Method for separating aromatic hydrocarbon from alkane by ionic liquid and membrane process coupling technology

A technology for separating aromatics from ionic liquids, applied in the new technology field of separating aromatics/alkanes in naphtha, can solve the problems of limited processing capacity in pervaporation membrane separation process, difficulty in realizing large-scale industrial application, and large amount of adsorbent, etc. Achieve long-term stable operation, improve operating conditions and working environment, and reduce solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

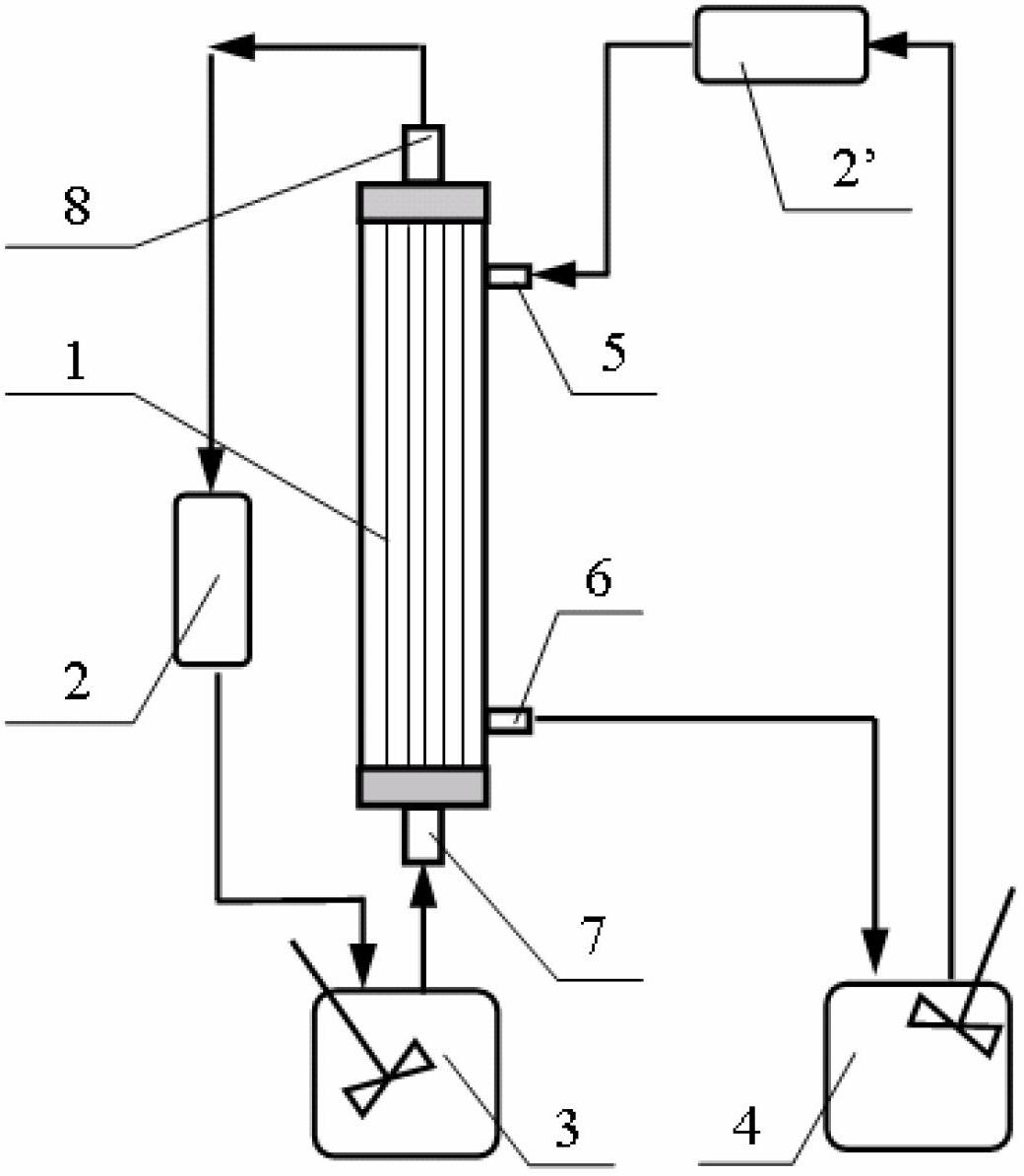

[0021] use figure 1 For the device shown, the structural parameters of the hollow fiber membrane used are shown in the following table:

[0022] Table 1. Structural parameters of hollow fiber membranes

[0023] Membrane inner diameter / m Membrane length / m Membrane number Membrane outer diameter / mm Membrane inner diameter / mm Membrane material 0.155 0.3 22 1.38 0.79 Polyvinylidene fluoride

[0024] Prepare a mixture of toluene and n-heptane with a toluene concentration of 0.368g / ml (50wt.%) as the material liquid phase, and use the ionic liquid [Bmim][BF 4 ] As the extraction agent, n-dodecane is the stripping phase, and the volume of the stripping phase and the feed liquid phase is 150ml.

[0025] First circulate the extractant through the tube side of the hollow fiber membrane device, and adjust the tube side pressure to be higher than the shell side pressure to ensure that the micropores of the hollow fiber membrane are filled with the extractant

Embodiment 2

[0029] Other operating conditions were the same as in Example 1, except that the temperature of the stripping phase was changed to 50° C., and the concentration of toluene in the liquid phase was changed to 0.599 g / ml (75 wt.%). After 12 hours of treatment, the mass transfer flux of toluene is 140.2g m -2 h -1 , the separation factor was 14.5, and the toluene in the mixture of toluene and n-heptane separated from the stripping phase accounted for 95.6 wt.%, which was 20.6 percentage points higher than that in the feed liquid phase.

Embodiment 3

[0031] Other operating conditions are the same as in Example 1, the inlet flow of the liquid phase is changed to 25ml / min, the inlet flow of the stripping phase is changed to 64ml / min, and the temperature of the stripping phase is changed to 50°C. After 12 hours of treatment, the mass transfer flux of toluene is 44.5g m -2h -1 , the separation factor was 20.7, and the toluene in the mixed liquid of toluene and n-heptane separated from the stripping phase accounted for 97.6 wt.%, which was 47.6 percentage points higher than that in the feed liquid phase.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap