Ternary metal catalyst with excellent chlorine resistance and efficient catalytic oxidation of mixed VOCs

A ternary metal and catalytic oxidation technology, which is applied in the field of catalytic chemistry and nanoscience, can solve the problems of little research on mixed VOCs and supported ternary metal catalysts, and achieve excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

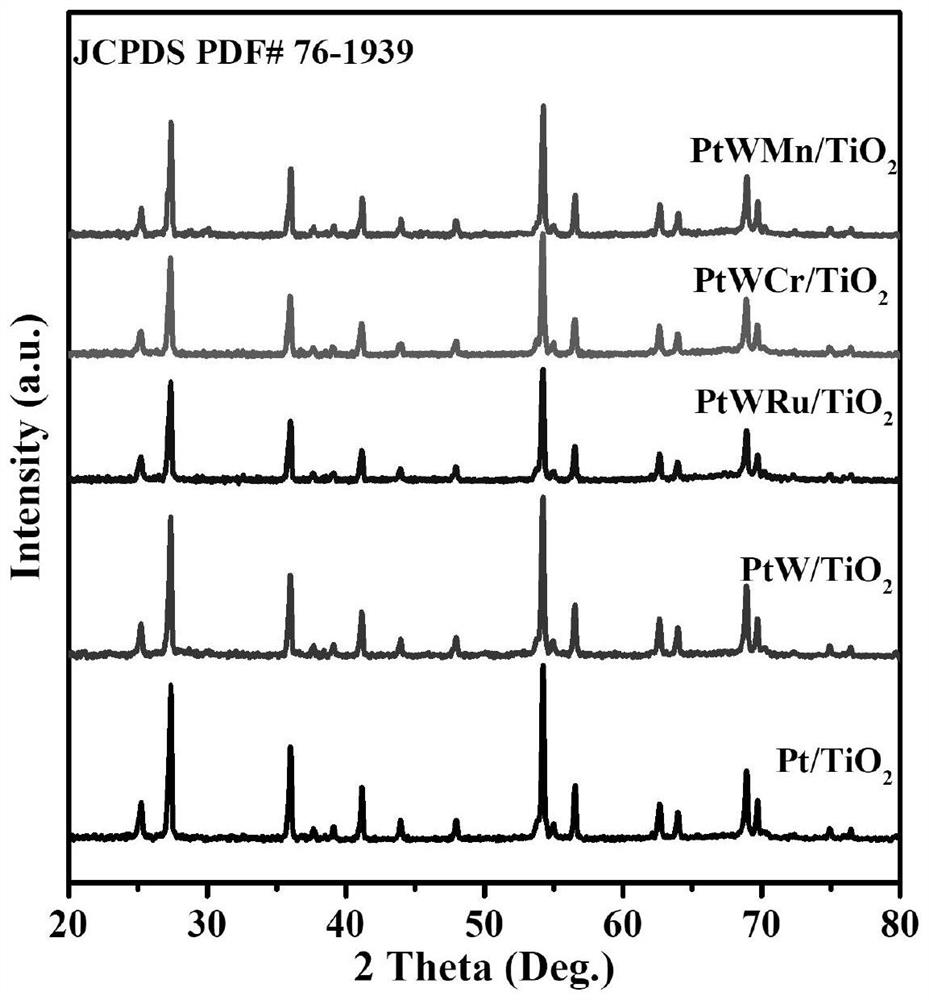

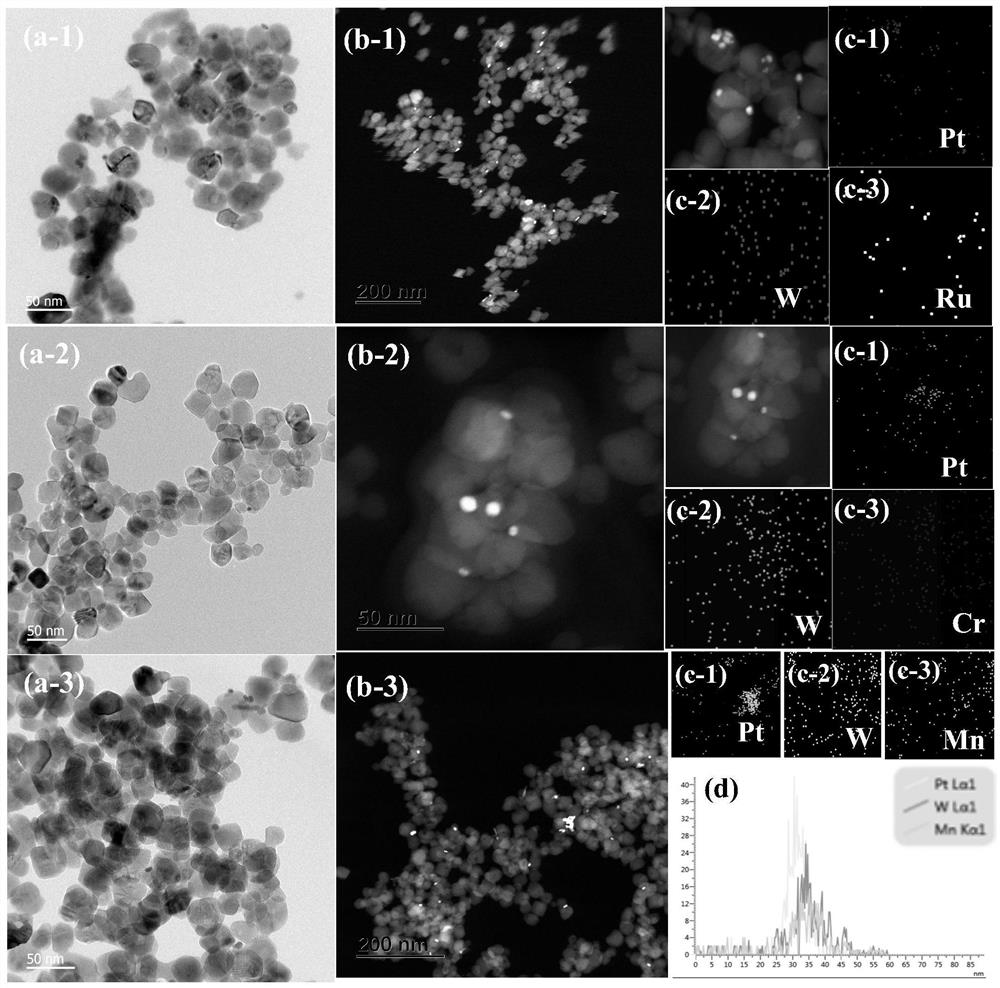

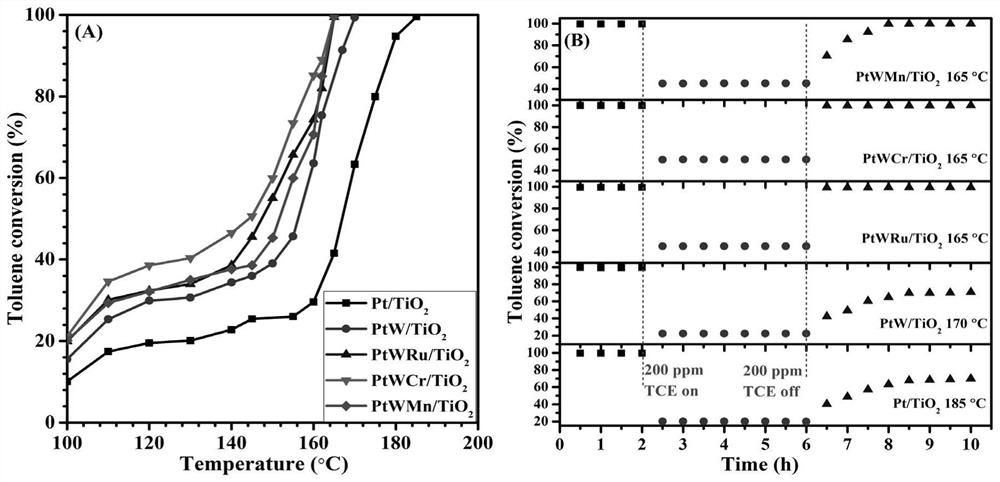

[0015] Weigh 5.1120mg platinum acetylacetonate, add 2.5mL octadecene, 2.5mL oleylamine, 0.5mL oleic acid, stir and dissolve at room temperature for 20min, then add 49.3164mg ascorbic acid, continue stirring for 5-10min, then weigh 49.2660mg hexacarbonyl Add tungsten and 21.3110 mg triruthenium dodecacarbonyl into the mixed solution to finally form a mixed precursor solution, continue stirring at room temperature for 10-20 minutes, then put it into a reaction kettle, and react in an oven at 200 ° C for 8 hours. After cooling to room temperature, pour the reacted solution into a centrifuge tube, and centrifugally wash with a mixed solution of cyclohexane and ethanol for 3-4 times to obtain PtWRu ternary alloy nanoparticles. The prepared PtWRu ternary alloy nanoparticles were uniformly dispersed in about 10 mL of cyclohexane for storage. Using the adsorption method, a certain amount of r-TiO 2 The carrier was added to the cyclohexane solution containing nanocrystals, stirred for 6-

Embodiment 2

[0018] Weigh 5.1120mg platinum acetylacetonate, add 2.5mL octadecene, 2.5mL oleylamine, 0.5mL oleic acid, stir and dissolve at room temperature for 20min, then add 49.3164mg ascorbic acid, continue stirring for 5-10min, then weigh 49.2660mg hexacarbonyl Tungsten and 22.0060 mg of chromium hexacarbonyl were added to the mixed solution to finally form a mixed precursor solution. Stirring was continued at room temperature for 10-20 minutes, then loaded into a reaction kettle, and reacted in an oven at 200°C for 8 hours. After cooling to room temperature, pour the reacted solution into a centrifuge tube, and centrifugally wash with a mixed solution of cyclohexane and ethanol for 3-4 times to obtain PtWCr ternary alloy nanoparticles. The prepared PtWCr ternary alloy nanoparticles were uniformly dispersed in about 10 mL of cyclohexane for storage. Using the adsorption method, a certain amount of r-TiO 2 The carrier was added to the cyclohexane solution containing nanocrystals, stirred

Embodiment 3

[0021] Weigh 5.1120mg platinum acetylacetonate, add 2.5mL octadecene, 2.5mL oleylamine, 0.5mL oleic acid, stir and dissolve at room temperature for 20min, then add 49.3164mg ascorbic acid, continue stirring for 5-10min, then weigh 49.2660mg hexacarbonyl Add tungsten and 19.49885 mg of manganese decacarbonyl into the mixed solution to finally form a mixed precursor solution, continue stirring at room temperature for 10-20 minutes, then put it into a reaction kettle, and react in an oven at 200 ° C for 8 hours. After cooling to room temperature, pour the reacted solution into a centrifuge tube, and centrifugally wash with a mixed solution of cyclohexane and ethanol for 3-4 times to obtain PtWMn ternary alloy nanoparticles. The prepared PtWMn ternary alloy nanoparticles were uniformly dispersed in about 10 mL of cyclohexane for storage. Using the adsorption method, a certain amount of r-TiO 2 The carrier was added to the cyclohexane solution containing nanocrystals, stirred for 6-1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap