-corrosive and anti-static protection of a gas tank, a water gate and an underground pipeline.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Environmentally friendly polyvinyl chloride coating

InactiveCN104861793AGood weather resistanceImprove temperature resistanceAnti-corrosive paintsPolyamide coatingsChemical industryChemistry

The invention discloses an environmentally friendly polyvinyl chloride coating. The coating comprises, by mass, 35-70% of polyvinyl chloride resin, 5-10% of dioctyl phthalate, 5-15% of polyethylene resin, 5-10% of talcum powder, 3-8% of rutile titanium dioxide, 3-5% of polyether modified polysiloxane, 2-3% of N-hydroxyethylethylamine triacetic acid, 1-3% of polyether esteramide, 0.5-1.5% of a calcium and zinc stabilizer, 0.1-0.5% of polyoxyethylene amide, 0.5-1% of calcium stearate and 4-8% of polyisocyanate. The environmentally friendly polyvinyl chloride coating has the advantages of excellent weather resistance, excellent temperature tolerance, excellent corrosion resistance and good environmental protection performance, and can be used in the chemical industry, the petroleum industry, the pharmacy industry and the food industry to form protection coat layers of surfaces of devices, buildings and members.

Owner:殷培花

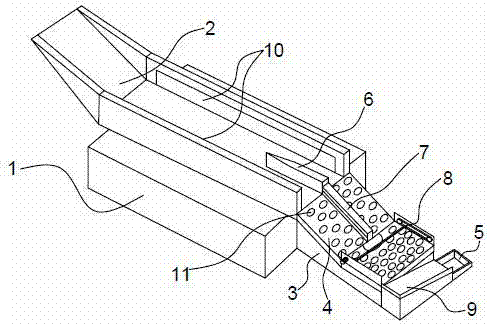

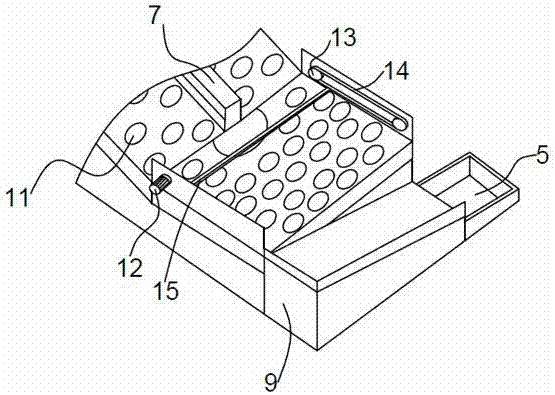

Separating device for fish and shrimps on boat

Owner:舟山汇丰冷藏物流发展有限公司

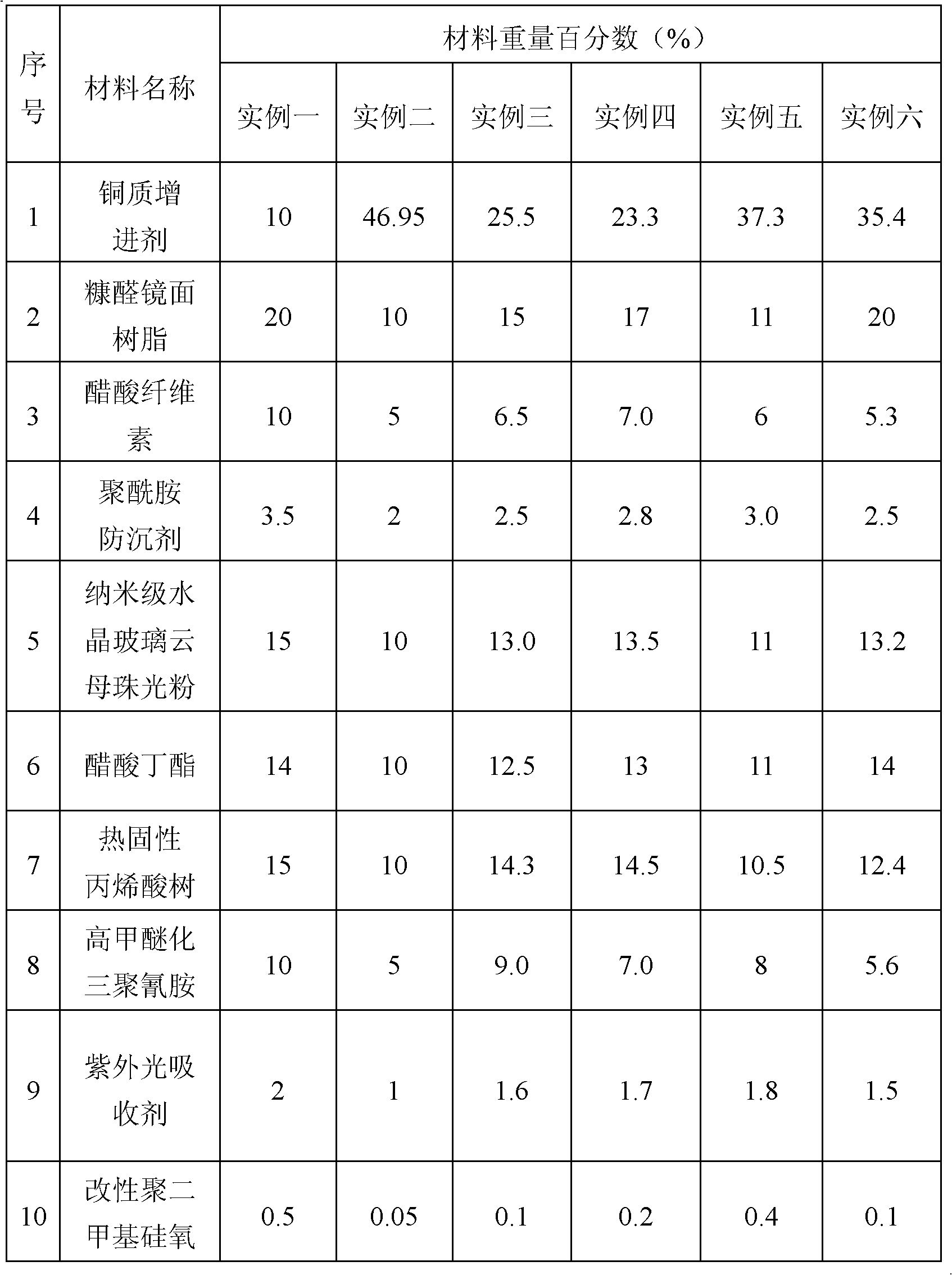

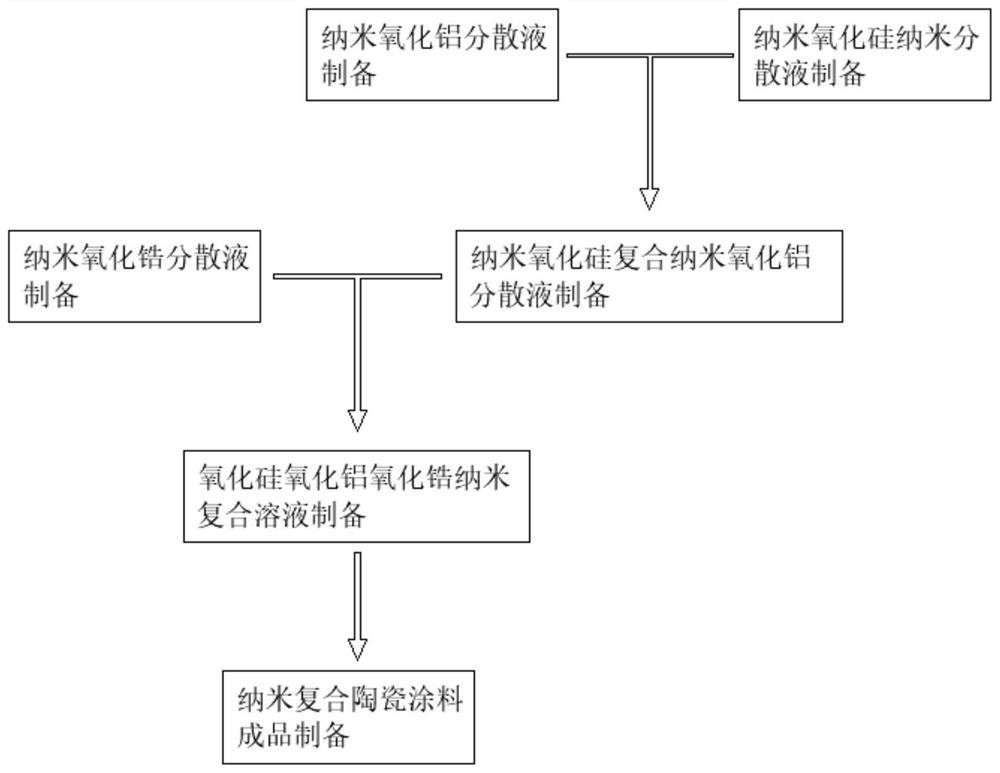

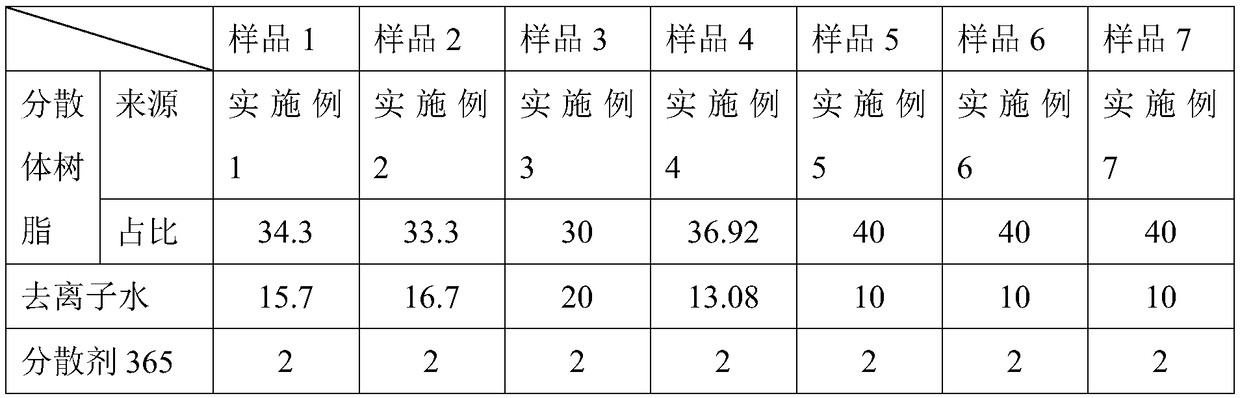

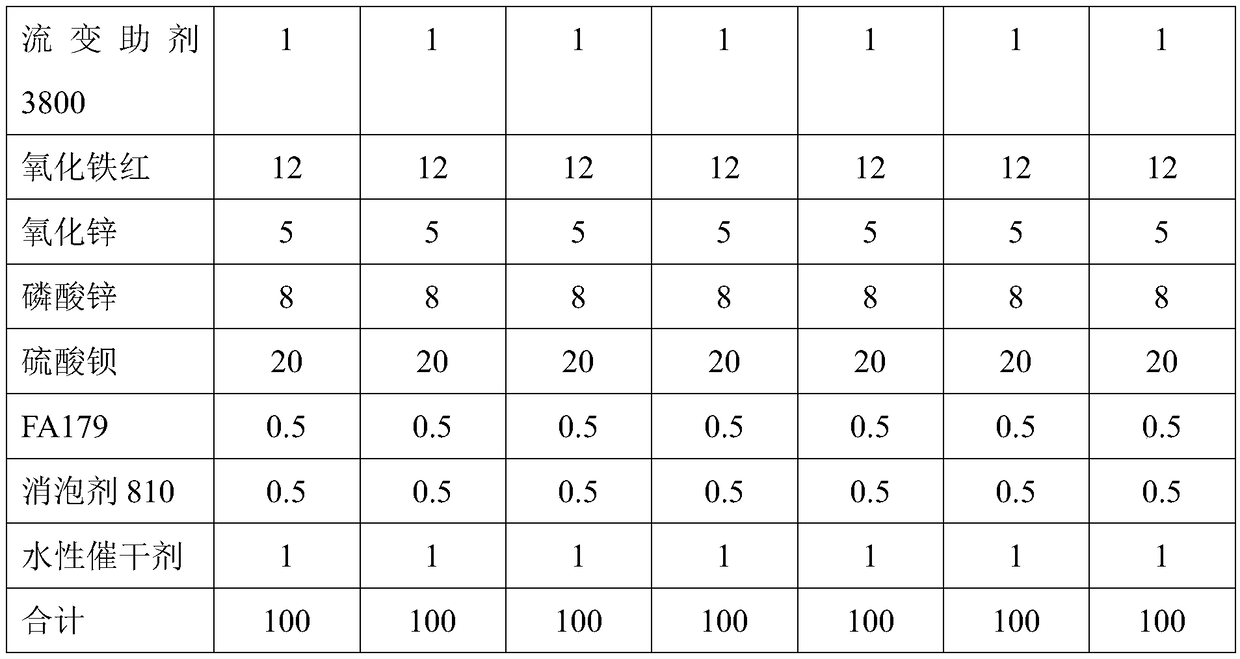

True copper metallic combination paint as well as preparation method and construction process thereof

InactiveCN102533056AImprove anti-corrosion performanceExcellent anti-rustPretreated surfacesAnti-corrosive paintsEpoxyProduction line

Owner:江苏佳尔利装饰材料有限公司 +1

Transparent high-temperature-resistant anti-corrosion nano composite ceramic coating suitable for welding part

InactiveCN112898806AEasy to useGood value for moneyFireproof paintsAnti-corrosive paintsNano siliconComposite ceramic

Owner:薛国旺

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

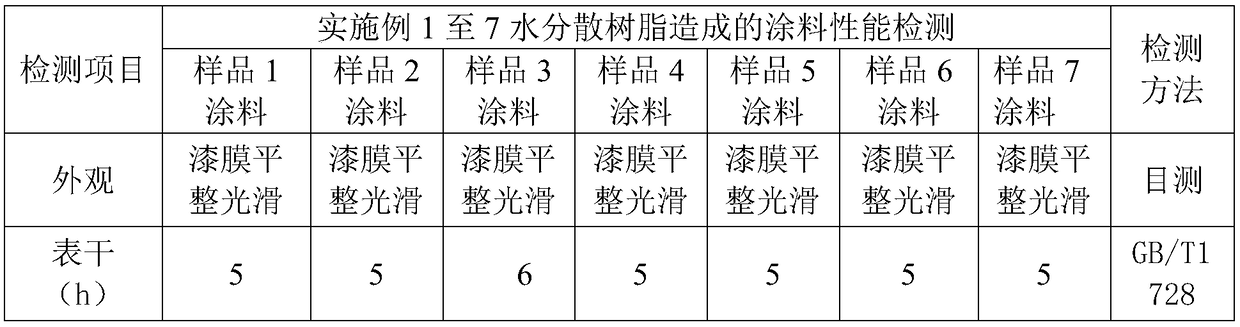

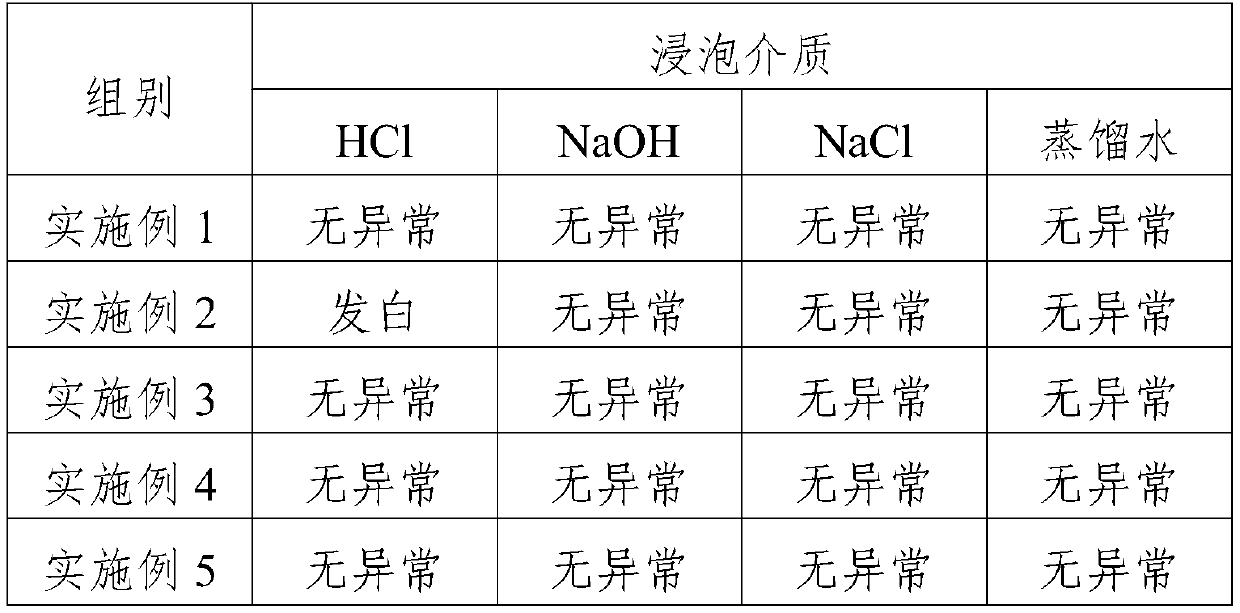

Water dispersible rein and a preparing method thereof

PendingCN108949000AWide variety of sourcesReduce pollutionAnti-corrosive paintsPolyurea/polyurethane coatingsWater dispersibleChemistry

Water dispersible rein is provided. The water dispersible rein is prepared mainly from, by weight, 25-40 parts of cardanol, 15-40 parts of epoxidized vegetable oil, 3-6 parts of diisocyanate, 2-5 parts of polyethylene glycol or hydroxy-terminated polymer and 40-60 parts of deionized water. A preparing method of the water dispersible resin is also provided. The water dispersible rein is prepared from purely-natural biologically extracted raw materials which are wide in source, high in quality and low in cost and are ideal biological-based raw materials. The water dispersible resin prepared fromnatural raw materials can reduce environment pollution, plays a role of continuously improving ecological environment and protecting the nature, and is a novel green product. The water dispersible resin, as a film forming substance in coating, can greatly reduce harm to environment or human during production or construction, and can be used for producing coating products which are nearly VOC-zero, and paint films are decorative, anticorrosion, and environmentally friendly. The resin is a newest environmentally friendly product at present.

Owner:山东奔腾漆业股份有限公司

Full-inorganic interior and exterior wall coating and preparation method thereof

InactiveCN111393881AImprove corrosion resistanceStrong hardnessAlkali metal silicate coatingsAnti-corrosive paintsBarium solutionBarium dichloride

Owner:国鼎(苏州)材料科技有限公司

Anticorrosive additive with polyaniline covering gas-phase nano-silica, and preparation method and application thereof

Owner:TONGJI UNIV

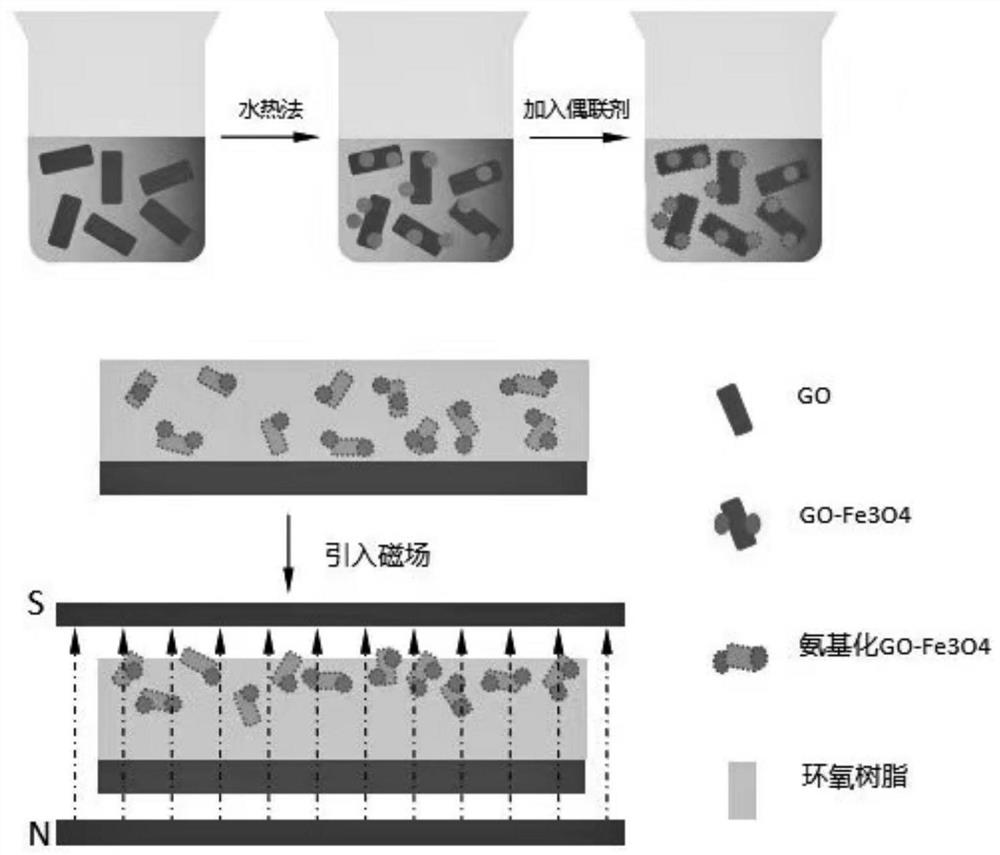

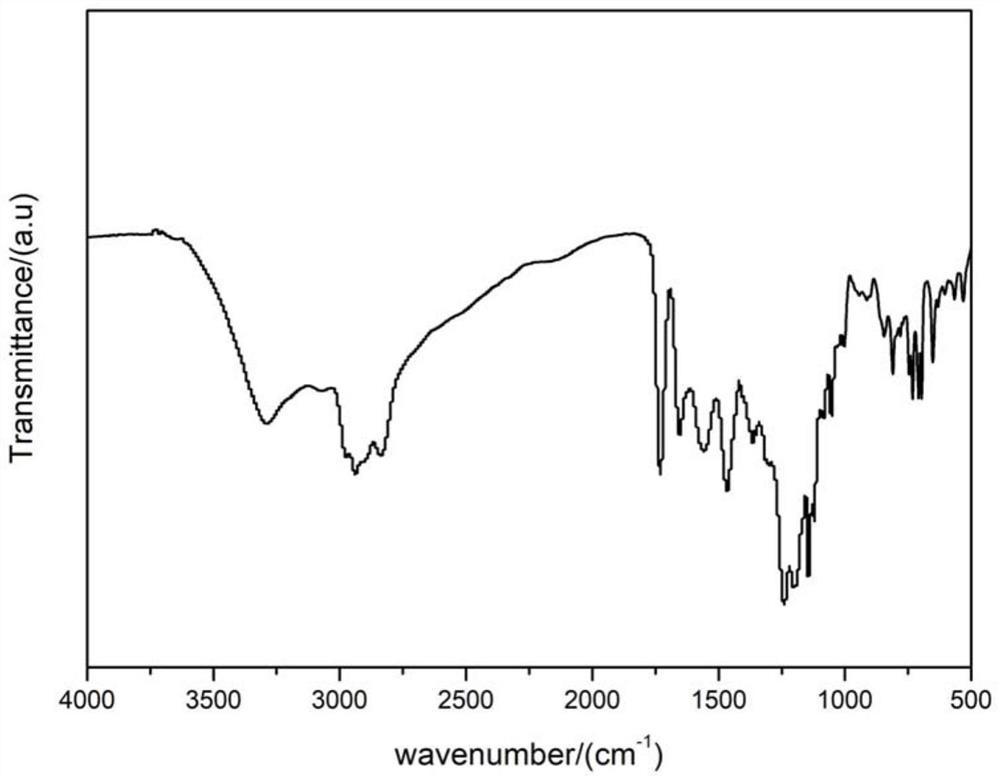

Preparation method of epoxy resin/GO super-hydrophobic anticorrosive coating

Owner:HUNAN UNIV OF SCI & TECH

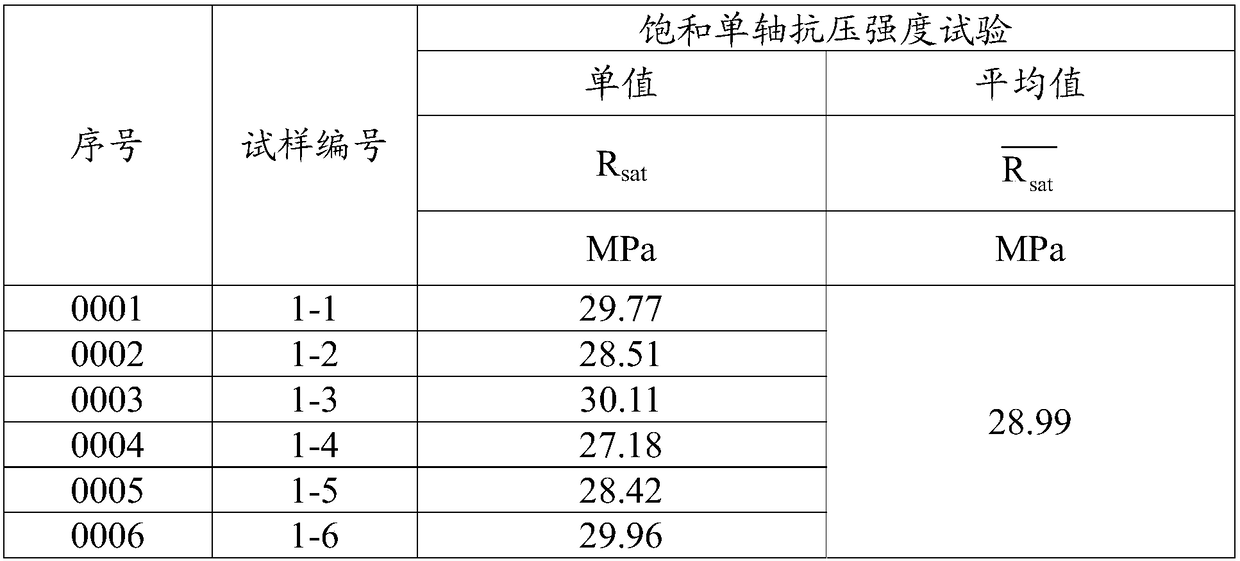

Anticorrosive coating material for reinforced concrete, preparation method and applications thereof

ActiveCN108300166AAvoid corrosionReduce film thicknessAnti-corrosive paintsEpoxy resin coatingsRebarPhenol

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Night vision compatible film and preparation method and application thereof

ActiveCN112409619AHigh light transmittanceImproves UV protectionAnti-corrosive paintsRadiation-absorbing paintsUv absorbanceAcrylic resin

The invention belongs to the field of materials, and discloses a night vision compatible film and a preparation method and application thereof. The night vision compatible film comprises a layer of transparent base material and a coating applied to the transparent base material. The coating is mainly prepared from acrylic resin, amino resin, nano TiO2 sol, graphene oxide, an ultraviolet absorbent,filler, a resin curing agent and a solvent. The night vision compatible film is high in light transmittance within the range of 400nm to 630nm and high in ultraviolet-proof capacity. The light transmittance within the range of 400nm to 630nm is 55% or above; the light transmittance within the range of 660nm to 930nm is 1.0% or less; and the light transmittance at 320-400nm is 1.2% or less. The night vision compatible film has good water mist resistance and salt mist resistance, can adapt to severe environments and is wide in application scene. The night vision compatible film can be applied to a night vision device.

Owner:BEIJING FALCON TECH CO LTD

High-weatherability anti-corrosive paint and iron tower assembly

InactiveCN102070986ANot easy to ageNot easy to corrodeLighting support devicesAnti-corrosive paintsUltravioletEngineering

Owner:CHANGSHU FENGFAN POWER EQUIP

Resin graphene composite material, preparation method and application thereof

InactiveCN108329520AImprove conductivityImprove thermal conductivityElectroconductive/antistatic filament manufactureAnti-corrosive paintsSlurryCvd graphene

The invention provides a resin graphene composite material, a preparation method and an application thereof, which belong to the technical field of the graphene composite material. The preparation method comprises the following steps: 1) mixing a metal auxiliary agent, a graphene material and water and stirring a mixture to obtain a slurry; 2) drying the slurry to obtain metal graphene; and 3) heating the metal graphene and thermoplastic resin and heating the materials under inert gas atmosphere to the temperature of 50-300 DEG C for a reaction. The preparation method composites the graphene material and the thermoplastic resin, through a Pi bond electron cloud of the graphene material, free electron transmission is carried out, the obtained resin graphene composite material has good conductivity and thermal conductivity, and can be used as a novel electric conduction and heat conduction composite material.

Owner:BEIJING NORTH GUONENG TECH CO LTD

Modified acrylic acid special type coating

Owner:上海海悦涂料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap