Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Petroleum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum (/pəˈtroʊliəm/) is a naturally occurring, yellowish-black liquid found in geological formations beneath the Earth's surface. It is commonly refined into various types of fuels. Components of petroleum are separated using a technique called fractional distillation, i.e. separation of a liquid mixture into fractions differing in boiling point by means of distillation, typically using a fractionating column.

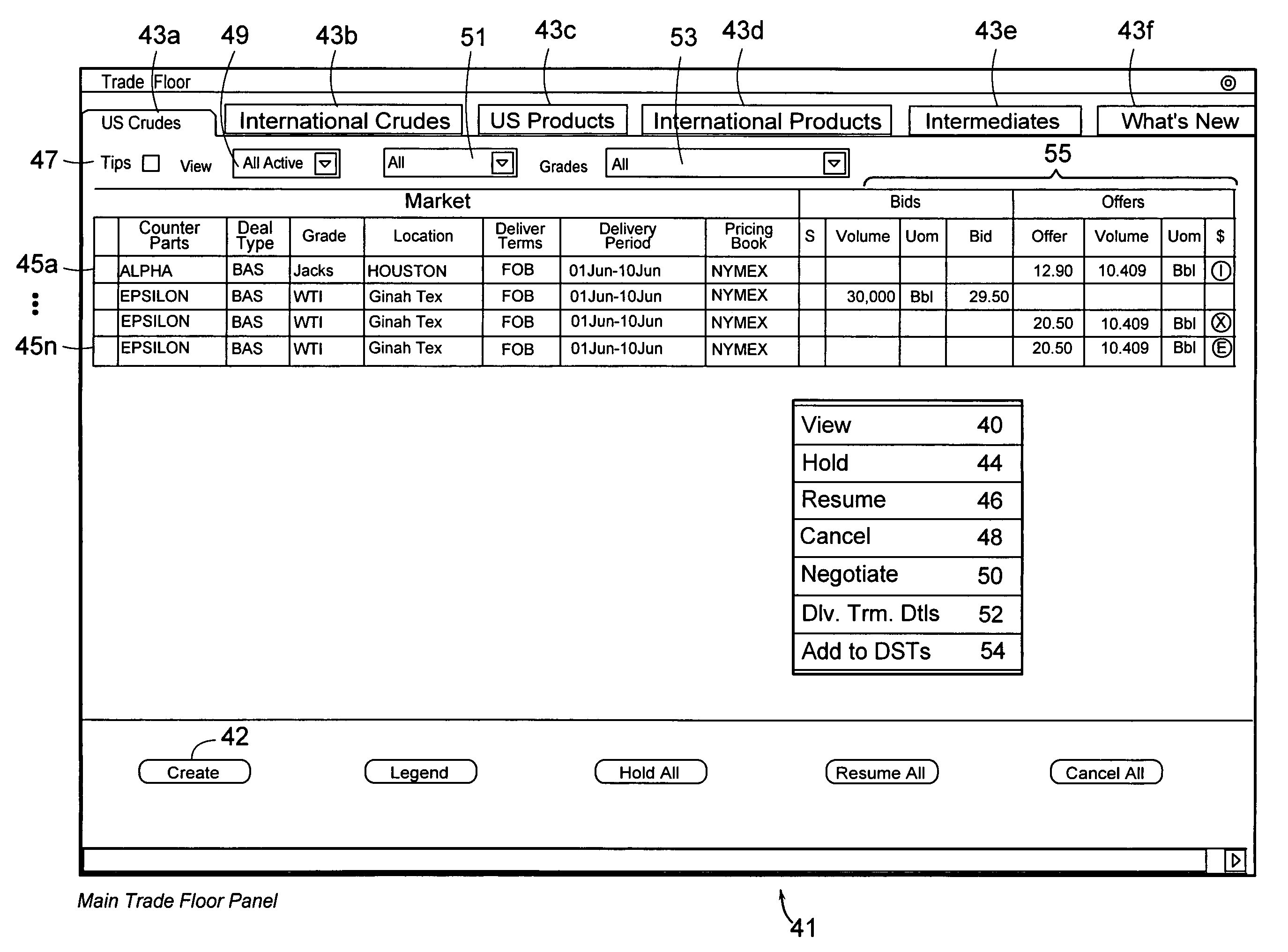

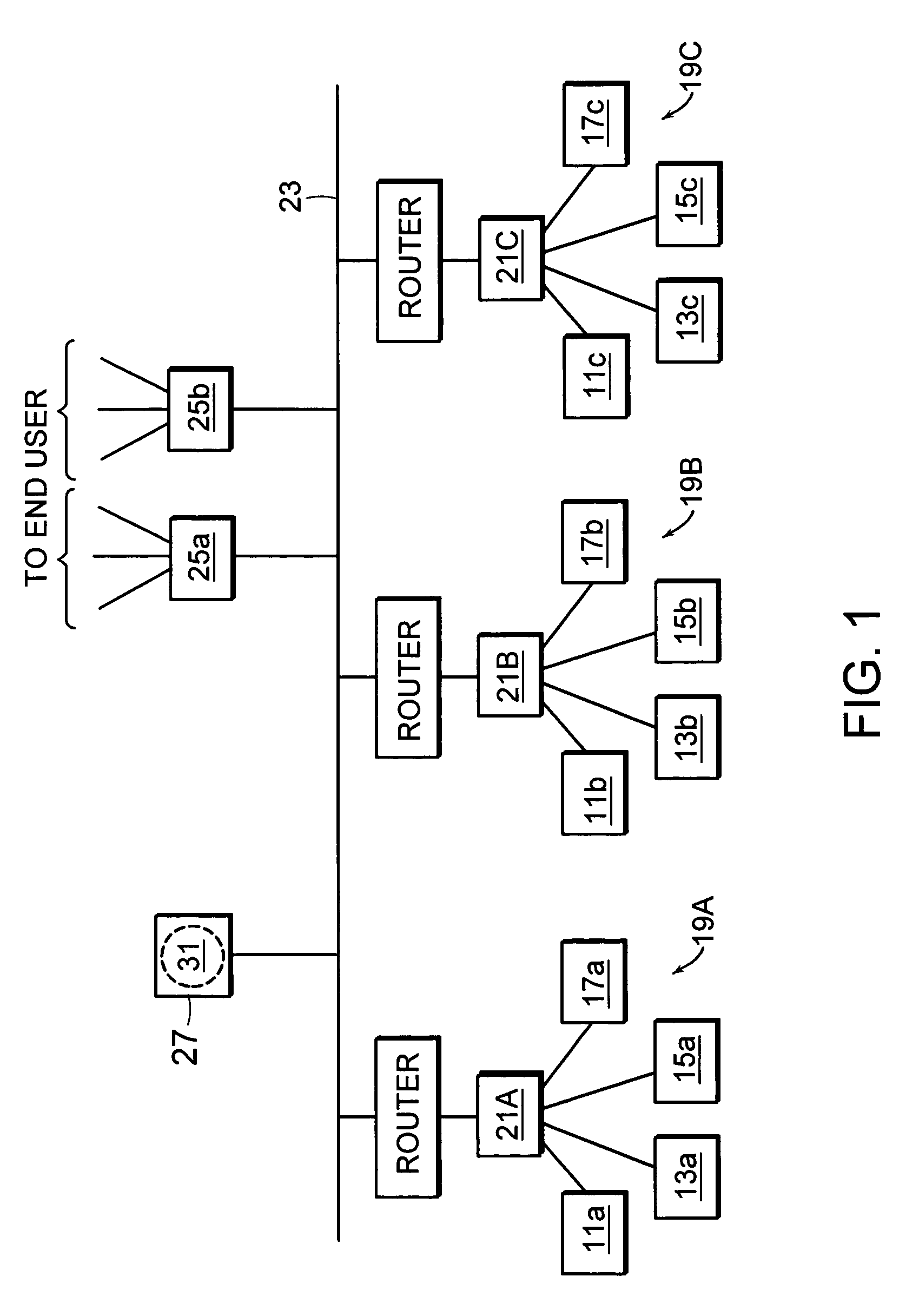

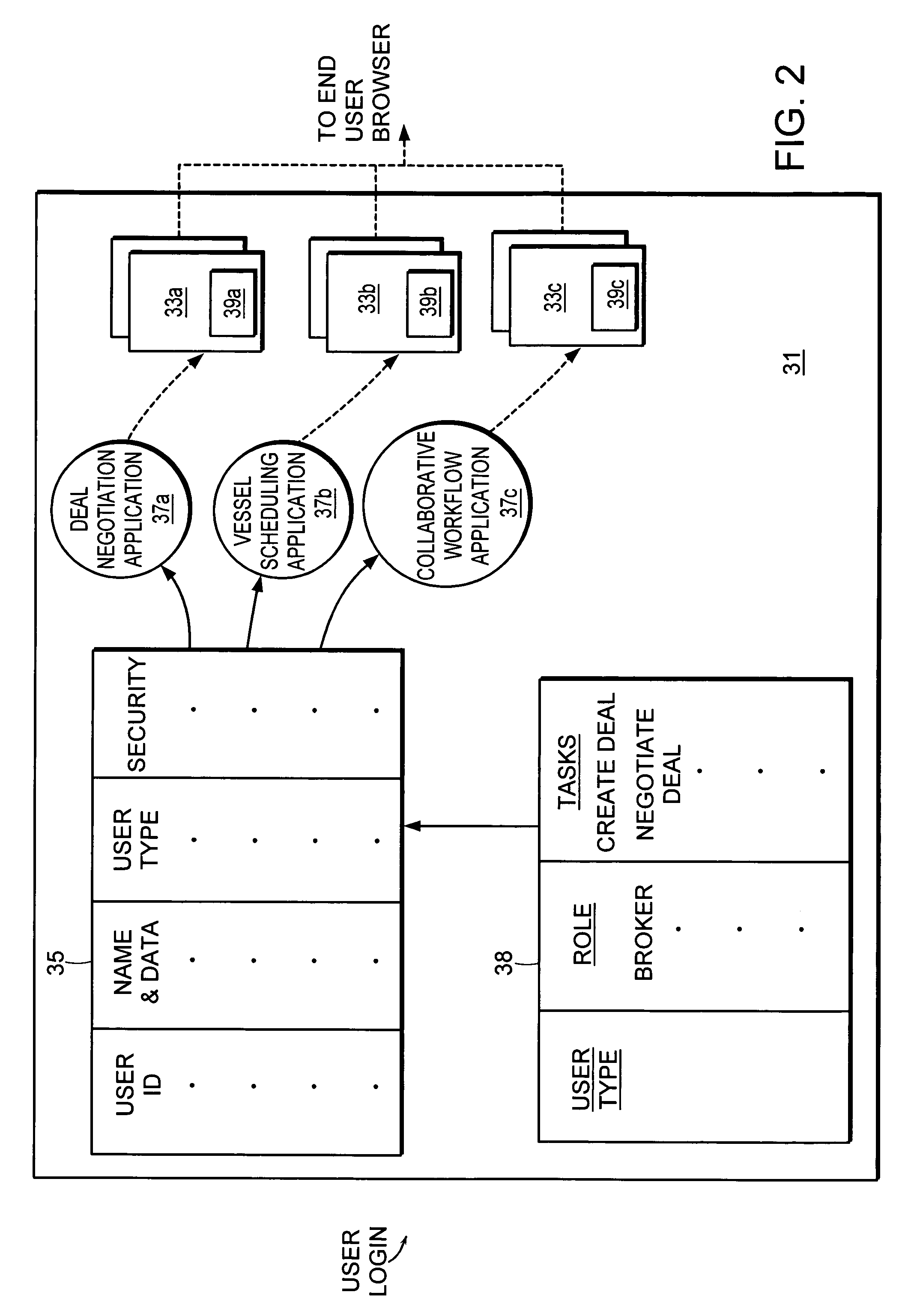

Computer method and apparatus for vessel selection and optimization

InactiveUS6983186B2Accurate dataFew typographical errorFinanceOffice automationLogistics managementComputer methods

Owner:ASPENTECH CORP

Methods for characterization of petroleum reservoirs employing property gradient analysis of reservoir fluids

ActiveUS20130151159A1Accurate representationElectric/magnetic detection for well-loggingConstructionsReservoir fluidPetroleum reservoir

A methodology for reservoir understanding employs analysis of fluid property gradients to investigate and distinguish between non-compartmentalization of the reservoir, compartmentalization of the reservoir, and lack of thermodynamic equilibrium in the reservoir.

Owner:SCHLUMBERGER TECH CORP

Technical method and schedule for preparation of foam carbon material used asphalt as raw material

Owner:DALIAN UNIV OF TECH

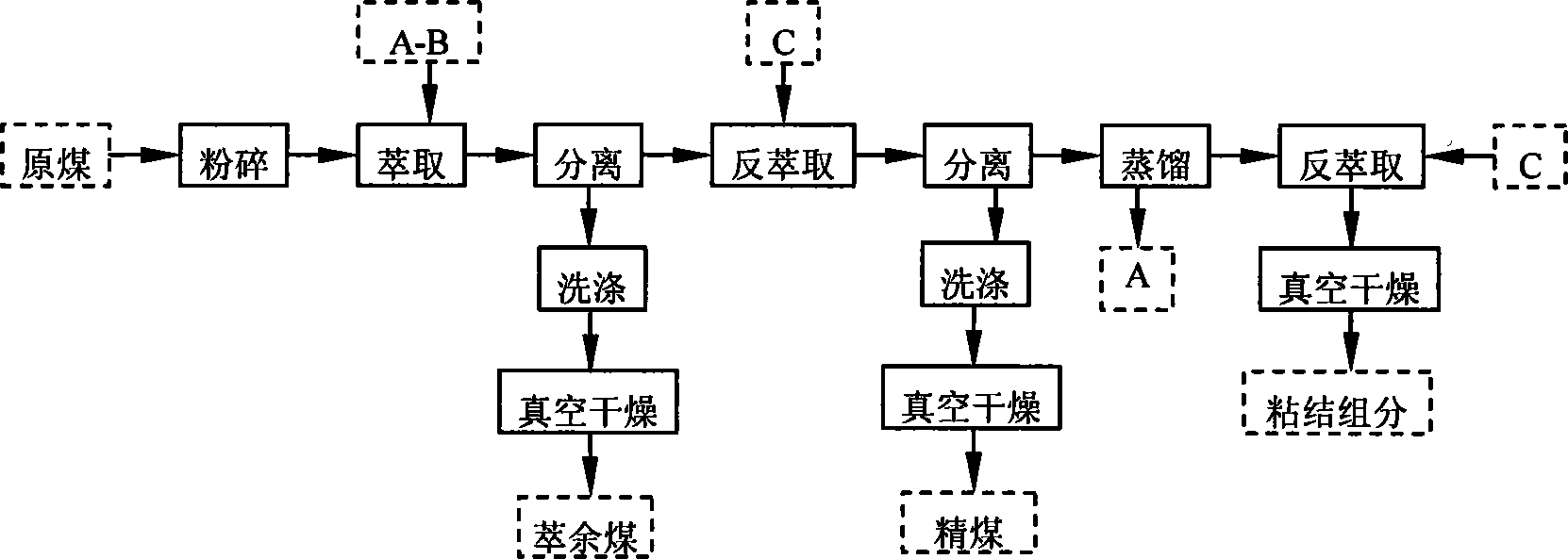

Mild coal-family component separation method based on extraction and back extraction

InactiveCN101070495AEasy to useImprove environmental benefitsSolid fuelsSolid solvent extractionWater useDistillation

Owner:CHINA UNIV OF MINING & TECH

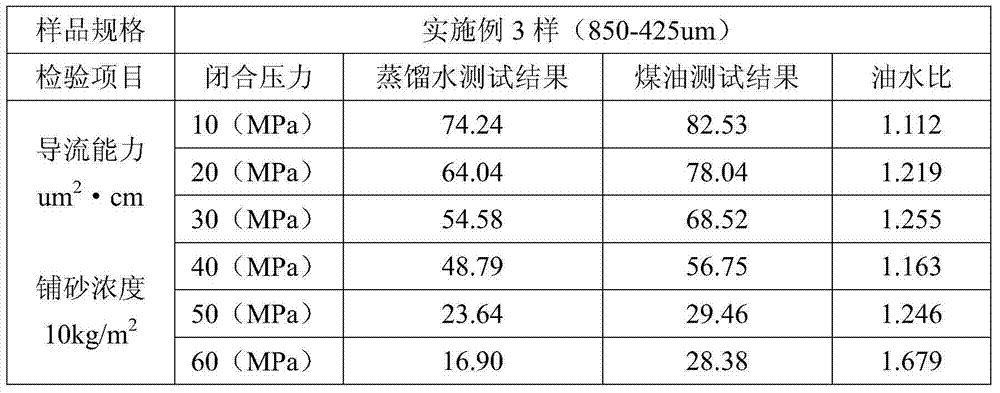

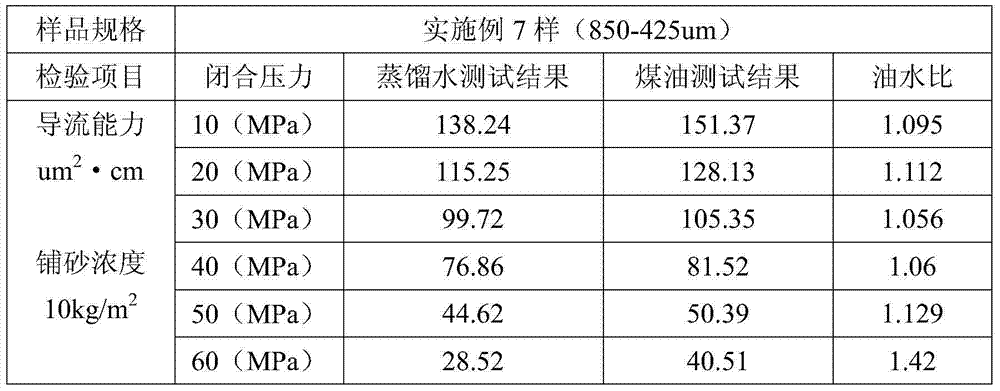

Preparation method of oleophilic hydrophobic coated proppant

InactiveCN104277821AIncrease oil outputIncrease productionFluid removalDrilling compositionProduction ratePlasticizer

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

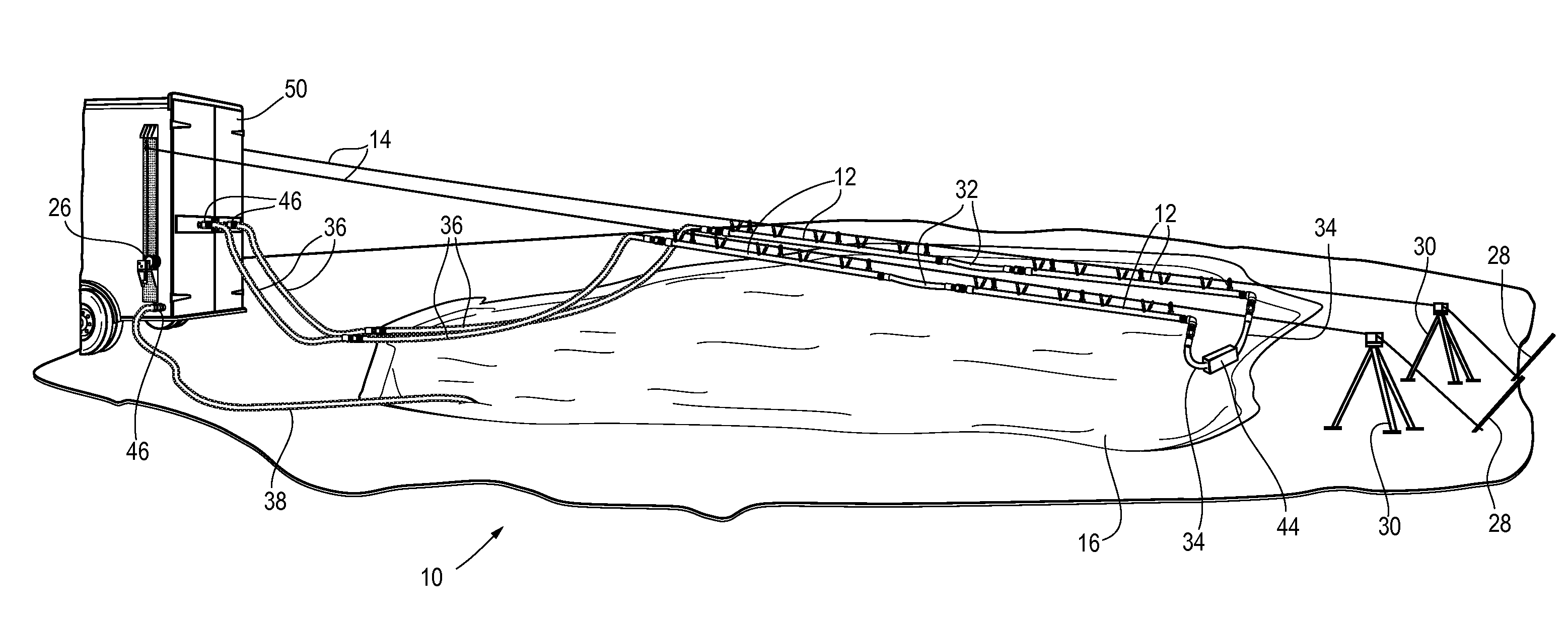

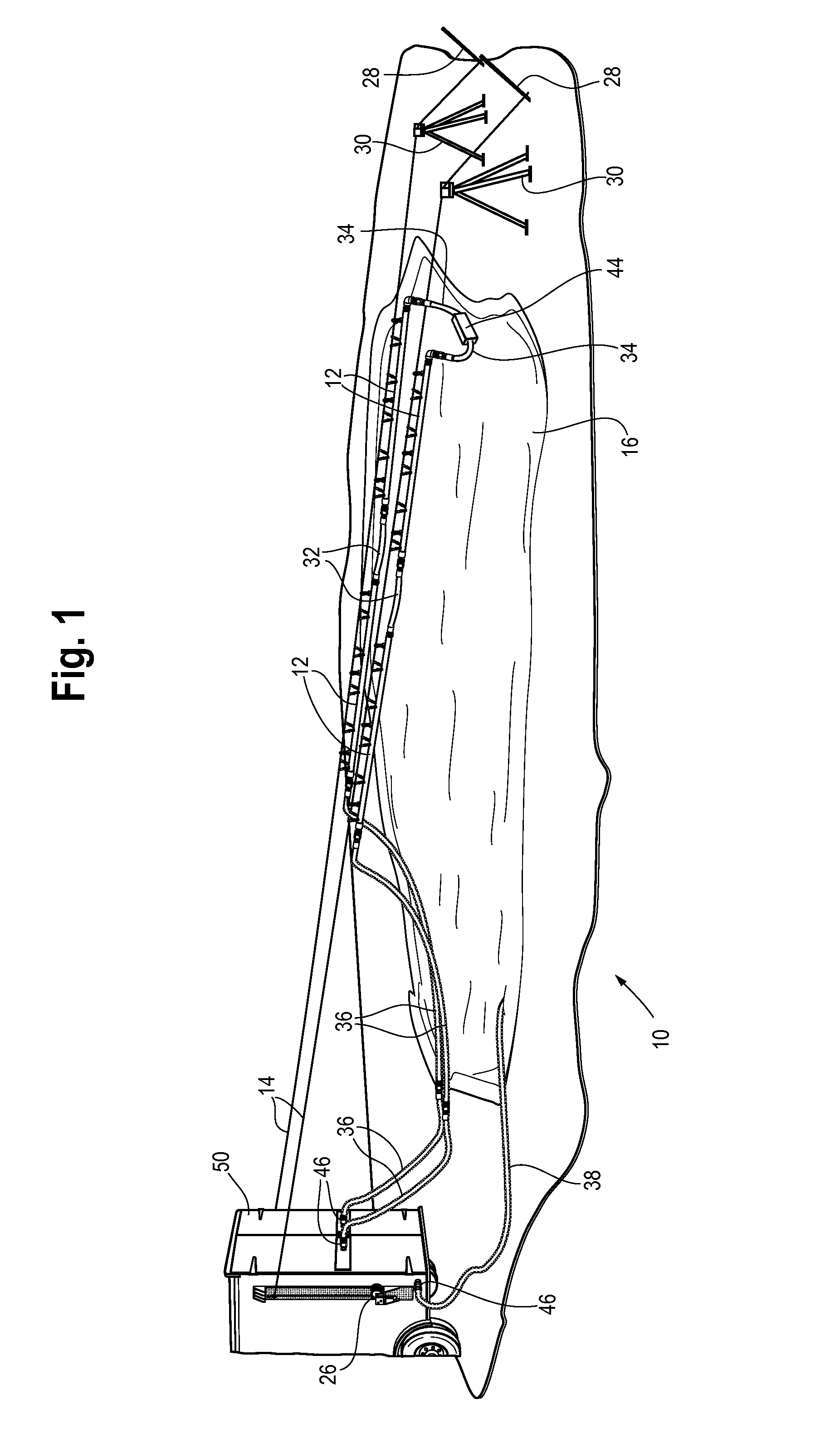

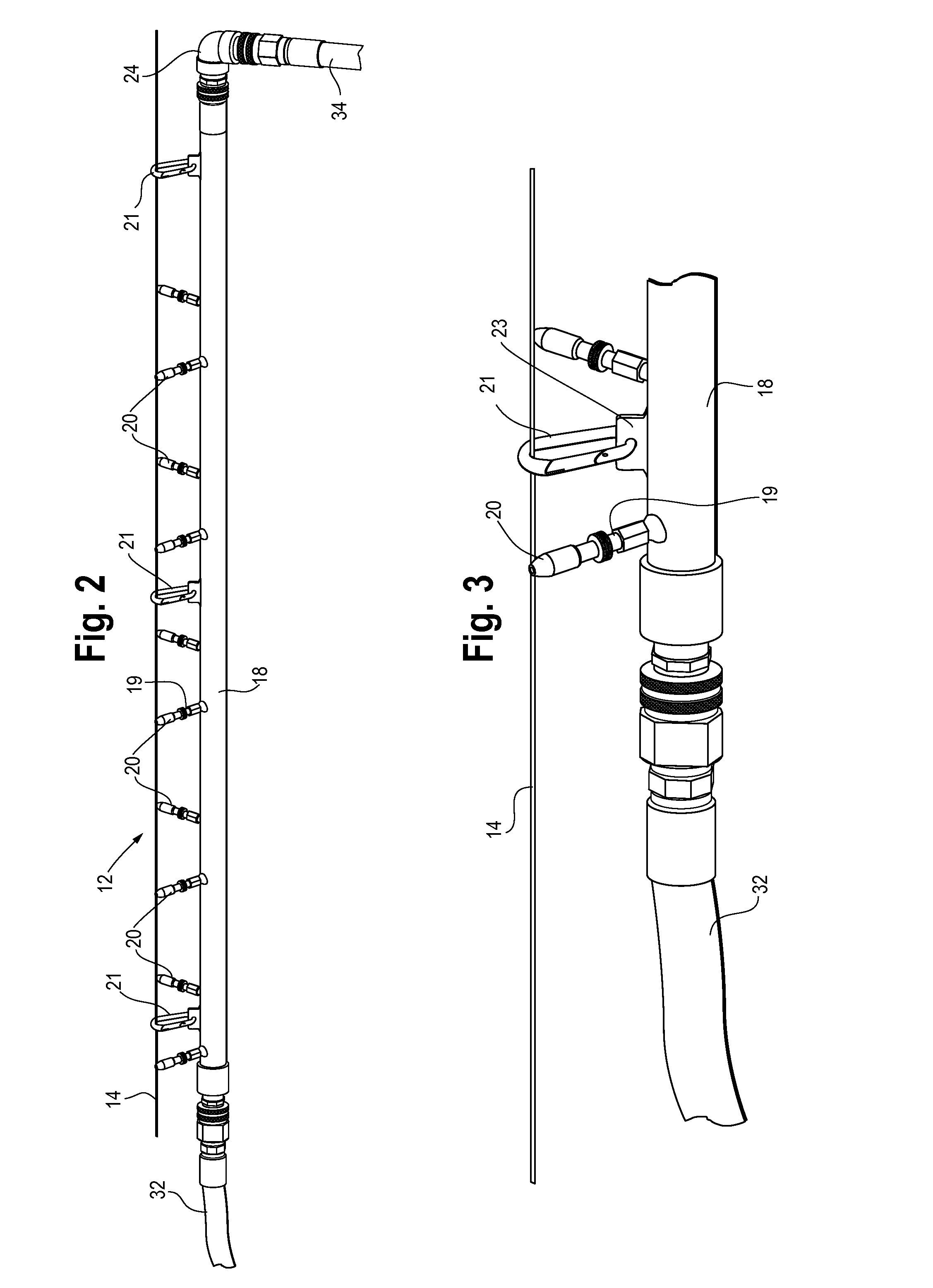

Water evaporation system using nozzles attached to a suspended cable

Owner:EVAPORITE SYST

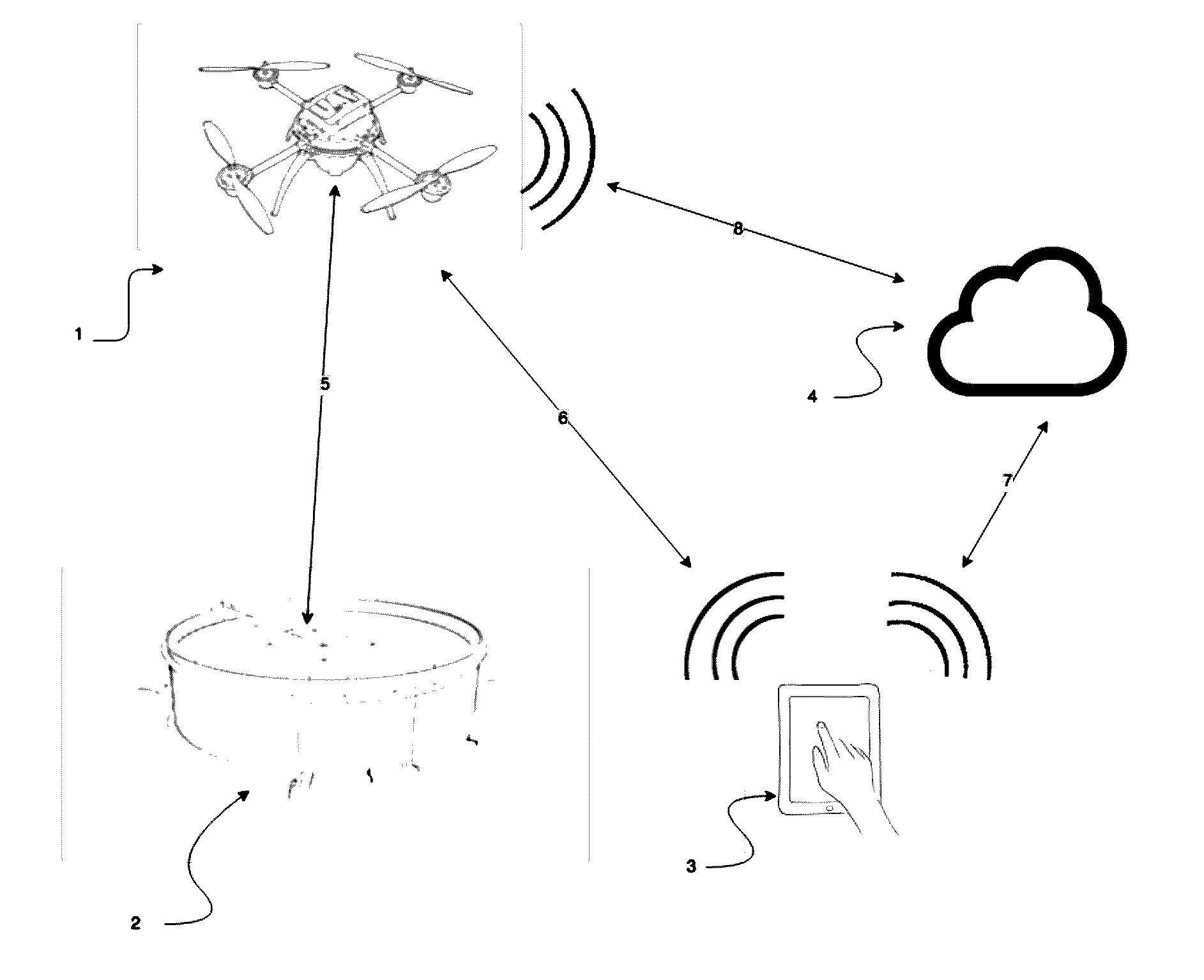

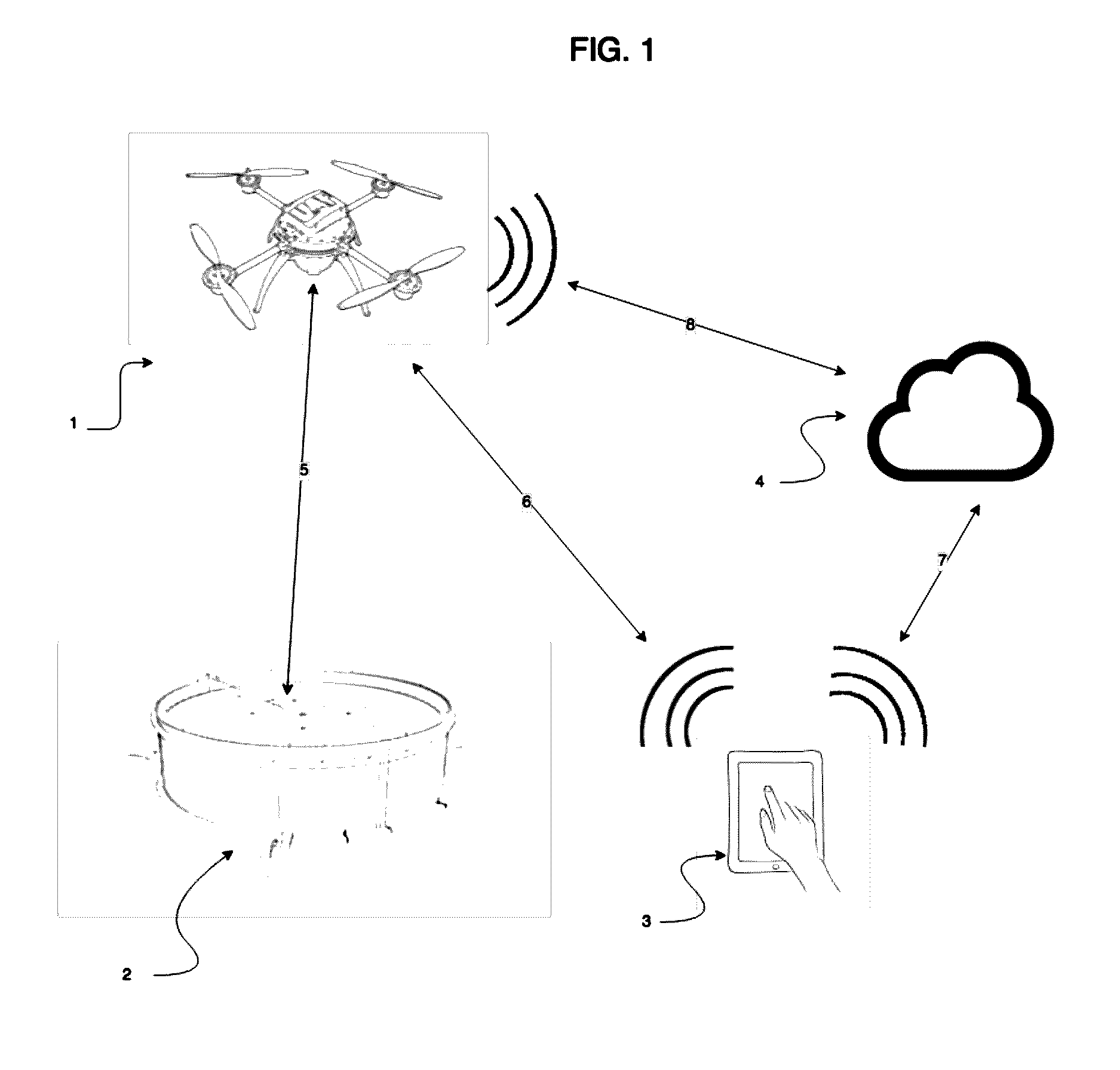

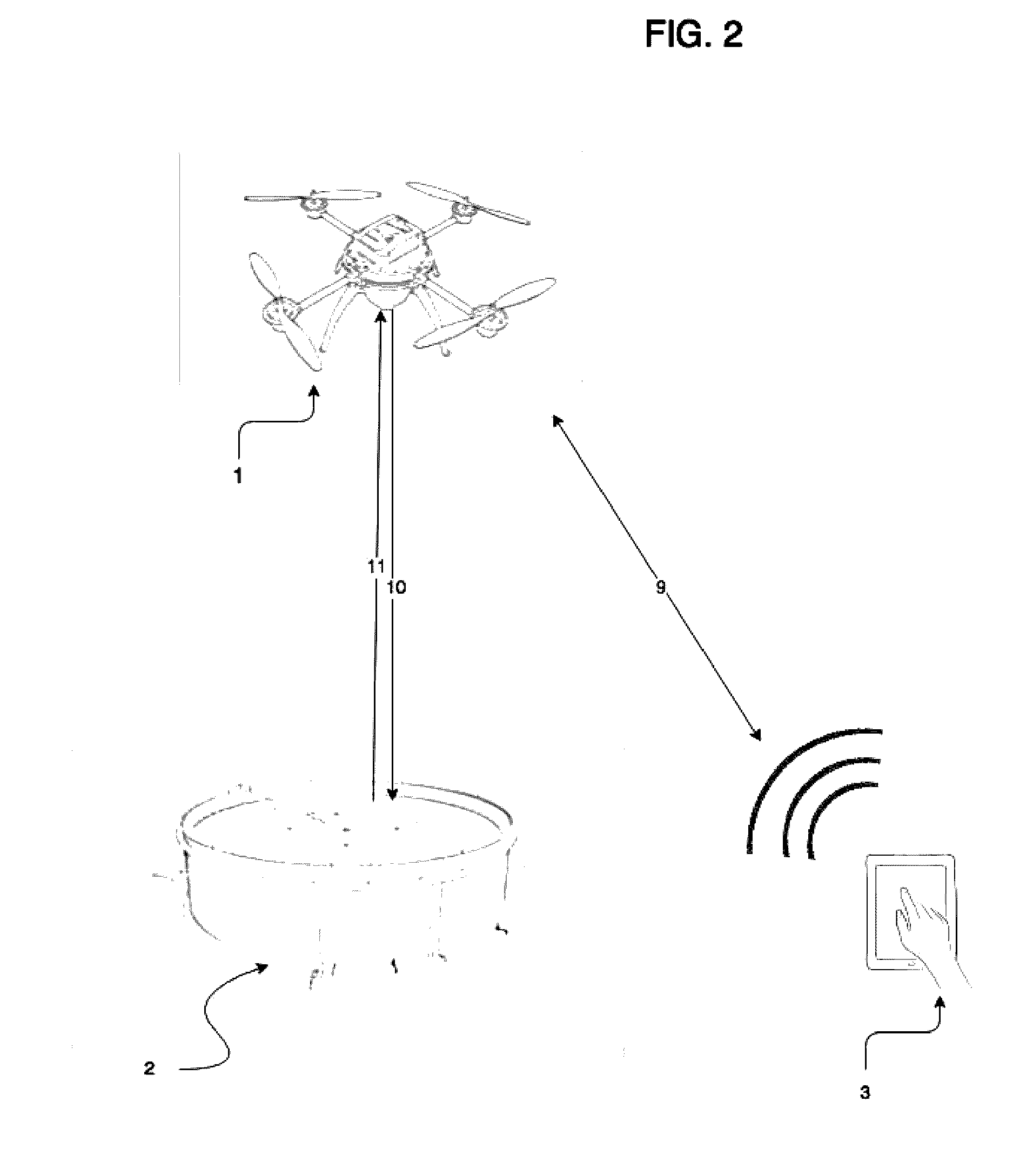

System and Method for Unmanned Aerial Vehicle Monitoring of Petroleum Storage Container Contents

InactiveUS20170023394A1Aircraft componentsVolume measurement apparatus/methodsPetroleumDistance measurement

Owner:AKBAR IMRAN

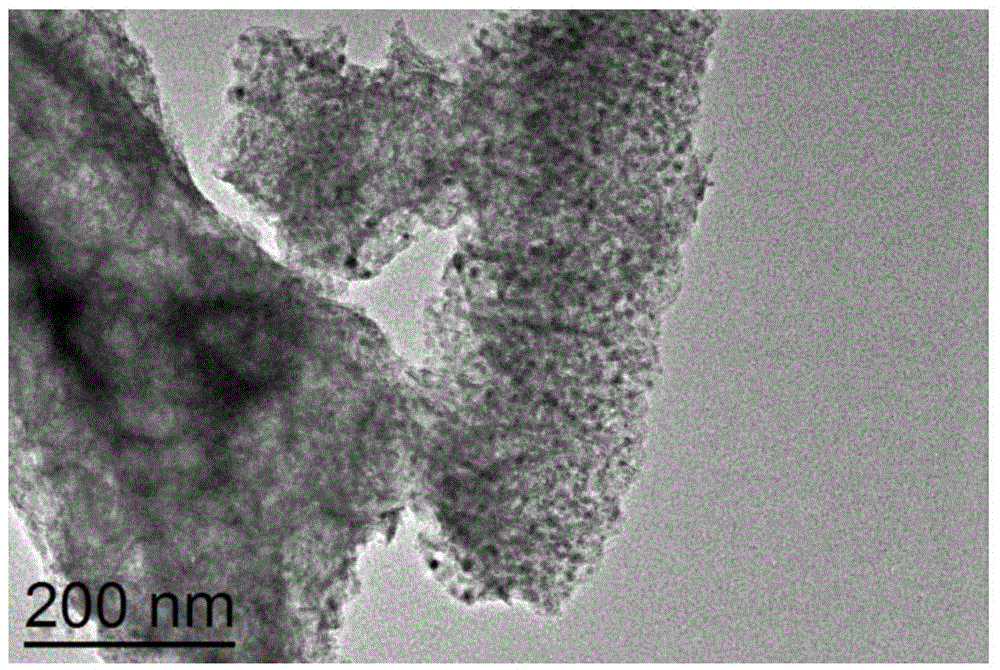

Catalyst for catalyzing hydrogenation of petroleum resin as well as preparation method and application thereof

Owner:DALIAN UNIV OF TECH

Preparation method of sialite binding material for well-cementing in oil-gas field

The invention discloses a preparation method of a sialite binding material for well-cementing in an oil-gas field, which belongs to the field of oil and gas development. The preparation method comprises the steps of mixing (by weight percentage) cement clinker 0-45%, granular blast-furnace cinder 55-95% and pulverized fuel ash 0-5%, and grinding together; mixing (by weight percentage) the ground mixed material 30-59.5%, pulverized fuel ash, coal-fired furnace cinder burnt clay or red mud 40-60% and a diagenetic agent, and grinding together; and mixing (by weight percentage) the ground mixed material 80-95% and ground expanded vermiculite 5-15% to obtain the sialite binding material for well-cementing. The preparation method is not only in favor of solving various problems in well-cementing in the oil-gas field, but also remarkably reduces emission of CO2 and other pollutants compared with that in the conventional oil-well cement production.

Owner:TSINGHUA UNIV +1

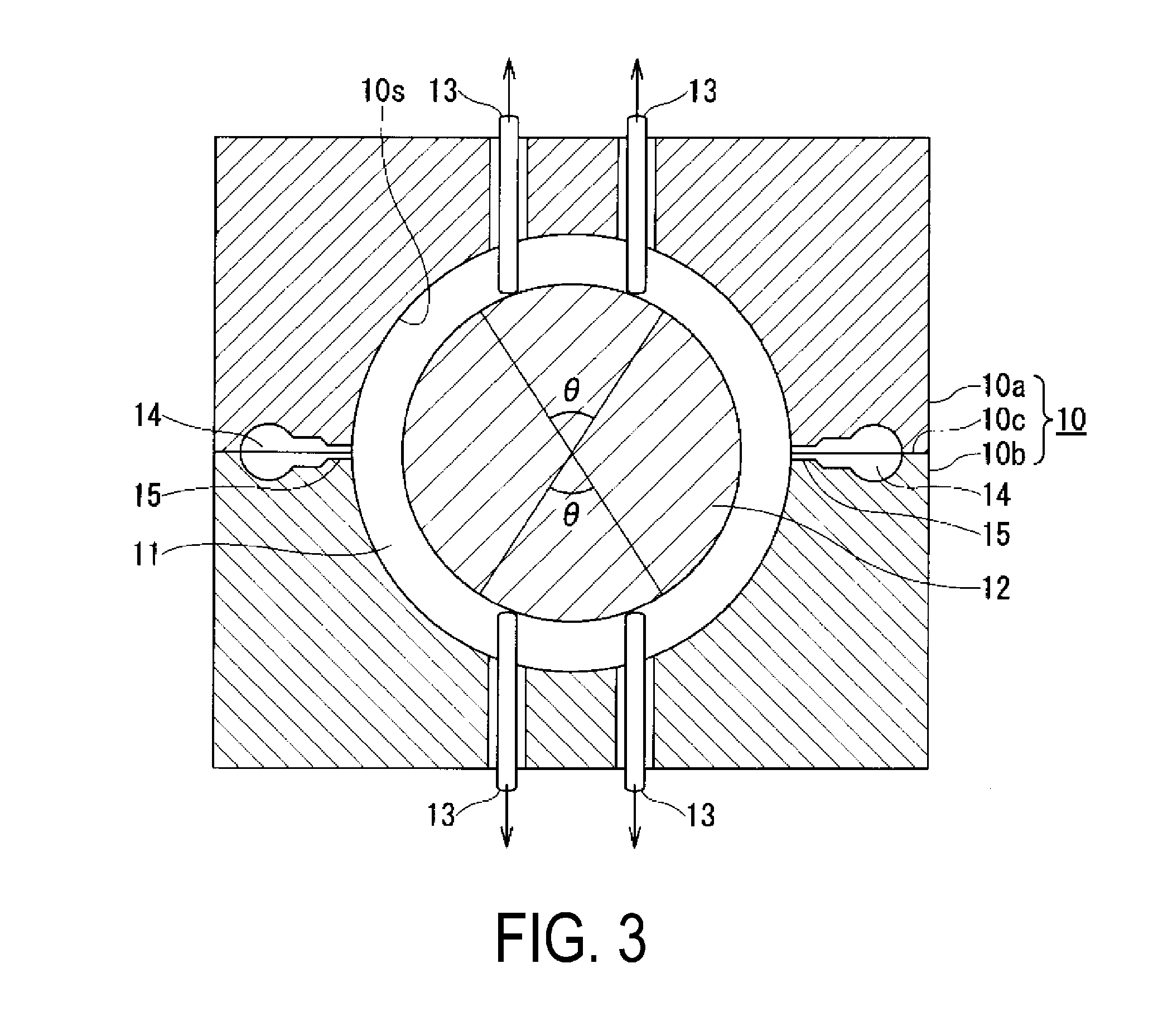

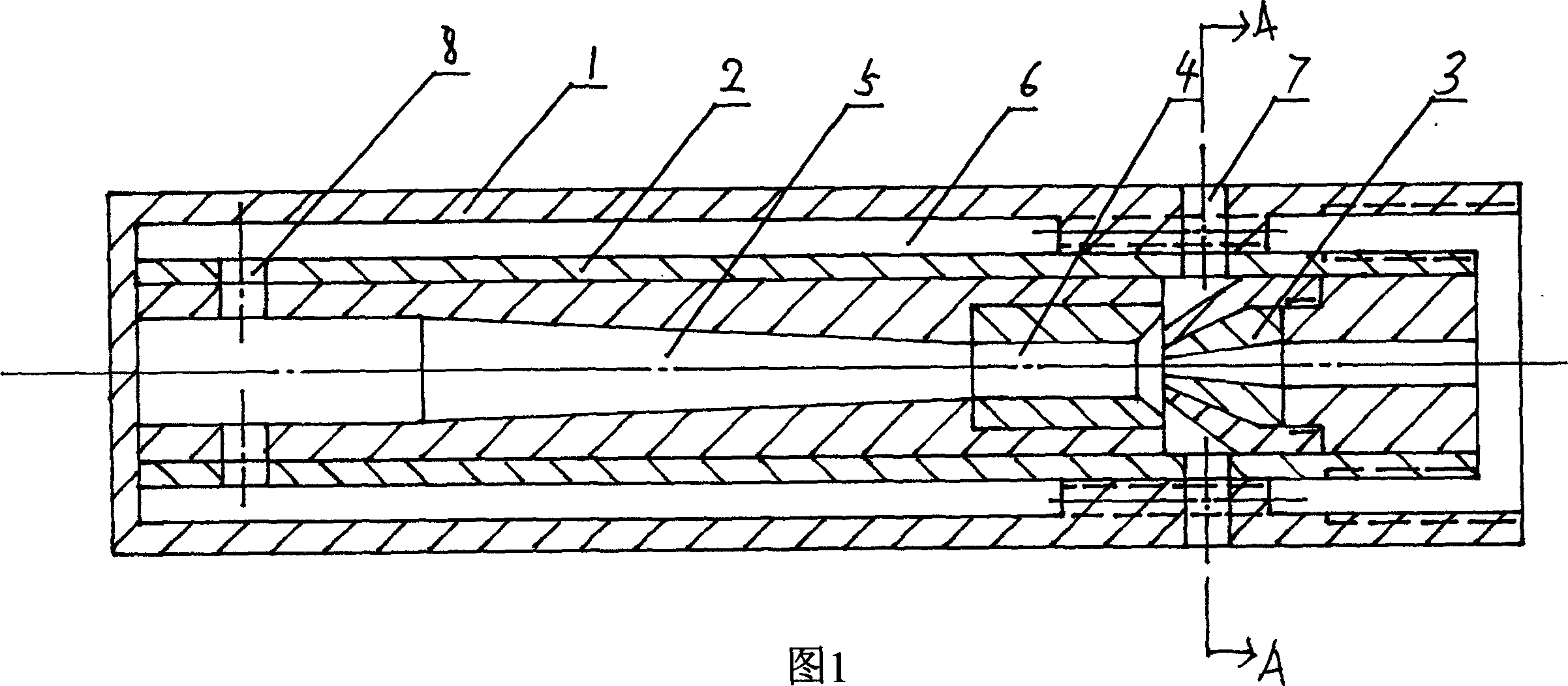

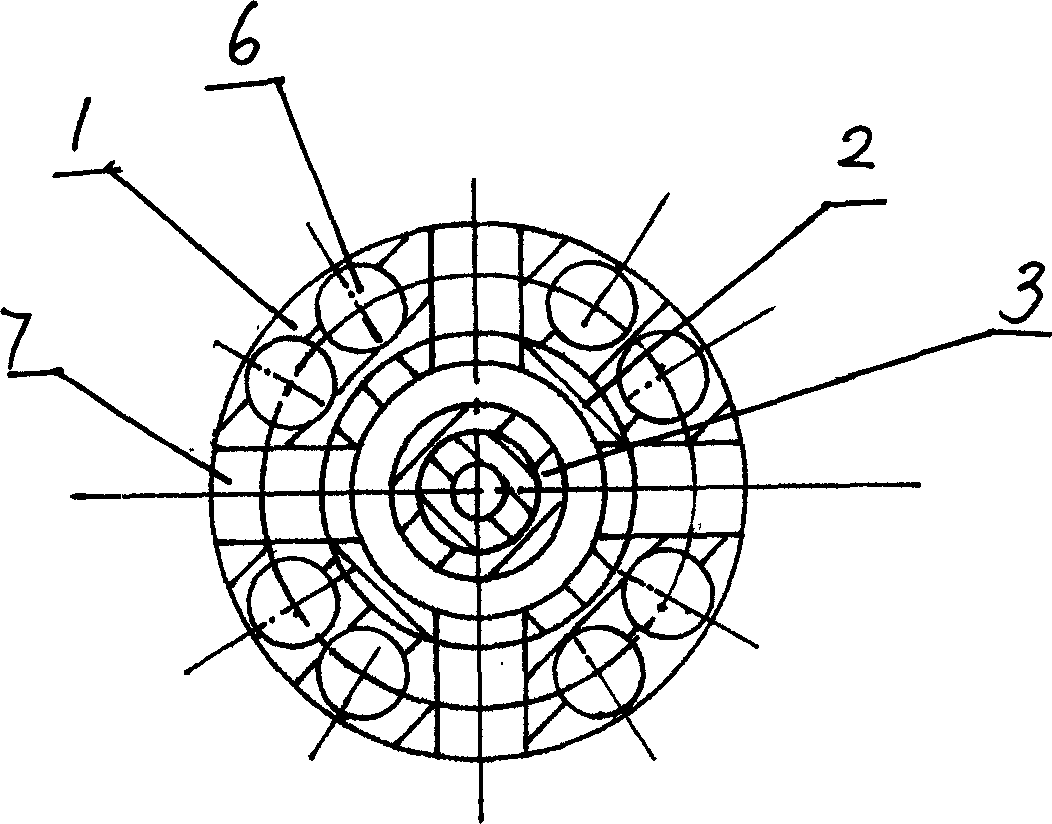

Magnetizing device capable of reducing petroleum viscosity in oil pipeline

InactiveCN101908402AReduce magnetic field strengthLow viscosityMagnetic bodiesPipeline systemsRing deviceMagnetization

The invention relates to a magnetizing device capable of reducing the petroleum viscosity in an oil pipeline, comprising a stainless steel pipe, a pipe-shaped magnetic yoke, non-magnetic tile-shaped blocks, an upper tile-shaped permanent magnet set and a lower tile-shaped permanent magnet set. The stainless steel pipe is arranged in the pipe-shaped magnetic yoke along the axis of the pipe-shaped magnetic yoke; both ends of the stainless steel pipe extend out of the pipe-shaped magnetic yoke; the upper tile-shaped permanent magnet set and the lower tile-shaped permanent magnet are spaced from each other by two non-magnetic tile-shaped blocks and are symmetrically arranged between the stainless steel pipe and the pipe-shaped magnetic yoke by taking the axis of the pipe-shaped magnetic yoke as a center; the tile-shaped permanent magnet set consists of at least two pairs of permanent magnets which have different thicknesses and are connected with each other by tile-shaped middle magnetizer heteroples; and the magnetization directions of the permanent magnets are consistent with the axial direction of the stainless steel pipe. The invention has the advantages that the device has simple structure, requires no outside resources and is convenient to use and install; the gradient magnetic field distribution reduces the magnetic field strength at the tail end of a magnetic ring device, relieves damage of petroleum flowing orderly as a result of strong magnetic field strength and reduces the viscosity of crude oil.

Owner:UNIV OF SCI & TECH BEIJING

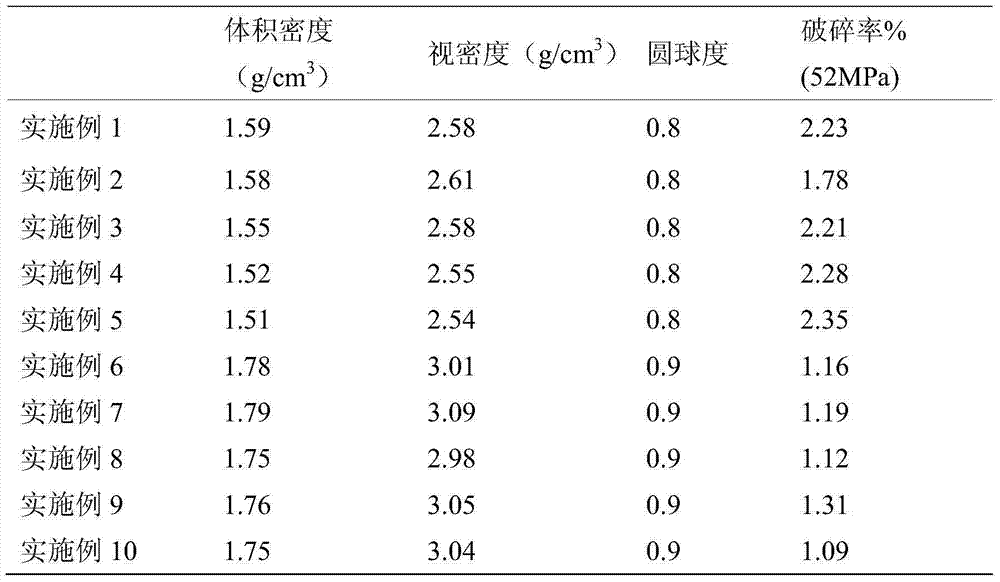

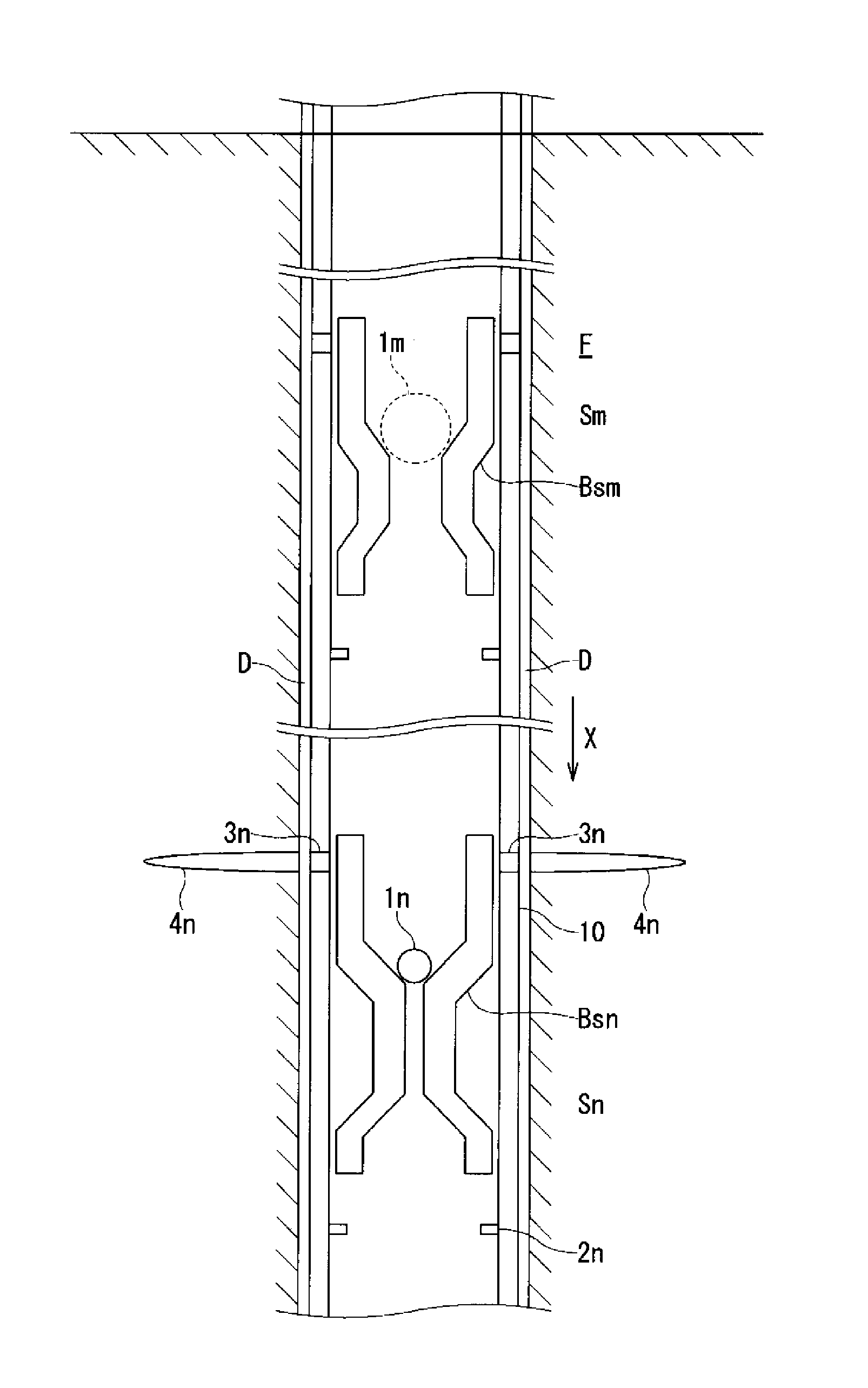

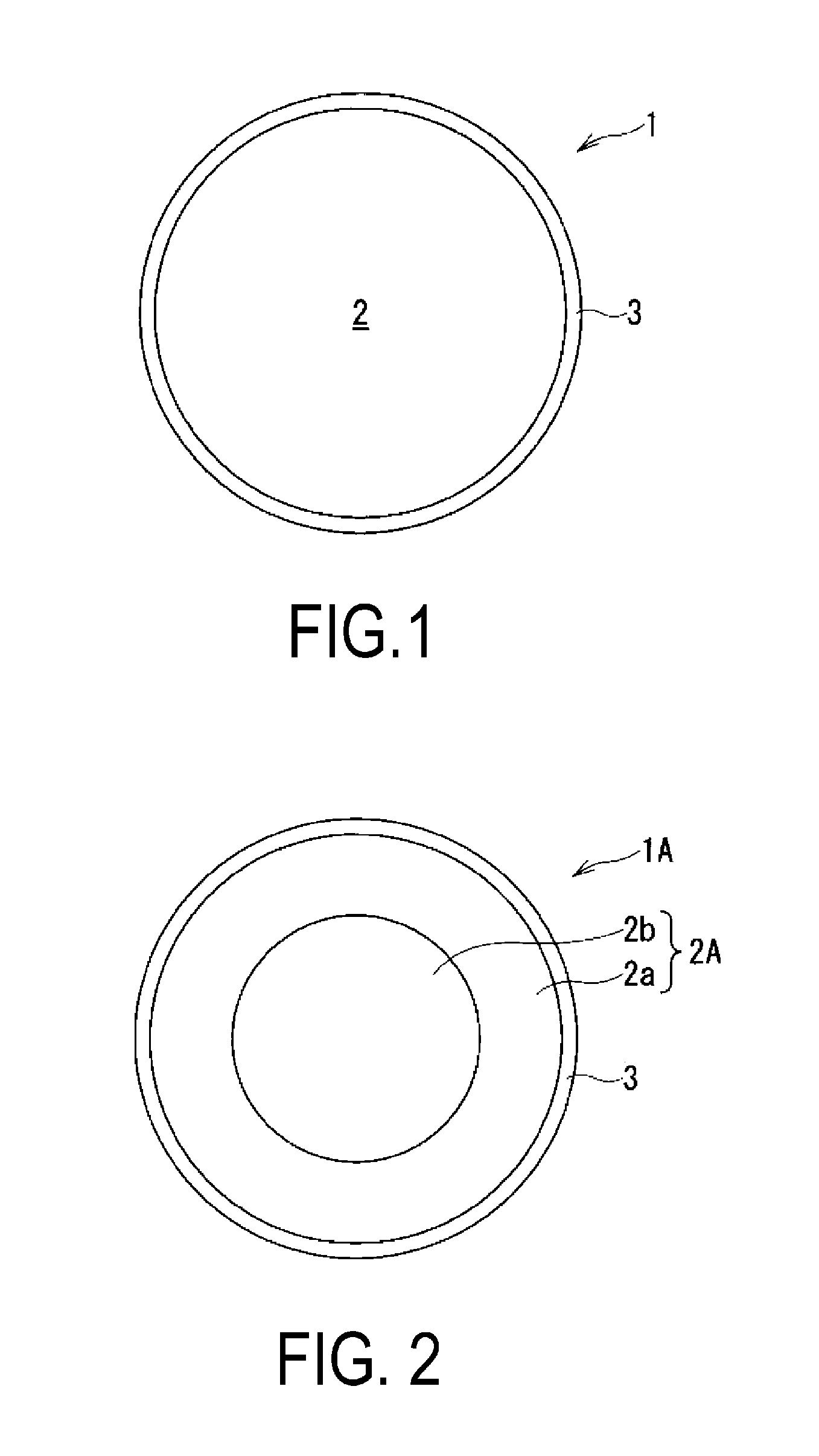

Ball sealer for hydrocarbon resource recovery, method for manufacturing same, and method for treating borehole using same

ActiveUS20160312111A1Improve impact resistanceDisintegrable aliphaticFluid removalDrilling compositionChemistryPetroleum

Owner:KUREHA KAGAKU KOGYO KK

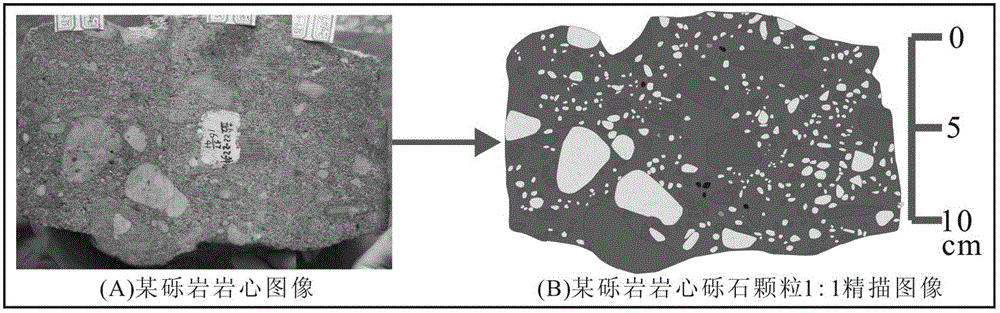

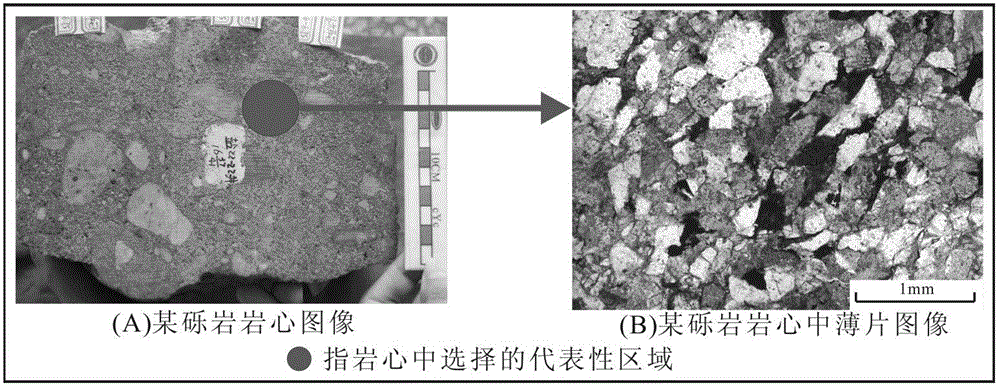

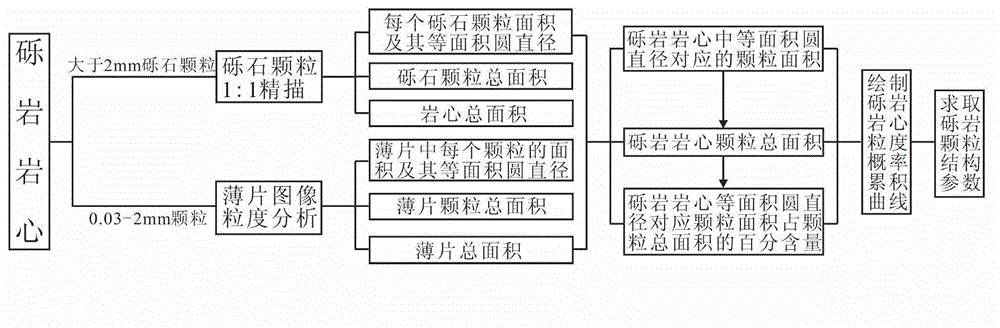

Analytical method for particle size in conglomerate core particle structure

ActiveCN103149130AAccurately obtain granular featuresParticle size analysisMacroscopic scaleChemical physics

Owner:东营市大学科技园发展有限责任公司

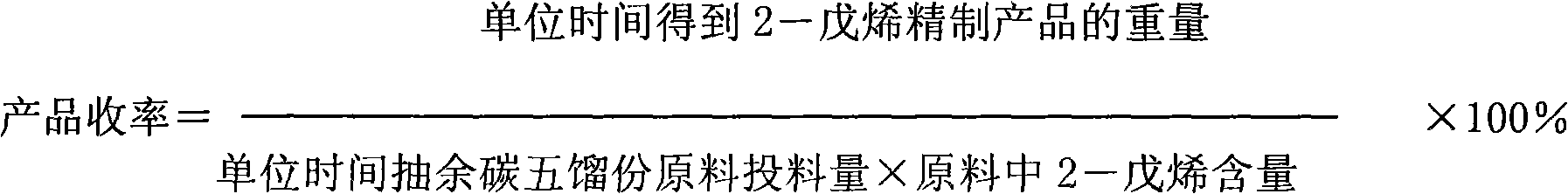

Process for preparing 2-amylene by separating C5 distillate of petroleum

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

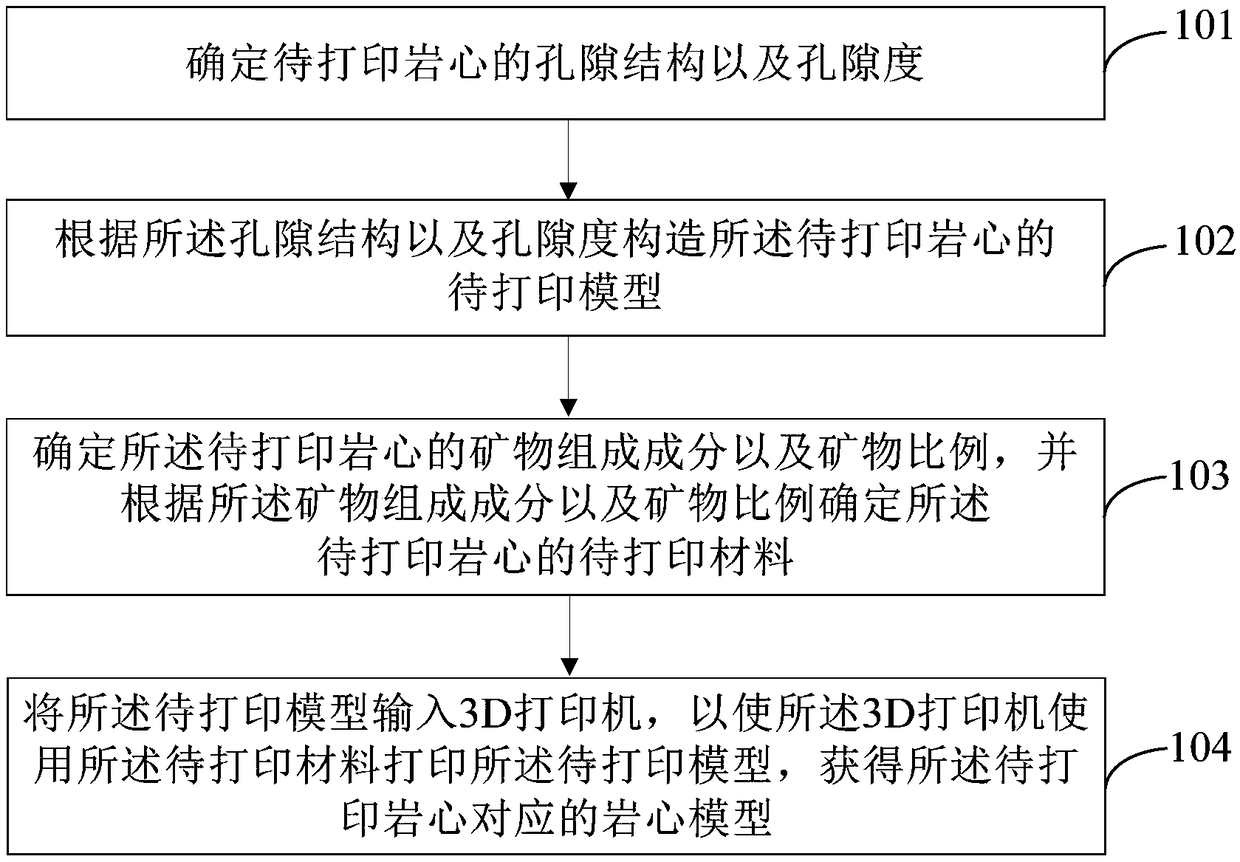

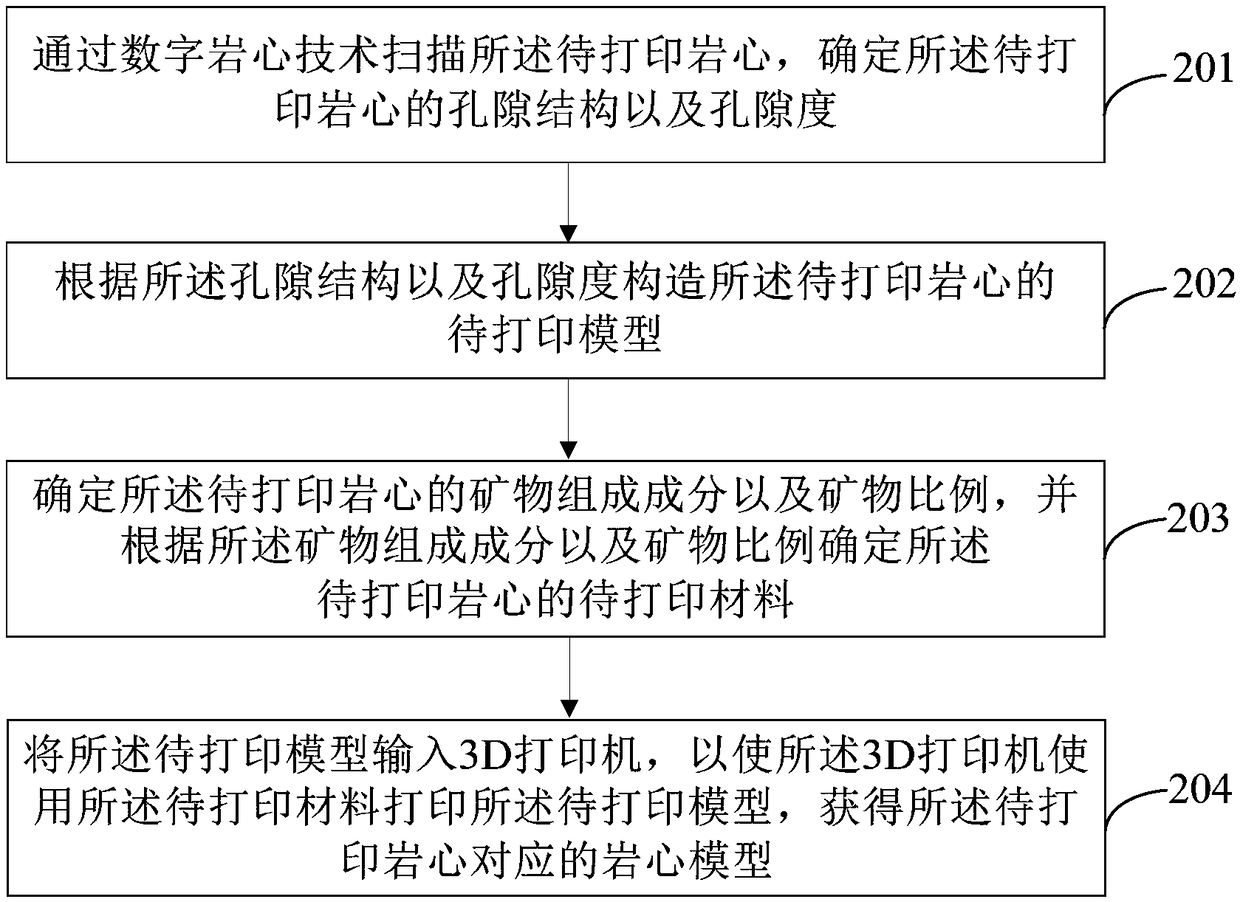

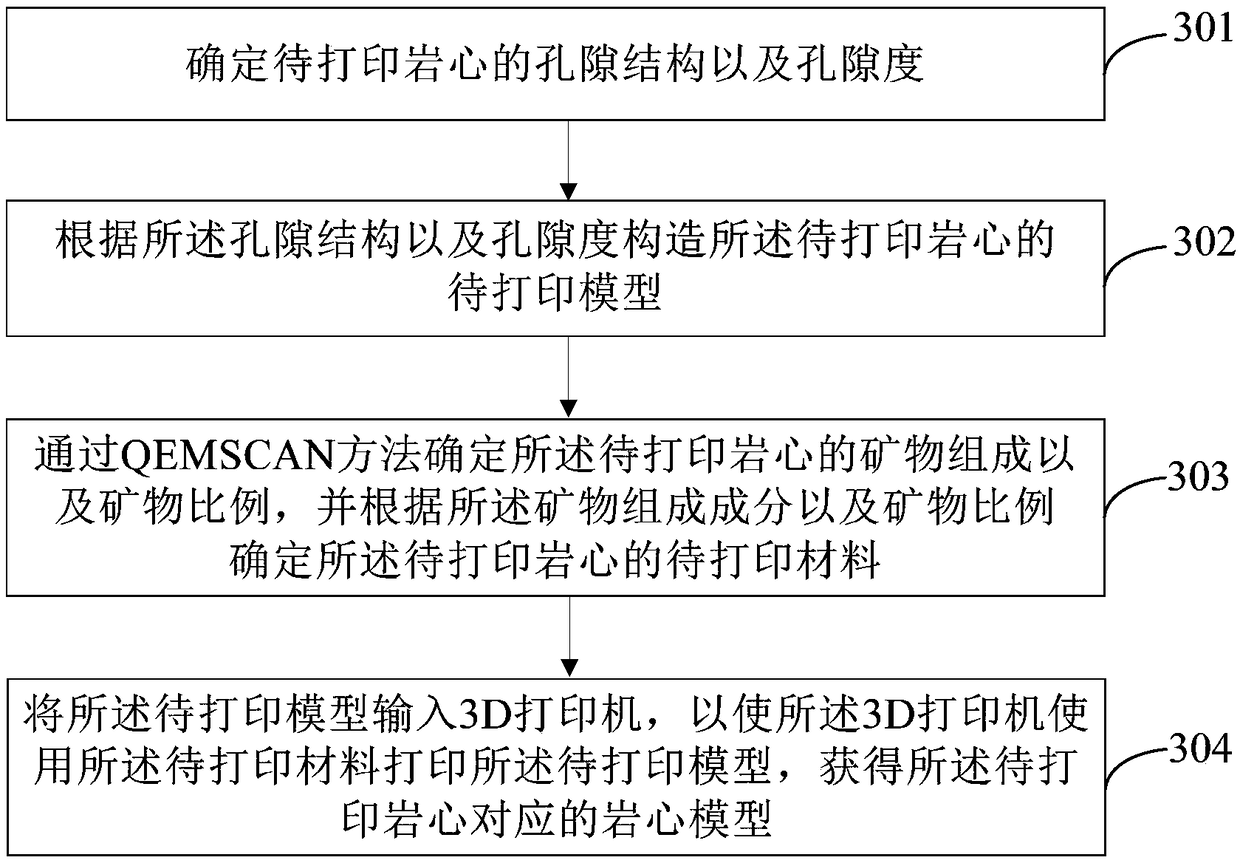

High-precision 3D printing method and device for unconventional rock model

InactiveCN108819215AAdditive manufacturing apparatusPreparing sample for investigationPetrologyPetroleum

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

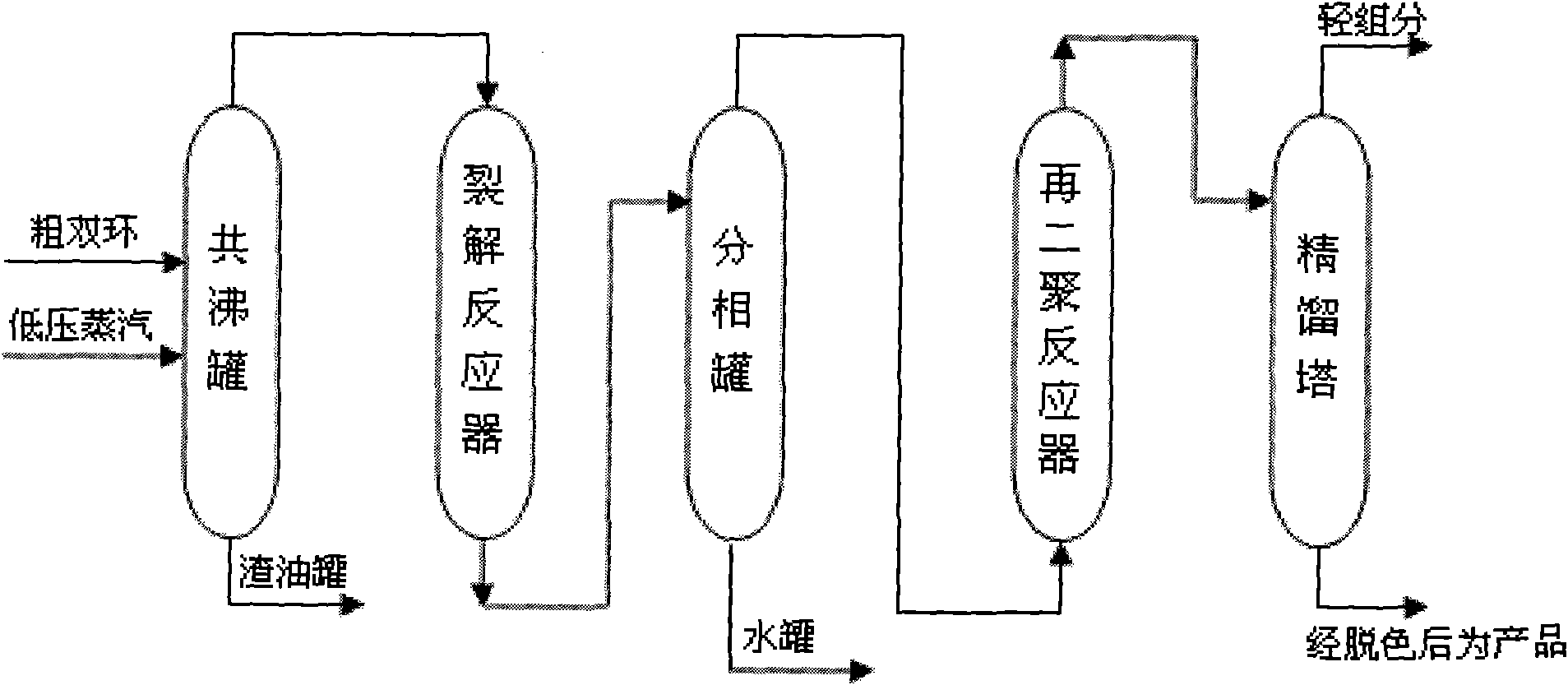

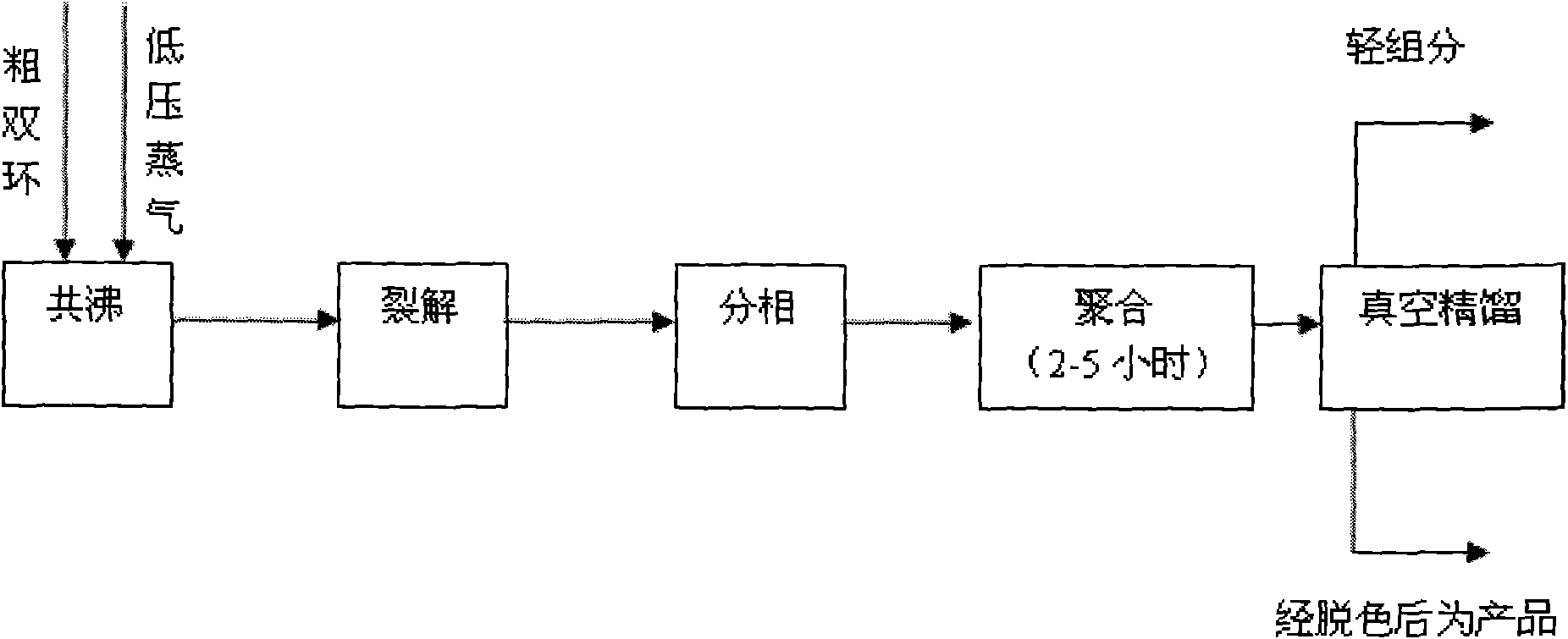

Preparation method of high purity dicyclopentadiene

ActiveCN101671224AHigh purification precisionEasy to industrializeDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionPetroleumChemistry

Owner:山东玉皇盛世化工股份有限公司

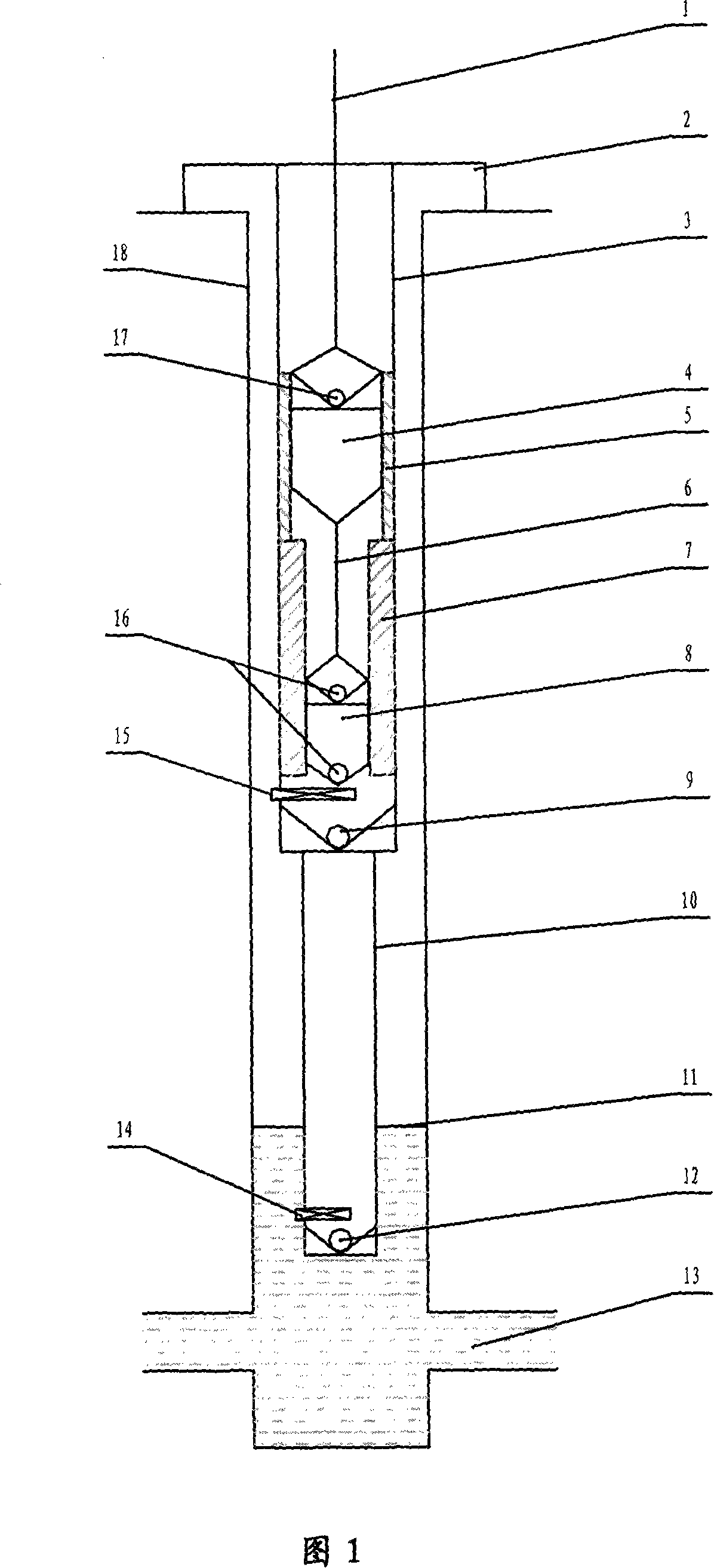

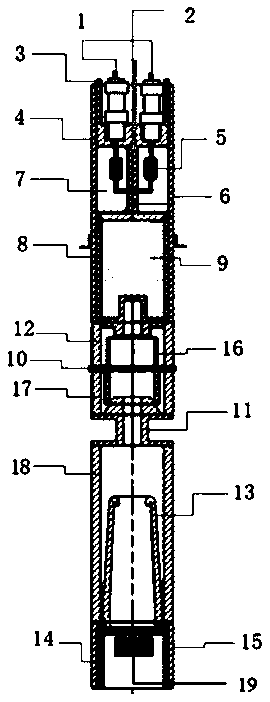

Device and method for measuring underground flow rate of petroleum well

The invention discloses a device and a method for measuring underground flow rate of a petroleum well. The device comprises a ground logging truck, and an instrument string which is connected through a cable and arranged in a sleeved oil pipe of an underground sleeve, wherein the instrument string comprises a halter, a first centering device, a magnetic positioning shot, a second centering device, a pressure difference density meter, a flow logger, a third centering device and a plug; a circuit system control motor or a hydraulic driving arm is mounted on the flow logger; static pressure sampling openings are respectively formed in the control motor or the hydraulic driving arm and the pressure difference density meter; the control motor or the hydraulic driving arm is opened or closed to measure underground flow rate of the petroleum well. According to the device, minimum annular section area between the arm and the sleeve is adjusted through the flow logger, so that the flow logger can be adapted to oil wells with various size and aperture; the construction processes are decreased; the working cost is saved; the working hours are reduced; the flow logger is applied to measuring of flow rate of a vertical shaft and a large-inclination-degree well, and the measuring precision is high.

Owner:XIAN WEISHENG ELECTRONIC INSTR CO LTD

Two-stage down-hole pipe pump oil extracting device

InactiveCN101109375AReduce suspension weightWith energy savingFlexible member pumpsFluid removalDouble stagePetroleum

Owner:姜楠 +2

Method for preparing gasoline rich in isoparaffin from methanol and/or dimethyl ether

InactiveCN106867564AImprove qualityBroaden the application marketMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention relates to a method for preparing gasoline rich in isoparaffin from methanol and / or dimethyl ether. A catalyst used in the method is prepared from a molecular sieve-loaded active metal component. Since the catalyst used in the method has excellent selectivity on isoparaffin in a gasoline fraction (hydrocarbons with a carbon atom number of 5 to 11; and low selectivity on olefins and aromatic hydrocarbons, the composition of the gasoline produced by using the method can meet the national gasoline standard VI in China, or even meet requirements on the contents of aromatic hydrocarbons and olefins in world advanced standards for clean fuels (such as the European standard V and standards for motor gasoline in California of the US). The method provides a feasible technical route for direct acquisition of non-petroleum resources and has good market prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Methanol gasoline

InactiveCN106957697ALow costImprove performanceLiquid carbonaceous fuelsFuel additivesGasoline fuelAntioxidant

Owner:泸州清大能源股份有限公司

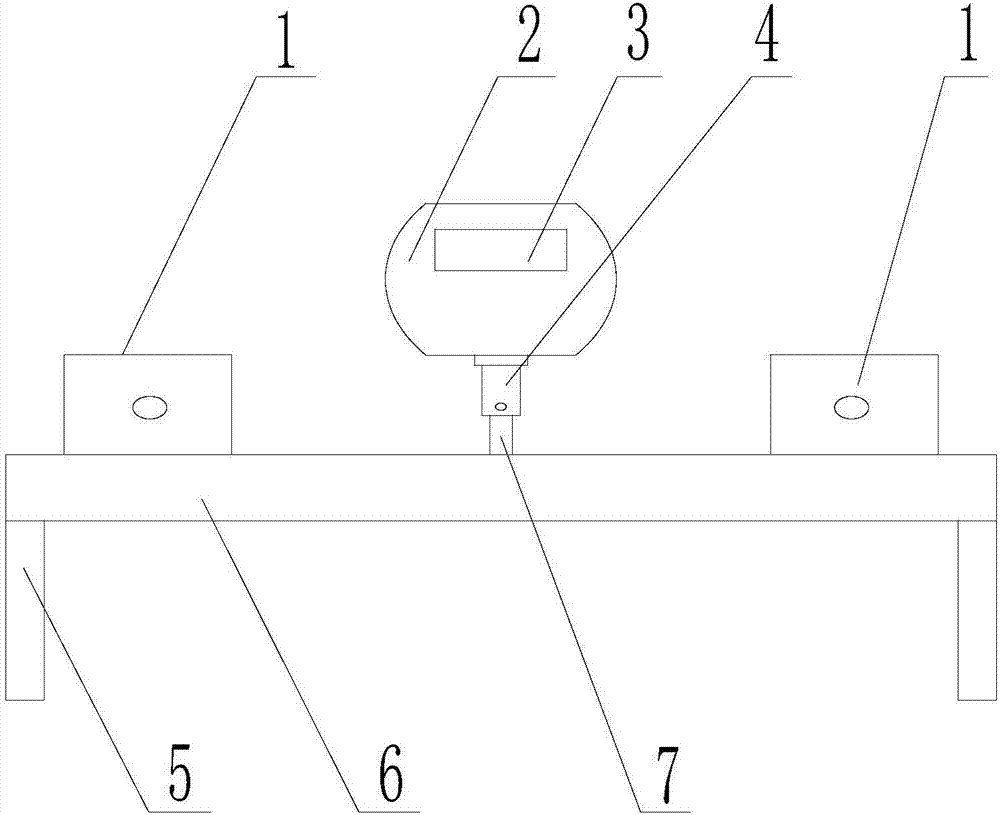

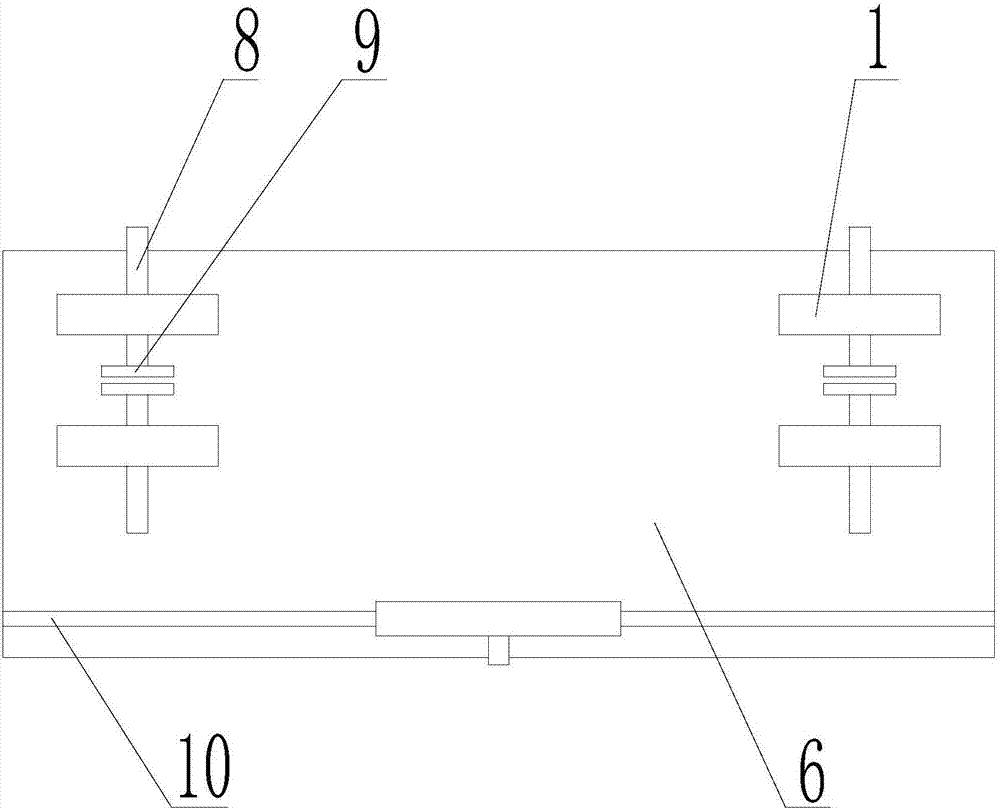

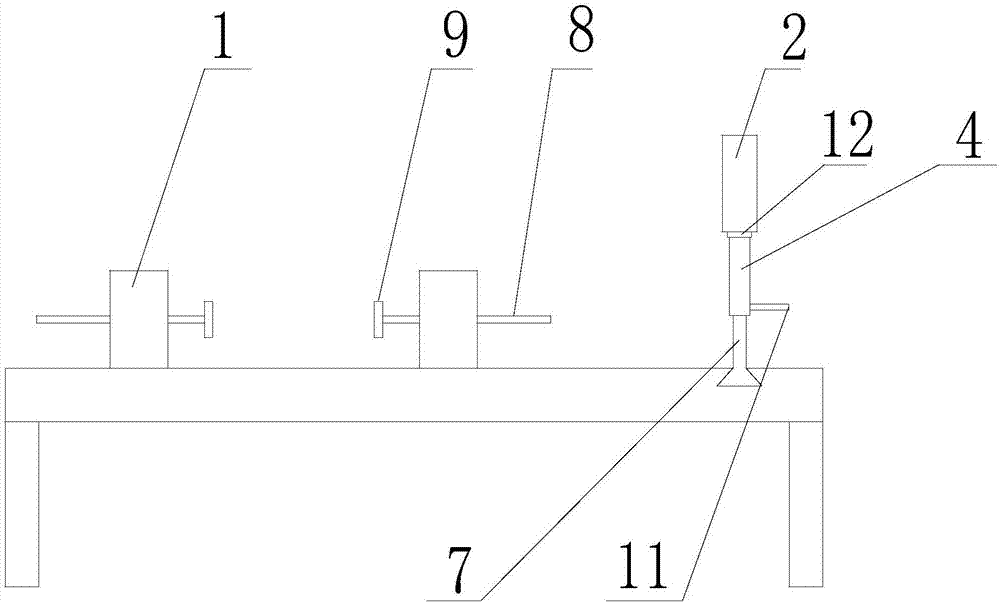

Fastening working table based on chemical pipeline welding

InactiveCN107052696AAvoid the embarrassing situation of one-handed operationPrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPetroleum

Owner:CHENGDU QIAOYI SAISI PETROLEUM TECH CO LTD

Oil and water impurity separating processing device for petrochemical industrial machine

InactiveCN109772008AImprove barrier propertiesEasy to rotate and dischargeMoving filtering element filtersOil waterPulp and paper industry

The invention discloses an oil and water impurity separating processing device for a petrochemical industrial machine. The device comprises an outer box, a forward and reverse motor, a heating wire and a top block. The forward and reverse motor is fixedly installed at the top of the outer box, a rotating rod is connected to the lower end of the forward and reverse motor, a first gear is fixedly arranged at the top of the rotating rod, an inner box is arranged at the inner side of the outer box, an inner cavity is formed inside the inner box, the right side of the rotating shaft is connected with a rotating disc, the lower portion of the rotating disc is connected with a connecting rod through a fastening bolt, the top block is fixedly arranged at the surface of the inner box, and a clamping groove is formed in the surface of the outer box. According to the oil and water impurity separating processing device for the petrochemical industrial machine, by arranging the threaded rotating rod and a spiral sliding groove, the rotating rod is driven by the forward and reverse motor to drive a supporting plate inside a filter net and a movable plate to move up and down inside the inner box,and dirt impurities are conveniently obstructed above the supporting plate through the supporting plate and the filter net.

Owner:朱德儒

Single-chamber heat accumulating type fluid petroleum heating system

InactiveCN104654860AStable temperature controlRealize acquisitionHeat storage plantsPipeline systemsTemperature controlSingle chamber

The invention aims to provide a single-chamber heat accumulating type fluid petroleum heating system, comprising a petroleum pipeline, petroleum, a shell, a solar energy focusing and acquisition system, heat insulation material, fluid and the like; the single-chamber heat accumulating type fluid petroleum heating system consists of petroleum flowing in a petroleum pipeline, a heat accumulator and a heat source; the heat source provides heat energy for the heat accumulator; the heat accumulator heats the petroleum by utilizing the stored heat energy for flowing of the petroleum; the heat accumulator is provided with one chamber; the chamber is provided with an inlet and an outlet for the fluid for enabling the heat energy to exchange heat with the heat accumulating materials in the heat accumulator, and is also provided with petroleum, a petroleum inlet and a petroleum outlet for carrying out heat exchange by utilizing the petroleum and the heat accumulating materials in the heat accumulator; after the chamber is filled up, the heat accumulator can accumulate heat on the site or be moved to the petroleum pipeline for heating the petroleum; after low-temperature petroleum is enabled to enter the heat accumulator from the inlet of the heat accumulator, the petroleum is in heat exchange with the heat accumulating materials in the heat accumulator, so that heating and temperature control for the petroleum can be realized.

Owner:CHENGDU AONENGPU TECH

Inner bore grinding device for oil drilling tool

InactiveCN102601696ASimple structureEasy to manufactureRevolution surface grinding machinesMiniaturizationOil drilling

The invention discloses an inner bore grinding device for an oil drilling tool, which comprises an air guide pipe, a middle joint, a motor, a shaft bushing, a shaft and a grinding wheel, which are axially connected in sequence. The middle joint is a pipe joint in a straight-through double-head threaded structure, and one end of the pipe joint is hermetically connected with the air guide pipe while the other end of the pipe joint is hermetically connected with an axial air inlet on a cylindrical motor shell. The motor shell and the shaft bushing are connected with each other and relatively static, the shaft is supported by an inner hole of the shaft bushing, one end of the shaft is rotatably directly connected with a rotor in the motor, the shaft end exposed out of the shaft bushing is a threaded section for axially mounting the grinding wheel, and the grinding wheel is connected with the shaft to form a rotary structure driven by the motor. Pressure air is used as a power source to drive the motor and the grinding wheel to rotate, the inner bore grinding device is simple in structure, small in radial dimension and favorable for miniaturization design, and since no power source is directly used, the inner bore grinding device is safe in operation and free of electric shock when extending into the oil drilling tool for grinding operation.

Owner:JIANGSU SHUGUANG HUAYANG DRILLING TOOL

Petroleum lifting pump

InactiveCN1556333ALarge displacementDistribute slowlyJet pumpsFluid removalEngineeringContinuous operation

Owner:关建华 +1

Preparation method of pyrite tailing ceramsite proppant

ActiveCN105801162AHigh strengthLight weightCeramic materials productionCeramicwareHigh pressureLow density

Owner:GONGYI CITY GUANGMING CHEM

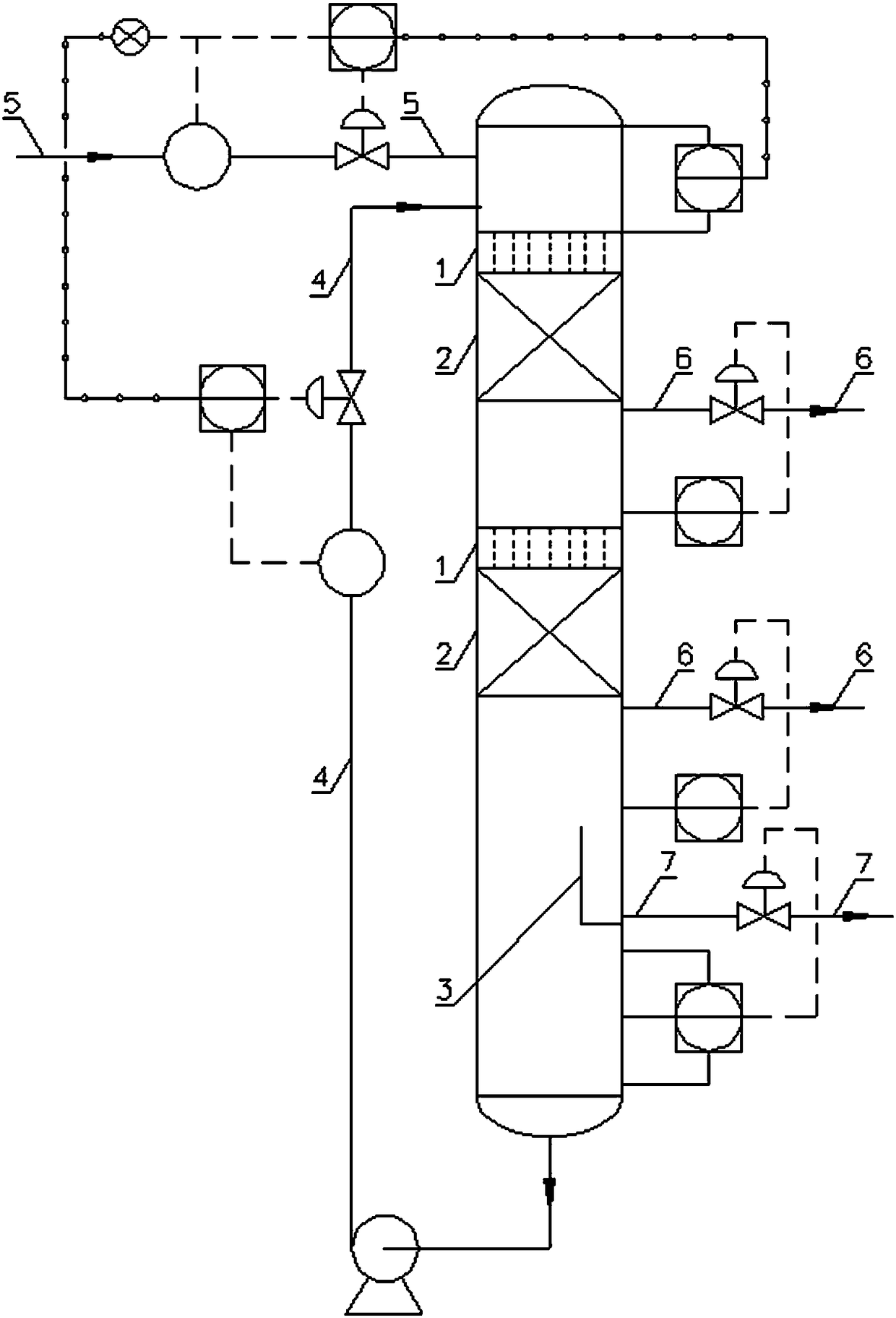

Horizontal and uniform acid distribution integrated experimental device and its operation method

The invention discloses a comprehensive experimental device for levelly and evenly distributing acid, which belongs to the petroleum exploitation field. The experimental device consists of two sections of oil pipes and a sleeve; the two sections of oil pipes are packed by an expanding packer, and the two sections of oil pipes is covered with a sleeve; a gap is left between the oil pipe and the sleeve; the two sections of oil pipes and the sleeve are respectively provided with a minisize flux control valve; the two sections of oil pipes are respectively provided with a flow meter; the two ends of the sleeve which corresponds to the two sections of oil pipes are respectively provided with a pressure gauge. The operation method includes measuring the liquid pressure at the two ends of the sleeve and the flux in a certain period, then feeding back the measured results to the real products, and choosing corresponding minisize flux control valve combination according to the permeability of the base. The device can simulate the heterogeneity characteristics of the oil reservoir in the real oil field and reasonably distribute the minisize flux control valve on the acid pipe according to the permeability in order to realize the purpose of even acid distribution and even acidification by the level and even acid distribution pipe.

Owner:ANTON INST OF GEOLOGICAL ENG TECH (BEIJING) CO LTD

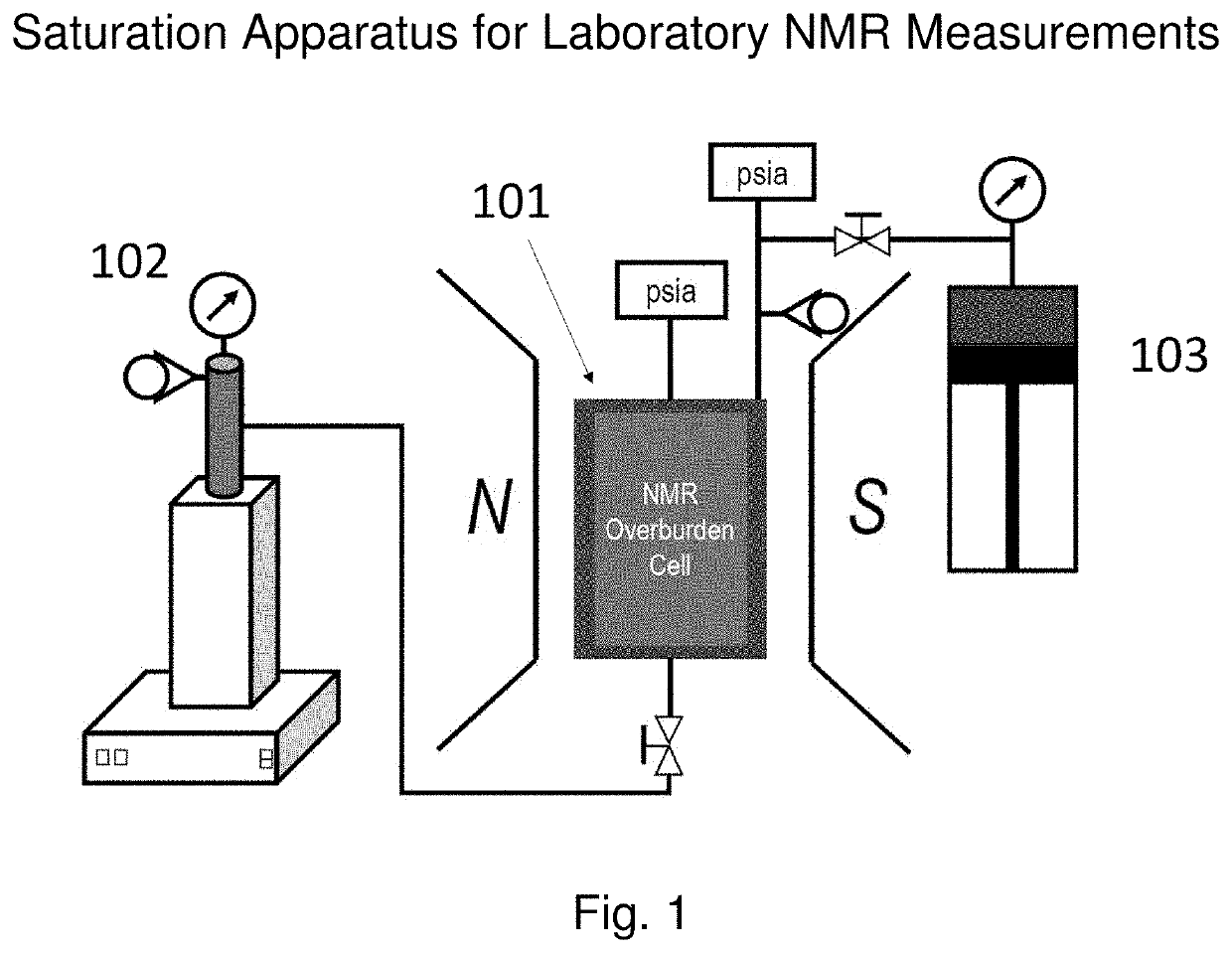

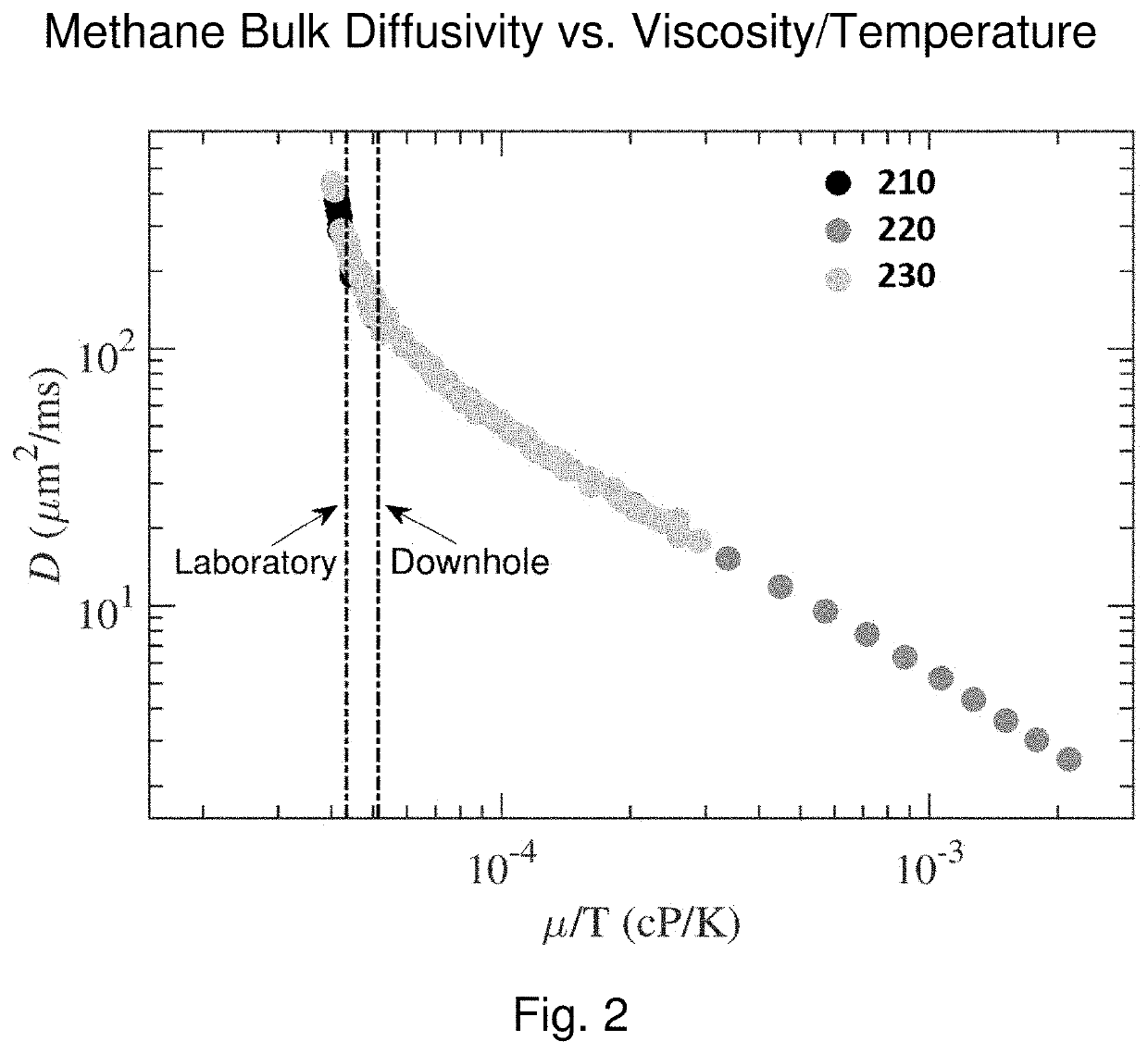

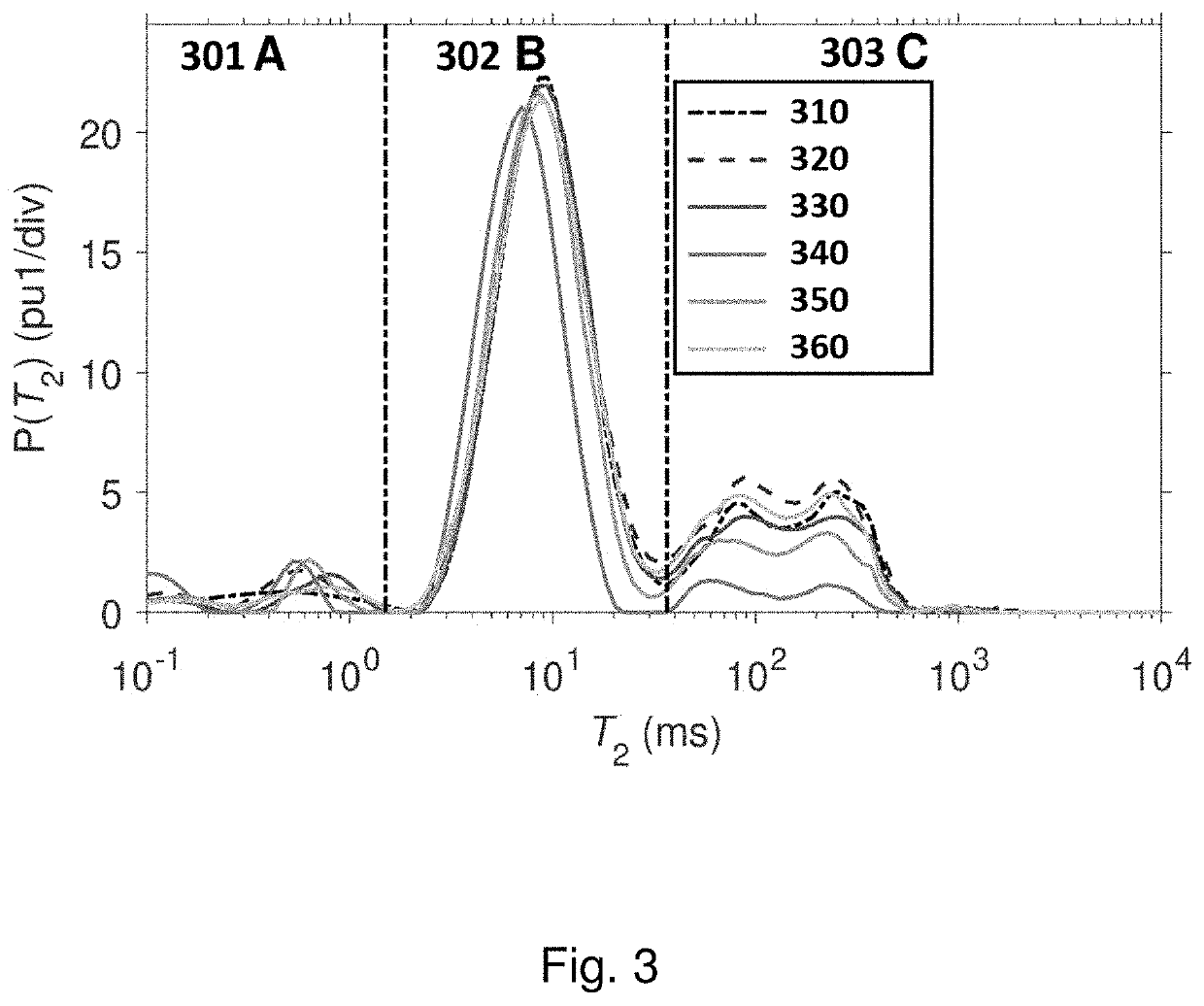

Method for determining the composition of natural gas liquids, mean pore-size and tortuosity in a subsurface formation using NMR

ActiveUS11099292B1Big contrastError minimizationElectric/magnetic detection for well-loggingEarth material testingNMR - Nuclear magnetic resonancePhysical chemistry

Owner:VINEGAR TECH LLC +1

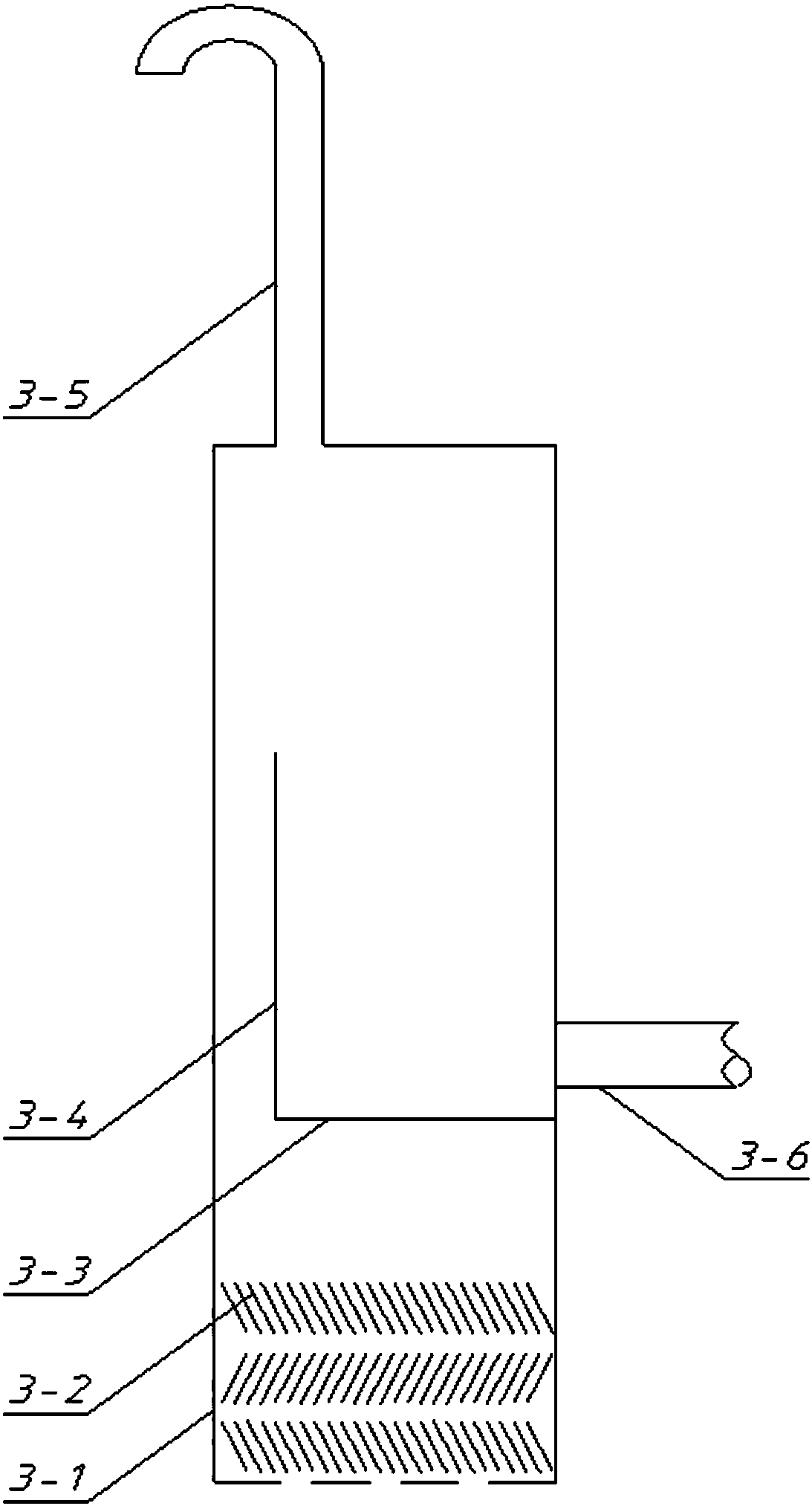

A subminiature neutron tube

ActiveCN109041397ASmall diameterReduce Design ComplexityDirect voltage acceleratorsHigh pressureExhaust pipe

Owner:珠海市纽创科技有限公司

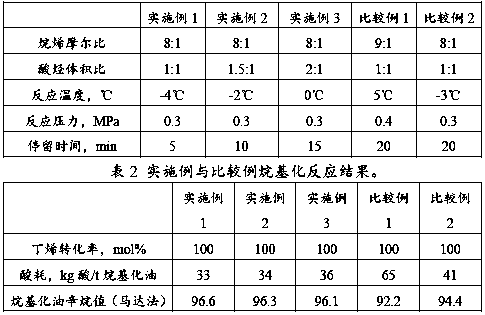

Silicon carbide micro-channel alkylation reactor and application method thereof

PendingCN108126637AImprove temperature distributionBoost octaneChemical/physical/physico-chemical microreactorsLiquid hydrocarbon mixtures productionTemperature controlAlkyl transfer

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for separating and refining non-basic nitrogen-containing compound in petroleum fraction

ActiveCN108795483ASuitable for batch separationTreatment with plural serial refining stagesBoiling pointChemical compound

Provided is a method for separating and refining non-basic nitrogen-containing compounds in petroleum fractions. The method for separating and refining the non-basic nitrogen-containing compounds in the petroleum fractions includes the steps of: (1) adding denitrogenation agents to petroleum-free fractions containing no moisture, stirring and standing, and separating into an oil layer and a complex layer; (2) adding complexing agents to the oil layer obtained in the first step, stirring and standing, and separating into an oil layer and a complex layer; (3) adding low boiling hydrocarbons to the complex obtained in the second step, stirring and standing, separating into an oil layer and a complex layer, adding the low boiling hydrocarbons to the complex layer again and repeating the step;(4) adding low boiling point hydrocarbons to the complex layer finally obtained in step (3), adding alkali solution to neutralization so that the pH value is greater than 7, stirring and standing, andseparating into an oil layer and an aqueous layer; (5) washing the oil layer obtained in step (4) with deionized water, washing off remaining salt and alkali and keeping the oil layer; (6) separatingthe low boiling hydrocarbons from the washed oil layer obtained in step (5) to obtain residues, the non-basic nitrogen compounds.

Owner:PETROCHINA CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap