Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Bulk chemical production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

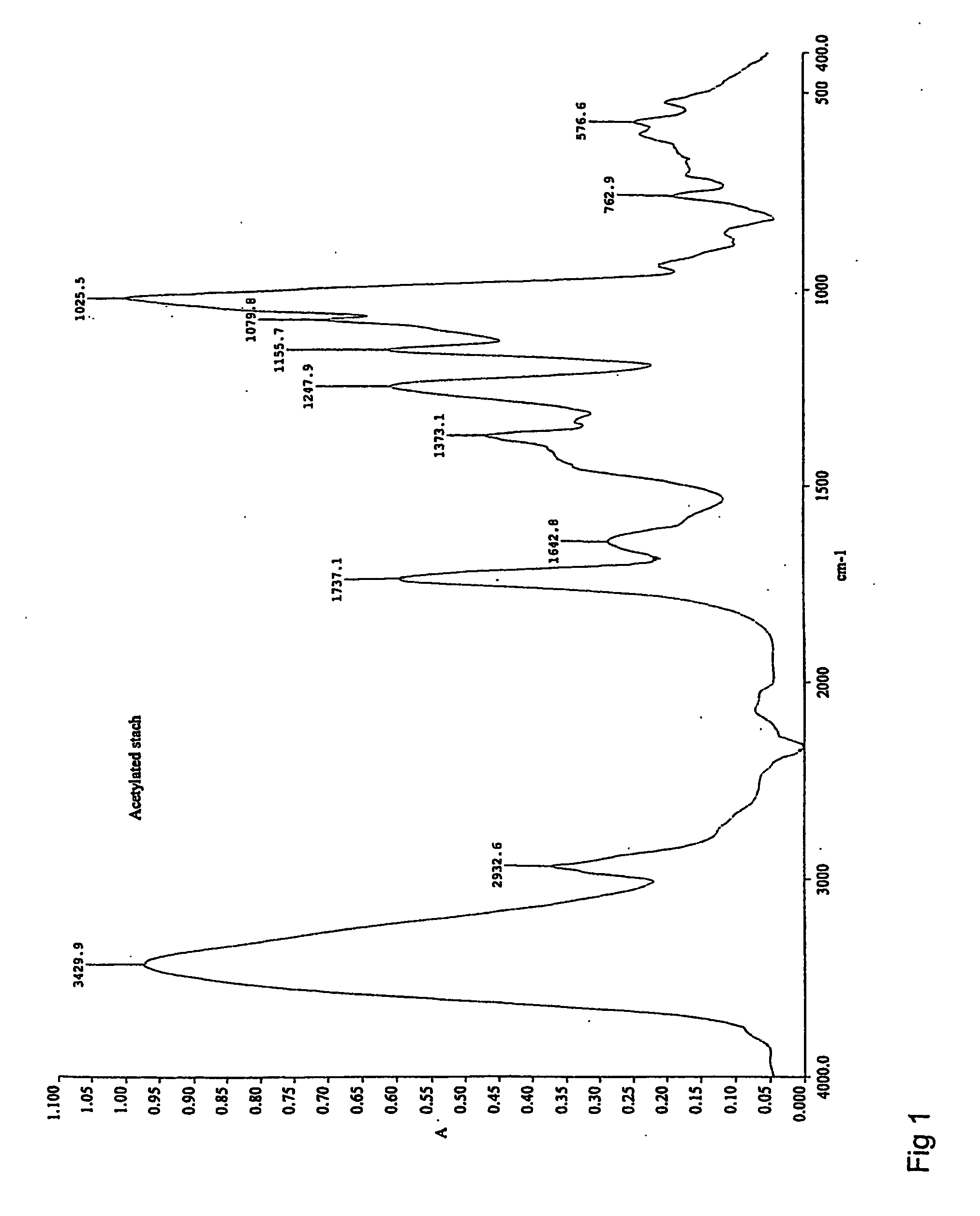

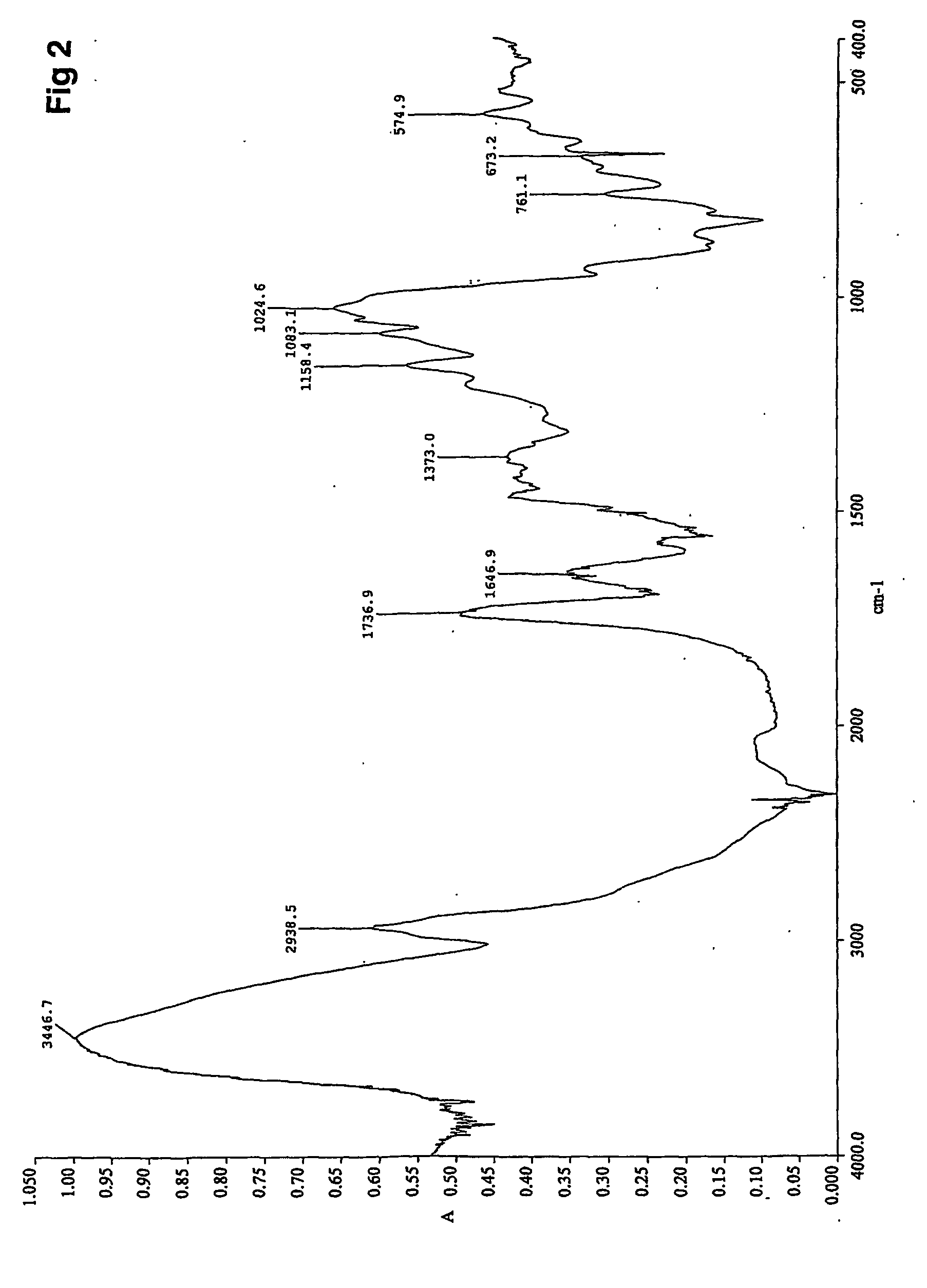

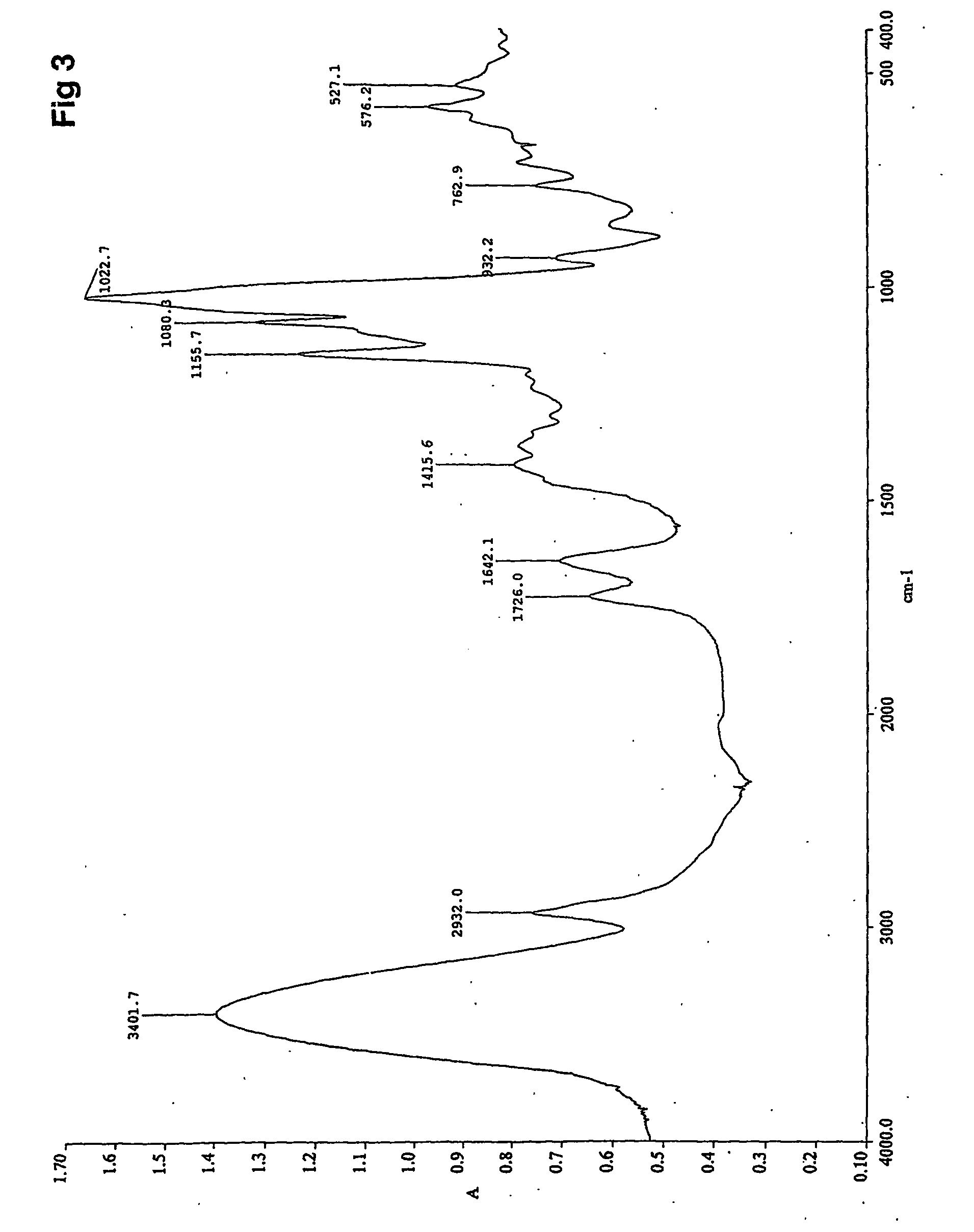

Starch esterification method

InactiveUS20070073051A1Efficient and gentle and environmentally benign preparationSimple and economical separationBulk chemical productionDissolutionSolvent

Owner:VESA MYLLYMAKI +1

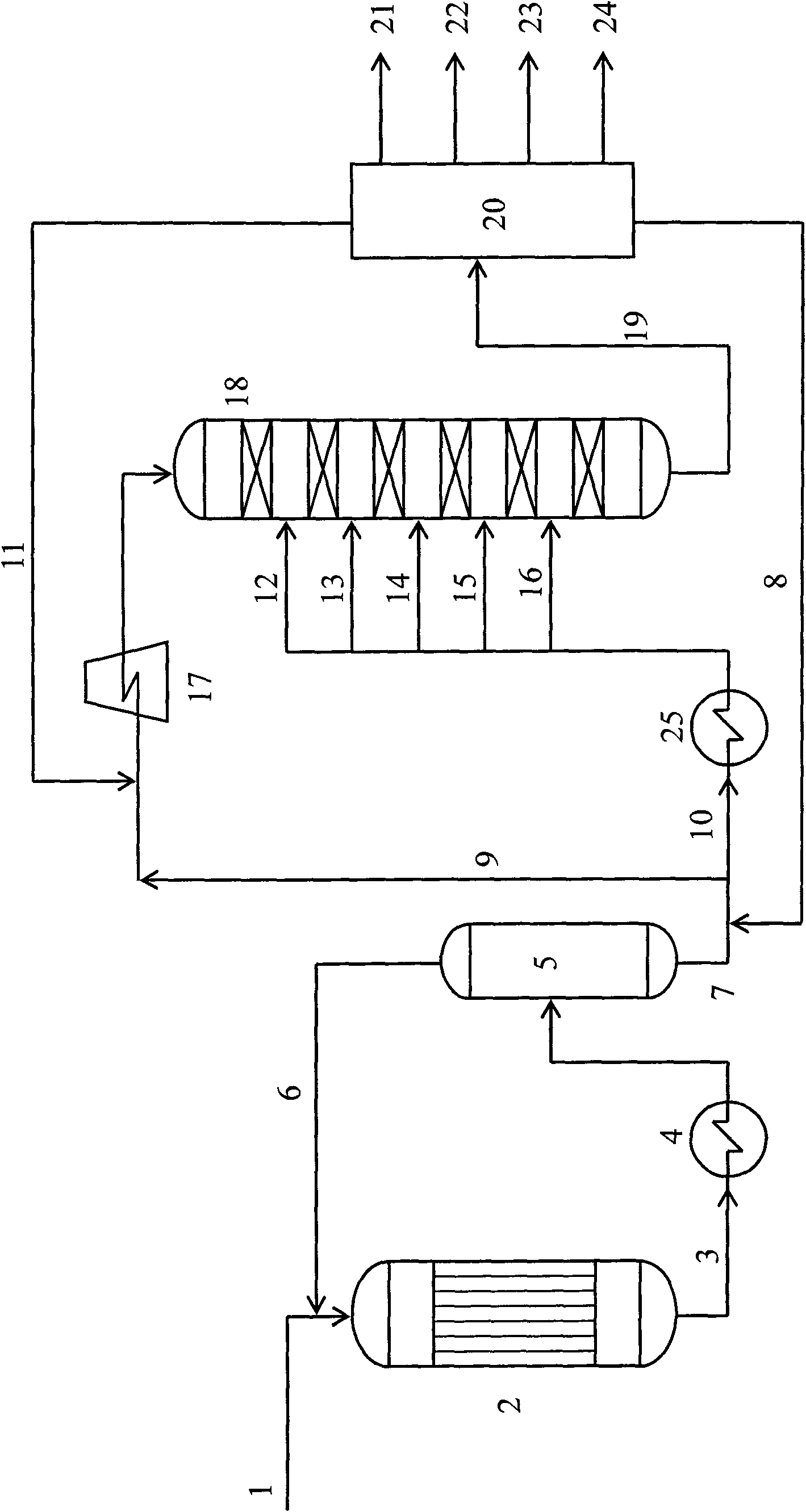

Membrane-Supported Catalysts and the Process of Oxidative Dehydrogenation of Ethane Using the Same

ActiveUS20130072737A1Heterogenous catalyst chemical elementsHydrocarbon preparation catalystsParaffin waxMixed oxide

The present invention provides a continuous process for the oxidative dehydrogenation of ethane to ethylene using a mixed oxide catalyst supported onto a ceramic membrane by supplying an oxygen containing gas (air or pure oxygen) and pure ethane to the opposite sides of the membrane, so that the paraffin and the oxygen do not directly mix in the reactor.

Owner:NOVA CHEM (INT) SA

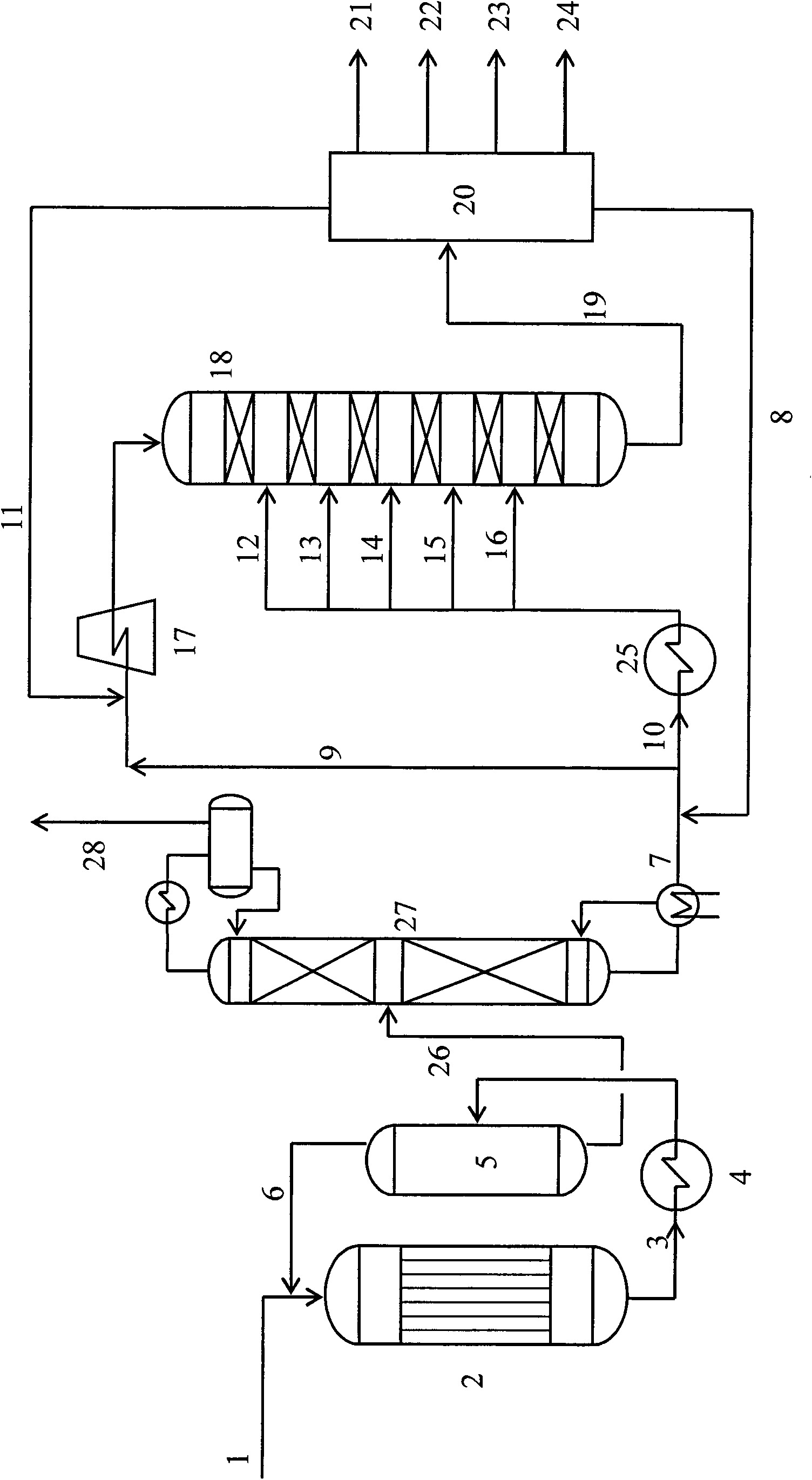

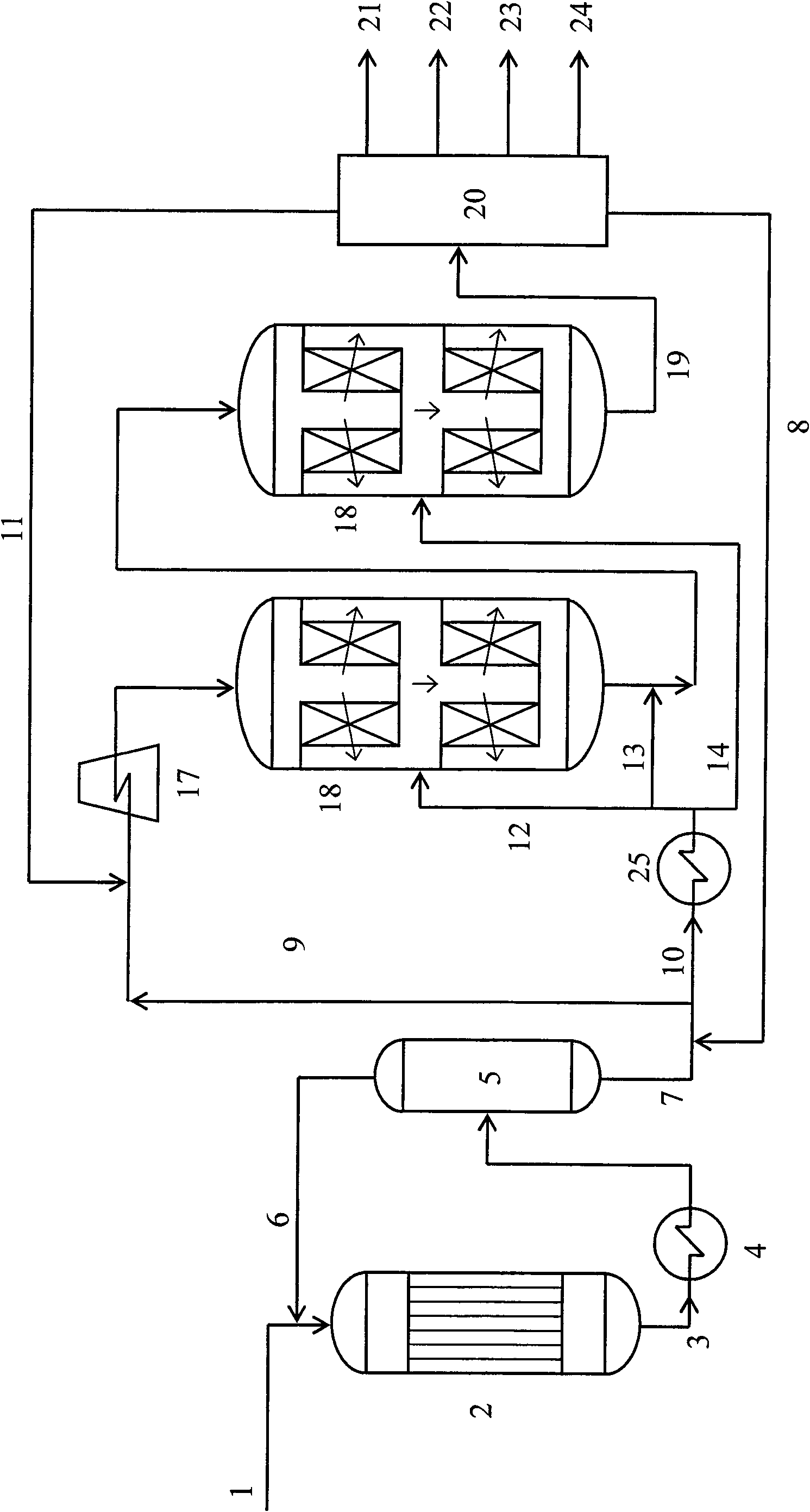

Method for directly preparing propylene from crude methanol

ActiveCN101659592ADistillation purification process omittedReduce energy consumptionHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveDiluent

Owner:WISON ENG

Multistage porous ZSM-5 molecular sieve and preparation method thereof as well as method for preparing PX catalyst using same

ActiveCN108178164AReduce economic costsThe synthesis process is simpleMolecular sieve catalystsMolecular sieve catalystMolecular sievePolyol

The invention relates to a multistage porous ZSM-5 molecular sieve. The molecular sieve comprises the following raw materials: a silicon source, an aluminum source, a template agent, water, an alkalisource, polyether polyol, a seed crystal, a cosolvent and a mineralizer. The invention provides a preparation method of the multistage porous ZSM-5 molecular sieve with a high silicon-aluminum ratio.The synthesis process is simple, and cheap template agent and porous agent are adopted, so that the economic cost of the molecular sieve is reduced. The ZSM-5 molecular sieve obtained by the method has a multistage pore channel structure, the relative crystallinity is higher than 90%, and the specific surface area is greater than 420m<2> / g.

Owner:REZEL CATALYSTS CORP

Ethylene oligomerization catalyst and use thereof

InactiveUS20110124938A1Easy to synthesizeLittle catalyst deteriorationHydrocarbons from unsaturated hydrocarbon additionCatalyst regeneration/reactivationOligomerPtru catalyst

Ethylene is oligomerized with a catalyst in which nickel is supported on a support containing silica and alumina. The catalyst has little deterioration over long periods and affords oligomers with high productivity.The ethylene oligomerization catalyst includes a support and a nickel compound supported on the support, the support including silica and alumina, and the amount of nickel supported is in the range of 0.0001 to 1 wt % based on the weight of the support, and the molar ratio of silica to alumina in the support (SiO2 / Al2O3) is in the range of 100 to 2000. In a process of the invention, ethylene is oligomerized with use of the catalyst.

Owner:MITSUI CHEM INC

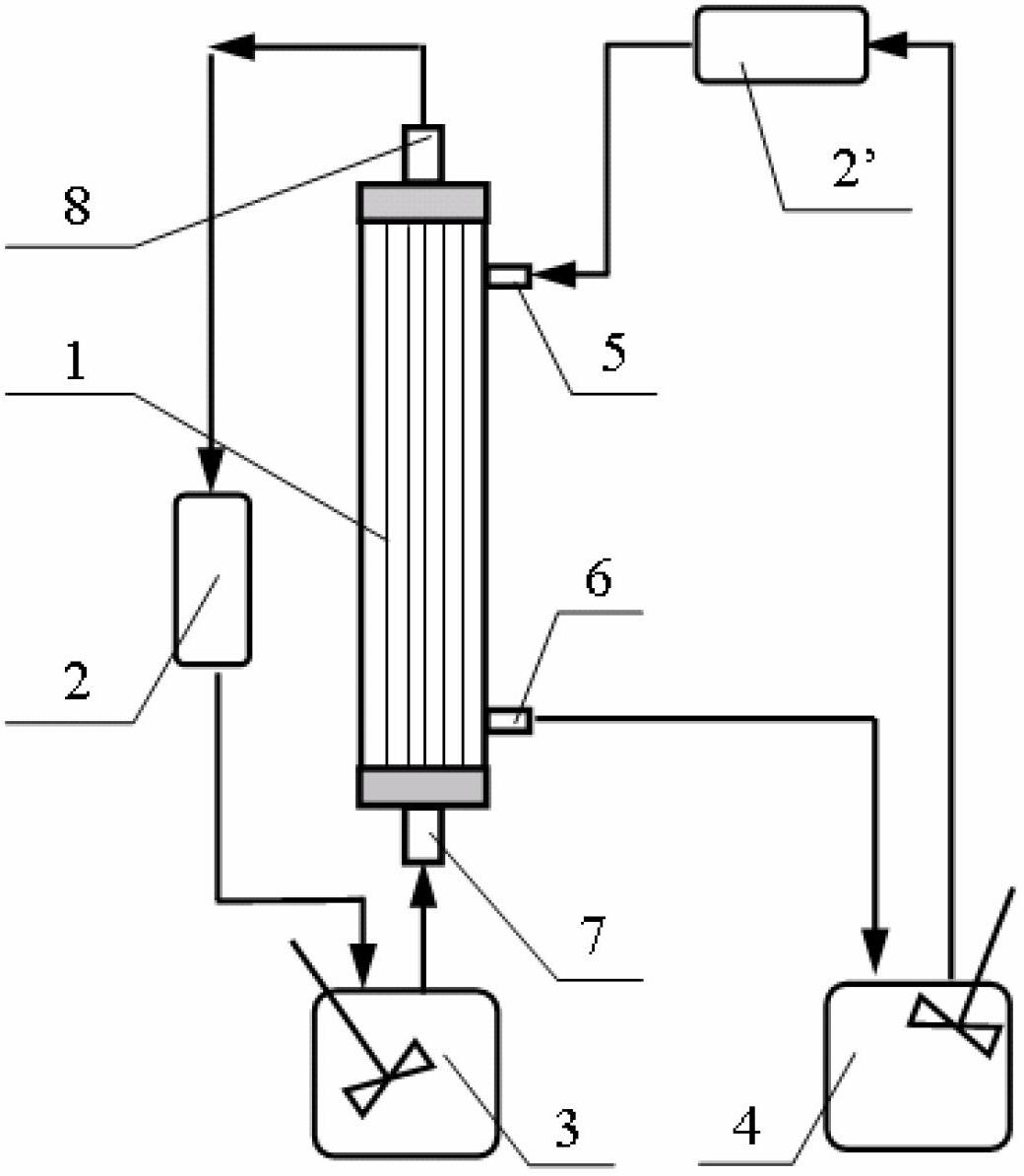

Method for separating aromatic hydrocarbon from alkane by ionic liquid and membrane process coupling technology

InactiveCN102688708AHigh separation selectivityAchieve the purpose of separationSemi-permeable membranesLiquid solutions solvent extractionAlkaneAromatic hydrocarbon

Owner:BEIJING UNIV OF CHEM TECH

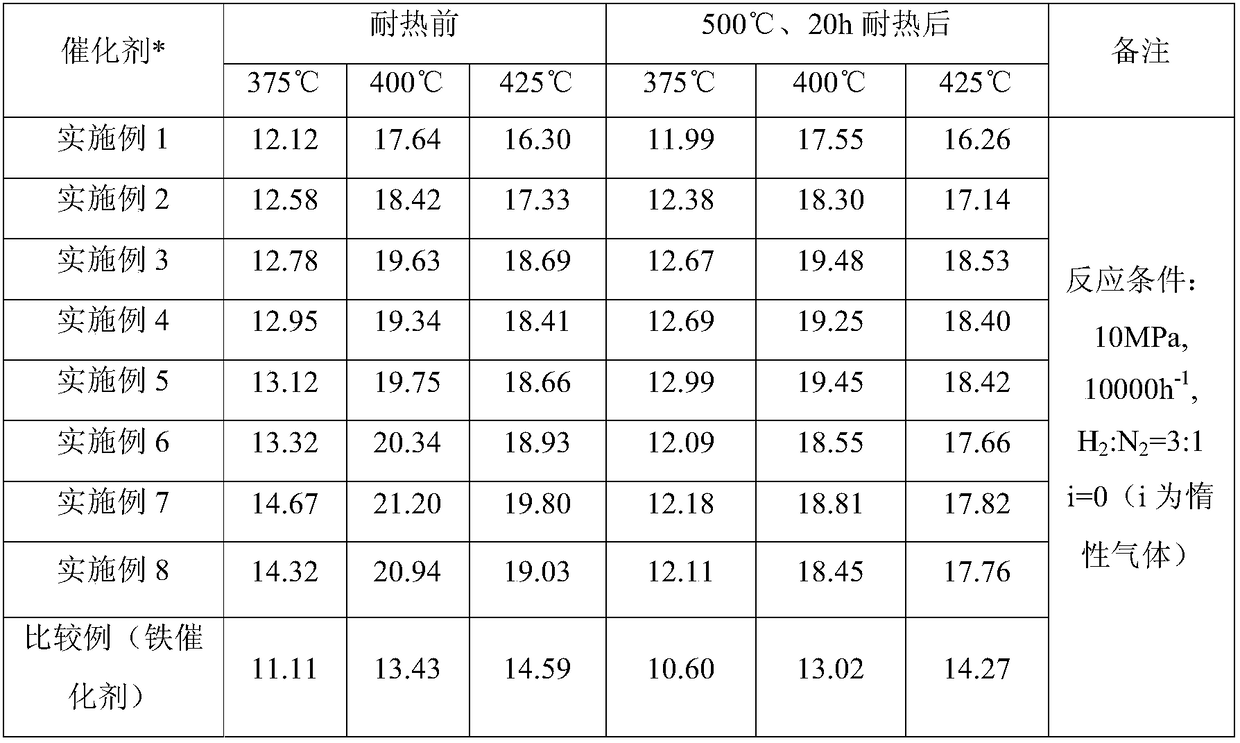

Activated carbon-supported ruthenium-based ammonia synthetic catalyst and preparation method thereof

ActiveCN108525663AGood chemical stabilityHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPotassium

Owner:福建省福大百阳化工科技有限公司

Furfural catalytic hydrogenation method under supercritical carbon dioxide and method for preparing catalysts

InactiveCN104059035AAchieve conversionNo carbon depositsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonLiquid product

Owner:ZHEJIANG UNIV

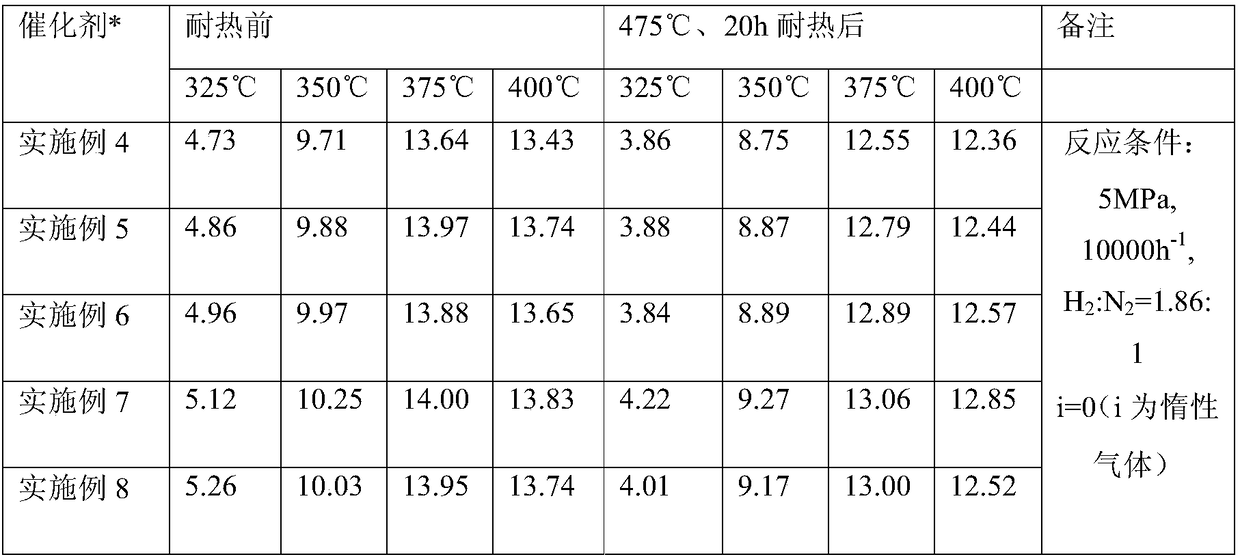

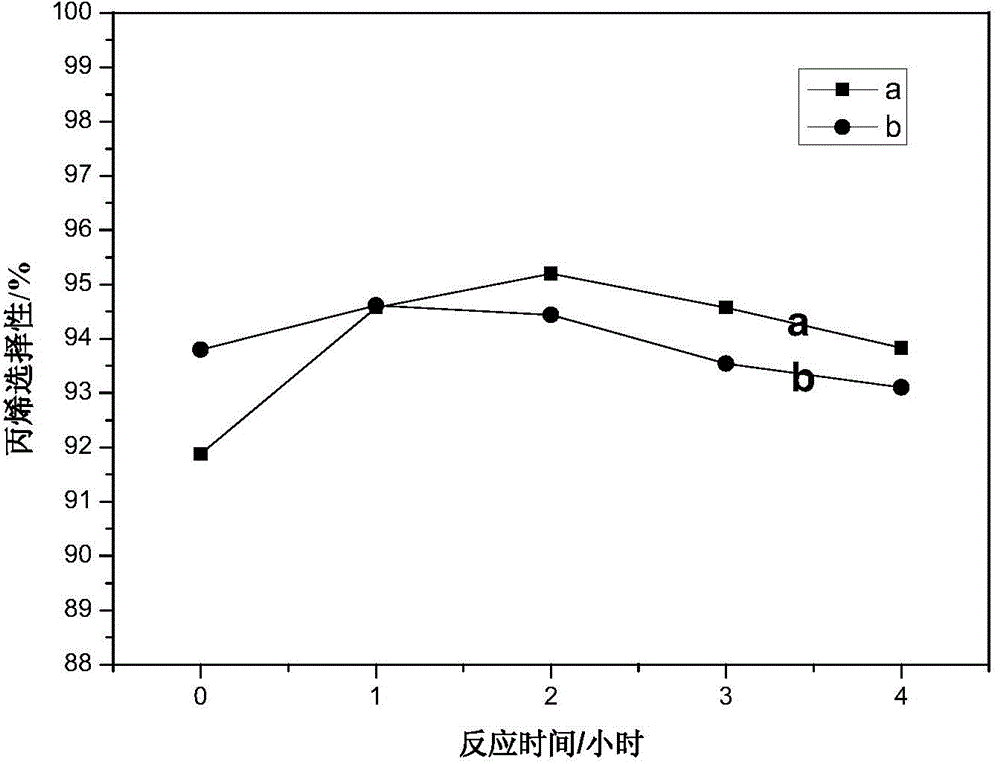

Catalyst for production of propylene through catalytic dehydrogenation of propane, and preparation method thereof

InactiveCN104941640AHigh selectivitySimple processHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

Owner:NANKAI UNIV

Method for extracting valuable metal elements from coal gangue

ActiveCN113061728ALow chemical stabilityAchieve primary separationSilicaCarbon compoundsFerric hydroxideCalcium silicate

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

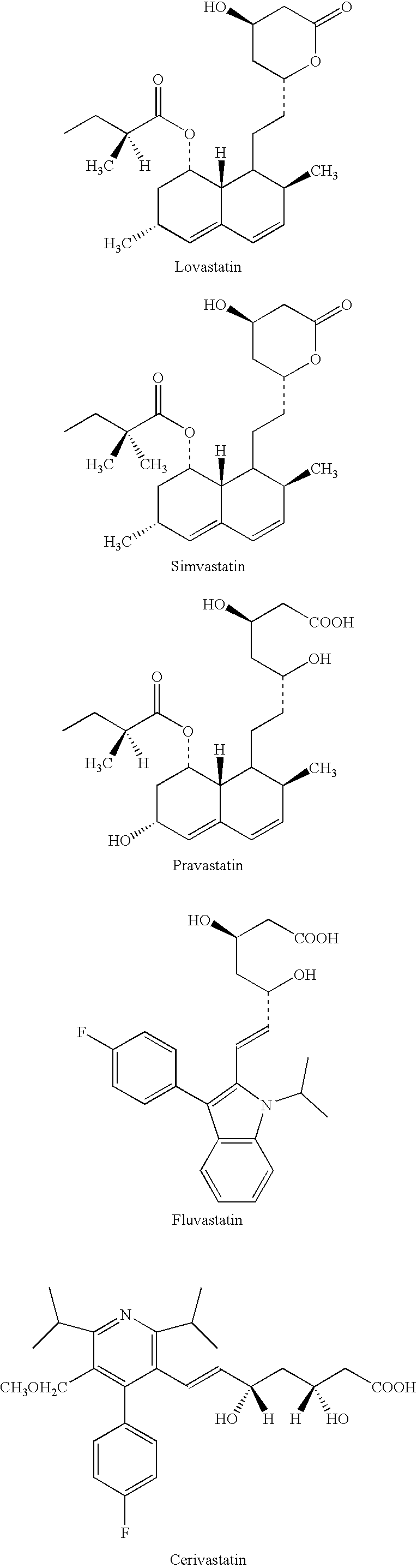

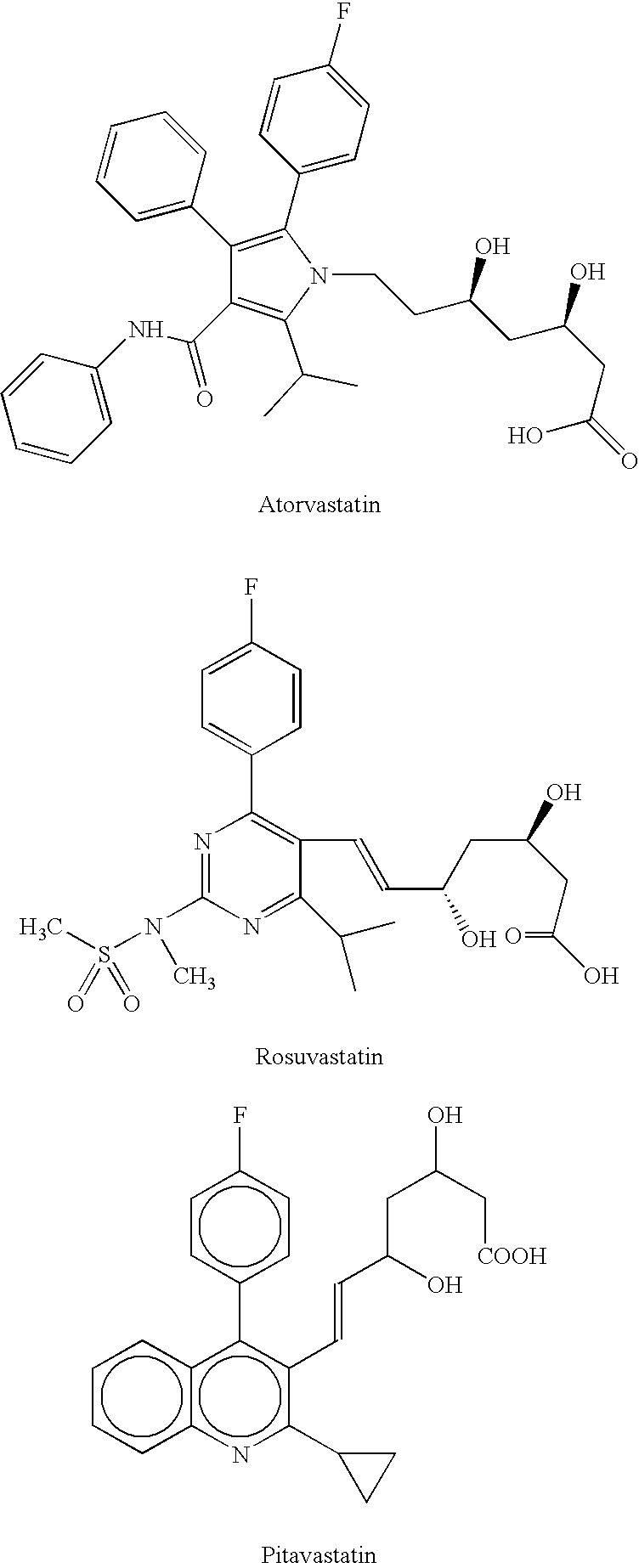

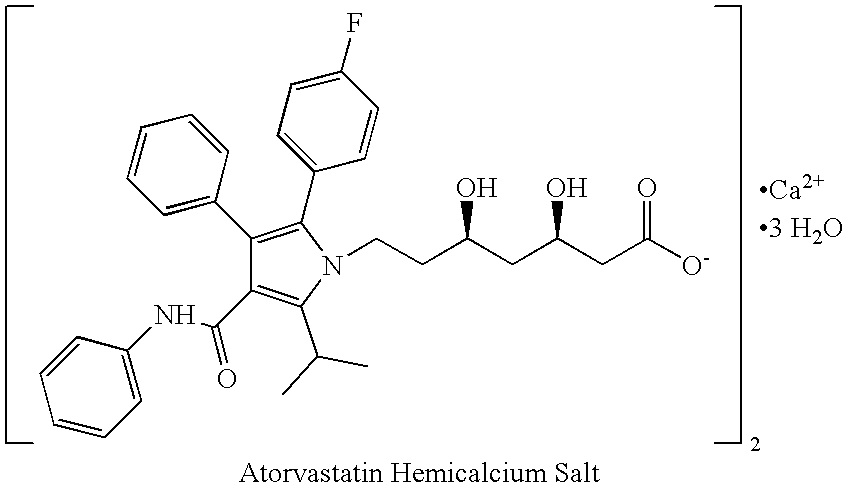

Processes for preparing calcium salt forms of statins

Owner:TEVA PHARMA IND LTD +1

Super heat insulation coating loaded with nano titanium dioxide and preparation method of super heat insulation coating

InactiveCN104610847ADelay the aging processImprove hydrophilicityEpoxy resin coatingsBulk chemical productionEpoxySilicon dioxide

Owner:WUHU BAOYI AMUSEMENT EQUIP

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

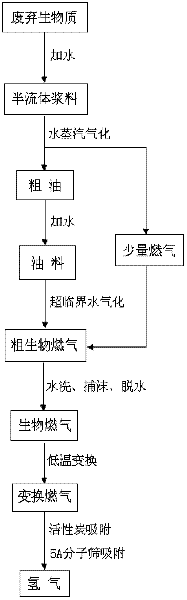

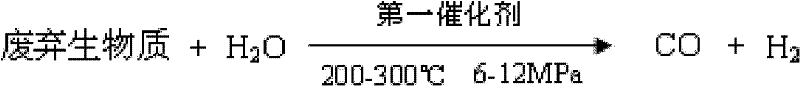

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

Lower olefins producing catalyst and method for producing lower olefins using same

ActiveUS20120116143A1Improve efficiencyHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystPtru catalystOxygen compound

A lower olefin producing catalyst which has high olefin production efficiency and maintains its activity for a long period of time when lower olefins are produced from an oxygen-containing compound, which is a solid catalyst used in producing lower olefins from an oxygen-containing compound, includes a solid-state catalyst component containing an MFI-type zeolite, in which, at a position where the shortest distance to the outer surface is maximum among all positions inside a structure of the solid catalyst, the thickness defined as a distance twice the shortest distance from the point to the outer surface is in a range of from 0.1 to 2.0 mm, and a method for producing lower olefins.

Owner:MITSUBISHI CHEM CORP +1

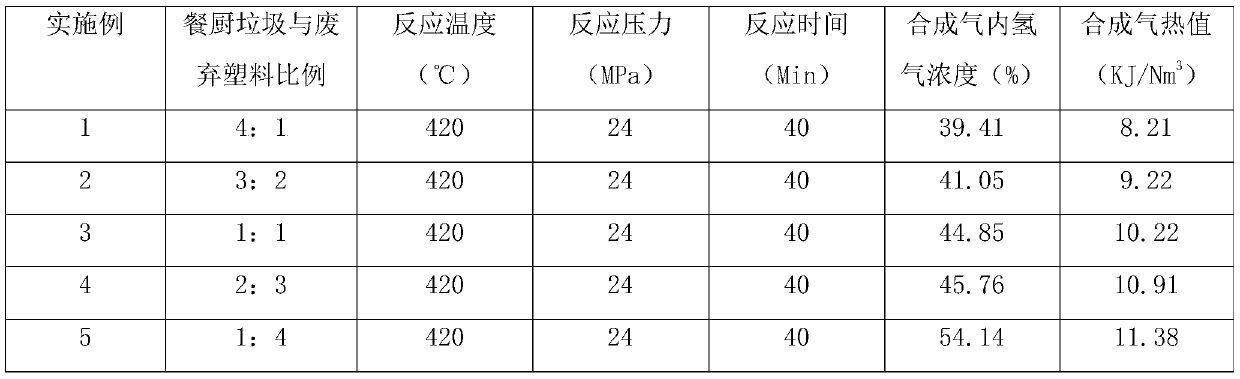

Combined method for treating kitchen waste and waste plastics to prepare hydrogen-rich fuel gas

InactiveCN110643392AEasy to handleIncrease the concentration of hydrogenGaseous fuelsGasification processes detailsSyngasAir pump

Owner:ZHEJIANG UNIV OF TECH

Process for producing polyethylene

The present invention relates to a process for producing ethylene copolymers in a multistage process comprising at least one slurry phase polymerization stage and at least one gas phase polymerization stage in the presence of Ziegler Natta catalyst comprising a solid catalyst component, a cocatalyst of a compound of group 13 metal and an external additive selected from alkoxysilanes of formula (I) R1nSi(OR2)4-n, (I) where n is an integer 0 to 3, each R1 are equal or different and are selected among H, halogen, alkyl groups of 1 to 6 10 carbon atoms optionally substituted with one or more halogen atoms, alkenyl groups of 2 to 6 carbon atoms optionally substituted with one or more halogen atoms, and aryl groups of 6 to 12 carbon atoms optionally substituted with one or more halogen atoms, or the R1 groups can form with the Si atom they are linked to a ring of 3 to 8 ring atoms, provided that all R1 are not hydrogen, R2 are equal or different and are selected among alkyl groups of 1 to 6 carbon atoms optionally substituted with one or more halogen atoms, alkenyl groups of 2 to 6 carbon atoms optionally substituted with one or more halogen atoms, and aryl groups of 6 to 12 carbon atoms optionally substituted with one or more halogen atoms, or the OR2 groups can form with the Si atom they are linked to a ring of 3 to 8 ring atoms, halogen is Br, Cl or F. The invention further relates to the catalysts and use thereof in said multistage process r for producing ethylene copolymers having melt flow rate ratio FRR21 / 5 at least 40 and / or polydispersity index PDI of at least 27.

Owner:BOREALIS AG

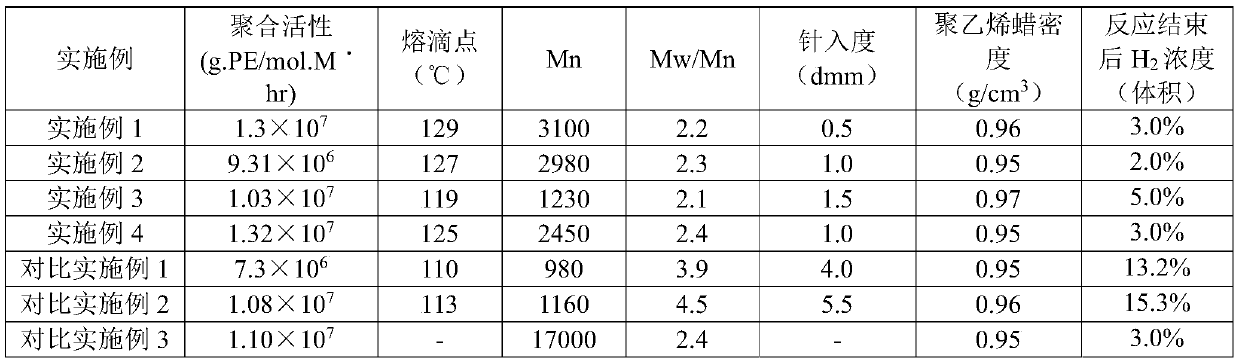

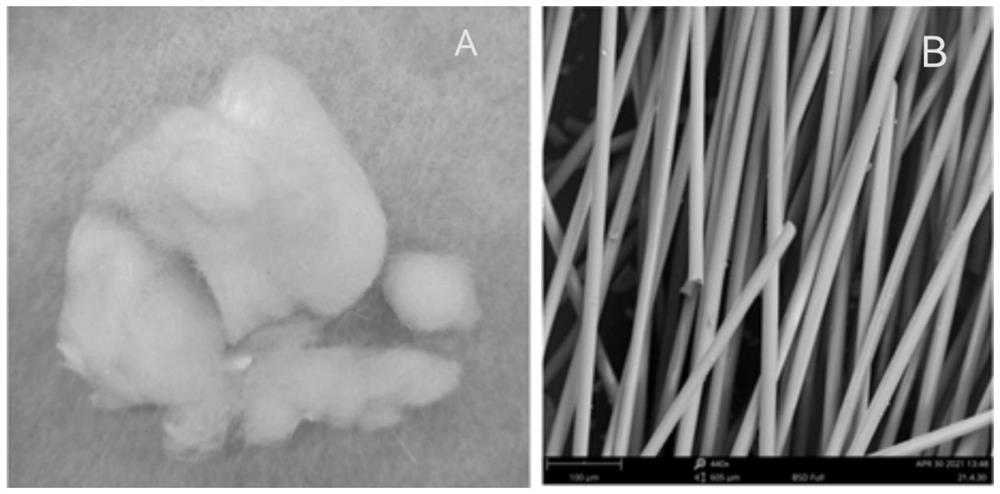

Metallocene catalyst component for preparing polyethylene wax and application thereof

Owner:山东清河化工科技有限公司

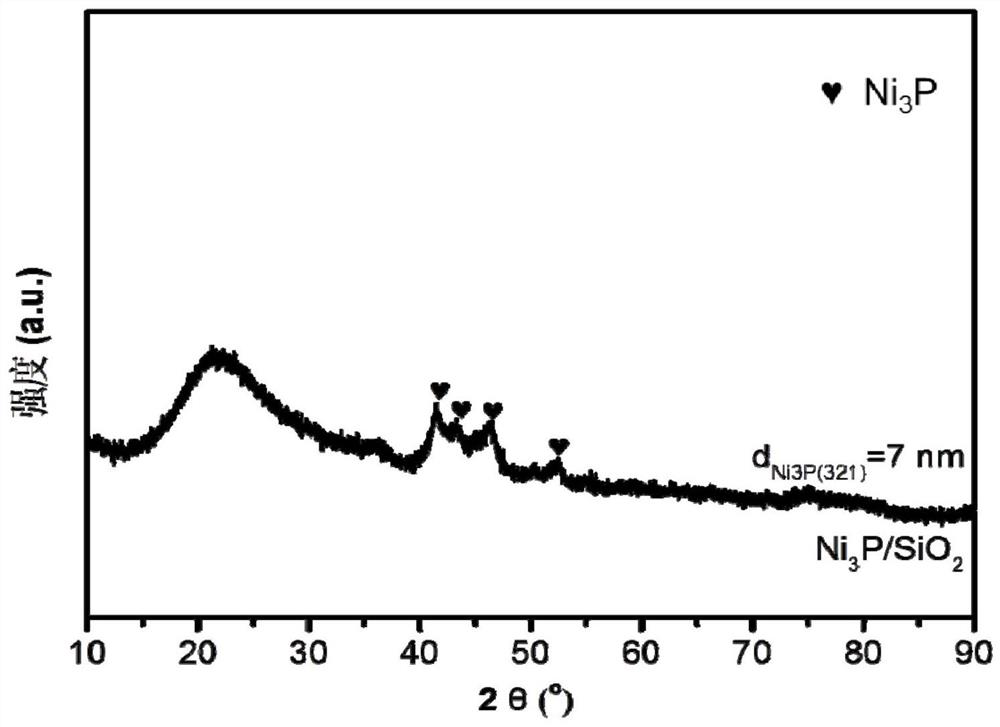

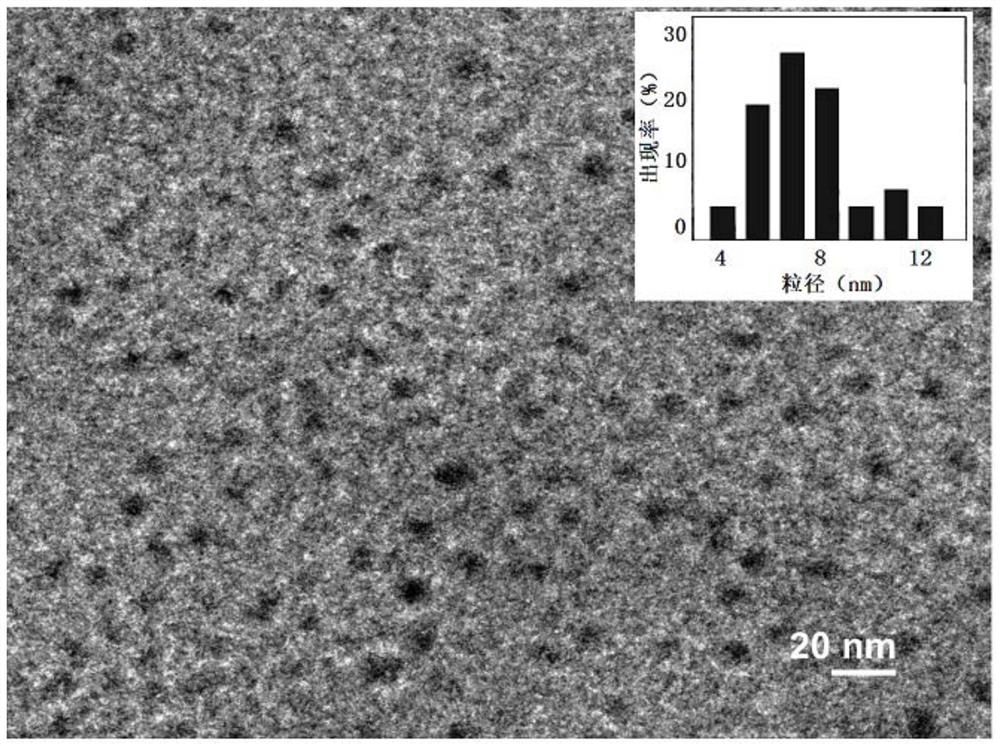

Ni3P/SiO2 catalyst as well as preparation method and application thereof

ActiveCN113145144AHigh selectivityAvoid signs of inactivationPhysical/chemical process catalystsOrganic compound preparationPtru catalystCombinatorial chemistry

Owner:EAST CHINA NORMAL UNIV

Recycling method of epoxy resin composite material, obtained glass fiber and application of glass fiber

Owner:GUANGDONG POWER GRID CO LTD +1

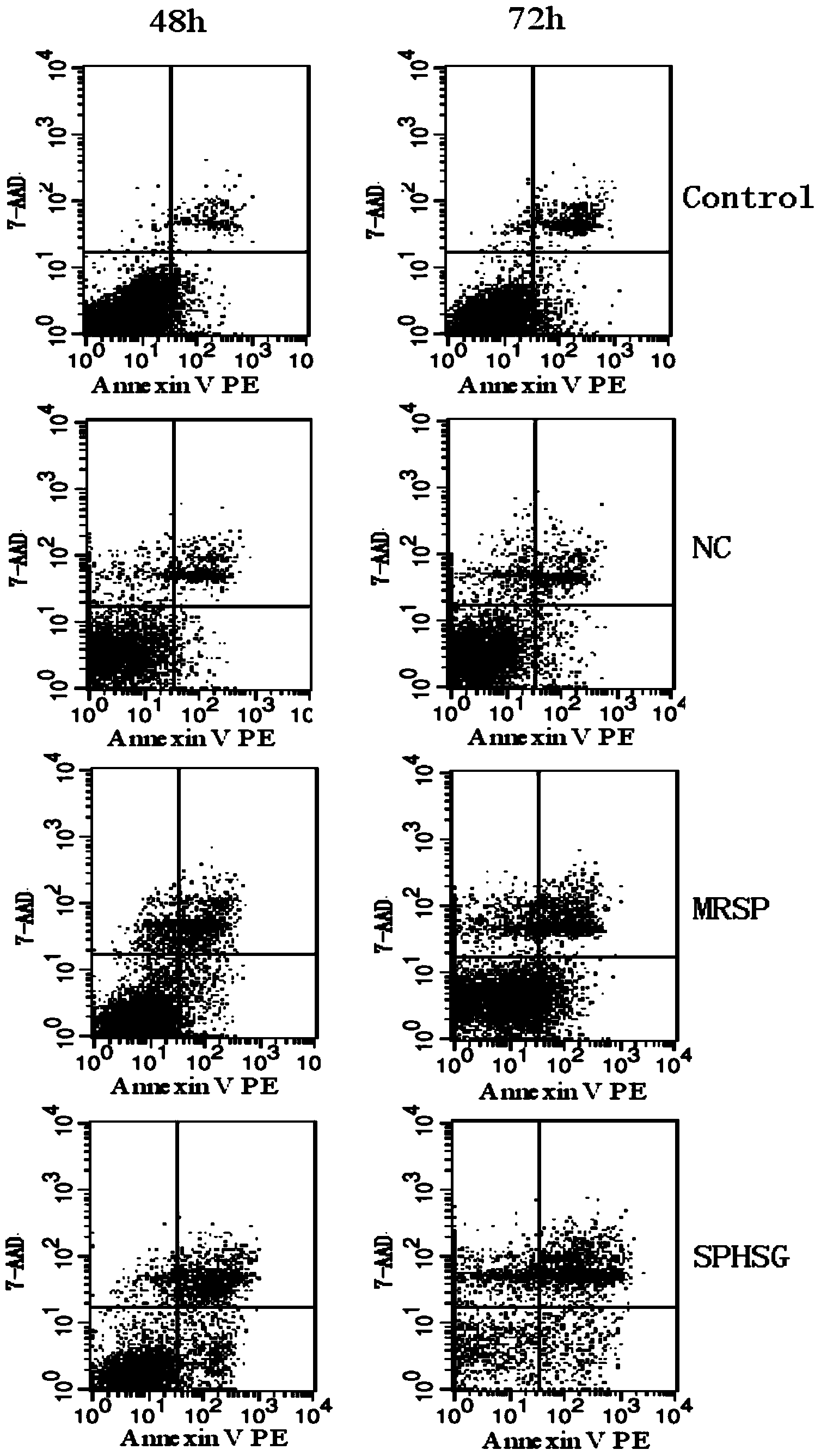

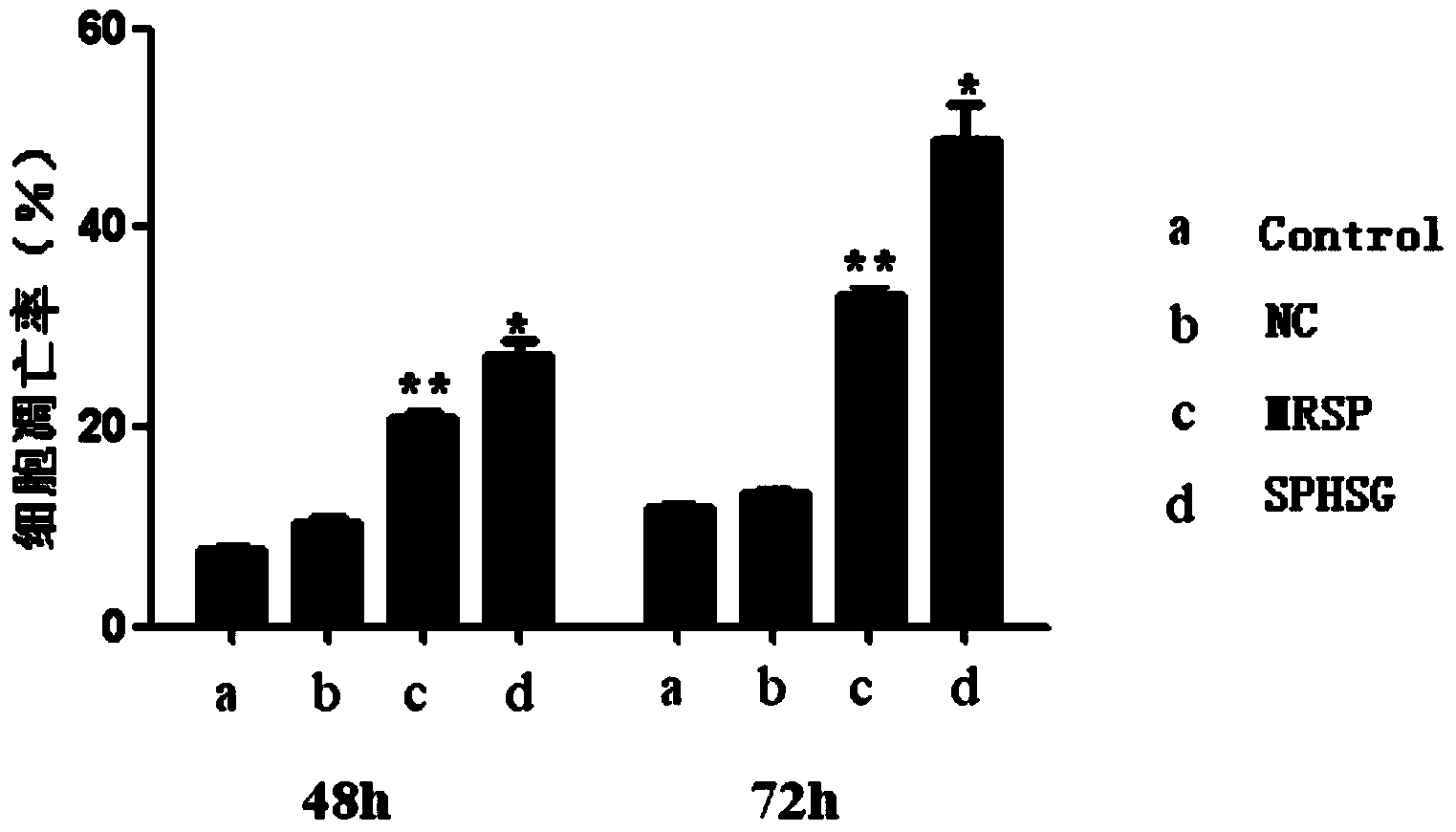

Polypeptide for inhibiting cell proliferation and inducing apoptosis and preparation method and use thereof

ActiveCN103613669AImprove long-term efficacyImprove securitySurgeryPeptide preparation methodsSide effectMFN2

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

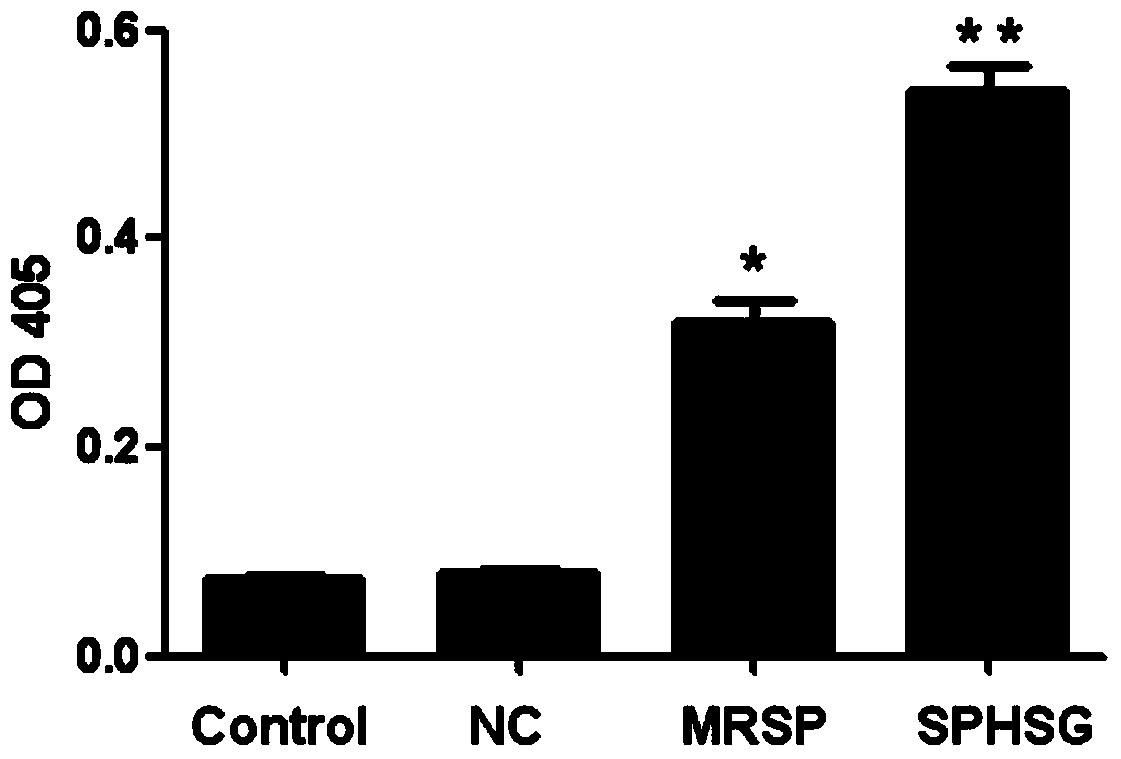

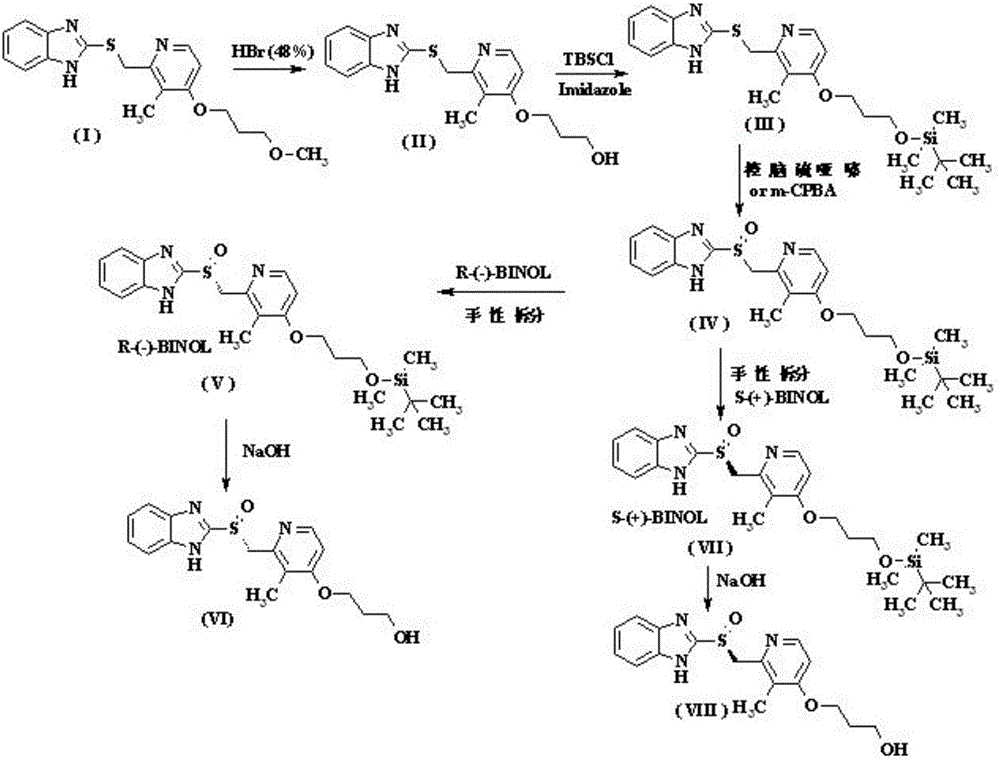

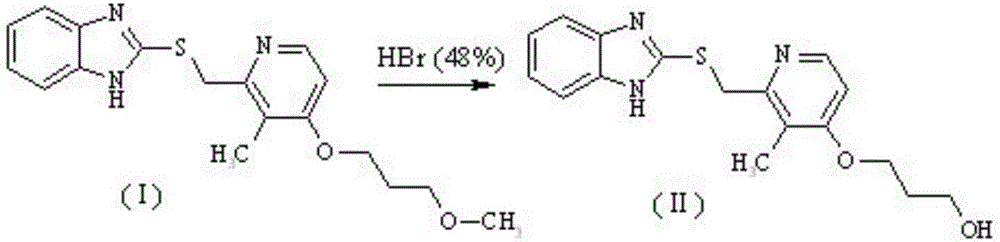

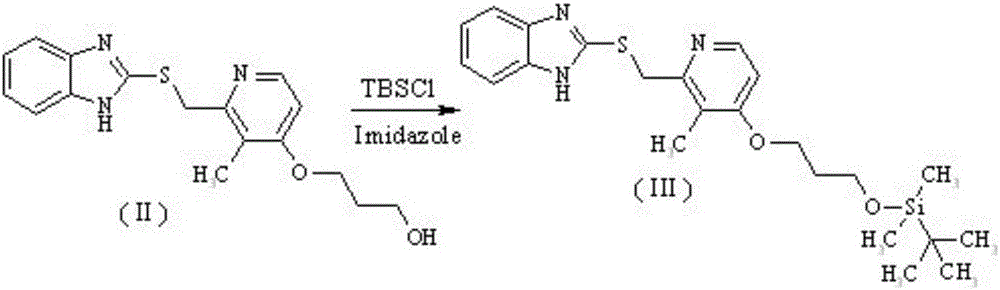

Synthesizing method of single-configuration rabeprazole metabolite

ActiveCN105801560AReasonable process designEasy to operateOptically-active compound separationBulk chemical productionRabeprazoleMetabolite

Owner:TLC NANJING PHARMA RANDD CO LTD

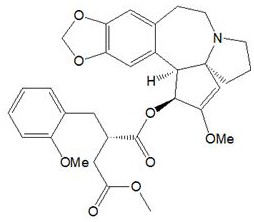

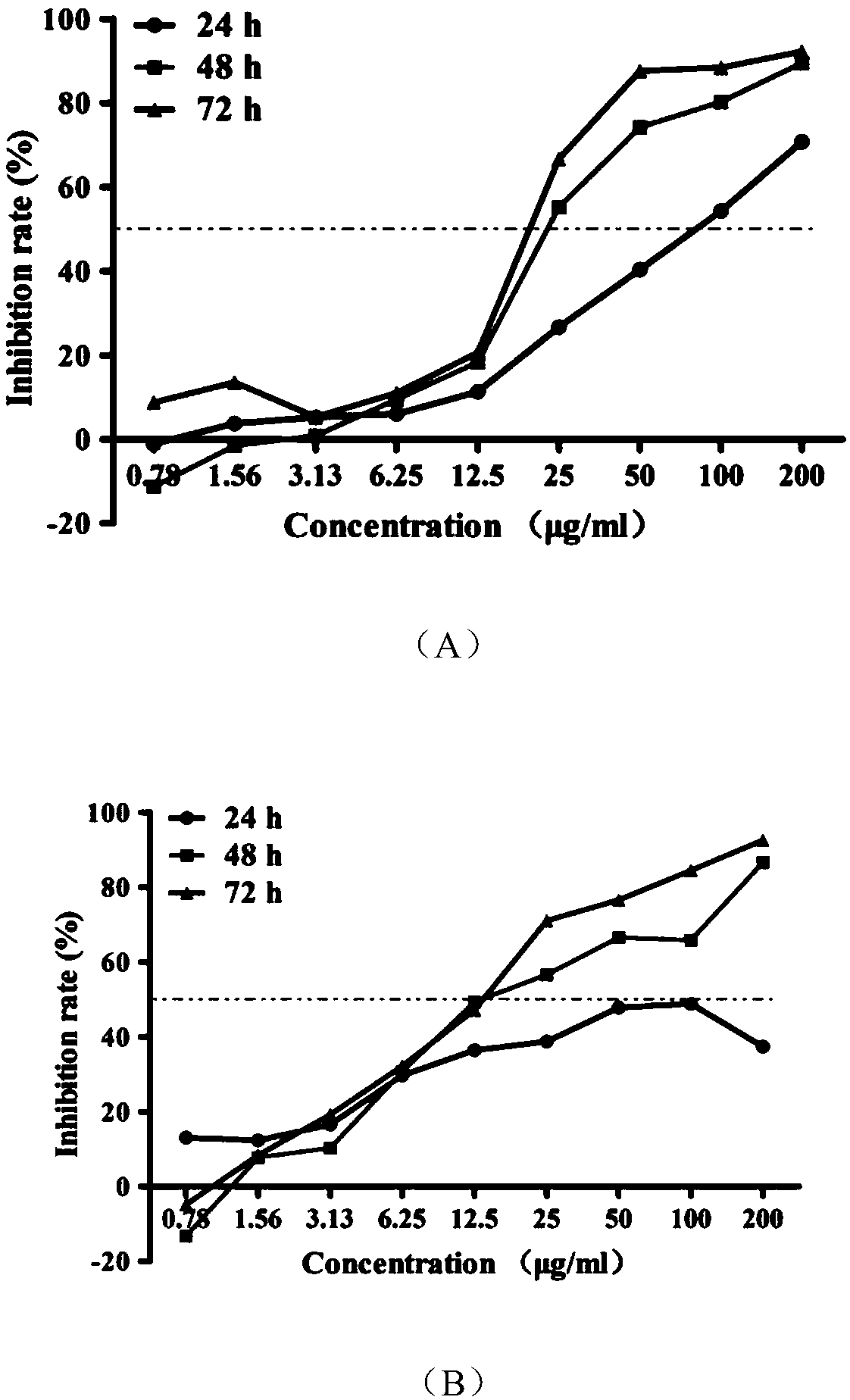

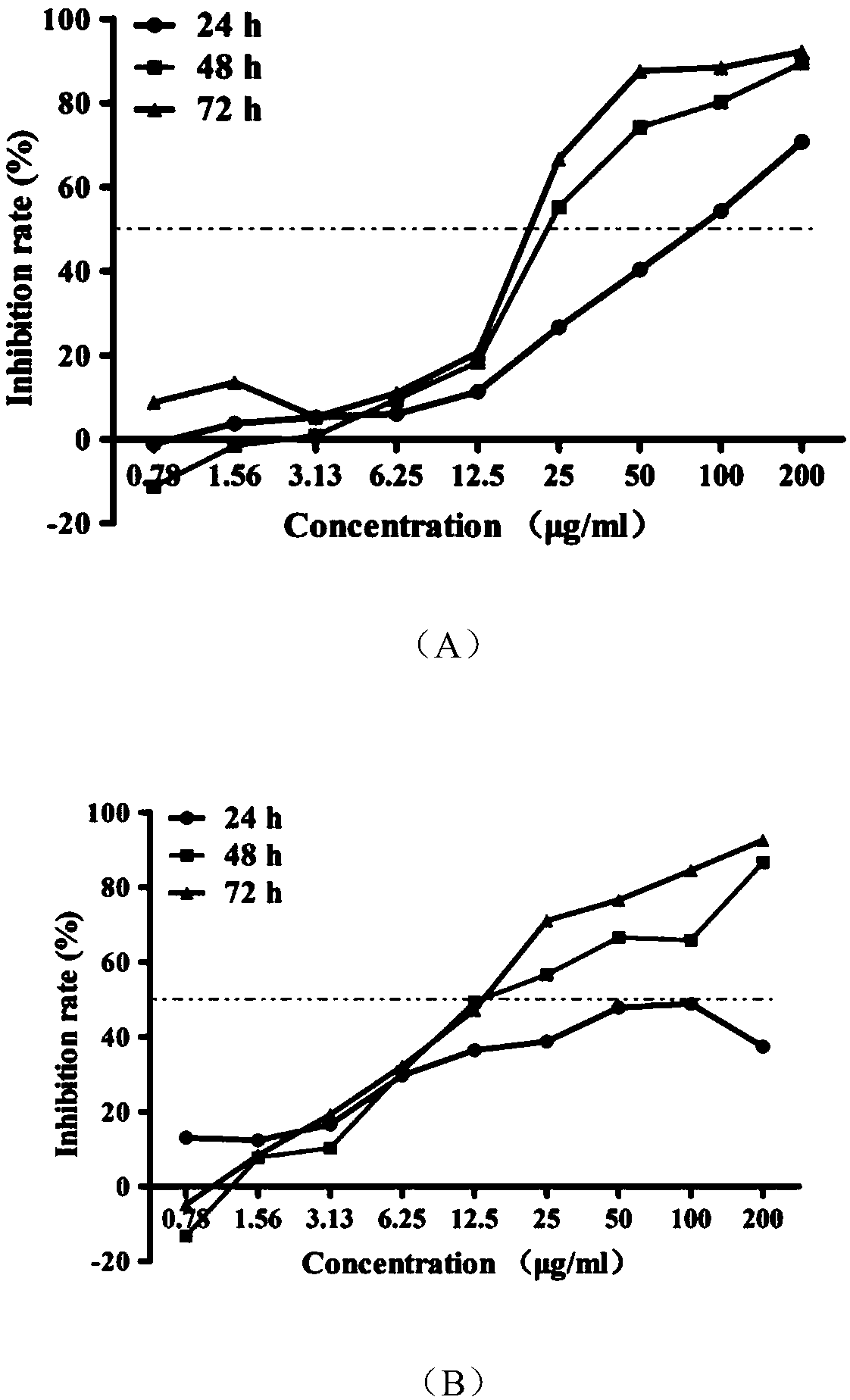

Cephalotaxine derivative as well as preparation method and application thereof

ActiveCN114181223AGrowth inhibitionOrganic chemistryAntineoplastic agentsPharmaceutical medicineTumor cells

Owner:广州艾格生物科技有限公司

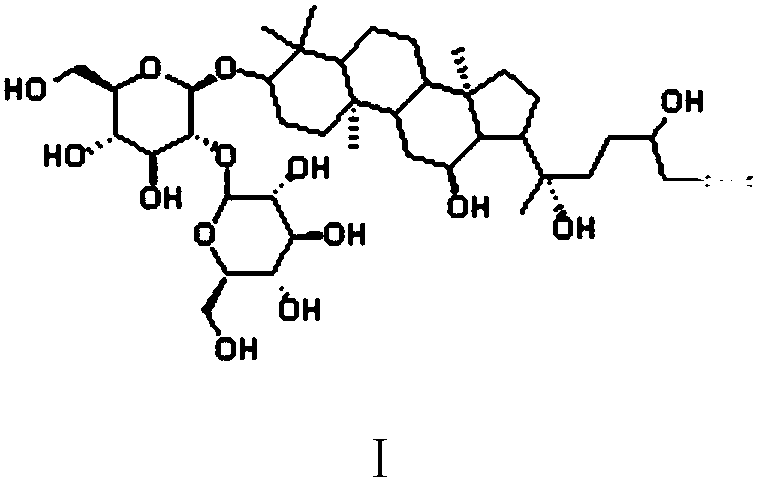

ABPP-based antitumor drug ginsenoside Rg3 active molecular probe, synthesis and applications thereof

InactiveCN109912677ARetain activityAchieve positioningOrganic active ingredientsSteroidsMechanism of actionChemical biology

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

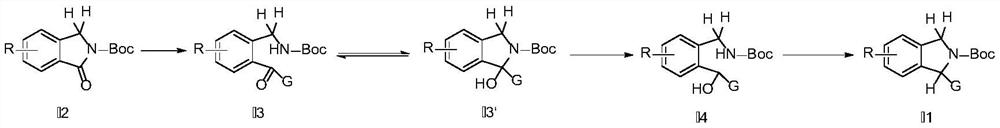

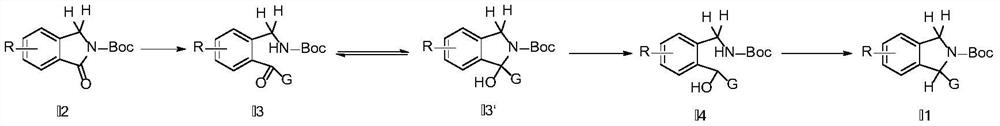

Preparation method of benzodiazepine nerve inhibitor intermediate compound

ActiveCN114644612ASimple post-processingImprove quality controlOrganic chemistryBulk chemical productionBenzodiazepineOrganic chemistry

The invention discloses a preparation method of a compound I, especially an isomer Ia thereof. The preparation method provided by the invention does not need extraction, washing, drying, concentration and other operations, post-treatment is simple, industrial production is facilitated, the preparation method is high in yield, the obtained product only contains one impurity, and subsequent quality control is facilitated.

Owner:CHENGDU EASTON BIOPHARMACEUTICALS CO LTD +1

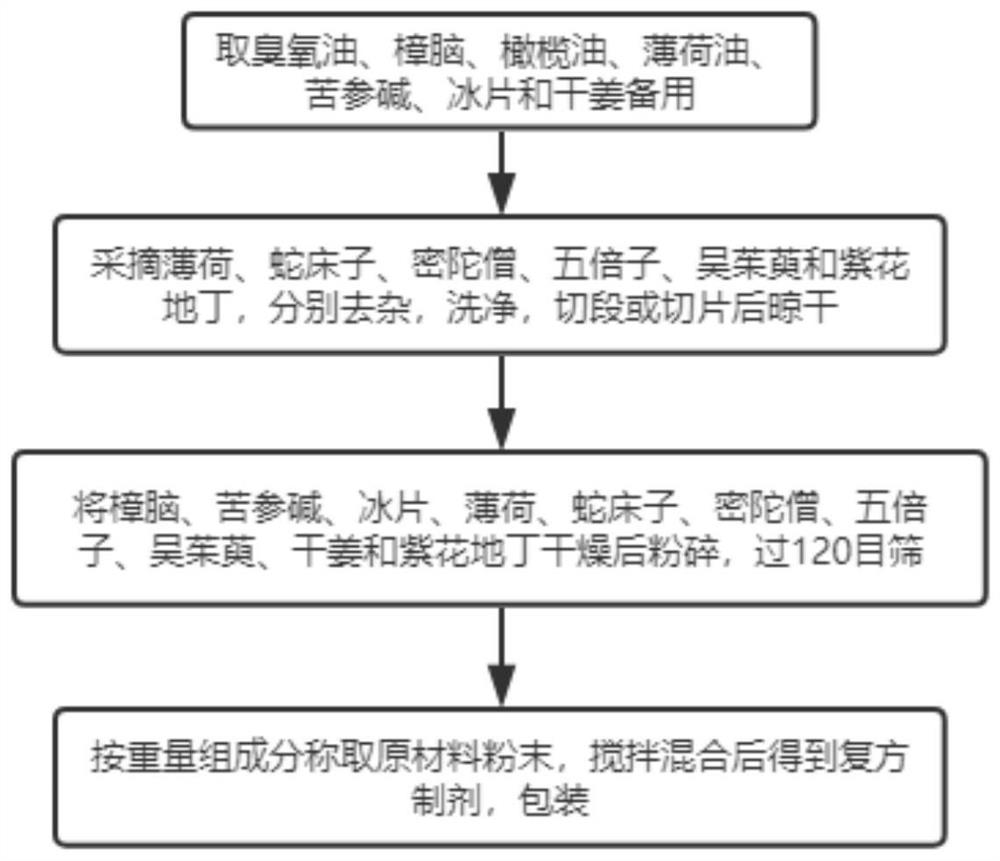

Compound preparation for treating skin diseases of animals, and preparation method of compound preparation for treating skin diseases of animals

InactiveCN111773367AImprove survival rateEasy to makePowder deliveryOrganic chemistryVeterinary DrugsCnidium

Owner:安徽氧趣生物科技有限公司

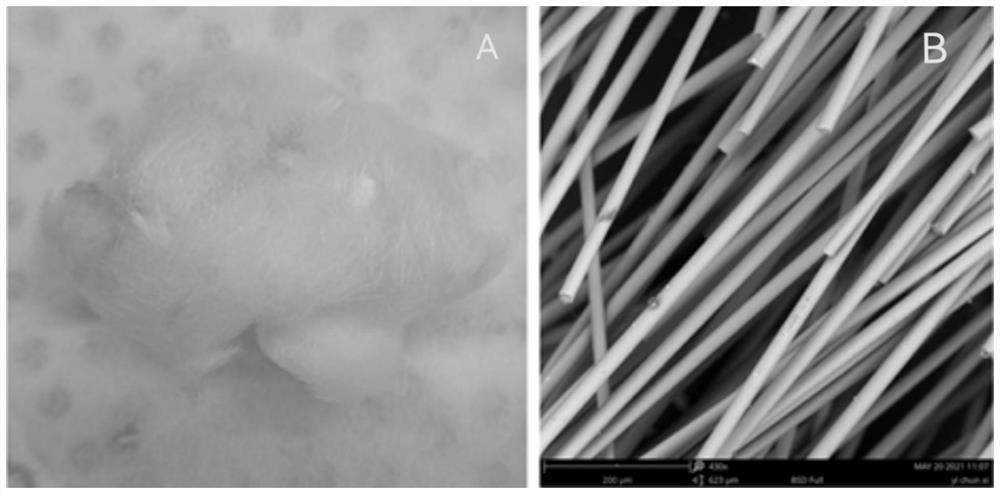

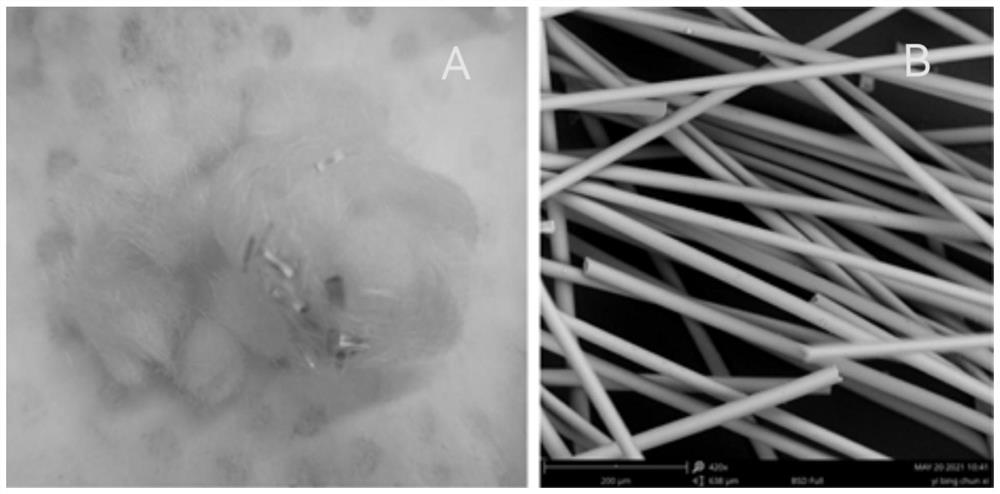

Mordenite catalyst with special morphology

ActiveCN108499595BImprove responseReactiveMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkyl transfer

The invention relates to a mordenite catalyst with a special morphology. While the chain morphology improves the efficient mass transfer performance of the molecular sieve catalyst, it mainly solves the problem of low activity and selectivity of the catalyst in the aromatic hydrocarbon alkyl transfer reaction. The catalyst adopts chain morphology. The technical solution uses mordenite with a morphological shape as a carrier, and the active components include at least one element selected from IIIB, at least one element selected from VB, and at least one metal element selected from IIIA, which better solves this technical problem. , can be used in the industrial production of aromatic hydrocarbons such as aromatic hydrocarbon alkylation reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting quercetin from semen plantaginis

Owner:南京西博恩生物科技有限公司

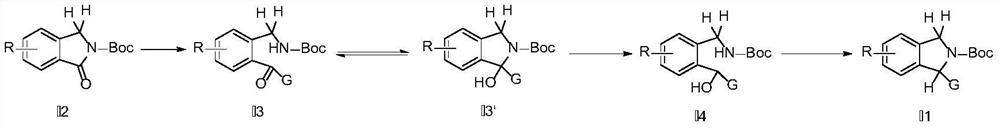

Synthesis method of substituted isoindoline

Owner:江阴迈康升华医药科技有限公司

Continuous processes for the selective conversion of aldohexose-yielding carbohydrate to ethylene glycol using low concentrations of retro-aldol catalyst

ActiveUS20220089515A1High selectivityLow costOrganic compound preparationChemical/physical/physico-chemical processesPolymer sciencePtru catalyst

Owner:TECH PRECESS TECH INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap