SAPO molecular sieve material with a layered structure and preparation method thereof

A technology of molecular sieve and pore size distribution, which is applied in the direction of molecular sieve catalyst, molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc. It can solve the problems of poor diffusion performance of SAPO molecular sieve, and achieve easy control, high crystallinity, and easy preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

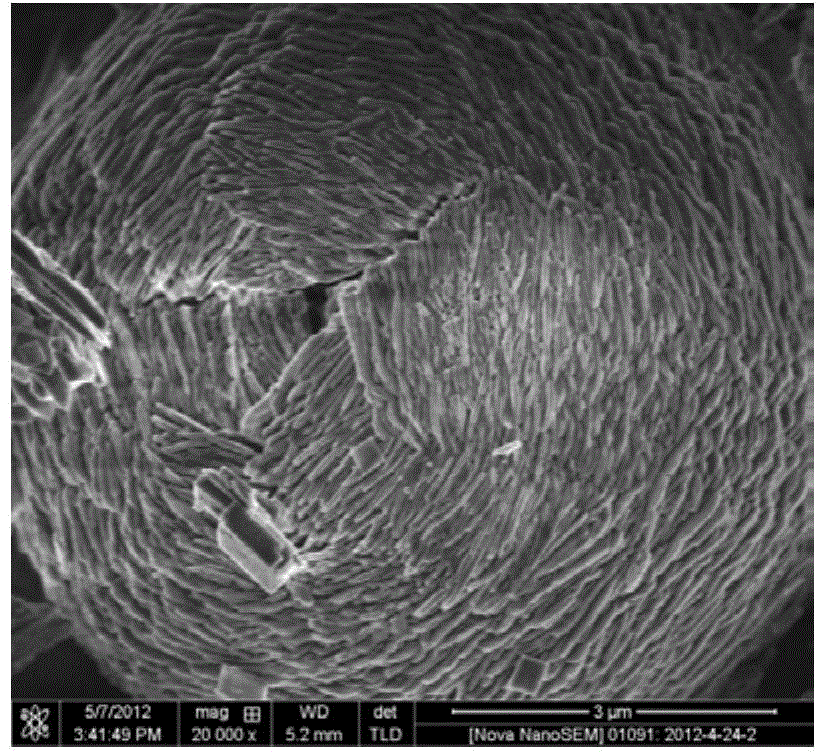

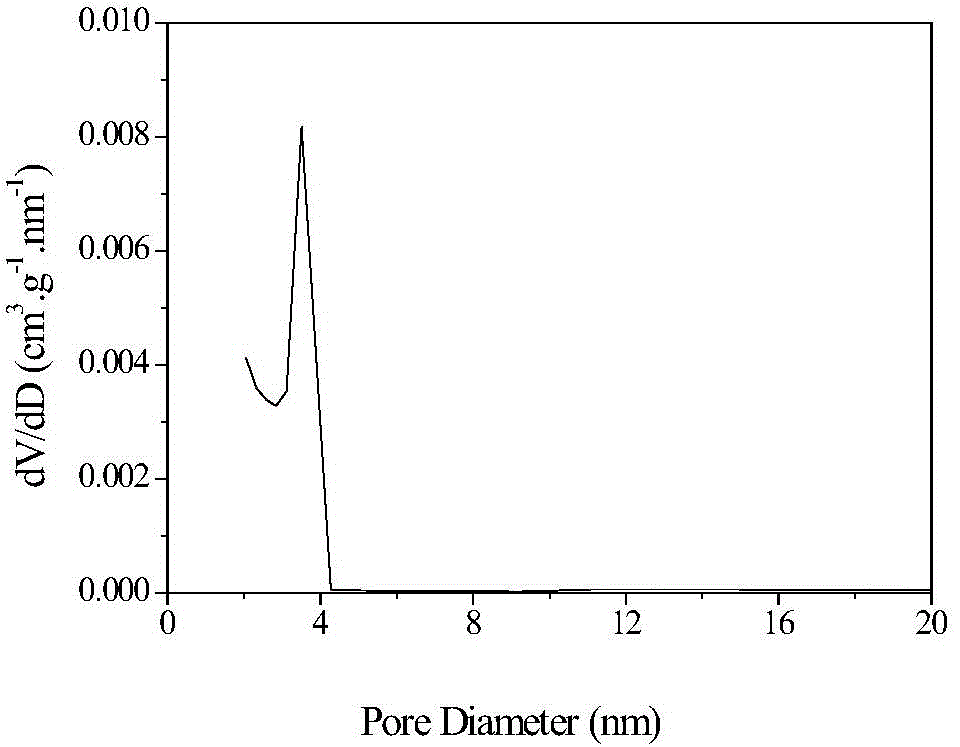

Image

Examples

Embodiment 1

[0024] Mix 1 gram of P123 (tri-block copolymer) and 45 grams of deionized water evenly, then add 12.3 grams of aluminum isopropoxide and 11.97 grams of orthophosphoric acid (85% by weight) to it, and form solution a after fully stirring; 60 grams Tetraethylammonium hydroxide (25% by weight) and 6 grams of silica sol (40% by weight) were mixed uniformly to form solution b; a and b were mixed and stirred at room temperature for 6 hours to obtain the crystallization solution of synthetic SAPO-34 molecular sieve; Stir and age the prepared crystallization solution at room temperature for 24 hours, put the aged crystallization solution into a crystallization kettle lined with polytetrafluoroethylene, and crystallize at 200°C for 24 hours;

[0025] The weight ratio of each component is: R1 / Al2O3=0.2; R2 / Al2O3=10; H2O / Al2O3=7; SiO2 / Al2O3=0.4; substance) and TEAOH (tetraethylammonium hydroxide).

[0026] The obtained product was washed, centrifuged, and dried at 110°C to obtain a

Embodiment 2~14

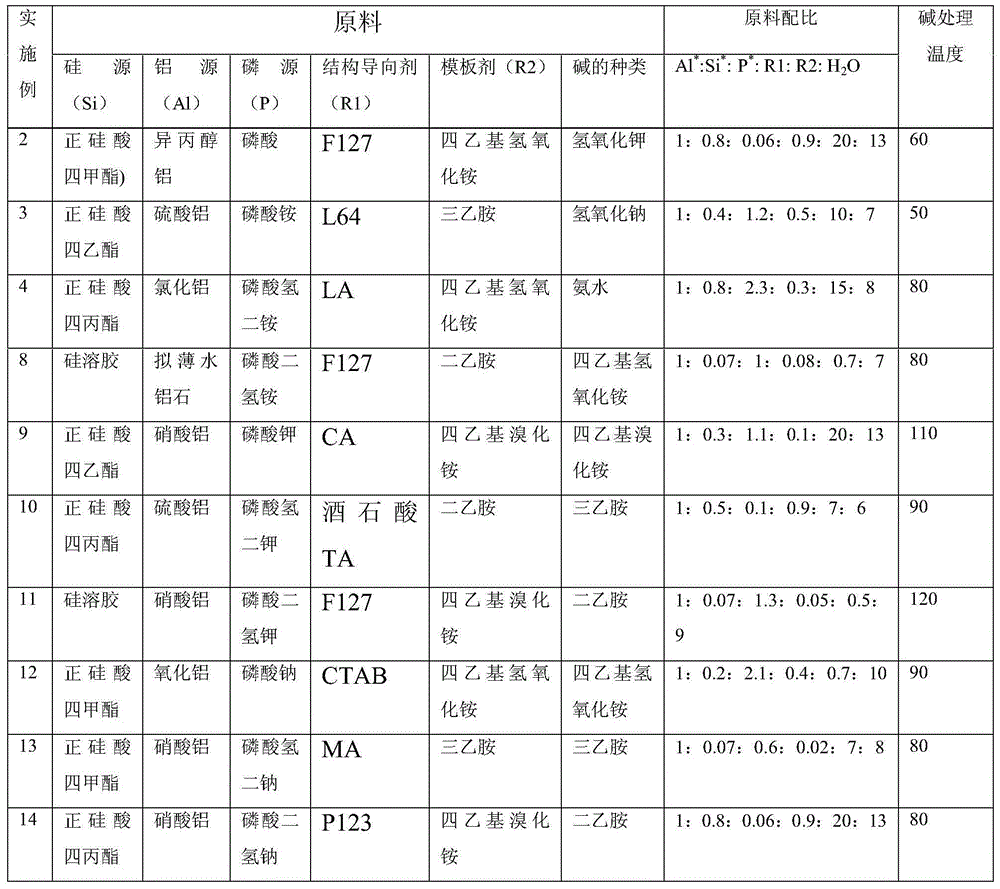

[0028] According to the various steps and conditions of [Example 1], a molecular sieve with a multi-level pore structure is prepared, only changing the ratio of raw materials (Table 1), the type of structure-directing agent R2 (polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight) 12000, F127), polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 2900, L64), cetyltrimethylammonium bromide CTAB, citric acid CA, lactic acid LA, tartaric acid TA, malic acid MA), Parameters such as the type of alkali and alkali treatment temperature are specifically listed in Table 1. The characterization of the synthesized product shows that it has a crystal structure similar to that of [Example 1] and the product, and its specific physical and chemical parameters are shown in Table 2.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

Embodiment 15

[0034] A fixed-bed catalytic reaction device is adopted, and the reactor is a stainless steel tube. The catalyst prepared in Example 1 and the cubic catalyst prepared by the traditional method are evaluated for the reaction activity of methanol conversion to light olefins. The process conditions used for the investigation are: catalyst loading 0.5 g, the reaction temperature is 450°C, the reaction pressure is 0.1MPa, the water / raw material weight ratio is 0.25, and the weight space velocity is 1h -1 . Online analysis of all products. The evaluation results are shown in Table 3.

[0035] table 3

[0036]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap