Petroleum lifting pump

A lift pump, oil technology, applied in the direction of pumps, jet pumps, non-displacement pumps, etc., can solve the problems of fast heat dissipation, high labor intensity, low efficiency, etc., achieve slow heat dissipation, reduce labor intensity, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

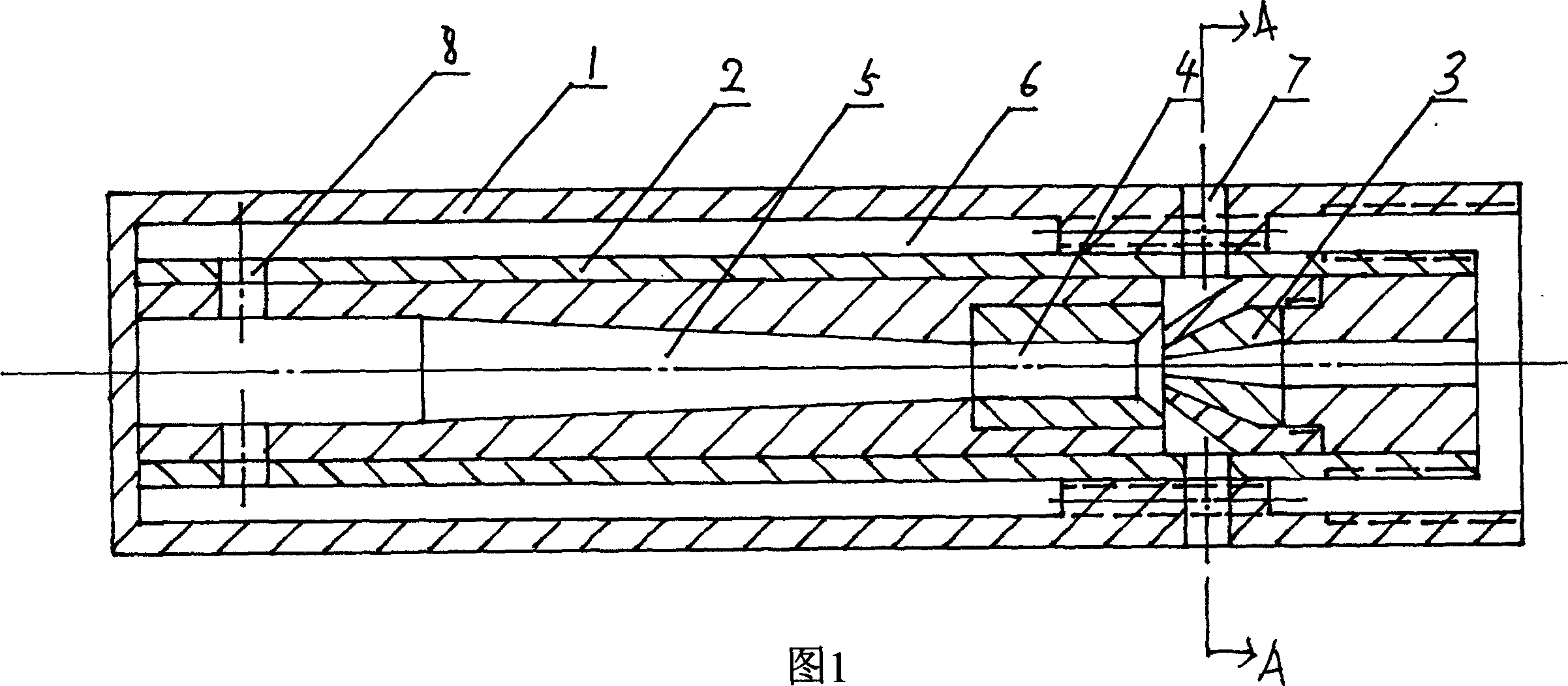

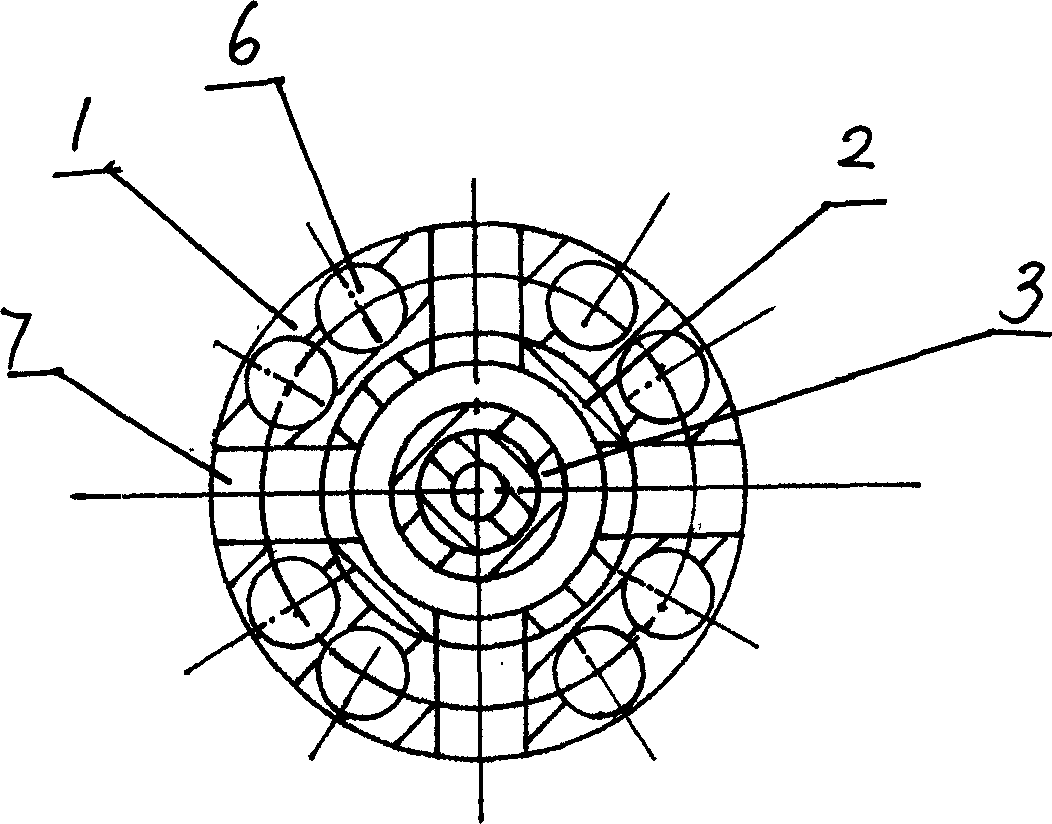

[0010] Figure 1, figure 2 As shown, the petroleum lift pump of the present invention includes an outer pipe 1, the lower end of the outer pipe 1 is a closed end, and the upper end is an open end. The outer pipe 1 is provided with an inner pipe 2, and the wall of the outer pipe 1 is thicker. There are several oil passages 6 on the wall of the outer pipe 1 between the pipes 2, and the nozzle 3, the throat pipe 4 and the diffuser pipe 5 are arranged in the cavity of the inner tube 2 from top to bottom, and the nozzle 3 and the cavity of the inner tube 2 are clamped. Shoulder connection, the nozzle 3 is thus fixed at a certain position in the cavity of the inner tube 2, and there is a gap between the throat 4 and the nozzle 3, when negative pressure is formed at the nozzle 3 in the cavity of the inner tube 2, oil in the oil well enters the throat through the gap The pipe 4 is provided with an oil outlet 8 connected to the lower part of the diffuser pipe 5 and the inner pipe 2. The oi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap