Method for synthesizing benzene sulfonamide compounds

A technology of benzenesulfonamide and compound, which is applied in the preparation of sulfonic acid amide, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc. The problem of poor reactivity of base ethers, etc., achieves broad-scale industrial application prospects and market potential, high-efficiency reaction, and mild reaction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

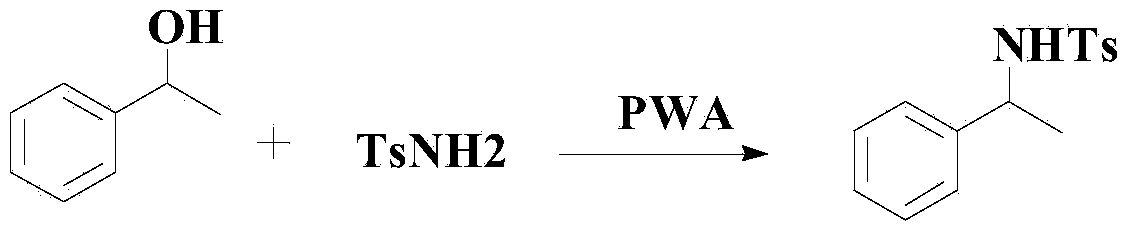

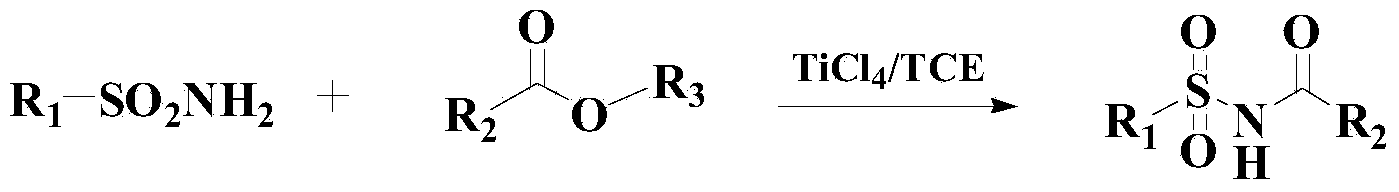

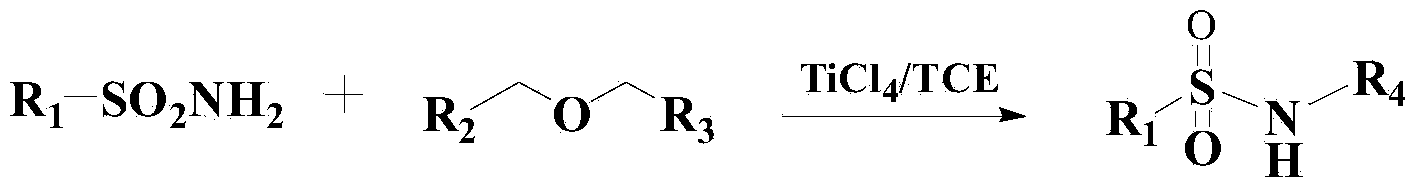

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0037] Weigh the mixture of ethyltriphenylphosphonium bromide, AgCl and porphyrin according to the mass ratio of 0.7:1.2:1, grind and mix evenly to obtain the catalyst of the present invention, which is used in the following specific examples according to the dosage.

Embodiment 1

[0039]

[0040] Add 300ml of toluene to the reactor, then add 1mol of methyl tert-butyl ether and 1.5mol of benzenesulfonamide, heat up to 60°C, then add 0.3g of catalyst, and stir the reaction for 8 hours under the thermometer. After the reaction, N-tert-butylbenzenesulfonamide was obtained by vacuum concentration, column chromatography separation and drying, with a yield of 96.3% and a purity of 98.2% (HPLC).

[0041] 1 H-NMR (CDCl 3 , 270MHz) δ: 7.92 (m, 2H), 7.49, (m, 3H), 4.82 (br, 1H), 1.21 (s, 9H).

[0042] MS m / z: 213.08 (M+1,100).

Embodiment 2

[0044]

[0045] Add 300ml of toluene to the reactor, then add 1mol of methyl tert-butyl ether and 1.4mol of p-toluenesulfonamide, heat up to 50°C, then add 0.5g of catalyst to it and stir for 7 hours. Chromatographic separation and drying gave N-tert-butyl p-toluenesulfonamide with a yield of 96.5% and a purity of 98.4% (HPLC).

[0046] 1 H-NMR (CDCl 3 ,270MHz) δ: 7.78(d,2H), 7.29(d,2H), 4.85(br,1H), 2.44(s,3H), 1.22(s,9H).

[0047] MS m / z: 227.06 (M+1,100).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap