Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Nickel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel is a chemical element with the symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile. Pure nickel, powdered to maximize the reactive surface area, shows a significant chemical activity, but larger pieces are slow to react with air under standard conditions because an oxide layer forms on the surface and prevents further corrosion (passivation). Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere.

Nonaqueous electrolyte secondary battery

InactiveUS20030180618A1Inhibit deteriorationImprove storage characteristicsPositive electrodesNon-aqueous electrolyte accumulator electrodesComposite oxideNickel

Owner:SANYO ELECTRIC CO LTD

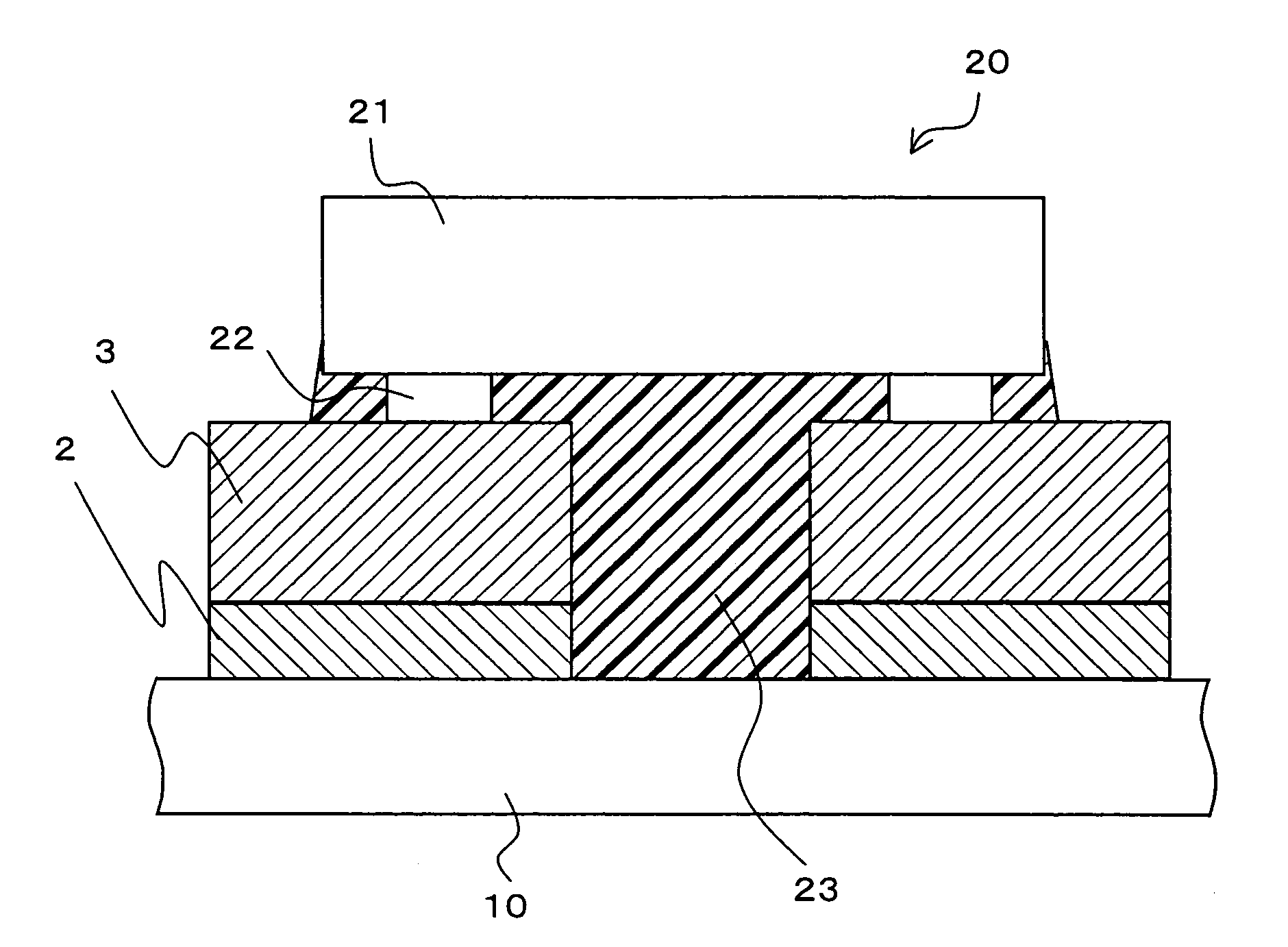

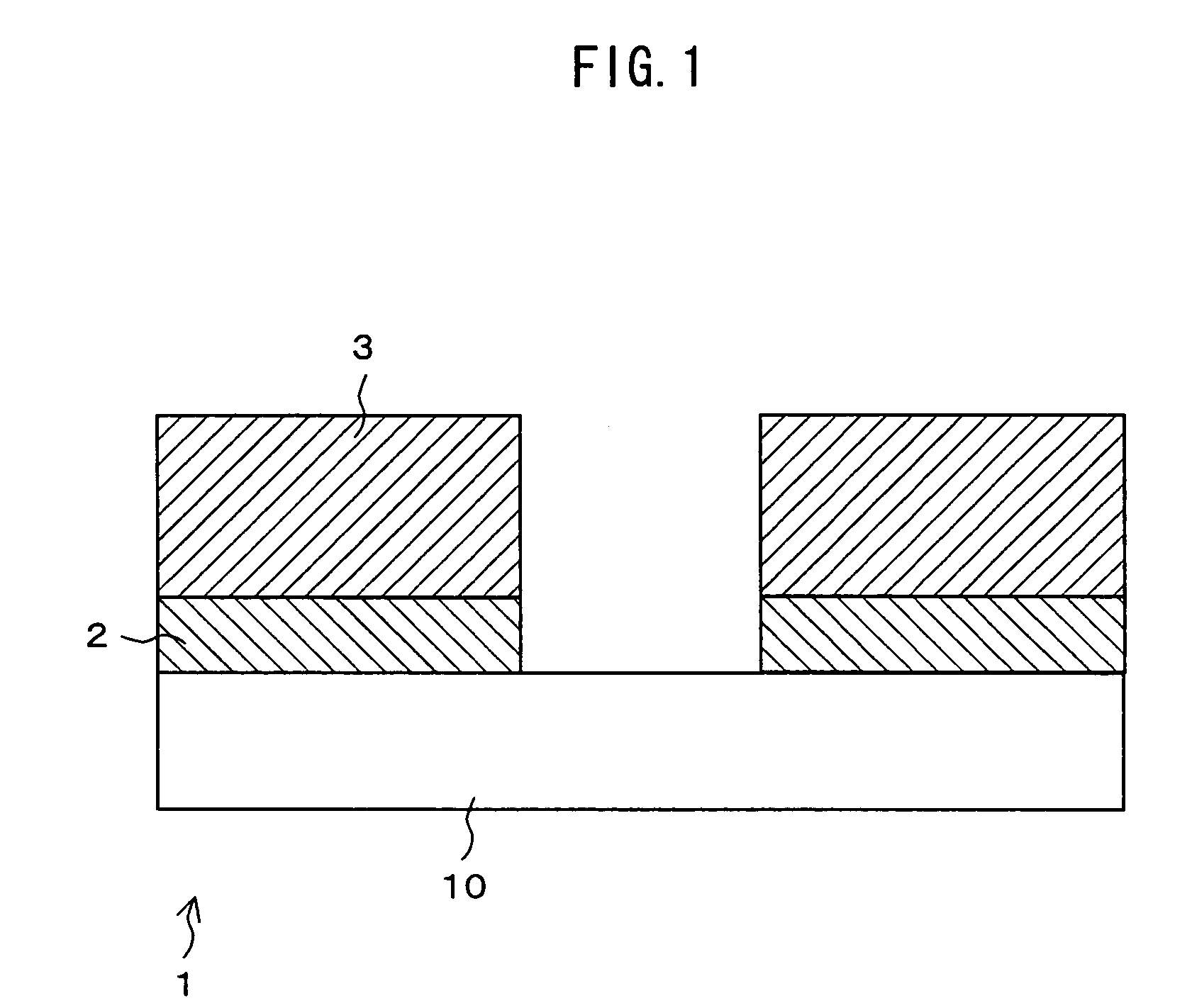

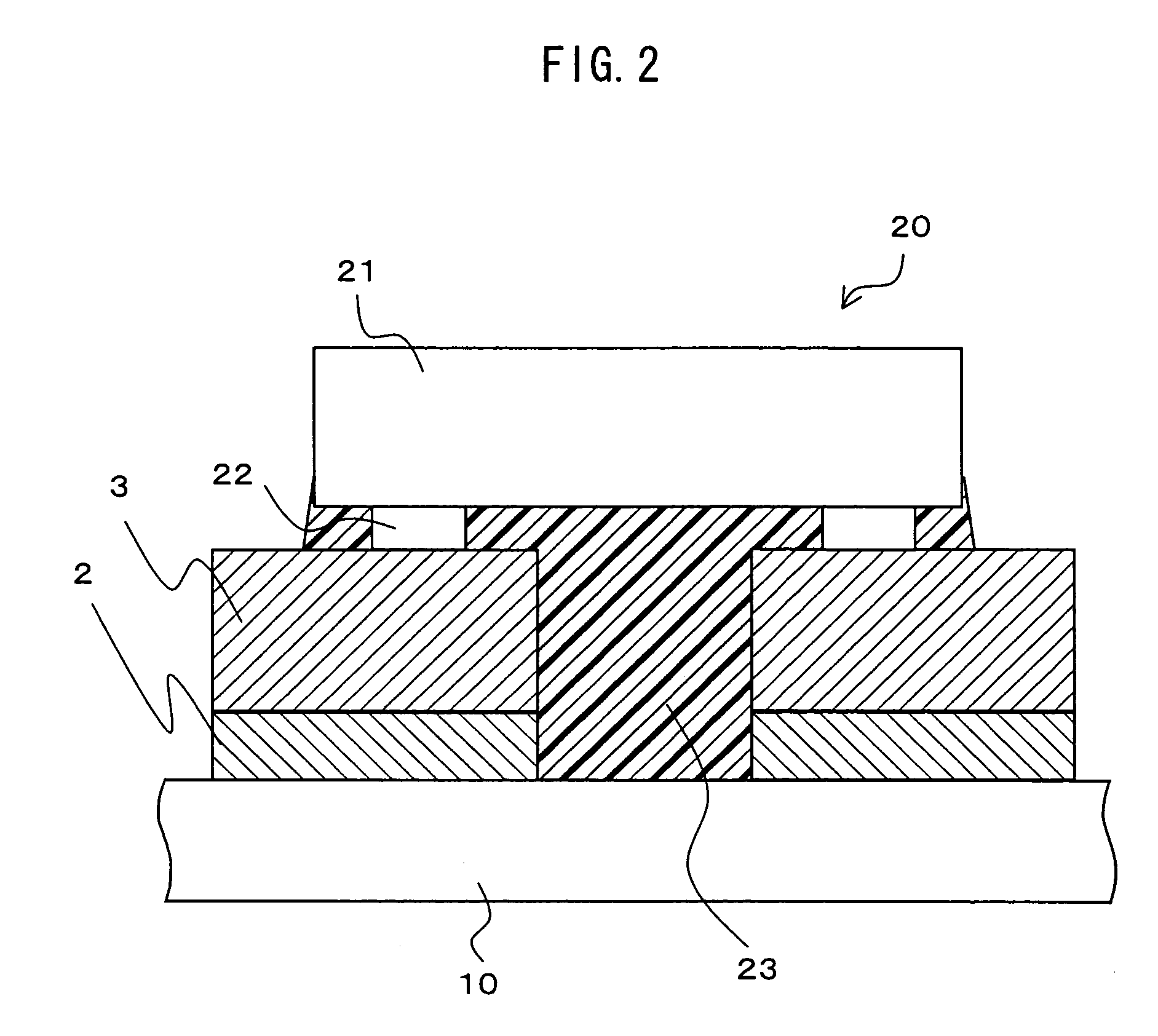

Semiconductor carrier film, and semiconductor device and liquid crystal module using the same

ActiveUS7164205B2Increase productionFine pitchSemiconductor/solid-state device detailsSolid-state devicesAlloyConductive materials

Owner:SHARP KK +1

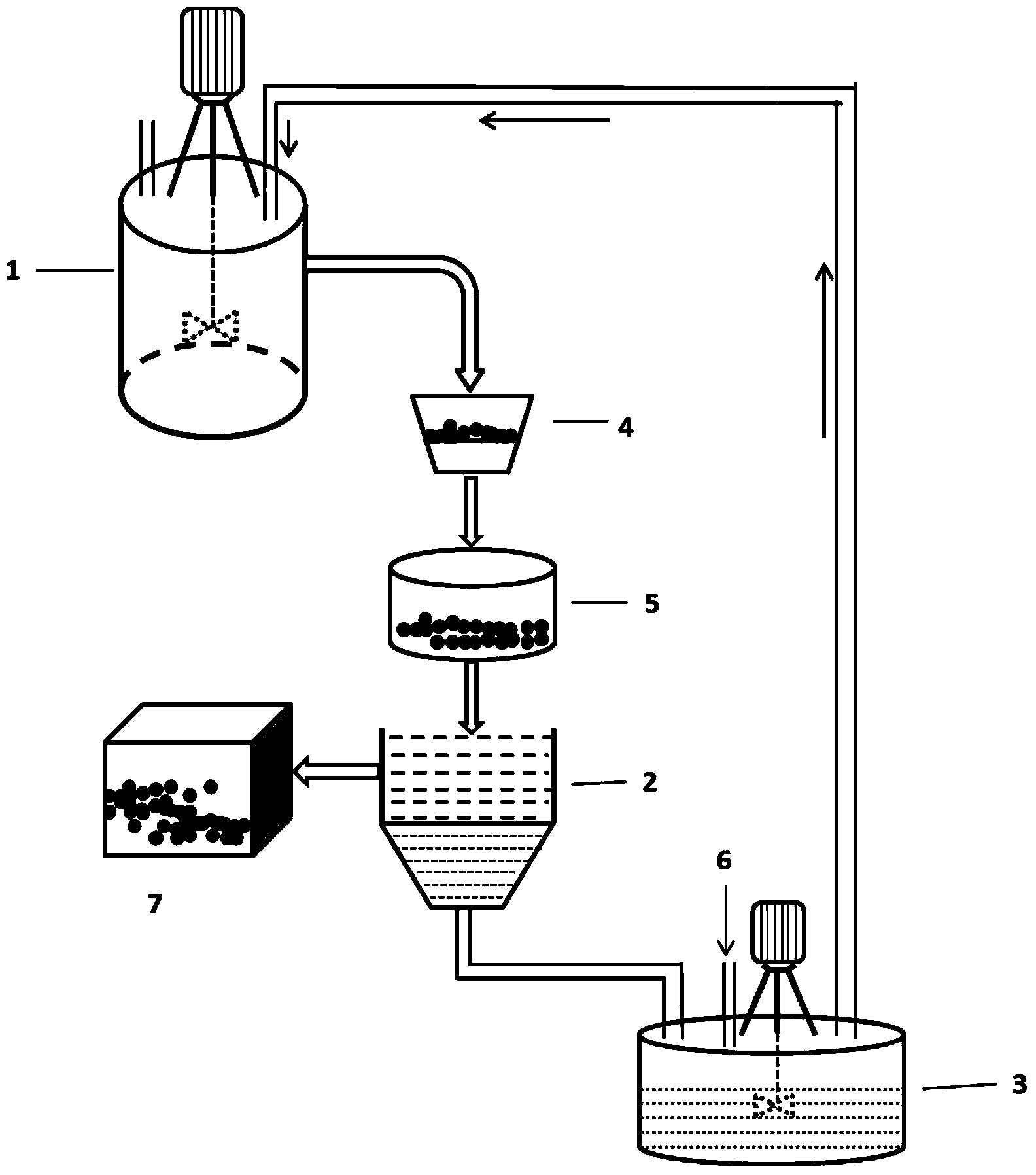

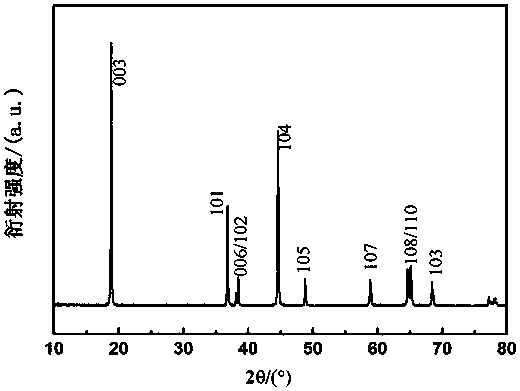

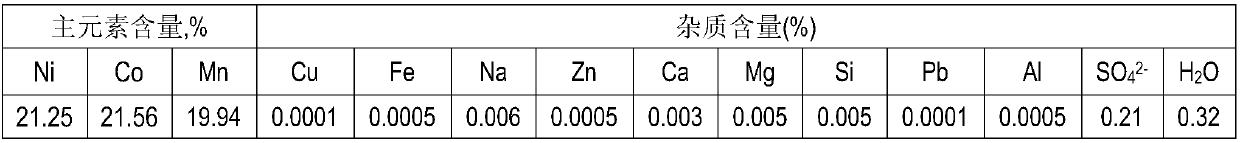

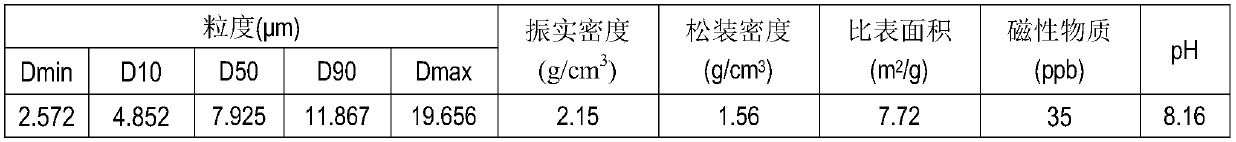

Method for preparing nickel-cobalt-manganese ternary material precursor

ActiveCN103943847ARealize comprehensive utilizationIncrease profitCell electrodesSecondary cellsManganeseCobalt

Owner:北京盟固利新材料科技有限公司

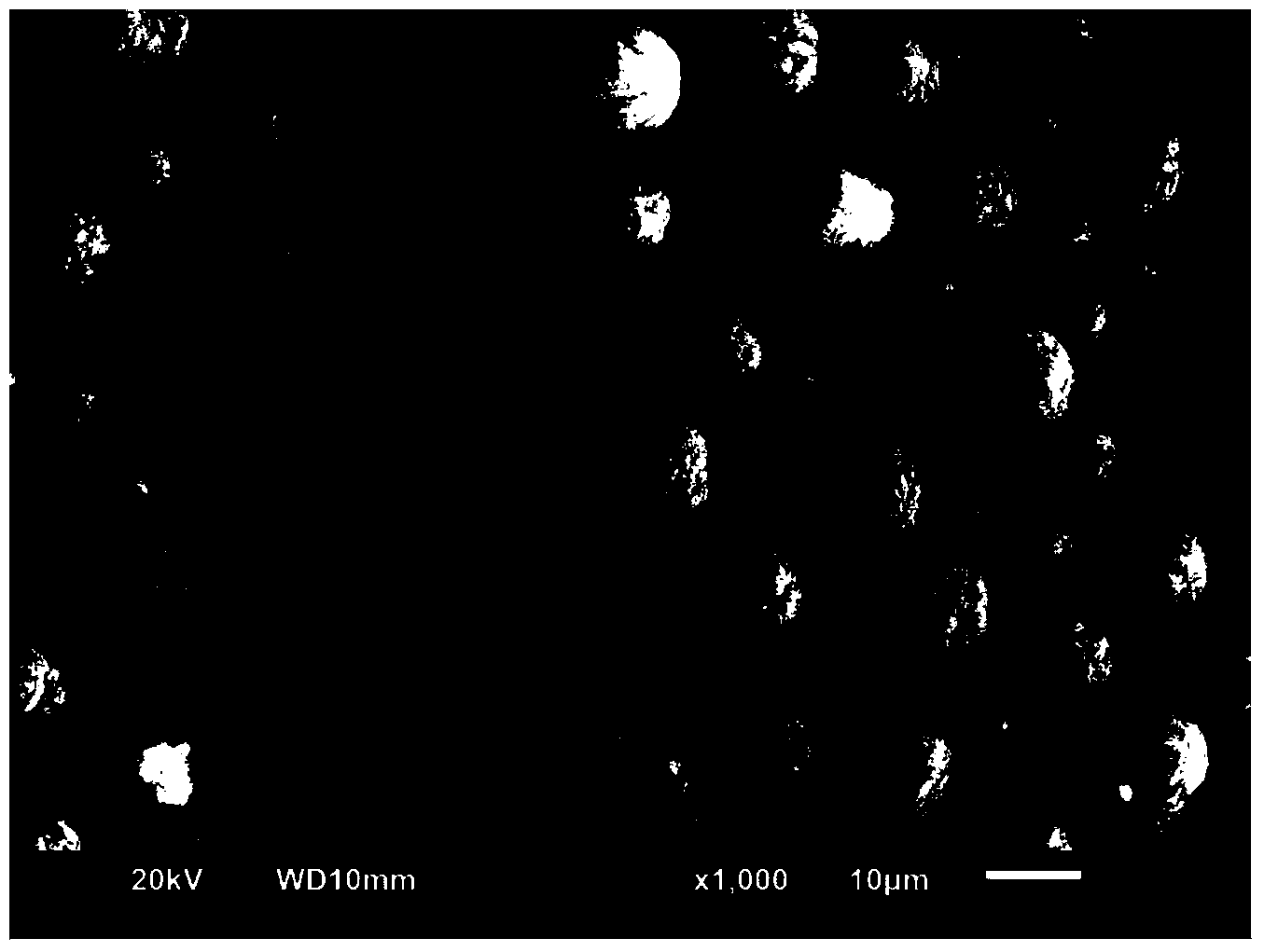

Self-supporting nickel phosphide catalyst and preparation method and application thereof

ActiveCN107694584AImprove thermal conductivityGood choiceOrganic compound preparationCarboxylic acid esters preparationOxalateNickel oxide hydroxide

The invention discloses a self-supporting nickel phosphide catalyst and a preparation method and application thereof. The self-supporting nickel phosphide catalyst is a nickel phosphide catalyst obtained by in-situ growing of a nickel oxalate or nickel hydroxide crystal layer on a framework matrix through a hydrothermal method and performing phosphating while secondary forming is not needed, and the nickel phosphide catalyst is composed of the framework matrix and a nickel-phosphorus compound, wherein the nickel-phosphorus compound is at least one of Ni3P, Ni12P5, Ni2P and Ni5P4, total mass ratio of the nickel-phosphorus compound is 0.1-50%, and the balance is the framework matrix. Experiments show that the self-supporting nickel phosphide catalyst is high in stability and thermal conductivity, easy to form and fill, high in flux and low in pressure drop, especially has the advantages of high low-temperature activity, high dimethyl oxalate conversion rate and high methyl glycolate selectivity and can be used as a reaction catalyst for hydrogenating dimethyl oxalate to prepare methyl glycolate.

Owner:EAST CHINA NORMAL UNIV

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

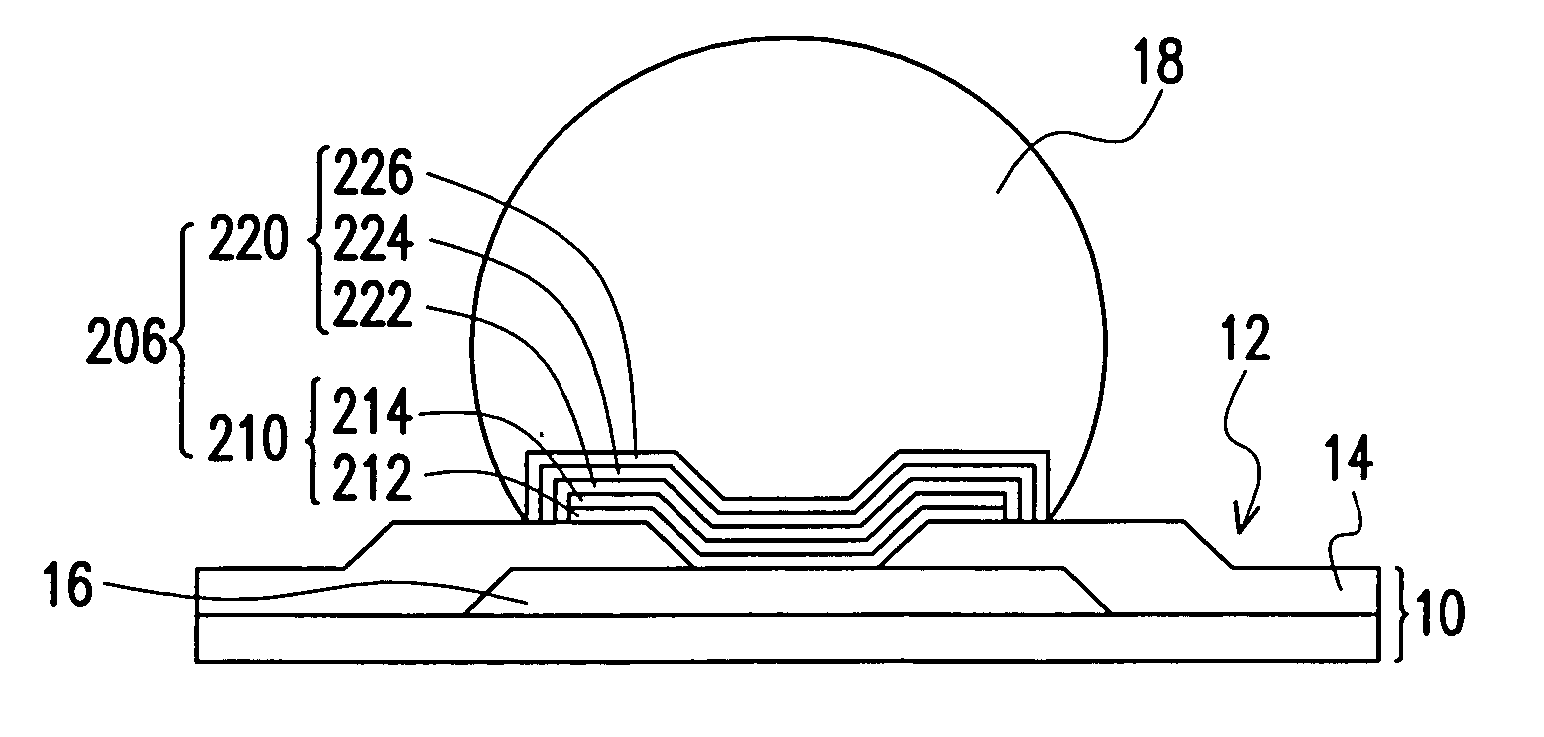

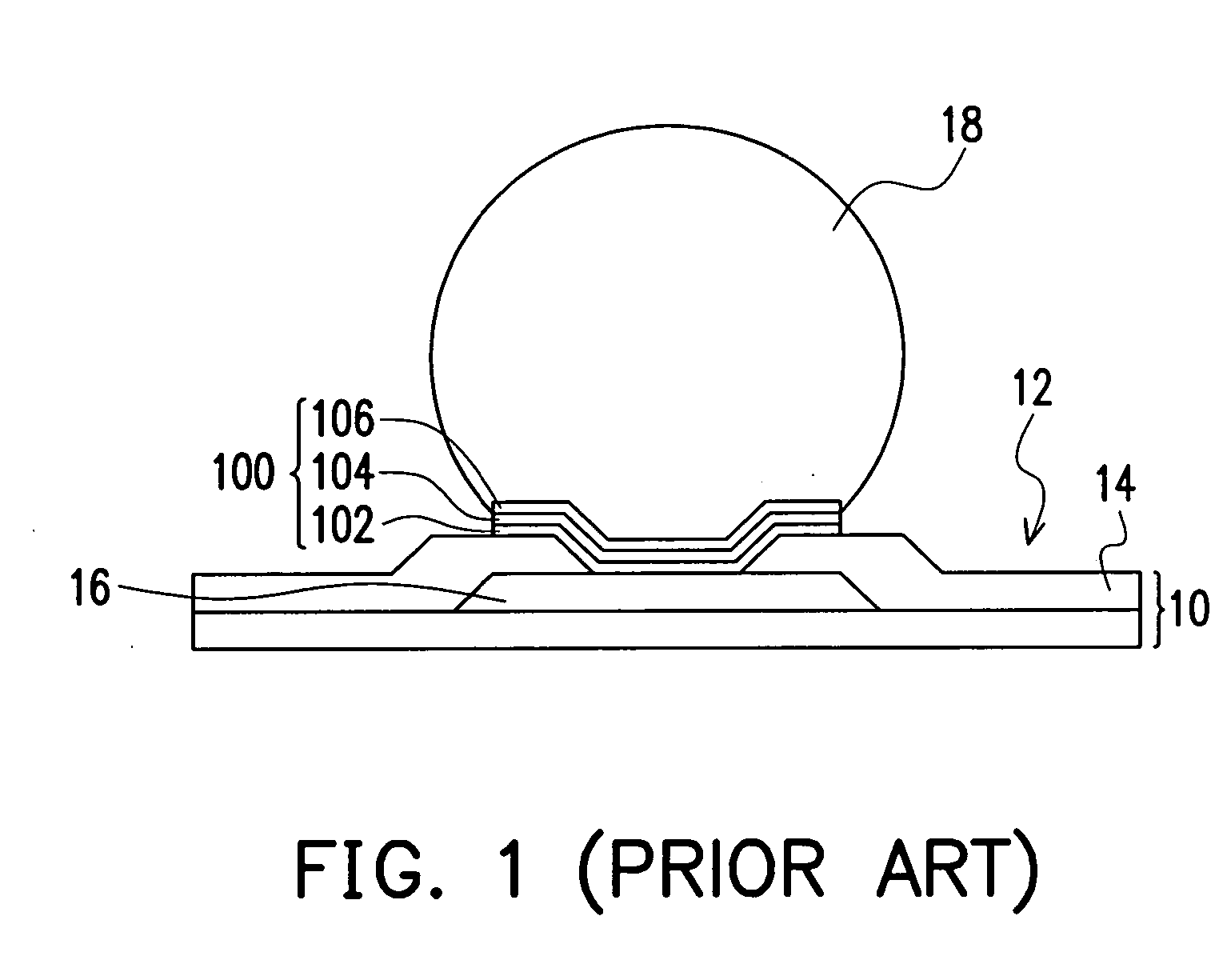

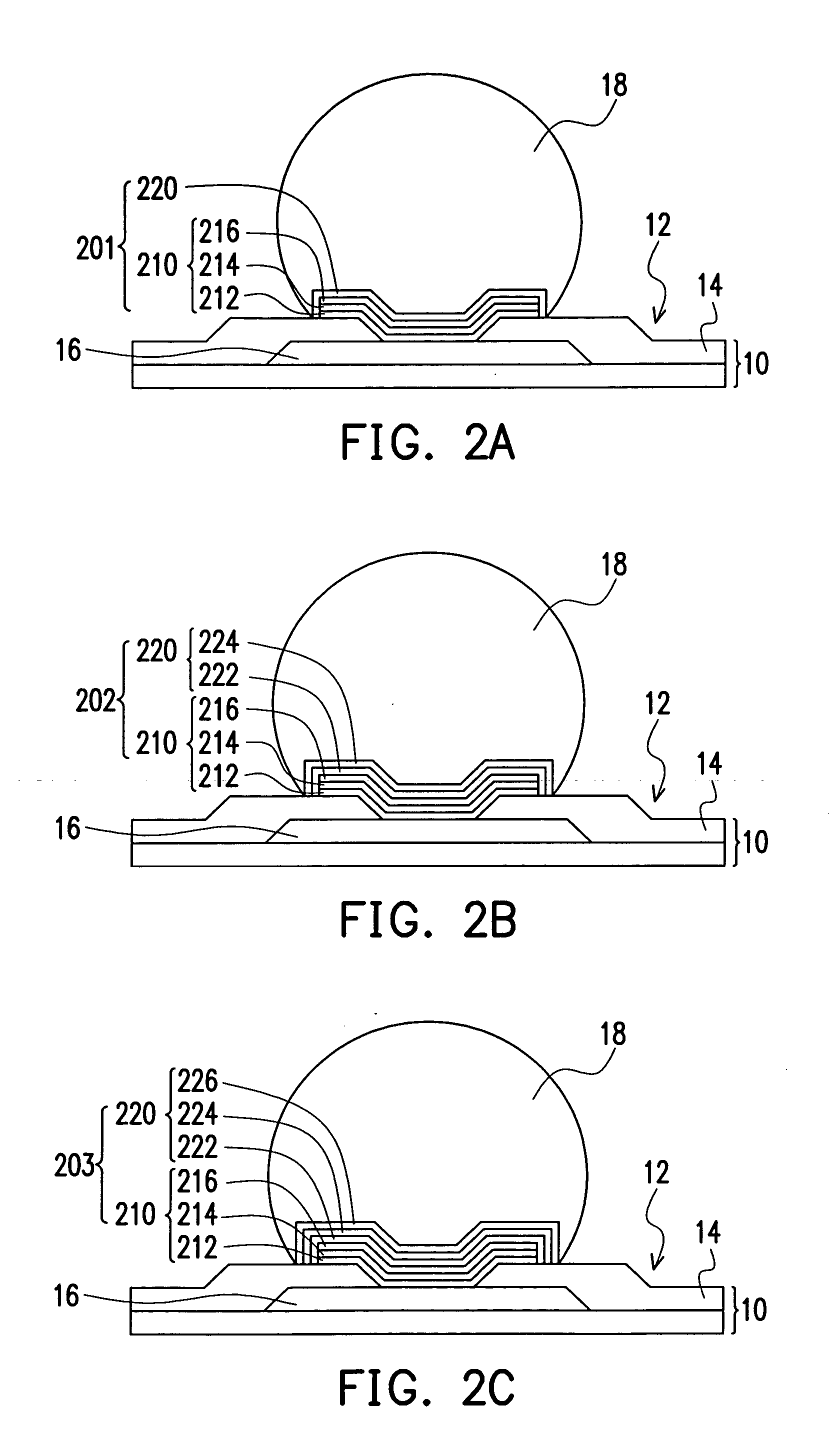

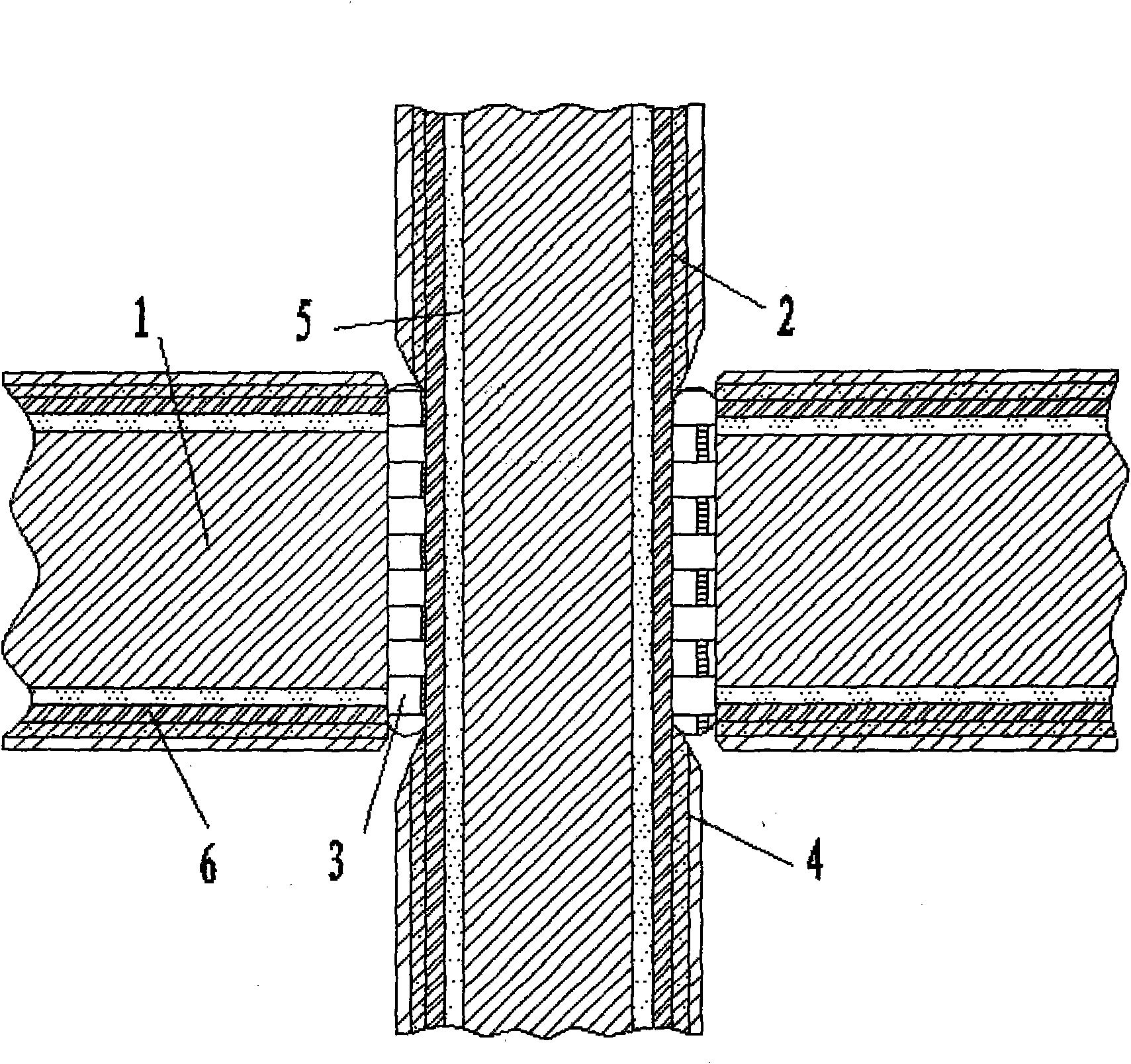

Under-bump metallugical structure

InactiveUS20050012211A1Solder bump is reducedImprove performanceSemiconductor/solid-state device detailsSolid-state devicesNickelCopper

An under-bump metallurgical structure between the bonding pad of a die or a substrate and a solder bump such that the principle constituent of the solder bump is lead-tin alloy or lead-free alloy. The under-bump metallurgical structure at least includes a metallic layer and a buffer metallic structure. The metallic layer is formed over the bonding pads of the die. Major constituents of the metallic layer include copper, aluminum, nickel, silver or gold. The buffer metallic structure between the metallic layer and the solder bump is capable of reducing the growth of inter-metallic compound due to chemical reaction between the metallic constituents of the metallic layer and tin from the solder bump.

Owner:KUNG MORISS +1

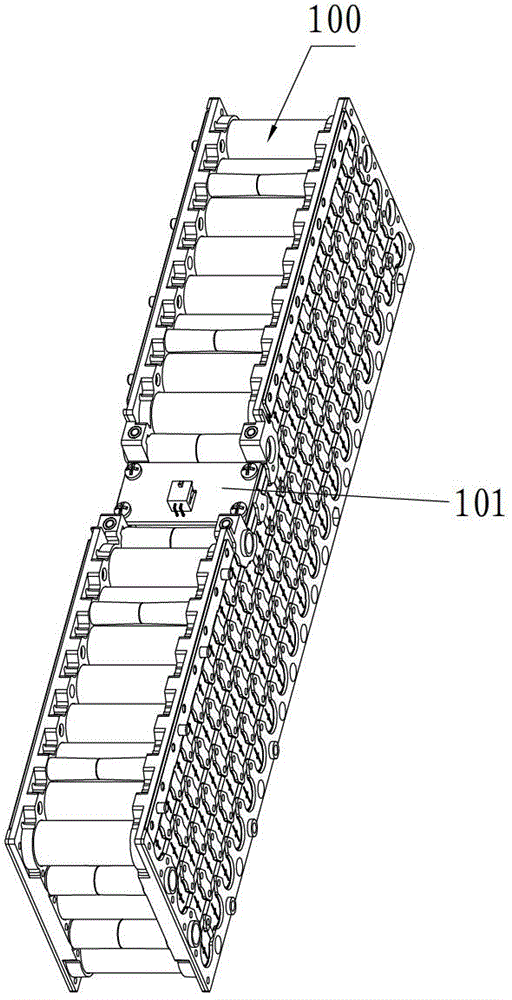

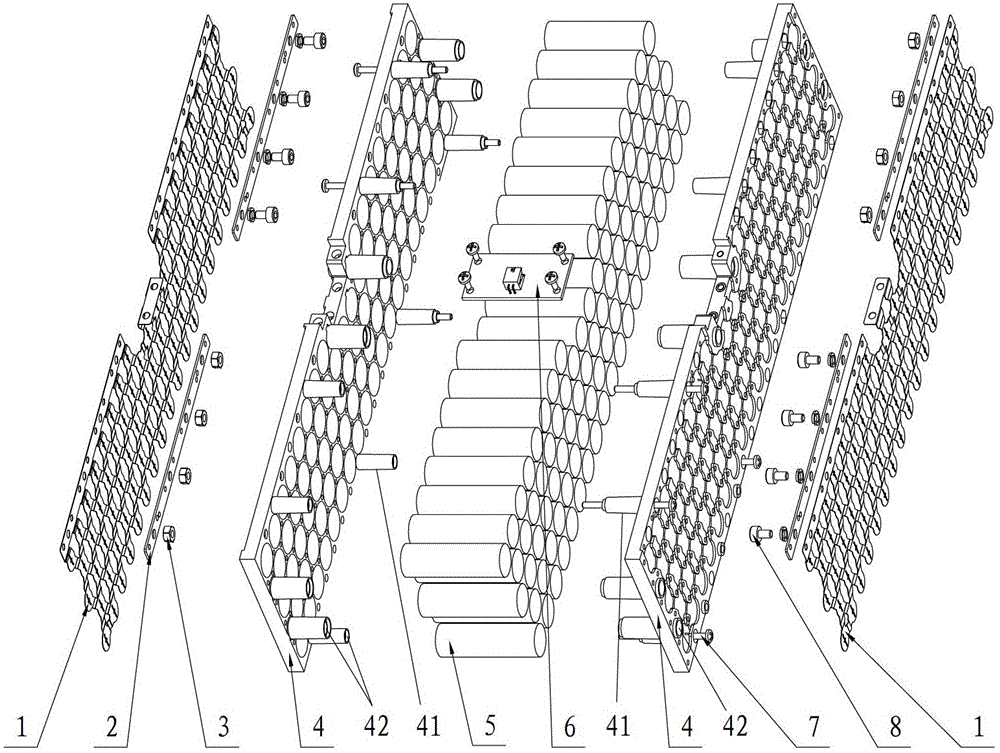

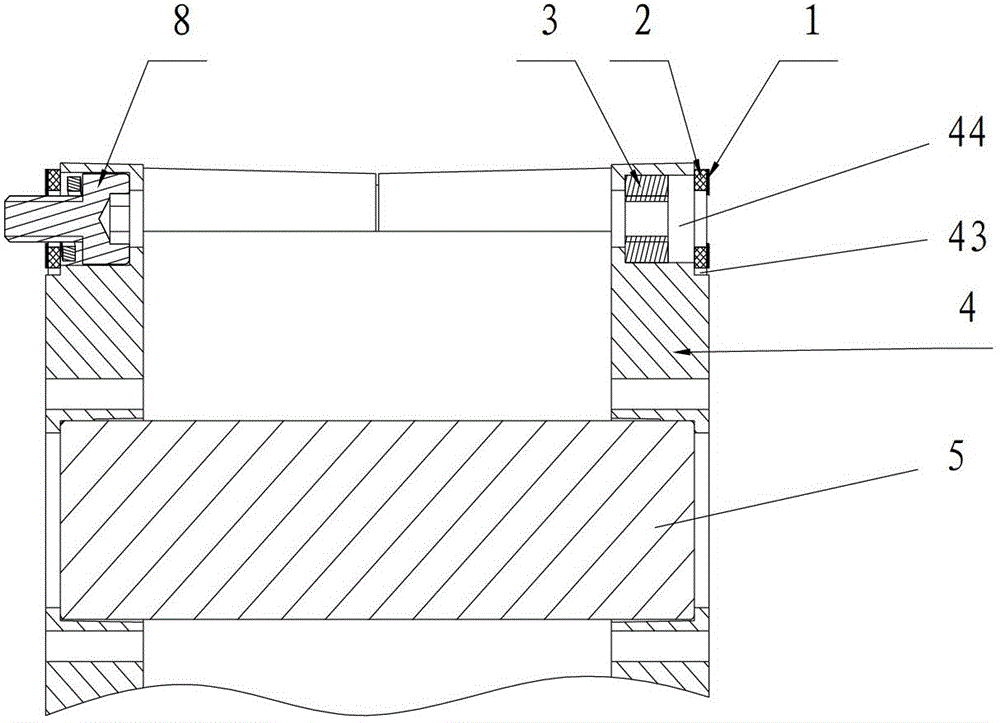

Cylindrical power battery module structure

Owner:欣旺达惠州新能源有限公司

Nickel slag processing method for efficiently recovering iron resource

InactiveCN104988302APromote resource reuseSafe and easy to recycleProcess efficiency improvementSlagMagnetic separation

The invention provides a nickel slag processing method for efficiently recovering an iron resource. The method includes the steps that nickel slag is fused, the temperature is kept, a modification agent is added, heat preservation is carried out, and modified nickel slag with the alkalinity ranging from 1.0 to 1.4 is obtained after complete reacting is made; air or oxygen is blown from the bottom or from the top below the liquid face, weak oxidation treatment is carried out on the modified nickel slag, and oxidized nickel slag is obtained; after the temperature of the oxidized nickel slag falls to 1200 DEG C with the temperature fall rate smaller than or equal to 5 DEG C / min, water quenching cooling is carried out, and solidified nickel slag is obtained after complete solidification; the solidified nickel slag is crushed and ground until the particle size is smaller than 200 meshes; and magnetic separation is carried out on slag obtained after cracker grinding, magnetic materials are recovered, and nickel slag processing is completed. By means of the processing method, the iron resource can be recovered from the nickel slag, harmful elements in the nickel slag cannot be brought into iron-rich phases, and an iron ore concentrate can be completed replaced in use. Low-energy-consumption, low-cost and safe and easy processing recovery of the iron resource is achieved, and the method is of great significance in promoting nickel slag resource recycling, enterprise energy saving and emission reduction and environmental protection.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

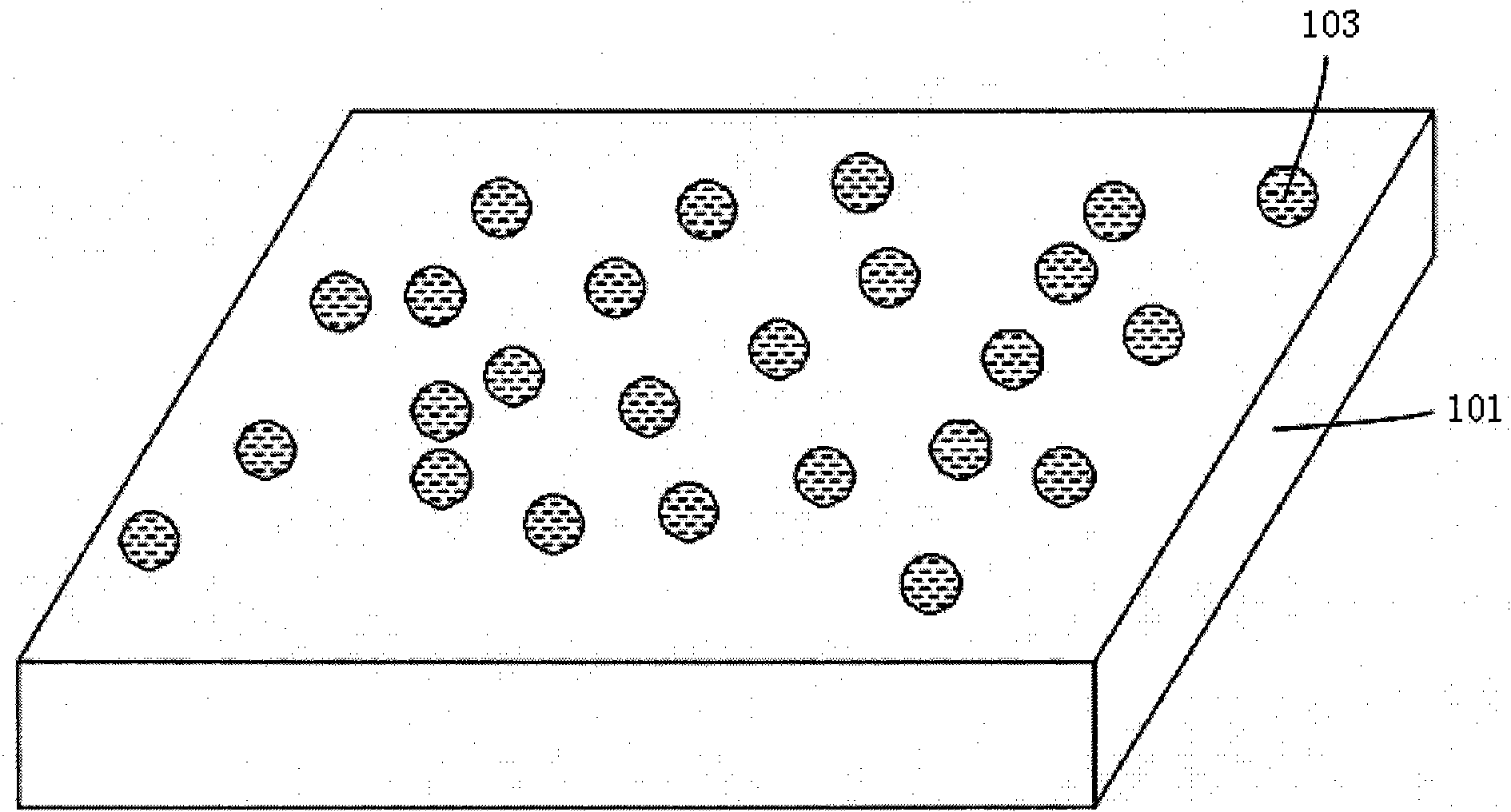

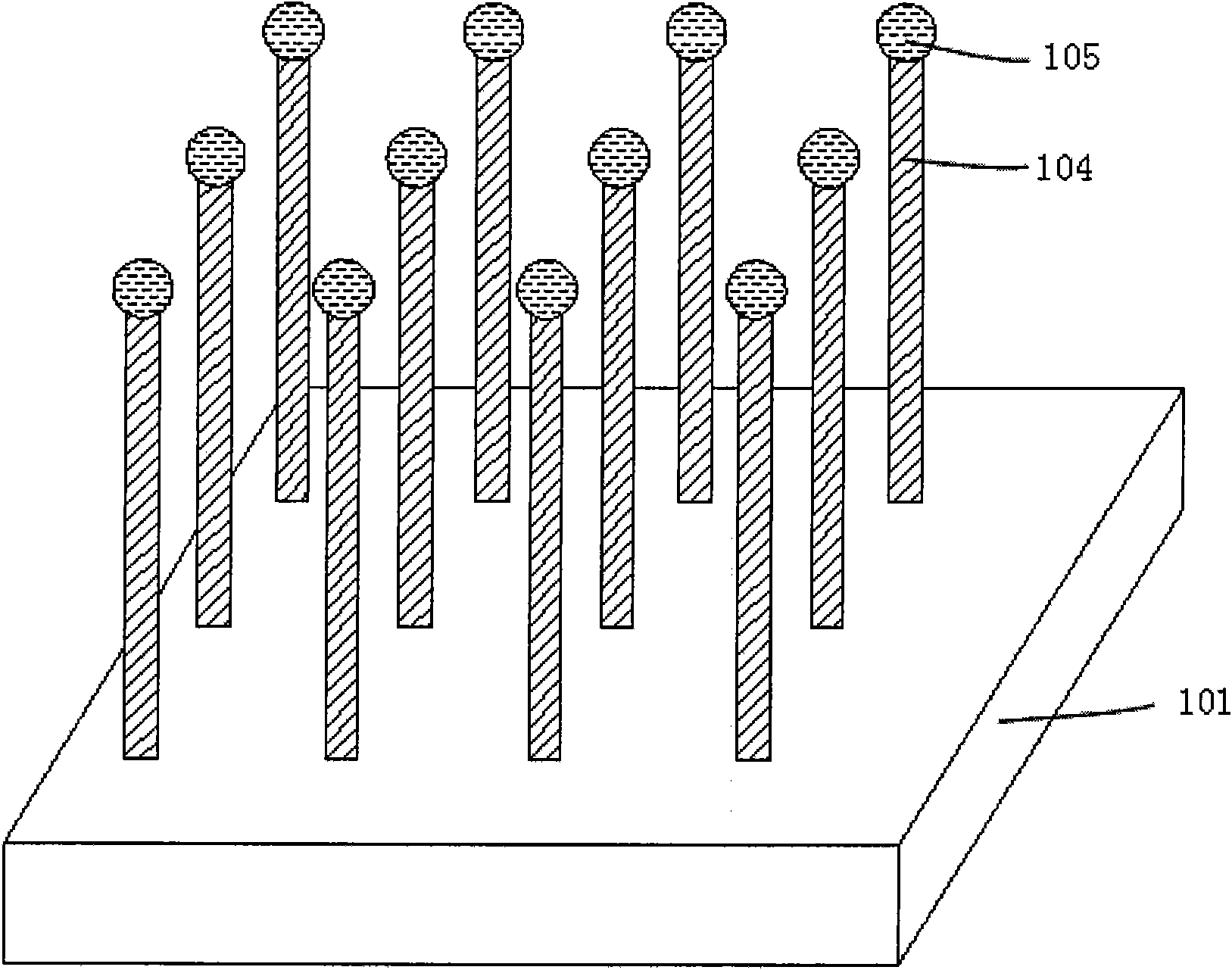

Titanium-carbide-based steel-bonded cemented carbide material and preparation method thereof

Owner:WUXI XINQUN NEW MATERIAL TECH CO LTD

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Quantum dot molecular light emitting device

InactiveCN102097564ABroad luminescence spectrumHigh strengthLaser detailsSemiconductor lasersMetal electrodesWaveguide

The invention relates to a quantum dot molecular light emitting device, which sequentially comprises the following structures from bottom to top: a lower gold germanium nickel metal electrode layer (1), a gallium arsenic substrate (2), a gallium arsenic buffer layer (3), a n-type aluminum gallium arsenic lower cladding layer (4), a gallium arsenic lower waveguide limiting layer (5), a quantum dotmolecular active area, a gallium arsenic upper waveguide limiting layer (9), a p-type aluminum gallium arsenic upper cladding layer (10), a p-type gallium arsenic ohmic contact layer (11), a dioxide silicon insulating layer (12) and an upper titanium platinum gold metal electrode layer (13), wherein the quantum dot molecular active area comprises n quantum dot molecular layers each of which comprises quantum dot molecules (6), a stress buffer layer (7) and an isolated layer (8), and n is a natural number not less than 1. According to the invention, the laterally coupled quantum dot molecules are utilized to manufacture an active area structure and corresponding light emitting devices, thereby widening the applicable scope of quantum dot and improving the performance of low dimension semiconductor device.

Owner:HUAZHONG UNIV OF SCI & TECH

Nanowire MOS transistor based on III-V element and preparation method thereof

InactiveCN101783367ASimple structureEasy to manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesNanowireSource material

Owner:FUDAN UNIV

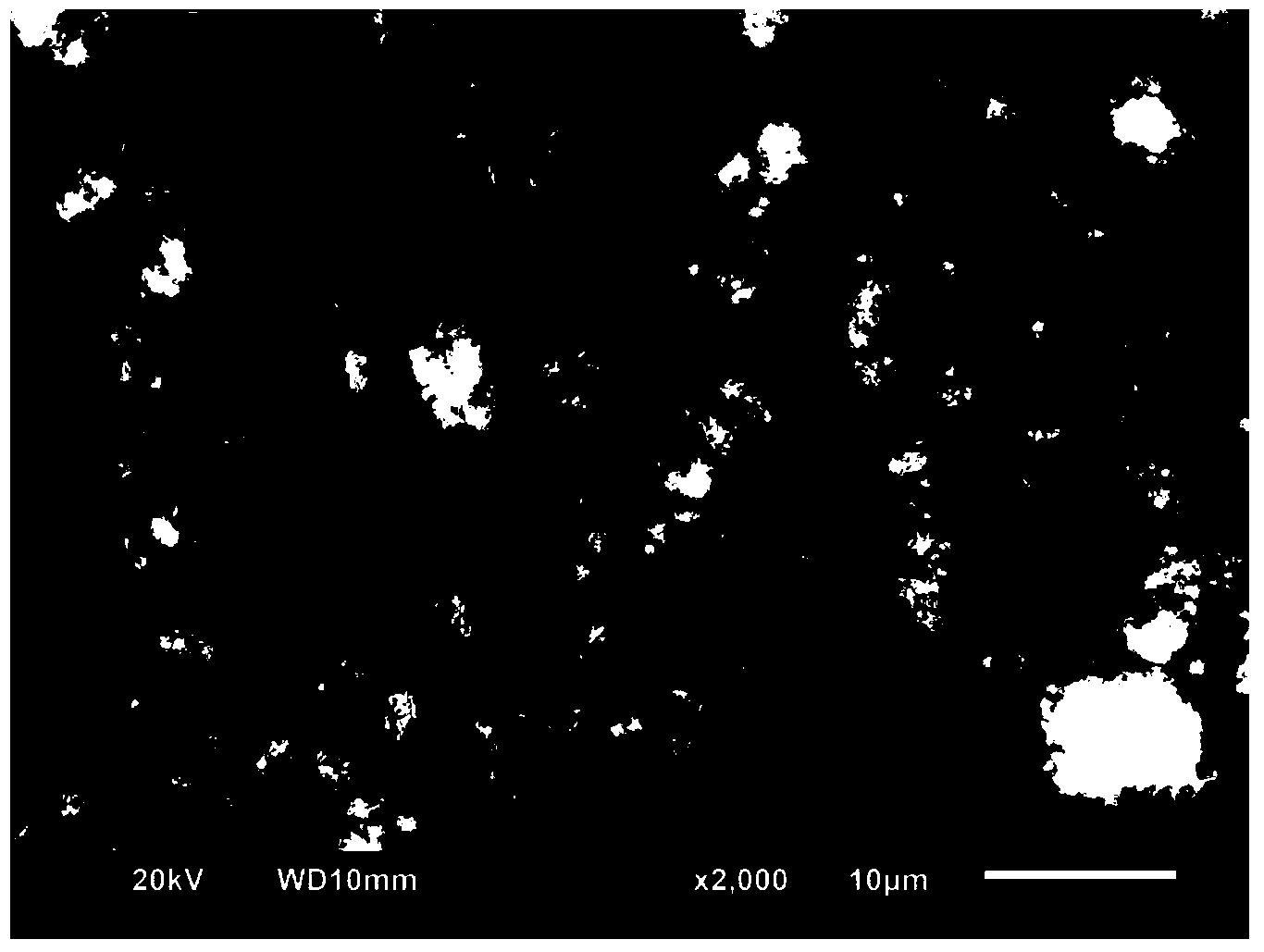

NiCoP nanoparticles grown on surface of g-C3N4 in situ as well as preparation method and application of NiCoP nanoparticles

InactiveCN107617443ASimple and fast manufacturing methodEasy to operatePhysical/chemical process catalystsHydrogen productionHydrogenNanoparticle

The invention provides NiCoP nanoparticles grown on the surface of g-C3N4 in situ as well as a preparation method and application of the NiCoP nanoparticles to production of hydrogen by photocatalytically decomposing water, and belongs to the technical field of photocatalytic decomposition of the water to prepare the hydrogen. The preparation method comprises the following steps: firstly, preparing g-C3N4powder particles; then adding 10mL to 30mL of secondary distilled water into 200mg to 400mg of the g-C3N4 powder particles; after carrying out ultrasonic treatment for 1h to 3h, stirring for 1h to 3h; then adding 10mg to 150mg of a nickel source and 10mg to 150mg of a cobalt source; after carrying out the ultrasonic treatment for 5min to 20min, stirring for 5min to 20min; then adding 50mgto 600mg of a phosphorous source; after carrying out the ultrasonic treatment for 1h to 3h, stirring for 1h to 3h; then drying under the condition that the temperature is 50 DEG C to 80 DEG C; after the water is completely volatilized, sufficiently grinding a product; then calcining for 1h to 3h in a nitrogen atmosphere under the condition that the temperature is 200 DEG C to 400 DEG C; finally, centrifuging and washing by utilizing the secondary distilled water and ethanol; drying a centrifugal product for 10h to 20h under a vacuum condition, so as to obtain the NiCoP nanoparticles grown on the surface of the g-C3N4 in situ.

Owner:JILIN UNIV

Boron-bearing chromium molybdenum nickel wear-resistant alloy and preparation method thereof

Owner:GUANGXI UNIV

NiCuSiFe alloy

Owner:WUFAN ALLOY ALUMINUM WUJIN

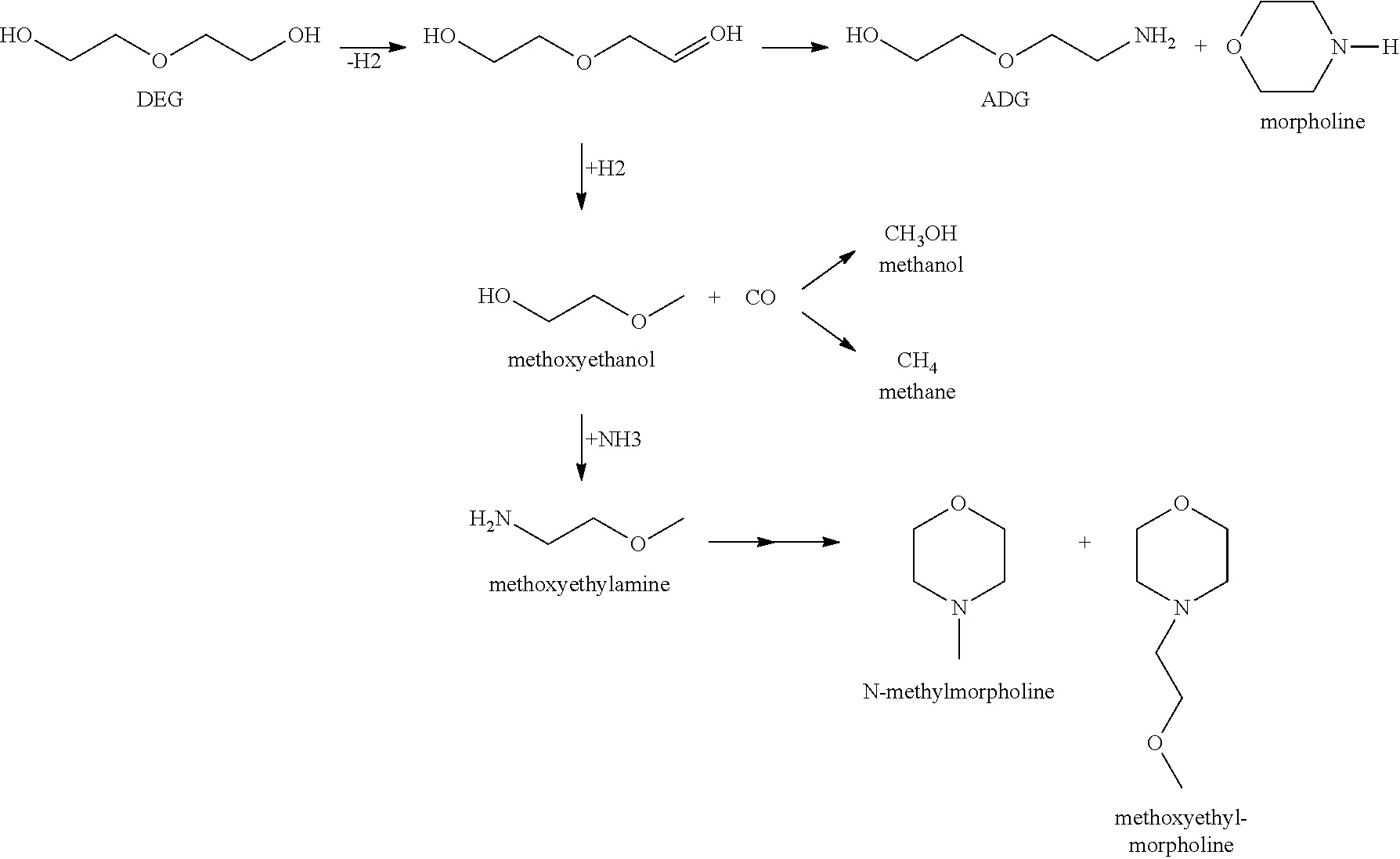

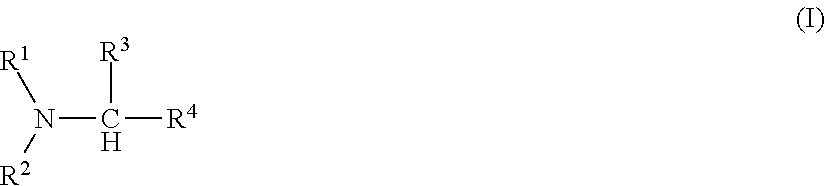

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

Nickel-based alloy powder material for repairing crystallizer foot roller and repairing method

ActiveCN112680634AImprove antioxidant capacityImprove thermal shock resistanceIncreasing energy efficiencyMetallic material coating processesOxidation resistantWear resistance

The invention discloses a nickel-based alloy powder material for repairing a crystallizer foot roller. The nickel-based alloy powder material comprises the following chemical components in percentage by mass of 22-28% of Cr, 8-12% of Mo, 3-4% of Nb, 1.0-2.5% of Si, 0.8-1.6% of B, 0.8-2% of V, 0.05-0.08% of C and the balance of Ni. The invention further discloses a repairing method of the crystallizer foot roller. The method comprises the following steps of 1, rough turning; 2, pre-flaw detection; 3, laser cladding, wherein a cladding layer comprises two layers, a base coat is iron-based alloy powder, a functional layer is cladded on the base coat, and the functional layer is made of nickel-based alloy powder; 4, finish turning; 5, grinding; and 6, post-flaw detection. The crystallizer foot roller repaired by using the material and the method provided by the invention has the advantages that the properties such as high-temperature oxidation resistance, cold and hot fatigue resistance and wear resistance are obviously improved, and the corresponding service life is also greatly prolonged.

Owner:TAIER (ANHUI) IND TECH SERVICE CO LTD

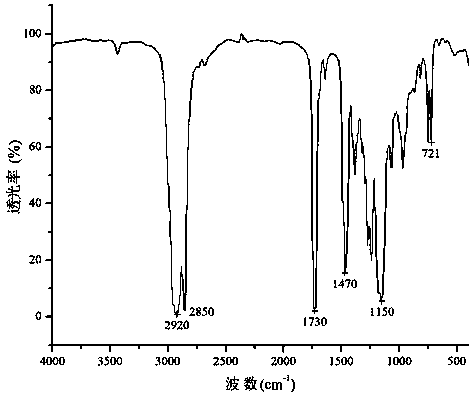

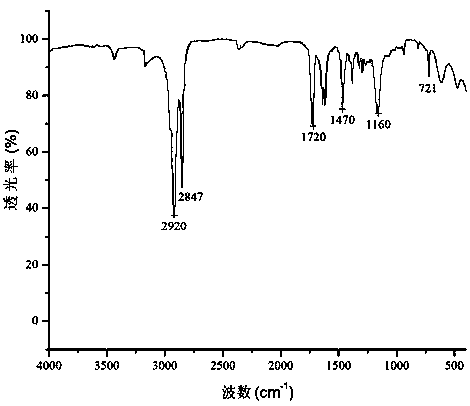

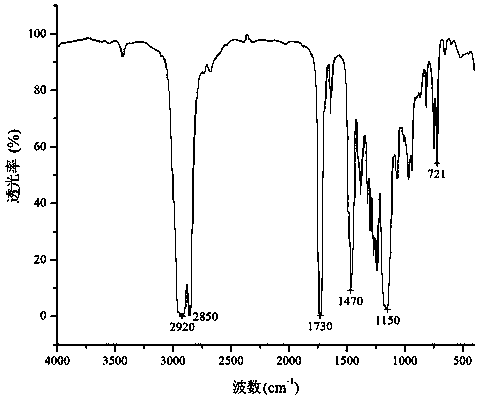

Polymethylacrylic acid higher ester pour point depressant, and preparation method and application thereof

Owner:XI'AN PETROLEUM UNIVERSITY

Forging method of nickel base alloy containing copper and nickel base alloy containing copper

ActiveCN104741494AImprove plasticityAvoid defects such as cracking and scrappingMetal-working apparatusIngotHeating furnace

The invention provides a forging method of nickel base alloy containing copper and the nickel base alloy containing copper and belongs to the technical field of forging technologies. The forging method overcomes the defects that because copper is added to the nickel base alloy, the hot working character is poor, and forge cracking is caused, and the yield can be effectively improved. The forging method comprises the steps of conducting billet forging, wherein preprocessed nickel base alloy ingots containing copper are placed in a heating furnace, the nickel base alloy ingots containing copper are heated to the temperature T1, the temperature T1 is kept, forging is conducted according to the forging ratio y1, so that forging stocks are obtained, the temperature T1 is 1120+ / -10 DEG C, and y1 is smaller than or equal to 1.4; conducting initial forming, wherein the forging stocks are arranged in the heating furnace to be heated, the temperature is kept, and forged pieces which are initially formed are obtained through forging; conducting final forging, wherein the initially formed forged pieces are arranged in the heating furnace to be heated to the temperature T3, the temperature T3 is kept, forging is conducted according to the forging ratio y3, so that finished forged pieces are obtained, the temperature T3 is higher than 1000 DEG C and lower than 1080+ / -10 DEG C, and y3 is larger than 1.5 and smaller than 2. The forging method can be used for forging of the nickel base alloy containing copper.

Owner:ENN ENVIROTECH CO LTD

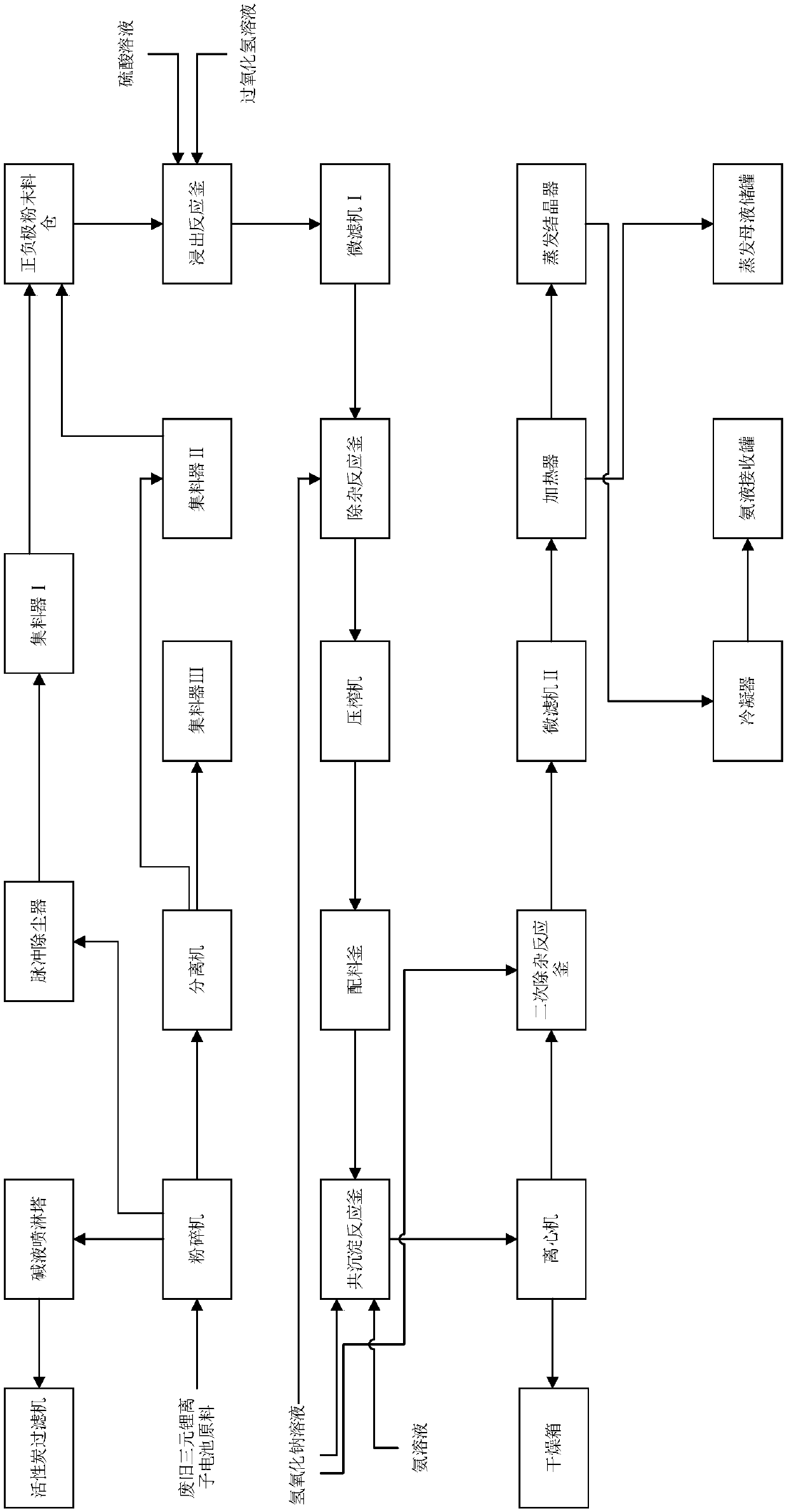

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

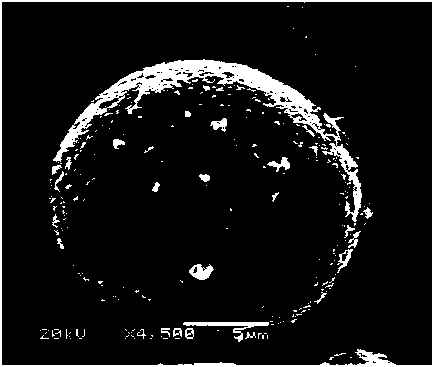

Method for preparing polysilicon

InactiveCN1727525AReduce the temperatureLower threshold voltagePolycrystalline material growthSemiconductor/solid-state device manufacturingFine lineSemiconductor materials

A process for preparing polycrystal silicon includes preparing non-crystal silicon film on glass substrate, preparing a thin Ni layer, photoetching the Ni layer to become fine lines, laser annealing, removing excessive Ni, and laser annealing again for crystallizing the silicon film. Its advantages are short time and low substrate temp.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

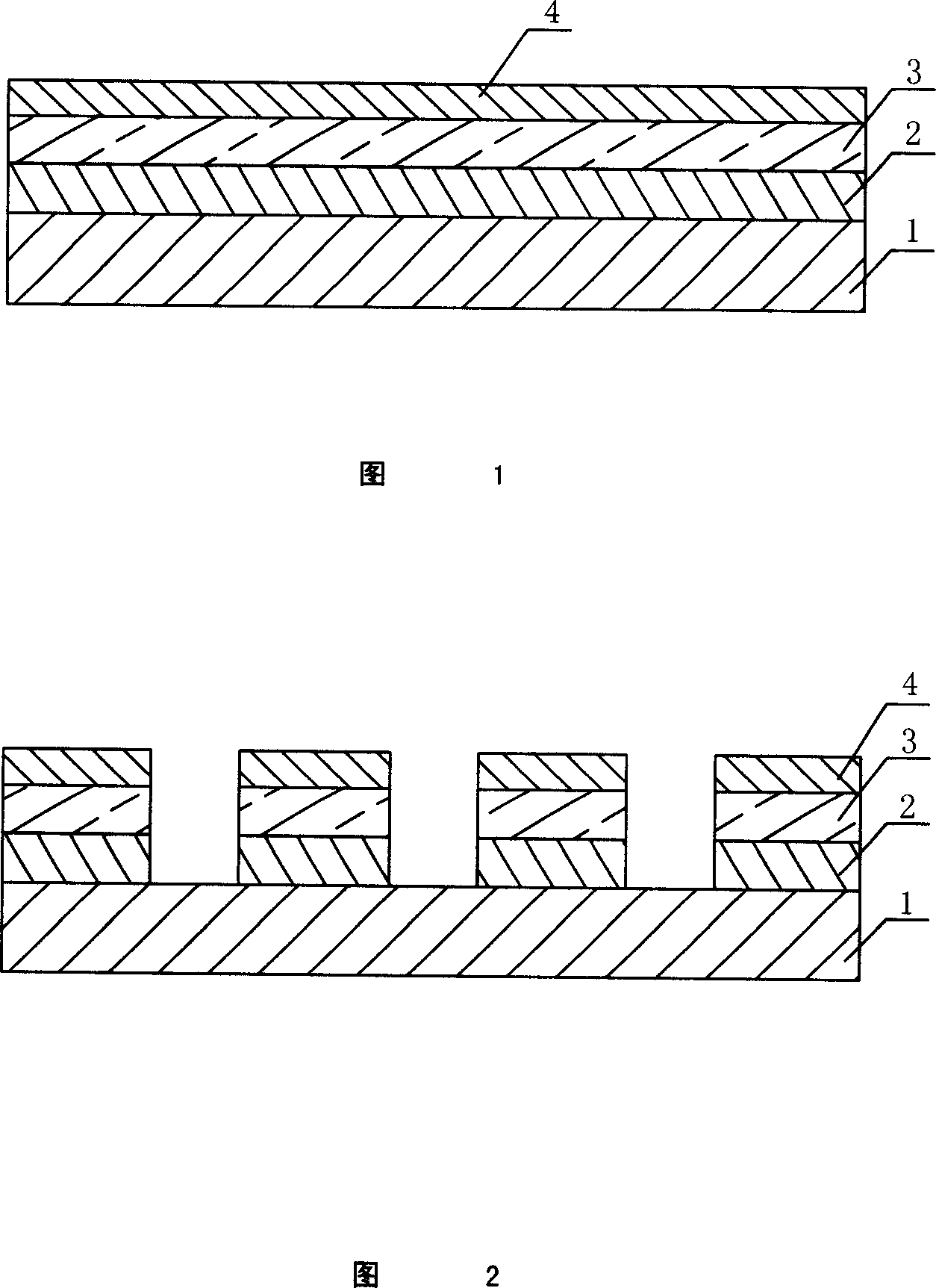

Ceramic PCB manufacturing method through metal line filling

InactiveCN105407649AWide thickness rangeSimple processConductive pattern formationCopper foilLED lamp

Owner:深圳恒宝士线路板有限公司

Method for preparing laser cladding layer through double-layer organic coating iron-based alloy powder

ActiveCN105081313AWith metallic lusterControl gas compositionMetallic material coating processesDistillationSlurry

The invention discloses a method for preparing a laser cladding layer through double-layer organic coating iron-based alloy powder. 15%-19% of chromium, 2%-9% of nickel, 0.05%-0.15% of boron, 0.1%-0.7% of silicon, carbon less than 0.3% and the balance iron are selected; and then rosin accounting for 0.06%-0.2% of the total weight of the iron-based alloy powder and industrial starch accounting for 0.15%-0.4% of the total weight of the iron-based alloy powder are selected. The selected rosin is added to absolute ethyl alcohol, and the iron-based alloy powder is added to the absolute ethyl alcohol with the dissolved rosin; and rosin film coated iron-based alloy powder is prepared through drying by distillation, drying and breaking. Then, the industrial starch is added to pure water to be heated and stirred to obtain an even pasty solution, and the rosin film coated iron-based alloy powder is put in the pasty industrial starch; secondary mixed slurry is obtained; and the double-layer organic coating iron-based alloy powder can be obtained through stirring, drying by distillation and breaking. The laser cladding layer of the powder is flat in surface, has metal luster and is high in comprehensive quality.

Owner:NANHUA UNIV

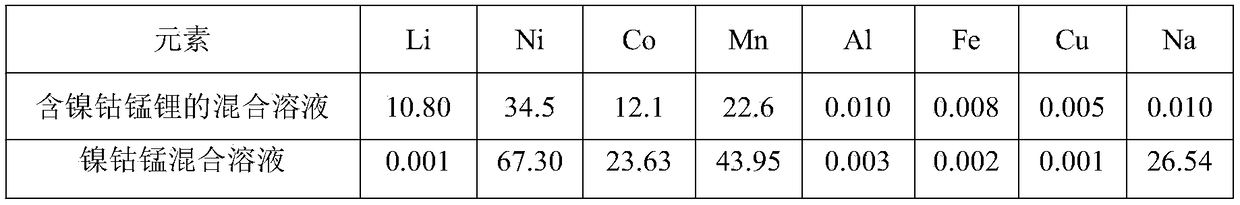

Method for efficiently separating valuable metal from mixed solution containing nickel, cobalt, manganese and lithium

Owner:CHANGSHA RES INST OF MINING & METALLURGY

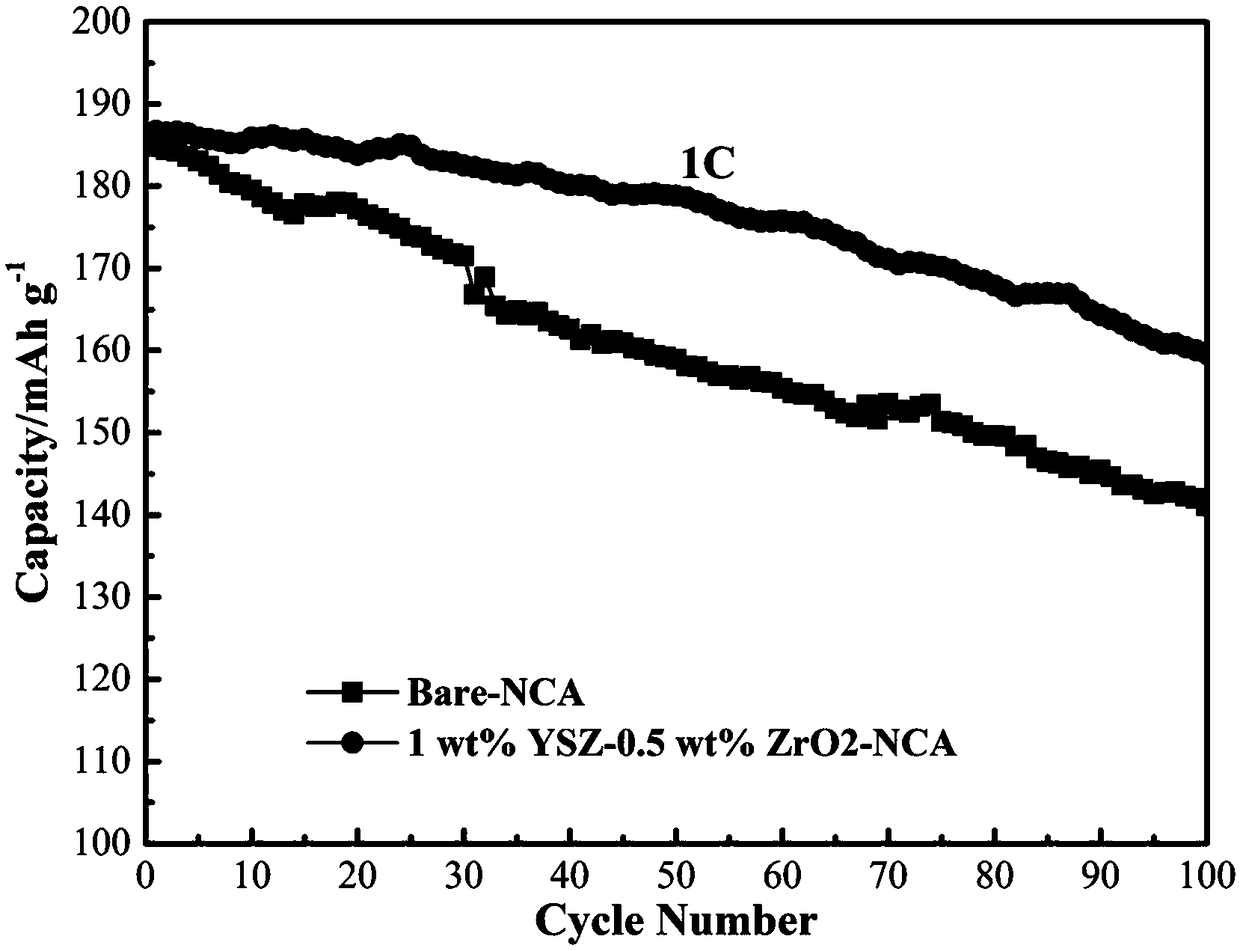

A surface modify ternary cathode material, a preparation method thereof, and a battery made of that surface modified ternary cathode material

ActiveCN109065858APromote migrationFast migration rateCell electrodesSecondary cellsOxygen vacancyMagnification

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

High-strength high-conductivity rare earth copper-magnesium alloy contact wire and manufacturing method thereof

InactiveCN106555073AMeet performance requirementsHigh elongationSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementCerium

Owner:HENAN UNIV OF SCI & TECH

An organic light-emitting display device electrode substrate

InactiveCN1971936ALower resistanceImprove display efficiencySemiconductor/solid-state device detailsSolid-state devicesIndiumNickel

This invention discloses one organic light display electrode baseboard, which orderly comprises electrode layer, wire layer and protection layer composed of vanadium indium and zinc or nickel, wherein, the wire layer adopts silver, copper or aluminum metal or alloy and mixture with low electrode resistance to improve display effect; the materials is easily damaged by the oxidation or fulguration element and so this invention sets one protection layer composed of vanadium, indium or zinc or nickel element on the wire layer.

Owner:KUNSHAN VISIONOX DISPLAY TECH +1

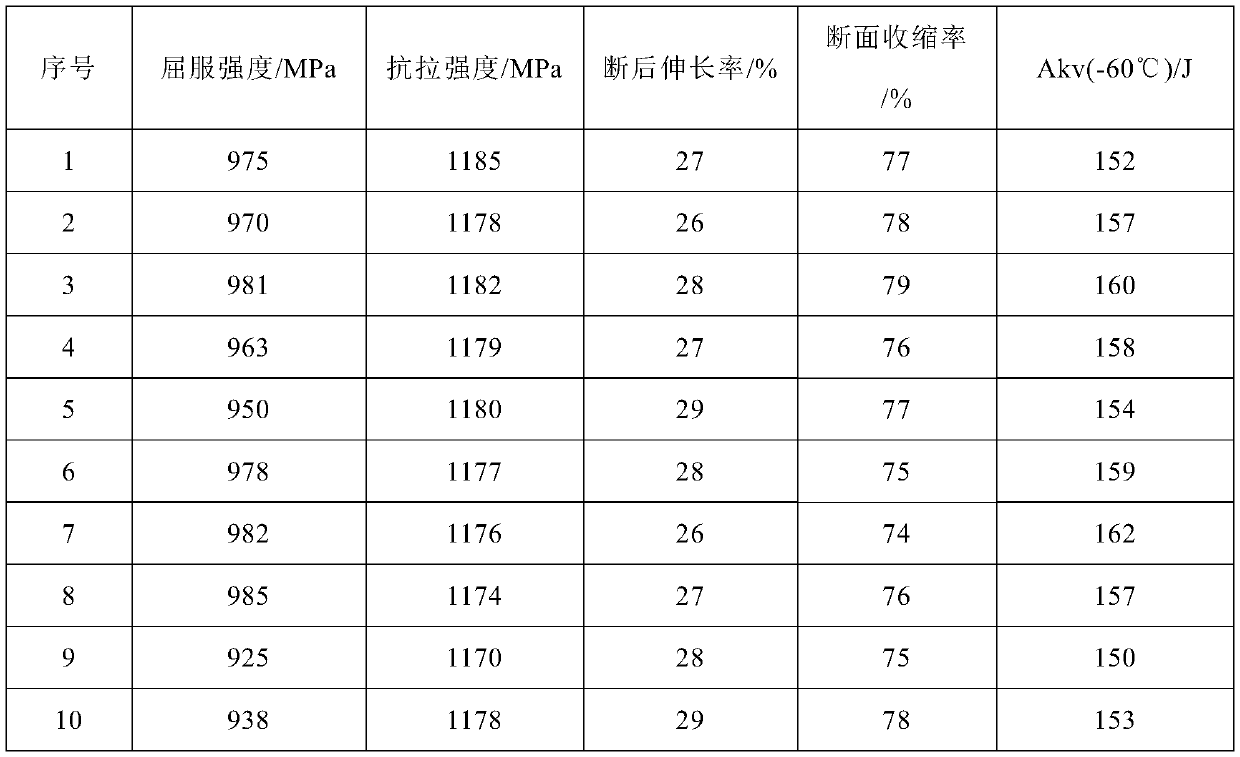

High-strength 23Mn2CrNiMnVERA steel for railway train connection and preparation method thereof

Owner:SHANDONG XIWANG SPECIAL STEEL

Plating layer for electrochemistry corrosion resistant electronic encapsulation shell

InactiveCN101649456ASemiconductor/solid-state device manufacturingMetallic material coating processesCorrosion resistantNickel

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

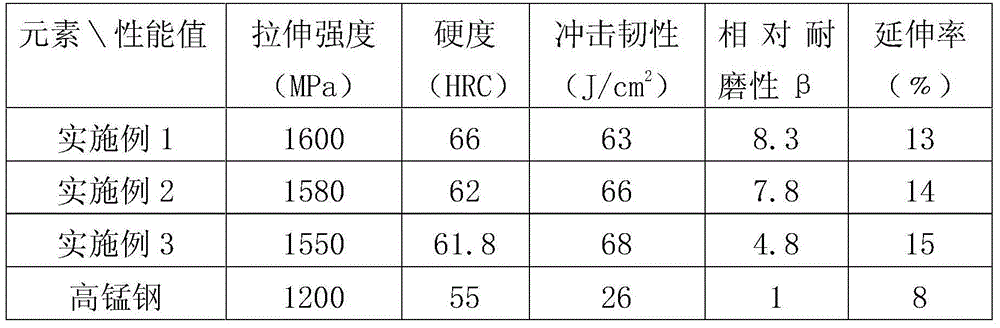

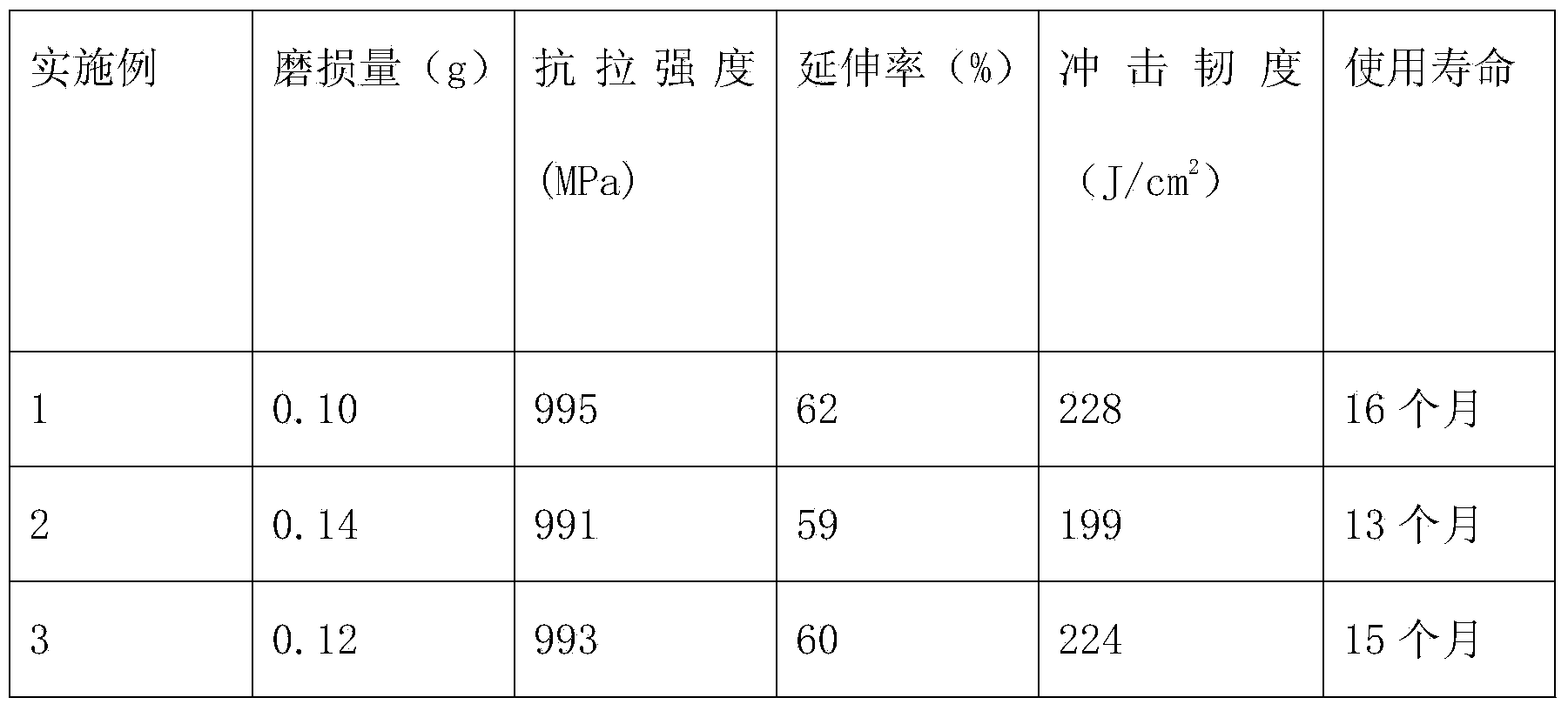

Anti-corrosion and anti-wear high manganese steel and preparation method thereof

Owner:江苏久华环保科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap