Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about "Molecular sieve catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

AEI-type zeolite, its synthesis and its use in the conversion of oxygenates to olefins

ActiveUS20050197519A1Aluminium compoundsSilicaCrystalline materialsOxygen compound

A crystalline material is described that has an AEI framework type, wherein the material, in its calcined, anhydrous form, has a composition involving the molar relationship: (n)X2O3:YO2, wherein X is a trivalent element, Y is a tetravalent element n is from 0 to less than 0.01. The material is normally synthesized in a halide, typically a fluoride, medium and exhibits activity and selectivity in the conversion of methanol to lower olefins, especially ethylene and propylene.

Owner:EXXONMOBIL CHEM PAT INC +1

Catalytic composition and process for the alkylation and/or transalkylation of aromatic compounds

Owner:ENICHEM SPA

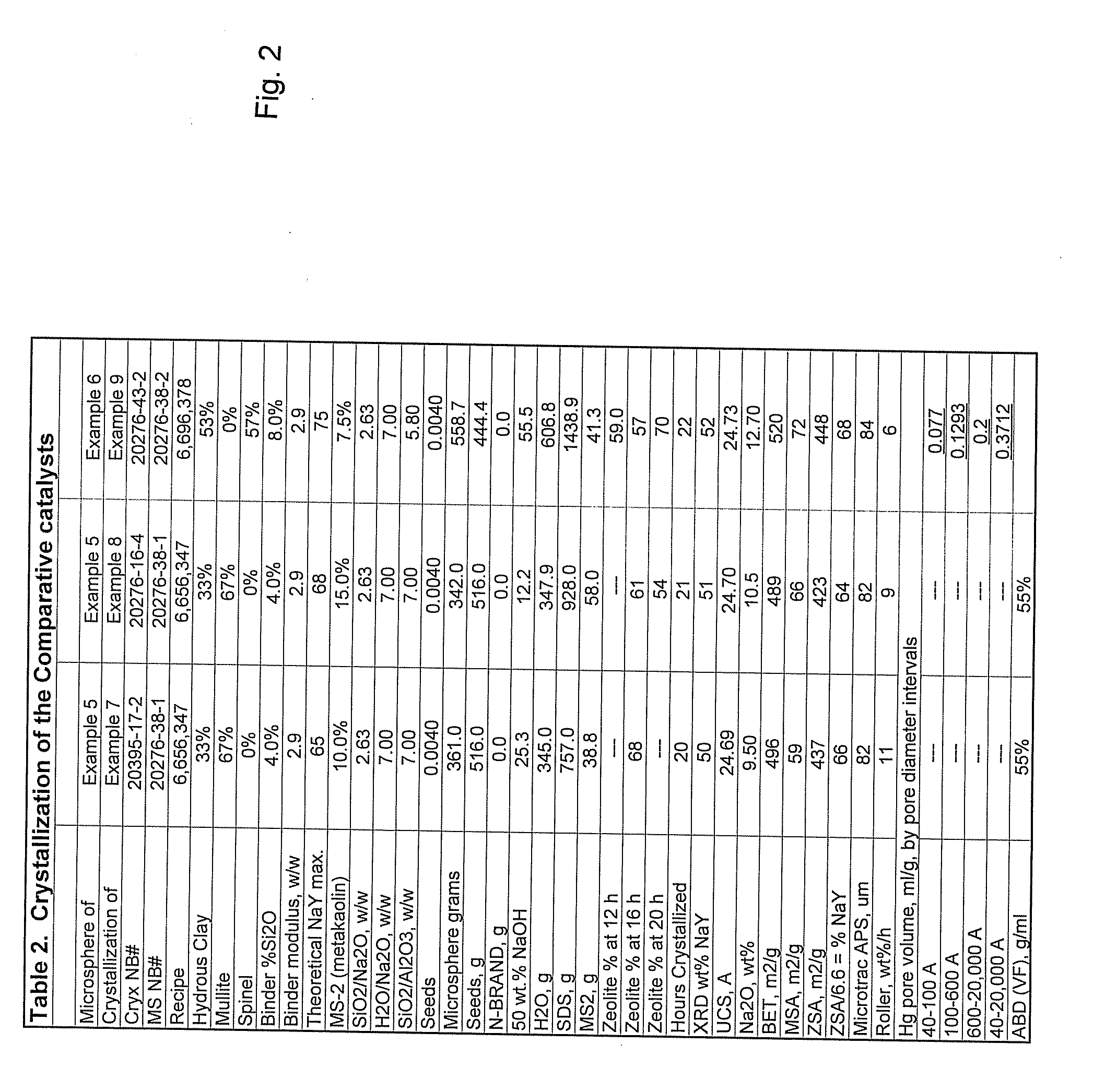

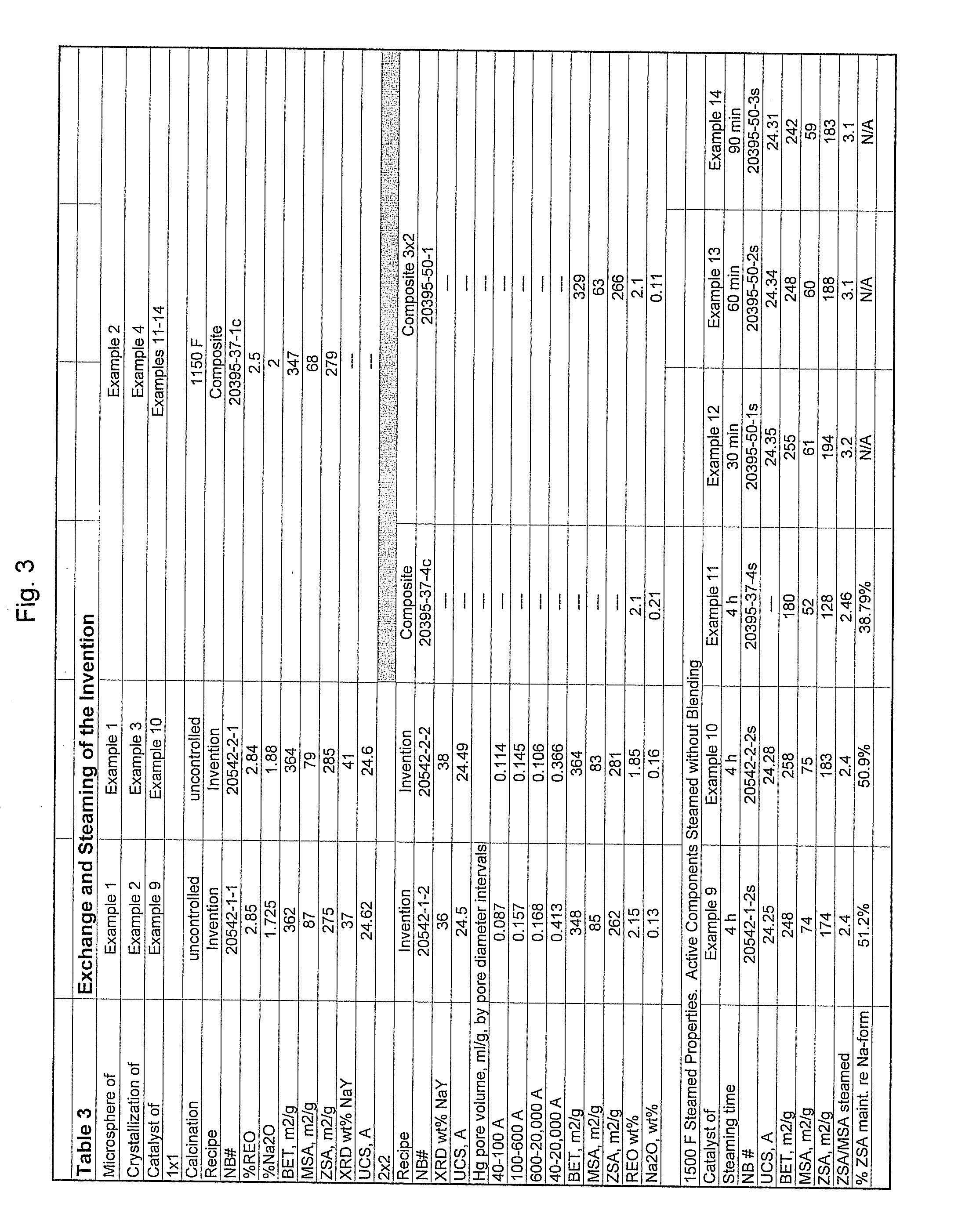

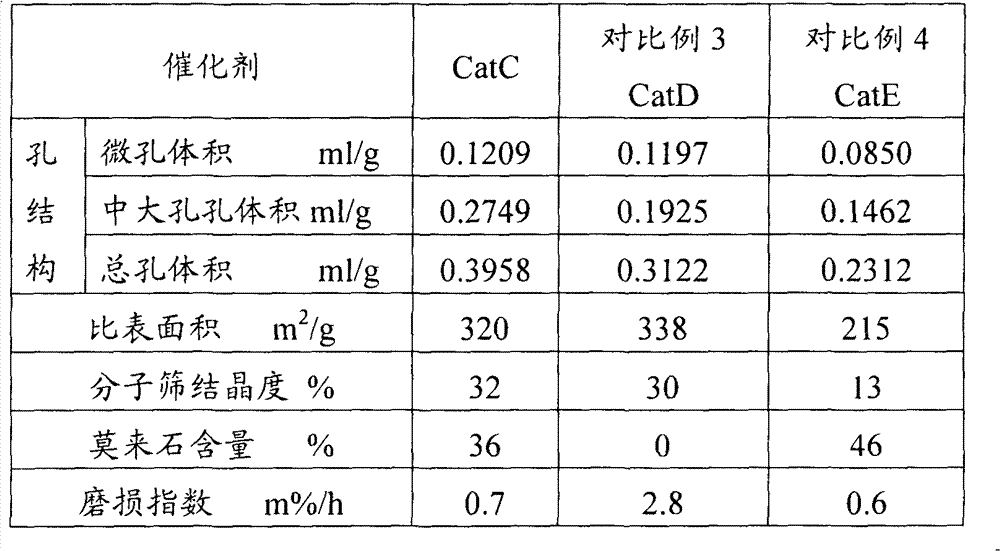

Structurally enhanced cracking catalysts

InactiveUS20080314798A1Reduced pore volumeIncrease coverageThermal non-catalytic crackingCatalytic crackingOrganic chemistry

Owner:BASF CORP

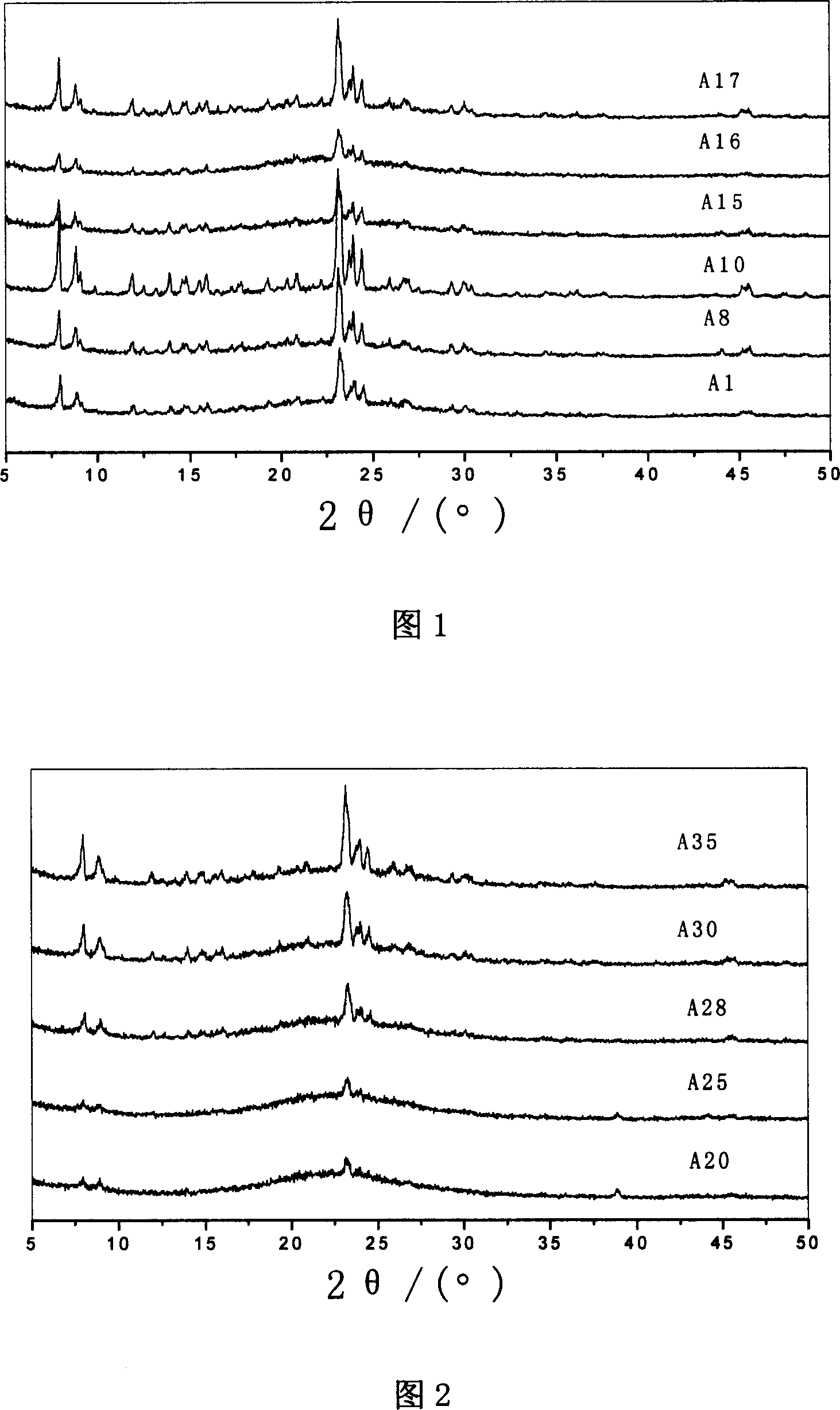

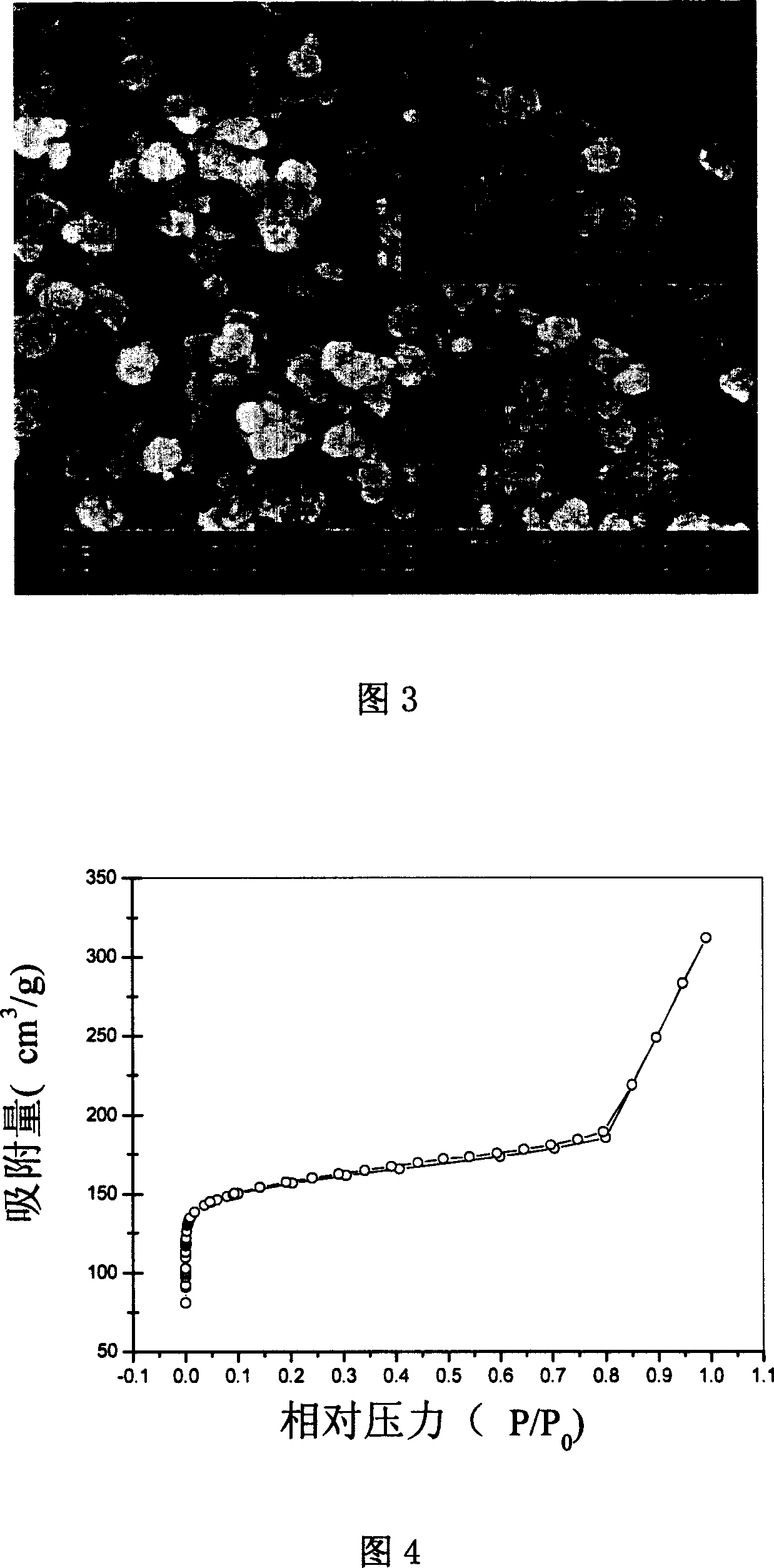

Method for synthesizing ZSM-5 zeolite with multilevel pore canals

ActiveCN101003380AThe operation process is simpleReduce manufacturing costMolecular sieve catalystsPentasil aluminosilicate zeoliteSucrose solutionCompound s

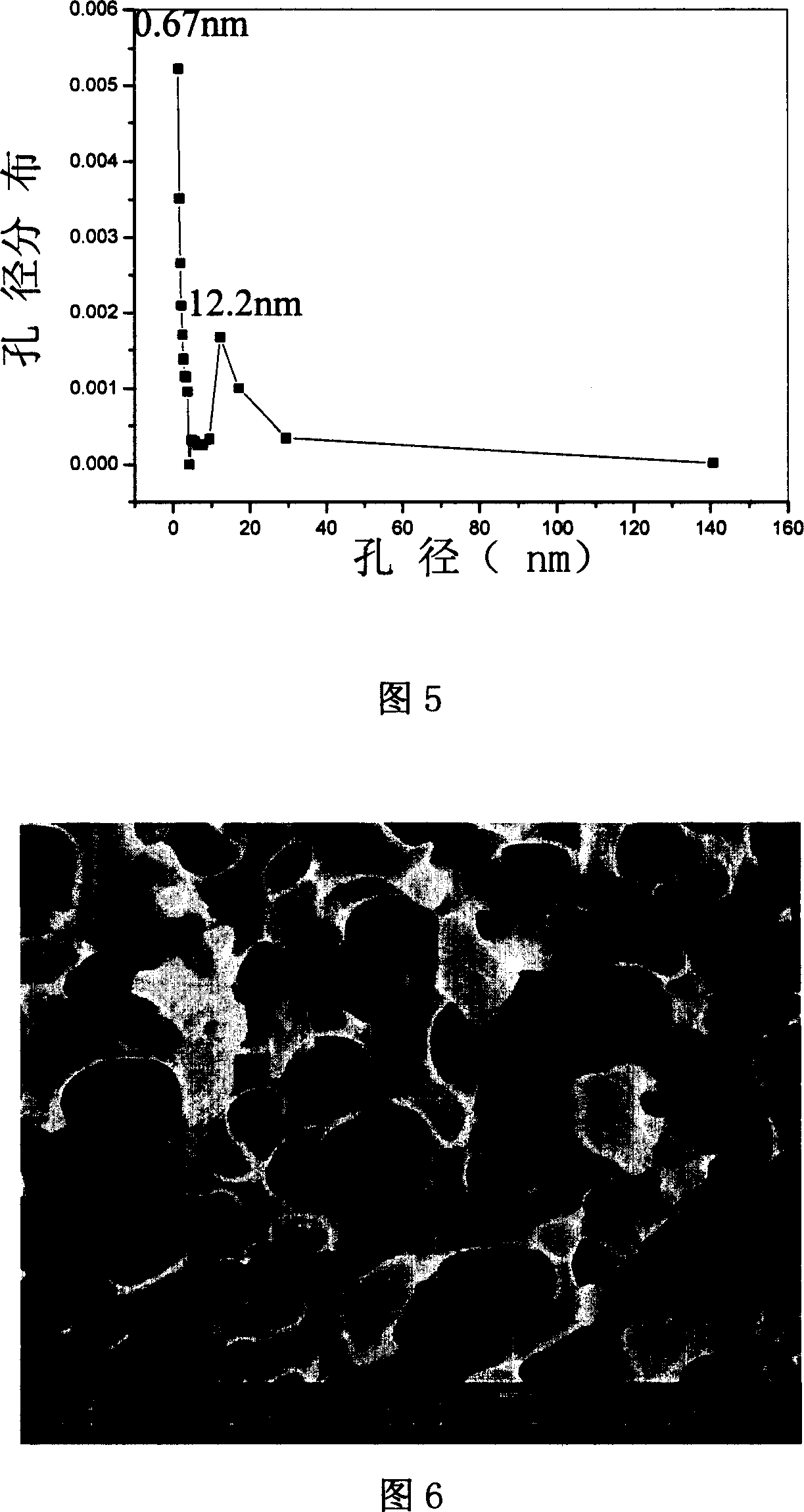

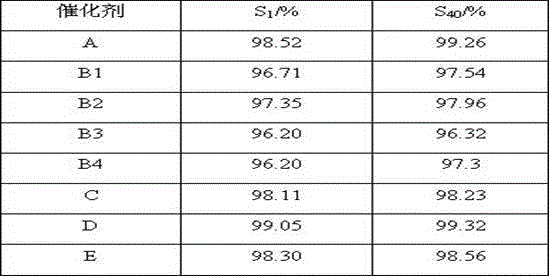

This invention discloses a method for synthesizing multi-level porous ZSM-5 zeolite. The method comprises: soaking monolithic silica gel column in sucrose solution, drying, polymerizing, carbonizing to obtain C-Si composite, wetting the C-Si composite with a mixed solution of Al source, inorganic alkali, organic amine and water, crystallizing, and recovering the product. The obtained ZSM-5 zeolite has multi-level pores, including micrometer-scale macropores, mesopores and micropores. The macropores can shorten the diffusion distances of reactive molecules, reduce the pressure decrease of the equipment, raise the unit processing capacity of the equipment, and make the adjustment and control of the product selectivity easier. The mesopores can provide large inner specific surface area, which is meaningful to the catalytic reaction of macromolecules.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for making molecular sieves and novel molecular sieve compositions

Owner:ABB LUMMUS GLOBAL INC

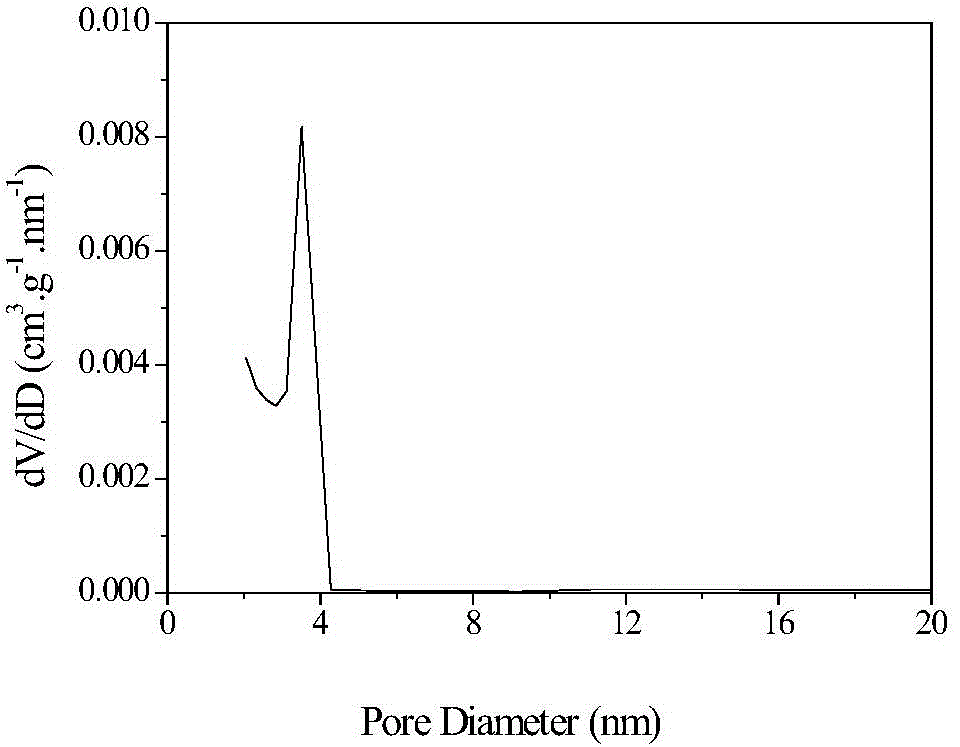

Multistage porous ZSM-5 molecular sieve and preparation method thereof as well as method for preparing PX catalyst using same

ActiveCN108178164AReduce economic costsThe synthesis process is simpleMolecular sieve catalystsMolecular sieve catalystMolecular sievePolyol

The invention relates to a multistage porous ZSM-5 molecular sieve. The molecular sieve comprises the following raw materials: a silicon source, an aluminum source, a template agent, water, an alkalisource, polyether polyol, a seed crystal, a cosolvent and a mineralizer. The invention provides a preparation method of the multistage porous ZSM-5 molecular sieve with a high silicon-aluminum ratio.The synthesis process is simple, and cheap template agent and porous agent are adopted, so that the economic cost of the molecular sieve is reduced. The ZSM-5 molecular sieve obtained by the method has a multistage pore channel structure, the relative crystallinity is higher than 90%, and the specific surface area is greater than 420m<2> / g.

Owner:REZEL CATALYSTS CORP

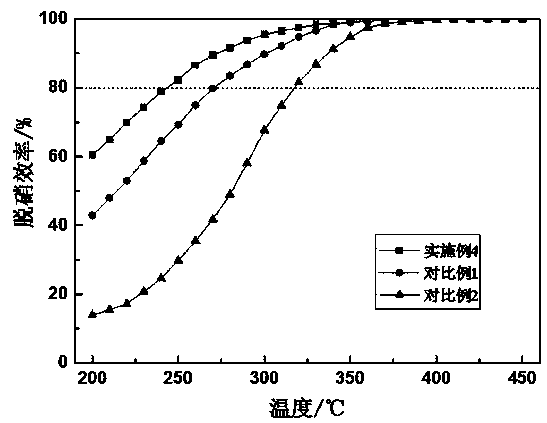

Dehydrogenation catalyst for light alkanes and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing low-carbon olefine by catalytic cracking using fluidized-bed and preparation method and use thereof

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalytic cracking catalyst containing Y-type molecular sieve and preparation method thereof

Owner:PETROCHINA CO LTD +1

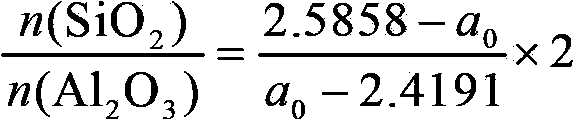

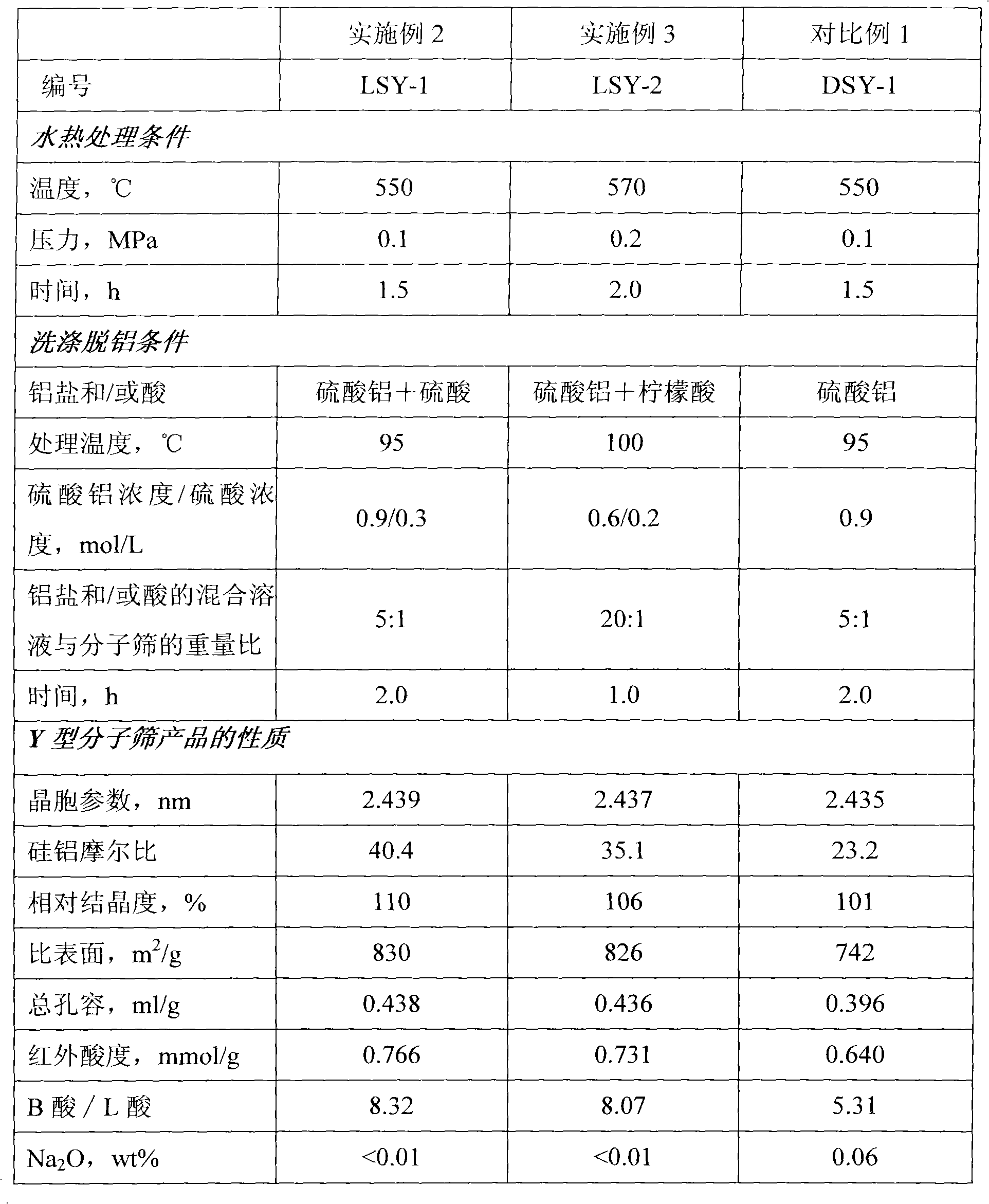

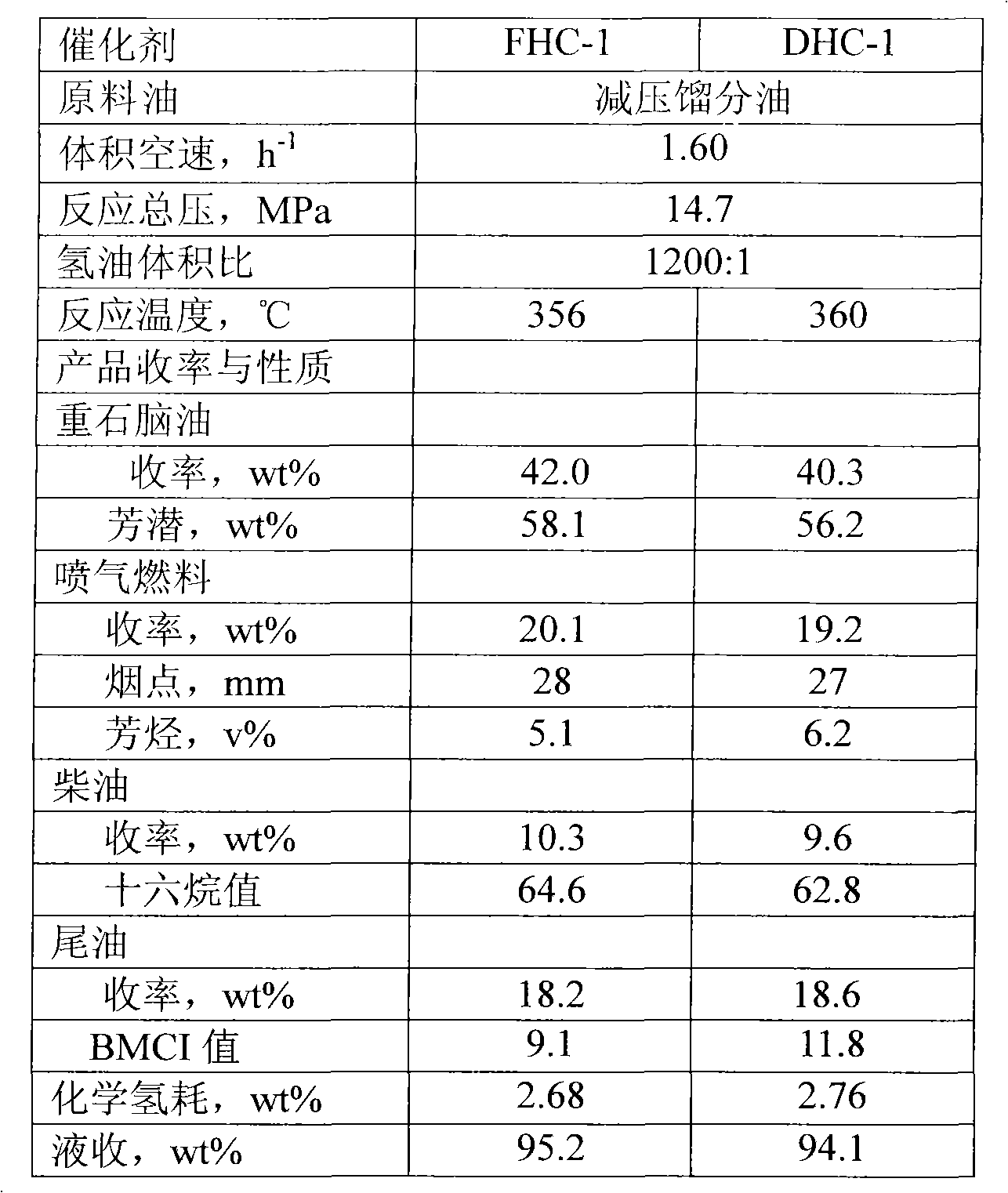

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347AHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper and iron compound honeycomb coating type denitrification catalyst as well as preparation method and application thereof

InactiveCN109499607AImprove thermal stabilityImprove anti-sulfur poisoning performanceMolecular sieve catalystsDispersed particle separationIon exchangeVacuum coating

Owner:VALIANT CO LTD

Visible-light-driven photocatalyst for degrading dye in wastewater, and preparation and application thereof

ActiveCN106732741AHigh activityGood dispersionWater/sewage treatment by irradiationMolecular sieve catalystsMesoporous silicaLight driven

Owner:BINZHOU UNIV

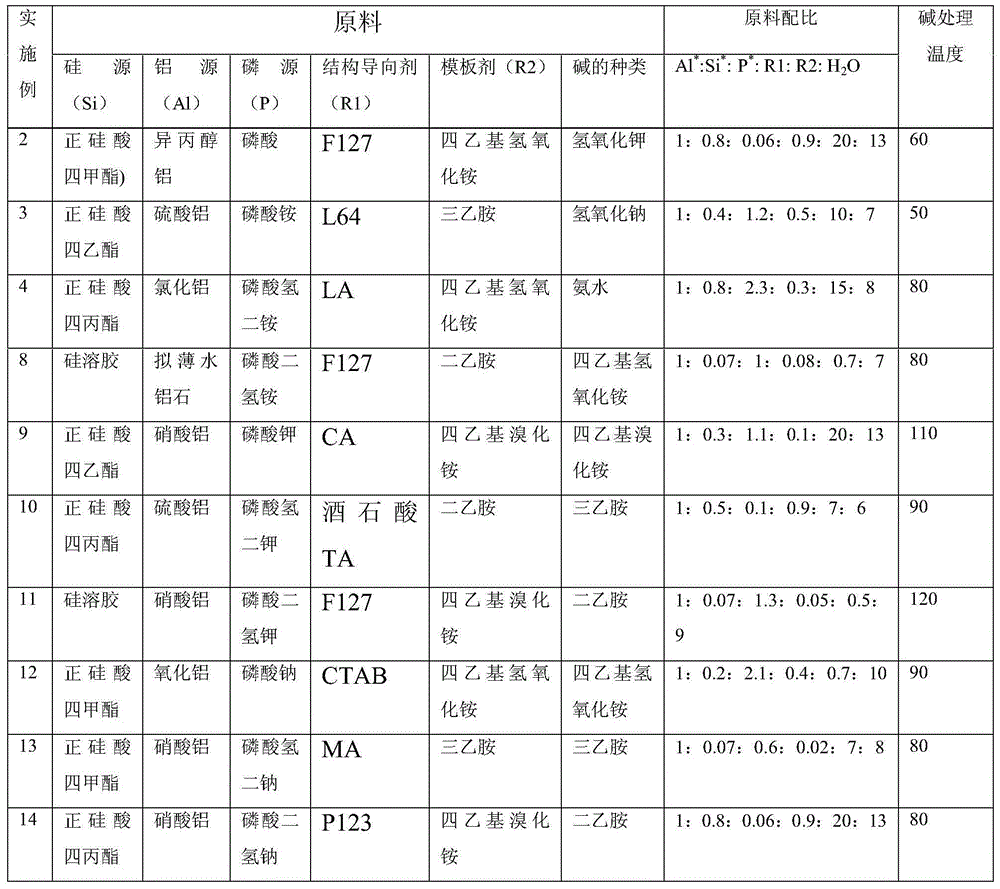

Phosphor-doped CHA molecular sieve, and preparation method and application thereof

ActiveCN108083292AGood activity at low temperatureMolecular sieve catalystsDispersed particle separationPotassium hydroxideCrystallinity

Owner:LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

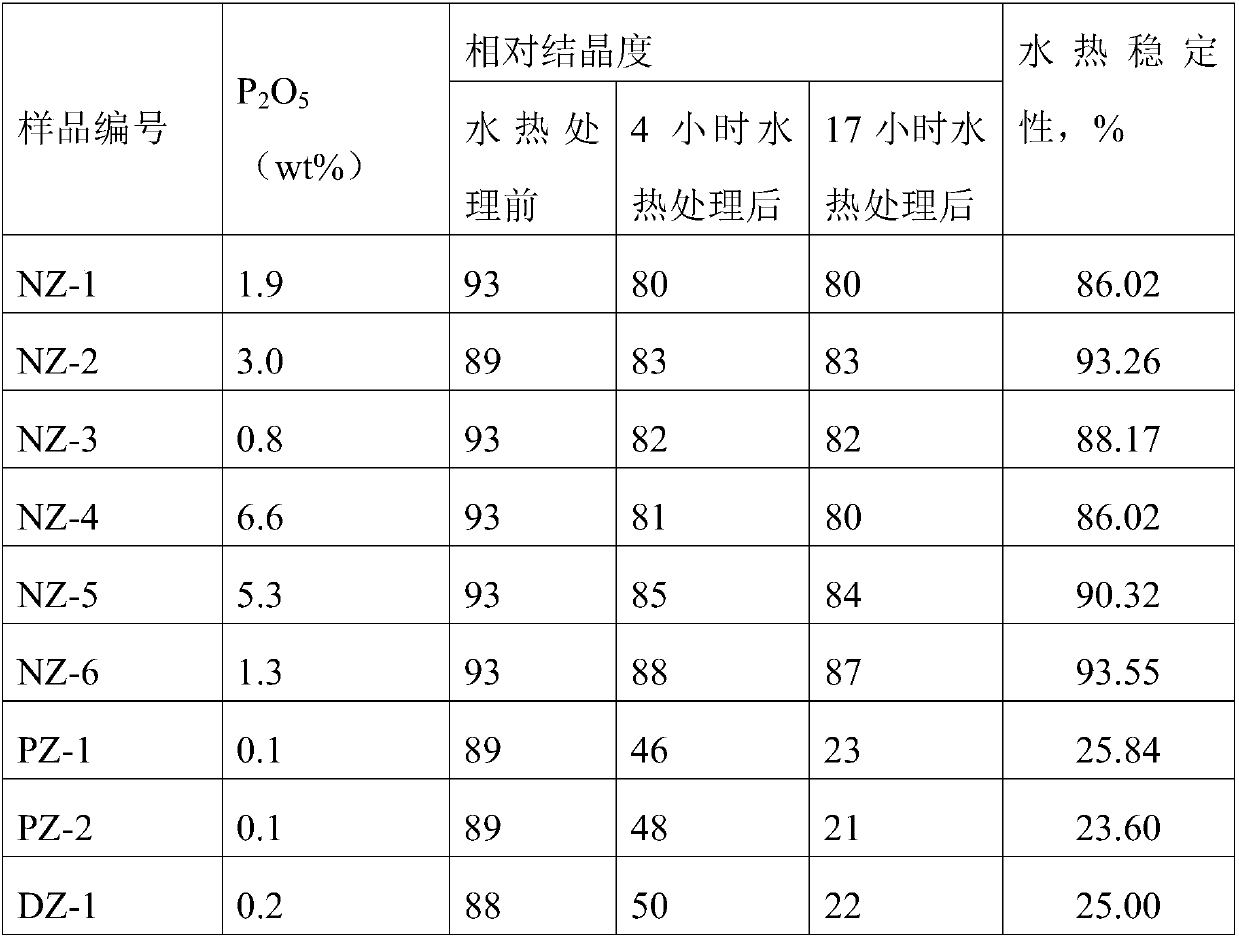

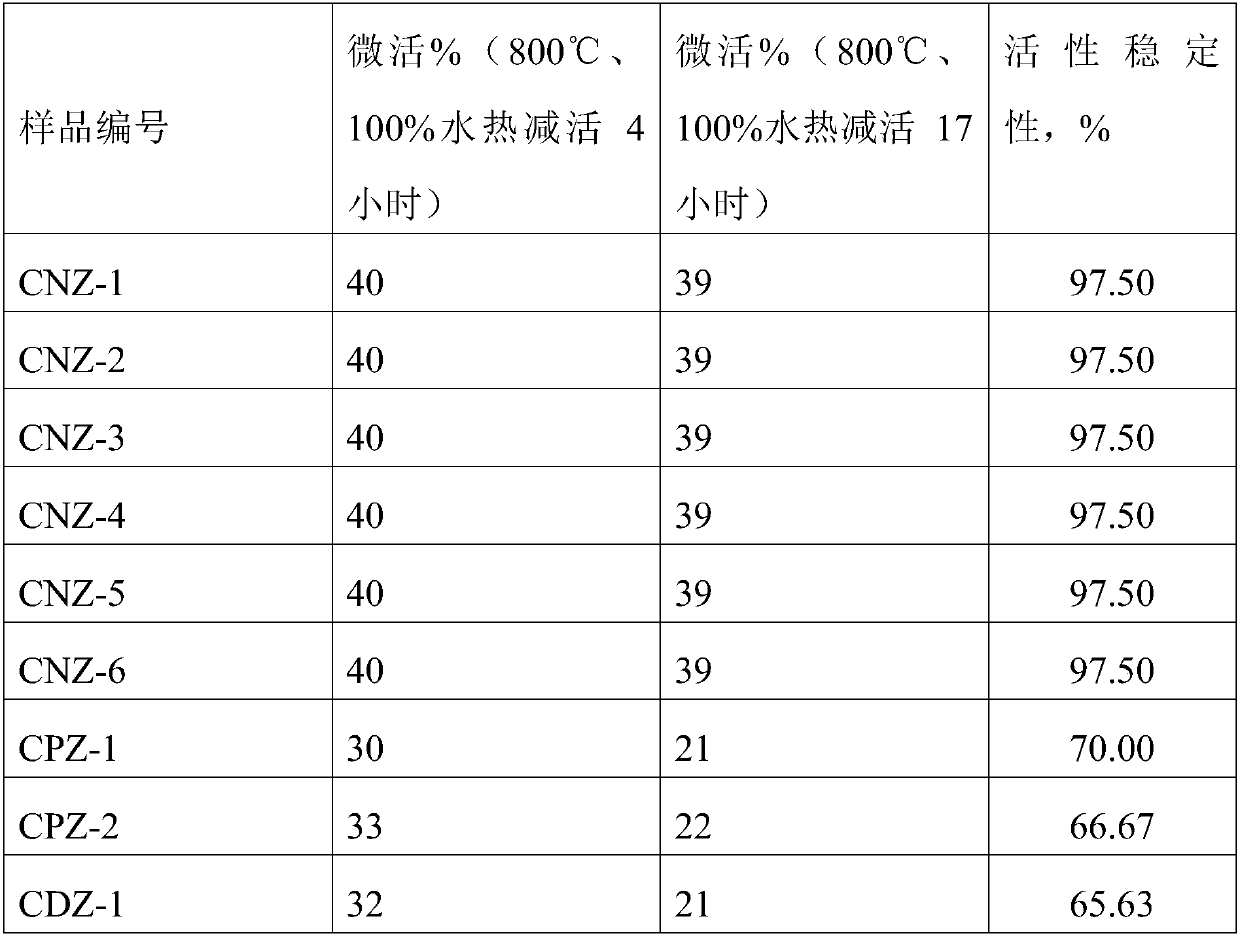

Ferrierite molecular sieve, preparation method thereof and application

ActiveCN107010636AGood choiceImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationCrystallinity

The invention provides a ferrierite molecular sieve, a preparation method thereof and an application. The preparation method includes the steps: mixing silicon sources, alkalinity conditioning agents, aluminum sources, template agents and water to form uniform sol; controlling the molar ratio of SiO2, Al2O3, R, Na2O to H2O to be 1.0:(0.005-0.10):(0.05-1.2):(0.03-0.50):(5.0-100.0), and enabling a pH (potential of hydrogen) value to be lower than 12.8; performing pre-crystallization, crystallization, drying and calcination to obtain molecular sieve raw powder; performing acid treatment on the obtained molecular sieve raw powder; mixing the molecular sieve raw powder, the template agents and the water or further mixing the molecular sieve raw powder, the template agents, the water and the silicon sources to form water solution; performing water-heat treatment, drying and calcination to obtain the ferrierite molecular sieve. R is the template agents. The prepared ferrierite molecular sieve is high in relative crystallinity and silica alumina ratio, large in specific surface area and crystal particle and adjustable in acidity and has excellent selectivity and stability when being applied to linear-chain olefin skeletal isomerization reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

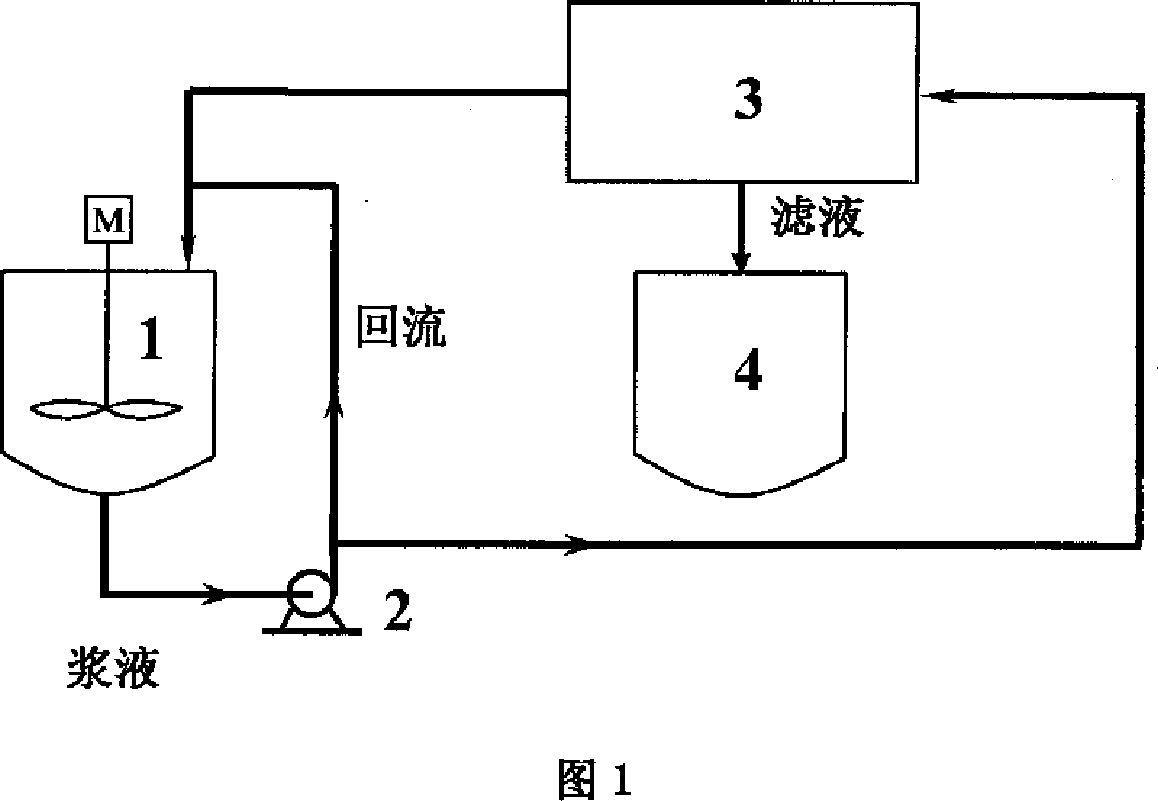

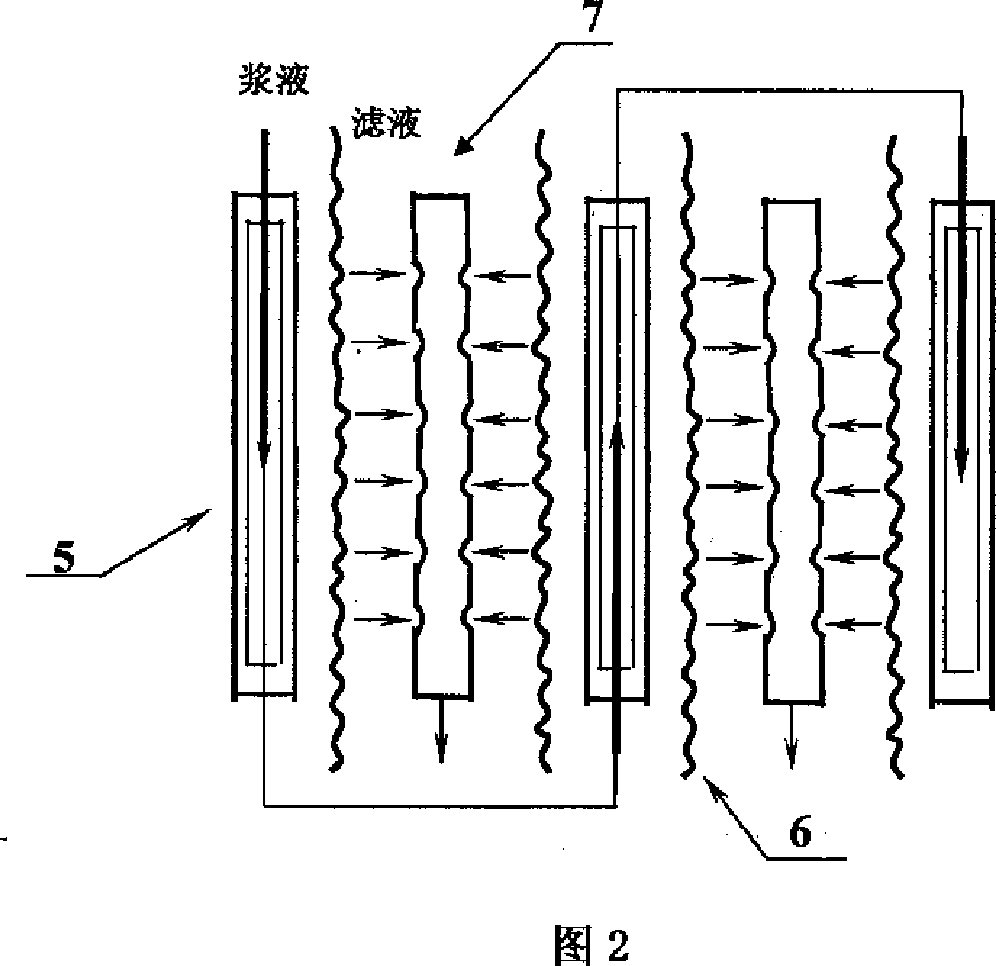

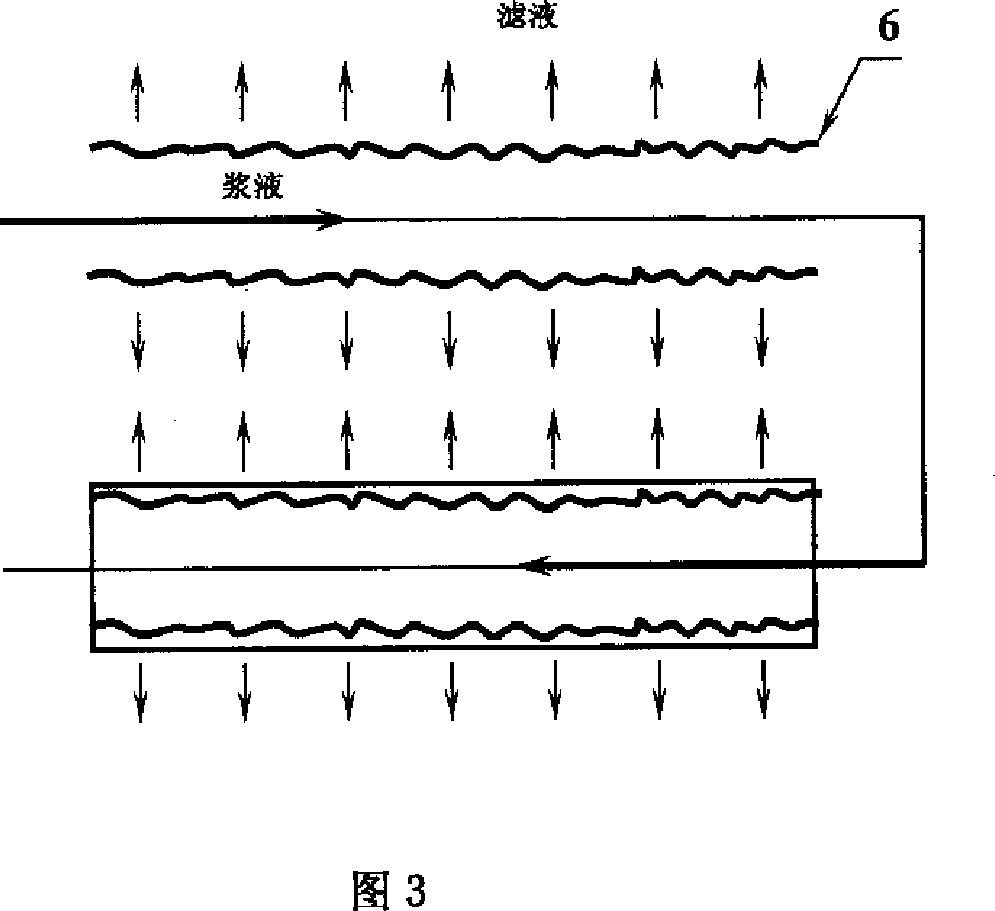

Superfine molecular sieves filtering separating and mother solution recovering method

ActiveCN101053712AMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveChemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

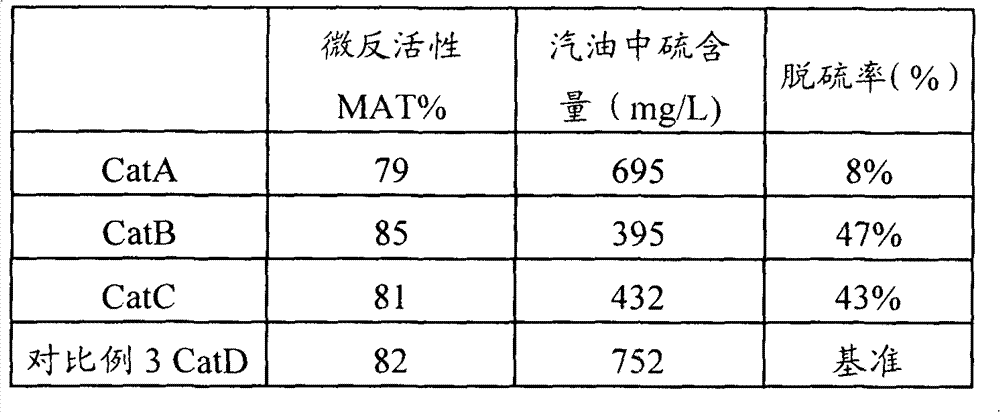

Wear-resistant heavy oil catalytic cracking catalyst capable of reducing sulfur content of gasoline and preparation method thereof

ActiveCN103028432AImprove wear resistanceHigh activityCatalytic crackingMolecular sieve catalystsMicrosphereWear resistant

Owner:EAST CHINA UNIV OF SCI & TECH +1

Nickel catalyst, process for the preparation thereof, process for hydrogenation of m-dinitro benzene to m-phenylene diamine

InactiveUS20050070740A1Speed up the processLong catalyst lifeMolecular sieve catalystsOrganic compound preparationSolventSilicon dioxide

Owner:COUNCIL OF SCI & IND RES

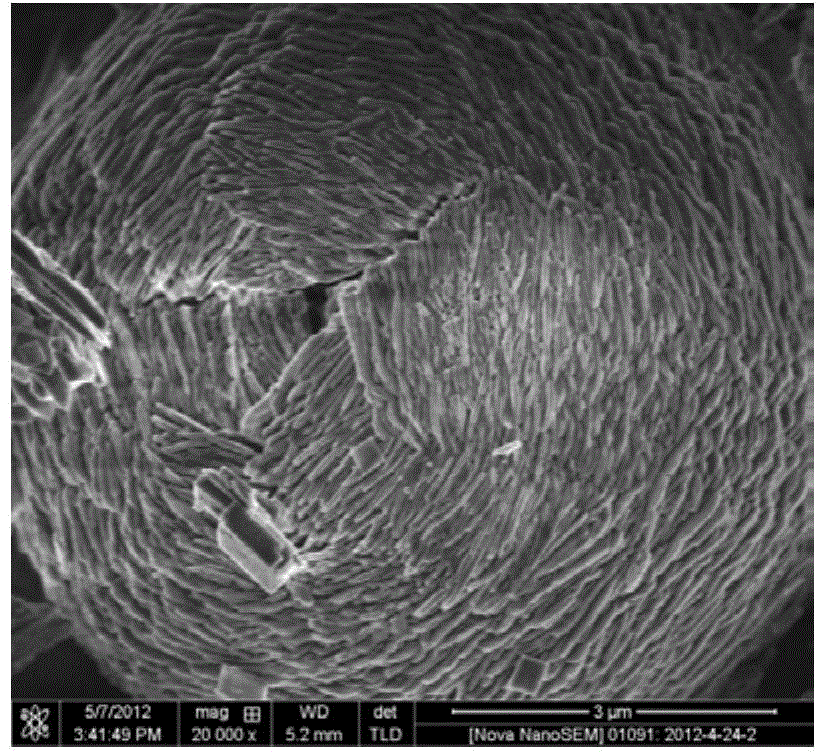

SAPO molecular sieve material with a layered structure and preparation method thereof

InactiveCN105460944AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsLayered structureMolecular sieve

Owner:CHINA PETROLEUM & CHEM CORP +1

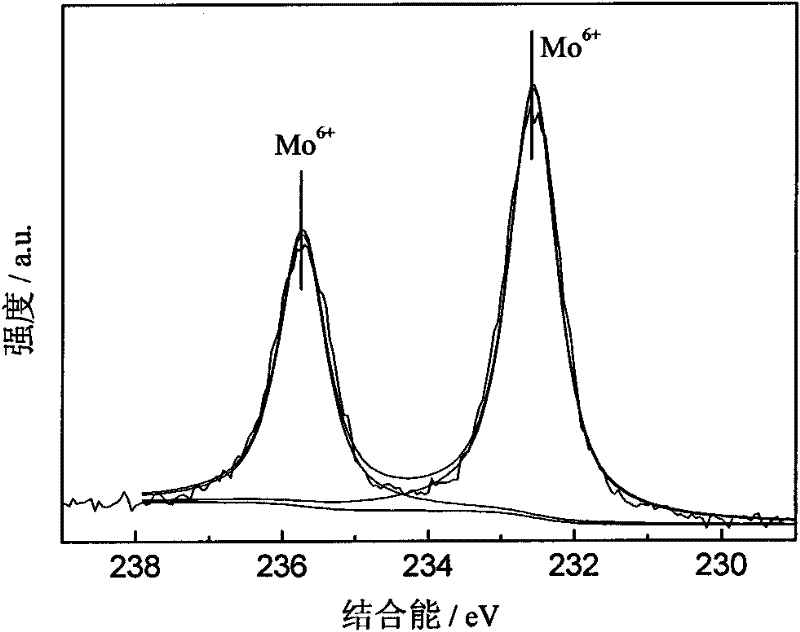

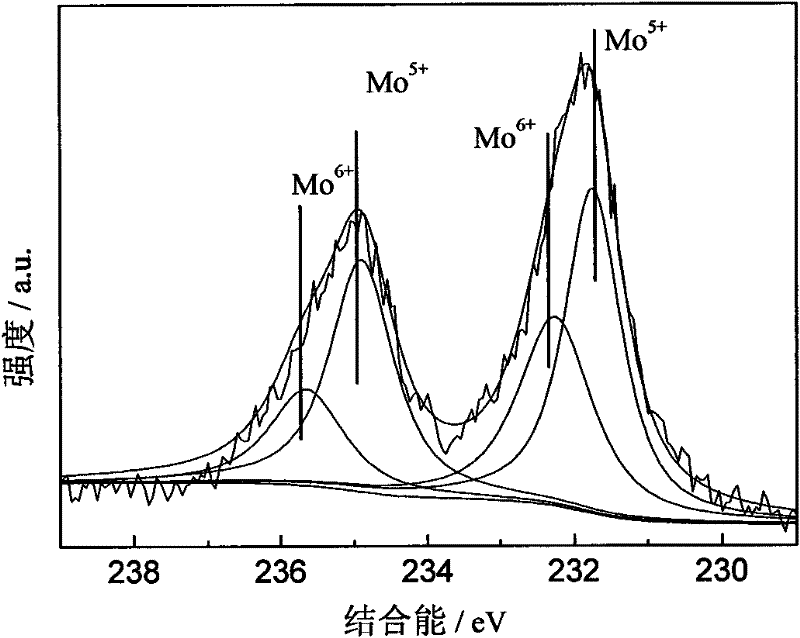

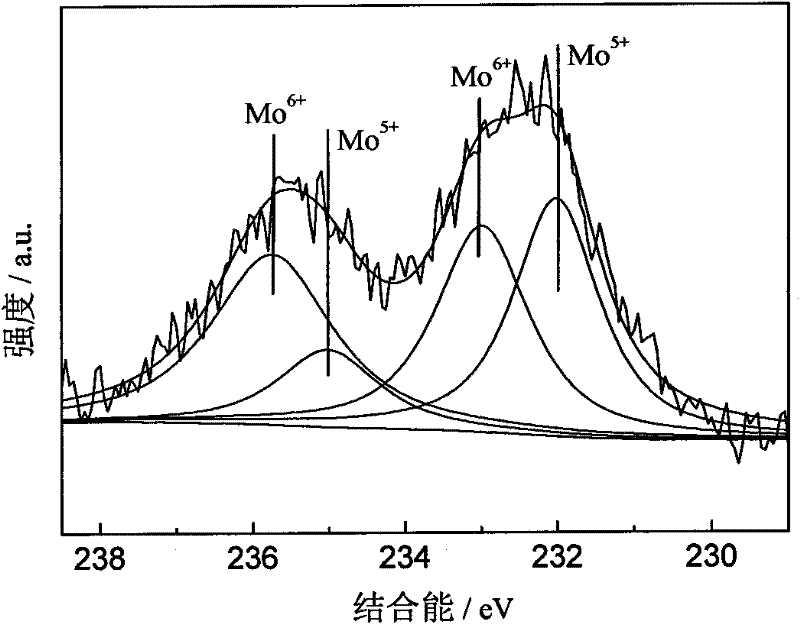

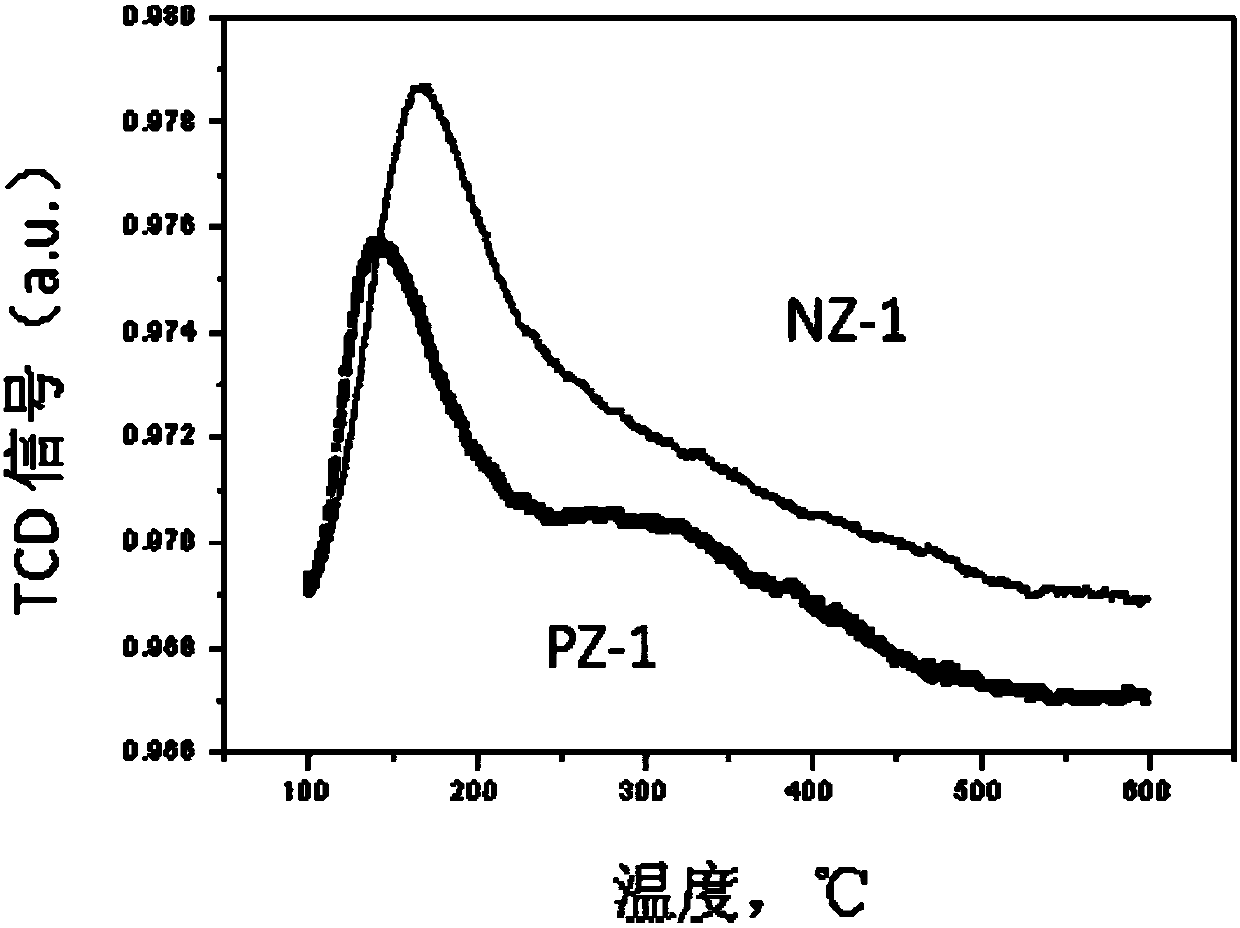

Preparation method for supported Mo-based oxidation and desulfurization catalyst

InactiveCN102294236AHigh activityRealize deep desulfurizationMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPetrochemical

Owner:DALIAN UNIV OF TECH

Double-component modification method of molecular sieve in FCC catalyst and molecular sieve modified through method

Owner:PETROCHINA CO LTD

Lower olefins producing catalyst and method for producing lower olefins using same

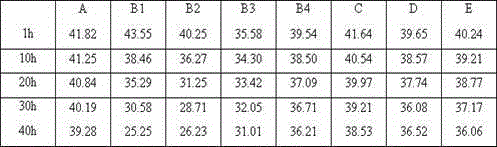

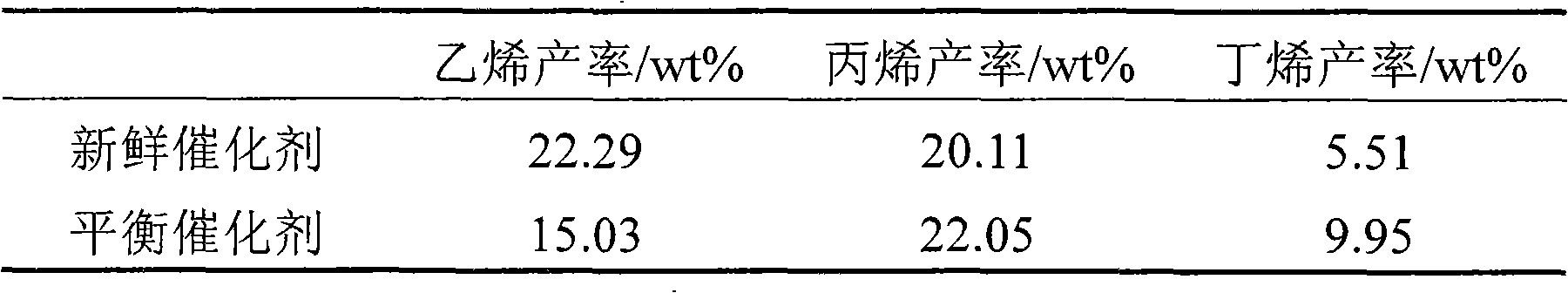

ActiveUS20120116143A1Improve efficiencyHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystPtru catalystOxygen compound

A lower olefin producing catalyst which has high olefin production efficiency and maintains its activity for a long period of time when lower olefins are produced from an oxygen-containing compound, which is a solid catalyst used in producing lower olefins from an oxygen-containing compound, includes a solid-state catalyst component containing an MFI-type zeolite, in which, at a position where the shortest distance to the outer surface is maximum among all positions inside a structure of the solid catalyst, the thickness defined as a distance twice the shortest distance from the point to the outer surface is in a range of from 0.1 to 2.0 mm, and a method for producing lower olefins.

Owner:MITSUBISHI CHEM CORP +1

Method for preparing gasoline rich in isoparaffin from methanol and/or dimethyl ether

InactiveCN106867564AImprove qualityBroaden the application marketMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention relates to a method for preparing gasoline rich in isoparaffin from methanol and / or dimethyl ether. A catalyst used in the method is prepared from a molecular sieve-loaded active metal component. Since the catalyst used in the method has excellent selectivity on isoparaffin in a gasoline fraction (hydrocarbons with a carbon atom number of 5 to 11; and low selectivity on olefins and aromatic hydrocarbons, the composition of the gasoline produced by using the method can meet the national gasoline standard VI in China, or even meet requirements on the contents of aromatic hydrocarbons and olefins in world advanced standards for clean fuels (such as the European standard V and standards for motor gasoline in California of the US). The method provides a feasible technical route for direct acquisition of non-petroleum resources and has good market prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Mesostructured aluminosilicate material made of spherical particles of specific size

ActiveUS20110105300A1High aluminum contentMolecular sieve catalystsOther chemical processesPetrochemistryPolymer chemistry

Owner:INST FR DU PETROLE

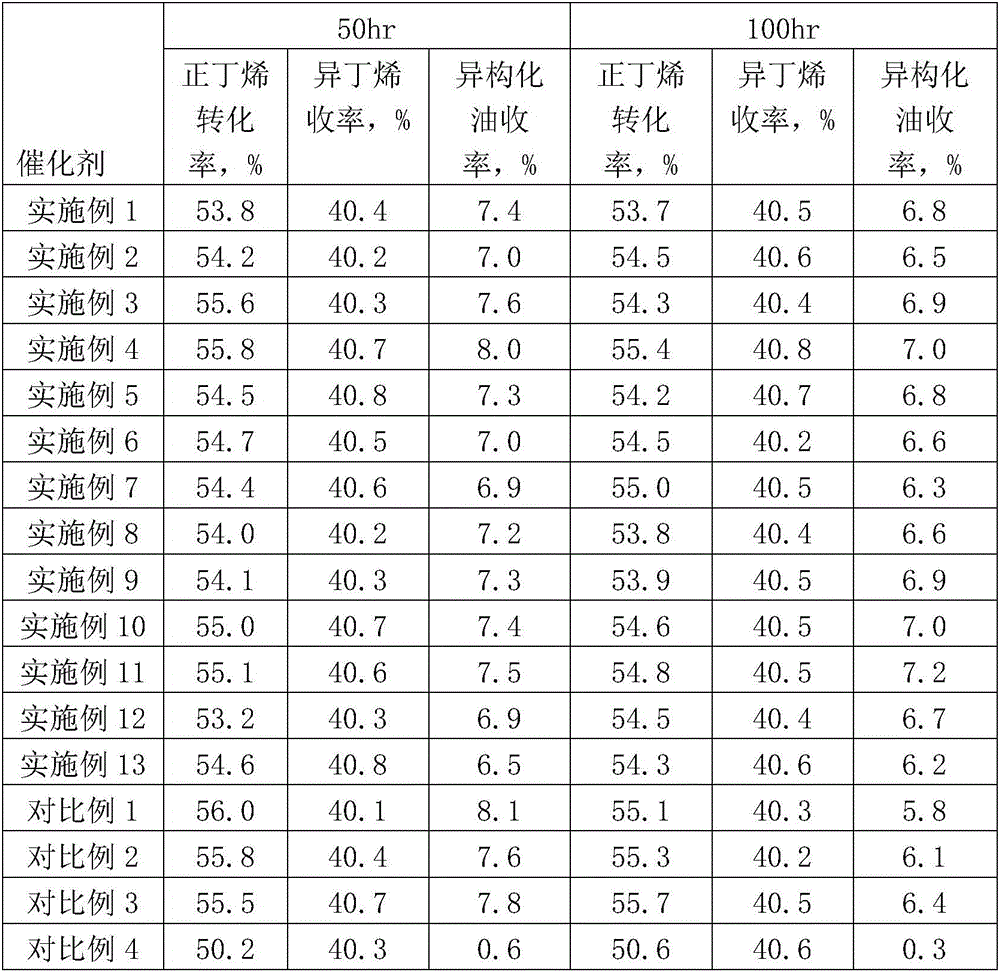

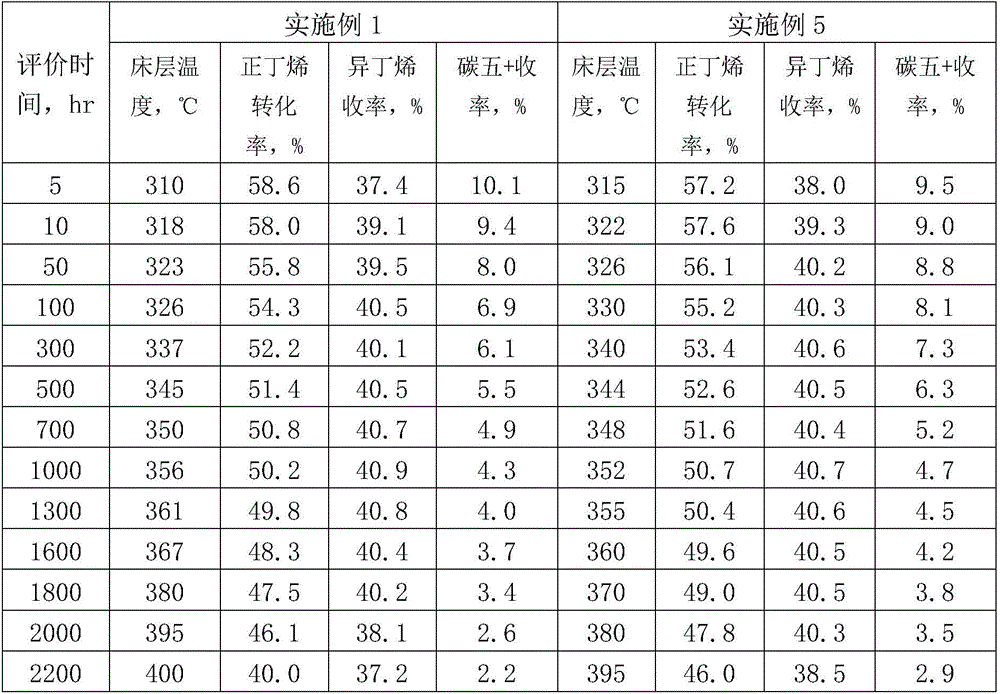

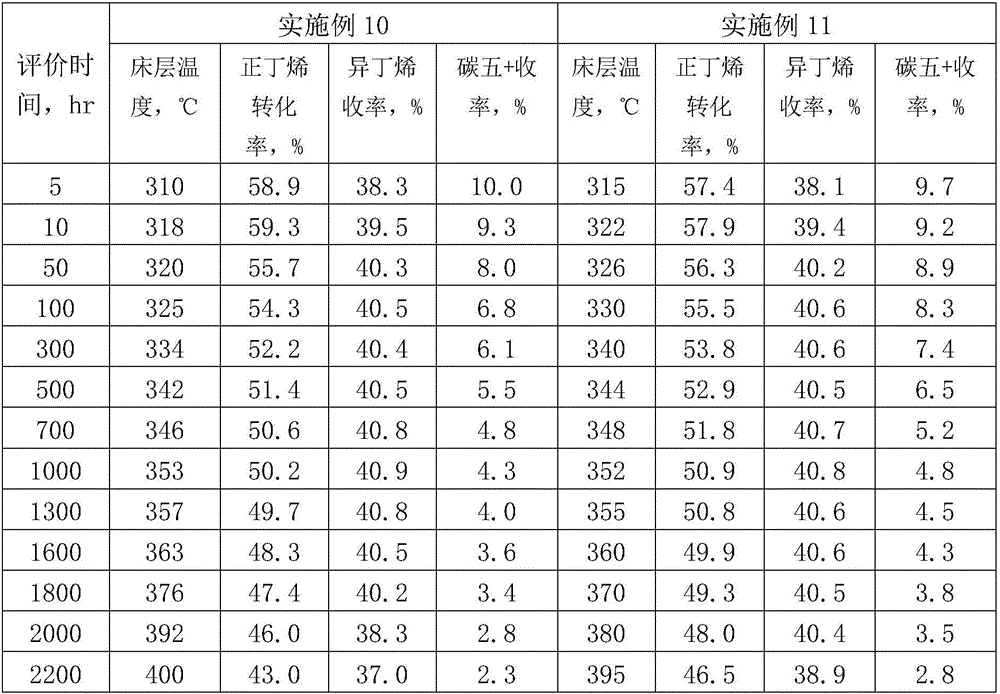

N-alkene isomerization catalyst and preparation method and application thereof

ActiveCN106076408AReduce in quantityReduce cokingHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

Owner:山东迅达化工集团有限公司

Preparation method and application of hierarchical porous molecular sieve-supported PtRu catalyst

ActiveCN107971019AHighly reactive bit density CelsiusOpen cell structureMolecular sieve catalystsOrganic compound preparationMolecular sieveEmulsion

The invention relates to a preparation method for a hierarchical porous molecular sieve-supported PtRu catalyst and a method for reducing 4-nitrophenol. According to the present invention, PtRu alloynano-particles are successfully introduced into microporous channels of a hierarchical porous molecular sieve EMT-FAU / SBA-15 by using of microwave assisted heating and a specific blended microcrystalline emulsion synthetic method, and the PtRu alloy nano-particles prepared by the method has relatively high stability because of confinement effect of the molecular sieve, meanwhile, the prepared PtRu / EMT-FAU / SBA-15 catalyst shows excellent catalytic performance in a reduction reaction of 4-nitrophenol, and results show that the element proportions in PtRu alloy plays an important role in the reduction reaction of 4-nitrophenol.

Owner:UNIV OF JINAN

Additive for maximizing light olefins in fcc and process for preparation thereof

InactiveUS20090099006A1Improve performanceCatalytic crackingMolecular sieve catalystsAlkaline earth metalPhosphate

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Catalyst for pyrolysis C9 two-stage hydrogenation and preparation method thereof

Owner:WUHAN KELIN FINE CHEM

Preparation method of catalyst for methyl difluoroacetate hydrogenation to produce difluoroethanol

Owner:格润化学(东营)有限公司

Monolithic catalyst with organic waste gas selective adsorption and catalytic oxidation functions as well as preparation method and application thereof

ActiveCN112169827AHigh load rateImprove firmnessGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap