Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Water vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water vapor, water vapour or aqueous vapor is the gaseous phase of water. It is one state of water within the hydrosphere. Water vapor can be produced from the evaporation or boiling of liquid water or from the sublimation of ice. Unlike other forms of water, water vapor is invisible. Under typical atmospheric conditions, water vapor is continuously generated by evaporation and removed by condensation. It is less dense than air and triggers convection currents that can lead to clouds.

Surface protection film for polarizer film

InactiveUS20080166549A1Low costGood antifoulingLiquid surface applicatorsSynthetic resin layered productsActive agentWater vapor

The present invention provides a film for the protection of the surface of polarizer film. Said film surface has anti-static coated layer. The coating solution contains polythiophene, surfactant, binding resin and water. According to the present invention, said protection film on the surface on the polarizer film has the excellent anti-static, transmittance, anti-foul and water repellence. It is able to prevent the invasion of imbuing with dust, accumulative anti-static and water vapor from the processing of assembling and transportation so as to influence the quality of polarizer film.

Owner:NANYA PLASTICS CORP

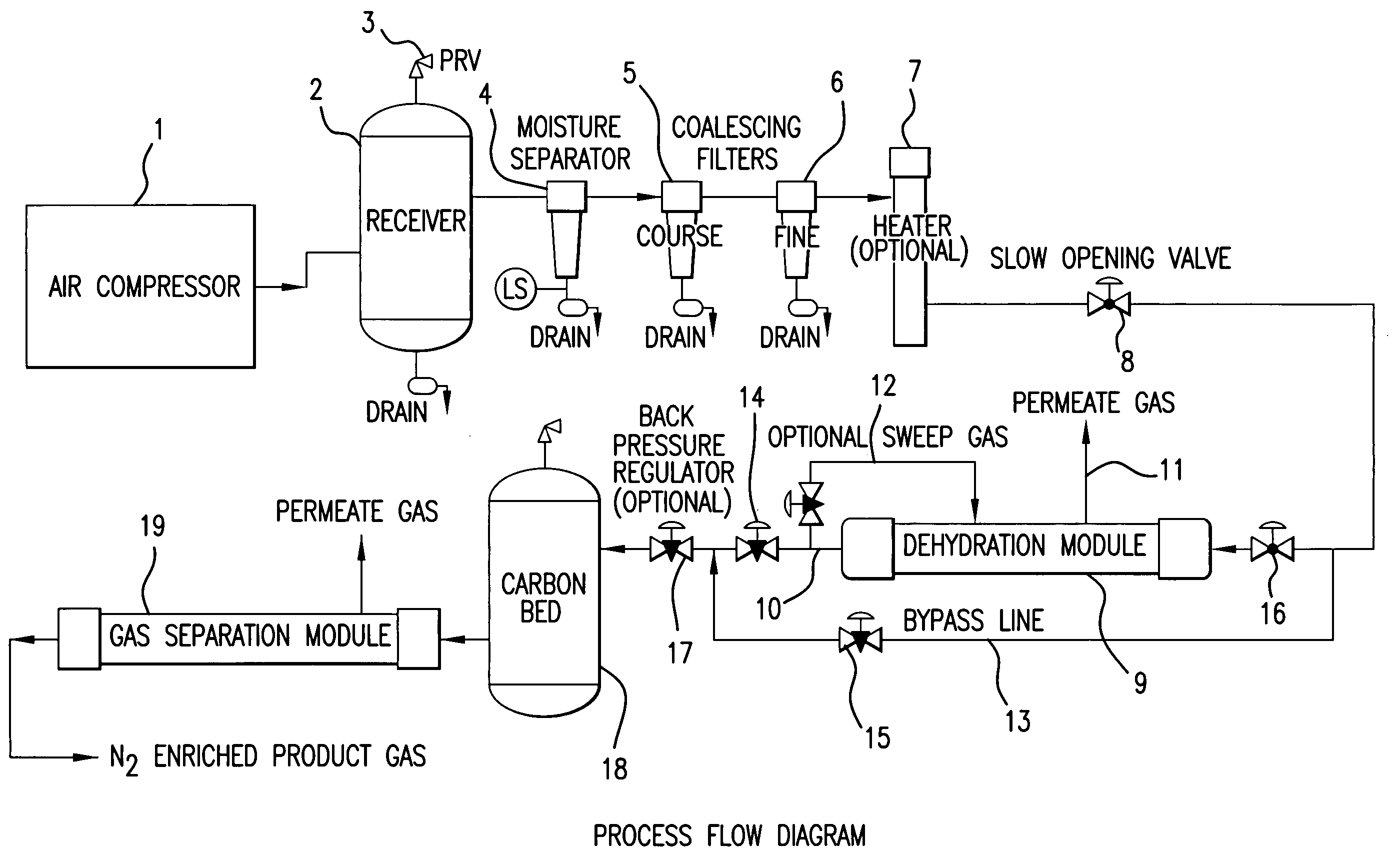

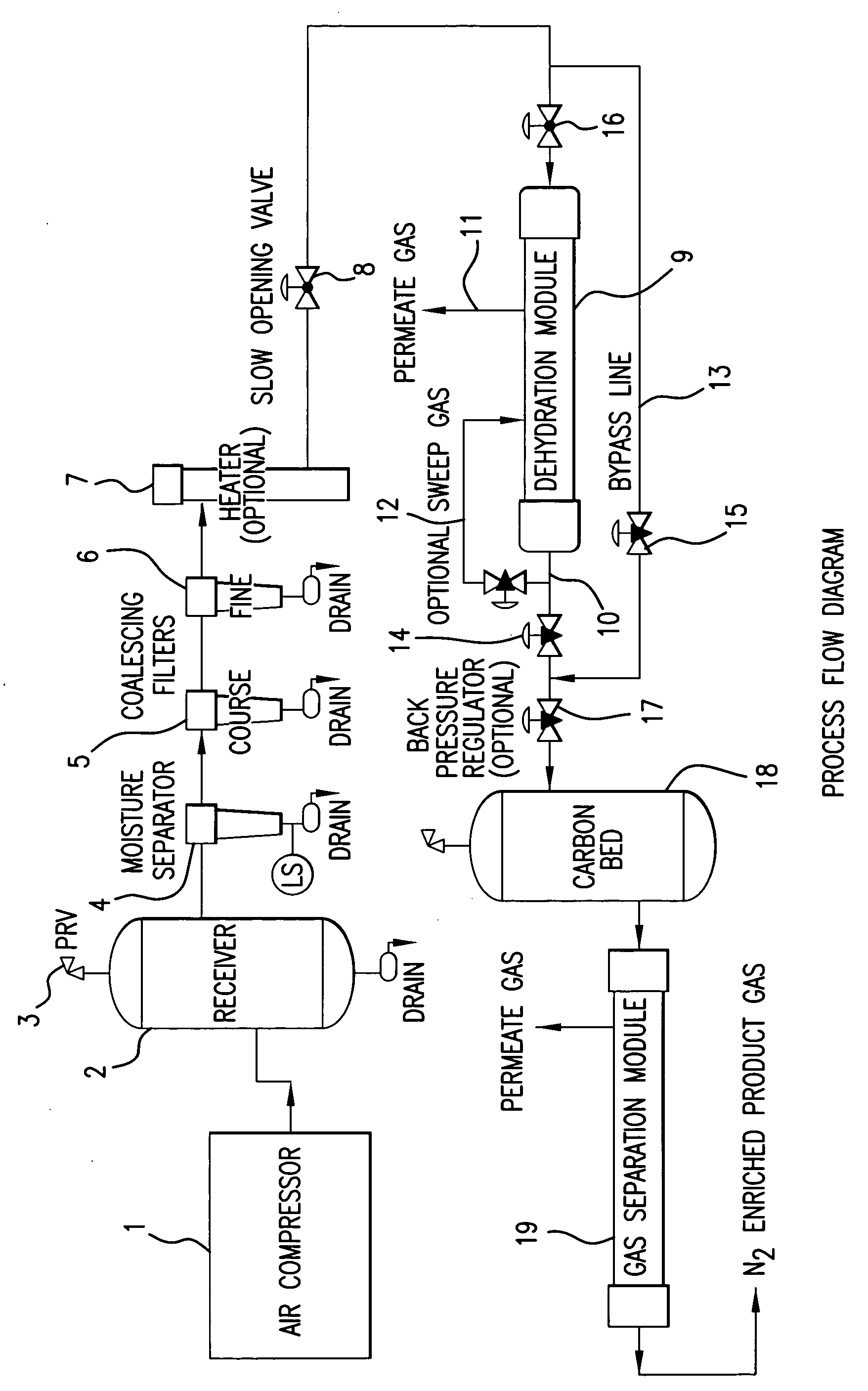

Air separation system using dehydration membrane for pretreatment of compressed air

Owner:GENERON IGS

Preparation method for high-purity rhenium powder

Owner:湖南元极新材料有限公司

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

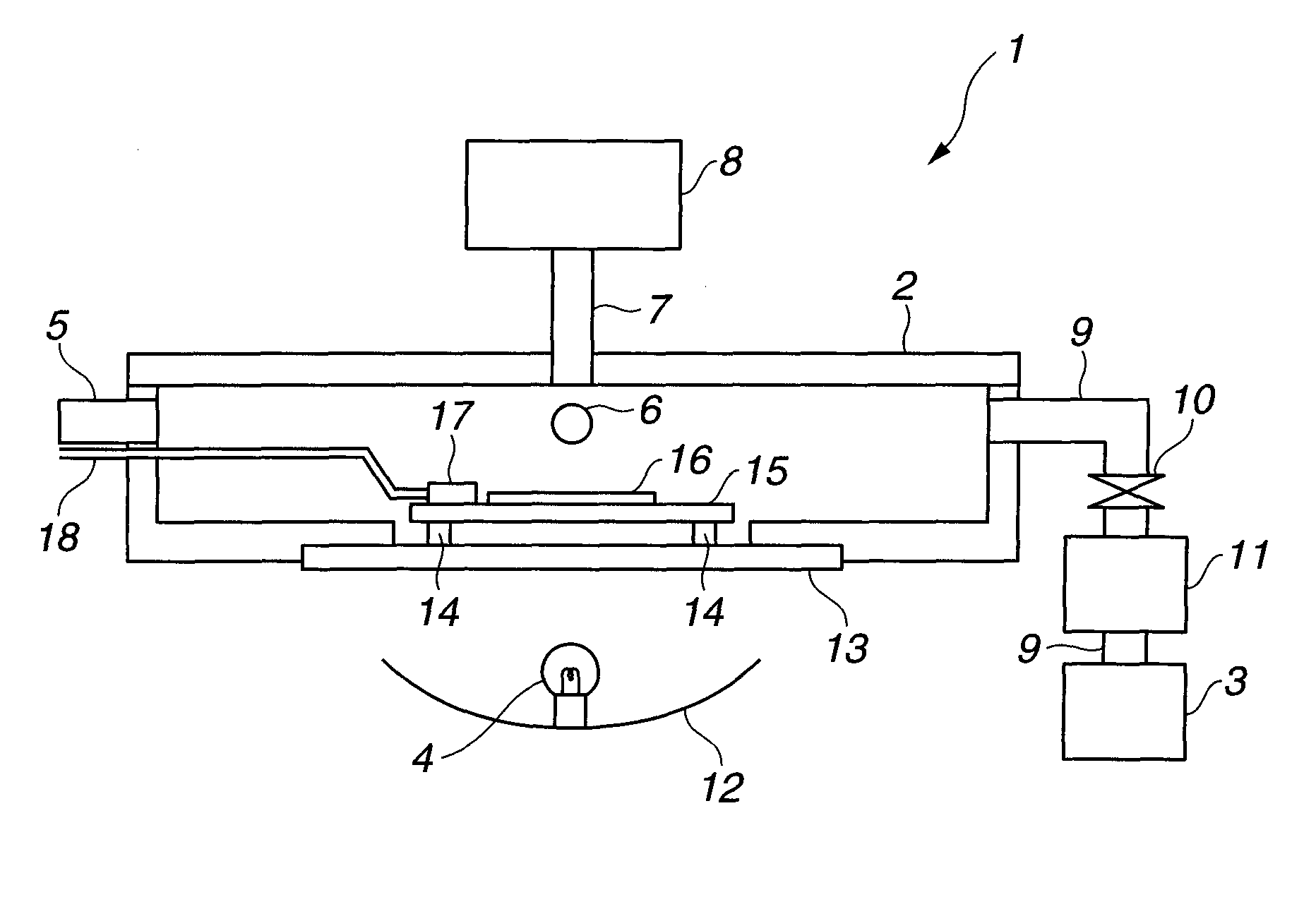

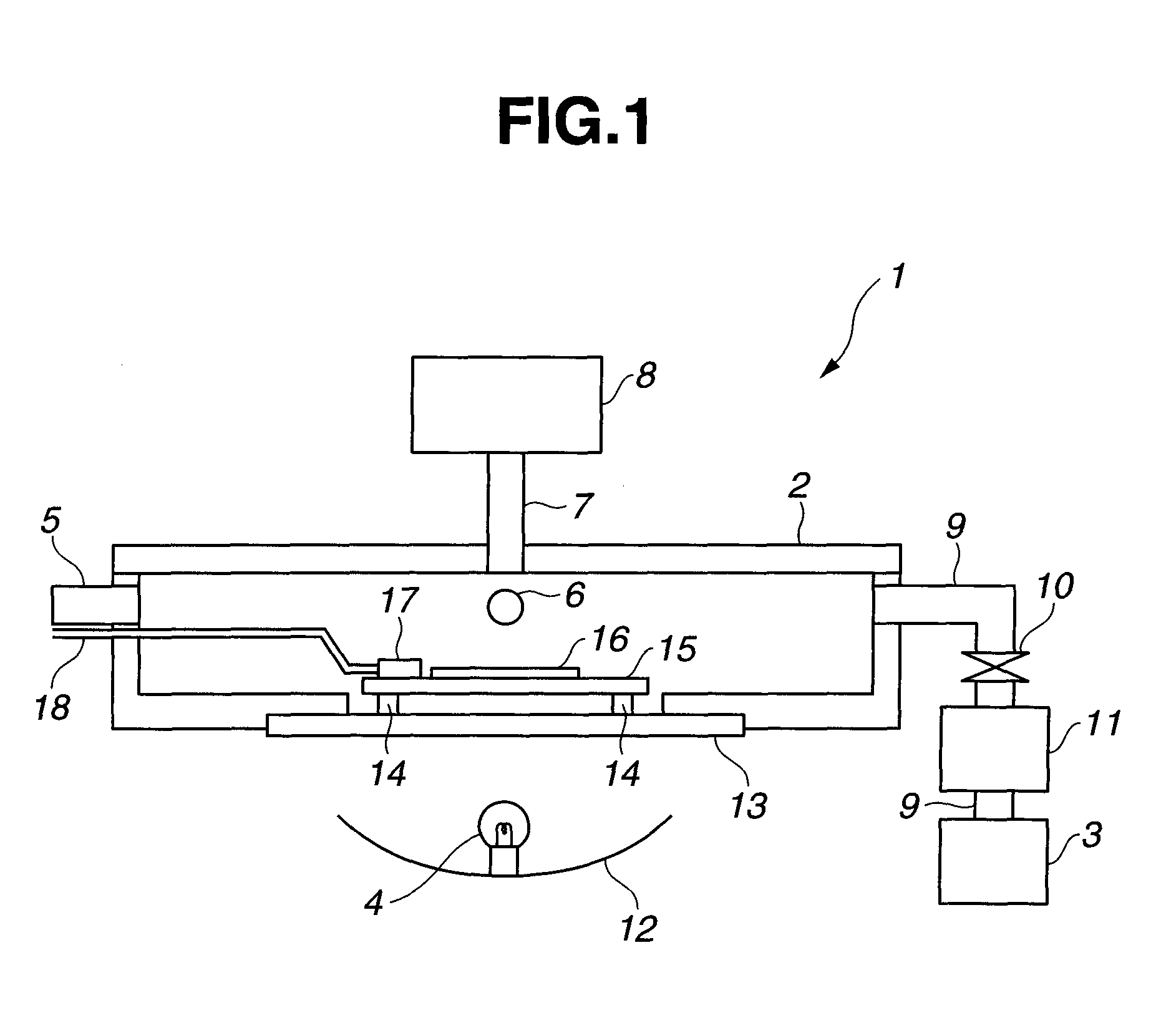

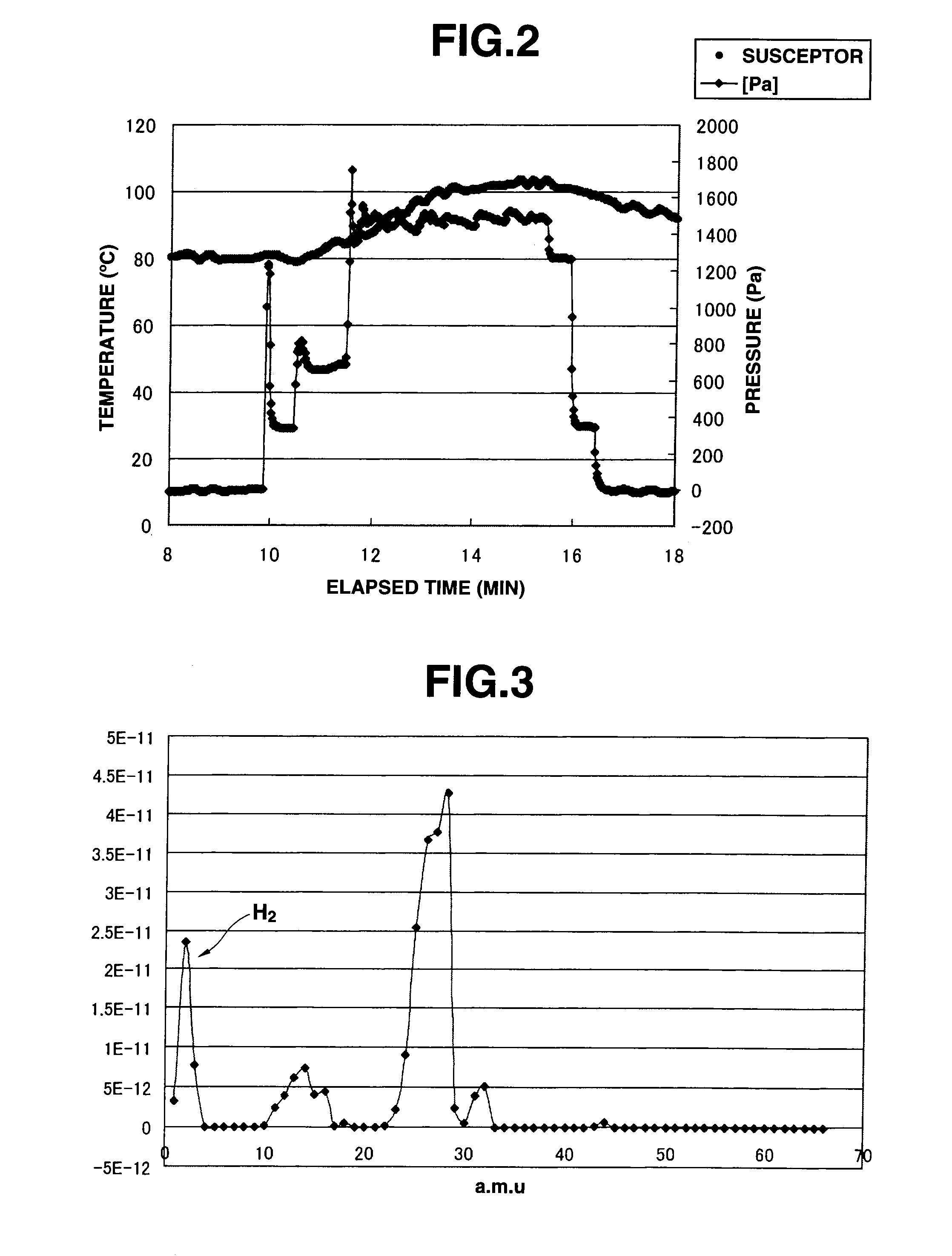

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

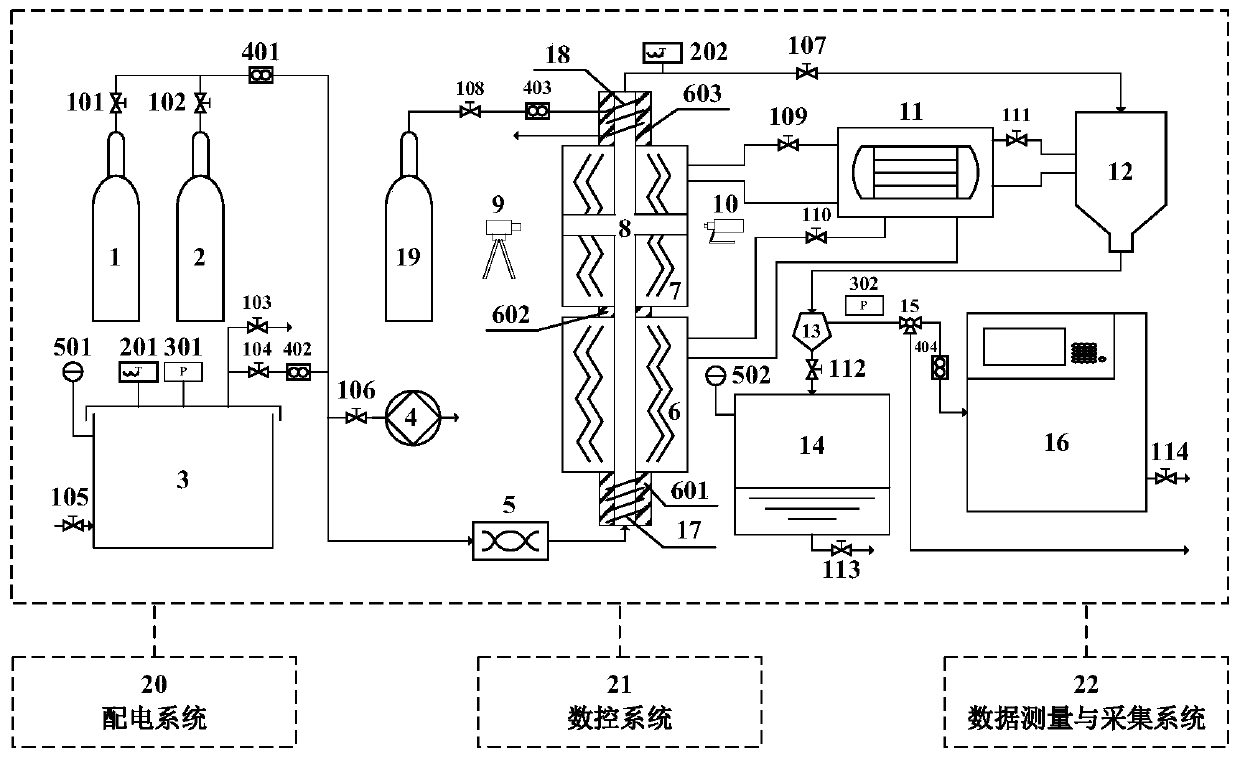

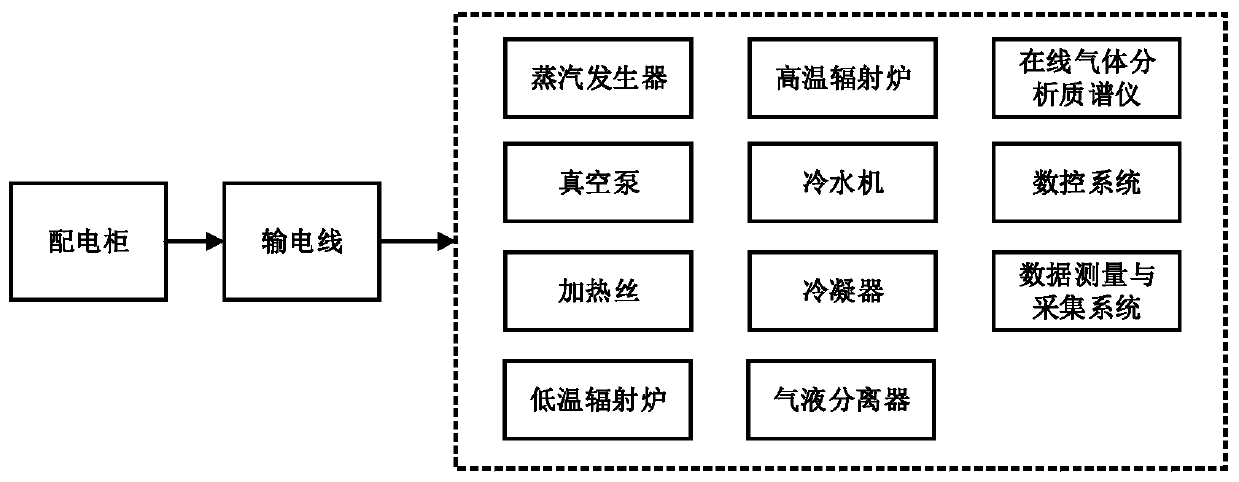

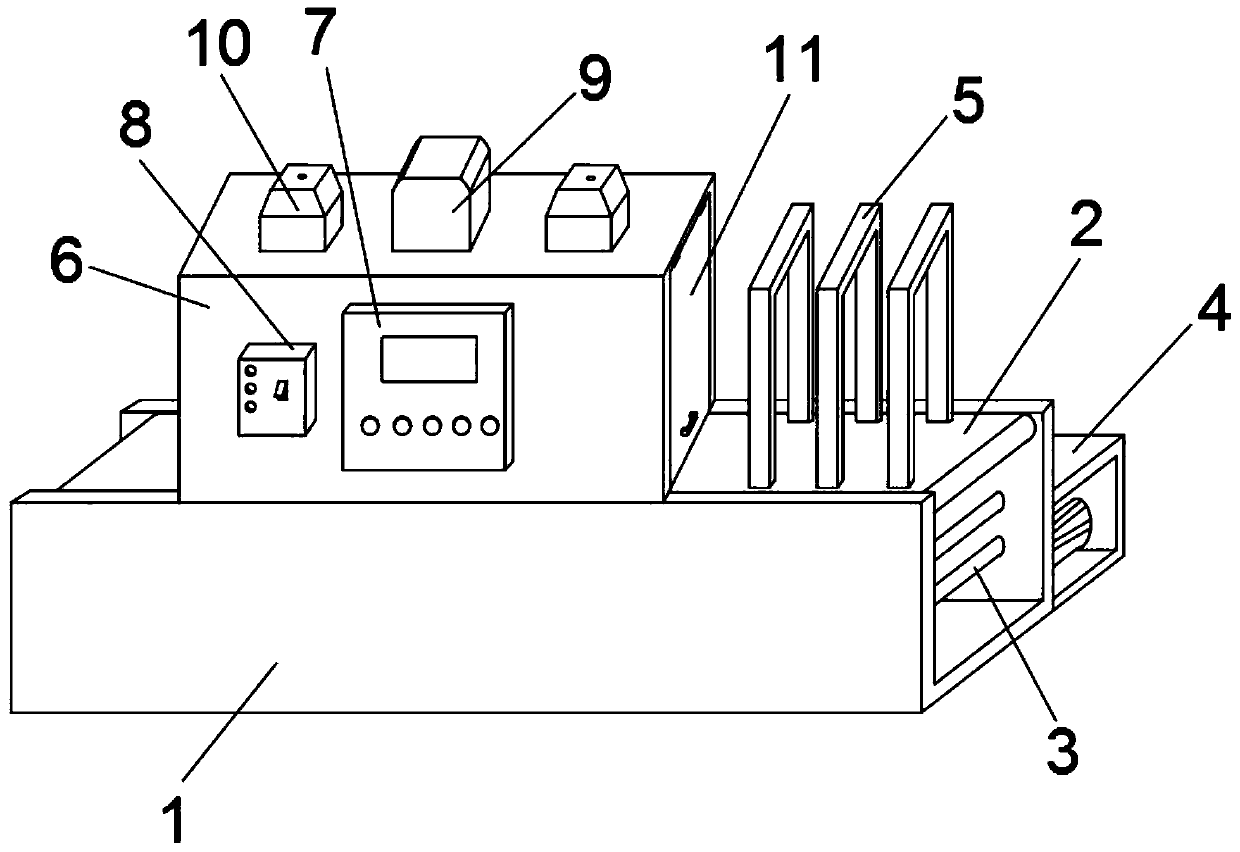

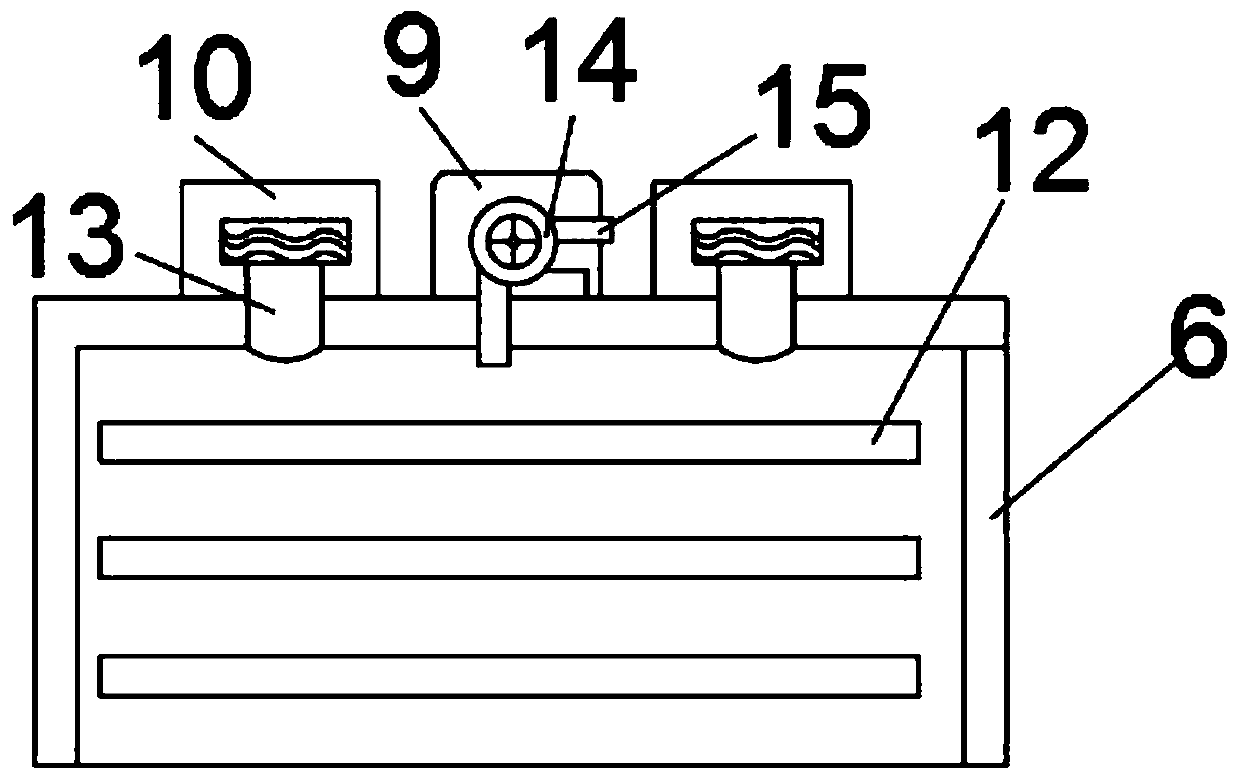

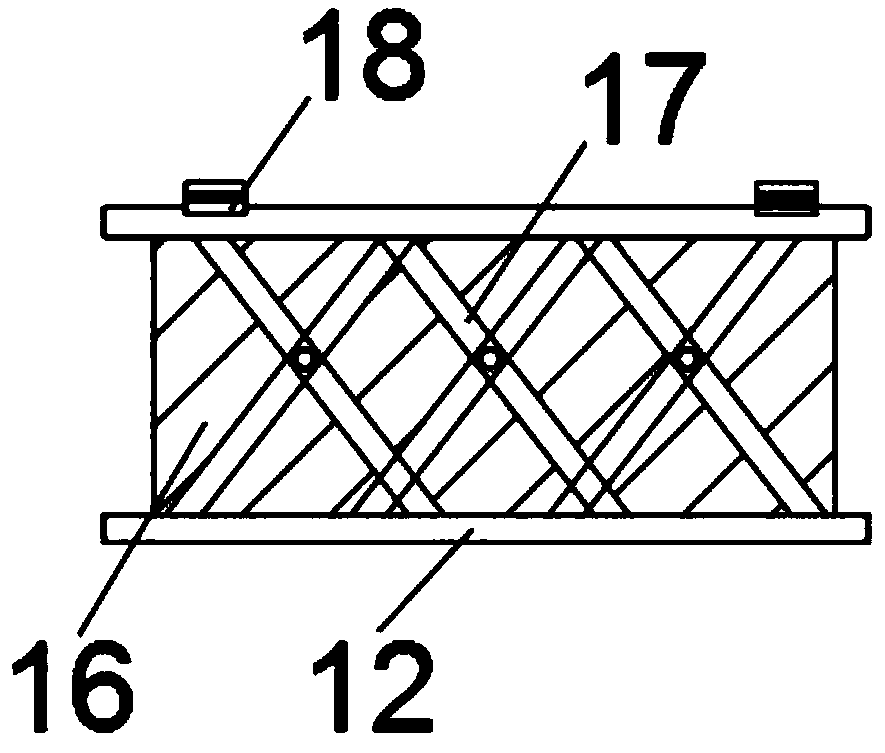

Structural material ultra-high temperature corrosion experiment system and method under serious accident of nuclear reactor

ActiveCN110553974AReduce space consumptionGuaranteed tightnessWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansContinuous measurementCorrosion reaction

Owner:XI AN JIAOTONG UNIV

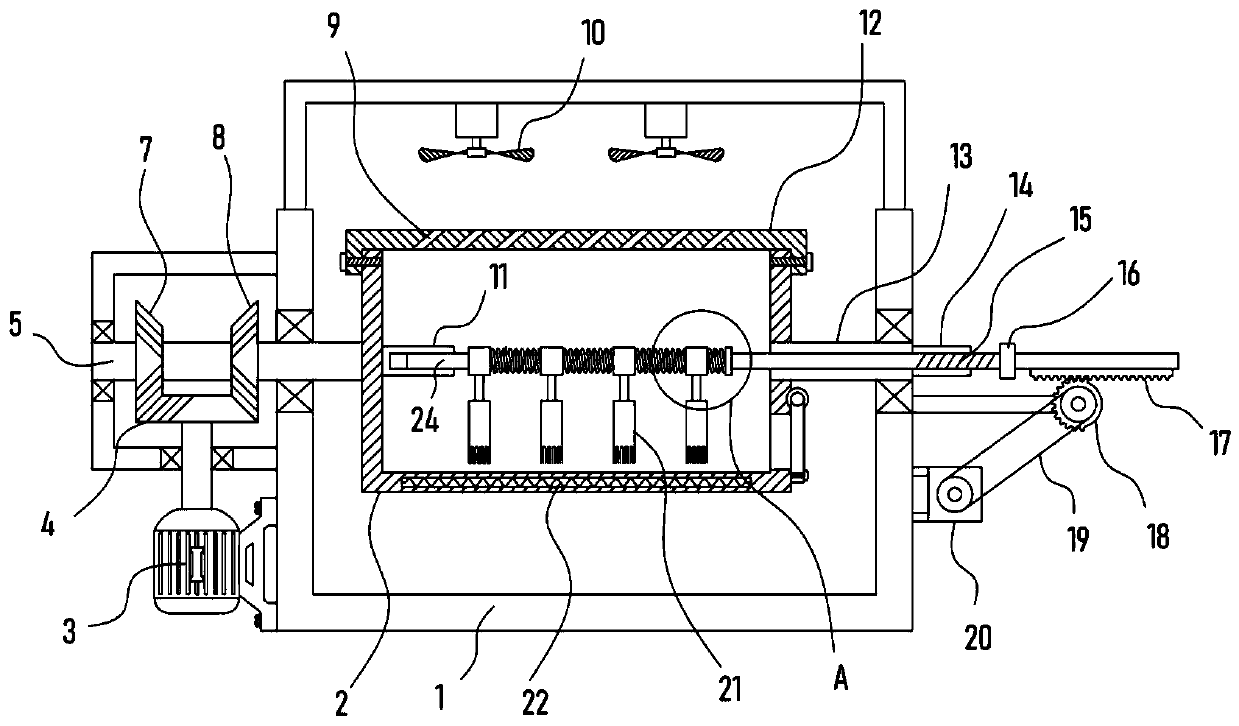

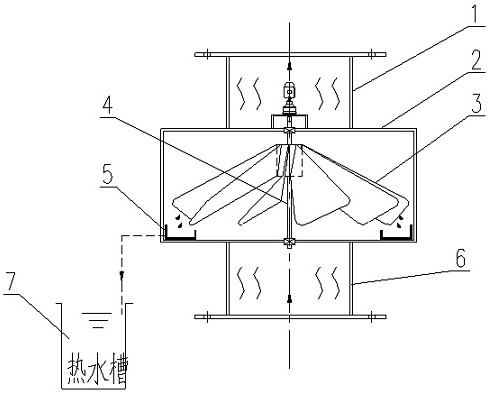

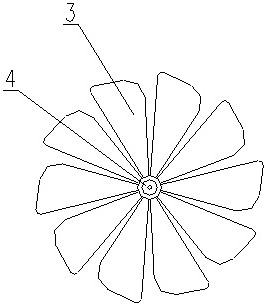

Ceramic glaze drying device

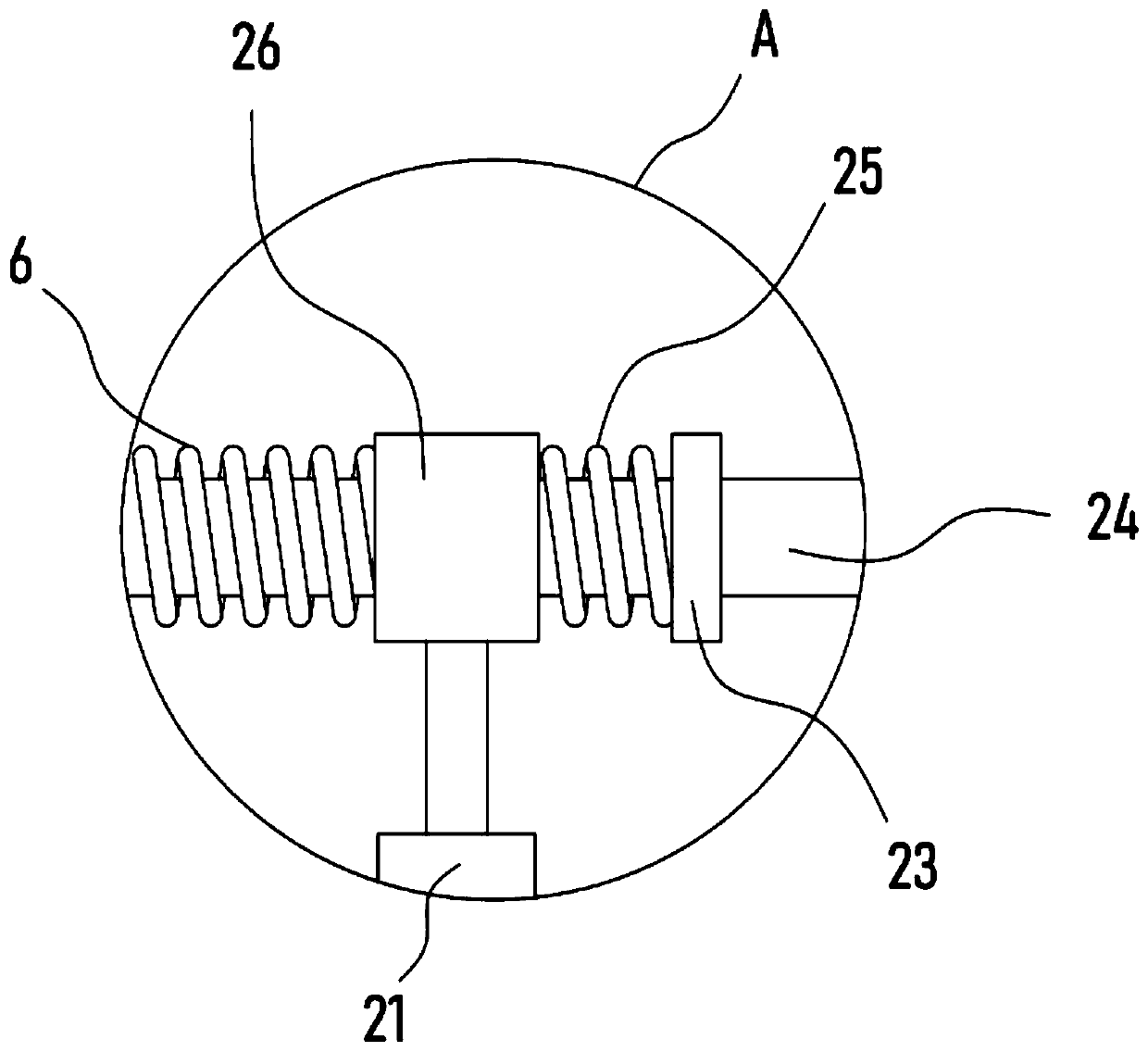

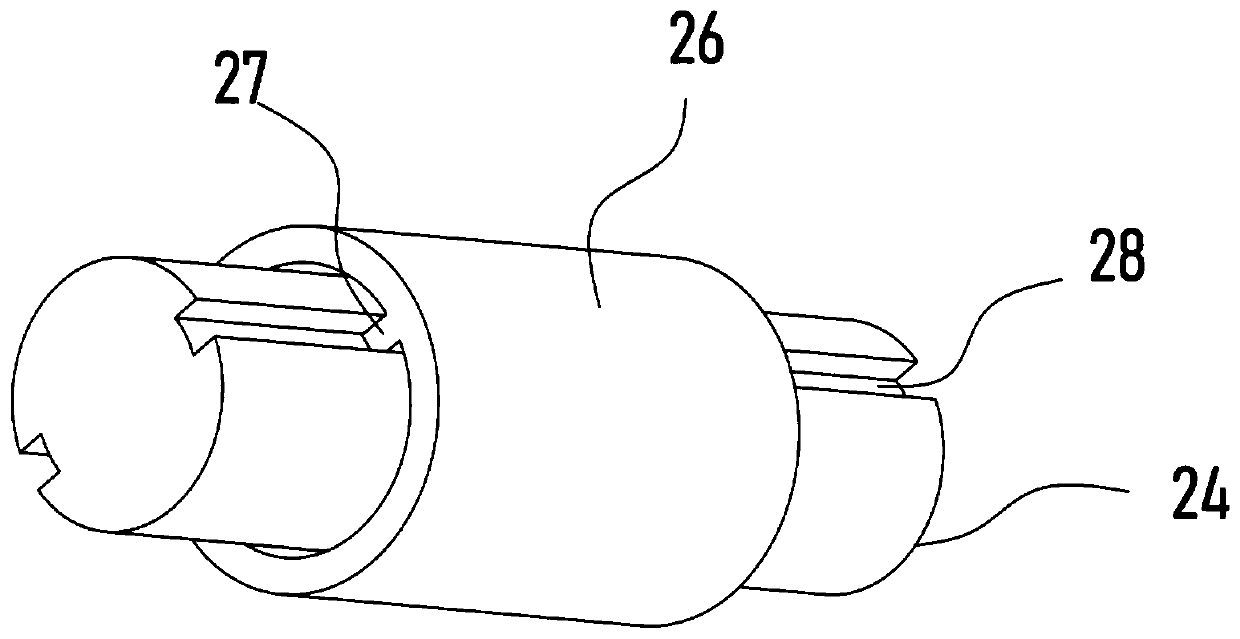

ActiveCN110044137APromote shakingFull heating effectDrying solid materials with heatDrying gas arrangementsWater vaporDrive shaft

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

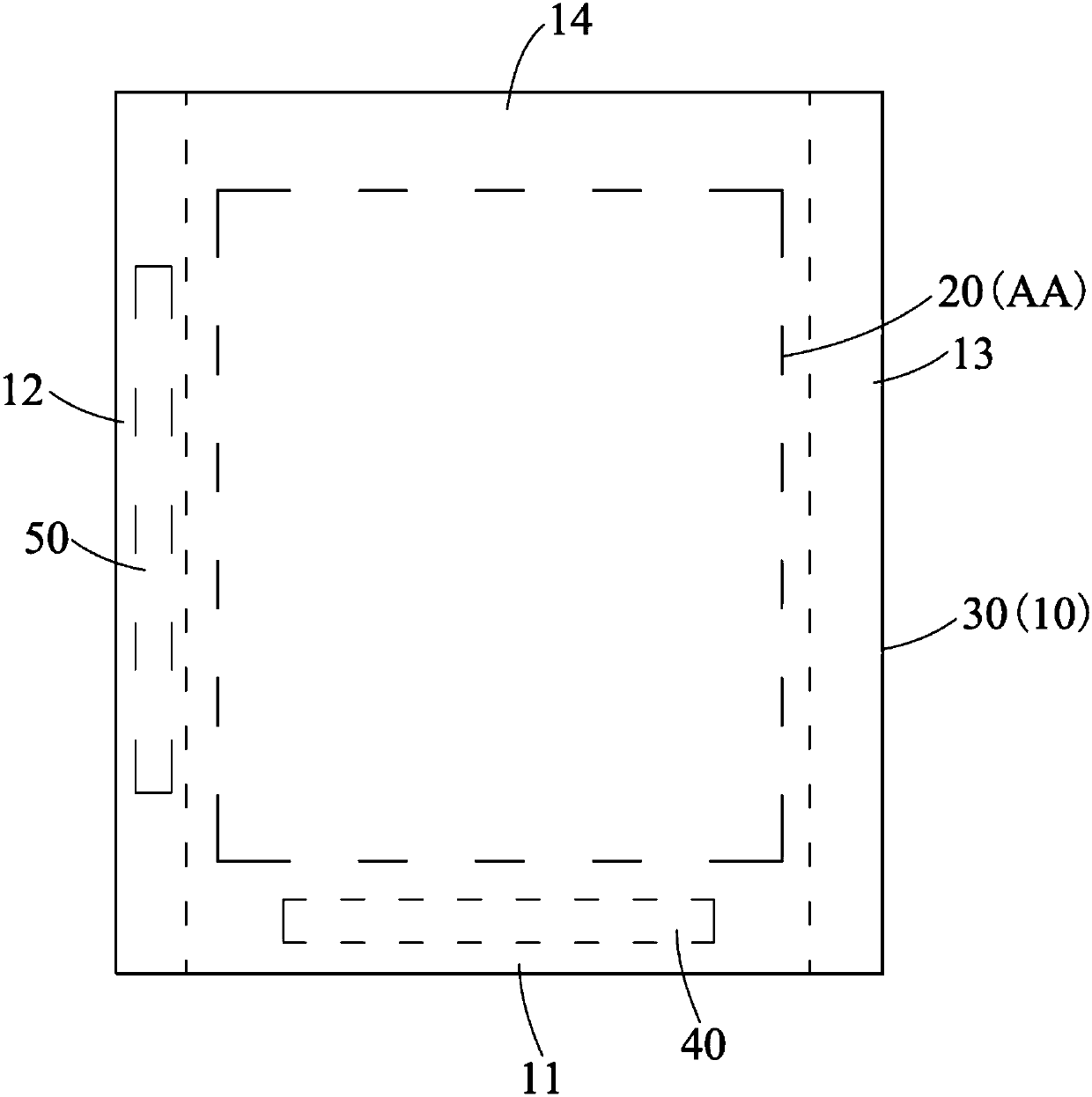

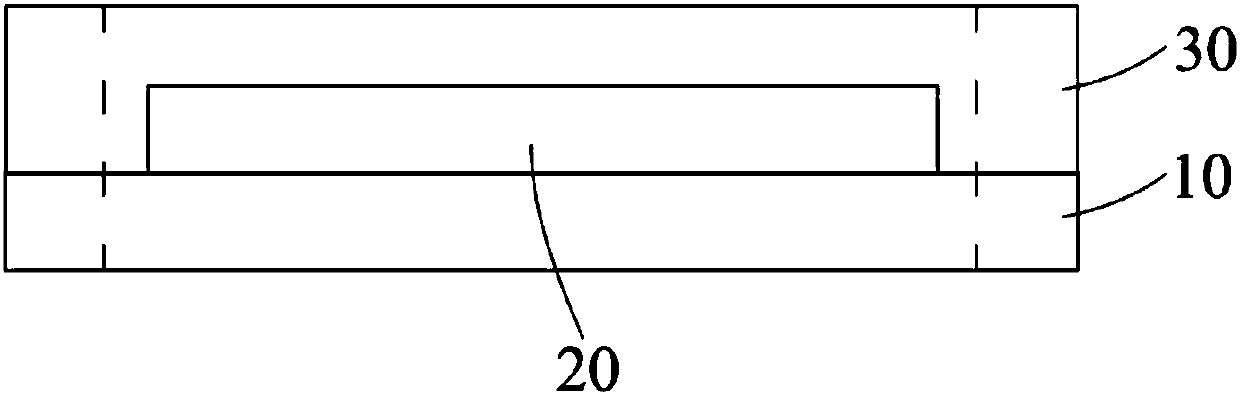

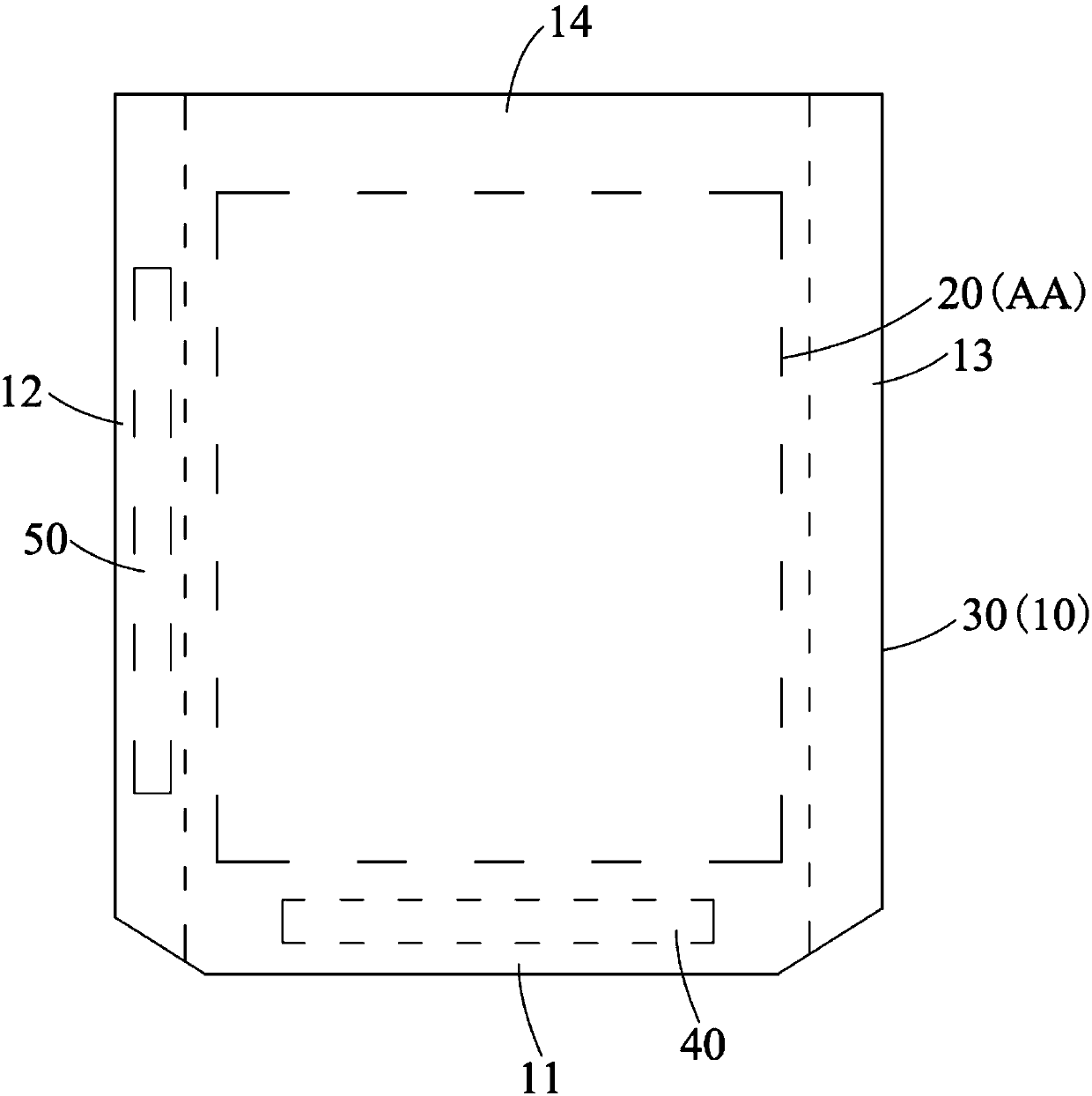

Flexible display device

InactiveCN107863452AImprove package strengthHigh intrusion performanceSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporDisplay device

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

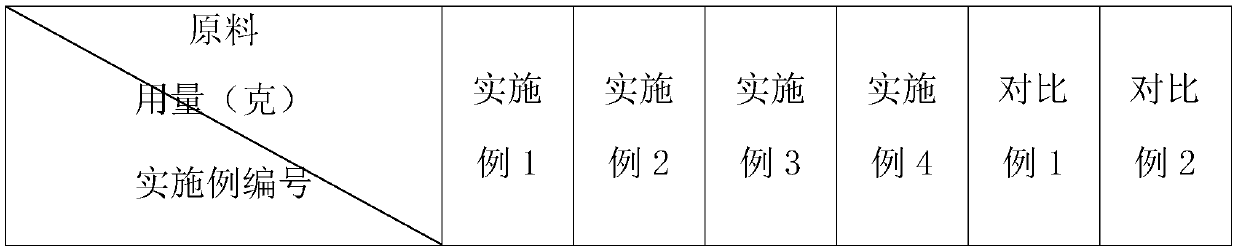

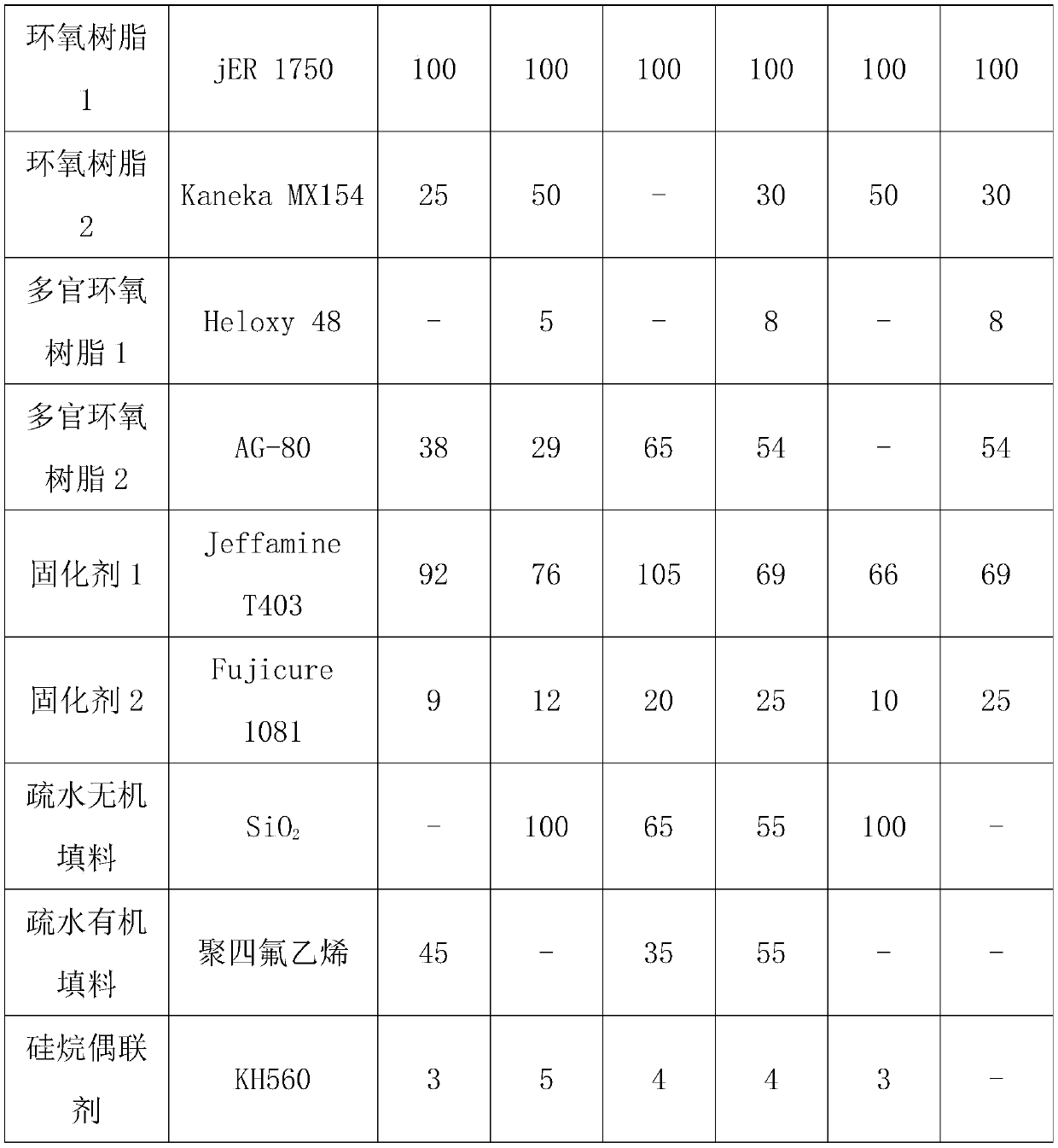

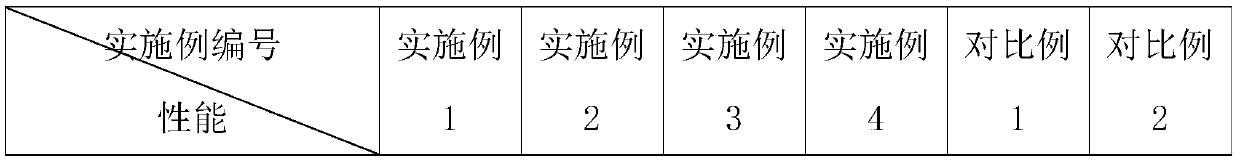

Single-component epoxy structure adhesive for waterproof sealing and preparation method thereof

InactiveCN110564347AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHigh humidity

Owner:上海汉司实业有限公司

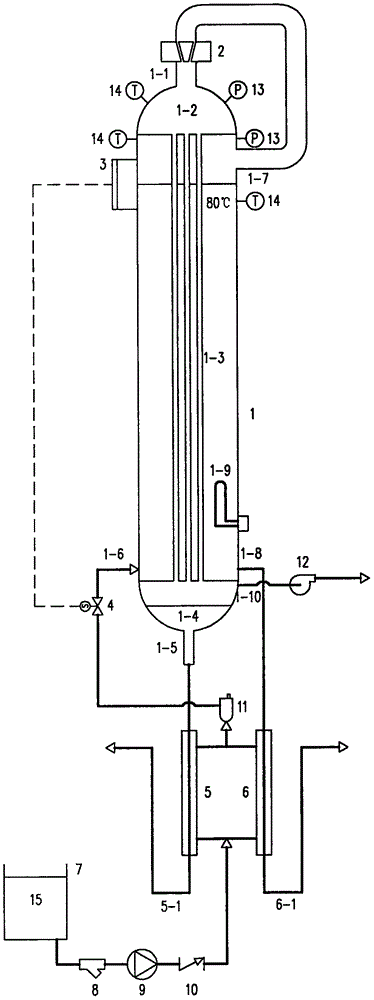

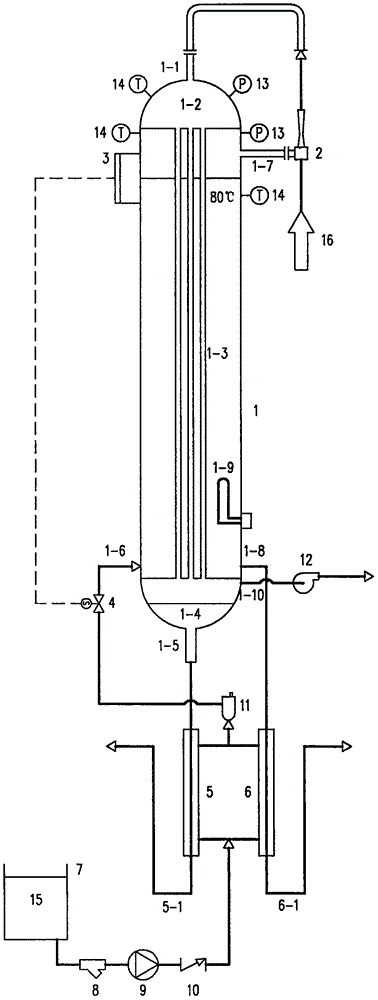

Technology of treating high-concentration organic wastewater with wet type catalytic oxidation

InactiveCN109455808AImprove processing efficiencyReduce energy consumptionWater/sewage treatment by oxidationHigh concentrationWater vapor

The invention discloses a technology of treating high-concentration organic wastewater with wet type catalytic oxidation. The technology comprises the following steps that the technology adopts COD concentration online detection and is automatically correlated to an oxygen concentration regulation device, organic wastewater with the COD content being 10000-50000 mg / L and the liquid space velocityof the wastewater being 0.5-2.5 h<-1> is mixed with enriched oxygen, the device automatically regulates the oxygen volume concentration to be 25-99 percent, water which is sent into a wastewater reactor charged with a catalyst for treatment is directly discharged or sent to a next treatment work section, and tail gas containing nitrogen, oxygen, carbon dioxide and water vapor is directly exhaustedto atmosphere, wherein the space velocity of the enriched oxygen is 34-39 times the liquid space velocity of the wastewater, and the oxygen supply quantity is 1.1-1.2 times the theoretical oxygen demand. The technology disclosed by the invention has the advantages that high-concentration COD in acid or alkaline organic wastewater can be effectively removed.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Vegetable noodle production process and microwave drying device thereof

InactiveCN109751838AIncreased versatilityMeet drying needsDrying solid materials with heatDrying chambers/containersMicrowaveWater vapor

Owner:ANHUI QINGSONG FOOD

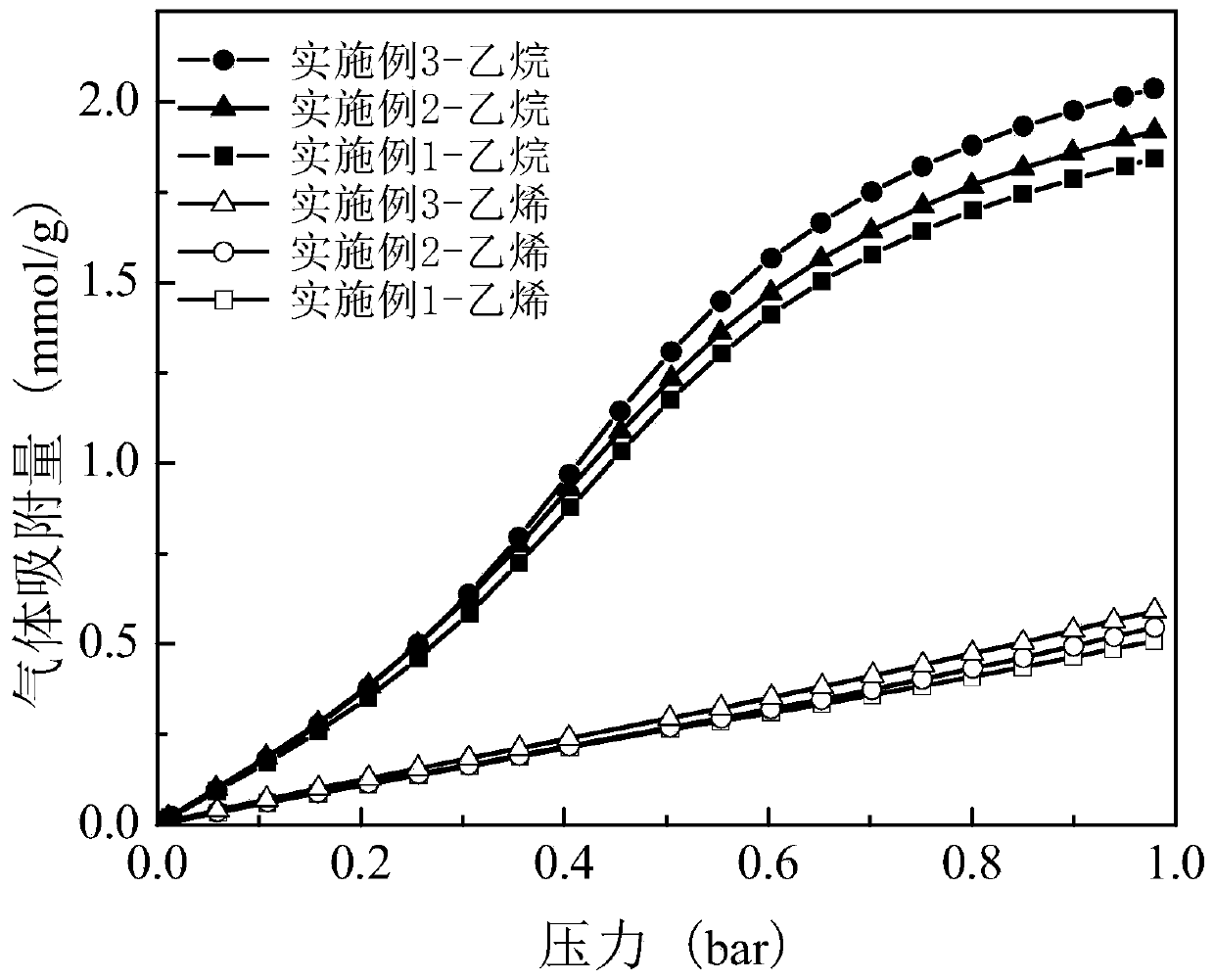

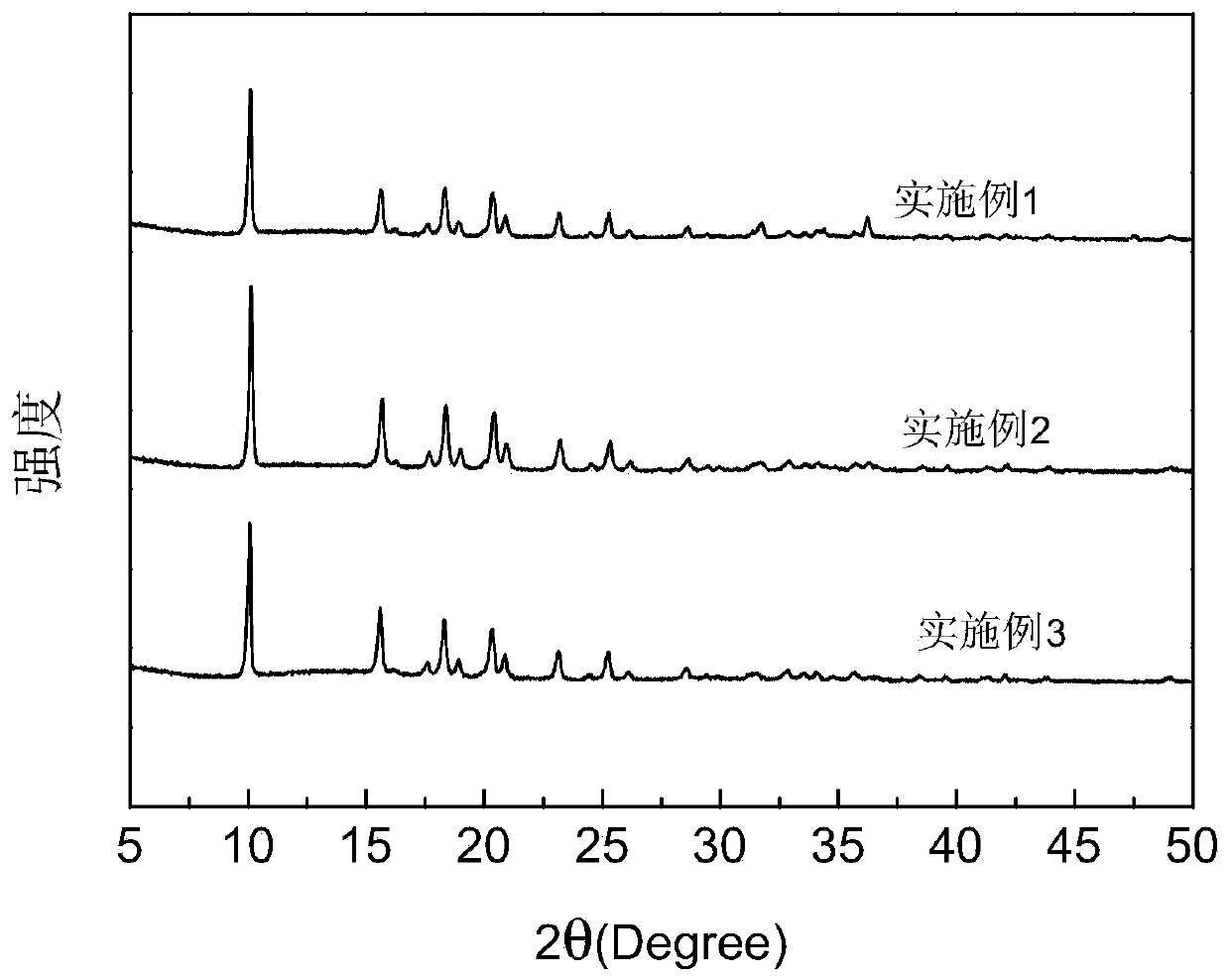

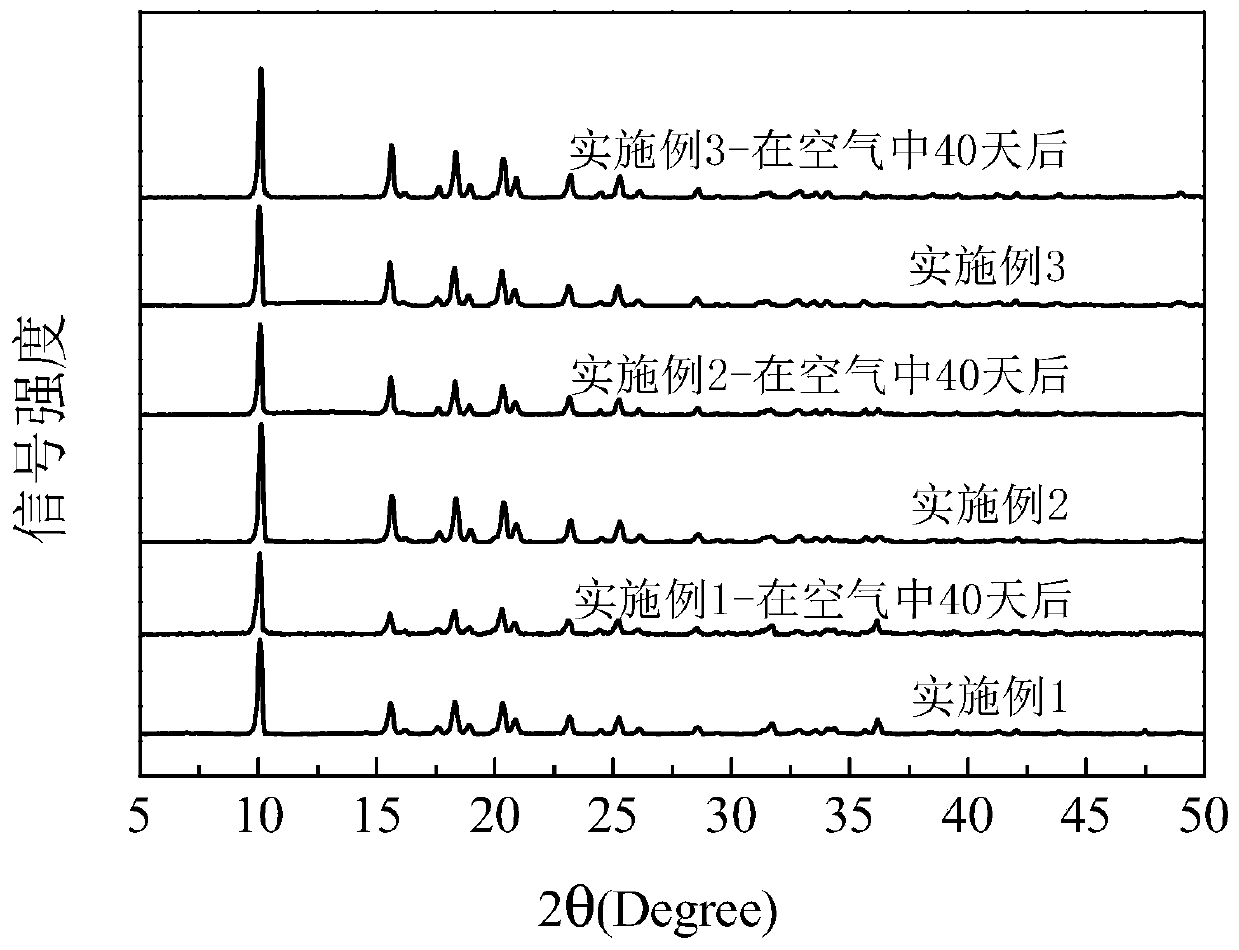

Room-temperature preparation method of metal-organic framework material preferentially adsorbing ethane

PendingCN110075805AGood alkane selectivityGood adsorption and separation performanceGas treatmentOther chemical processesAlkaneN dimethylformamide

Owner:SOUTH CHINA UNIV OF TECH

Two-section system and method for coproducing coal-based graphite and carbon nano-tubes

Owner:HUAZHONG UNIV OF SCI & TECH

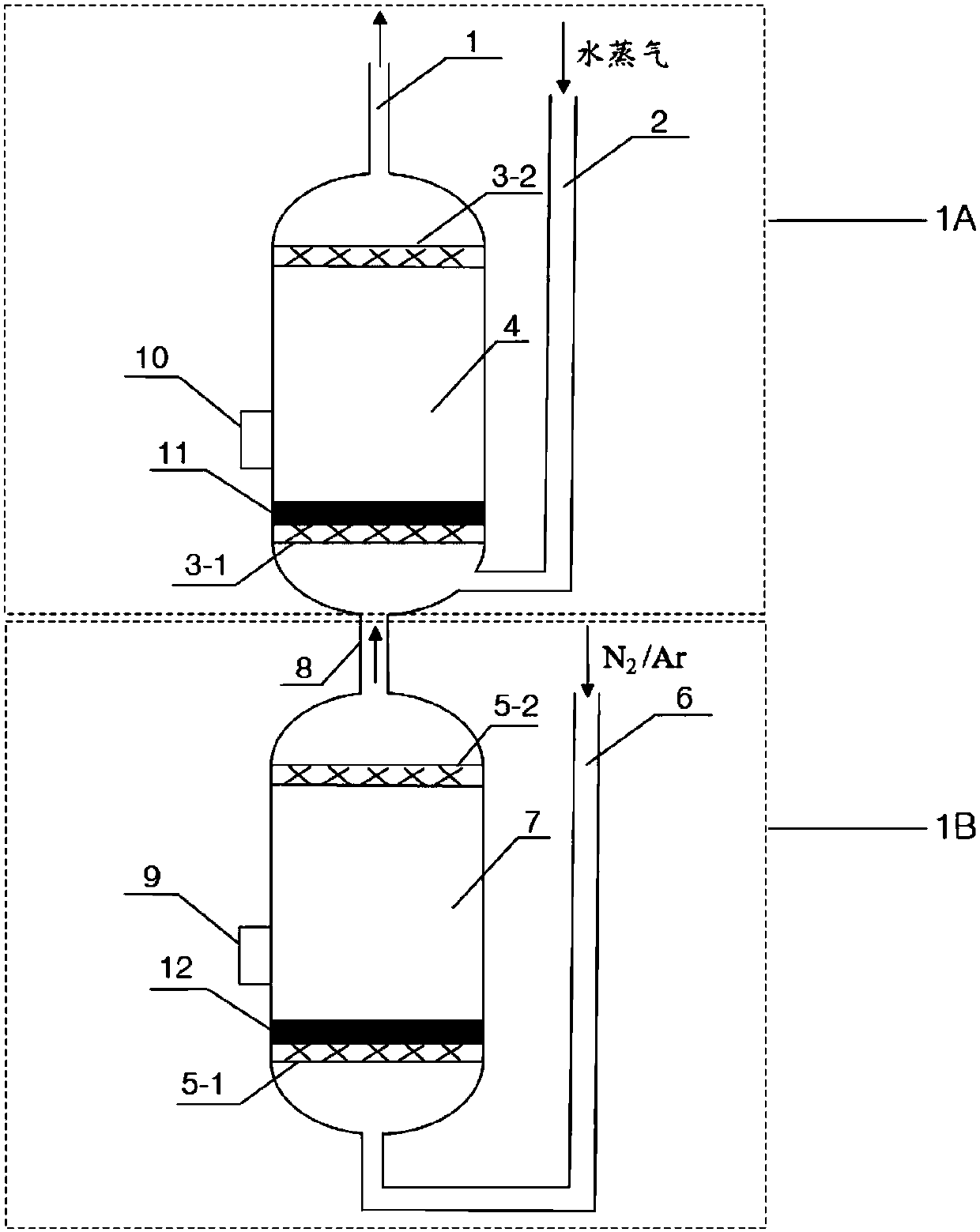

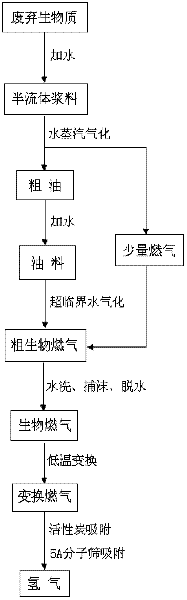

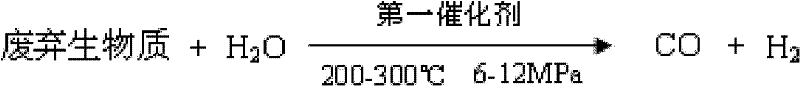

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

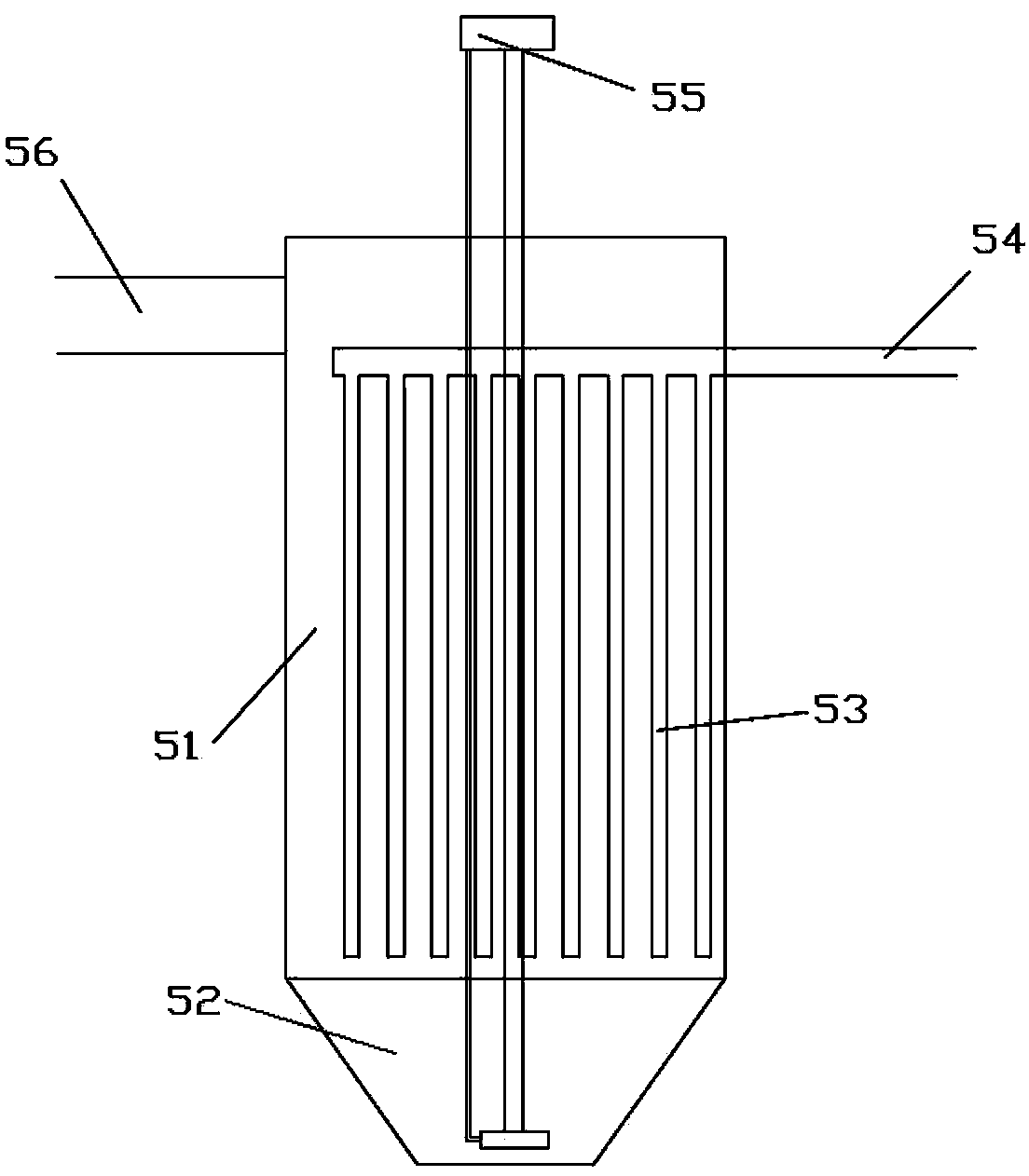

Siphon circulation, contraflow heat regeneration and vapor compression distillation device

InactiveCN105920863ASave investmentSave power consumptionEvaporation with vapour compressionSeawater treatmentSiphonWater vapor

Owner:侴乔力 +1

Process for modifying FCC gasoline distillation and co-producing low-carbon olefine and catalyst thereof

InactiveCN1844323AGood transitivityGood reaction selectivityOrganic chemistryNaphtha reformingLiquid productMolecular sieve

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

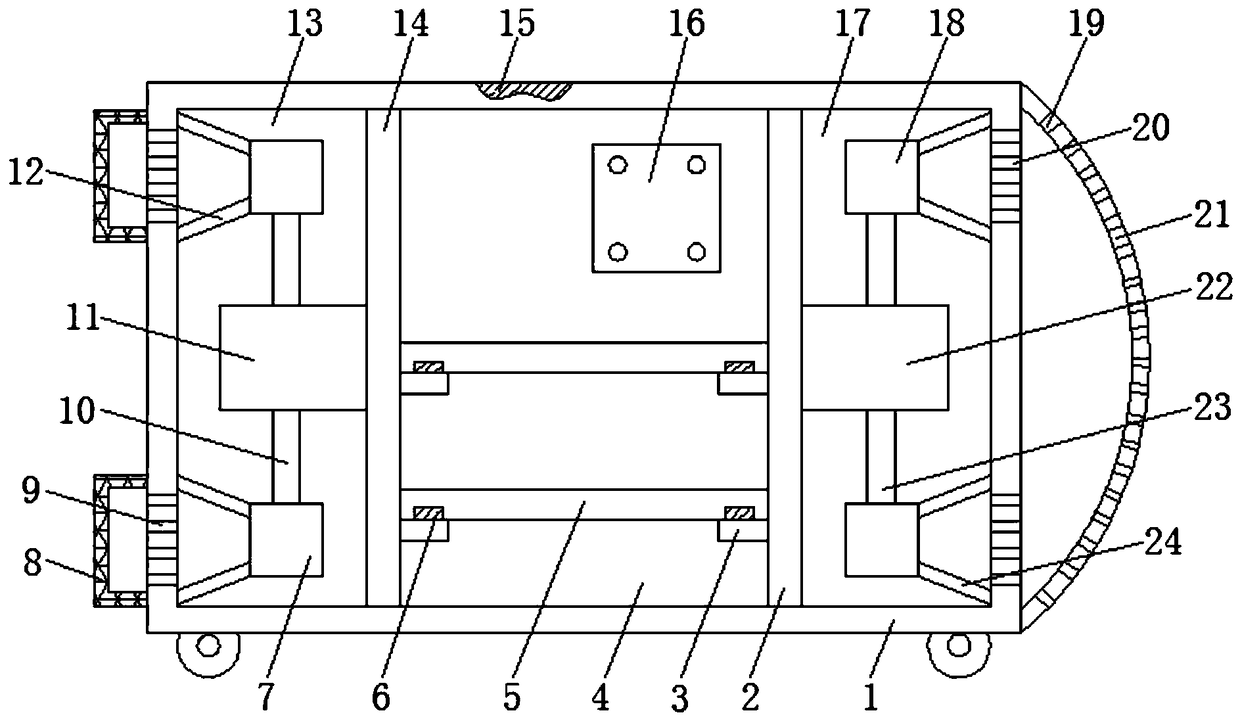

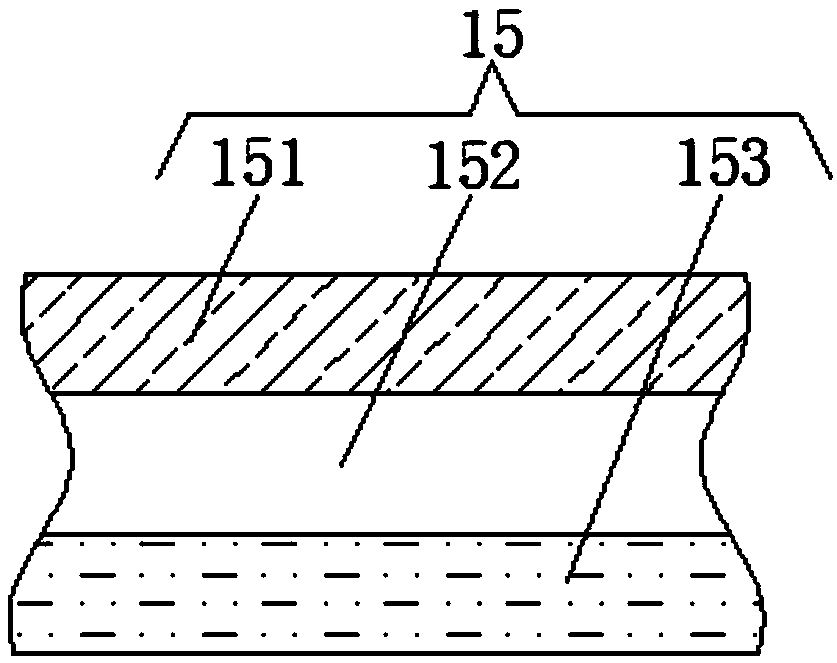

Microwave curing process used for electrode plate of lead-acid storage battery

ActiveCN107887577AImprove heating uniformityEasy to operateFinal product manufactureLead-acid accumulator electrodesWater vaporEngineering

Owner:HENAN CHAOWEI POWER SUPPLY

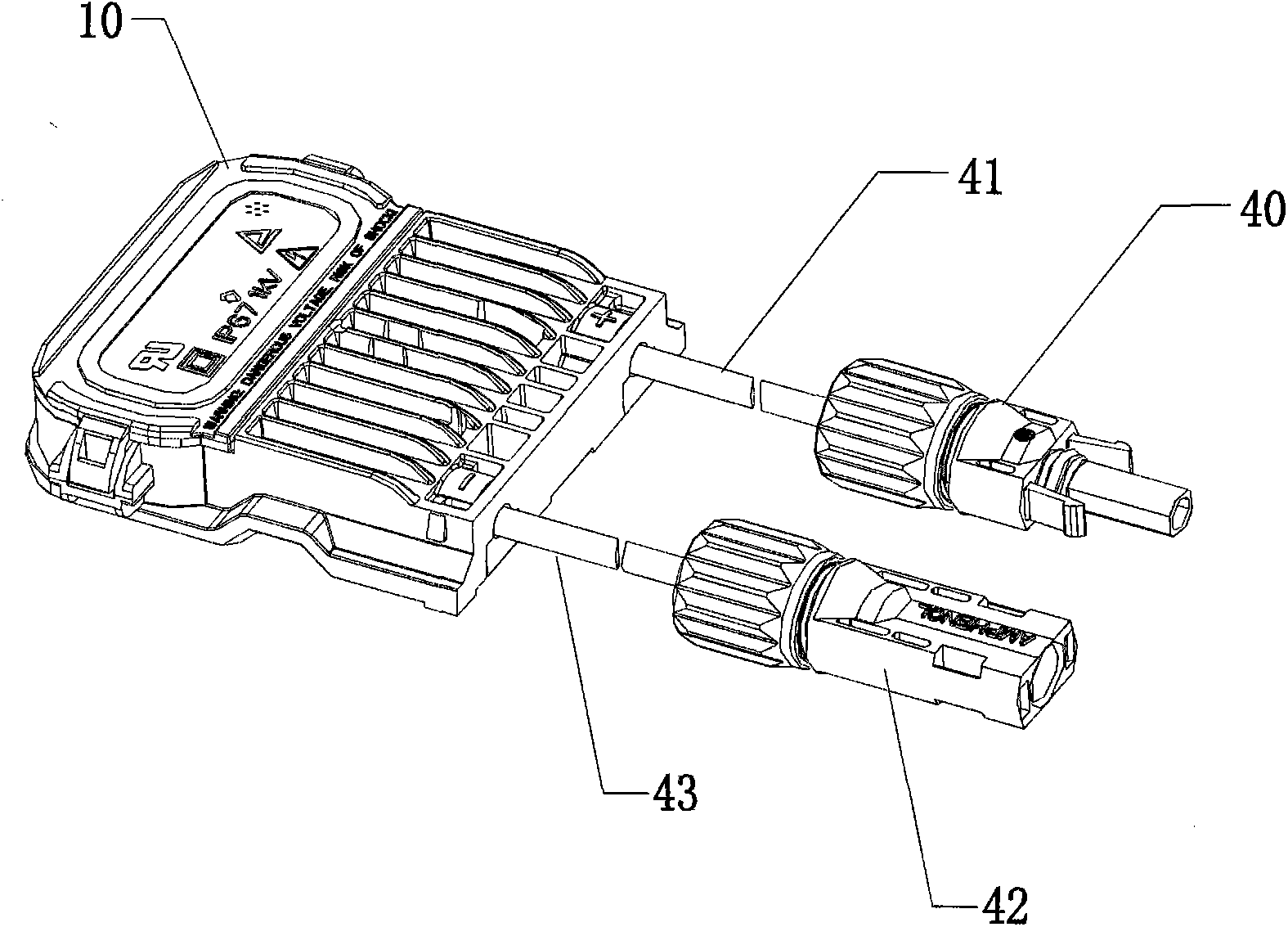

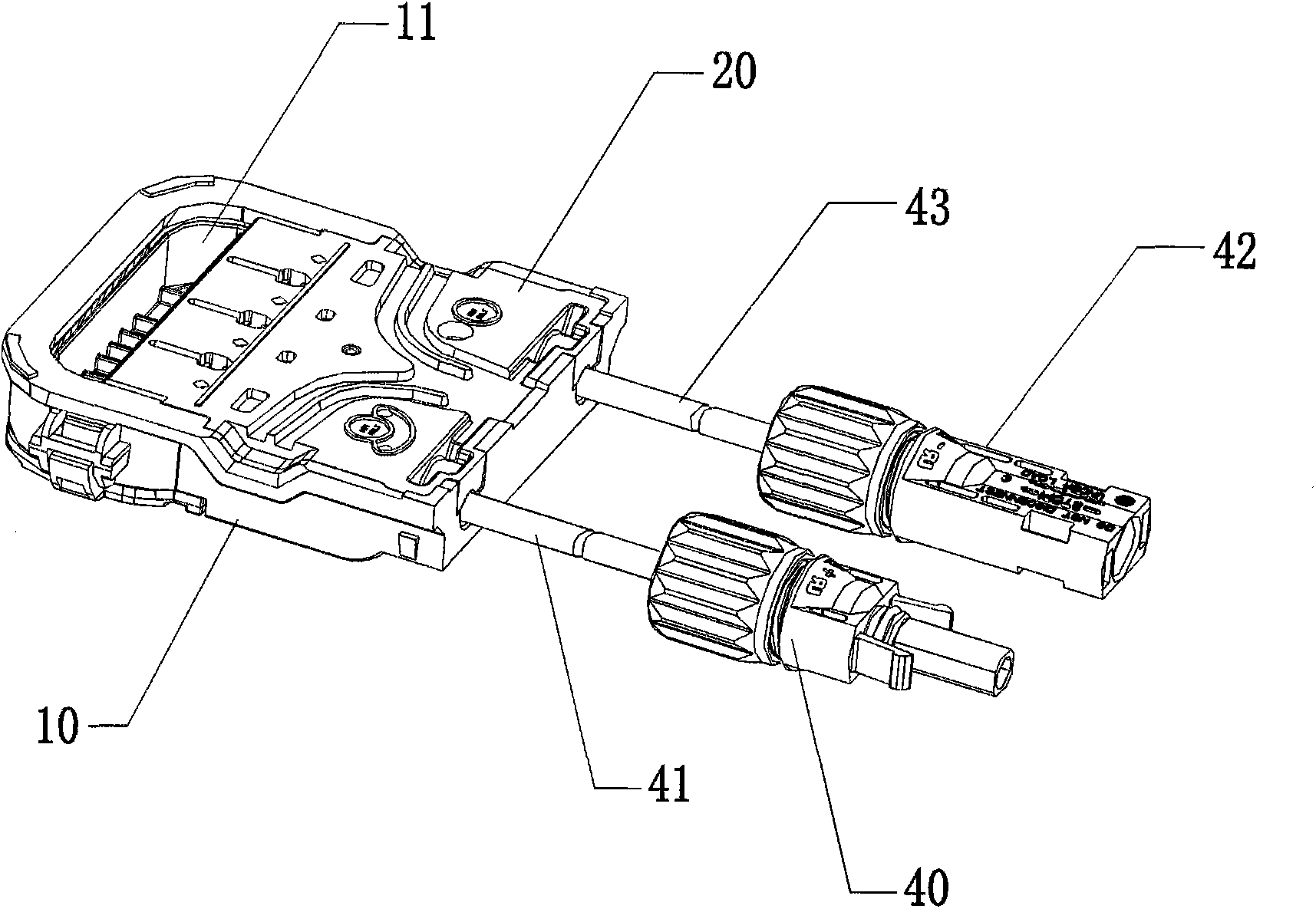

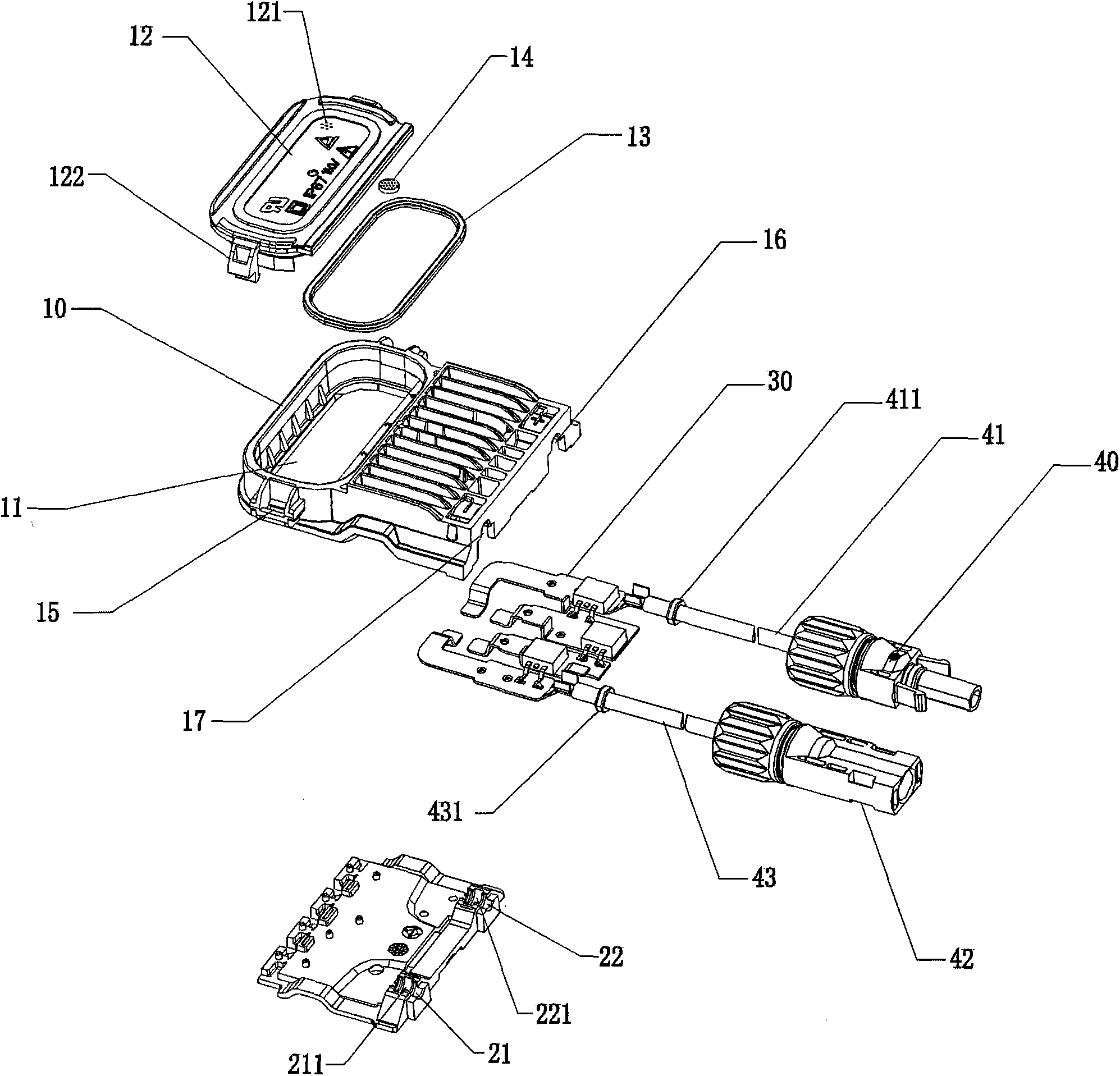

Waterproof and ventilating structure of solar junction box

InactiveCN103413853ANot prone to performance degradation issuesAvoid enteringClimate change adaptationPhotovoltaic energy generationEnvironment effectWater vapor

Owner:AMPHENOL TECH (SHENZHEN) LTD CO LTD

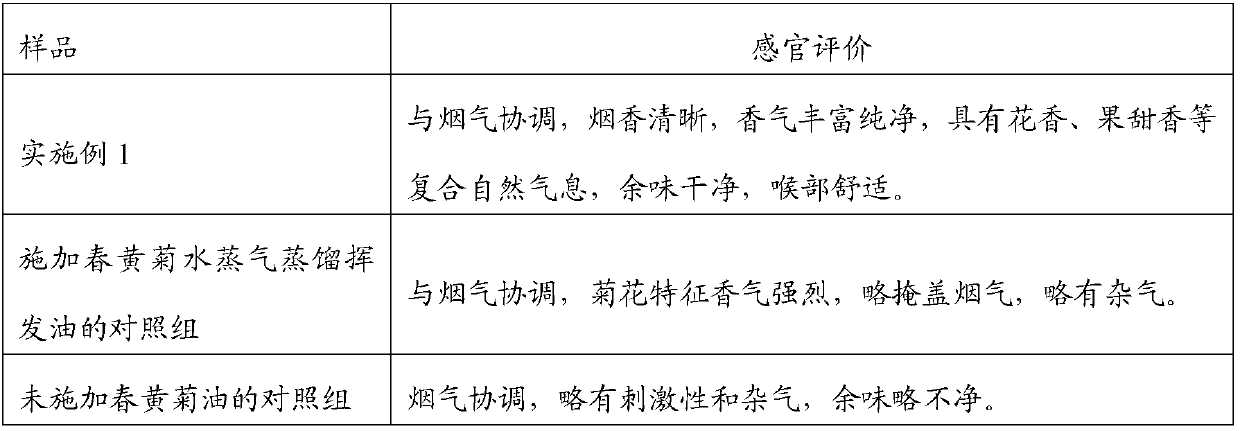

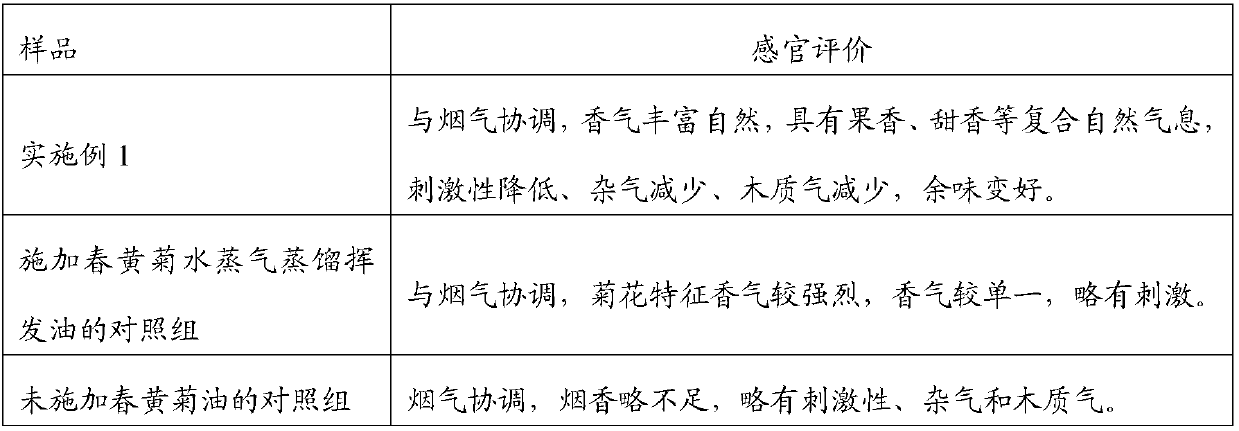

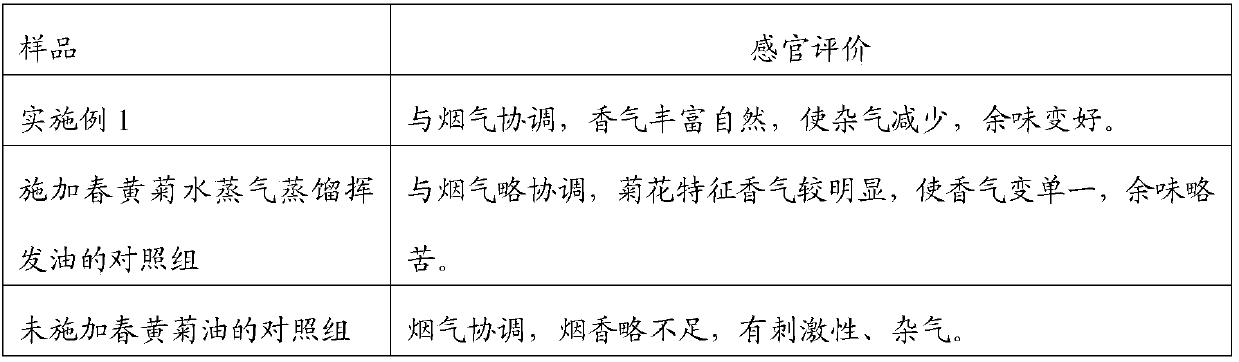

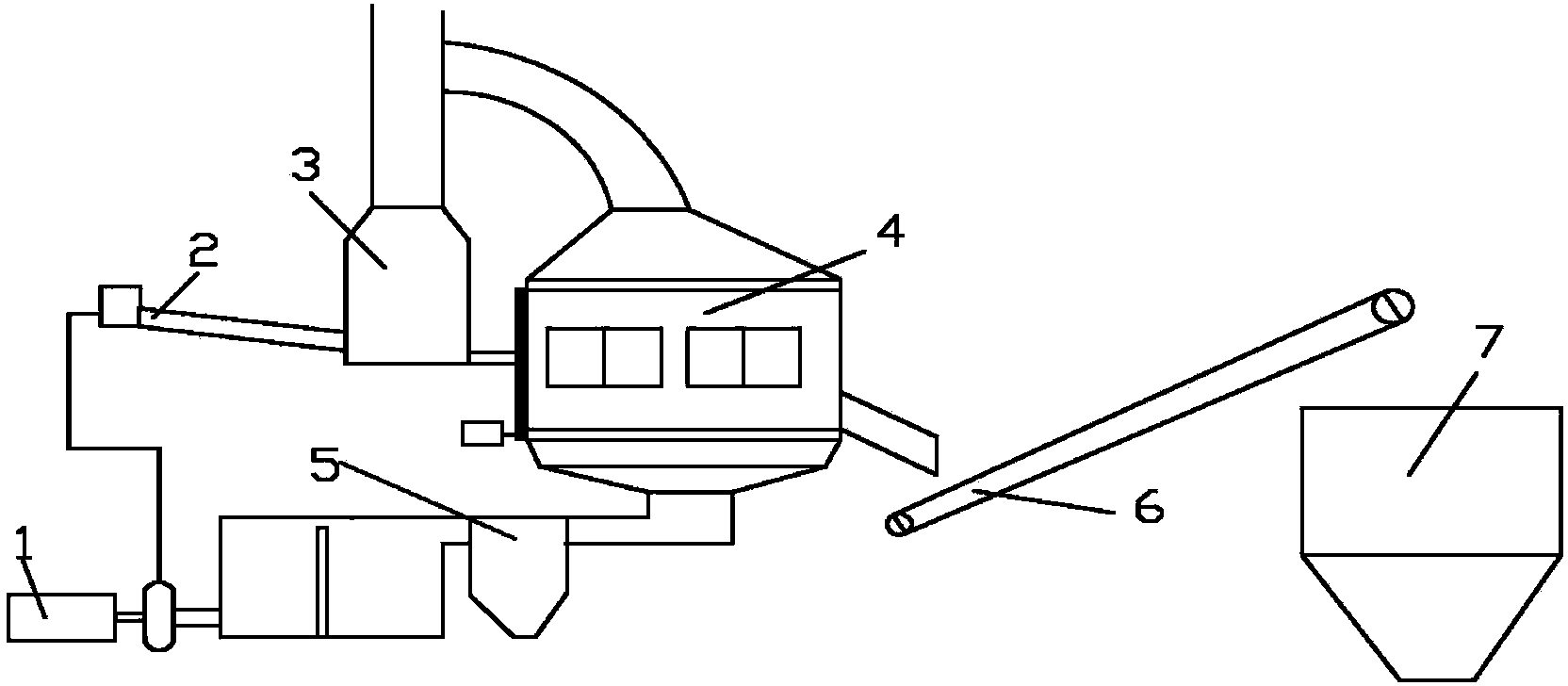

Method for improving euryops pectinatus oil aroma quality and application thereof

InactiveCN107699352ALarge fermentation hydrolysis degreeImprove extraction efficiencyTobacco preparationEssential-oils/perfumesWater vaporIrritation

Owner:HUBEI CHINA TOBACCO IND

Processing method of high-oryzanol rice bran oil

InactiveCN107474942ASpeed up extractionImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionWater vaporRice Bran Extract

Owner:衢州刘家香食品有限公司

Method and device for water quenching of yellow phosphorus furnace slag

Owner:HUBEI XINGFA CHEM GRP CO LTD

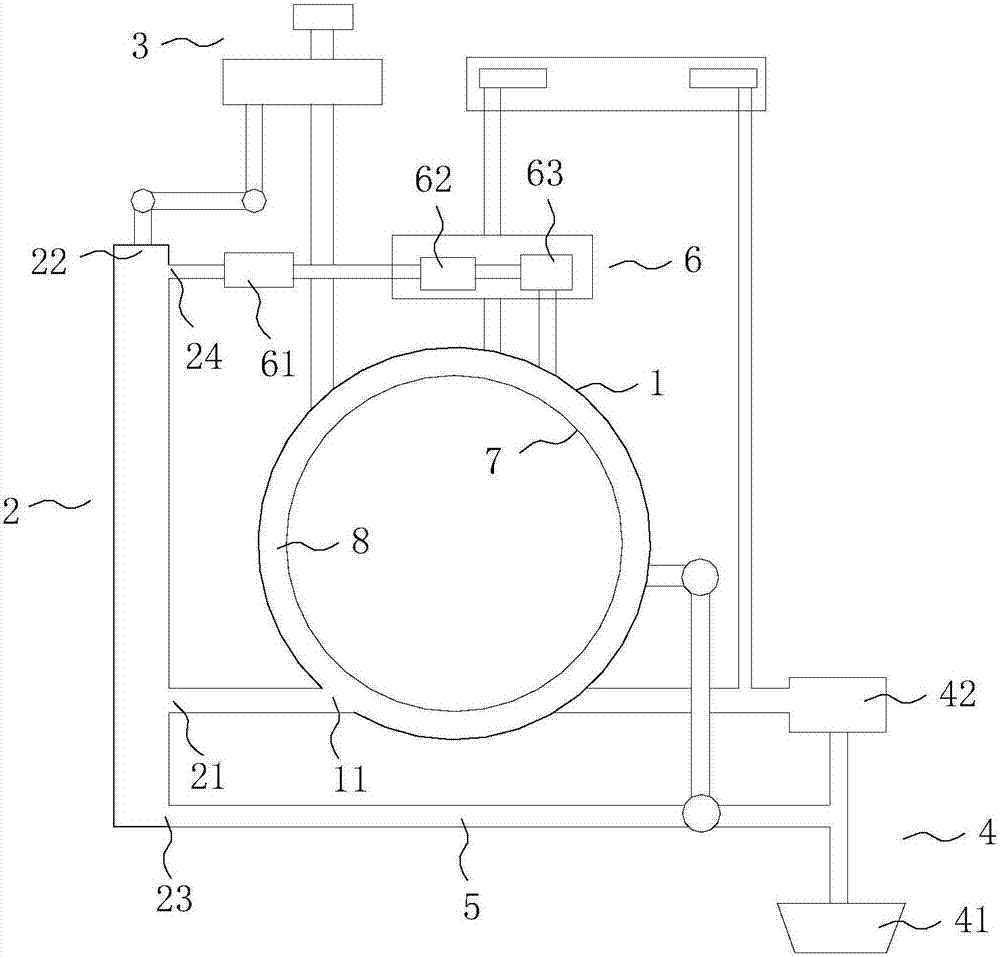

Washing and drying all-in-one machine

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Extraction process of plant mildew-proof preservative

InactiveCN1672536AInfectiousEnhanced inhibitory effectFruit and vegetables preservationSodium bicarbonateWater vapor

Owner:CROPS BREEDING CULTIVATING INST SHANGHAI AGRI SCI ACAD

Method for recycling waste gas generated by combusting water or water vapor and hydrogen

InactiveCN101691850AReduce electricity costsReduce manufacturing costNon-fuel substance addition to fuelInternal combustion piston enginesElectricityHydrogen

Owner:JIANGYIN SHANGFENG NEW ENERGY TECH DEV

A computer host box with a good moisture-proof function

Owner:SUZHOU ANTEK INDAL

Online wet and hot water vapor recovery device for electroplating treatment

InactiveCN113398714AReduce heating energy consumptionCapture implementationCellsGas treatmentWater vaporEnvironmental engineering

Owner:中航长沙设计研究院有限公司

Infrared sensor

InactiveCN104614079AWide operating temperature rangePyrometry using electric radation detectorsCapacitanceEnvironment effect

The invention provides an infrared sensor. The sensitive materials have humidity sensitive property and temperature sensitive characteristic, namely, the concentration of water vapor is high and the capacitance value is large under a fixed temperature condition; the temperature is high and the capacitance value is low under a fixed water vapor concentration condition; a hollow cavity is full of water vapor of which the concentration is more than a jumping threshold; when the concentration of the water vapor is more than the jumping threshold, the variation rate of the temperature sensitive characteristic curve of the sensor prepared from the sensitive materials is more than 0.01pF / mk; the temperature sensitive characteristic curve is a curve that the capacitance value varies as temperature caries under the fixed water vapor concentration condition. According to the infrared sensor, the sensitive materials with the humidity sensitive property and temperature sensitive characteristic is fully exposed in the environment with a certain of water vapor concentration; when the sensitive materials suffer from infrared radiation, the surface temperature raises, and the capacitance value is accordingly changed, on that principle, the infrared radiation can be detected; the operation is convenient and reliable; the environmental influence is minimized, and the applicable working temperature scope is wide.

Owner:SOUTHEAST UNIV

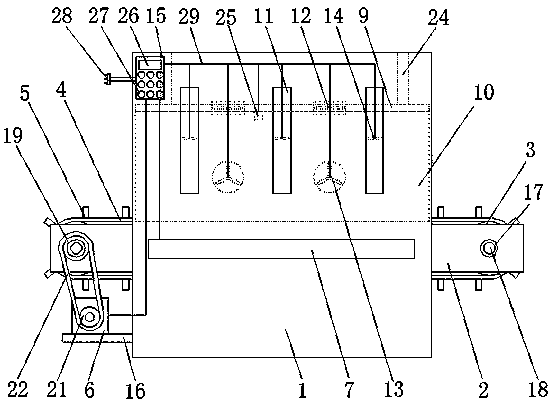

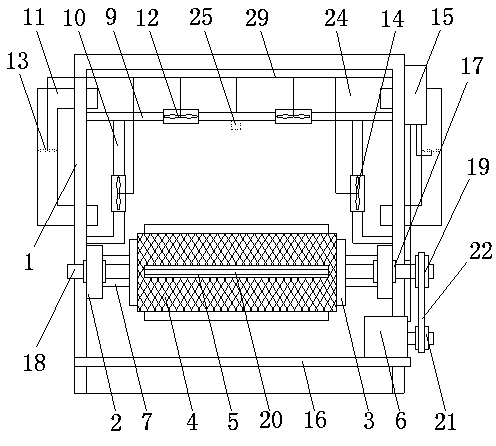

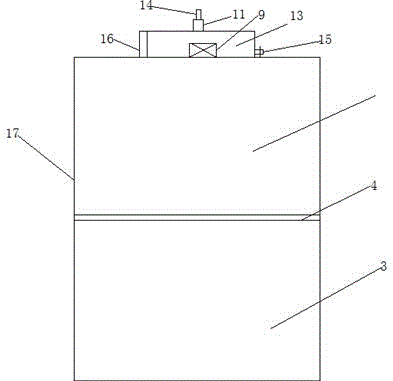

Heat cycle type wood plank drying device suitable for furniture processing

InactiveCN108518958AReduce wasteImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsWater vaporFixed frame

Owner:萧县智鑫知识产权运营有限公司

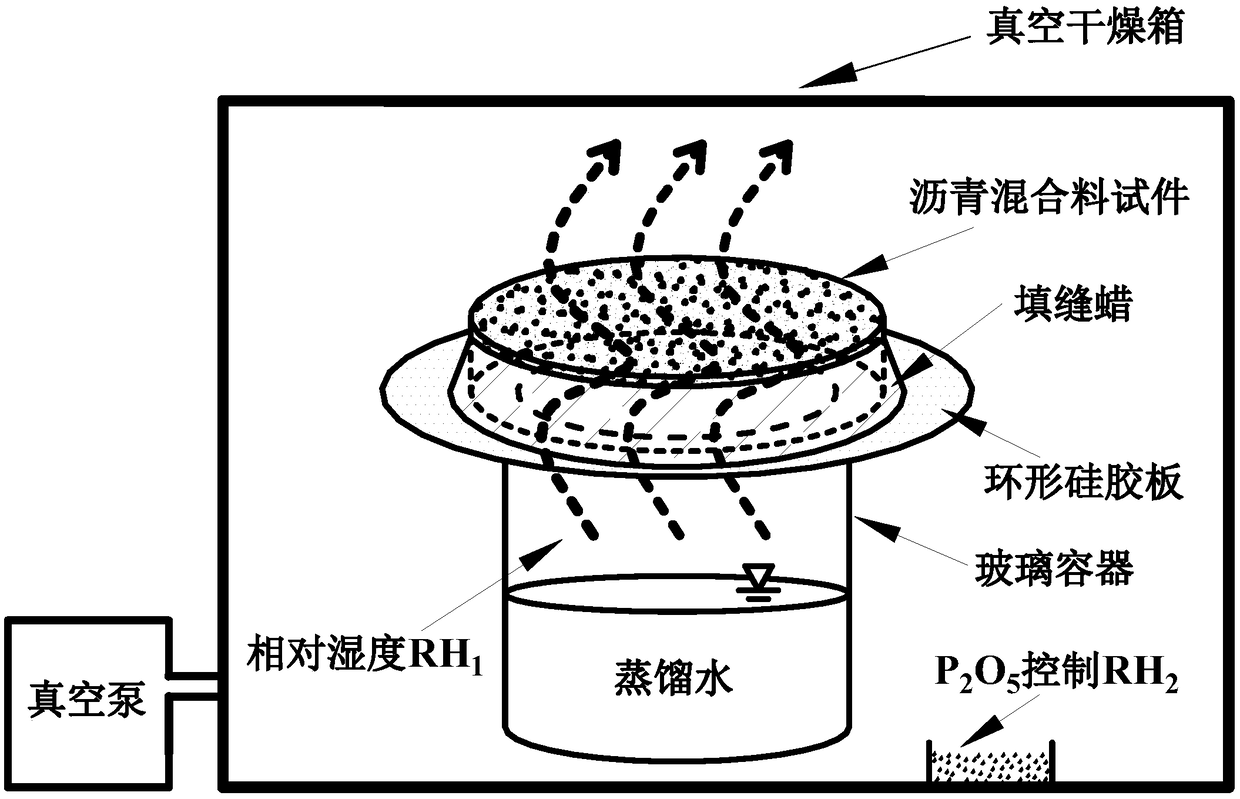

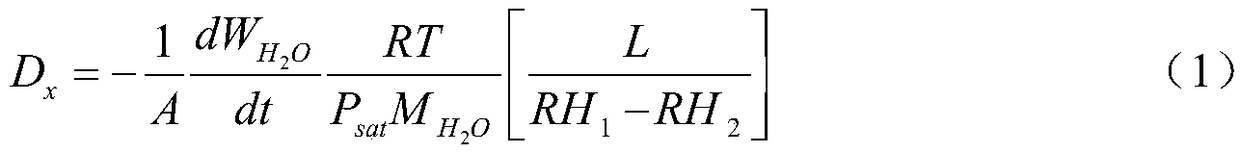

A method for detecting the penetration type water vapor diffusion coefficient of a large-thickness low-porosity asphalt mixture

ActiveCN108776084ARealize humidity gradient driveIncrease humiditySurface/boundary effectPorosityWater vapor

Owner:WUHAN UNIV OF TECH

Spinning gauze lossless drying equipment

InactiveCN106766791AAcceptance balanceAvoid lossDrying gas arrangementsDrying machines with progressive movementsInternal pressureWater vapor

Owner:响水县嘉禾纺织制衣有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap