Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Copper foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

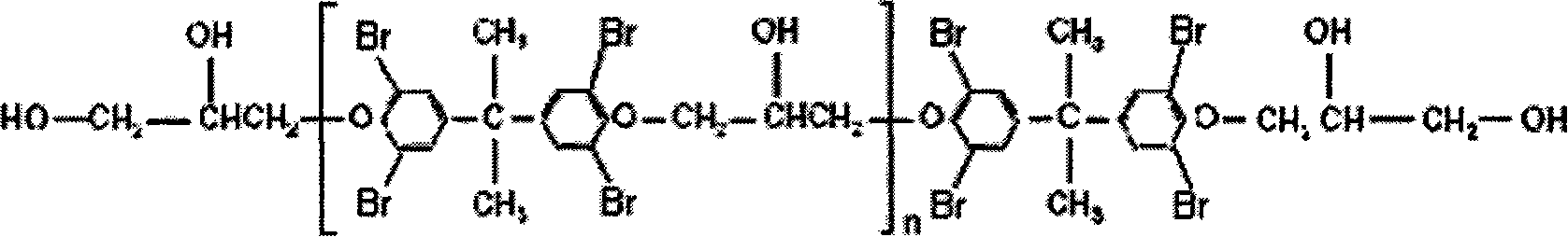

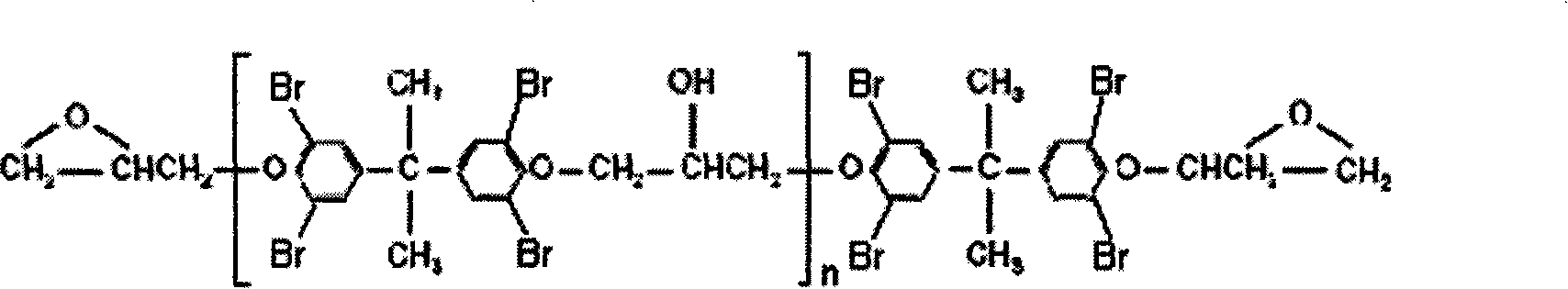

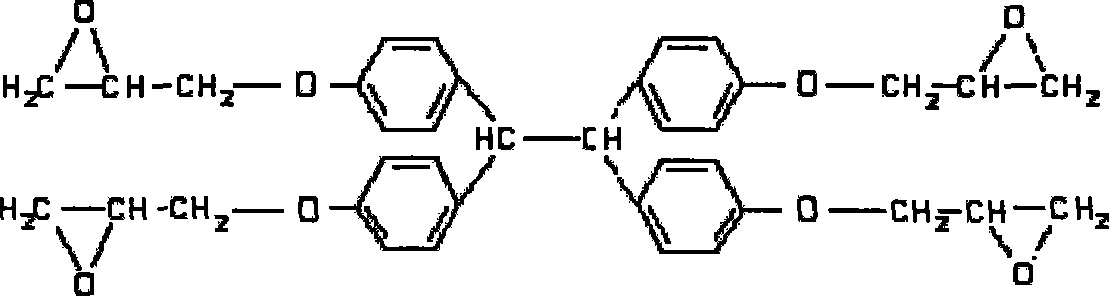

Resin composition and semi-solidifying sheet for printed board prepared from the same

Owner:GUANGDONG SHENGYI SCI TECH

Method for manufacturing copper clad laminated board adapted to leadless process

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

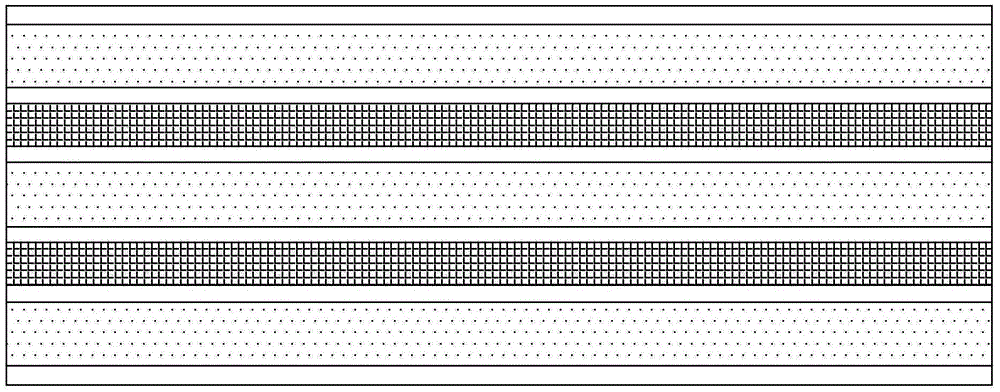

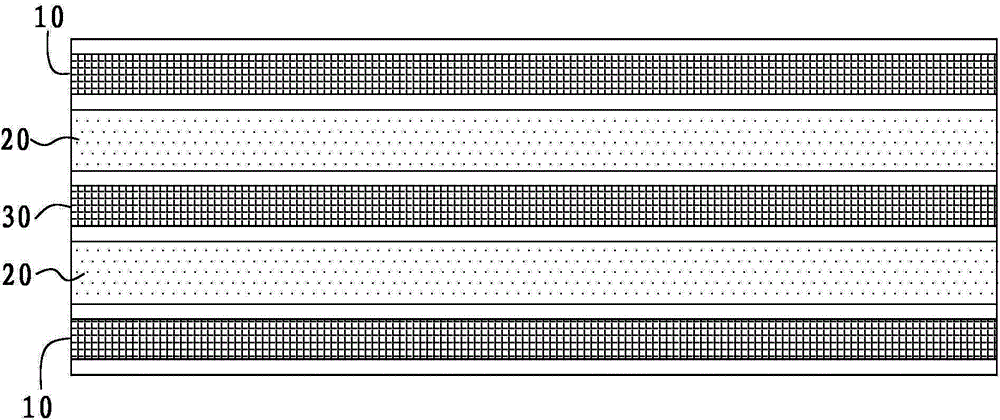

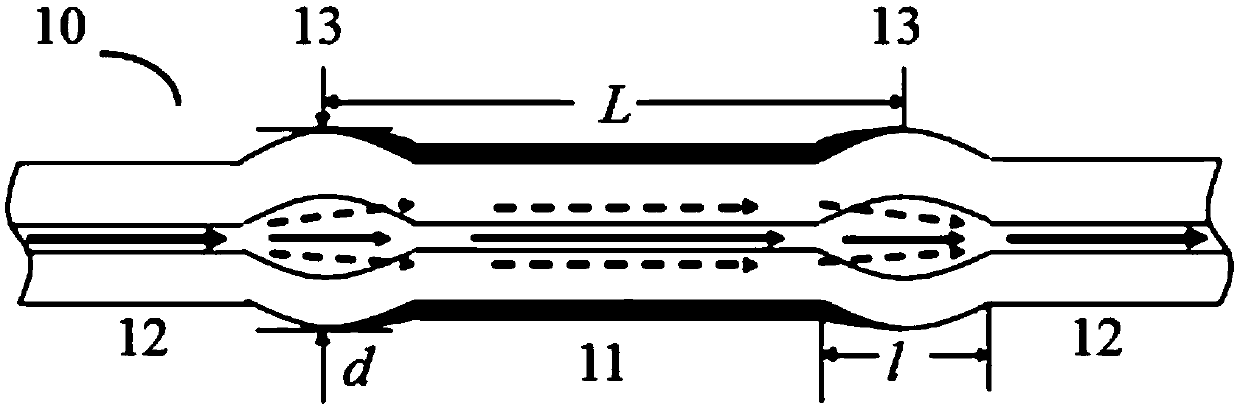

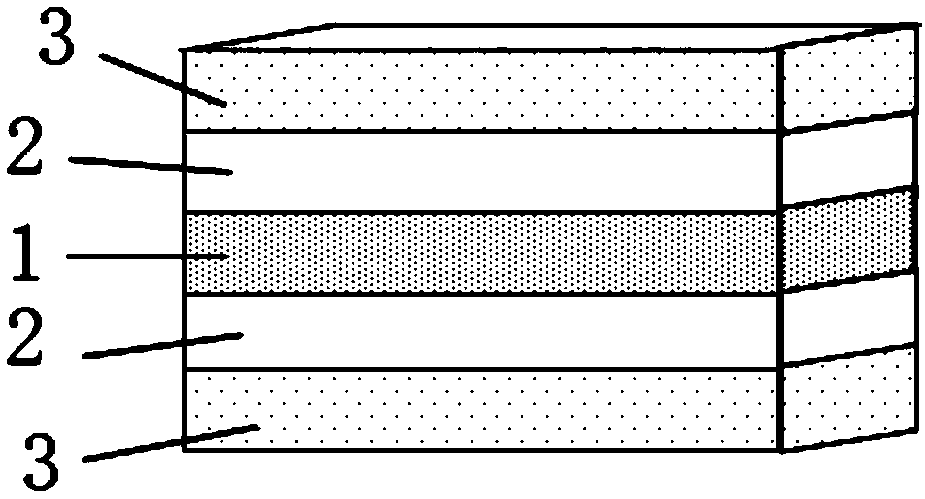

Broadband polarization insensitive meta-material wave absorber

InactiveCN103647152AAchieving Broadband TargetsChange the working frequency bandAntennasCopper foilElectromagnetic wave equation

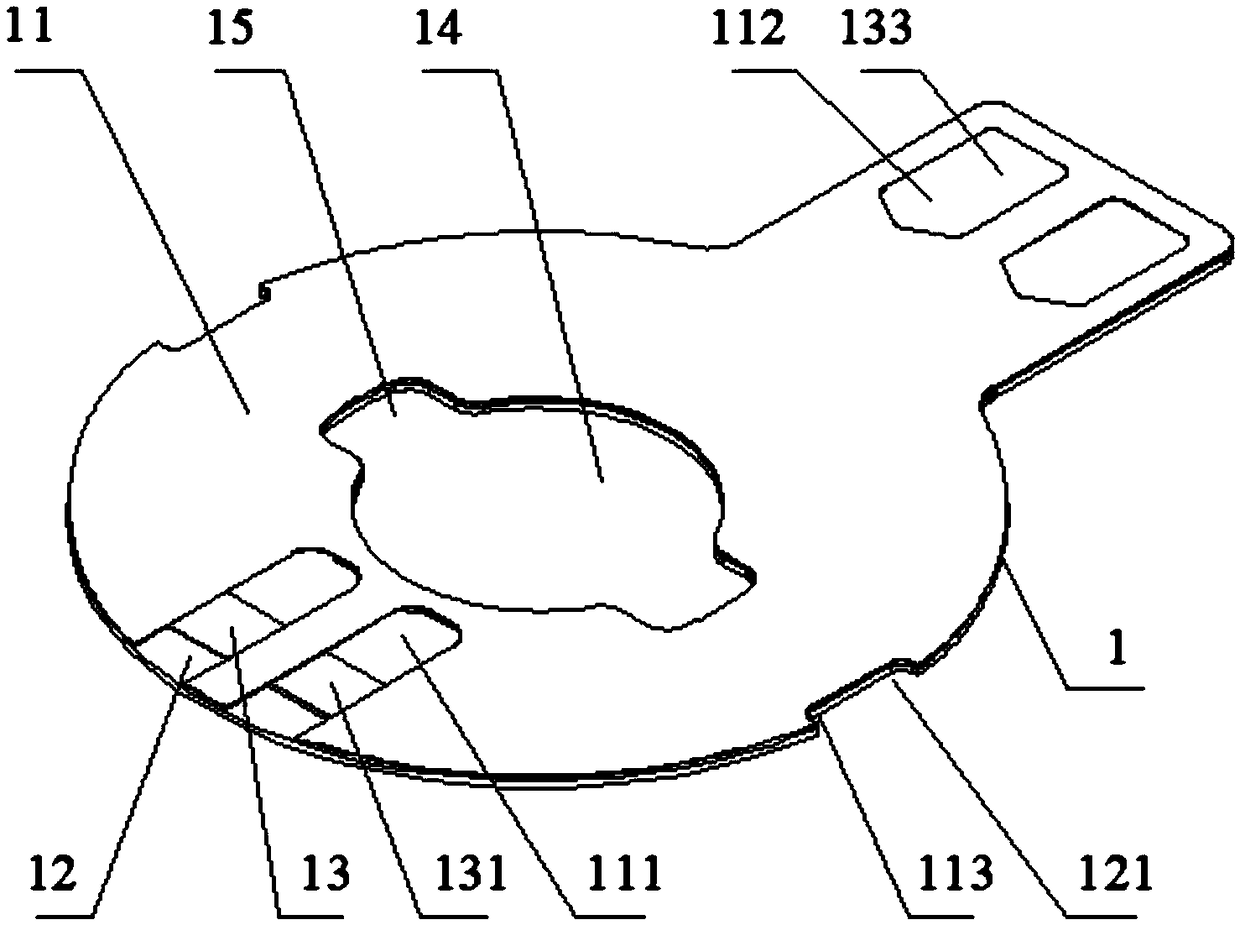

The invention belongs to the technical field of microwave antenna engineering, and discloses a broadband polarization insensitive meta-material wave absorber, for the purpose of solving the problems of narrow working bandwidth and sensitivity of incident electric field wave polarization directions of a conventional meta-material wave absorber. The broadband polarization insensitive meta-material wave absorber comprises a top-layer resonance structure, a middle-layer medium plate and bottom-layer copper foil, wherein the resonance structure comprises an opening resonance ring and a metal sheet disposed in the ring; when electromagnetic waves are incident to the wave absorber, the resonance structure generates a magnetic field loop, the medium plate generates dielectric loss, and electromagnetic energy is converted into heat energy through loss so that loss of the electromagnetic waves is absorbed. The wave absorber has absorption effects for incoming waves from different polarization directions so that the wave absorber is insensitive to the polarization directions of the incoming waves. At the same time, the working bandwidth of the wave absorber reaches 9.20 GHz. The broadband polarization insensitive meta-material wave absorber is applied to the field of electromagnetic interference shielding and stealth technologies and the like.

Owner:HARBIN INST OF TECH

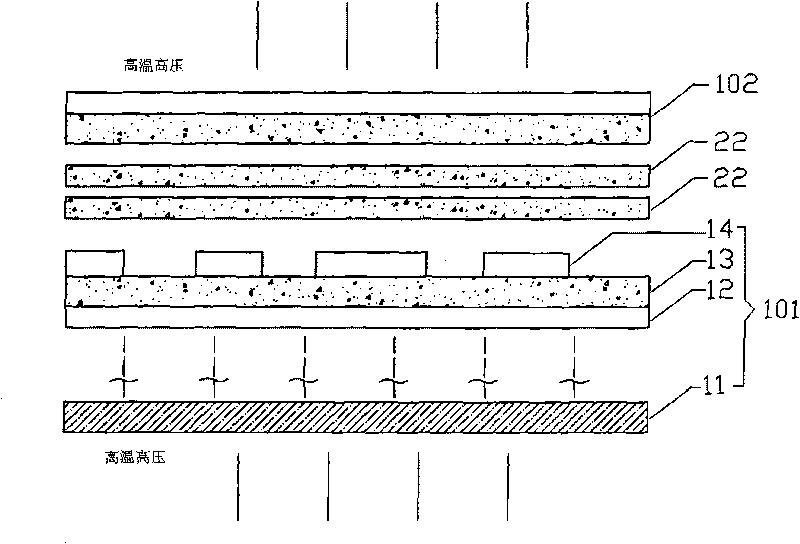

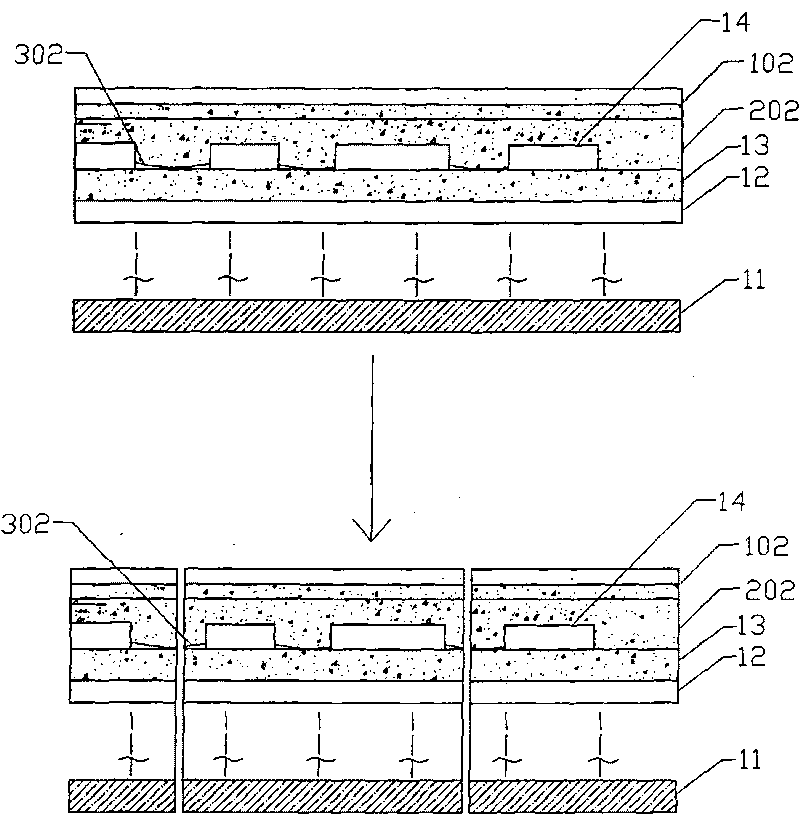

Process for pressing galvanized PCB boards and multi-layer PCB board

InactiveCN101711101APrevent glue shortageAvoid quality problemsPrinted circuit detailsMultilayer circuit manufactureEngineeringWork in process

Owner:SHENNAN CIRCUITS

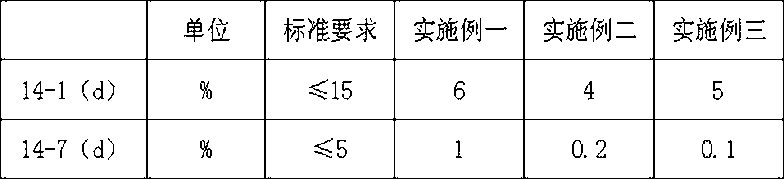

Additive and method for producing 6 micron high-hardness electrolytic copper foil by using additive

The invention relates to an additive. The additive comprises a hardness agent and a brightening agent; the hardness agent is an aqueous solution A containing 1,3-thiazolidin-2-one, DPS and MESS, wherein in the aqueous solution A, the concentration of 1,3-thiazolidin-2-one is 0.5-10 ppm, the concentration of DPS is 10-50 ppm, and the concentration of MESS is 1-20 ppm; and the brightening agent is an aqueous solution B containing SPS and Cl-, wherein in the aqueous solution B, the concentration of SPS is 10-50 ppm, and the concentration of Cl- is 10-30 ppm. According to 6 micron electrolytic copper foil made through the method, a HVS-1000 desktop hardness meter is adopted for detecting a hardness value, hardness is remarkably improved (can reach 120-150 HV), water ripples are greatly relieved, and the added technical value is remarkably improved.

Owner:LINGBAO WASON COPPER FOIL

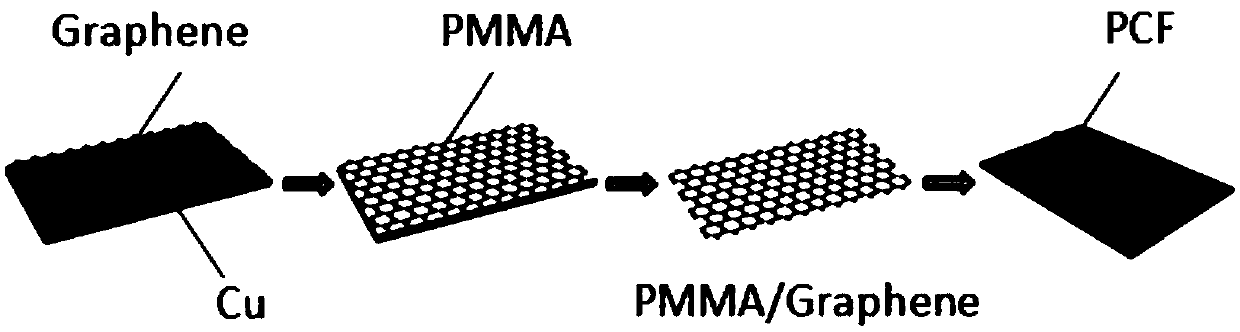

Manufacturing process of graphene transparent conductive film

Owner:苏州瑞邦塑胶有限公司

Printed circuit board and preparation method thereof

InactiveCN104159392ASmall expansion and contractionUniform media thicknessPrinted circuit detailsMultilayer circuit manufactureCopper foilElectrical impedance

Owner:SHENZHEN SUNTAK MULTILAYER PCB

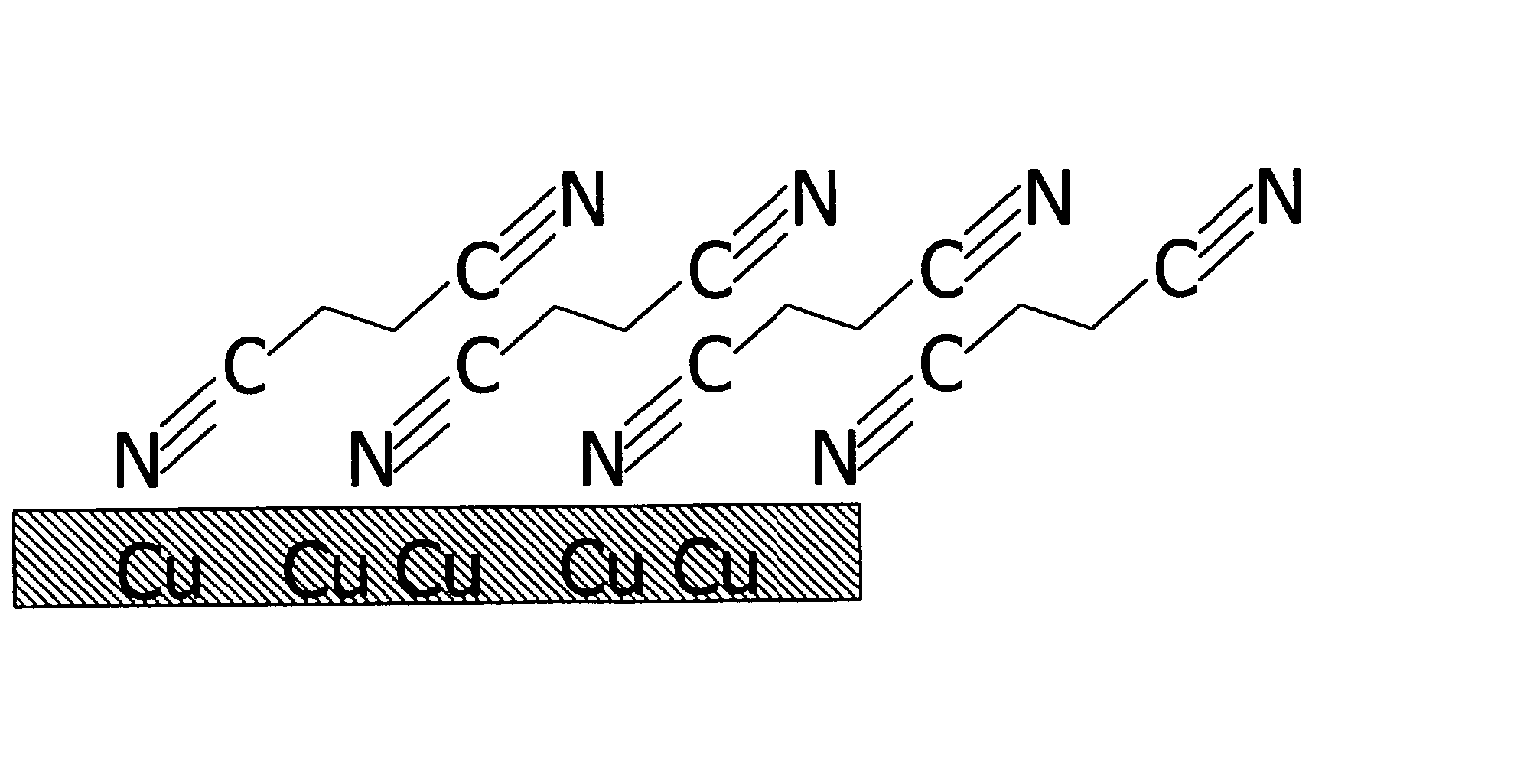

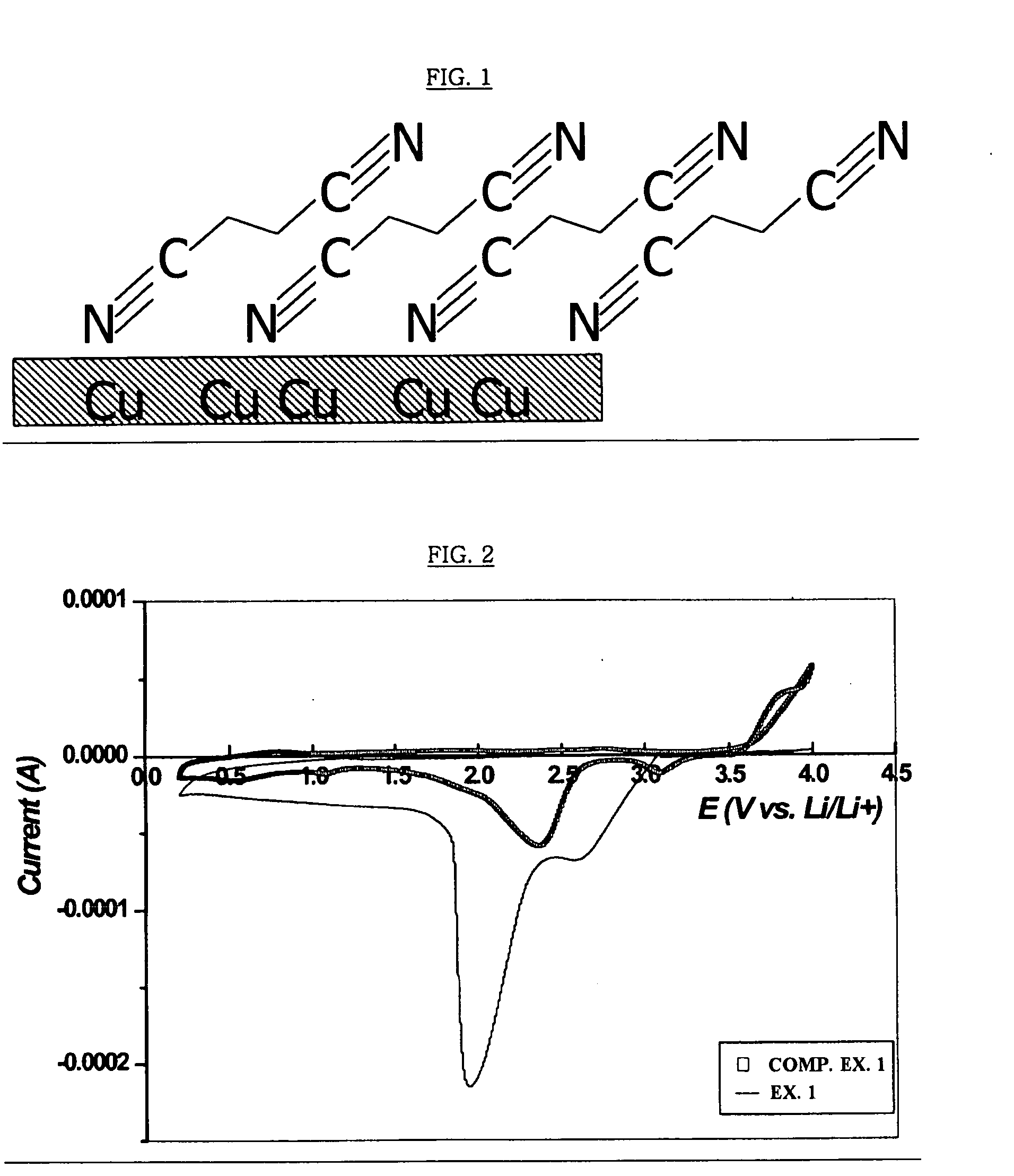

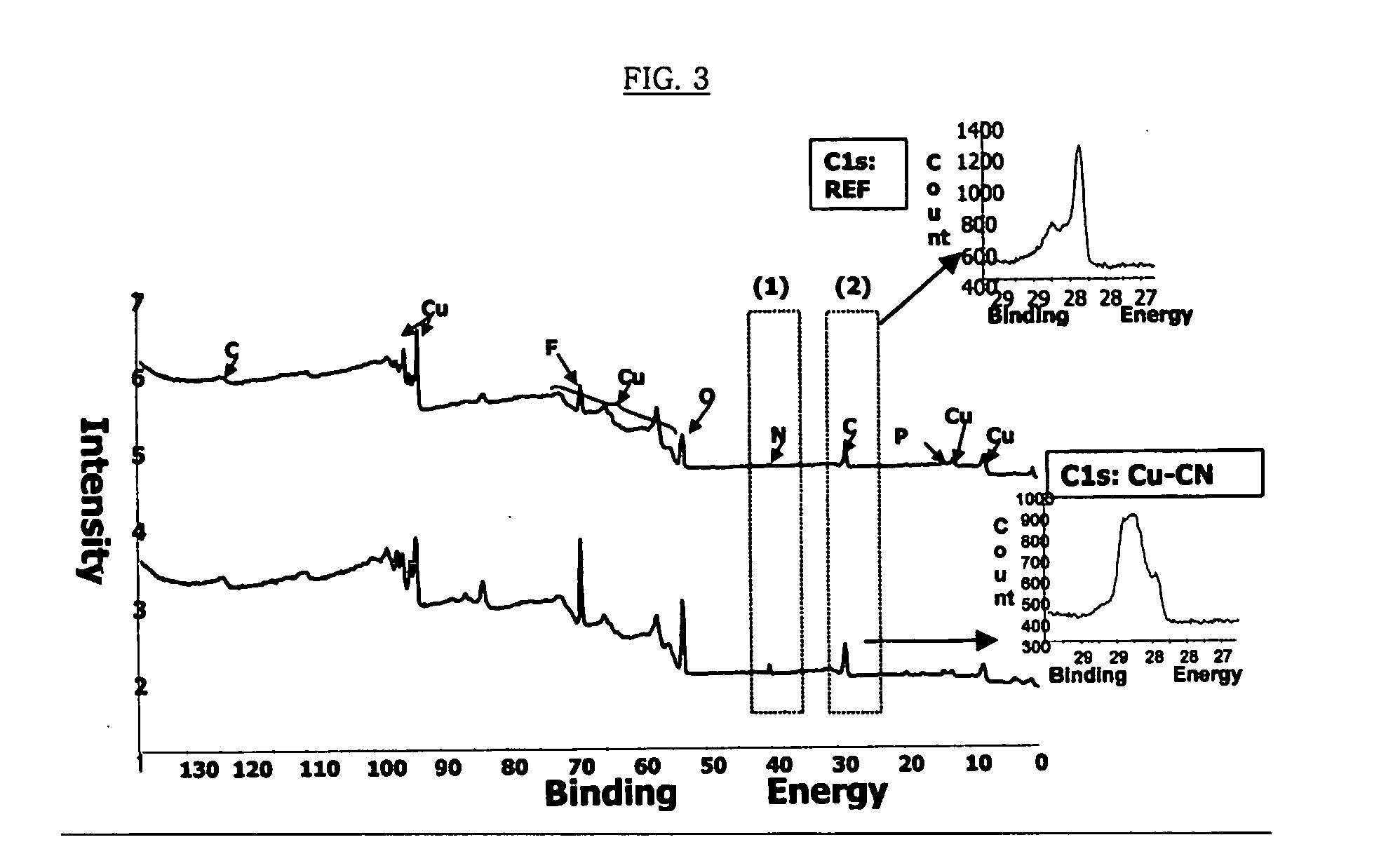

Copper collector for secondary battery comprising Cu-nitrile compound complex formed on surface thereof

ActiveUS20060147803A1Improve capacity restorabilityImprove battery qualityFinal product manufactureElectrode carriers/collectorsLithiumCopper foil

Owner:LG ENERGY SOLUTION LTD

Ceramic PCB manufacturing method through metal line filling

InactiveCN105407649AWide thickness rangeSimple processConductive pattern formationCopper foilLED lamp

Owner:深圳恒宝士线路板有限公司

Graphene optical fiber sensor and preparation method and application thereof

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Lithium secondary battery possessing stress relaxation layer

InactiveCN102420339AImprove cycle lifeFinal product manufactureElectrode carriers/collectorsAdhesiveEngineering

The invention provides a high-capacity lithium secondary battery which relaxes the stress on the electrode to prevent the falling or loosing of the electrode. The degradation of the lithium secondary battery caused by the charging-discharging circulation is not serious. The lithium secondary battery includes a winding group which is formed by winding the anode and the cathode together, and a baffle plate is arranged between the anode and the cathode. The anode and the cathode can absorb and discharge lithium ions reversibly. The lithium secondary battery also includes an organic electrolyte solution which dissolves the electrolytes containing the lithium ions. The cathode s formed by coating an agent-mixed layer which contains an active material and an adhesive on a collector electrode. The collector electrode is formed by arranging the stress relaxation layer possessing the inner stress on at least one side of a surface or the back of a copper foil.

Owner:HITACHI LTD

Manufacturing method of printed circuit board solder-resist plug hole structure, and printed circuit board

ActiveCN105451437AAvoid short circuitElectrical connection printed elementsPrinted element electric connection formationResistTime condition

The embodiment of the invention discloses a manufacturing method of a printed circuit board solder-resist plug hole structure, and a printed circuit board. The manufacturing method comprises the steps of: acquiring the printed circuit board after completing inner layer graph manufacturing and press-fit operation, and forming a via hole in a solder-resist region on an outer layer copper foil of the printed circuit board; filling the via hole with solder-resist ink after plating a metal layer on the hole wall of the via hole; baking the via hole filled with the solder-resist ink in a segmented manner for curing under preset temperature and time conditions; forming openings in portholes on both ends of the via hole filled with the solder-resist ink; and printing resin at the portholes on both ends of the via hole. The manufacturing method can solve the problems of open circuit of dense lines and open circuit of the via hole due to inexistence of metal therein.

Owner:SHENNAN CIRCUITS

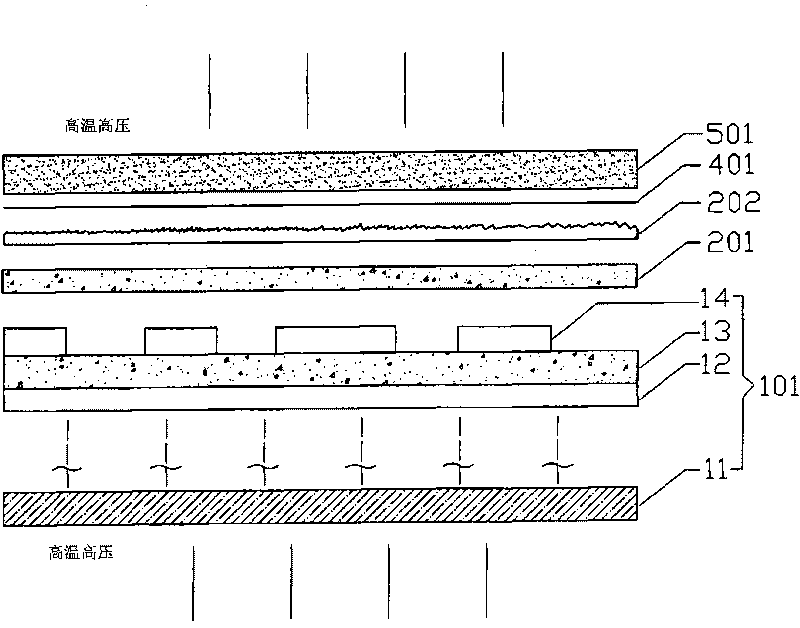

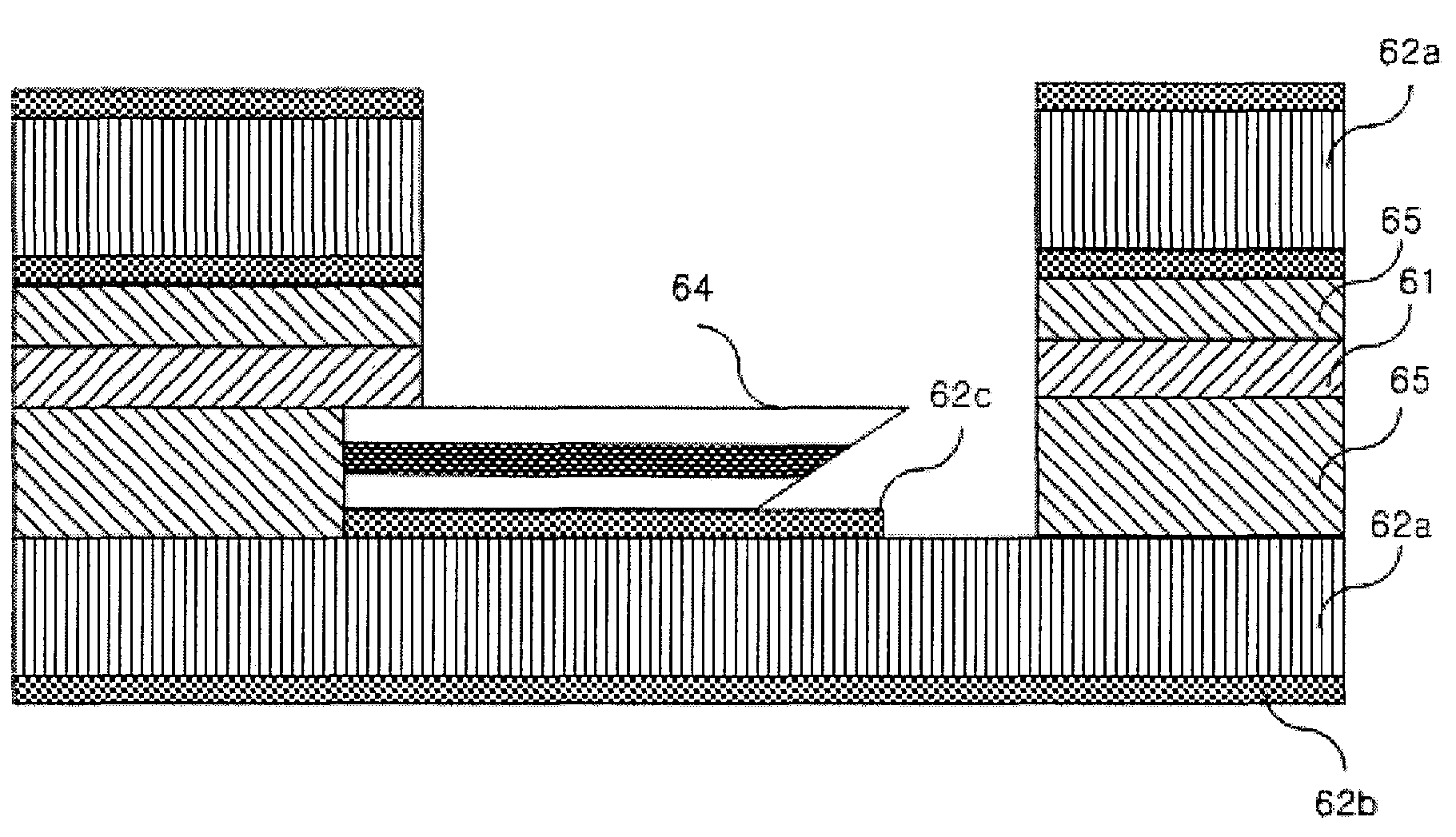

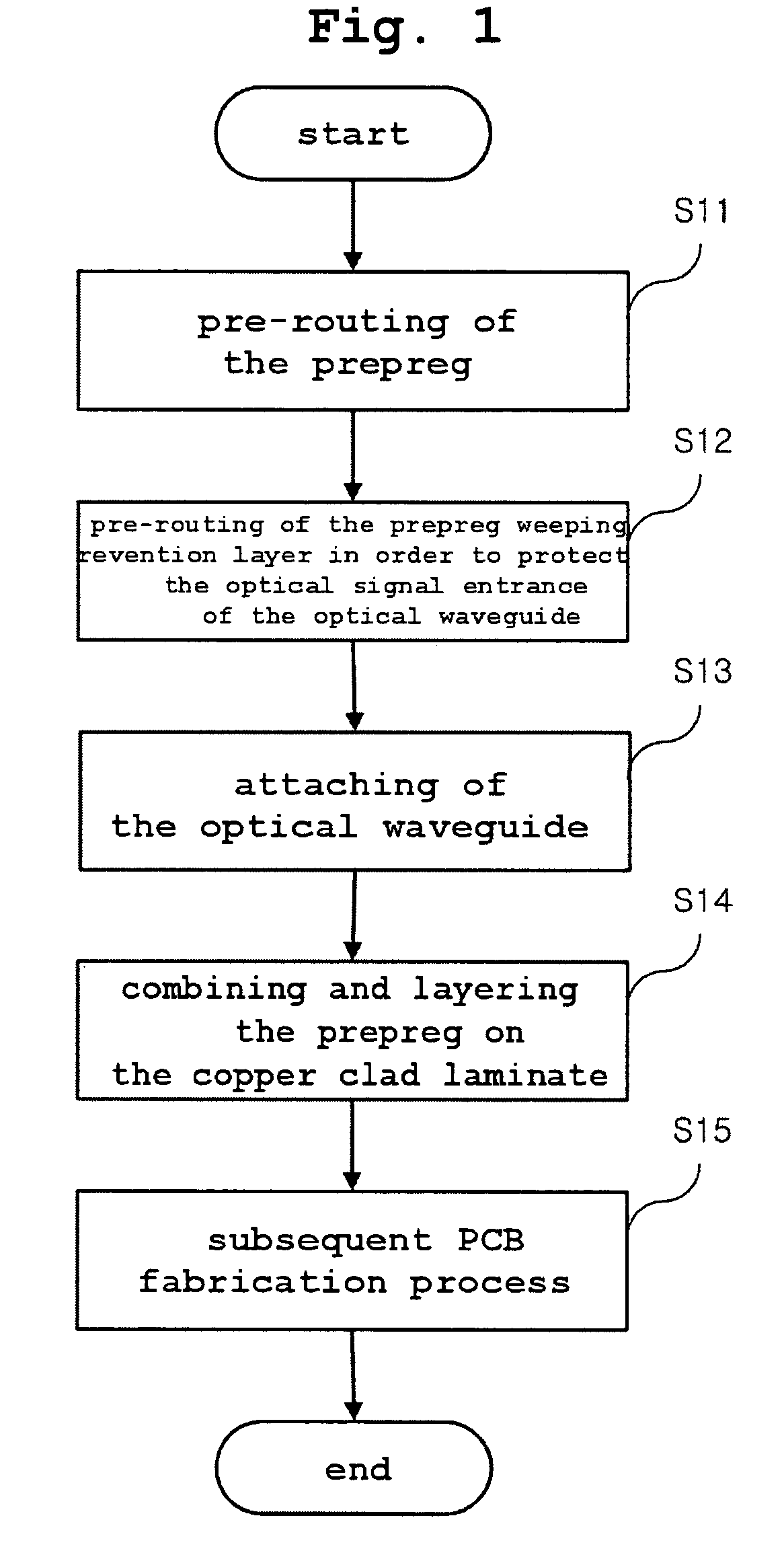

Method of fabricating multi-layered printed circuit board for optical waveguides

InactiveUS7046870B2Facilitating precise interfacing of optical signalPrinted circuit assemblingLine/current collector detailsAdhesiveCopper foil

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Silicon-based negative electrode material and preparation method thereof, lithium ion battery and electric appliance

InactiveCN112820847AImprove cycle stabilityHigh reversible capacityElectrode thermal treatmentNegative electrodesElectrical batteryCopper foil

The invention discloses a silicon-based negative electrode material and a preparation method thereof, a lithium ion battery and an electric appliance and relates to the technical field of battery electrode material preparation. The preparation method of the silicon-based negative electrode material comprises the following steps: annealing a primary negative electrode material which is obtained by cold spraying and is loaded with a Si-Cu coating on the surface in an inert gas atmosphere at the temperature of 500-800 DEG C, and preserving heat for 7-9 hours. The silicon-based negative electrode material is prepared by the preparation method. The lithium ion battery adopts the silicon-based negative electrode material as a negative electrode. The electric appliance takes the lithium ion battery as a power supply. After the primary negative electrode material of the Si-Cu coating is obtained through cold spraying on the copper foil, the Si-Cu3Si-Cu composite material obtained through annealing treatment at the proper temperature and the proper heat preservation time is used as the negative electrode material of the lithium ion battery and has good cycle stability and reversible capacity.

Owner:GUANGDONG INST OF NEW MATERIALS

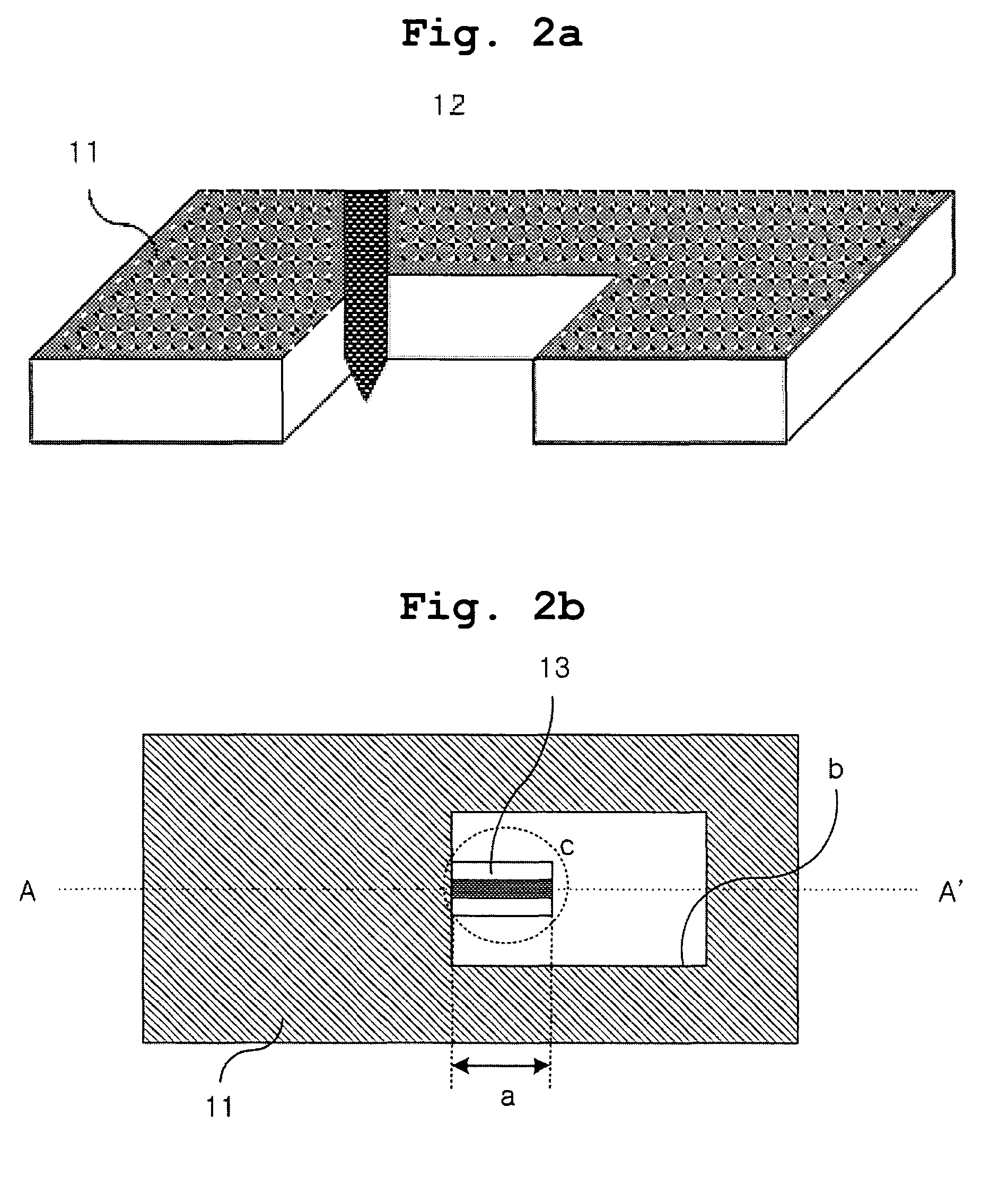

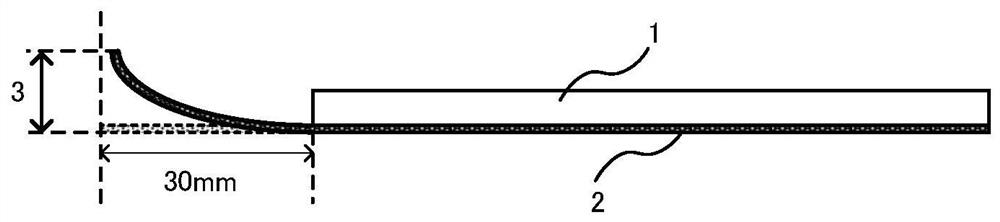

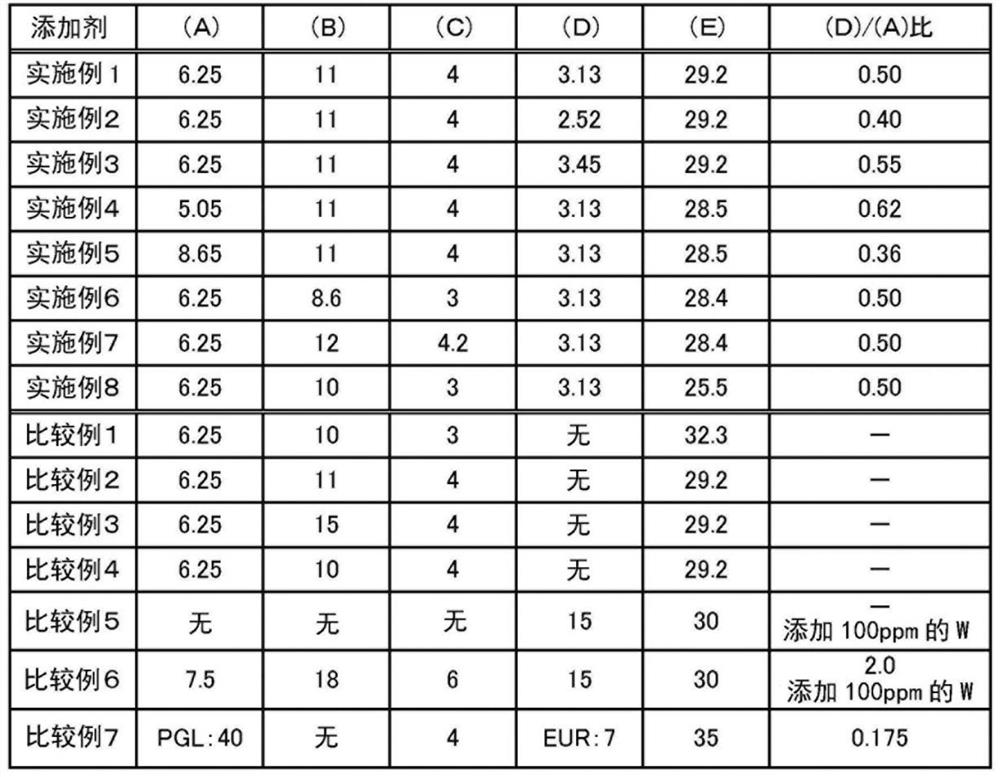

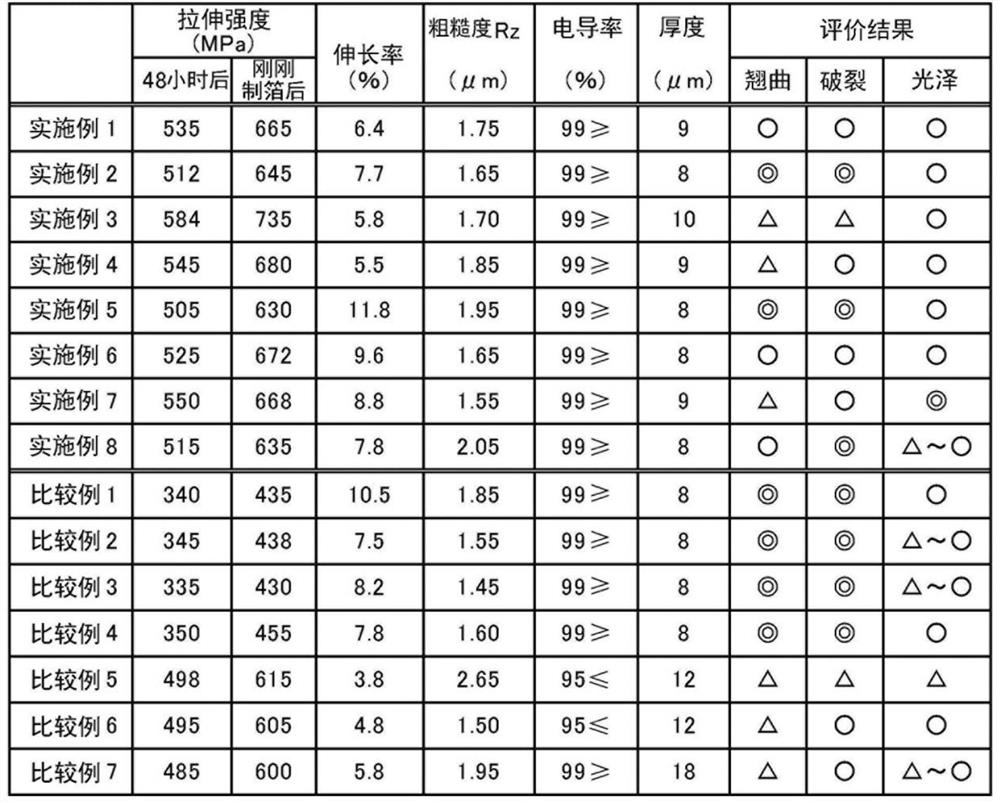

Method for producing electrolytic copper foil

ActiveCN112543822AElectrode carriers/collectorsPrinted circuit aspectsElectro conductivityCopper foil

Owner:泰科斯科技股份有限公司

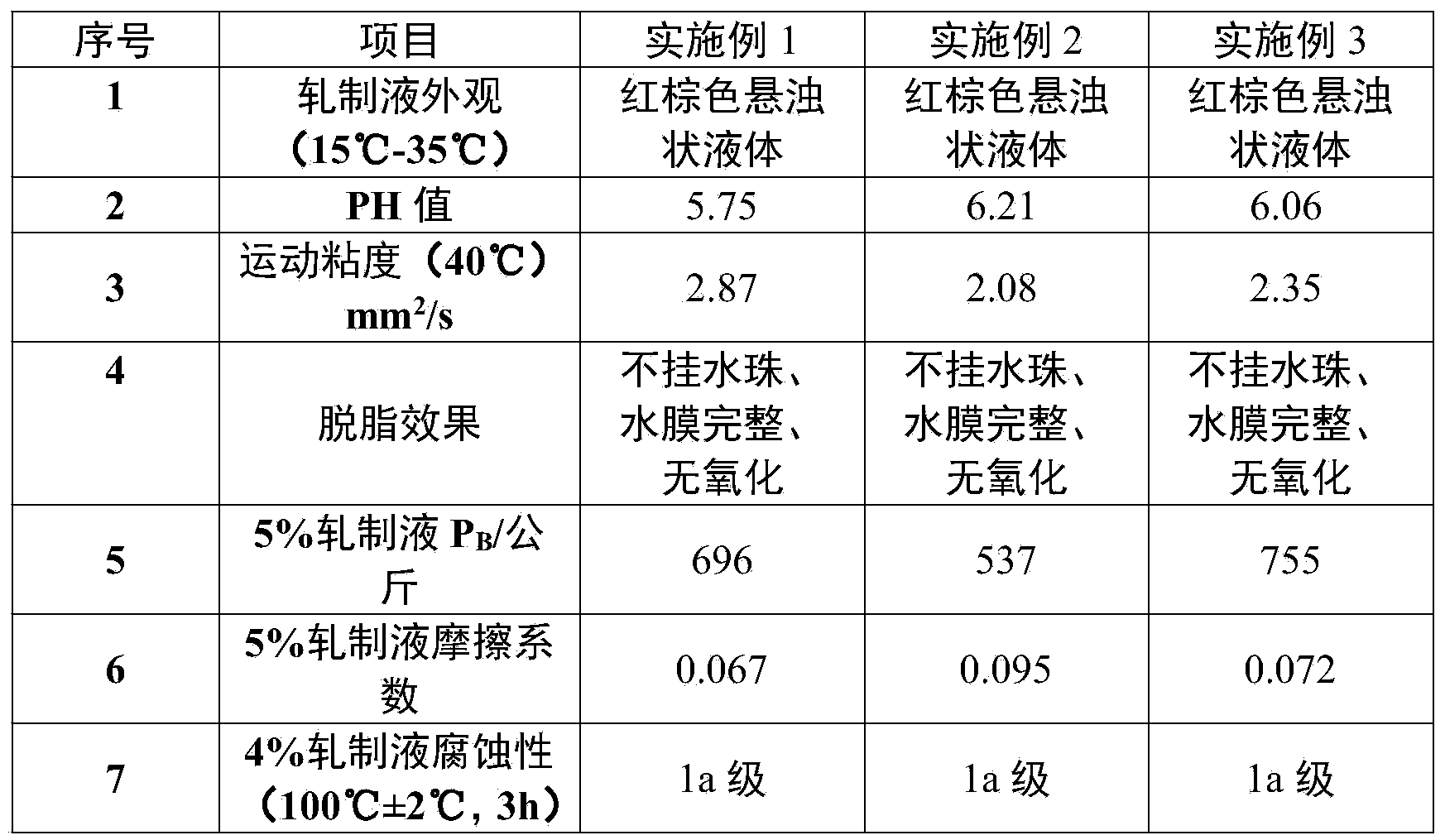

Functional rolling liquid of water-based nano Cu and preparation method of functional rolling liquid

Owner:UNIV OF SCI & TECH BEIJING

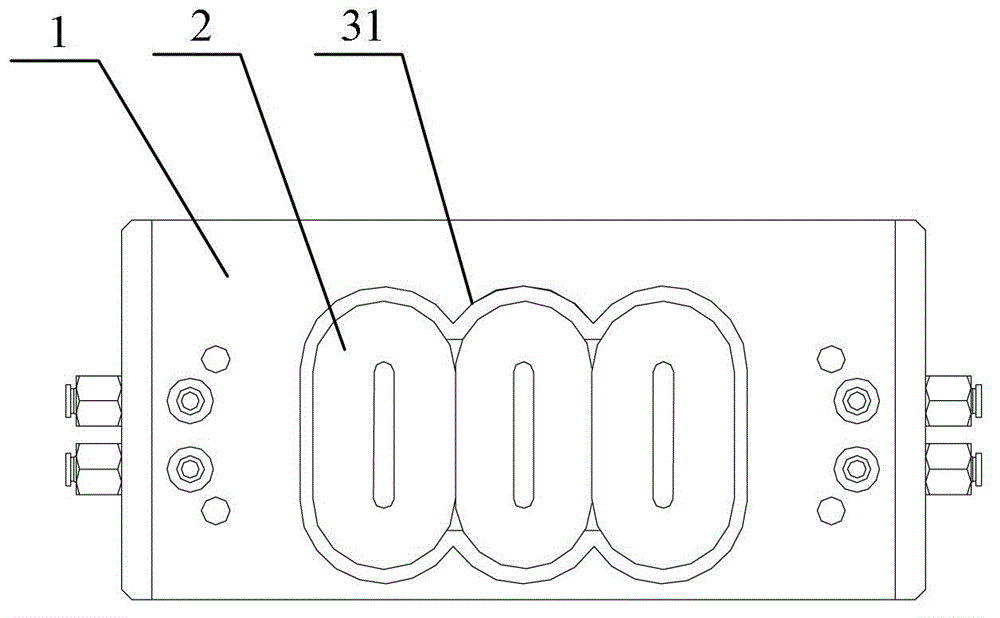

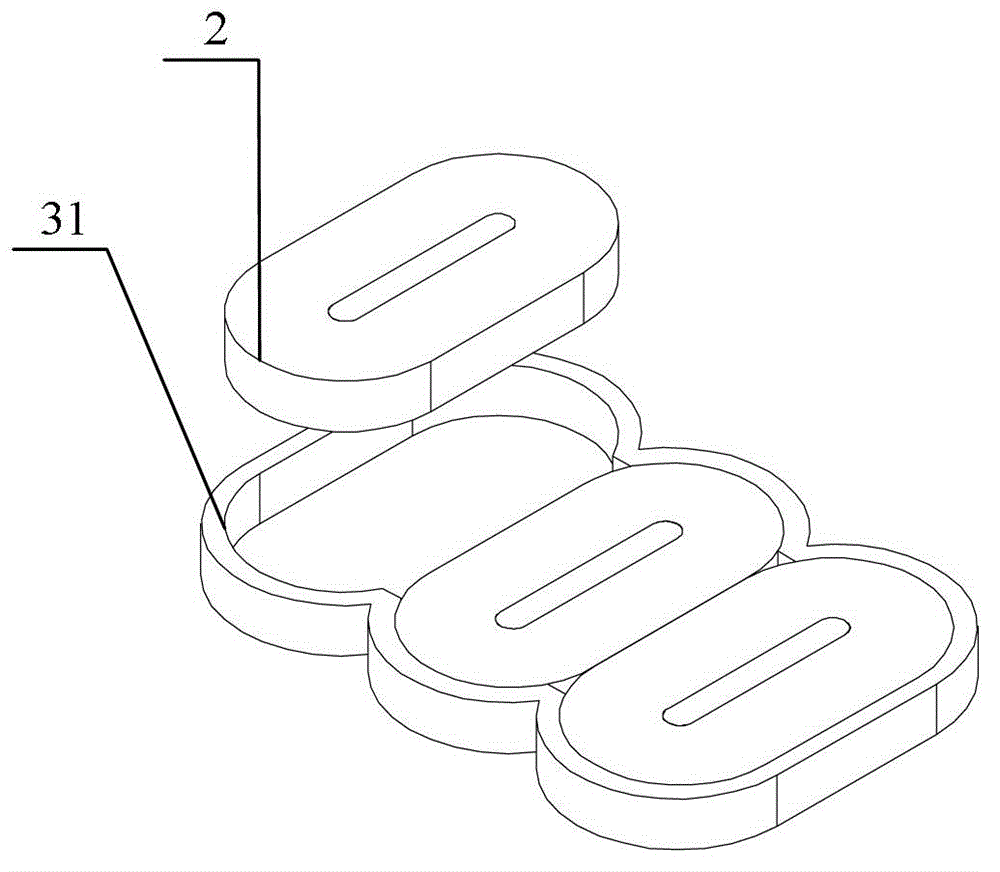

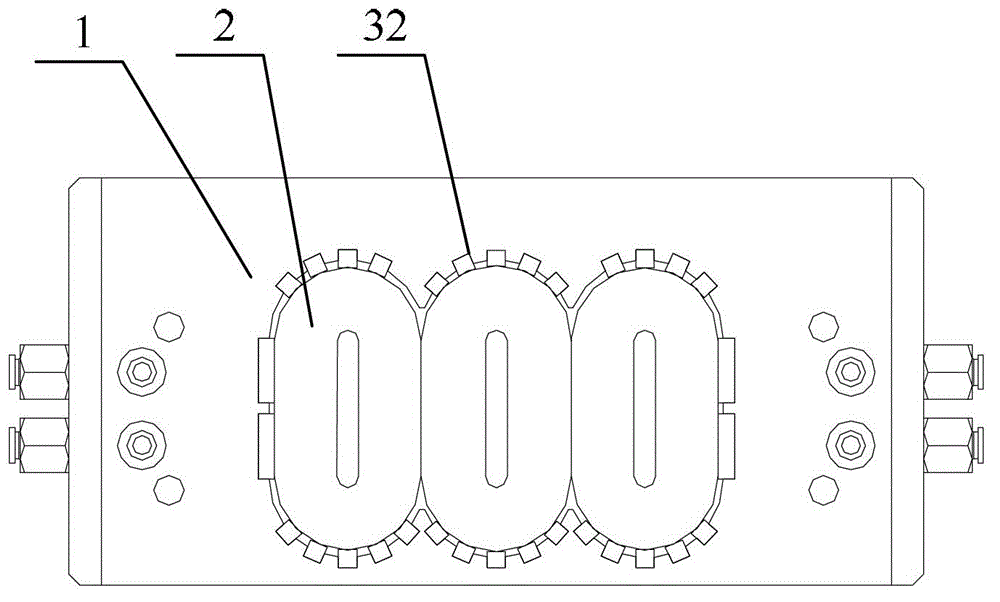

Cooling structure for ultraprecise linear motor

ActiveCN102882314ADo not change the ambient temperatureIncrease thrustCooling/ventillation arrangementCopper foilEngineering

The invention relates to a cooling structure for an ultraprecise linear motor and belongs to the technical field of linear motors. The cooling structure solves the problem of proneness to heat exchange with environment caused by high side temperature of two-side surface-mounted cooling structures of existing linear motors. The cooling structure comprises a winding supporting portion, a winding and a heat conductive portion, wherein the winding is fixed on the surface of the winding supporting portion, the heat conductive portion is arranged on the surface on the outer side and fixedly connected with the winding supporting portion, the heat conductive portion is a copper foil ring which fits the outer profile of the winding and is sleeved and fixed on the surface on the outer side of the winding, or the heat conductive portion is a copper foil heat conductive ring formed by arraying multiple copper foil sections in a dispersed manner, the copper coil heat conductive ring fits the outer profile of the winding, and each copper coil section is fixed on the surface on the outer side of the winding. The cooling structure for the ultraprecise linear motor is suitable for cooling of linear motors.

Owner:HARBIN INST OF TECH

Preparation method of electrostatic spinning lithium ion battery negative electrode plate

InactiveCN108735976AIncrease transfer rateLower internal resistanceElectrode manufacturing processesSecondary cellsWater basedElectrical battery

The invention discloses a preparation method of an electrostatic spinning lithium ion battery negative electrode plate. The preparation method comprises the following steps of dissolving polyoxometallate salt into deionized water to form a polyoxometallate solution; adding graphite into the polyoxometallate solution, and adding a surfactant sodium dodecyl benzene sulfonate and a water-based adhesive La13<x> to form a spinning solution; putting the spinning solution into an electrostatic spinning instrument for spinning, and performing spinning of the spinning solution on a copper foil, whereinwire strips are dense and are uniformly adhered to the copper foil; and then drying the copper foil adhered with the wire strips to obtain the battery negative electrode plate. Compared with a traditional stirring and coating process, the preparation method adopting the electrostatic spinning process has the advantages that the process time is shortened, and the production efficiency is improved.

Owner:DONGFANG ELECTRIC CORP

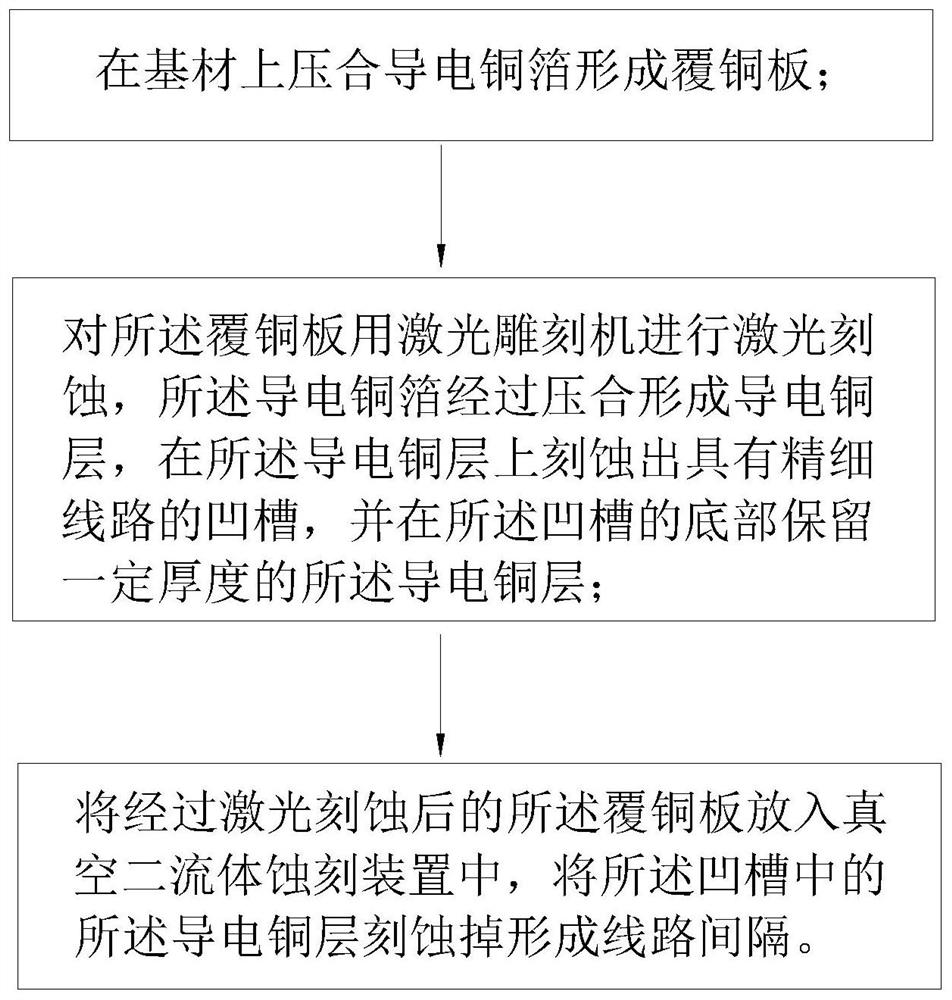

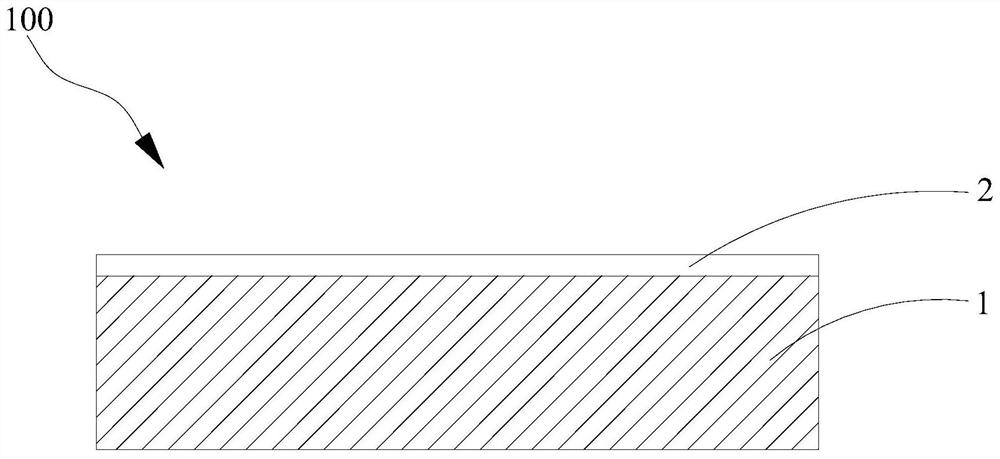

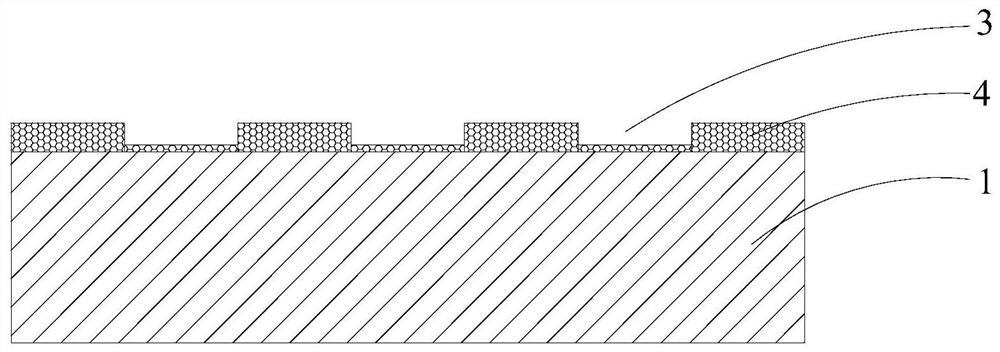

Method for manufacturing circuit of circuit board through laser etching

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

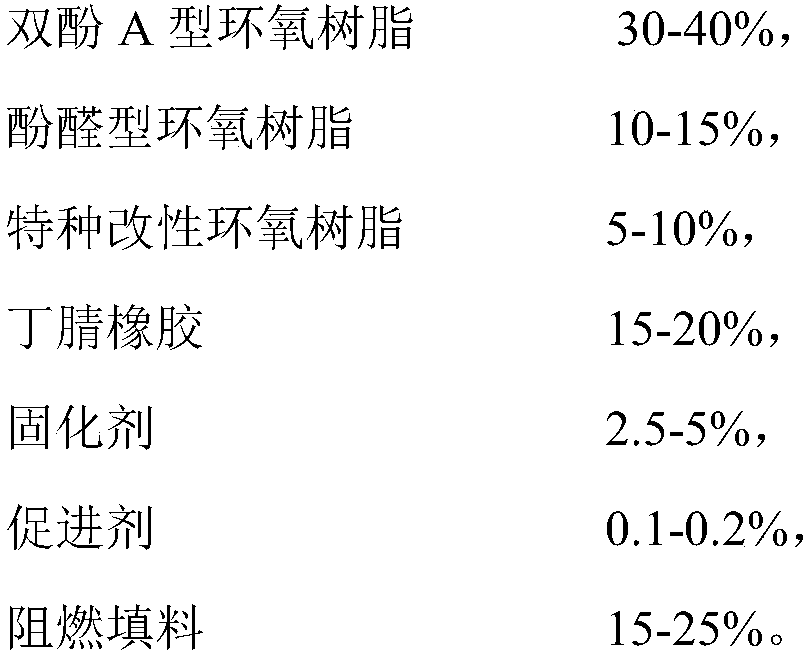

FPC film for LED lamp strip and preparation method thereof

InactiveCN109251694AReduce manufacturing costExcellent adhesionNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyHot melt

Owner:广东新时代新材料科技有限公司

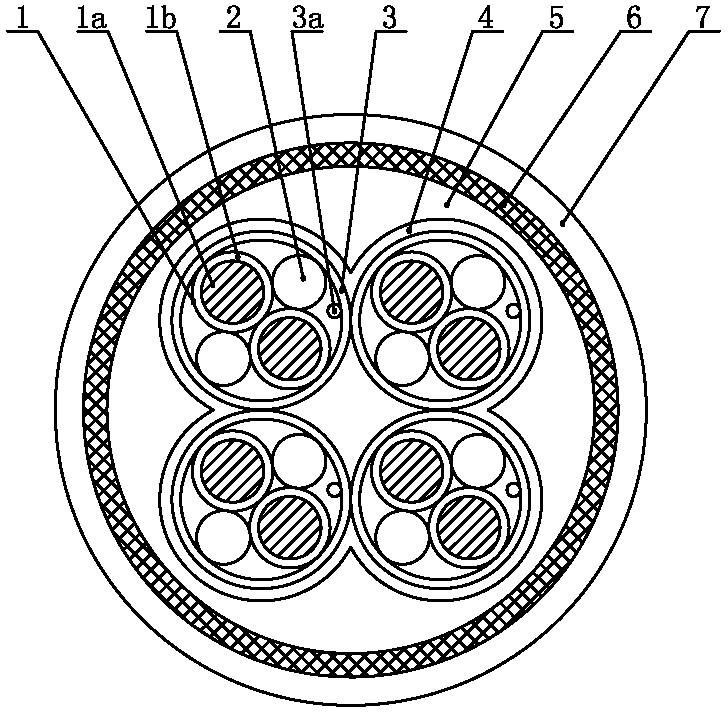

Pair-twist shielding instrument cable for flame-retardant fireproof boat and manufacturing method thereof

Owner:嘉兴君宏光学有限公司

Ceramic support for pre-oxidating copper sheet

ActiveCN103632983ASemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDBcCopper foil

Owner:上海富乐华半导体科技有限公司

Copper foil and method for producing copper foil

Owner:FURUKAWA ELECTRIC CO LTD

High-stability thermistor manufacturing process

ActiveCN107705944AImprove reliabilityImprove stabilityEnvelope/housing resistor manufactureFinal product manufactureNormal resistanceCopper foil

Owner:KUNSHAN SUHANG CIRCUIT BOARD

Manufacturing process of copper clad laminate substrate

ActiveCN110191576ANo curling upShorten the folding timeCircuit susbtrate materialsNatural stateEngineering

Owner:DONGGUAN XIANGSI ELECTRONICS TECH CO LTD

FPC board and linear motor using same

Owner:LEADING TECH DONGTAI CO LTD

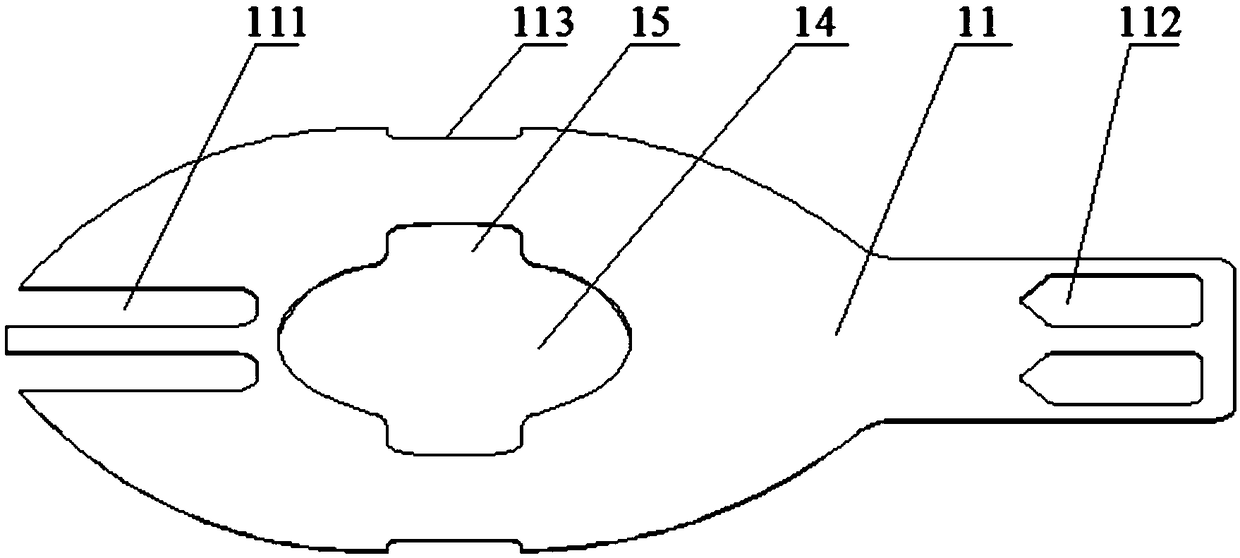

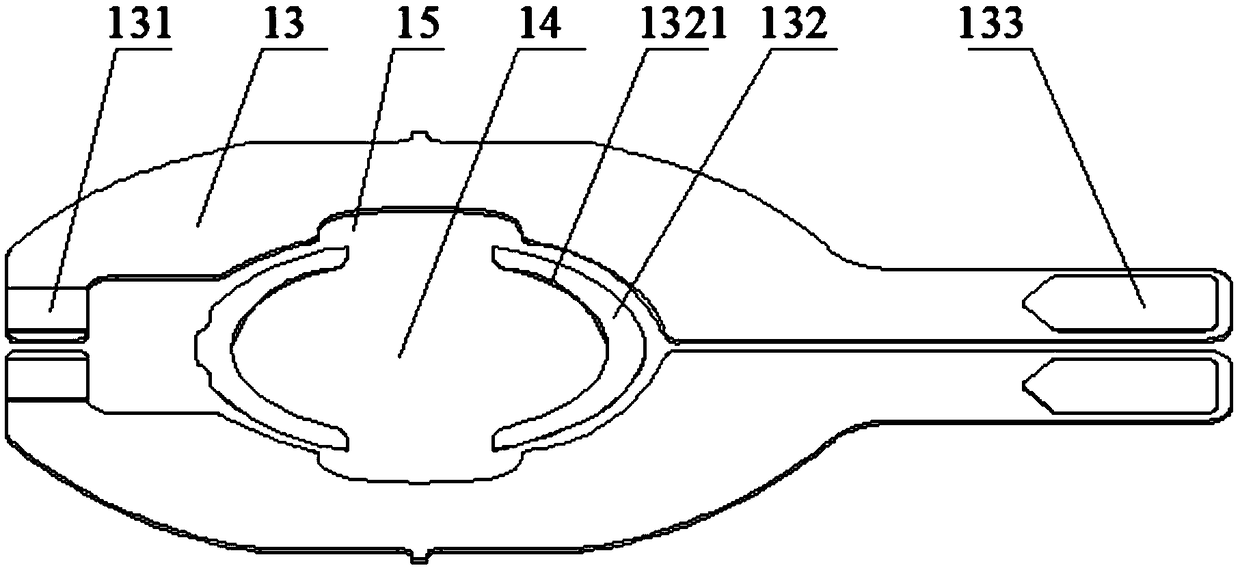

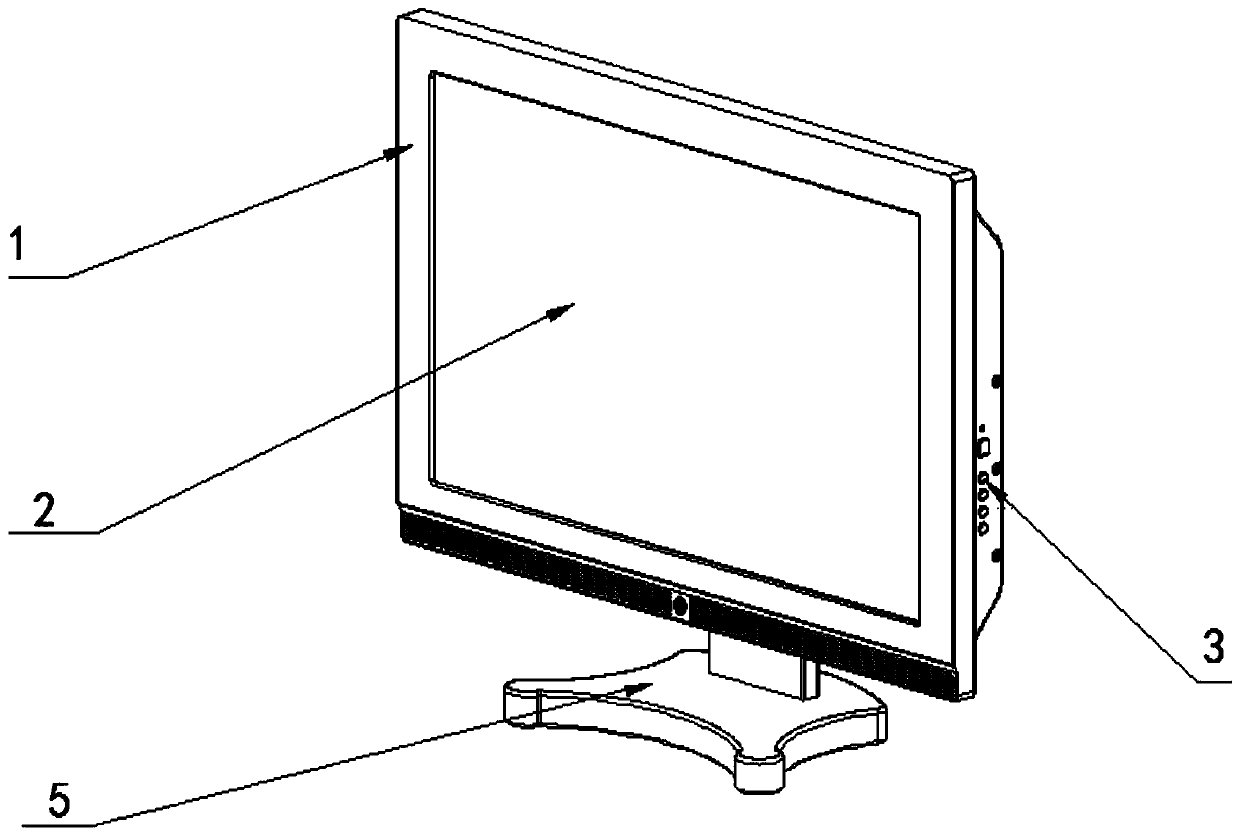

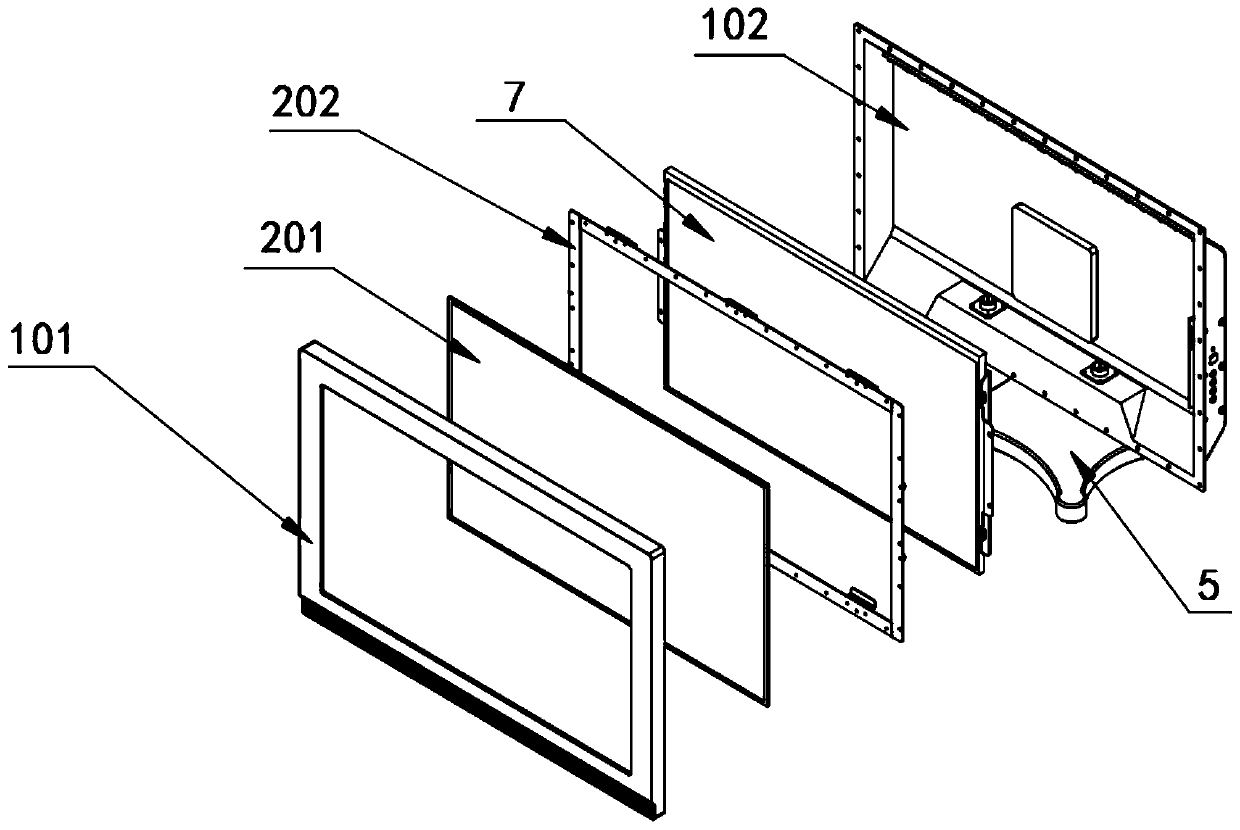

Shielding window mounting structure and electromagnetic information safety protection display

PendingCN110868845AEasy to installClosely connectedScreening casingsNon-linear opticsDisplay deviceTransmittance

Owner:ANFANG HI TECH ELECTROMAGNETIC SAFETY TECHN BEIJING

Thin film all-solid-state battery

PendingCN114530628AHigh strengthIncrease the interface contact areaCell electrodesFinal product manufactureSolid state electrolyteElectrical battery

The invention belongs to the technical field of electrochemistry, and particularly relates to an all-solid-state thin film battery. The all-solid-state thin film battery comprises a positive electrode layer, a negative electrode layer, an all-solid-state diaphragm layer and a flexible battery polar plate, wherein the positive electrode layer and the negative electrode layer are positioned in the same plane; a gap is formed between the positive electrode layer and the negative electrode layer; the positive electrode layer is formed by mixing a positive electrode active material, a solid electrolyte, a conductive additive and a binder according to a certain process; the negative electrode layer is formed by compounding graphite and a solid electrolyte, or consists of lithium metal and Li-Al, Li-In and Li-Sn alloy; the all-solid-state diaphragm layer is composed of a solid electrolyte with ultrahigh ionic conductivity; the flexible battery pole plates are respectively composed of ultrathin aluminum foils and copper foils; and the contact sides of the solid electrolyte layer and the positive electrode and the negative electrode adopt latticed extension structures. According to the invention, the risk of contact short circuit caused by the stacking structure of the positive electrode layer and the negative electrode layer is fundamentally avoided, and the ionic conductivity is greatly improved.

Owner:FUDAN UNIV

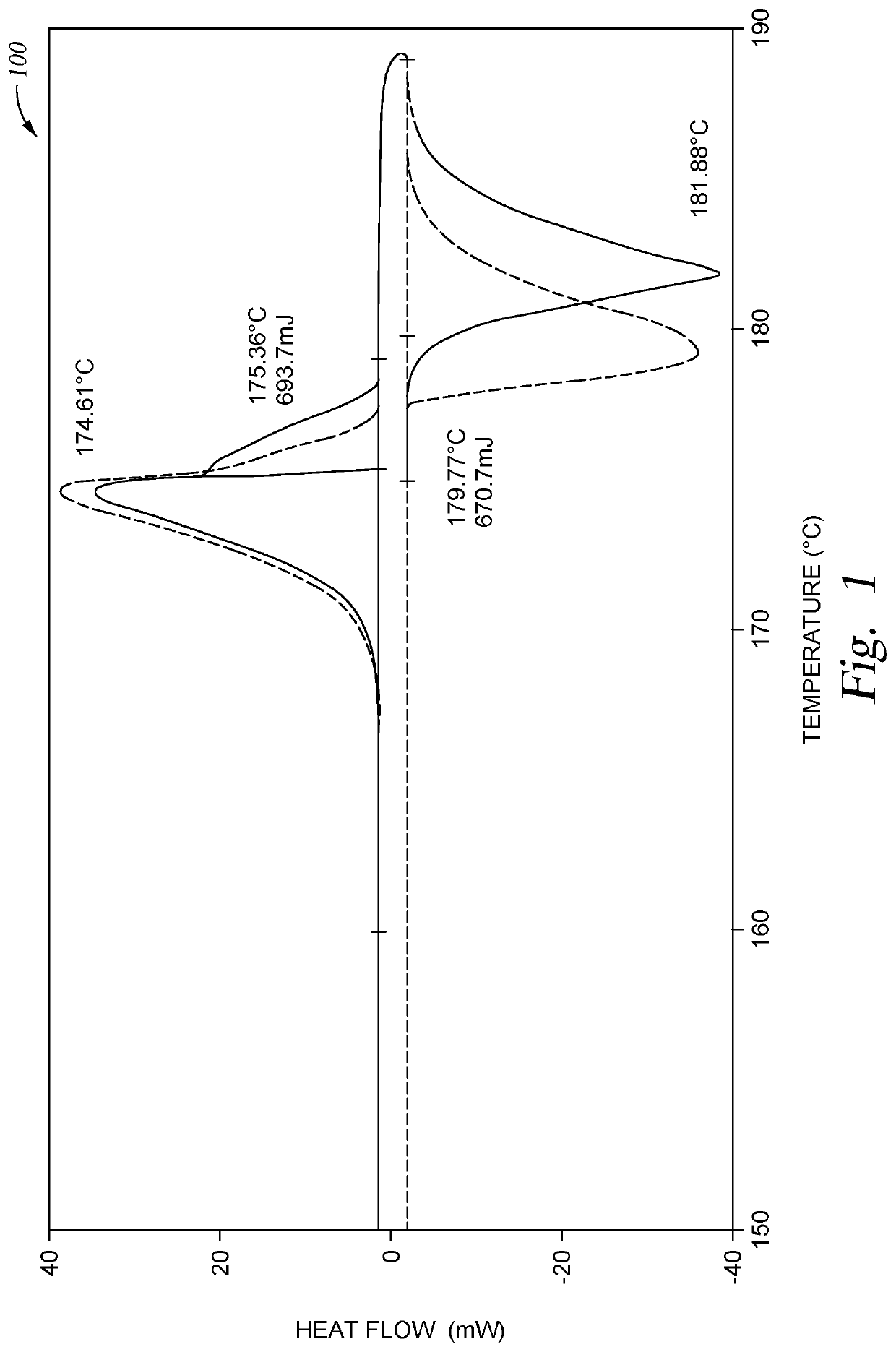

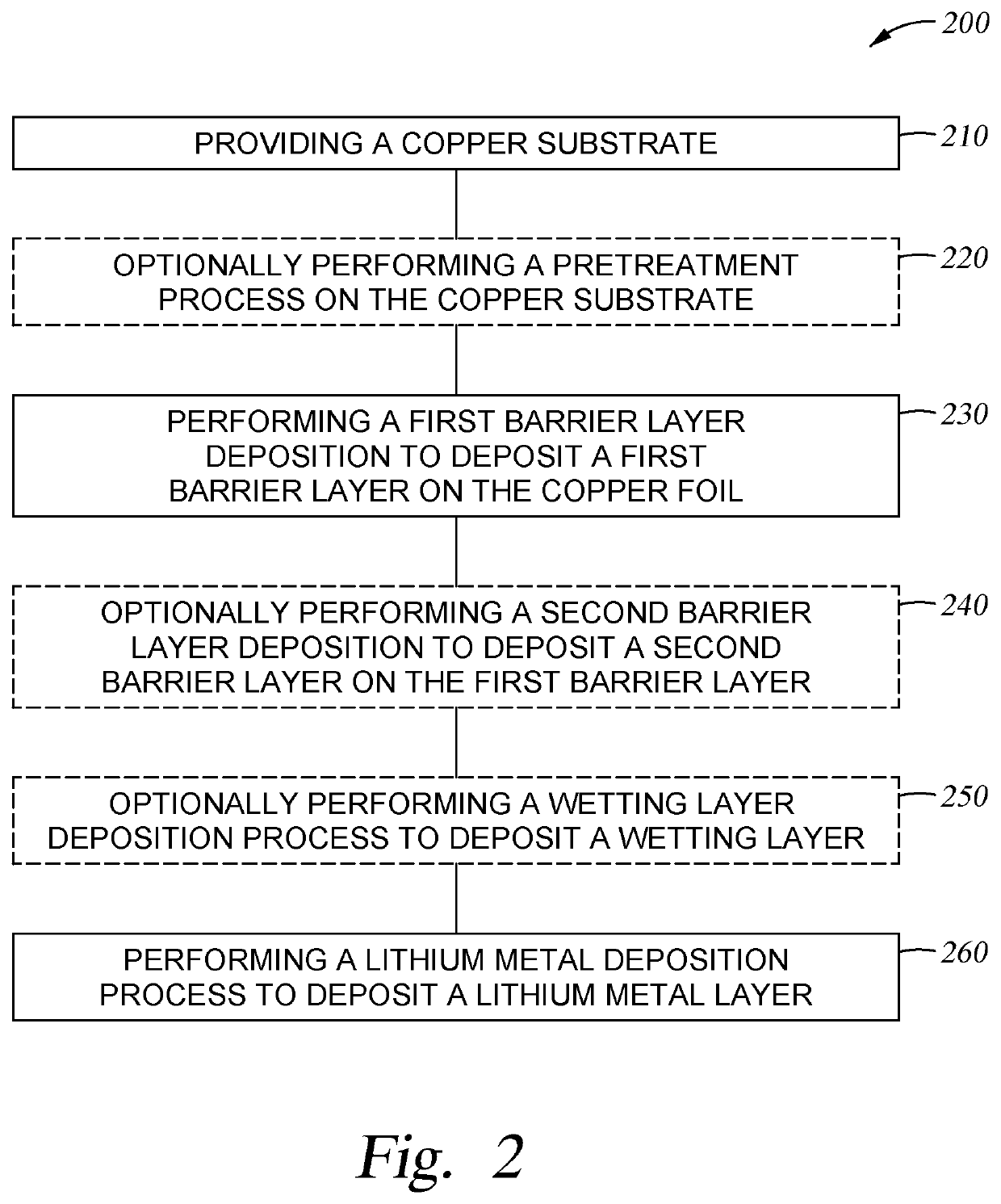

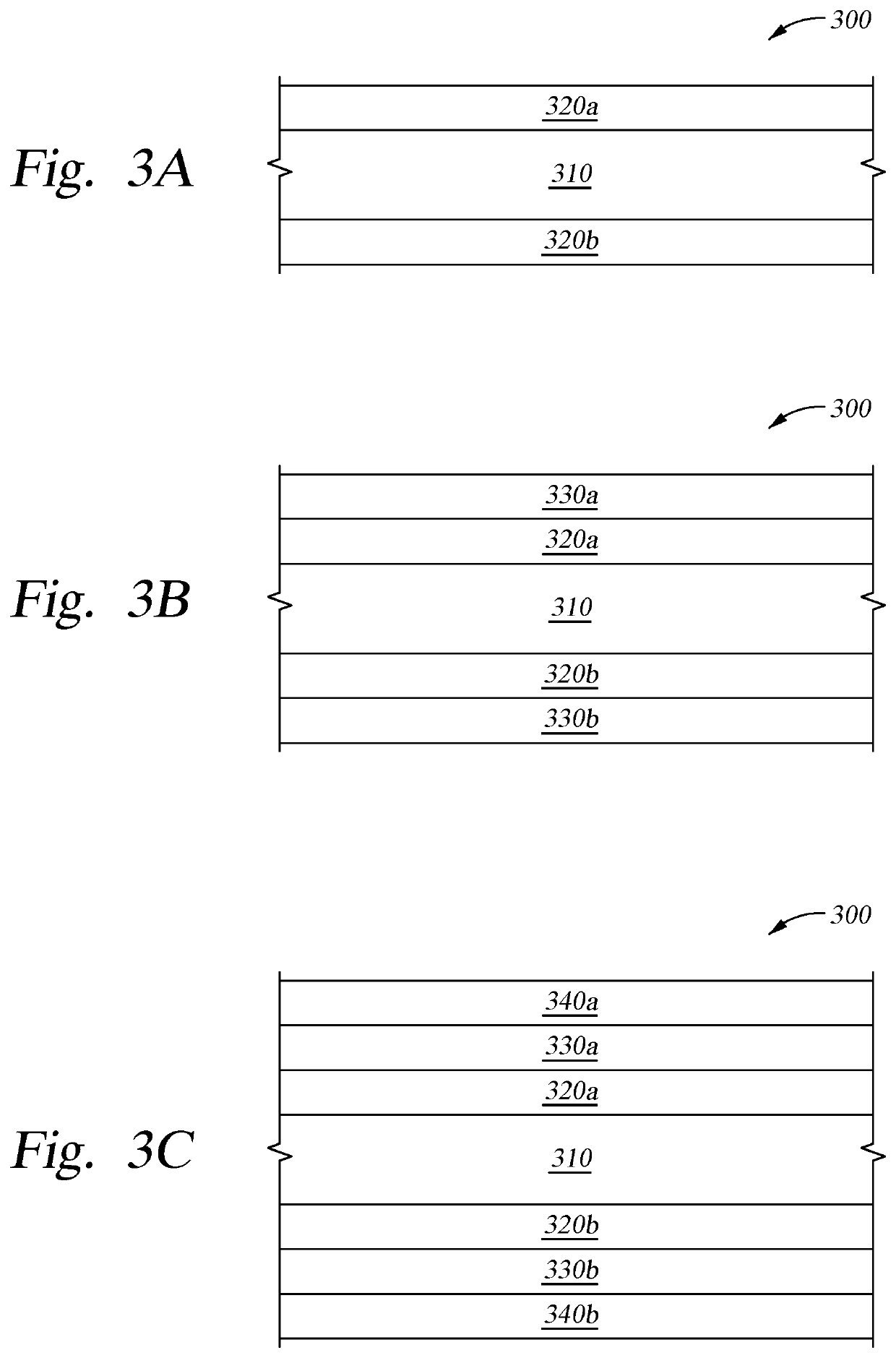

Diffusion barrier films enabling the stability of lithium

Owner:APPLIED MATERIALS INC

Manufacturing method of aluminum-based copper foil-clad laminated board

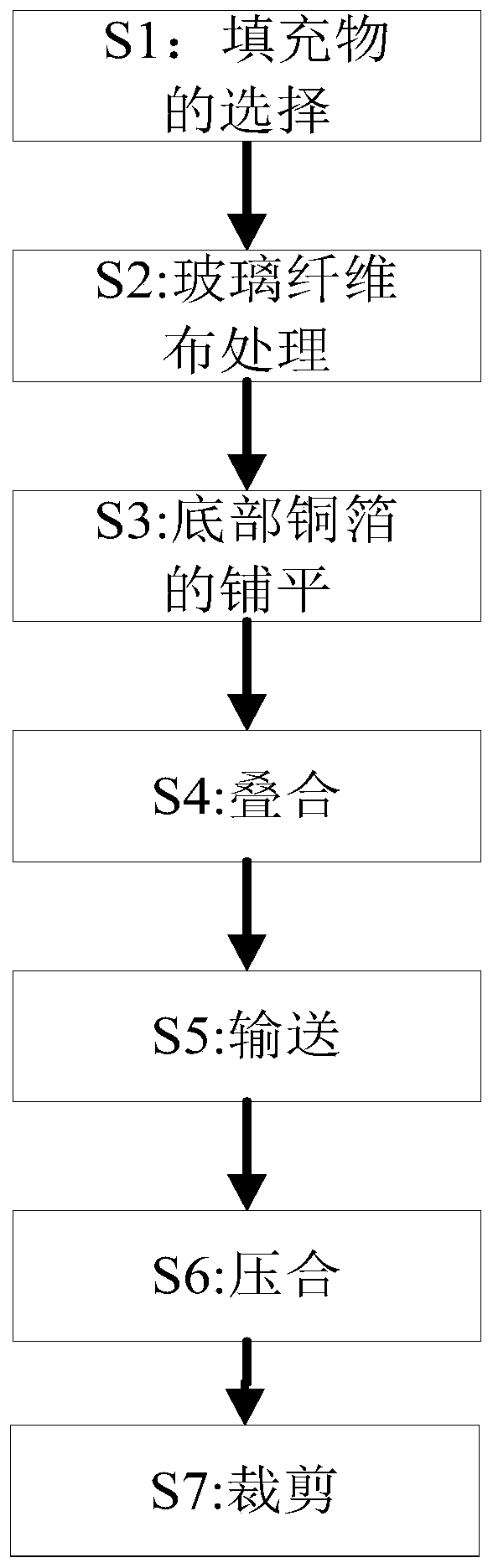

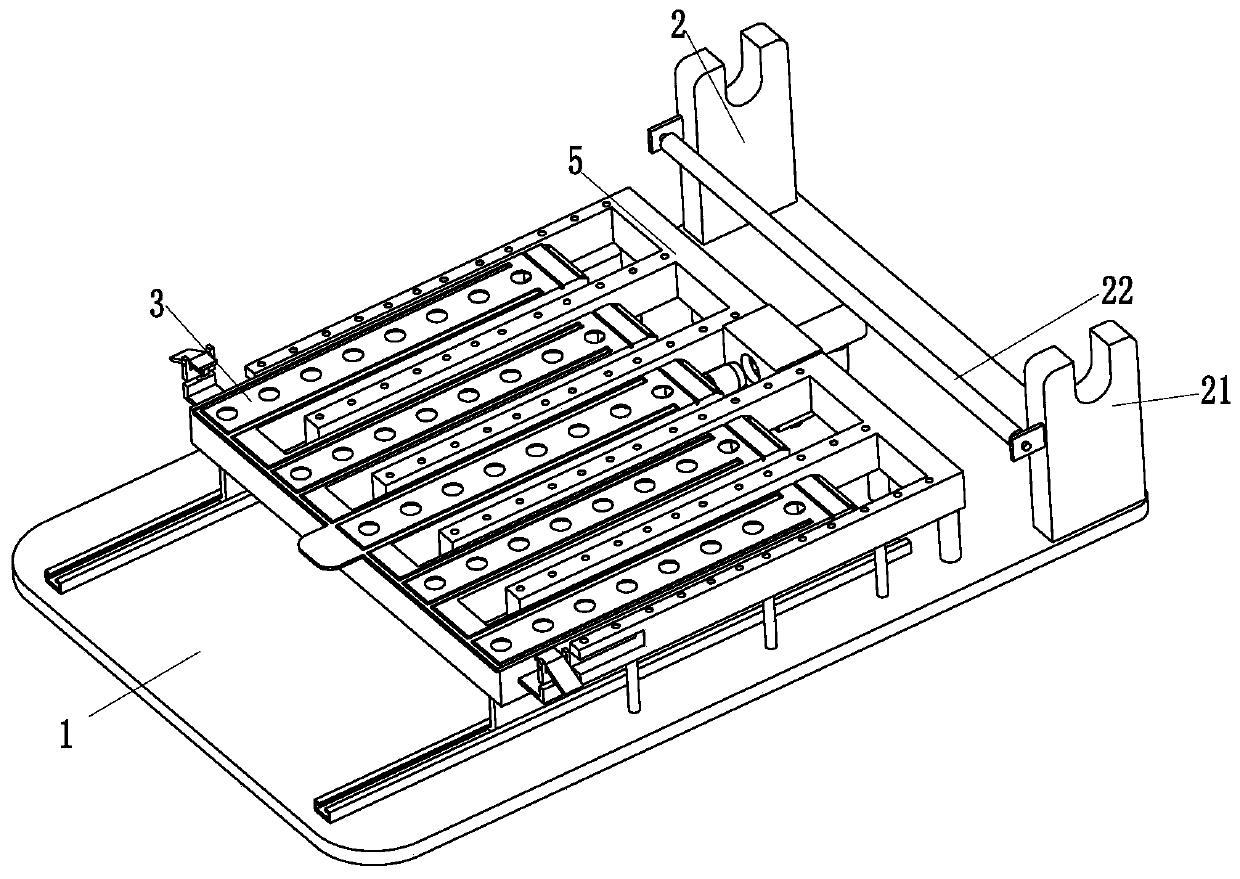

InactiveCN106671515ASimple processAvoid burning phenomenonSynthetic resin layered productsLaminationGlass fiberCopper foil

The invention relates to a manufacturing method of an aluminum-based copper foil-clad laminated board. The manufacturing method comprises the following steps: step 1: preparing raw materials; step 2: immersing an electronic glass fiber fabric into resin; step 3: coating ceramic powder and silicon dioxide; and step 4: mounting a copper foil. According to the copper-clad board manufactured by the manufacturing method, a process is simple and a lot of investment cost is saved; and the ceramic powder and silicon dioxide are adopted, and then the high heat radiation performance can be improved in a utilization process, so that a phenomenon that the copper-clad board is burnt due to overheating in a post-period utilization process is prevented from occurring.

Owner:TONGLING HUAKE ELECTRONIC MATERIAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap