Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Catalytic oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic oxidation are processes that oxidize compounds using catalysts. Common applications involve oxidation of organic compounds by the oxygen in air. Such processes are conducted on a large scale for the remediation of pollutants, production of valuable chemicals, and the production of energy.

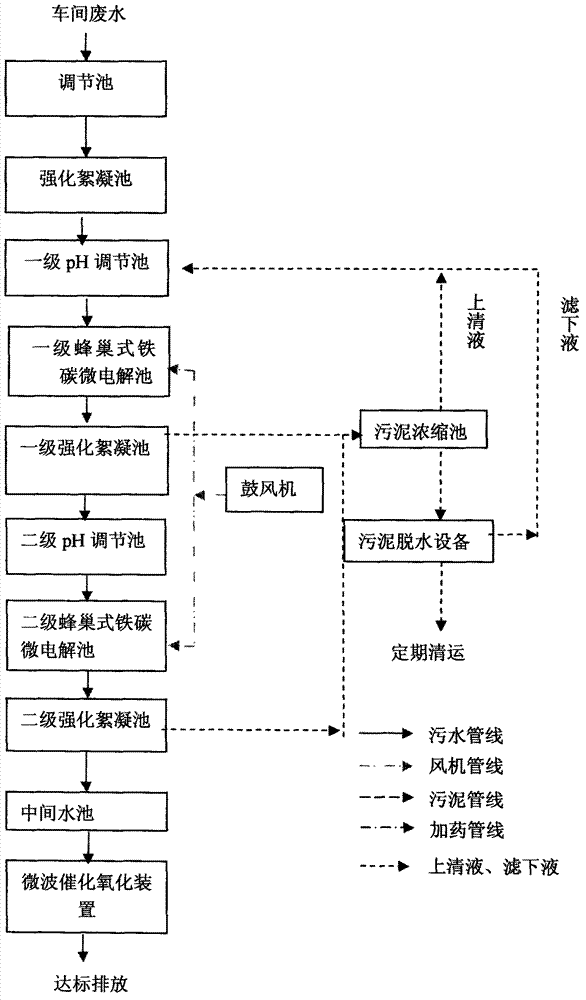

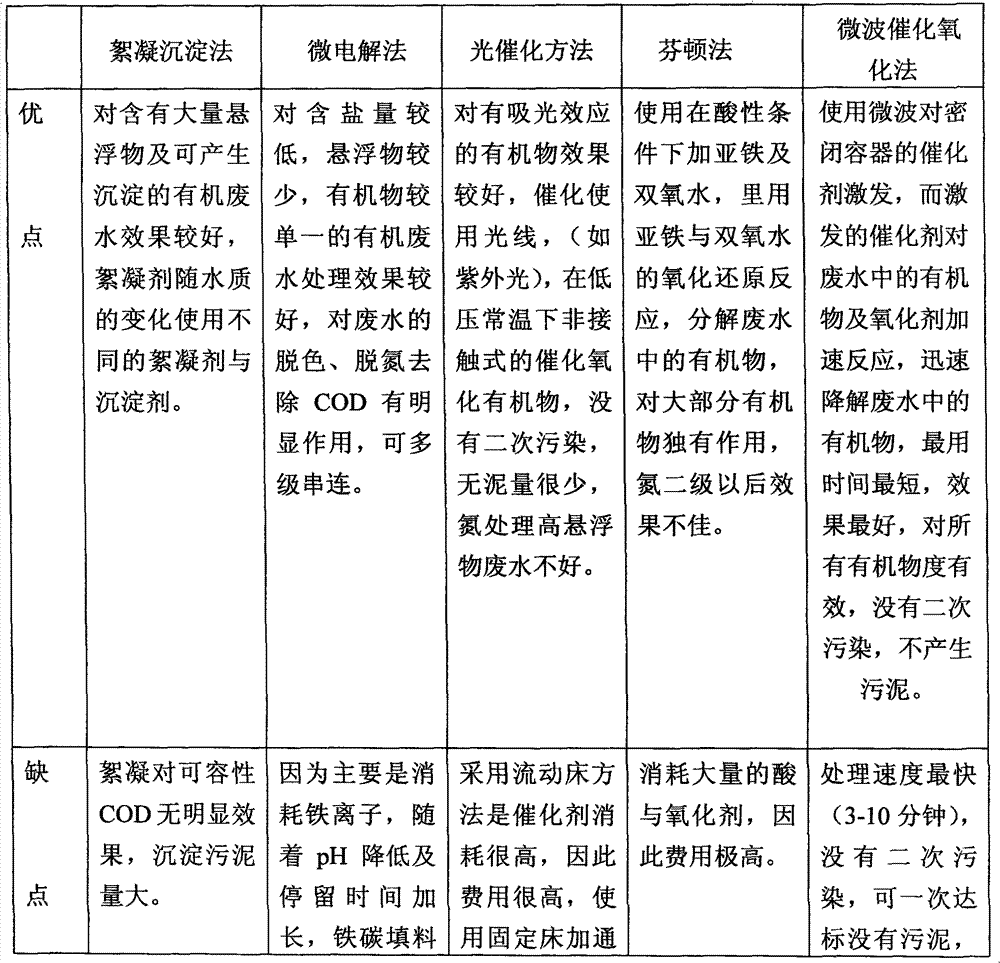

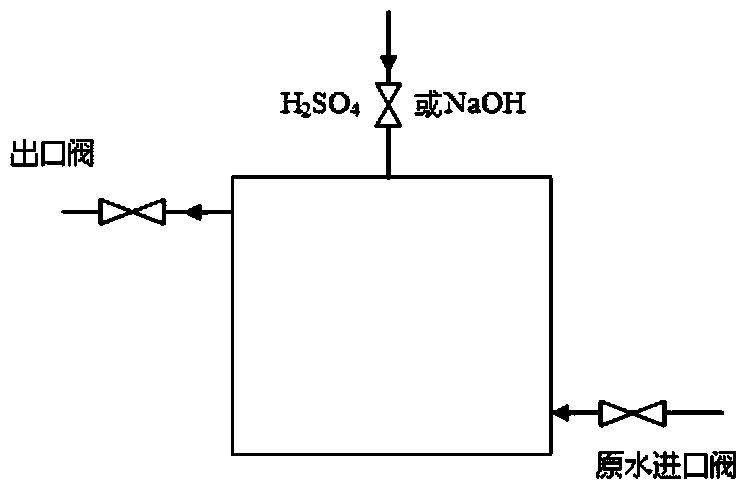

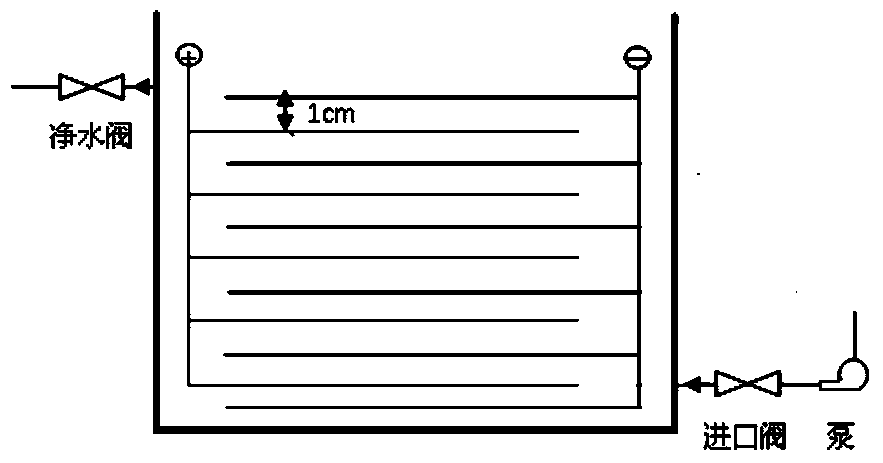

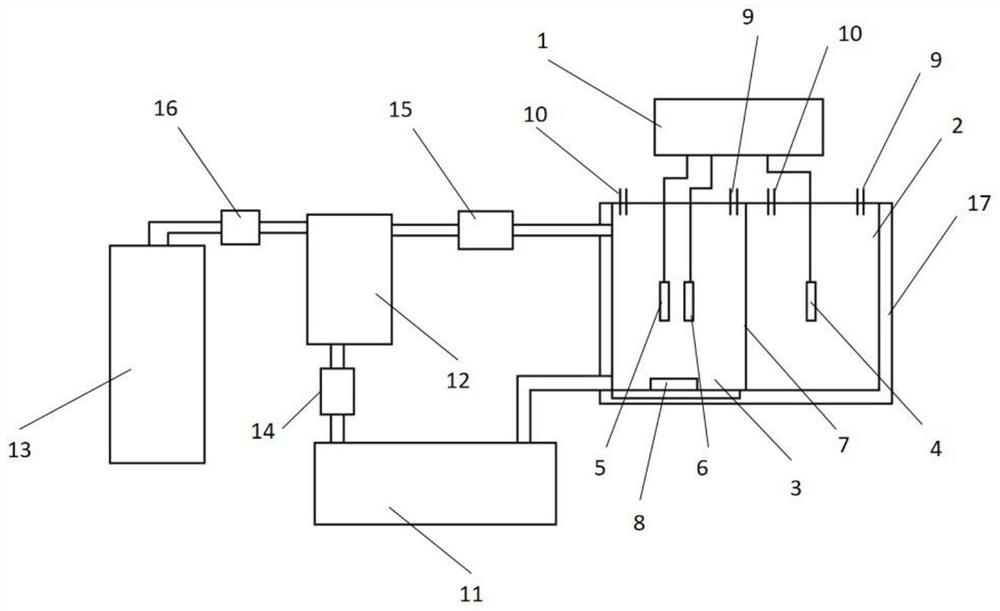

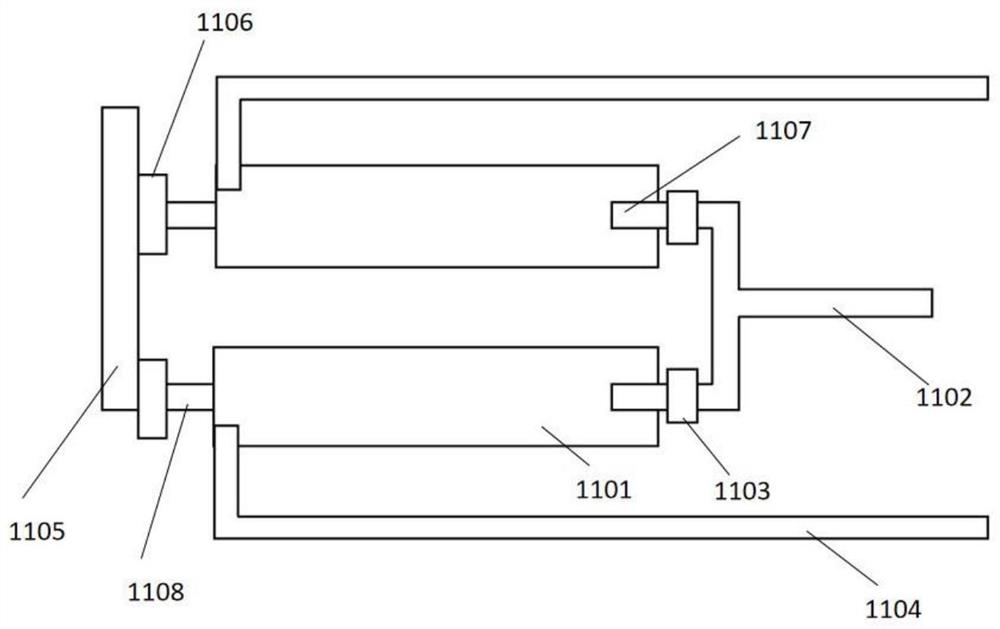

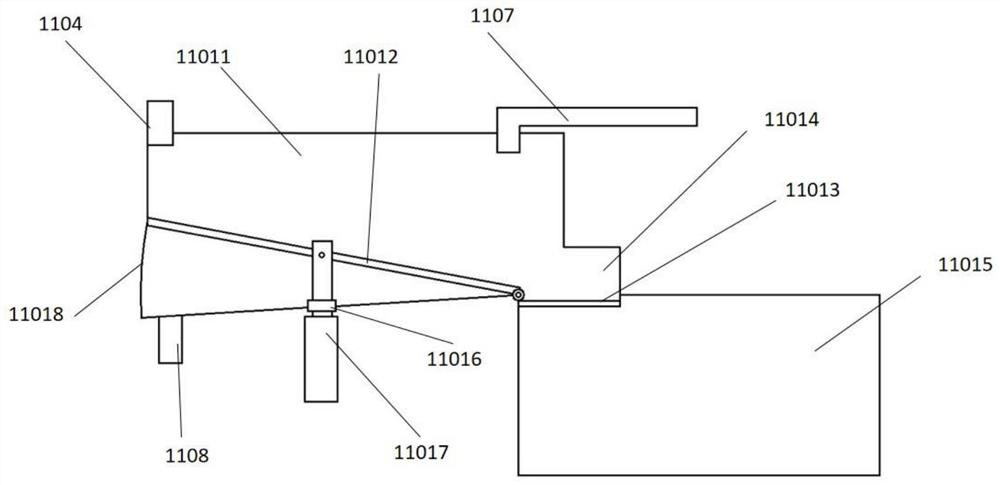

Method and system for modularized combined treatment of high-difficulty organic waste water

ActiveCN102826697AImprove applicabilityEasy to handleWater contaminantsMultistage water/sewage treatmentTreatment effectSludge

Owner:山东泰山行星环保科技有限公司

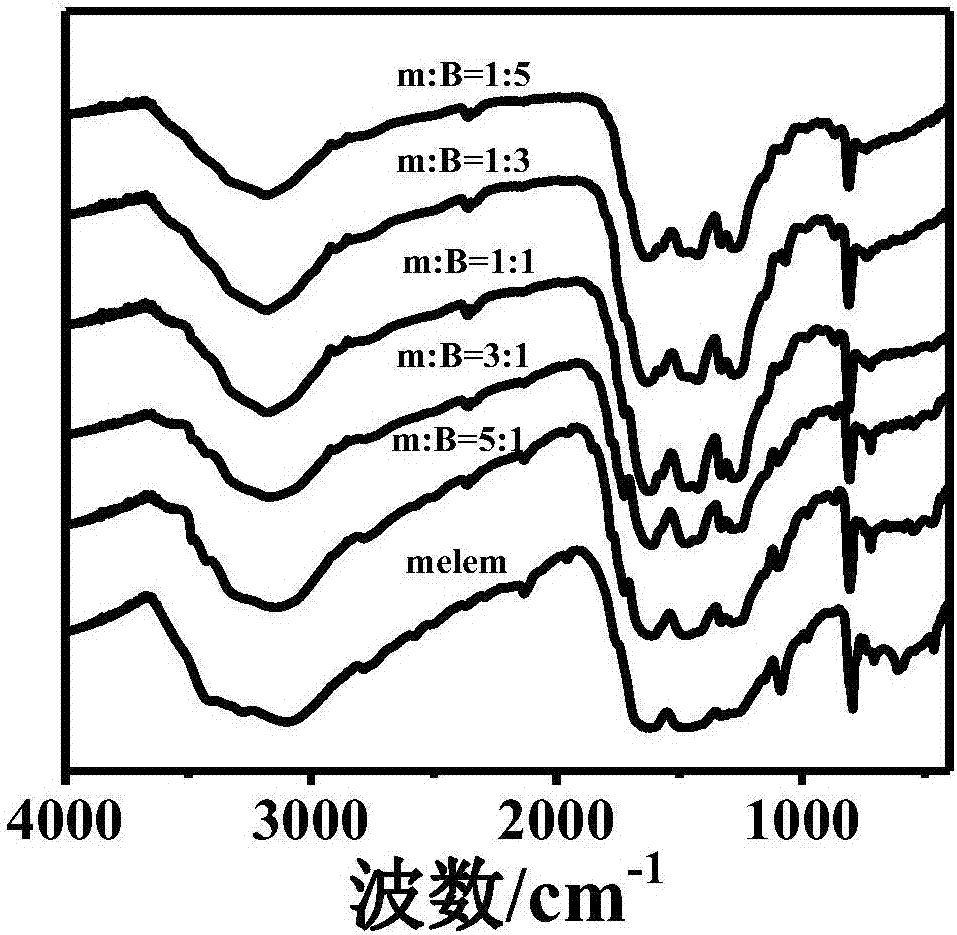

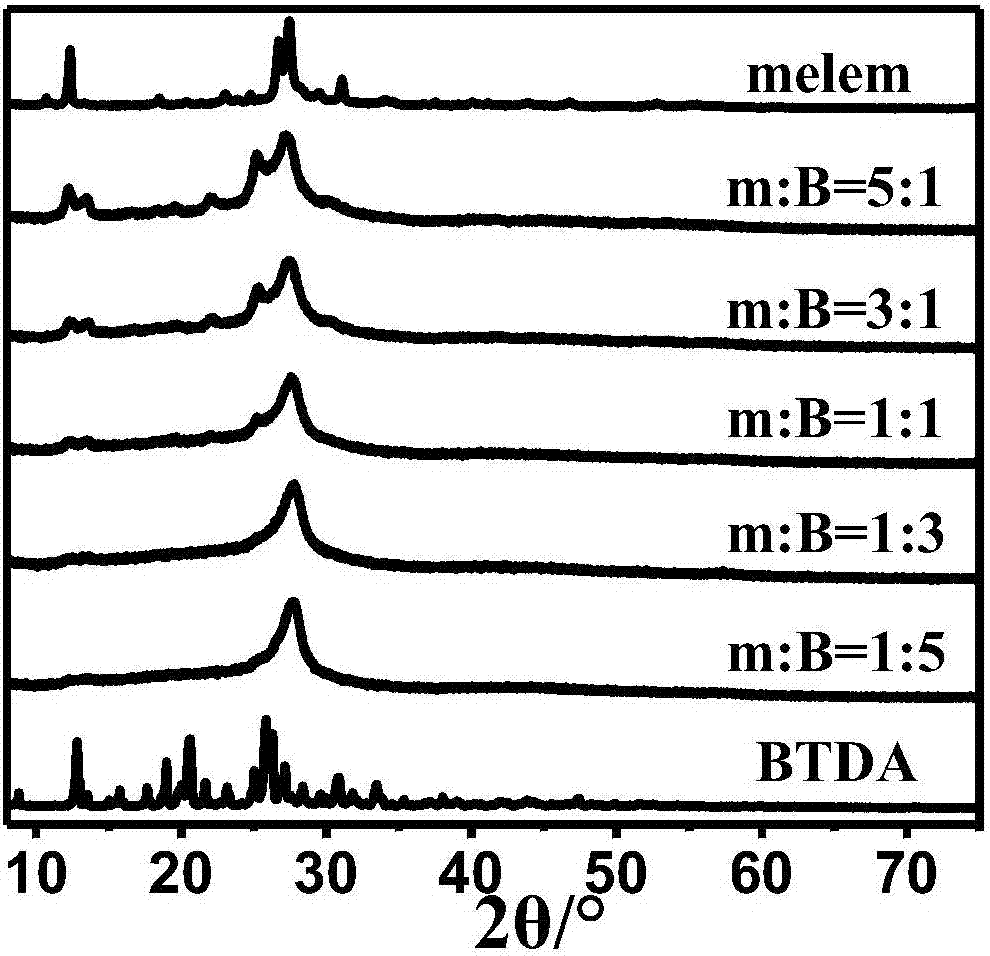

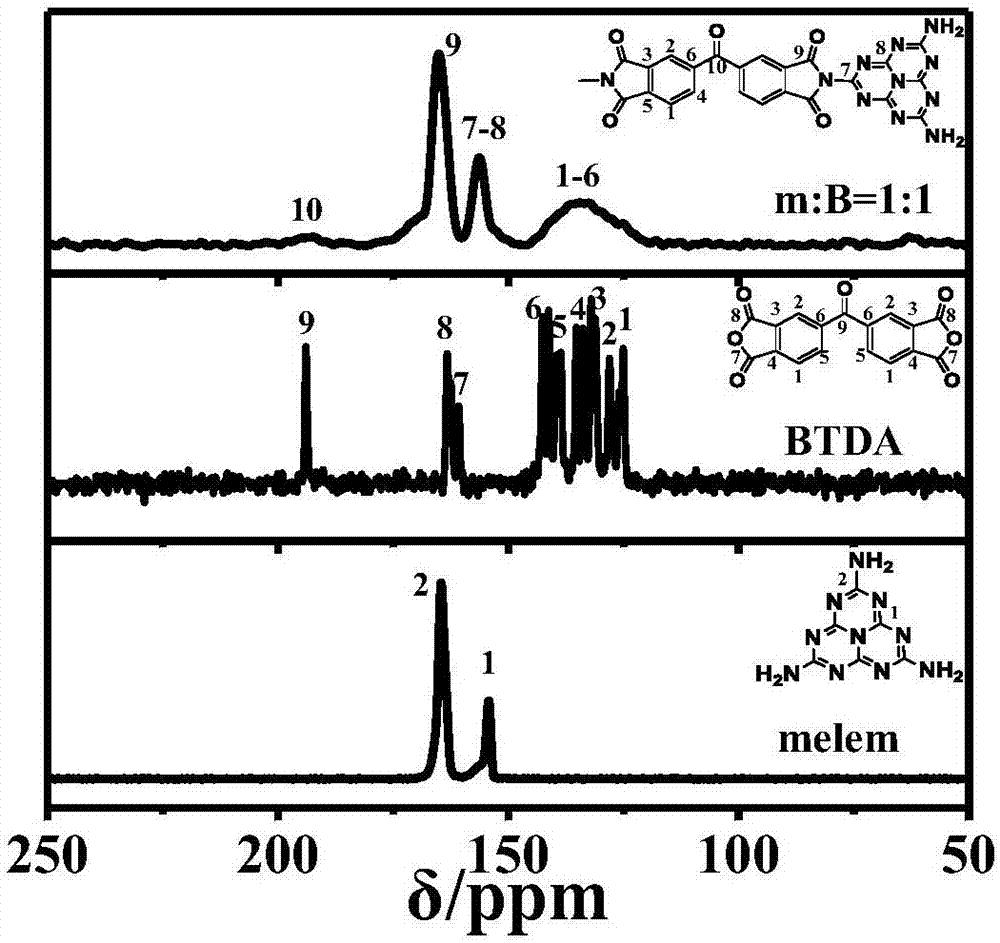

One-step copolymerization method for preparing efficiently-selective carbon nitride photocatalyst

ActiveCN106902876AEasy to separateRaw materials are easy to getQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsValence bandSinglet oxygen

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

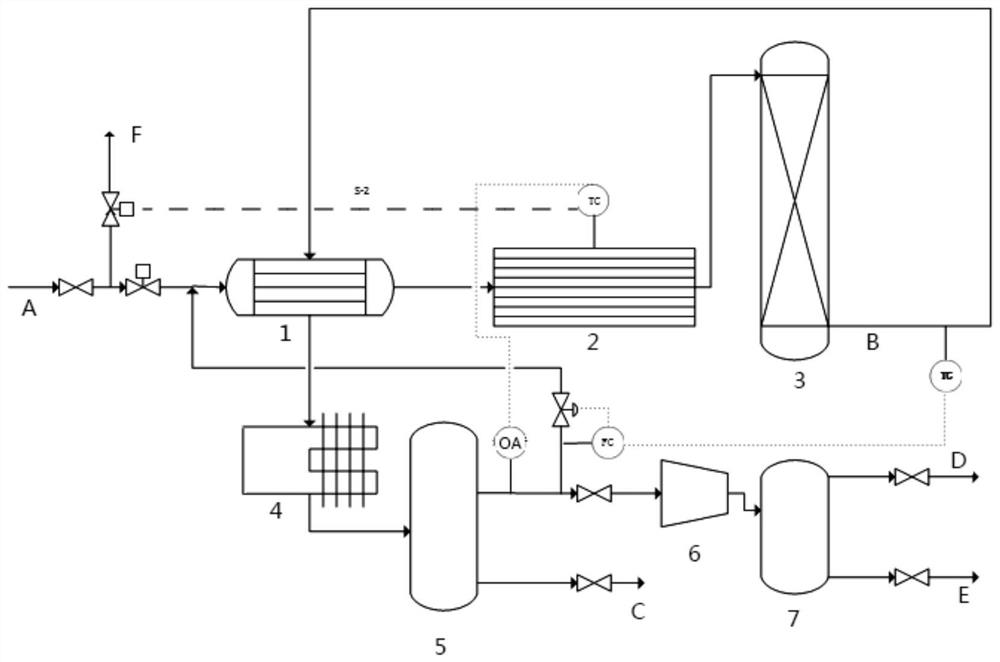

Technology of treating high-concentration organic wastewater with wet type catalytic oxidation

InactiveCN109455808AImprove processing efficiencyReduce energy consumptionWater/sewage treatment by oxidationHigh concentrationWater vapor

The invention discloses a technology of treating high-concentration organic wastewater with wet type catalytic oxidation. The technology comprises the following steps that the technology adopts COD concentration online detection and is automatically correlated to an oxygen concentration regulation device, organic wastewater with the COD content being 10000-50000 mg / L and the liquid space velocityof the wastewater being 0.5-2.5 h<-1> is mixed with enriched oxygen, the device automatically regulates the oxygen volume concentration to be 25-99 percent, water which is sent into a wastewater reactor charged with a catalyst for treatment is directly discharged or sent to a next treatment work section, and tail gas containing nitrogen, oxygen, carbon dioxide and water vapor is directly exhaustedto atmosphere, wherein the space velocity of the enriched oxygen is 34-39 times the liquid space velocity of the wastewater, and the oxygen supply quantity is 1.1-1.2 times the theoretical oxygen demand. The technology disclosed by the invention has the advantages that high-concentration COD in acid or alkaline organic wastewater can be effectively removed.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

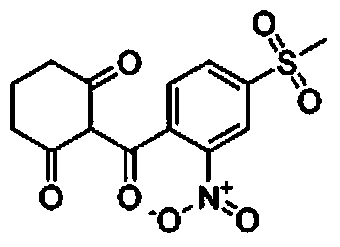

Method for electrochemical pretreatment on methyl sulcotrione pesticide wastewater

InactiveCN104030409AImprove biodegradabilitySimple methodWater/sewage treatmentTin dioxideHigh concentration

Owner:YANCHENG INST OF TECH

Mine acidic iron-containing wastewater treatment method and system

PendingCN110950464AReduce dosageLess investmentWaste water treatment from quariesSpecific water treatment objectivesSludgeCatalytic oxidation

Owner:SICHUAN INST OF GEOLOGICAL ENG INVESTIGATION

Monolithic catalyst with organic waste gas selective adsorption and catalytic oxidation functions as well as preparation method and application thereof

ActiveCN112169827AHigh load rateImprove firmnessGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Catalyst and catalytic oxidation deoxidation method for gas containing unsaturated hydrocarbon

ActiveCN113244931AReduce generationSuppress generationGas treatmentHydrocarbon purification/separationAlkaline earth metalPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method for energy utilization of sludge or organic waste

ActiveCN105927986ASimple processLess investmentIncinerator apparatusCombustionHydrocotyle bowlesioides

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

Catalyst for production of conjugated diolefin and method for producing same

InactiveUS20180208685A1High hardnessLong-term stabilityMolybdeum compoundsHeterogenous catalyst chemical elementsGlass fiberDehydrogenation

Owner:NIPPON KAYAKU CO LTD

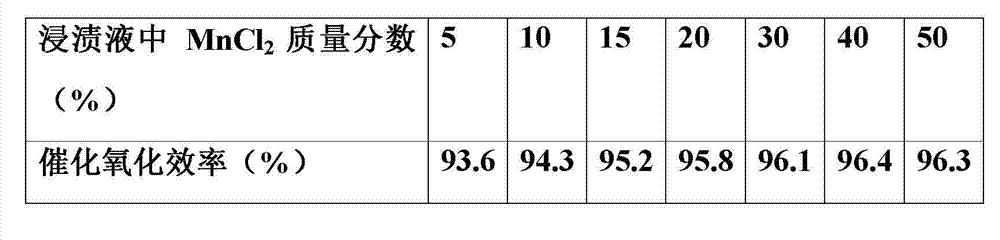

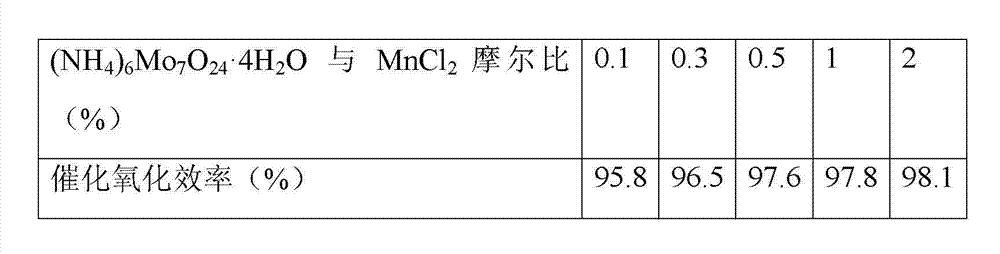

Modified catalyst for gaseous-state elemental mercury oxidation and preparation method of modified catalyst

ActiveCN102962083AAchieve sustainable developmentImprove catalytic oxidation efficiencyPhysical/chemical process catalystsDispersed particle separationSulfurCatalytic oxidation

Owner:KUNMING METALLURGY INST

Device and method for removing arsenic from yellow phosphorus through continuous electrocatalytic oxidation

PendingCN112458481AEffective continuous productionAchieve mutual separationCellsPhosphorus compoundsElectrolytic agentCatalytic oxidation

Owner:KUNMING UNIV OF SCI & TECH

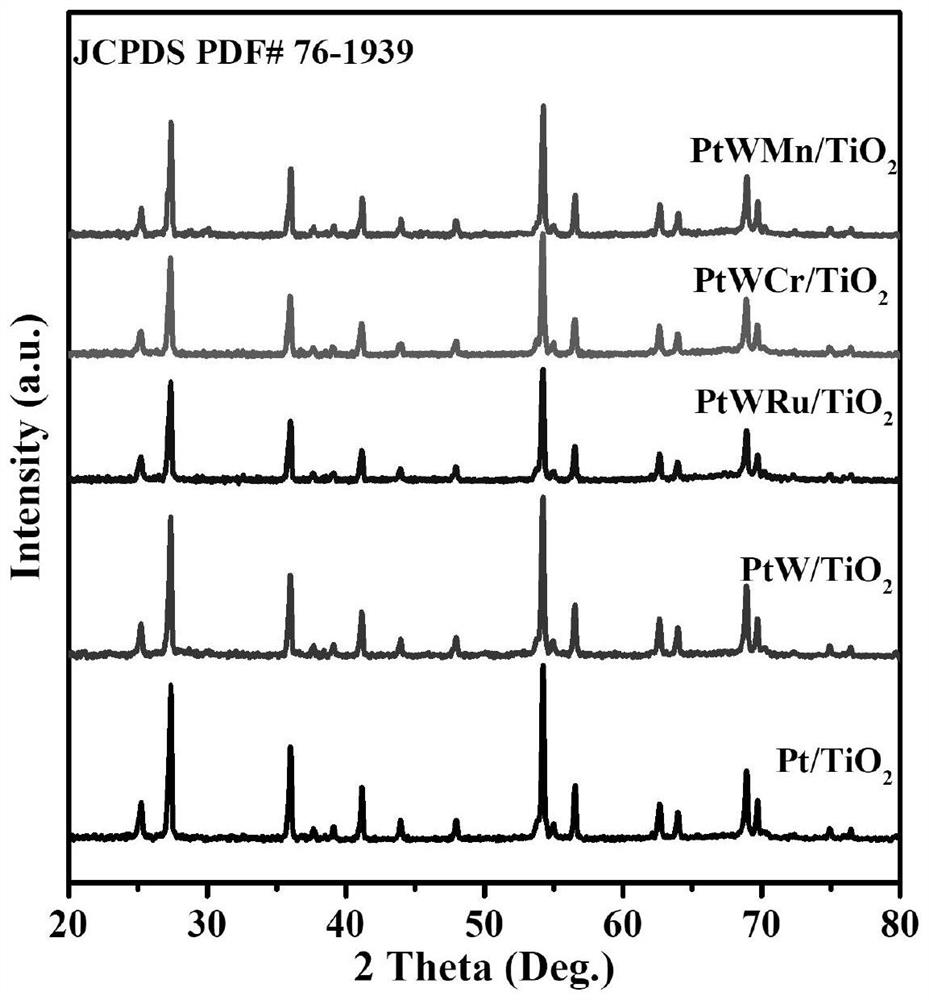

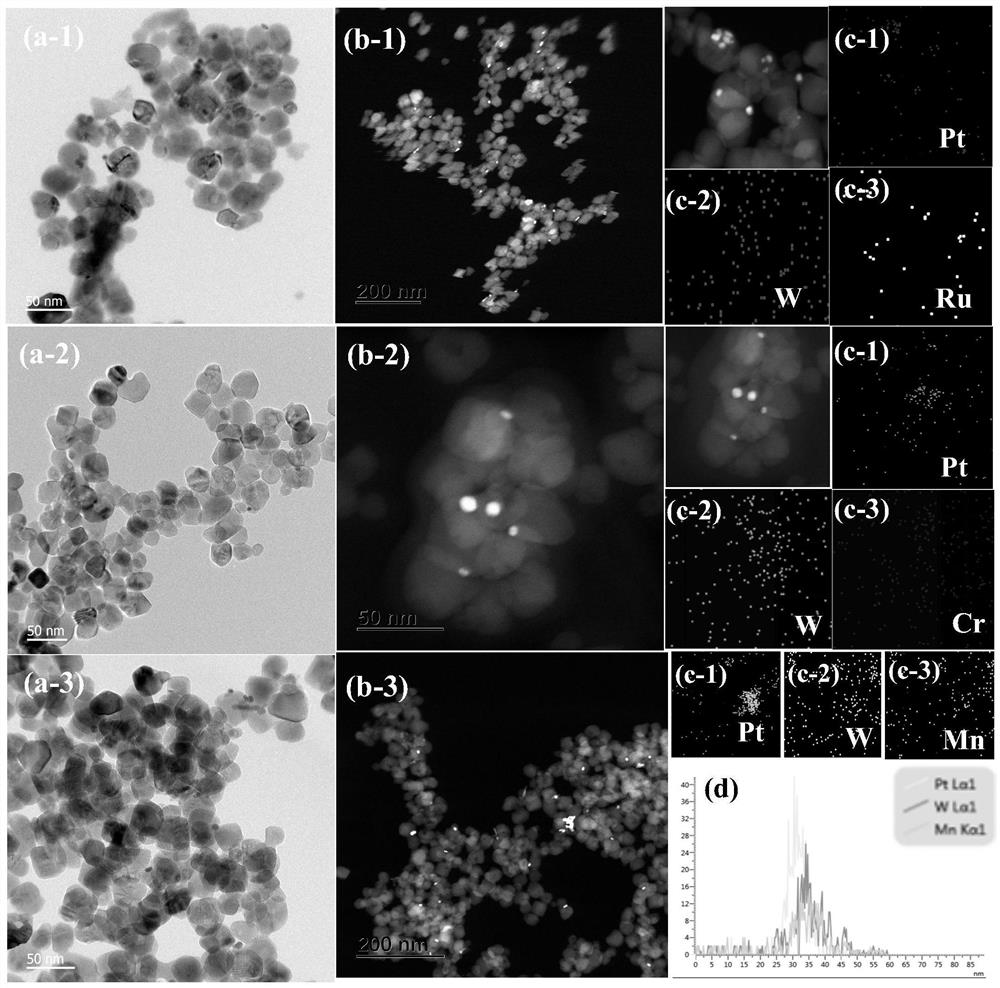

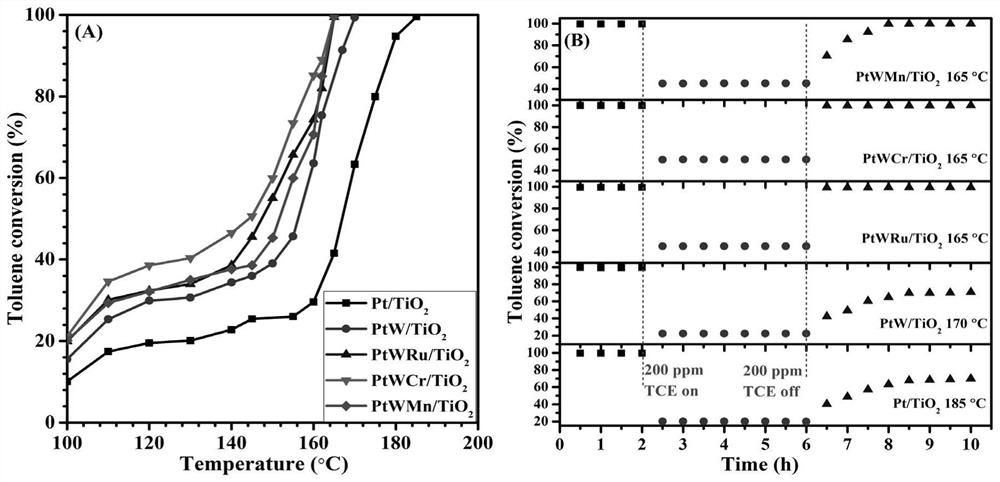

Ternary metal catalyst with excellent chlorine resistance and efficient catalytic oxidation of mixed VOCs

PendingCN114345335AImprove catalytic performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetal catalyst

Owner:BEIJING UNIV OF TECH

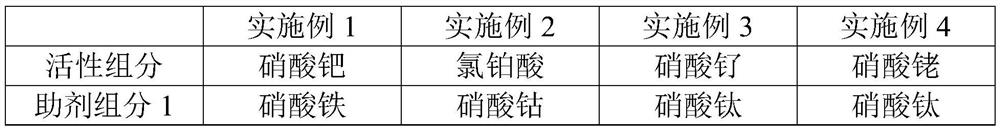

Preparation method of catalyst for catalytic oxidation synthesizing of acrolein through propylene

InactiveCN103285913AHigh catalytic activityMolecular sieve catalystsOrganic compound preparationCatalytic oxidationManganese

Owner:陈和平

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap