Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Benzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzene is an organic chemical compound with the chemical formula C₆H₆. The benzene molecule is composed of six carbon atoms joined in a ring with one hydrogen atom attached to each. As it contains only carbon and hydrogen atoms, benzene is classed as a hydrocarbon.

Method for synthesizing citric acid ester type compound

InactiveCN101830803AHigh catalytic activityRich sourcesOrganic compound preparationCarboxylic acid esters preparationChemical synthesisBenzene

The invention discloses a method for synthesizing a citric acid ester type compound, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: using citric acid and fatty alcohol as main raw materials, and using benzene sulfonic acid or amino benzene sulfonic acid as a catalyst; and performing esterification and the purification processes of acetylation, neutralization, washing, drying, distillation and the like. The catalyst has rich sources, a low cost and high activity, can be separated from an esterification liquid easily after the neutralization, is coke-free during the distillation, has less corrosion to equipment, and is safe and environment-friendly; the water generated by the esterification is separated out by adopting a binary heterogeneous separation technique, and no water separating agent is additionally added; and acetyl citric acid ester is produced by adopting an esterification-acetylation continuous synthesis method, the flow is greatly simplified, and a synthesis process is shortened. The citric acid ester prepared by the method has the advantages of high quality, high purity, low degree of color and wide applicationrange.

Owner:NORTHWEST NORMAL UNIVERSITY

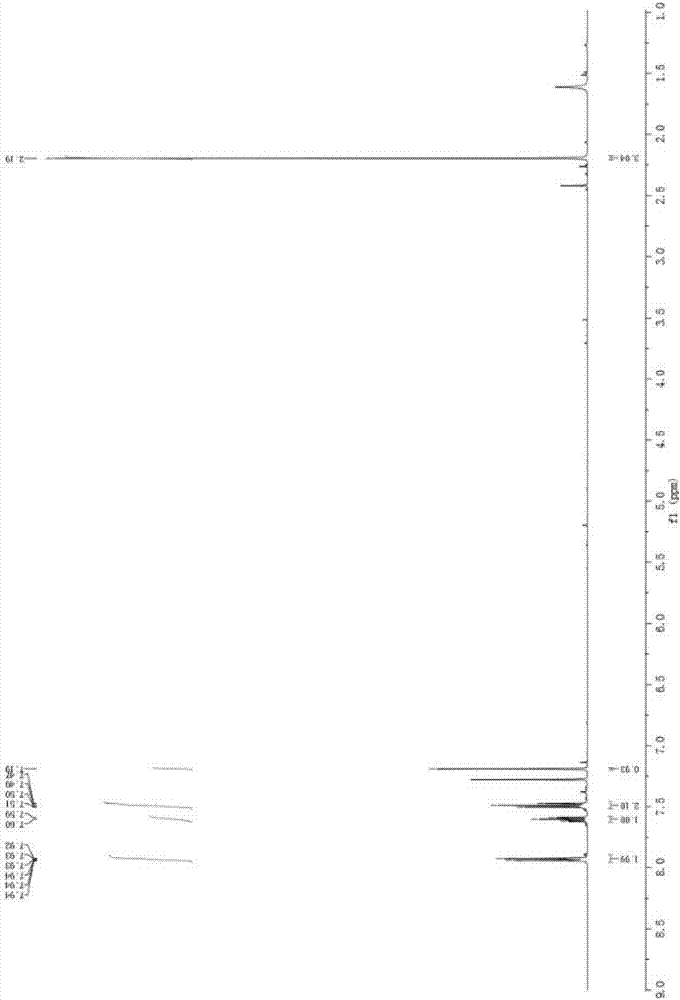

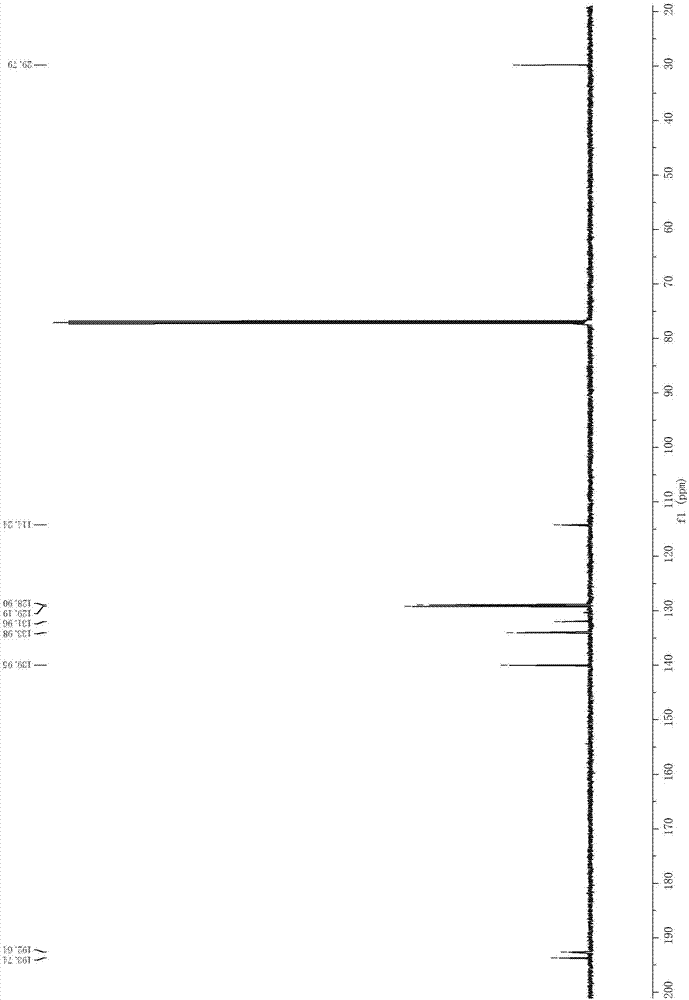

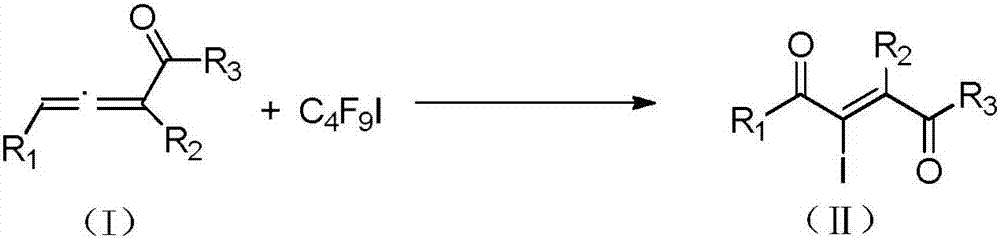

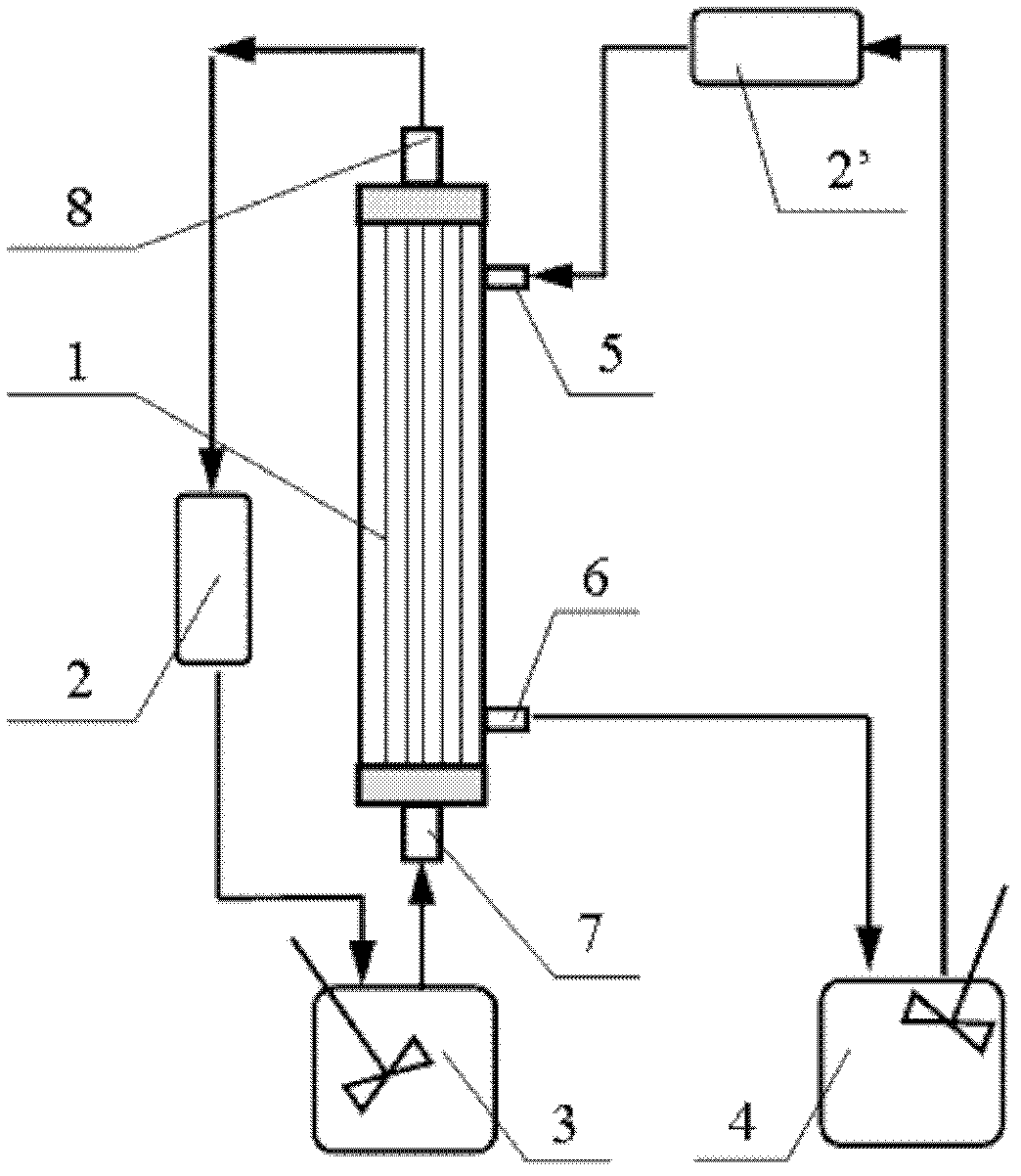

Method for preparing 2-iodine amyl -2-ene-1,4-diketone derivative by adopting visible light catalysis

ActiveCN107011145AMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic acid esters preparationIodidePollution

Owner:ZHEJIANG UNIV OF TECH

Method for producing coating ultra-sense paper

InactiveCN101250835AProcessing into excellent performanceEasy to processSpecial visual effect coatingsCoatings with pigmentsFiberBenzene

The invention relates to a method for preparing a coating hypersensitive paper, which comprises the following steps: firstly, adopting fiber 100% as raw material, beating, dispensing, drawing the vibrator for fixation, modeling, drying, gluing and drying to produce the hypersensitive base stock which is provided with natural and native texture. The hypersensitive base stock is coated and manufactured through a 1760mm coater which velocity is 150 / min and the coating quantity area is 15g / m2. The coating paint comprises dye and latex adhesive, wherein the dye is selected from specially processed titanium oxide and kaolin, the particle size of titanium oxide and kaolin is less than 2 mum. The latex adhesive adopts benzene latex and starch to blend together. The hypersensitive base stock surface of the invention forms a natural and native texture dull base stock on the net without pressing, polishing and dressing. The prepared coating hypersensitive paper has the advantages of reducing manufacturing procedure, increasing natural and native texture of the paper and stereo aesthetics, reducing reflection light, which is non-excited in eyes, soft and comfortable in scene, easy in preparation and low in preparation cost.

Owner:SHANDONG KAILI SPECIAL PAPER

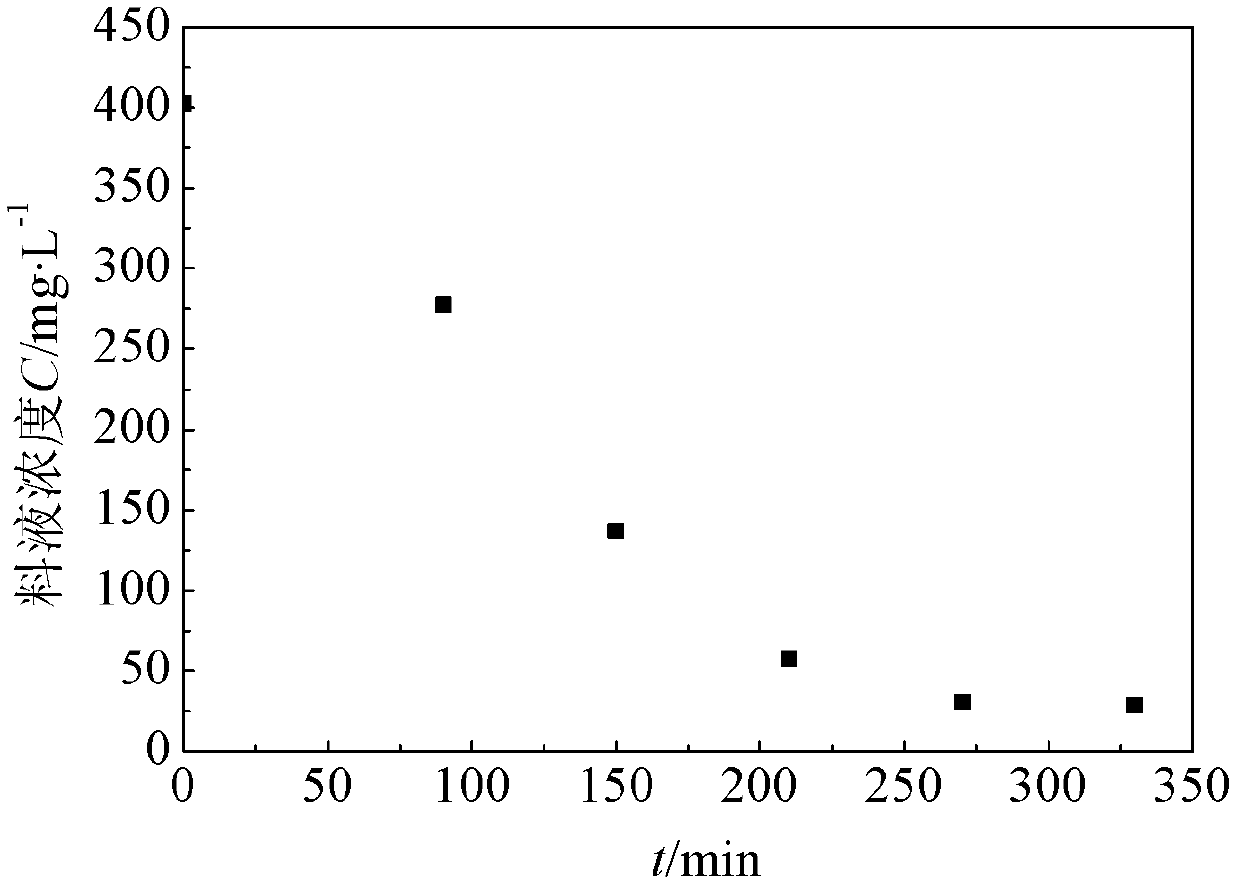

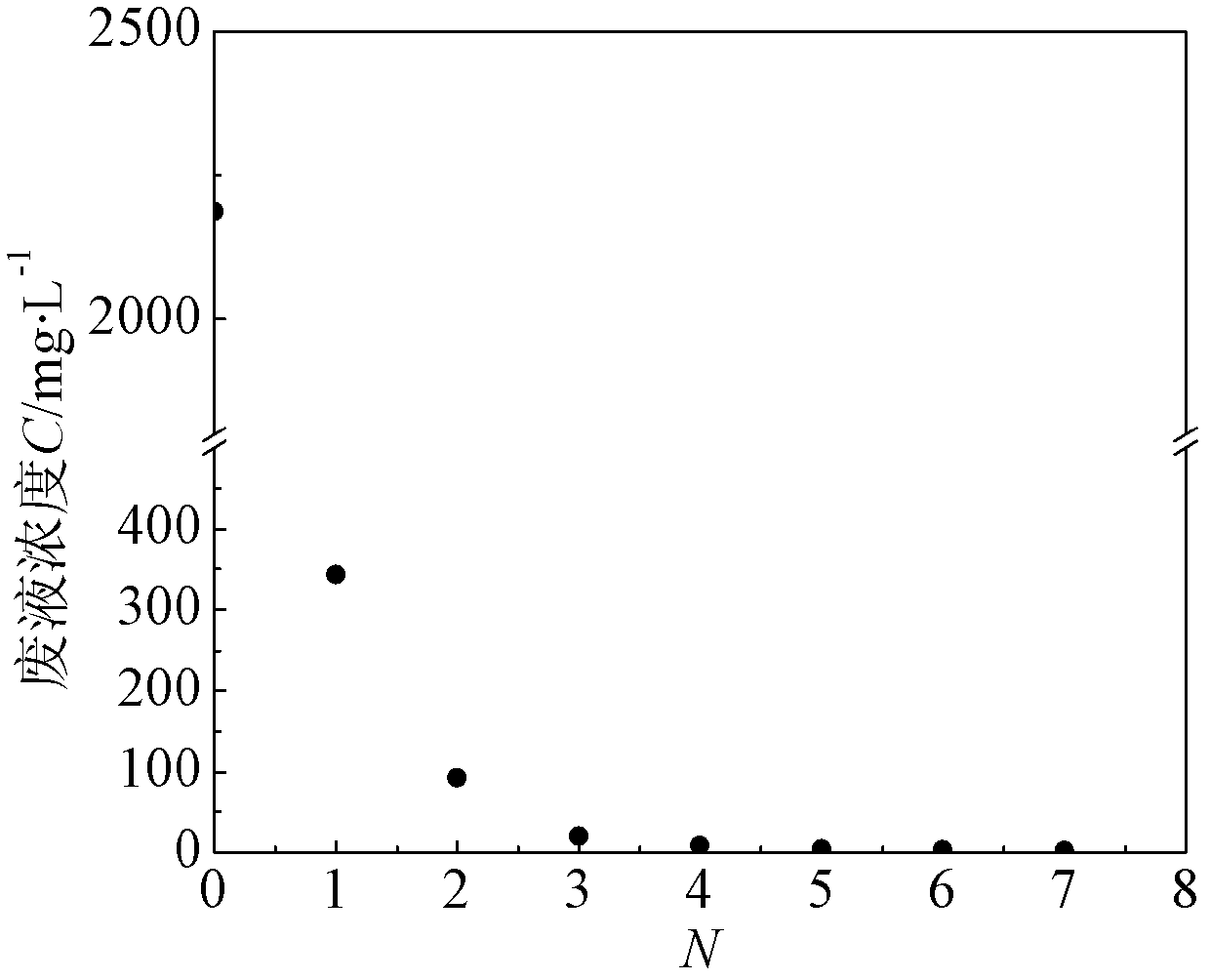

Method for removing phenol in phenol contained wastewater by using hollow fiber membrane

InactiveCN103304005AImprove stabilityImprove mass transfer efficiencyWater contaminantsWater/sewage treatment bu osmosis/dialysisHollow fibre membraneBenzene

Owner:BEIJING UNIV OF CHEM TECH

1,4-di(2,4-diamino phenoxy) benzenoid form high-temperature epoxy adhesive and preparation method thereof

InactiveCN103122231AGood adhesionGood viscosity controllabilityEpoxynovolac adhesivesBenzeneOrganic solvent

Owner:DONGHUA UNIV +1

Nickel catalyst, process for the preparation thereof, process for hydrogenation of m-dinitro benzene to m-phenylene diamine

InactiveUS20050070740A1Speed up the processLong catalyst lifeMolecular sieve catalystsOrganic compound preparationSolventSilicon dioxide

Owner:COUNCIL OF SCI & IND RES

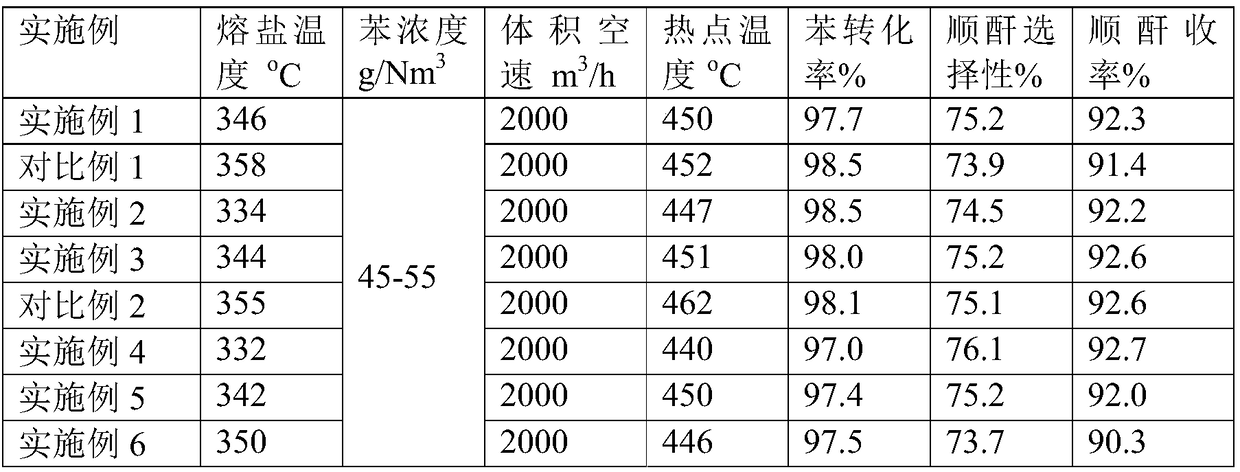

Catalyst for oxidation of benzene to maleic anhydride, preparation method and application thereof

InactiveCN109201095AHigh activitySave electricity energyPhysical/chemical process catalystsOrganic chemistryBenzeneMolten salt

Owner:CHINA PETROLEUM & CHEM CORP +1

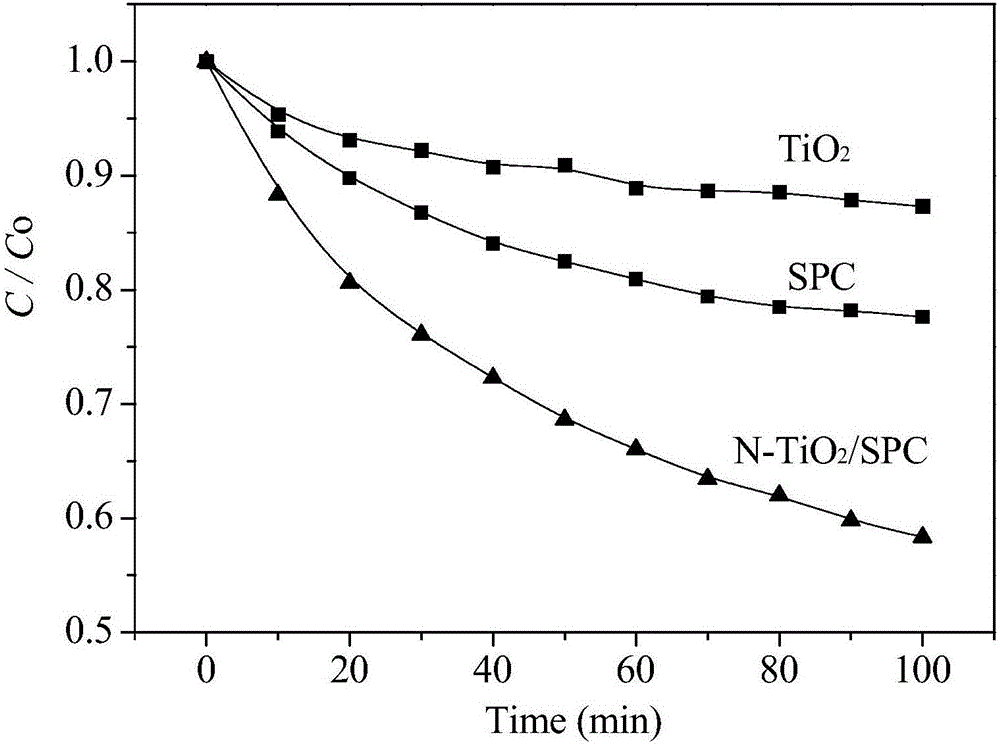

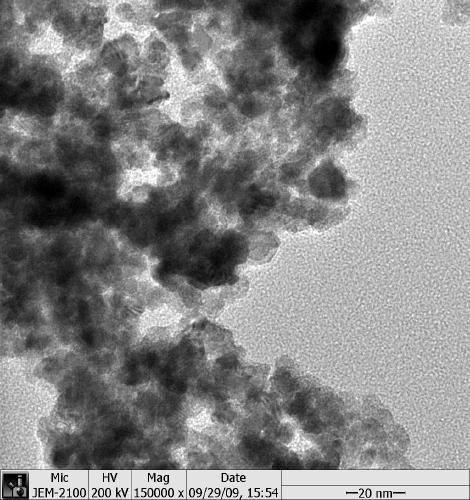

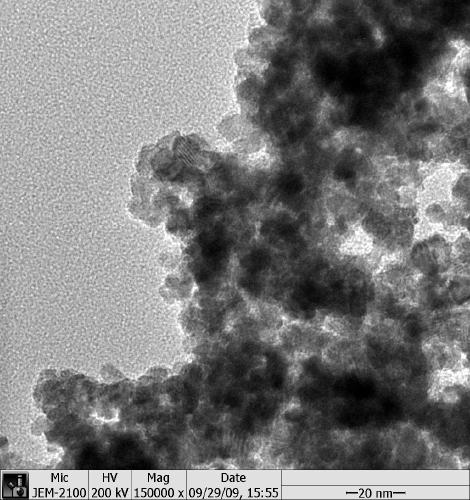

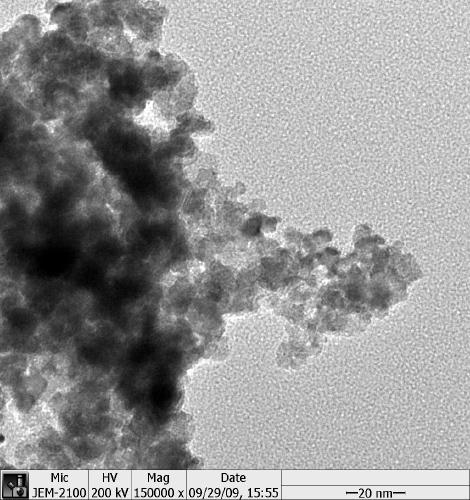

Bifunctional adsorbent of N-TiO2 silkworm-excrement porous carbon and preparation method of bifunctional adsorbent

InactiveCN106268641AGood dispersionHigh reactivityGas treatmentPhysical/chemical process catalystsPorous carbonShielding gas

Owner:GUANGXI UNIV

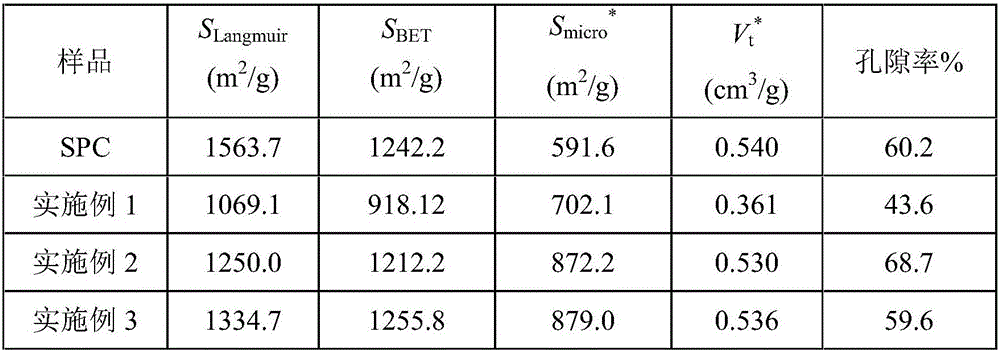

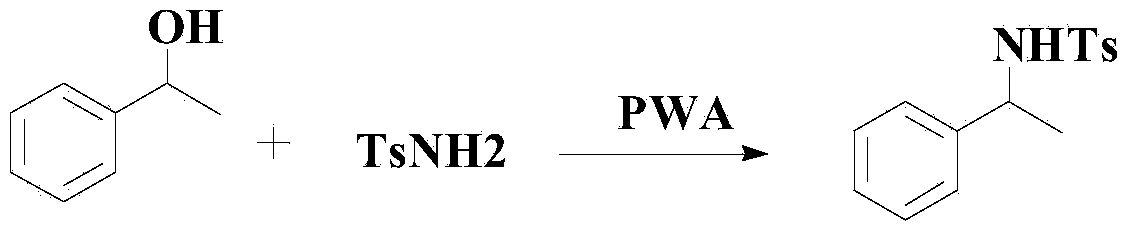

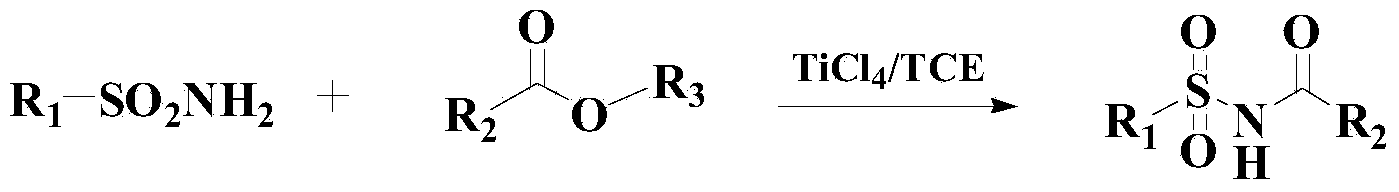

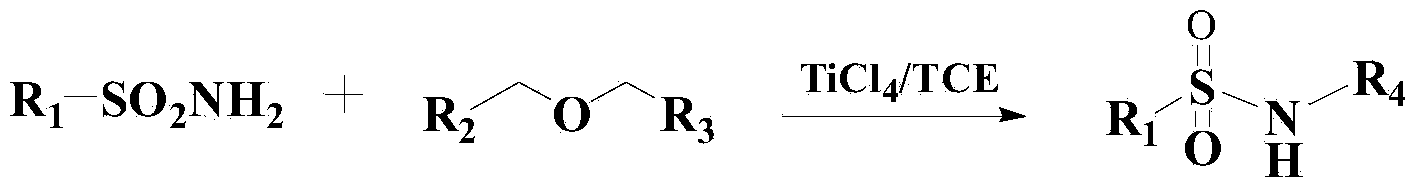

Method for synthesizing benzene sulfonamide compounds

InactiveCN103819369AOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acid amide preparationBenzeneMethyl tertiary butyl ether

Owner:甘肃皓骏药业有限公司

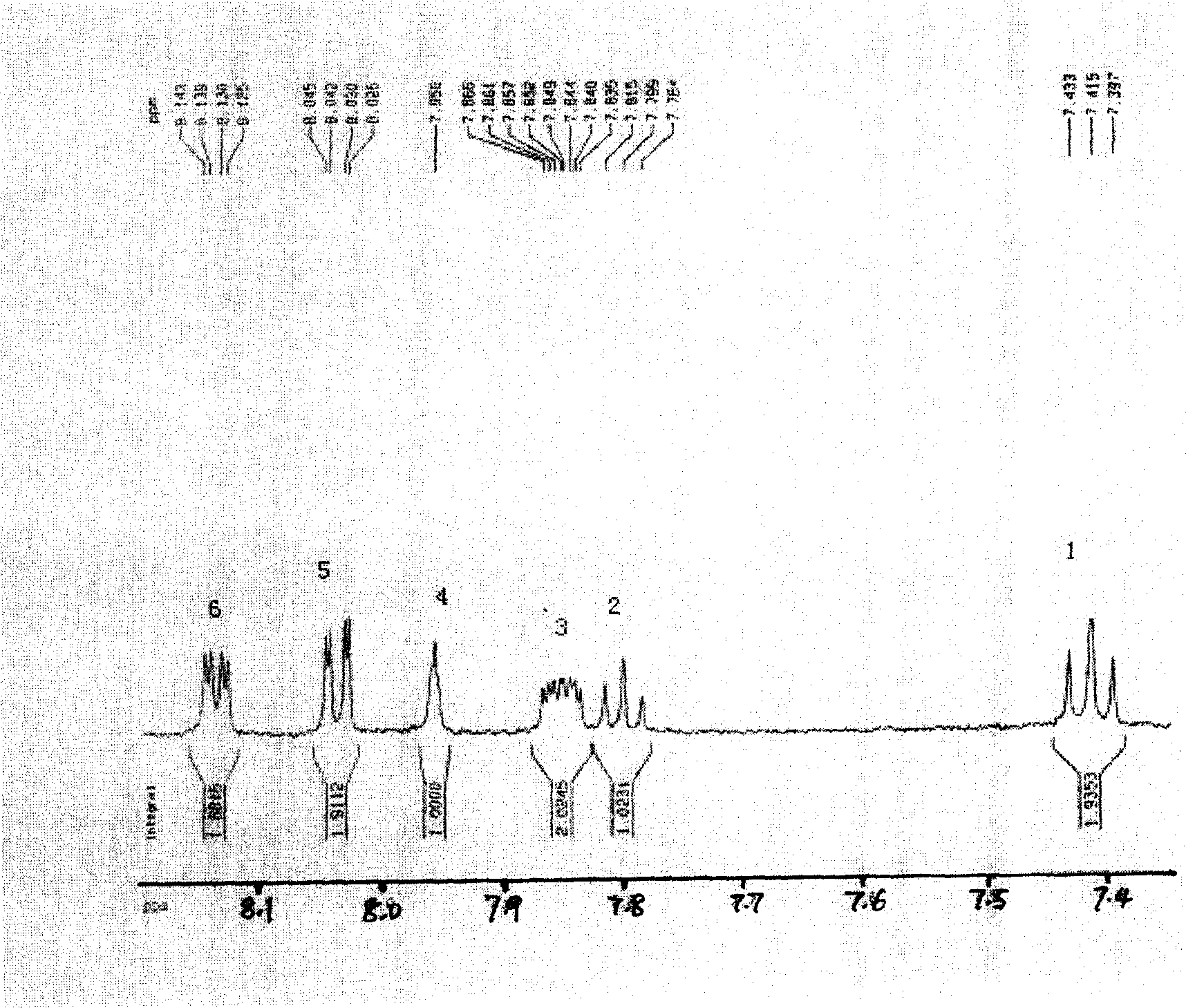

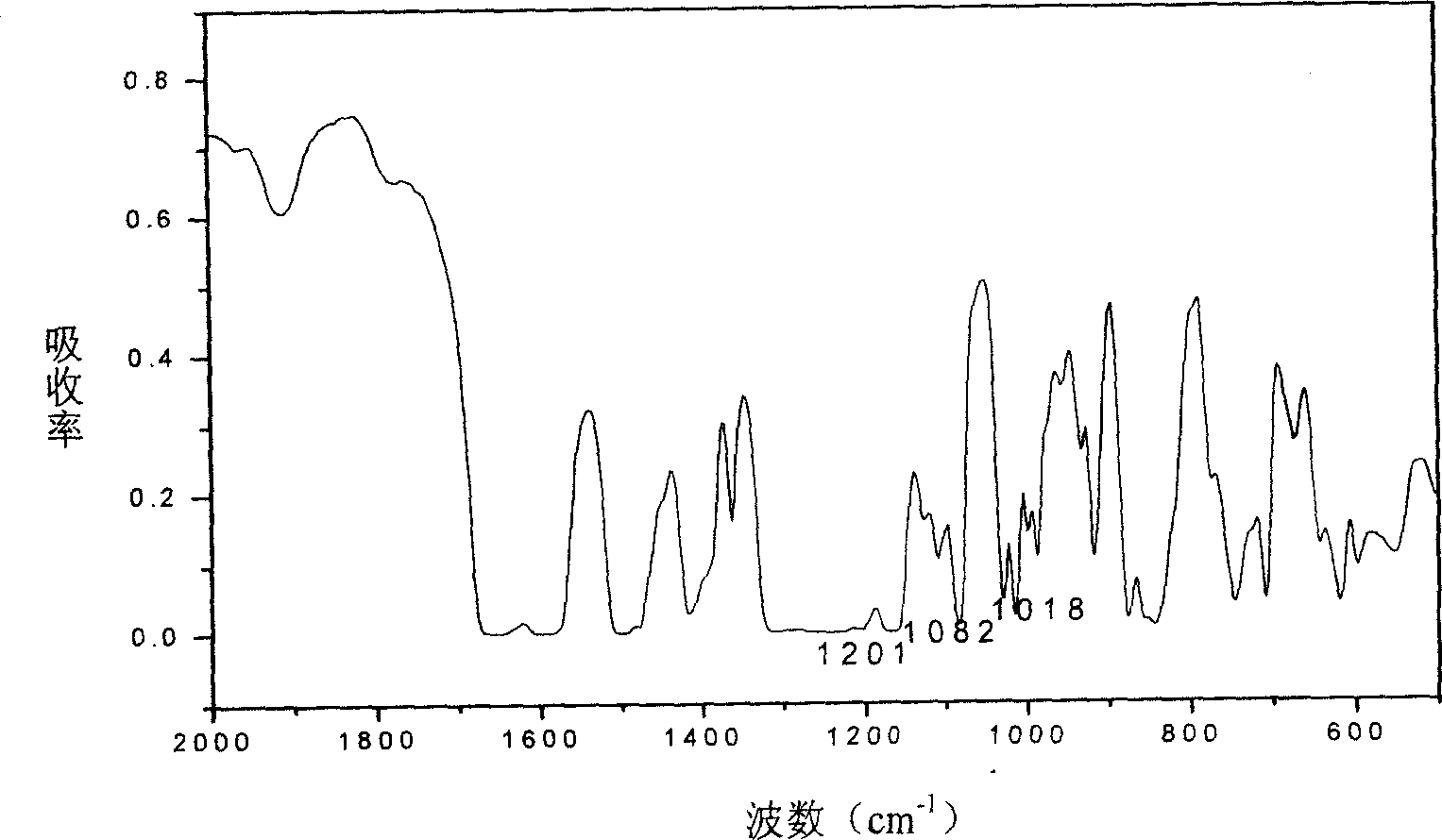

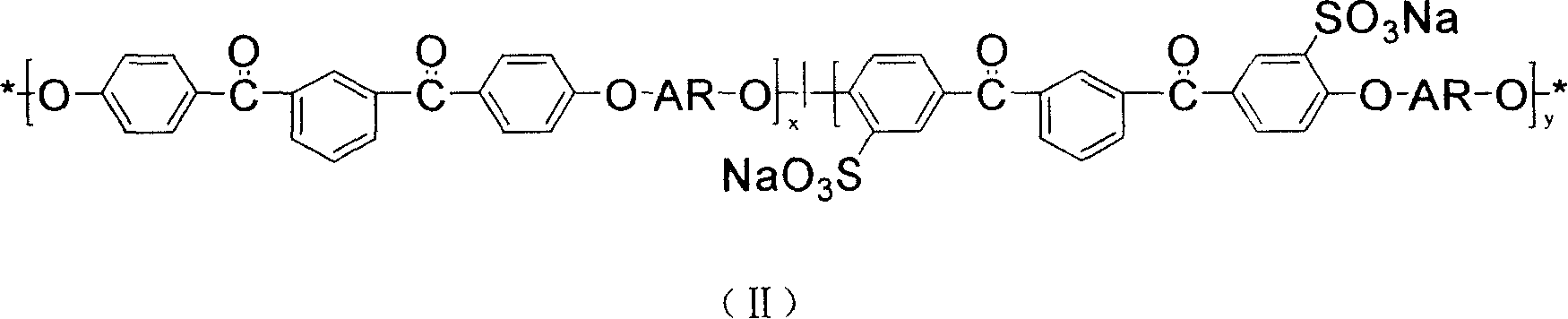

Sulfonated copolymer synthetized by 1,3-2(3-diisobutyl sodium-4-fluroben-formoyl) and its method

Owner:JILIN UNIV

Wear-resistant and high-temperature resistant capacitor aluminum case film coating paint and preparation method thereof

InactiveCN102373006AEffective protectionExtended service lifePolyurea/polyurethane coatingsMeth-Ketone

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

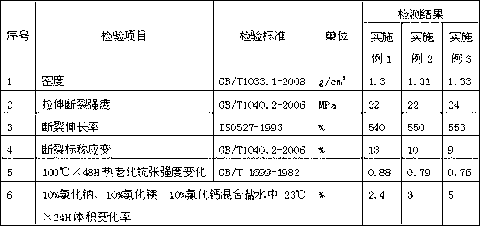

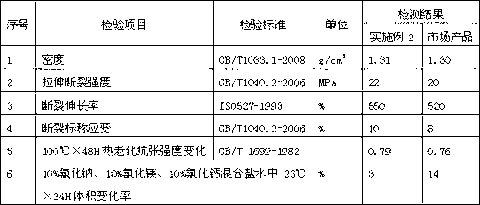

High-strength marine rubber fender

InactiveCN103012863AImprove tensile strength at breakRubber materialSulfide

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

Preparation method of non-woven fabric

InactiveCN108517621AImprove toughnessImprove wear resistanceBiochemical fibre treatmentNon-woven fabricsCardingPyrophosphate

Owner:徐冬

Synthesis of Azo Bonded Immunoregulatory Compounds

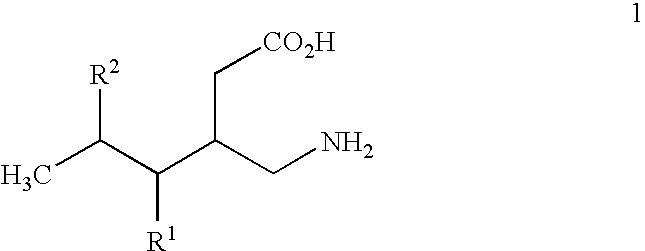

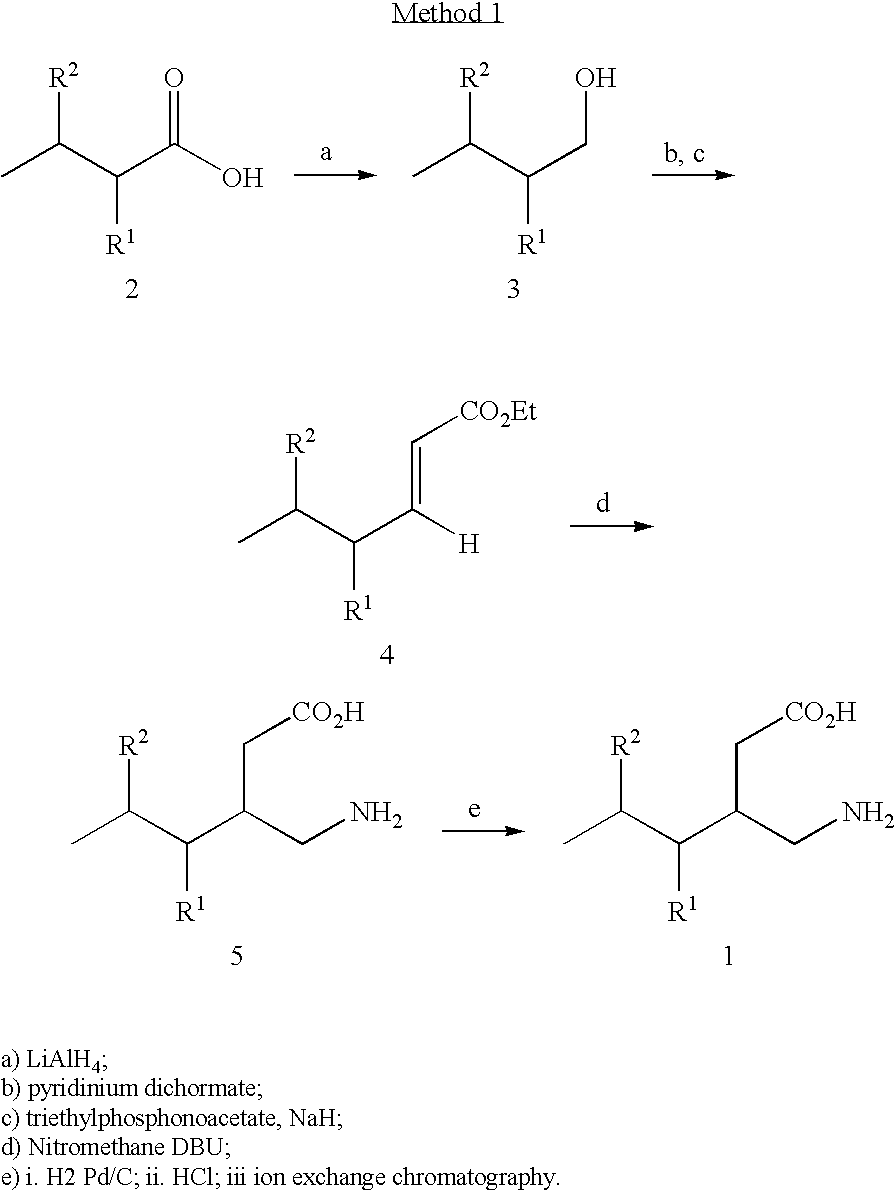

Methods are disclosed for preparing compounds of Formula I: where R1, R3, and R4are independently hydrogen or C1 to C4 alkyl, and R2 is: where R5 is selected from the group consisting of hydrogen and C1 to C4 alkyl, or where R6, R7 and R8 are independently hydrogen or C1 to C4 alkyl; or the esters or pharmacologically acceptable salts thereof. The methods can involve converting a suitably functionalized aniline compound to a diazonium salt (which aniline compound can be first formed by reduction of a nitrobenzene) and coupling the diazonium salt with a suitably functionalized benzene compound. The suitably functionalized aniline compound either includes a primary alcohol or aldehyde group, which is then oxidized to a carboxylic acid group, or includes a nitrile or amide group, which is hydrolyzed to a carboxylic acid group. The methods can also involve the direct coupling (via reduction of nitro groups to form an azo linkage) of suitably functionalized nitrobenzenes. The compounds and or their metabolites can be used to treat or prevent various diseases, particularly inflammatory conditions of the GI tract.

Owner:BIOCON LTD

Production method of 2,2'-dimethyl[1,1'-biphenyl]-4,4'-diamine

ActiveCN110590596AHigh selectivityHydrazine preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneHydroxyanthraquinone

Owner:CHANGZHOU SUNLIGHT PHARMA

Purification method of vitamin K3

ActiveCN101941898ALow costNo pollution in the processQuinone separation/purificationBenzeneActivated carbon

Owner:安徽泰格生物技术股份有限公司

Anti-cracking epoxy ceramic paint and preparation method thereof

InactiveCN108864898AHigh hardnessImprove mechanical propertiesFireproof paintsAnti-corrosive paintsWater resistantDodecylbenzene

The invention provides anti-cracking epoxy ceramic paint, which is prepared from the following raw materials in parts by weight: diatomite, silicon carbide powder, corn starch, coconut oil acid diethanolamide, aluminum oxide, C12 alcohol ester, triphenyl phosphate, diethylene glycol monobutyl ether, expanded vermiculite, nanometer silicon dioxide, barium sulfate, styrene-acrylate emulsion, tri(dodecyl benzene sulfonyl) titanium isopropoxide, carbon fiber, epoxy resin E-44, diluents 660A, triglycidyl p-aminophenol, bisoxaldihydrazone, water glass, hydroxypropyl methyl cellulose and a proper amount of deionized water. The prepared epoxy ceramic paint has excellent characteristics that the coating is compact and smooth, and is firm as ceramics; the bonding is firm; the thickness is uniform; the water-resistant, anti-corrosion and electric insulation performance is excellent, and the like.

Owner:黄春梅

Preparation method of fiber mesh-compounded diatom ooze coating

InactiveCN112266631AGuaranteed flatnessImprove structural strengthCovering/liningsAntifouling/underwater paintsBenzeneFiber

The invention relates to the technical field of diatom ooze coatings, and discloses a preparation method of a fiber mesh-compounded diatom ooze coating. The preparation method comprises the followingstep: S1, preparing raw materials including a fiber mesh, 25-35 parts of deionized water, 15-25 parts of diatomite, 2-8 parts of a humectant, 15-25 parts of an odor-free pure benzene emulsion, 10-18 parts of a filler, 2-6 parts of quartz powder and 0.5-1 part of a dispersant. The invention further provides a construction method of the fiber mesh-compounded diatom ooze coating. The construction method comprises the following steps: S1, cleaning a wall surface, namely cleaning the wall surface to be constructed by using a tool; and S2, fixing the fiber mesh. According to the invention, the overall structural strength of a diatom ooze coating composite layer is improved, and the diatom ooze coating is distributed in meshes of the fiber mesh and bonded and compounded to the fiber mesh and a wall surface base layer, so the flexibility of the diatom ooze coating composite layer is improved, construction is convenient, formaldehyde, benzene and other organic matters can be effectively decomposed, and a good air purification effect is achieved.

Owner:佘丽辉

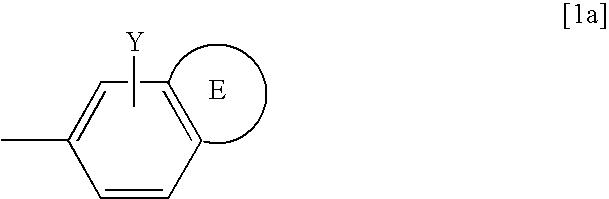

Preparation method of heterocyclic benzene compound

The invention relates to a preparation method of a heterocyclic benzene compound. The preparation method comprises the step of carrying out coupled reaction between a compound as shown in formula I and the compound as shown in formula II under the effect of a catalyst A, so as to obtain the compound as shown in formula III; and the reaction is shown as follows, wherein Ar, R1, R2, X and A are identified as the specifications shown. According to the method of synthesizing the heterocyclic benzene compound, described in the technical scheme, the reaction yield is greatly increased; the 'one-pot' method is carried out, so that the reaction process is safe and simple; and the method is very suitable for industrial production.

Owner:NANJING YOKO PHARMA GRP CO LTD

Cyclohexene Ru@Y2O3 catalyst prepared by selective hydrogenation of benzene and preparation method and application of cyclohexene Ru@Y2O3 catalyst

Owner:ZHENGZHOU NORMAL UNIV

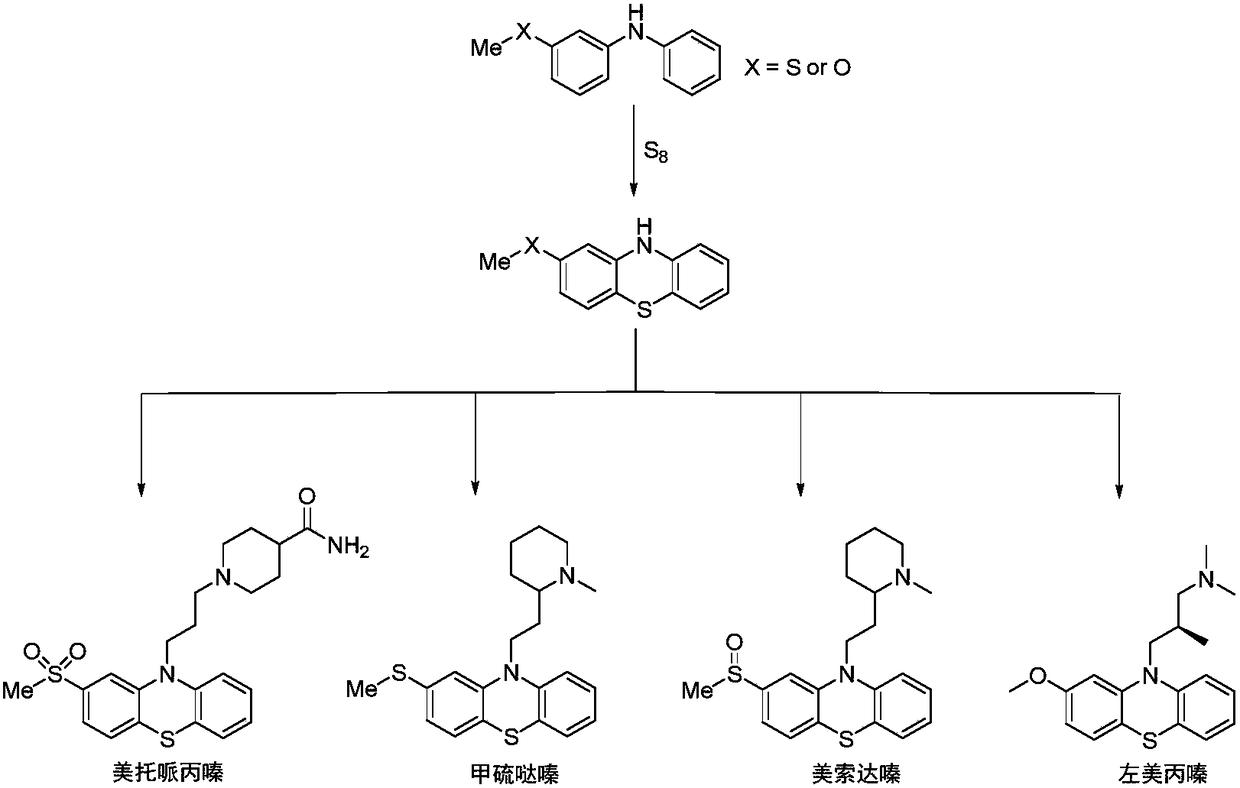

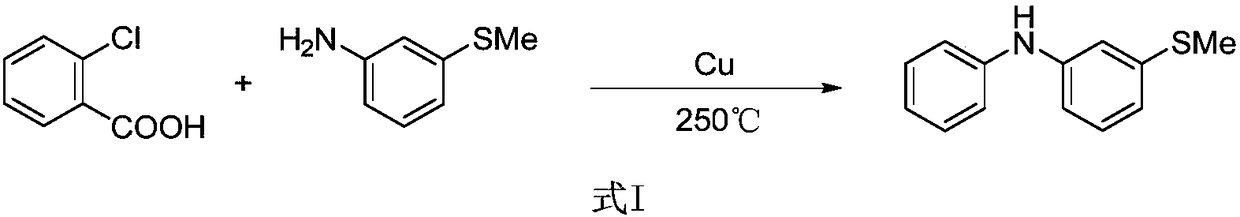

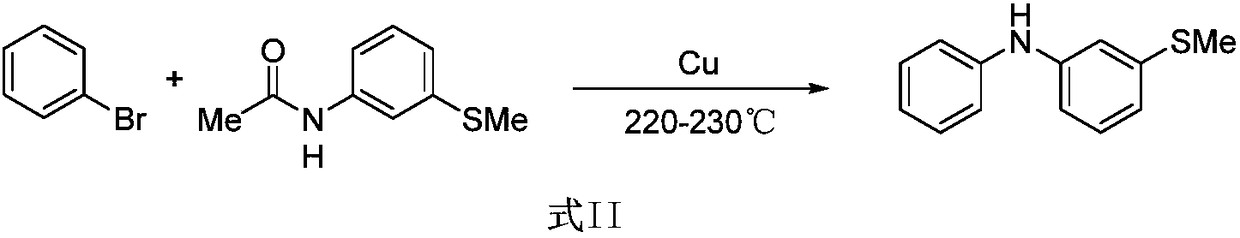

Method for synthesizing 3-(methylthio) dibenzenamine by light/nickel concerted catalysis

ActiveCN108409618AMild reaction conditionsHigh coupling efficiencySulfide preparationNickel saltBenzene

The invention discloses a method for synthesizing 3-(methylthio) dibenzenamine by light / nickel concerted catalysis. According to the method, cheap 3-(methylthio) benzenamine and halogeno benzene are used as raw materials, a light / nickel concerted catalysis strategy is used for constructing C-N bonds for the first time, and pyridazines drug key intermediate 3-(methylthio) dibenzenamine is synthesized. The method has the advantages that 1) the use amount of a photocatalyst is low, and is 0.01-0.02% of the molar weight of the halogeno benzene; 2) nickel salt is directly used as a metal catalyst such as nickel bromide, and an external ligand is not required; 3) reaction conditions are gentle, and can be effectively carried out at the temperature of 40-50 DEG C; and 4) the product can be directly obtained by reduced pressure distillation and is easily separated. By the remarkable advantages, the method has good industrial application prospect.

Owner:SHAANXI NORMAL UNIV

Special palm wax for car paint environmental protection and preparation method thereof

InactiveCN108102553AIncrease brightnessImprove paddlingPolishing compositionsSalicylic acidBULK ACTIVE INGREDIENT

Owner:西安随心呼汽车服务有限公司

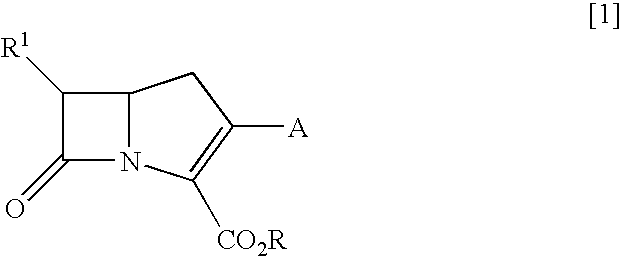

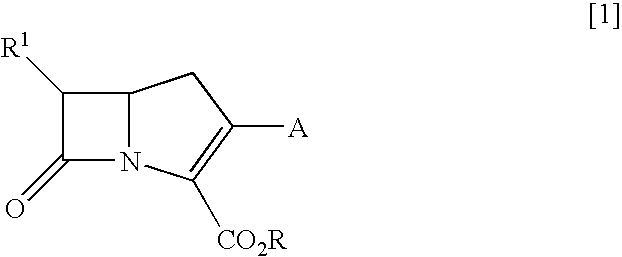

Novel Carbapenem Compound

InactiveUS20070265242A1High antibacterial activityPromote oral absorptionBiocideOrganic active ingredientsHalogenBenzene

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

Chlorobenzene directional dual-catalytic chlorination method

Owner:江苏淮江科技有限公司

Method for preparing magnesium sulfate from byproduct sulfuric acid of benzene sulfone chloride

PendingCN111977675AIncrease concentrationEasy to separateSulfur compoundsMagnesium sulfatesSulfonyl chlorideChlorosulfuric acid

The invention discloses a method for preparing magnesium sulfate from byproduct sulfuric acid of benzene sulfone chloride. The method comprises the following steps: (1) sulfonation reaction: chlorosulfonic acid and pure benzene are taken as raw materials; firstly, the chlorosulfonic acid is added into a reaction kettle; then, the reaction kettle is heated, and the reaction kettle is started; afterstarting, under the stirring state that the stirring rate is 100-150r / min, the pure benzene is dropwise added by employing a constant-pressure dropping funnel; and after being dropwise added, the pure benzene and the chlorosulfonic acid react for 2-3h to produce hydrogen chloride gas; then the produced hydrogen chloride gas is condensed and is absorbed by a secondary falling film to prepare a hydrochloric acid solution with mass concentration of 38%-45%; after the solution is obtained, 10-15g of sulfonation additive is added into the solution; then the reaction kettle is restarted for reaction; and after the reaction ends, cooling, hydrolyzing, crystallization, suction filtration, water washing and drying are performed to obtain the benzene sulfone chloride and by-products thereof; the sulfuric acid can be separated very conveniently, and the magnesium sulfate can be quickly prepared by using the sulfuric acid.

Owner:JIANGSU KANGXIANG GRP CORP +1

Method for producing gasoline blending component from dry gas

InactiveCN106244224AMolecular sieve catalystsLiquid hydrocarbon mixtures productionBenzeneWater vapor

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel preparation method of 2,4-dihydroxy benzene formyl chloride

InactiveCN108752195AGood technical foundationOrganic compound preparationCarboxylic compound preparationBenzeneChloride

Owner:SHANGHAI HUAJIN BIOTECH CO LTD

Alpha 2 Delta Ligands for Fibromyalgia and Other Disorders

Owner:PFIZER INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap