Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Simple production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AThe formula is scientific and reasonableSimple production processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSurface cleaning

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:BEIJING KAILAN AVIATION TECH CO LTD

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

Methods for producing fuel ethanol by using cellulosic waste plants

InactiveCN101613723AReduce removalEliminate omissionBiofuelsMicroorganism based processesChemistryEthanol fuel

The invention provides methods for producing fuel ethanol by using cellulosic waste plants. One method comprises the following steps of: cleaning and grinding the waste plants, adding dilute sulfuric acid to lead hemicellulose to be hydrolyzed, filtering, adding lime in filtrate, and removing precipitation; and carrying out delignification treatment on residue, adding sulfuric acid, heating to lead cellulose to be hydrolyzed, diluting till the weight percentage concentration of the sulfuric acid is 30-40%, recycling the sulfuric acid, heating acidiferous sugar liquor again, hydrolyzing, adding calcium oxide for neutralization, and removing calcium sulfate. The other method comprises the following steps of: cleaning and grinding the waste plants, adding waste dilute sulfuric acid to lead hemicellulose to be hydrolyzed, filtering, then adding lime in filtrate, and removing precipitation; adding waste concentrated sulfuric acid in residue, heating, cooling, diluting, heating again, hydrolyzing, adding calcium oxide for neutralization, and removing calcium sulfate; and adding yeast in the product obtained by the method for fermentation, distilling, and dehydrating to obtain the finished product of the fuel ethanol. The methods greatly reduce the cost, have simple process, and are convenient for wide range of generalization and application.

Owner:张羡信

Sea buckthorn powder albumen powder

Owner:曹峥峥

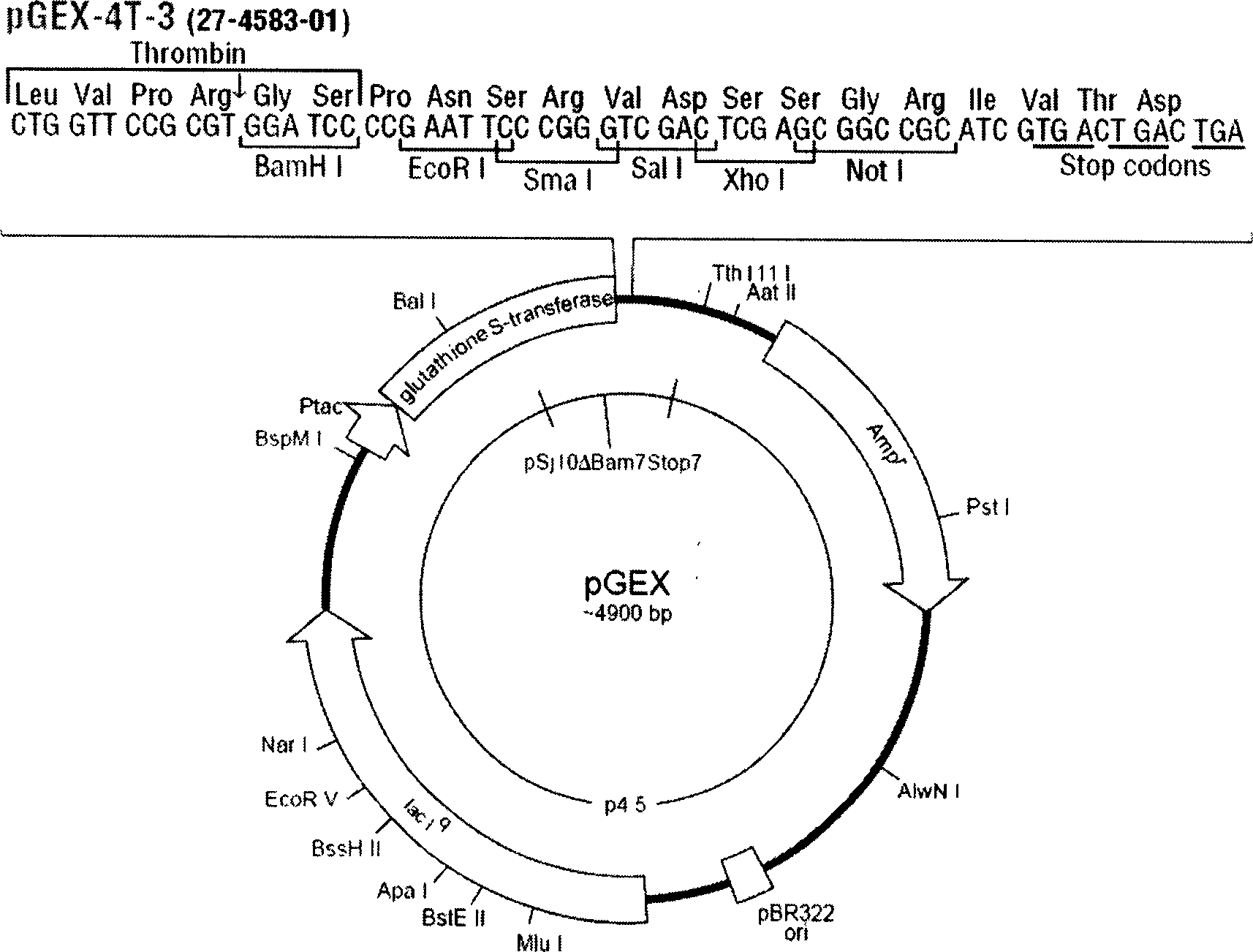

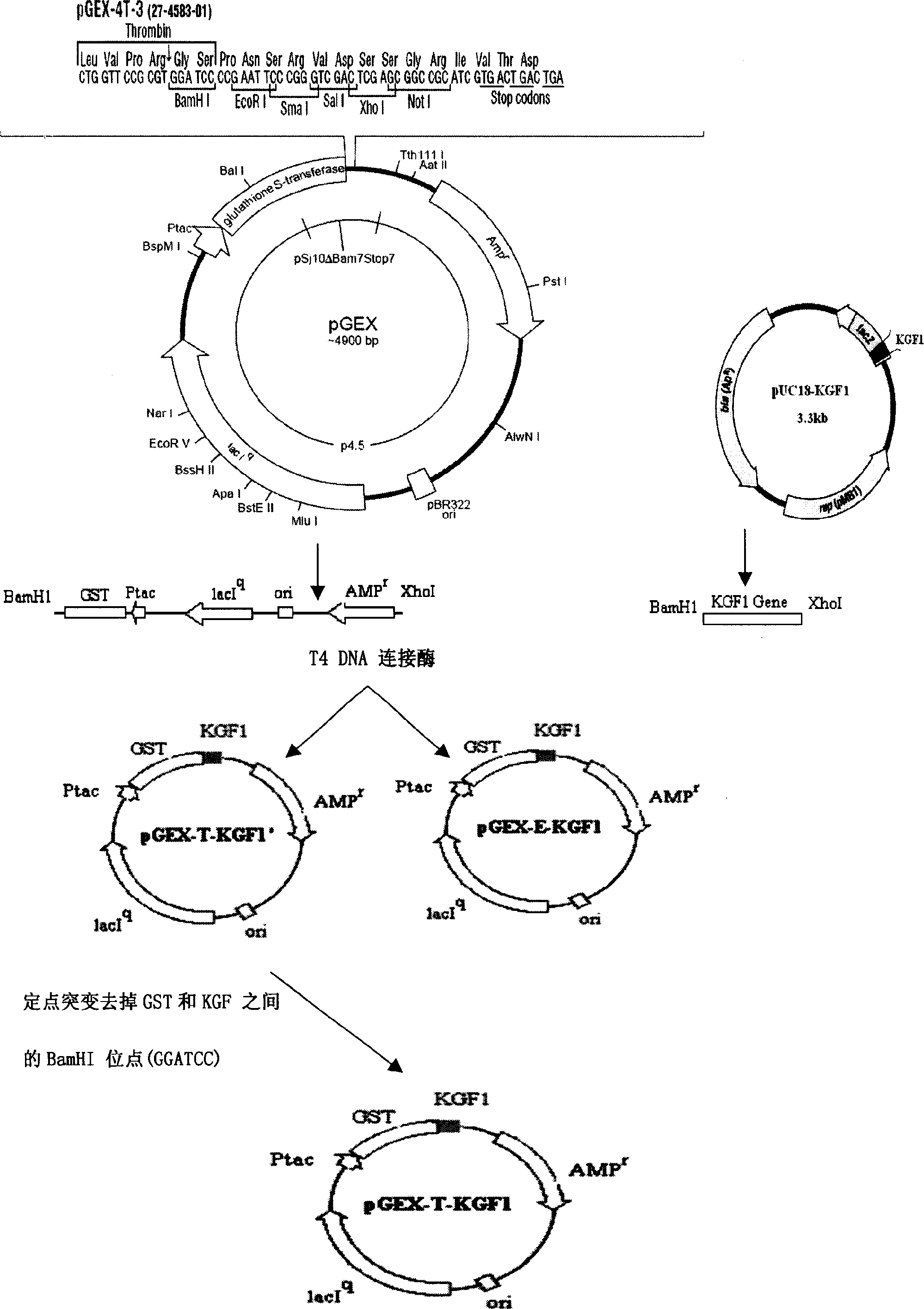

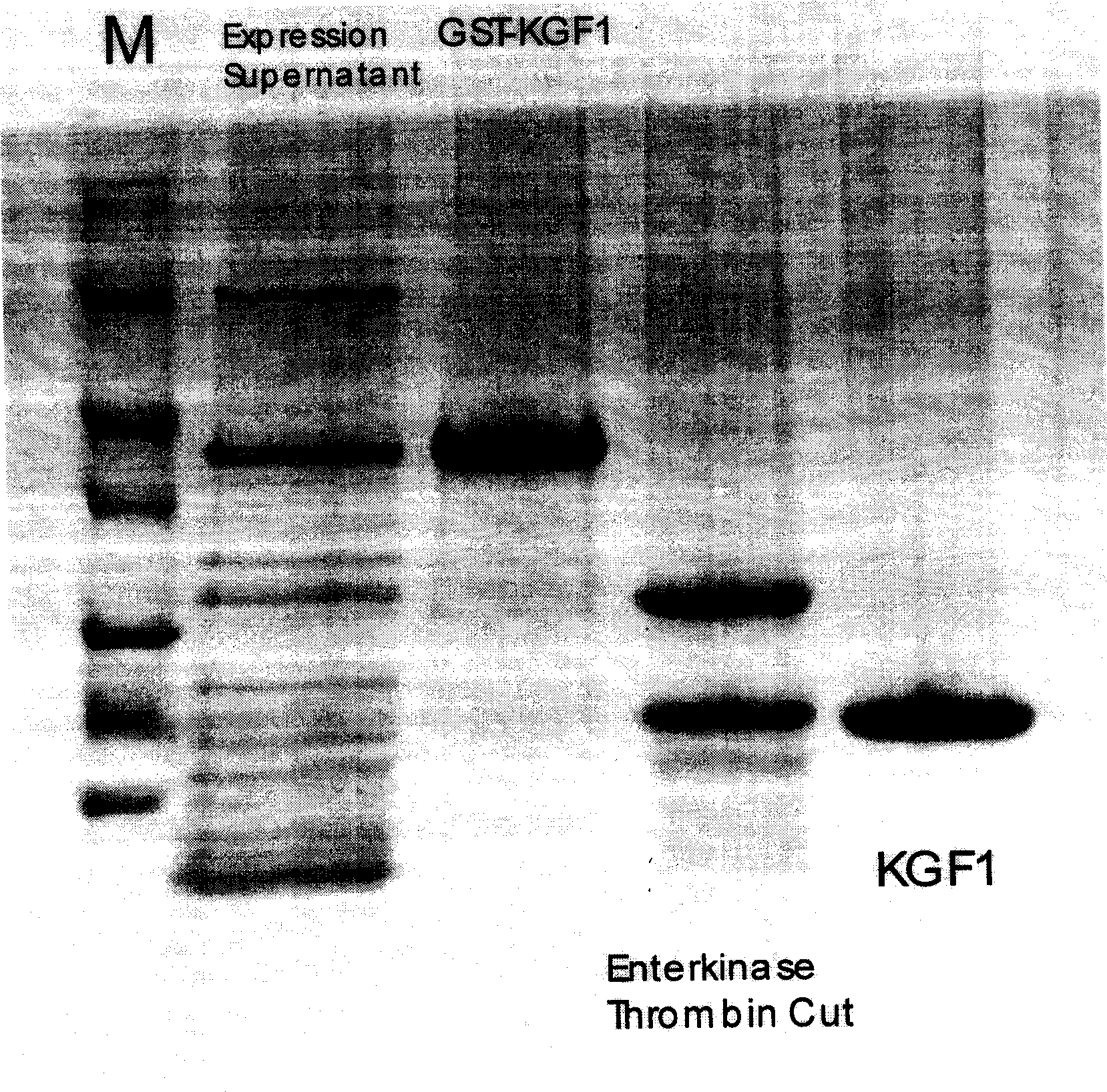

Recombinant human keratinized cell growth factor production method

InactiveCN1766107APeptide/protein ingredientsPeptide preparation methodsGenetic engineeringThrombin activity

Owner:信立泰(苏州)药业有限公司 +1

Method for preparing high-dispersion silver powder for photoetching touch screen silver paste

The invention relates to a method for preparing high-dispersion silver powder for photoetching touch screen silver paste, and belongs to the technical field of conductive metal powder preparing. The method includes the steps of reduced silver powder preparing, reduced silver powder surface modification, ball milling, airflow grading and the like. The method has the beneficial effects that a reaction system is kept at the constant temperature of 35+ / -2 DEG C in the manner that ice blocks are added into a reaction solution, so that the problems that a large amount of heat is emitted in the chemical reaction process, the temperature rises sharply, and silver powder is badly accumulated are solved; the size of a grinding medium is 1 mm, accumulated particles in the reduced silver powder can be sufficiently dispersed, the conductivity of the silver powder in slurry can be improved, and the adhesive force of the silver powder to a base material can be increased; and the prepared high-dispersion superfine silver powder with the largest particle size smaller than 4 microns is particularly suitable for laser engraving of the touch screen silver paste with the line width within the range from 20 microns to 30 microns, conductivity and other performance parameters are excellent, the production technology is simple, cost is low, and industrial production can be achieved.

Owner:KUNMING YINKE ELECTRONIC MATERIALS CO LTD

Fiber radical sewage decoloration and purification material and preparing method thereof

InactiveCN103466731AWide variety of sourcesEasy to manufactureOther chemical processesWaste water treatment from textile industryFlocculationReclaimed water

The invention discloses a fiber radical sewage decoloration and purification material which is characterized by comprising a component (I) and a component (II). The component (II) occupies 5%-10% of the total mass. The component (1) is a product obtained by reaction of 36% formaldehyde solutions, dicyandiamide, ammonium chloride and property-modifying additives A, wherein the mass ratios of the 36% formaldehyde solutions, the dicyandiamide, the ammonium chloride and the property-modifying additives A are sequentially 1.0-1.3:0.50-0.65:0.60-0.70:0.06-0.09. The property-modifying additives A are a mixture obtained by mixing magnesium sulfate and magnesium chloride according to a proportion, wherein the mass ratio of the magnesium sulfate and the magnesium chloride is 2.0-3.5:8.0-6.5. The component (II) is a natural fiber (plant and / or animal) which is modified by cation modifiers. The fiber radical sewage decoloration and purification material integrates multiple functions such as decoloration, flocculation, entanglement and COD removing. The decoloration ratio of sewage can reach more than 93%, the COD value removing rate is higher than that of the prior art by more than 10%, reclaimed water reusing can be achieved, and sewage discharging is reduced.

Owner:HEFEI DONGFANG MEIJIE MOLECULAR MATERIAL TECH CO LTD

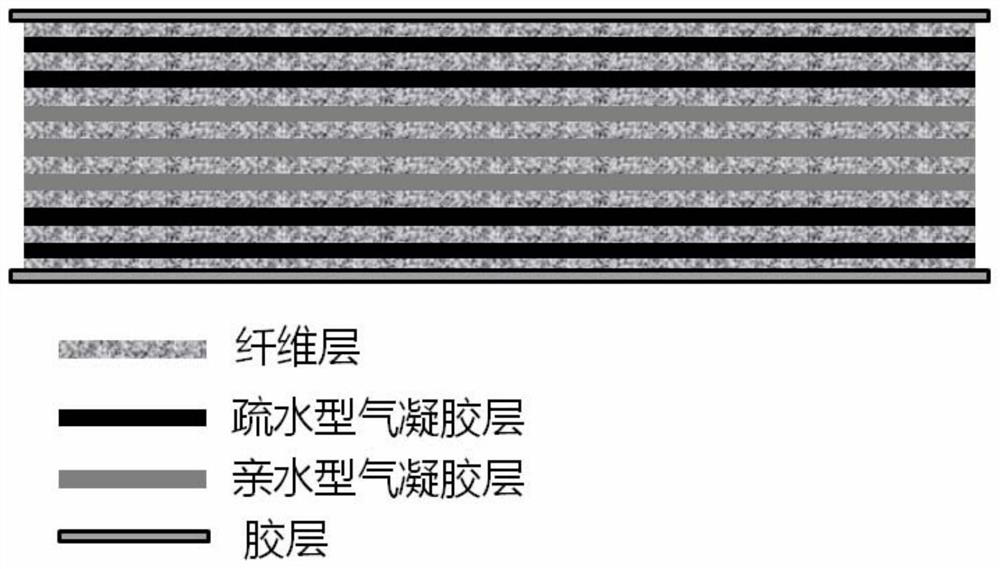

Non-dusting aerogel felt and production method thereof

PendingCN113352709ASimple production processEasy to produceGlass/slag layered productsSilane couplingPolymer chemistry

Owner:福建蓝烟新材料有限公司

Formaldehyde-free composite board special for flame retardant wooden house and preparing method of board

ActiveCN106514800AImprove bearing capacityTightly boundNon-macromolecular adhesive additivesStarch adhesivesPerliteParaffin oils

The invention relates to a formaldehyde-free composite board special for a flame retardant wooden house and a preparing method of the board. Plant fibers are adopted to be smashed, and the plant fibers and a phase change material are jointly machined into the board special for the wooden house. The board comprises a core layer with the flame retardant waterproof phase change energy storage function and a solid wood layer composited on the core layer through pressure; the core layer is prepared by raw materials including, by weight, 30 parts to 80 parts of expanded perlite or sepiolite, 30 parts to 40 parts of any phase change material in paraffin, n-octadecane, octadecanol, cetanol, tetradecyl alcohol, dodecanol, n-decanol, stearic acid, glyceryl stearate, palmitic acid, myristic acid, lauric acid, n-caprylic acid and stearic acid butyrin, 5 parts to 10 parts of Schiff alkaline gel factor, 10 parts to 20 parts of graphite, 20 parts to 40 parts of silica sol solutions, 20 parts to 40 parts of plant fibers, 10 parts to 20 parts of starch, 0.5 part to 5 parts of hydrogen peroxide, 5 parts to 10 parts of glass fibers, 2 parts to 10 parts of calcium carbonate, 0.5 part to 5 parts of a penetrating agent, 8 parts to 35 parts of a flame retardant agent, and 2 parts to 8 parts of a waterproof agent. The beneficial effects of saving a large amount of wood and adjusting the indoor temperature are achieved.

Owner:郑州一安水性高分子材料有限公司

Cation emulsified asphalt for reducing corrosivity during production process and preparation method thereof

InactiveCN107722656AChange state of chargeGood corrosion inhibition effectBuilding insulationsOrganic acidAsphalt

The invention relates to cation emulsified asphalt for reducing the corrosivity during a production process and a preparation method thereof. The cation emulsified asphalt is prepared from the following raw materials in percentage by weight: 53 to 70 percent of asphalt, 0.8 to 3.0 percent of an emulsifier, 3.0 to 5.0 percent of a modifier, and the balance of water. The cation emulsified asphalt has the innovation point of a difunctional asphalt emulsifier required for producing the cation emulsified asphalt; a basic component is prepared from organic polyamine and organic acid which serve as raw materials; then the basic component, an acidic component and organic aldehyde with the molar ratio being 1: (1-1.3): (1-1.3) are reacted, so that the difunctional asphalt emulsifier is formed; themolecular structure of the difunctional asphalt emulsifier comprises a plurality of adsorption centers which can form an adsorption protective film and have emulsification and corrosion inhibition double functions. The emulsified asphalt has low corrosivity during a preparation process, and the hidden danger of corrosion during emulsification, storage and conveying process can be greatly reduced without a corrosion inhibitor. The emulsified asphalt is simple in production technology, wide in source of raw materials and excellent in performance, and can be applied to micro-surfacing and slurrysurfacing.

Owner:WEIFANG UNIVERSITY

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

InactiveCN102516710ALow thermal conductivityImprove insulation effectPolymer sciencePolyvinyl alcohol

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

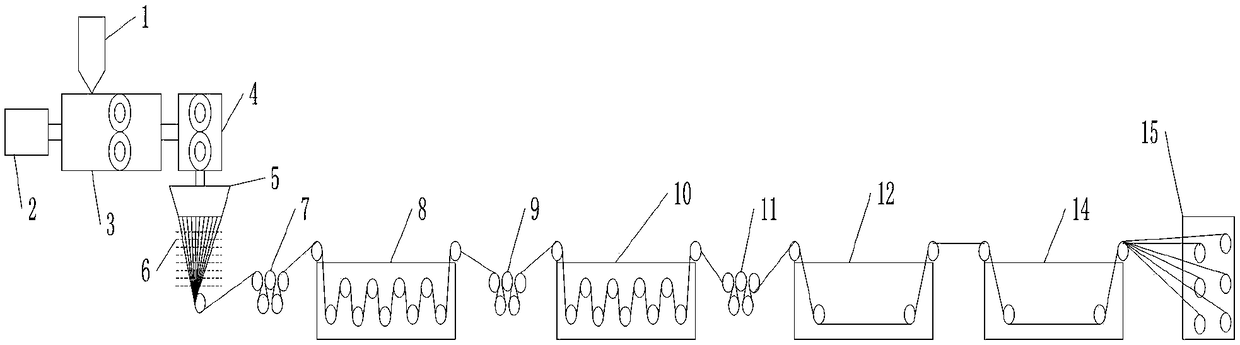

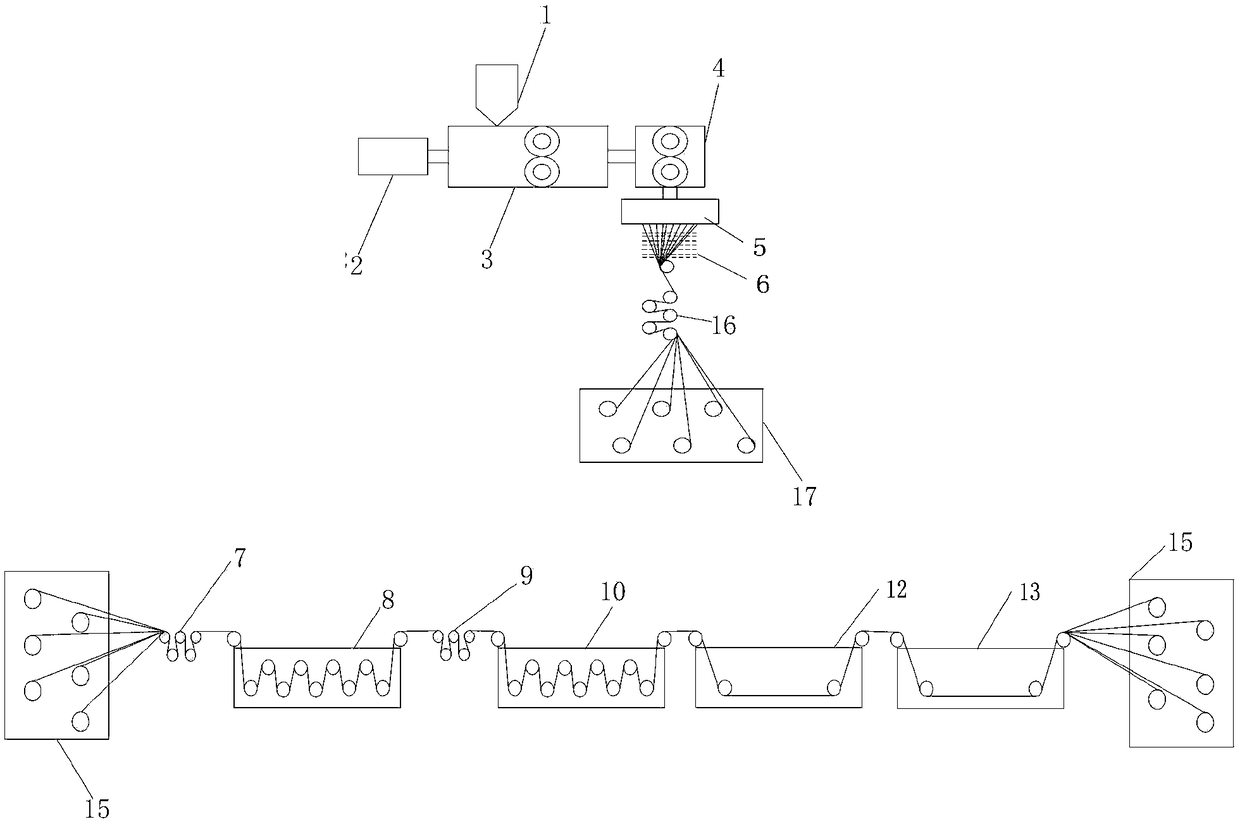

Preparation method of ultrahigh molecular weight polyethylene monofilament

InactiveCN109487349AHigh strengthImprove uniformityFilament forming substance formingSpinning head liquid feederEnvironmentally friendlyThermal treatment

The invention discloses a preparation method of an ultrahigh molecular weight polyethylene monofilament. The preparation method comprises the following steps that an ultrahigh molecular weight polyethylene composite agent obtained through melting and kneading treatment is adopted, a special screw extruding device is adopted for performing sufficient melting and mixing on the composite agent, and extrusion and conveying are performed; furthermore, a booster pump is adopted for improving pressure of a fusion system, meanwhile, a melt is quantitively pressed into a spinning die head or a spinningbox to perform extrusion spinneret, after water bath or oil bath or air bath cooling is performed, primary monofilaments are obtained, the obtained primary monofilaments are subjected to doffing, after multi-heating stretching is performed, the primary monofilaments can be directly and continuously subjected to water bath drafting, multi-stage heat roller drafting and hot air stretching and thensubjected to thermal treatment, and oiling is performed to obtain the high-strength high-modulus polyethylene monofilaments. The problems that molecules are nested and arranged difficultly, and macromolecule winding is series, so that melt flowability and uniformity are poor are well solved, and the monofilaments are high in strength, good in uniformity, simple in production technology, high in efficiency and environmentally friendly.

Owner:郭海洋

Compensating pyroelectric infrared unit detector

InactiveCN103474502AImprove performanceIncrease productivityFinal product manufactureSemiconductor devicesField-effect transistorPrinted circuit board

The invention discloses a compensating pyroelectric infrared unit detector belonging to the technical field of infrared detectors. The compensating pyroelectric infrared unit detector comprises a shell (1), and a window which is arranged at the head end of the shell, wherein an infrared filter (2), a base (3), pins (4), a double-sided circuit board (5), a field effect transistor (6), a pyroelectric infrared sensitive element (7), a pyroelectric compensation sensitive element (8) and a resistor (9) are arranged on the window; a through hole is formed in the center of the double-sided circuit board (5); the field effect transistor (6) is embedded in the through hole, and the bottom of the field effect transistor (6) is flush with the lower surface of the double-sided circuit board (5); the thickness of the field effect transistor (6) is smaller than the thickness of the double-sided circuit board (5); the pyroelectric infrared sensitive element (7) and the pyroelectric compensation sensitive element (8) are arranged above the through hole. The compensating pyroelectric infrared unit detector has the advantages of excellent performance, easiness in manufacturing, low production cost, high production efficiency and wide application range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

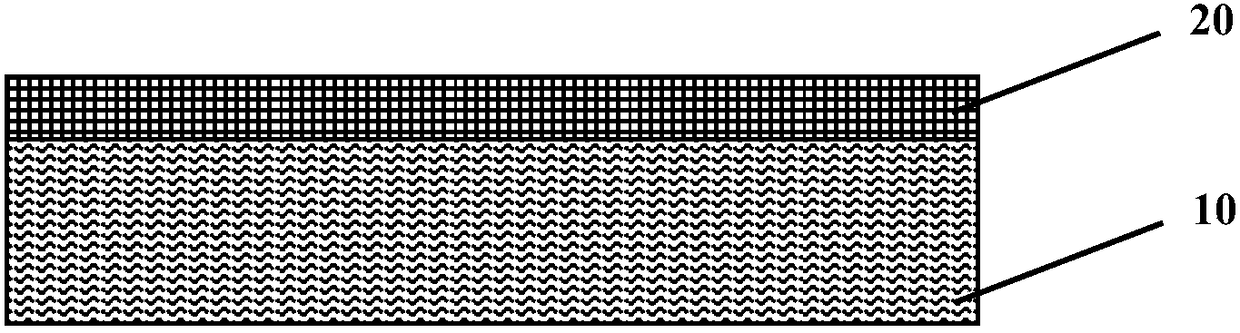

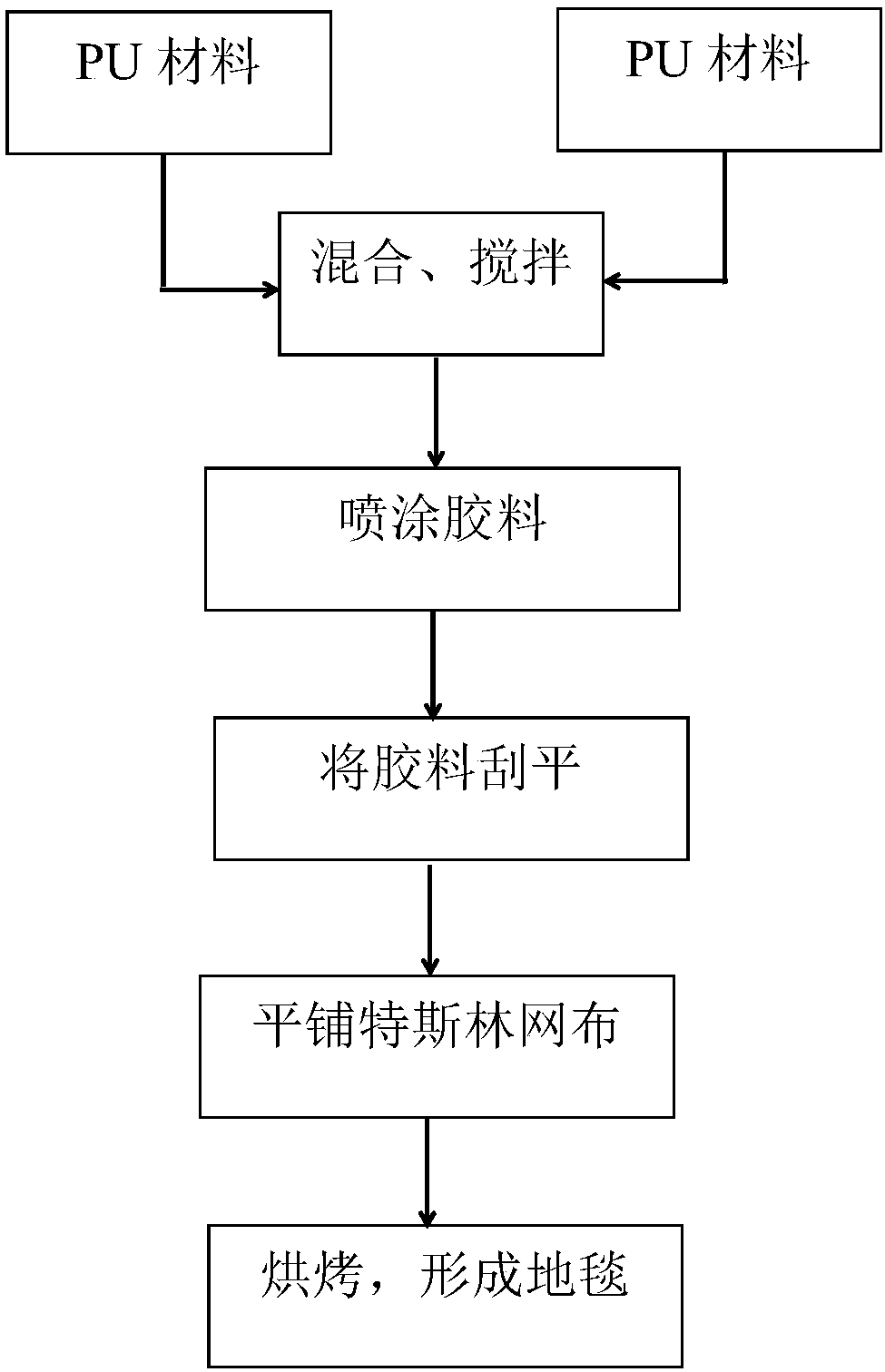

PU (Polyurethane) foaming woven pattern carpet and processing method

InactiveCN108221400AAvoid Debonding and DelaminationSimple production processCoatingsTextiles and paperEngineeringFormaldehyde

Owner:东莞市福巧纺织品有限公司

Method for cutting bamboo chips

InactiveCN103878837ASimple production processHigh yieldCane mechanical workingWood veneer joiningFinger jointEngineering

The invention provides a method for cutting bamboo chips. Bamboo is processed into arc-shaped bamboo blocks with variable cross sections, the inner cambered surface curvature radius of the bamboo blocks equals to the outer cambered surface curvature radius of the bamboo blocks, curved surface single bodies are formed through parallel lamination and gluing after the bamboo blocks are extended through longitudinal finger joint, a plurality of curved surface blanks are formed through transverse width splicing, and the curved surface blanks replace the existing cuboid blanks with rectangular sections for slicing. The method is simple in production process, high in outturn percentage, low in equipment investment and good in decorating effect.

Owner:吕子玉

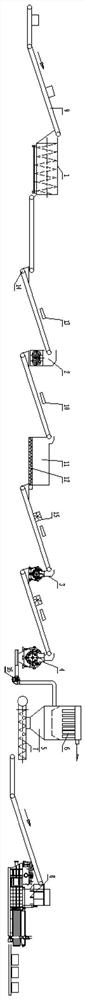

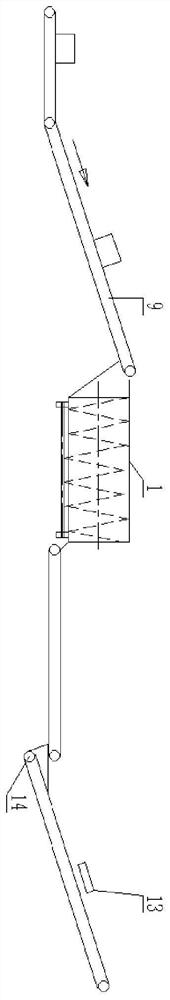

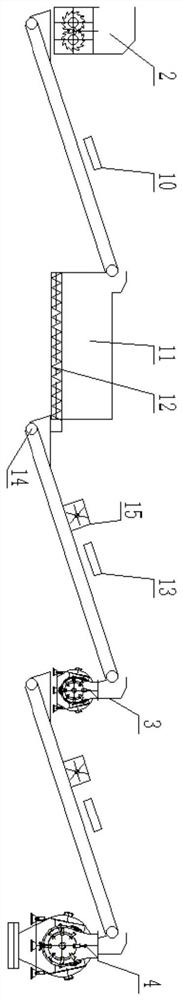

Dry pulping system and dry pulping process

ActiveCN112853788AAvoid water pollution and wasteAvoid dust pollutionPaper recyclingFibrous raw materialsMaterial SeparationProcess engineering

The invention provides a dry pulping system. The dry pulping system comprises a scattering unit, a crushing unit, a material separation unit, an impurity removal unit and a packaging unit, wherein the scattering unit comprises a bale breaking machine; the crushing unit comprises a shredding machine, a scattering and crushing machine and a fiber regeneration machine; the material separation unit comprises a material separation bin and a pulse dust collector; the impurity removal unit comprises a light impurity removal mechanism and a heavy impurity removal mechanism; the packaging unit comprises a screw extruder and a packaging machine; and the bale breaking machine, the shredding machine, the scattering and crushing machine, the fiber regeneration machine and the packaging machine are connected through a belt conveyor. The invention further provides a dry pulping process. The dry pulping process comprises the dry pulping system and further comprises the step that (1) waste paperboards are scattered and fed into the shredding machine for coarse crushing so as to obtain a long-strip-shaped material with a width ranging from 60 mm to 80 mm and a length ranging from 170 mm to 300 mm.

Owner:SHANDONG JIEFENG MACHINERY MFG

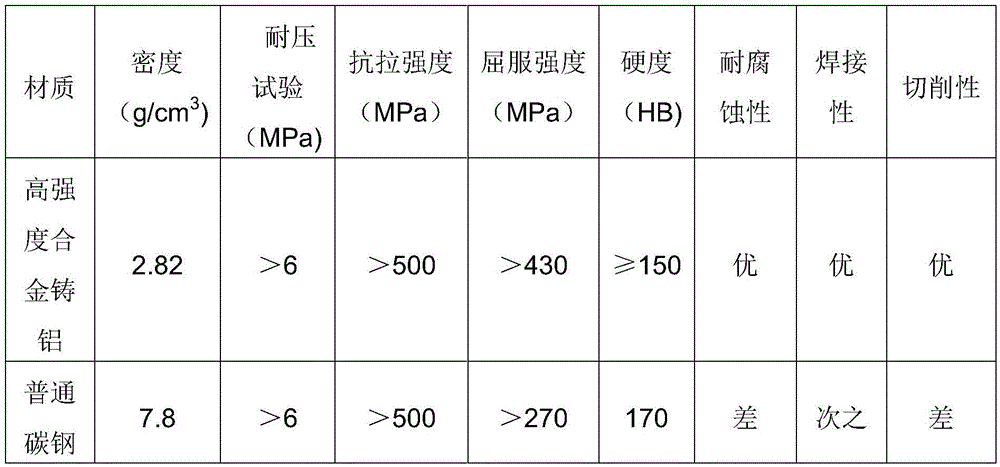

High-strength alloy cast aluminum spiral-flow constant-pressure pump material and preparing method and application of high-strength alloy cast aluminum spiral-flow constant-pressure pump material

ActiveCN105648291AThe production process is complicatedGood corrosion resistancePump componentsEngine componentsPetrochemicalCorrosion

The invention relates to a high-strength alloy cast aluminum spiral-flow constant-pressure pump material and a preparing method and application of the high-strength alloy cast aluminum spiral-flow constant-pressure pump material. The technical problem that the requirement for small weight of fire extinguishing pumps and the requirement for corrosion resistance of the pumps of the petrochemical industry cannot be met through an existing spiral-flow constant-pressure pump material is solved. The material comprises, by mass percent, 4.7-5.4% of Cu, 0.05-0.2% of Zr, 0.3-0.5% of Mn, 0.005-0.015% of B, 0.05-0.25% of V, smaller than 0.05% of Mg, 0.15-0.35% of Ti, smaller than 0.15% of Fe, smaller than 0.08% of Si, 0.15-0.25% of Cd and the balance Al. The invention further provides the preparing method and application of the high-strength alloy cast aluminum spiral-flow constant-pressure pump material. The high-strength alloy cast aluminum spiral-flow constant-pressure pump material can be widely applied to the field of manufacturing of spiral-flow constant-pressure pump materials.

Owner:SHANDONG HAOAN GOLDTECH NEW MATERIALS

PET film with coating layer and high ink adhesive force and preparation method thereof

PendingCN112062999ANot easy to fall offSimple production processPolyester coatingsBinding forceChemical treatment

Owner:安徽省长荣新材料科技有限公司

Drag reducer and preparation method thereof

ActiveCN103936898AReduce post-processingSimple production processPipeline systemsDrag reducing agentUser friendliness

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-ultraviolet PVC (Polyvinyl Chloride) gloves and preparation method thereof

InactiveCN108164883ADoes not affect initial colorabilityImproves UV resistanceGlovesProtective garmentEmulsionBenzotriazole

The invention discloses anti-ultraviolet PVC (Polyvinyl Chloride) gloves and a preparation method thereof. The anti-ultraviolet PVC gloves are prepared from the following raw materials in parts by weight: 100 parts of PVC, 78 to 82 parts of DOP, 10 to 15 parts of TXIB, 10 to 15 parts of D70, 2 to 2.5 parts of stabilizer, 2 to 2.5 parts of epoxidized soybean oil and 5 to 10 parts of anti-ultraviolet aid, wherein the anti-ultraviolet aid is prepared from the following raw materials in parts by weight: 12 to 15 parts of a fluorocarbon emulsion, 2 to 5 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methyl phenyl)-5-chloro-benzotriazole, 5 to 8 parts of 2-hydroxyl-4-methoxybenzophenone and 3 to 4 parts of a ceramic powder. The anti-ultraviolet PVC gloves disclosed by the invention have the advantagesof good anti-ultraviolet performance, long duration time, comfortableness in wearing and low cost; the adopted anti-ultraviolet agent does not affect the transparency of a product and also has no effects on the initial coloring of the PVC gloves; the production process of the anti-ultraviolet PVC gloves is simple and easy to operate.

Owner:JIANGSU HUAYUAN GLOVE

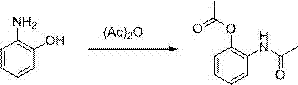

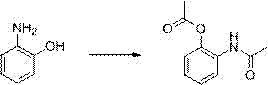

Novel preparation method of 3-amino-2-hydroxyacetophenone

InactiveCN106995366ACheap and easy to getRich choiceOrganic compound preparationCarboxylic acid amides preparationSolventTitanium tetrachloride

The invention provides a novel preparation method of 3-amino-2-hydroxyacetophenone. The novel preparation method comprises the following steps of using 2-aminophenol as an initial raw material; enabling the 2-aminophenol and acetic anhydride to synthesize 2-acetamidophenol acetate in a polar solvent under the alkaline or acid catalyzing condition; then, performing Fries rearrangement on the 2-acetamidophenol acetate in an aprotic solvent under the catalyzing action of anhydrous titanium tetrachloride, and adopting an acid hydrolysis one-pot method, so as to synthesize the 3-amino-2-hydroxyacetophenone. The novel preparation method has the advantages that the price of the used raw materials is low, the obtaining is easy, and the selection of the raw materials is diversified; the implementing of the production technology is easy, the management and control are easy, the purity of a final product is high, the dangerous technology is avoided, the equipment is simple, the synthesizing route is novel and short, the production capacity is increased, and the production and processing cost is reduced.

Owner:上海微巨实业有限公司

Comprehensive utilization method of waste residues generated in oryzanol production process

ActiveCN111039772ARealize comprehensive utilizationStable salesFood processingAnimal feeding stuffAlcoholProcess engineering

The invention provides a comprehensive utilization method of waste residues generated in an oryzanol production process. The comprehensive utilization method comprises the following steps: 1) hot-melting; 2) performing alkali alcohol reflux hydrolysis; 3) performing cold precipitation separation; 4) performing solvent recovery and solid-liquid separation; 5) mixing a precipitate with siraitia grosvenorii residues to prepare a feed matrix; 6) extracting and refining a filtrate; 7) adjusting the pH value and decolorizing with resin; 8) performing acid precipitation separation; and 9) drying to prepare natural ferulic acid. According to the method, 2-6% of low-content oryzanol which is difficult to recycle in the waste residues is made into natural ferulic acid with the purity of 98% or above, and grease precipitate in the process is used as a raw material for preparing the feed matrix, so that comprehensive utilization of the oryzanol production waste residues is realized; waste residuesreflow and are saponified in solvent dissolution, the temperature is easy to control, the conversion efficiency is high, and damage is little; purification is realized through dissolution differenceof different systems and temperatures of alkali alcohol and alcohol water and alkali liquor extraction, , and decoloration is realized by resin only adsorbing pigment without desorption; waste is turned into valuable things, and the environmental protection problem that waste residues are difficult to utilize in oryzanol production is solved.

Owner:HUNAN HUACHENG BIOTECH

Production method of high-acid high-ester flavoring liquor

ActiveCN104357299AEthyl caproate content prominentLong aftertasteBy-product recoveryAlcoholic beverage preparationSocial benefitsAlcohol

The invention discloses a production method of high-acid high-ester flavoring liquor, and belongs to the technical field of brewing. The invention aims at providing the method for producing high-acid high-ester flavoring liquor by using byproduct tail water oily matter (TOSL) in pure-grain Luzhou-flavor liquor brewing. The method comprises the following steps: firstly removing tail water and solid impurity from an acquired TOSL sample, refining, and then uniformly mixing refined TOSL with a high-degree edible alcohol water solution, rotary-evaporating the mixed solution, collecting fraction, reducing the degree of the fraction by using purified water to obtain the high-acid high-ester flavoring liquor. The byproduct in the brewing process is sufficiently utilized, the quality of the base liquor is improved, good economic benefit is brought, and the waste emission in the brewing process is reduced, and the environment pressure is lightened; and the production method meets the general trend of energy conservation and emission reduction initiated by the nation in the industrial production, and has good social benefit.

Owner:JIANGSU YANGHE BREWERY JOINT STOCK

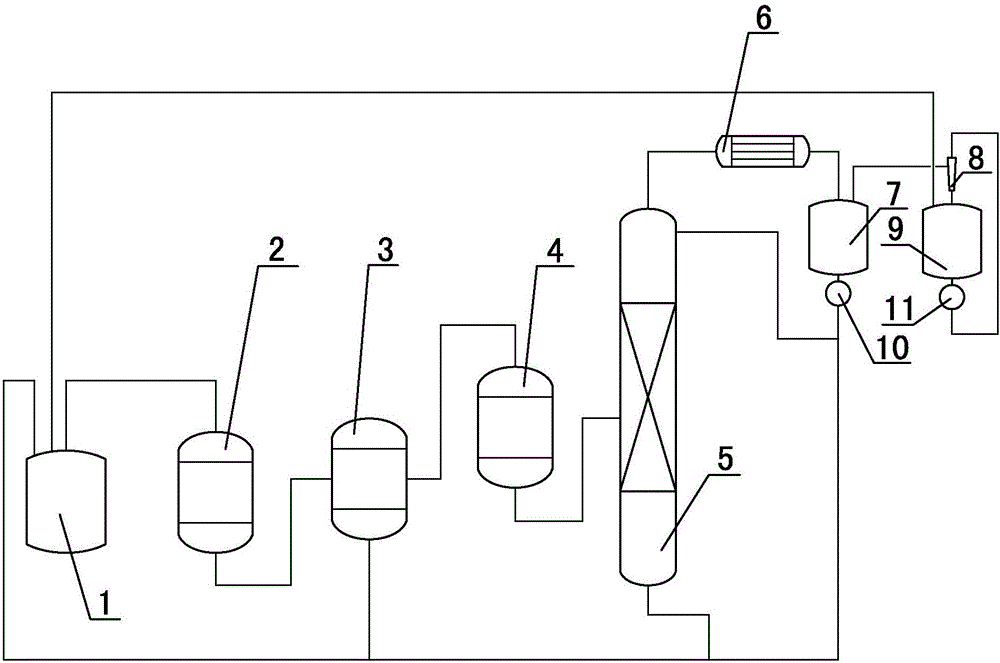

Production process of sulfoxide chloride

ActiveCN106672916ASimple production processReduce the probability of exposure to waterThionyl chlorideDecomposerInjector

Owner:SHANDONG KAISHENG NEW MATERIALS

Aqueous chlorhexidine iodine sterilizing spray and preparation method thereof

InactiveCN102727435ASimple production processReduce high costOrganic active ingredientsAntibacterial agentsIrritationSolvent

Owner:WUHAN GENERAL HOSPITAL OF GUANGZHOU MILITARY

Preparation method for high-purity betaine phosphate

InactiveCN103387503ASimple production processLess investmentOrganic compound preparationAmino-carboxyl compound preparationChemistryPhosphate

Owner:TIANJIN CHEM REAGENT RES INST

Anticancer nanometer targeted administered prescription

InactiveCN1546173ASmall toxicityActive targetingPowder deliveryMacromolecular non-active ingredientsCancer targetingMedicine

The invention discloses an anti-cancer targeting nano medicine administration preparation, wherein folic acid is connected with cow blood albumen to form the material for preparing nano balls, then the anti-cancer drugs are encapsulated. By using nano balls as the carrying agent, good constancy has been realized. íí

Owner:JIANGXI MEDICINE ACADEME

Soft magnet core material with high saturation magnetic flux transmission performance

InactiveCN105761863AEvenly dispersedImprove performanceInorganic material magnetismTransformers/inductances detailsIonMagnetic core

The invention discloses a soft magnet core material with high saturation magnetic flux transmission performance. The soft magnet core material is prepared from the following raw materials in parts by weight: 25-26 parts of nickel oxide, 58-62 parts of ferric oxide, 21-23 parts of zinc oxide, 6-8 parts of silicon dioxide, 0.3-0.5 part of propolis, 0.2-0.3 part of diphenyl silanediol, 0.8-1.1 parts of guanidine carbonate, 0.2-0.4 part of propylene glycol alginate, 0.7-0.9 part of stearic acid, 2.6-3 parts of a silane coupling agent kh550, 0.7-0.9 part of barium titanate, 2.6-3 parts of polyamide resin, 2-2.6 parts of sodium silicate, 1-1.4 parts of silica sol, 1-1.3 parts of polyvinyl alcohol, 0.5-0.6 part of nano dysprosium, 1.3-2 parts of magnetic carbon powder, 1.1-2 parts of nano lanthanum oxide and a proper amount of deionized water. The prepared core material is excellent in transmission performance, simple in production process, high in production efficiency and high in mechanical strength, and is more suitable for durably working in a high-temperature environment.

Owner:TIANCHANG TIANHAO REFRIGERATION EQUIP FACTORY

Multifunctional condensing projection cylinder

The invention discloses a multifunctional condensing projection cylinder which comprises a fixed loop, a convex lens, a connecting ring and a focusing ring. The multifunctional condensing projection cylinder has the advantages that the condensing projection cylinder can realize condensing projection via a convex lens and condensing projection via a single-lens reflex lens, two lenses are integrated, and the cost of a photographic condensing projection cylinder is reduced substantially; the condensing projection cylinder is simple in structure and principle, the manufacture cost is reduced greatly, a cold light source is used, a plastic material can be used, problems as heating can be avoided, the production difficulty is reduced greatly, and the production technology is simplified; and thecondensing projection cylinder can be fixed to a small cylinder in the front end of an existing light limiting cylinder in the market, and compared with a condensing projection cylinder of a traditional similar product, the production cost is reduced, the manufacturing difficulty is reduced, and the utilization efficiency of equipment is improved.

Owner:向茂勇

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap