Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about "Cooling/ventillation arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

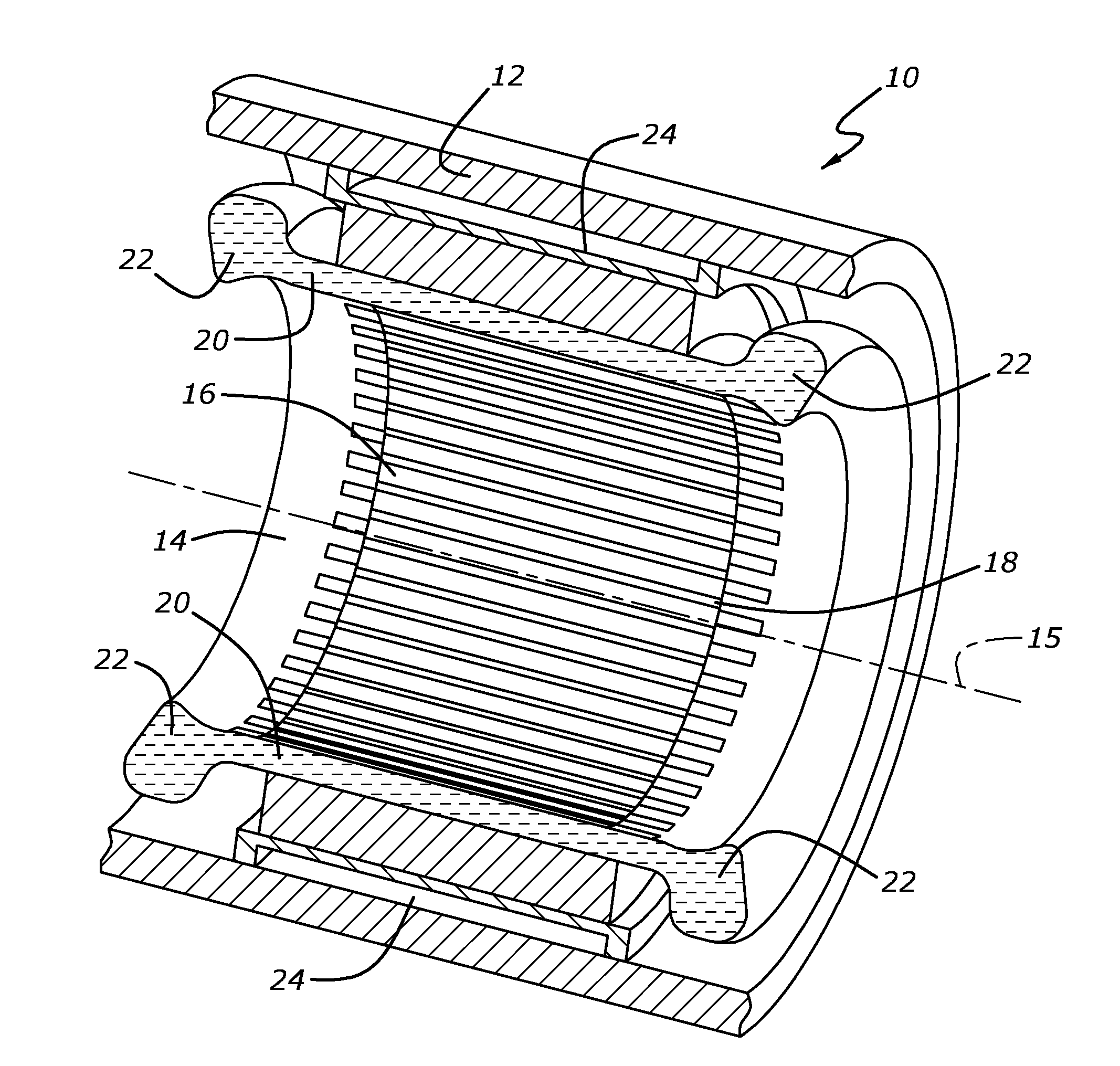

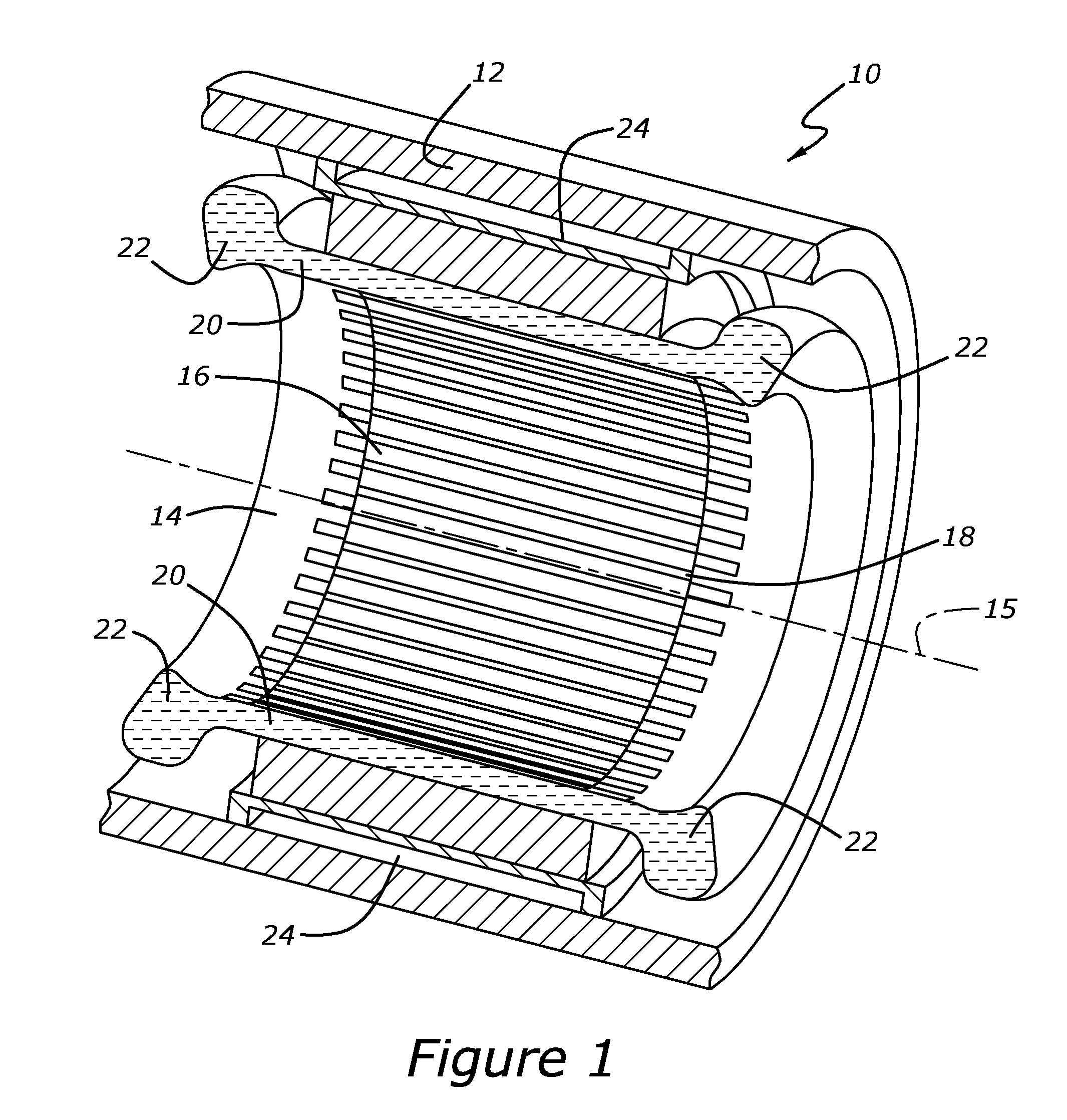

Electric motor with liquid-cooled end windings

ActiveUS8093770B1Great and uniform coolingExtend motor lifeCooling/ventillation arrangementWindings conductor shape/form/constructionStatorConductor Coil

Owner:FORD GLOBAL TECH LLC

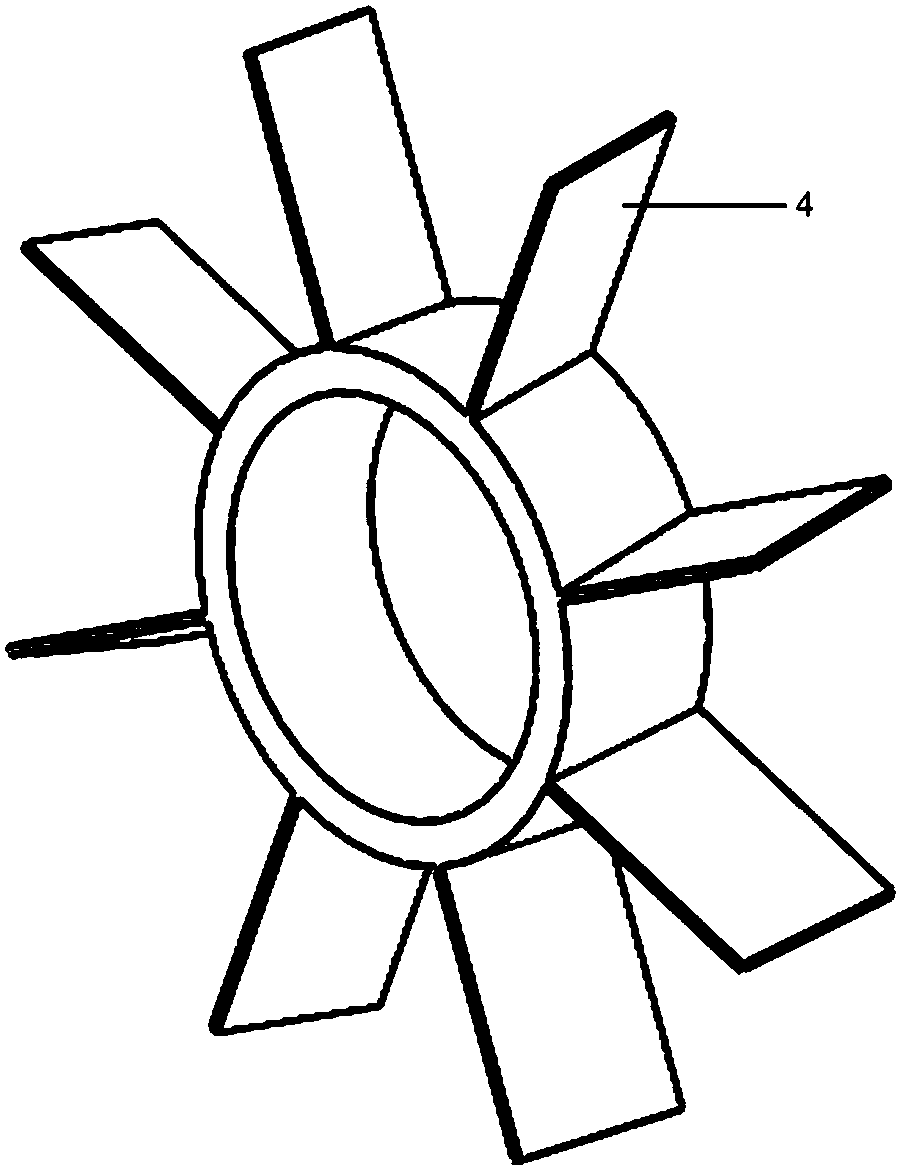

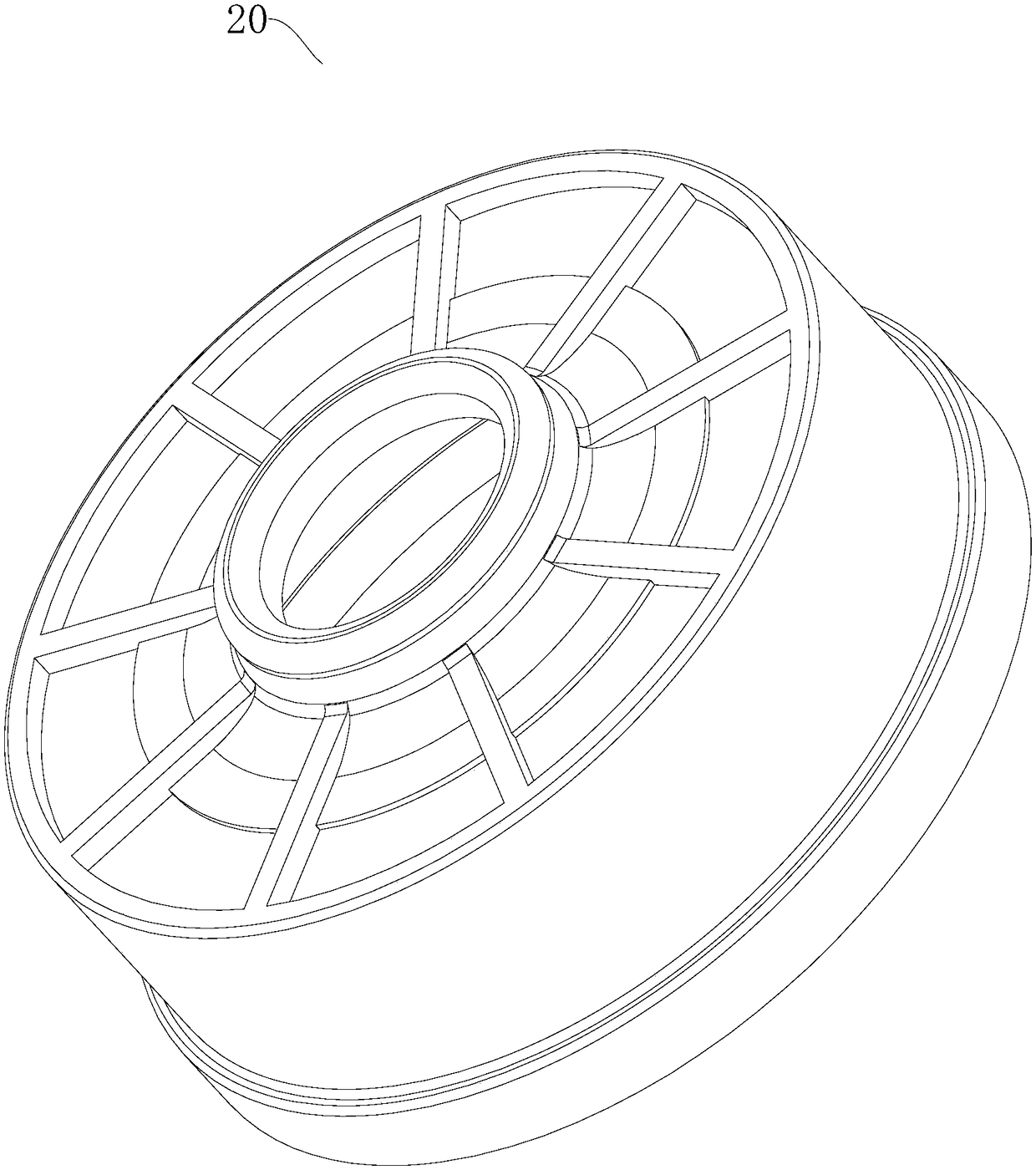

Alternator fan

InactiveUS20050106024A1High mechanical strengthImprove homogeneityPropellersPump componentsMobile vehicleAlternator

The invention is a fan for an alternator adapted to be coupled in rotation to the alternator rotor, and being of the type comprising a wheel part and a plurality of fan blades (47, 48) extending from the latter, the fan being moulded in a plastics material on an insert (50) which is preferably of metal and which constitutes the wheel part of the fan and is arranged to provide fastening of the fan on the rotor, being configured so as to constitute a means for increasing the mechanical strenght of the fan; the insert (50, 65) includes at least a portion of a blade (48, 69) of the fan. The invention is useful in the manufacture of a high power cooling fan for a motor vehicle alternator.

Owner:VALEO EQUIP ELECTRIC MOTEUR

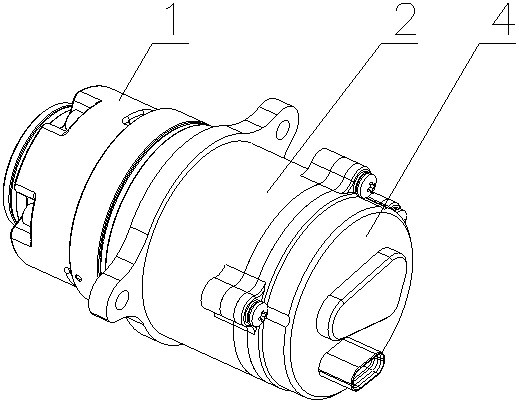

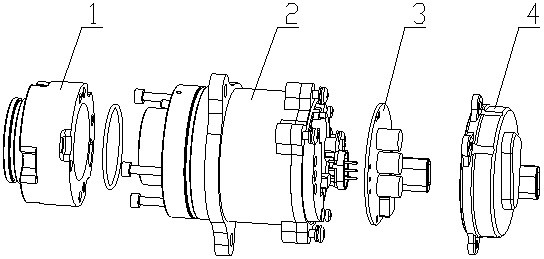

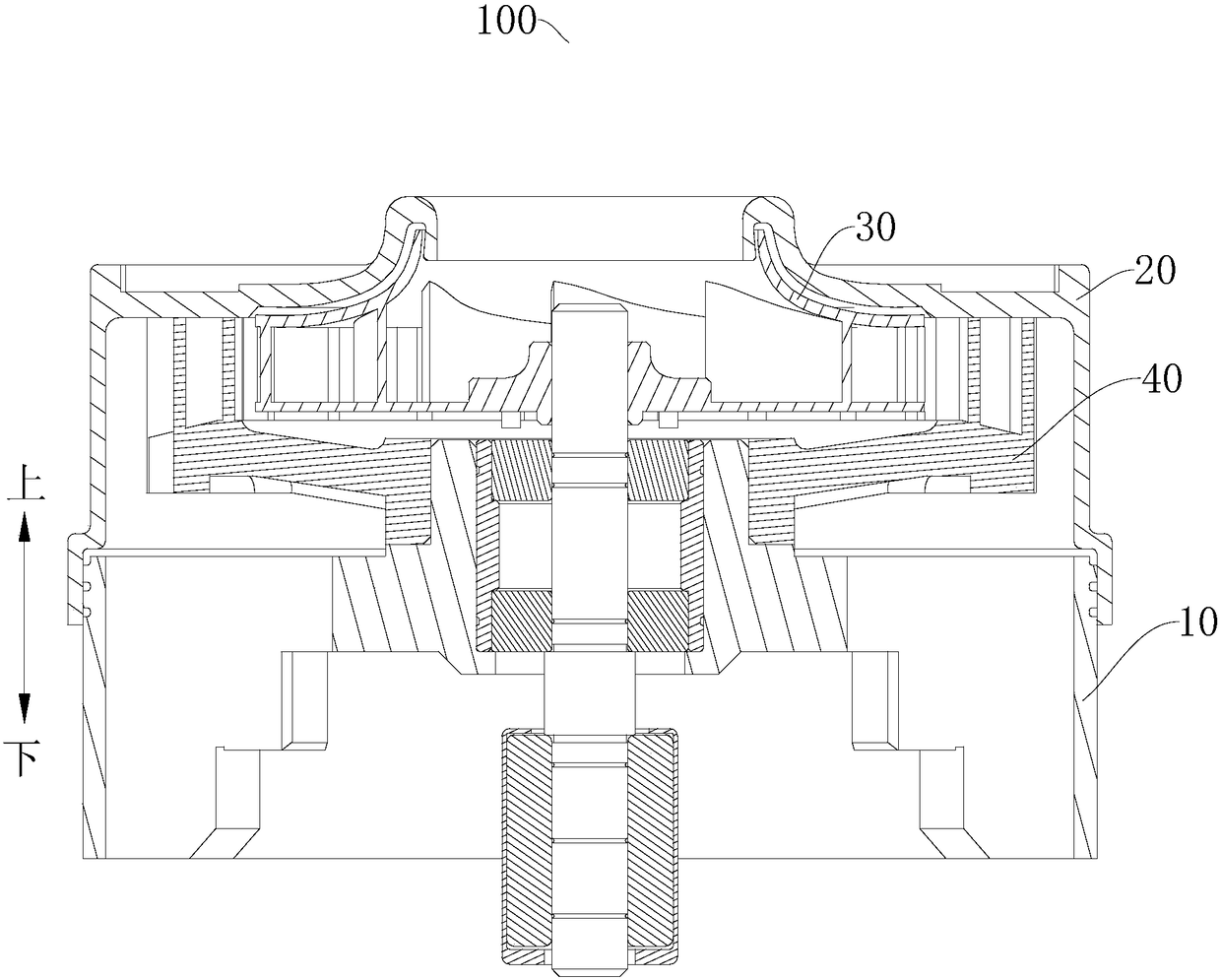

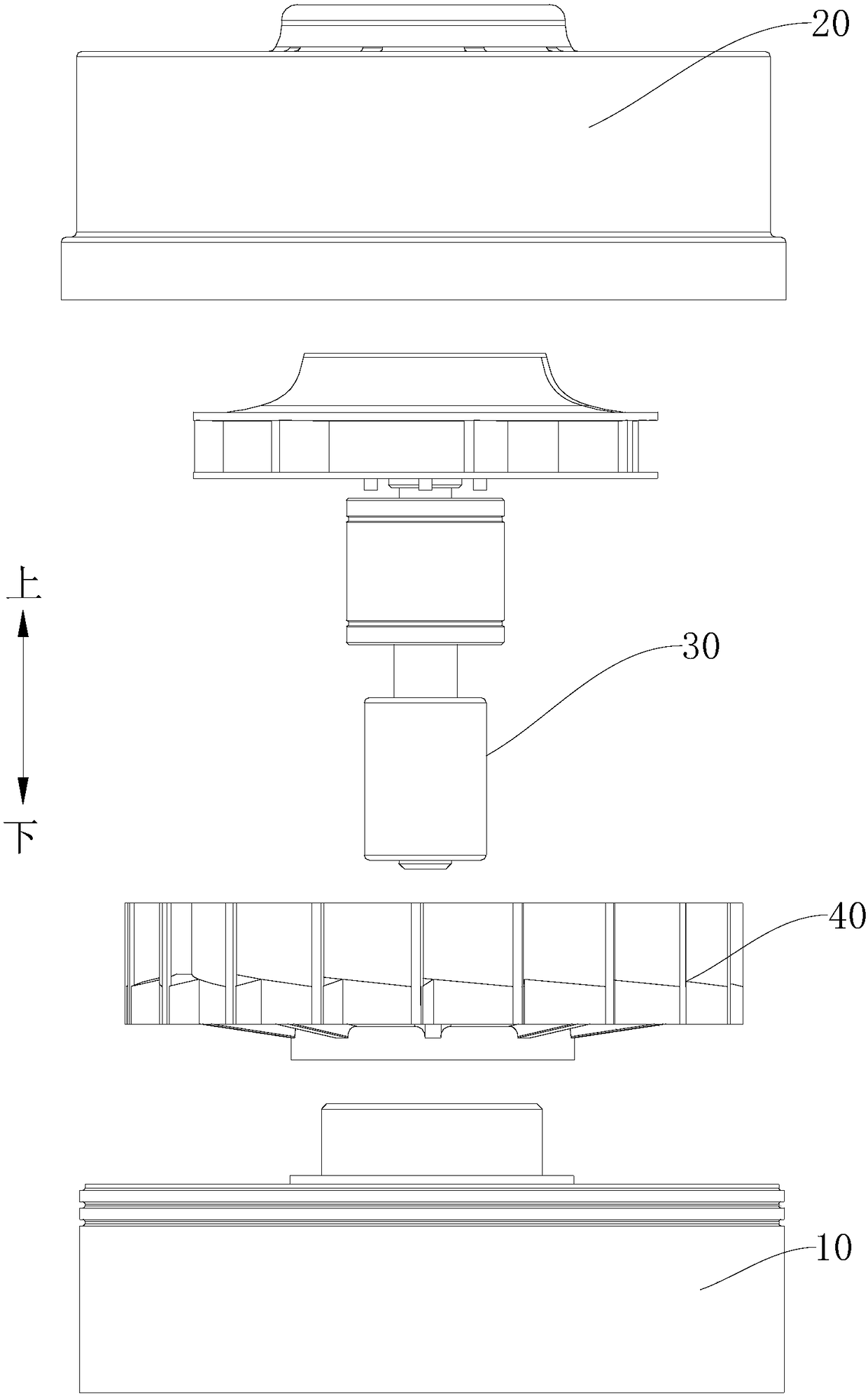

In-wheel actuator and in-wheel assembly comprising the same

An in-wheel assembly is provided, and the in-wheel assembly includes an in-wheel actuator and a wheel. The in-wheel actuator includes a driving motor; a decelerator which is disposed inside the driving motor and configured to reduce a rotational speed of the driving motor; and a hollow shaft which is disposed inside the driving motor and configured to transfer a rotational force of the driving motor to the decelerator, which is accommodated in a hollow of the hollow shaft, and circulates fluid inside of the driving motor with respect to a surface of the decelerator when driven to rotate by the driving motor. The wheel accommodates the in-wheel actuator and receives a rotational speed reduced by the decelerator to rotate.

Owner:SAMSUNG ELECTRONICS CO LTD

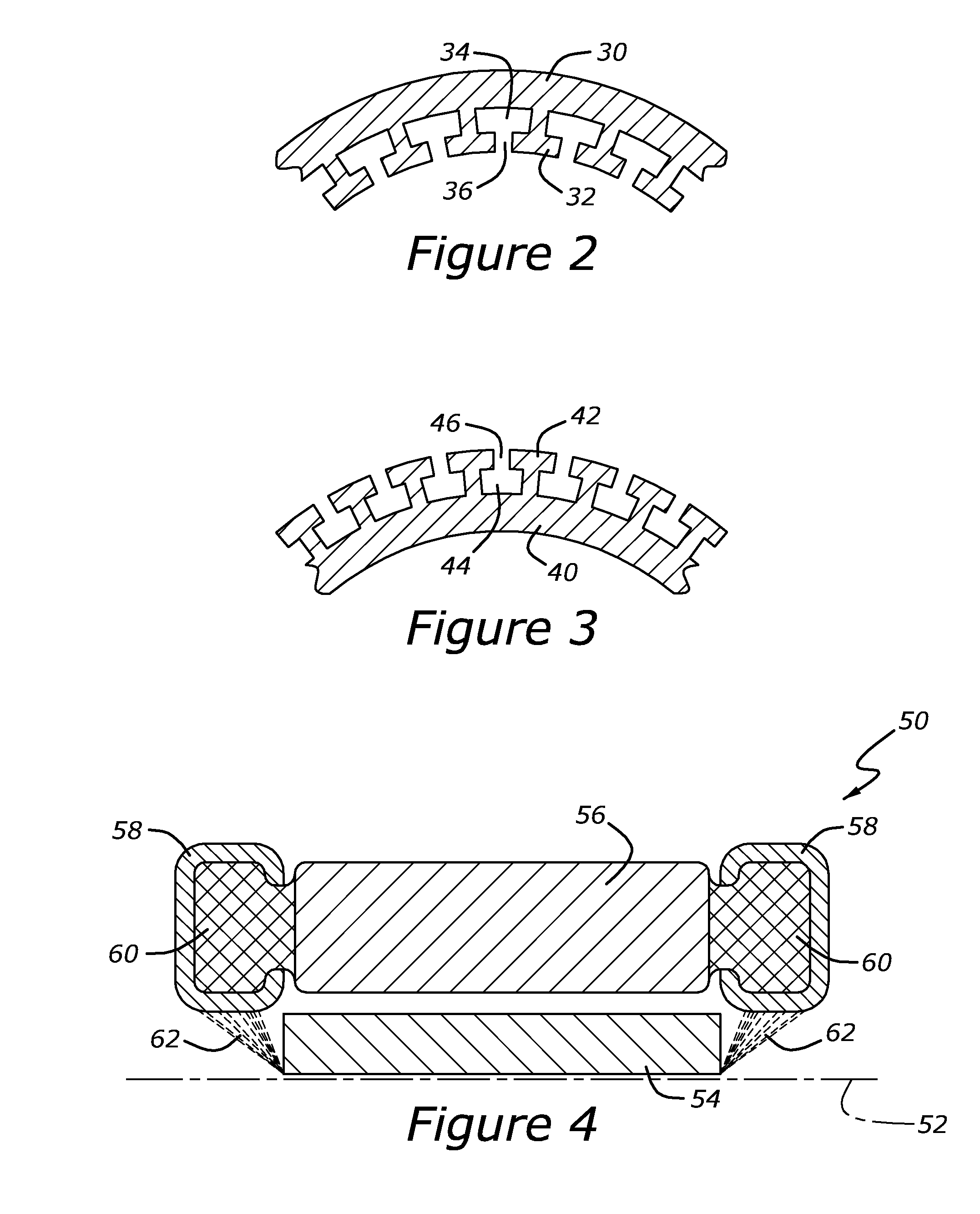

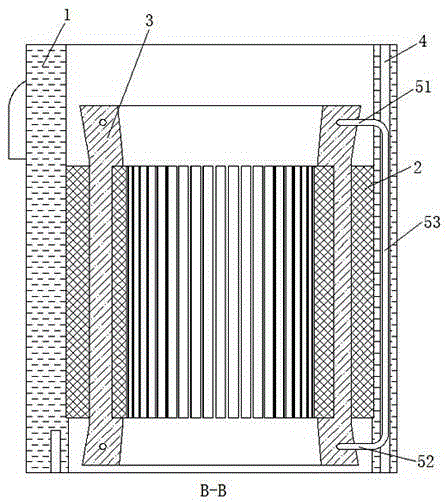

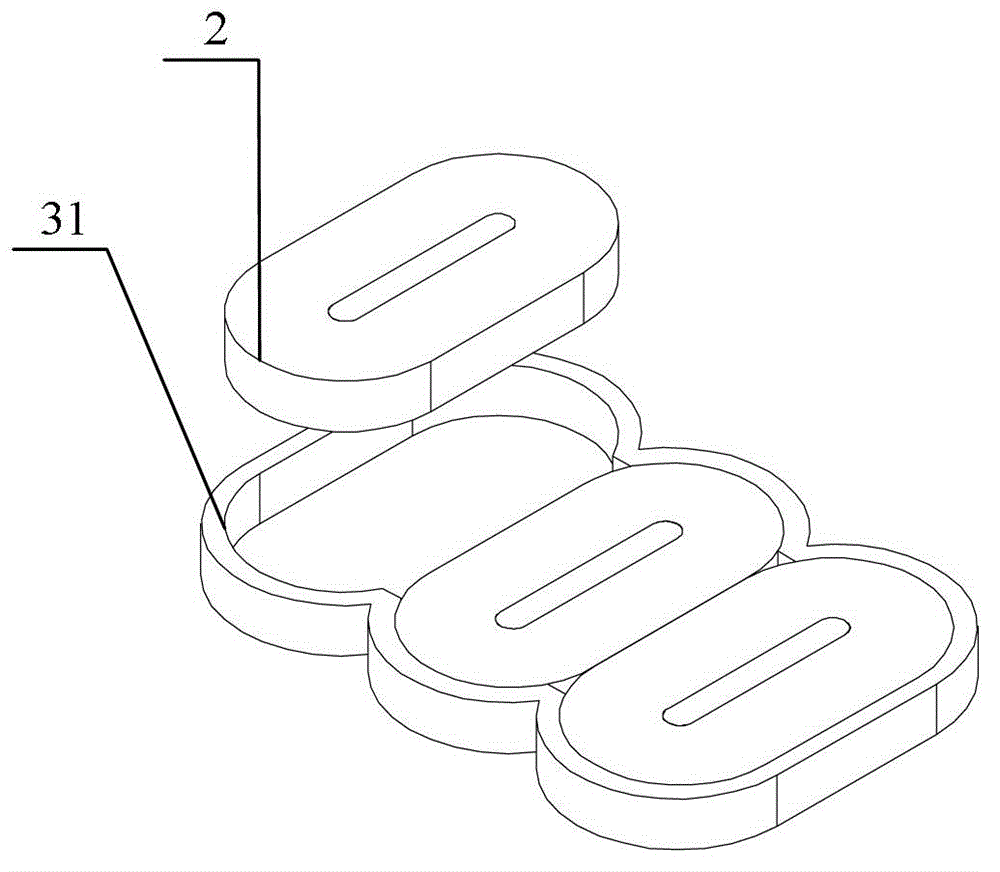

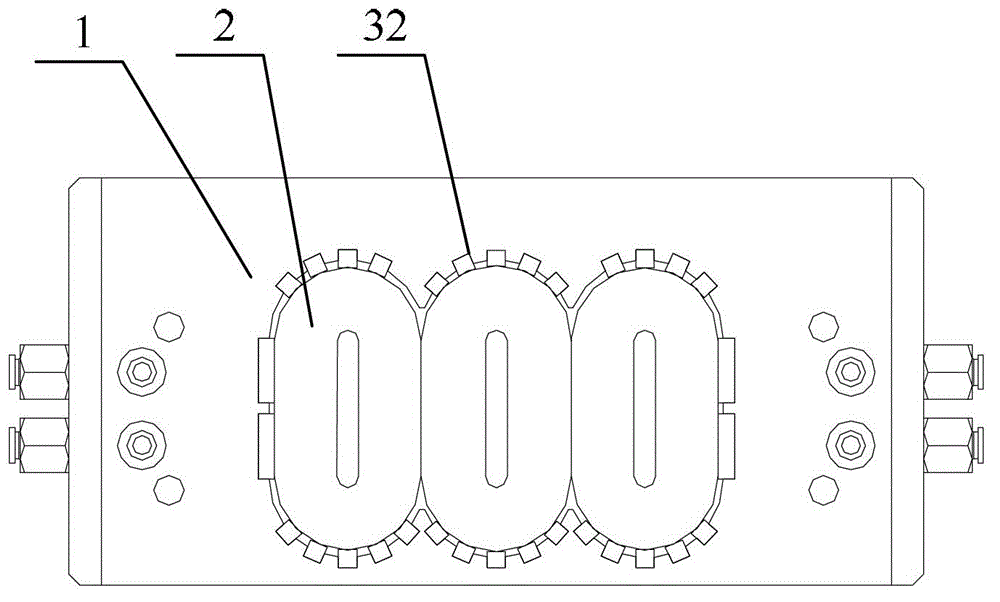

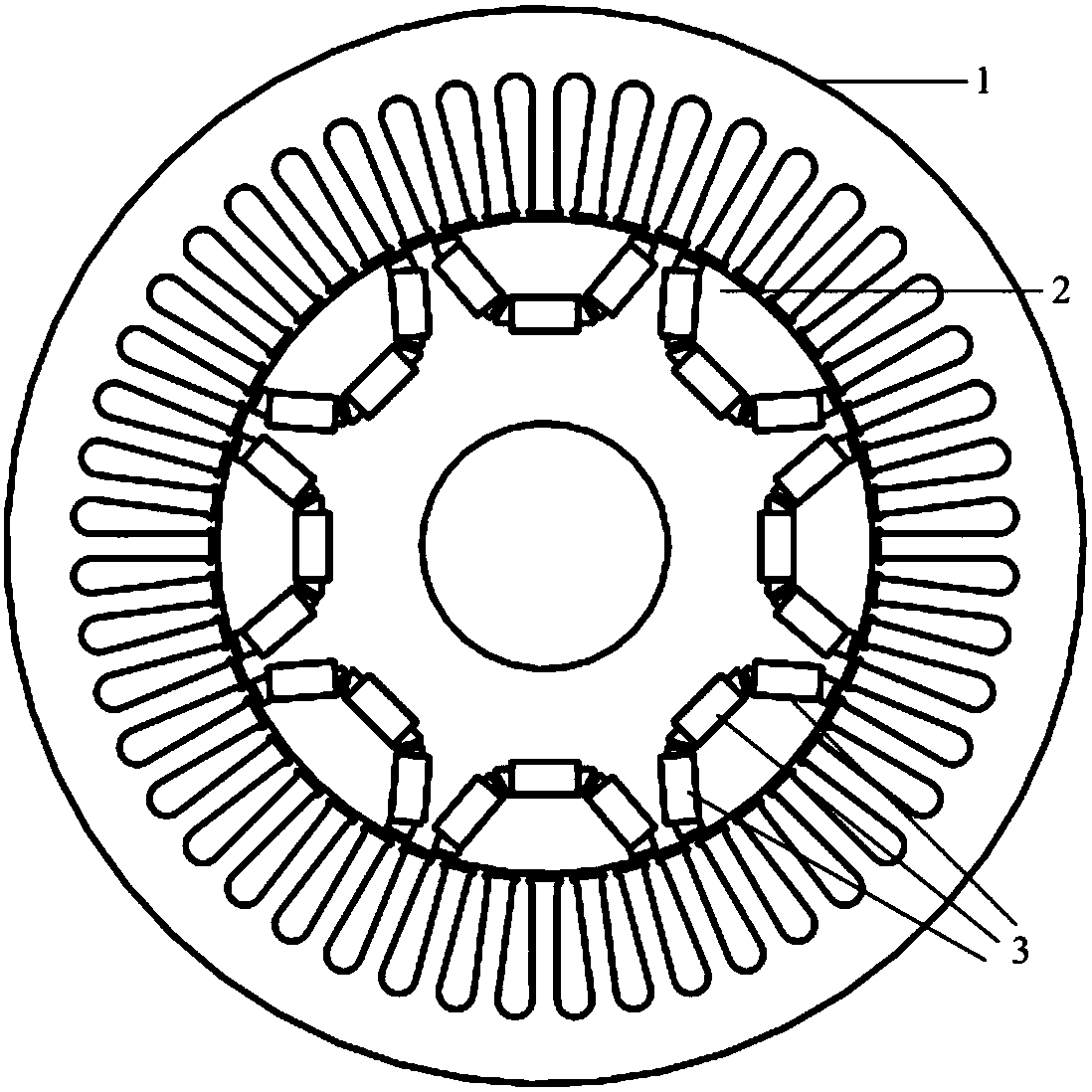

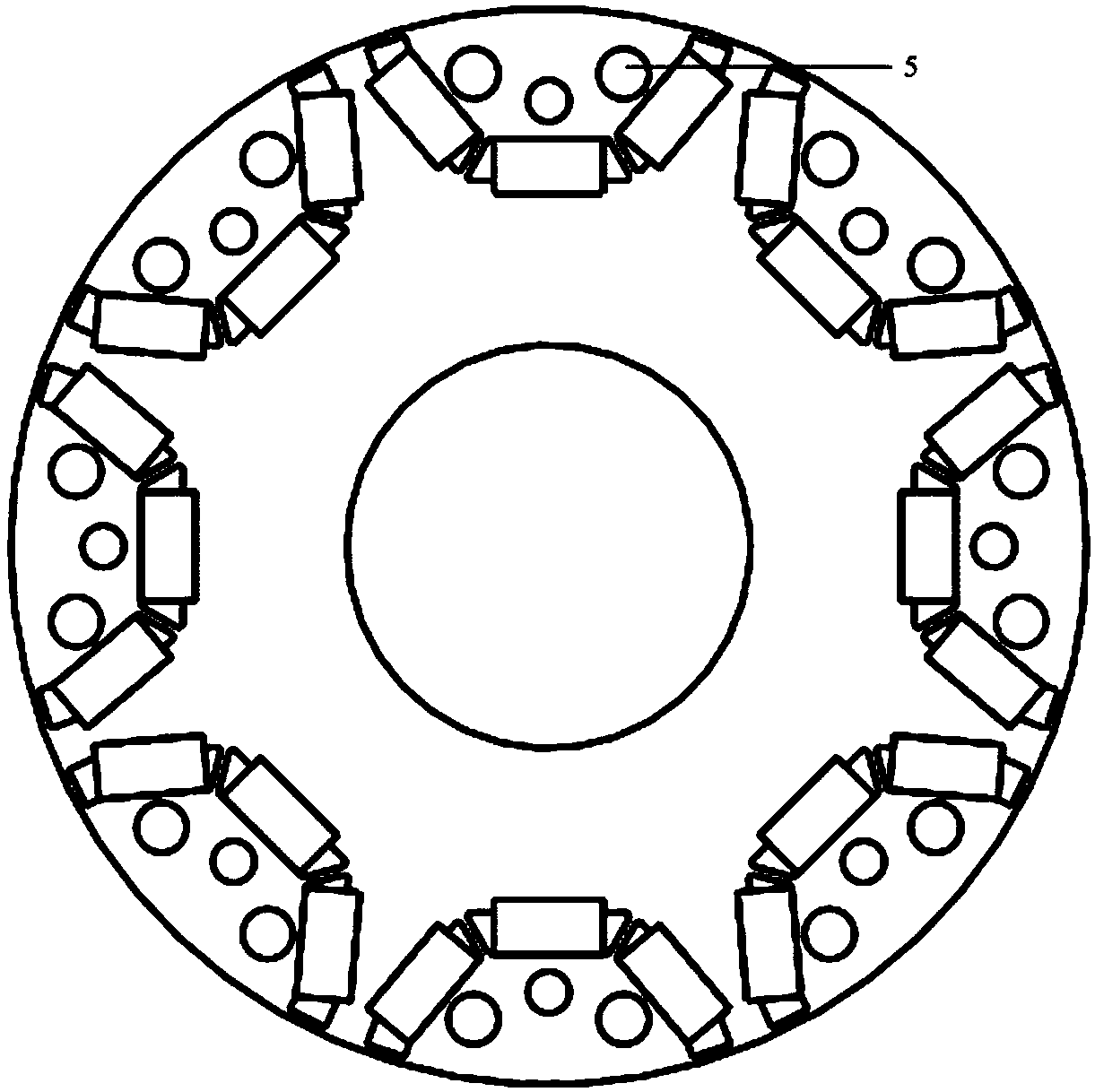

Motor stator heat radiation structure

InactiveCN105356671AGuaranteed cooling effectImprove thermal conductivityCooling/ventillation arrangementSupports/enclosures/casingsConductor CoilCooling pipe

Owner:HEFEI JUYI POWER SYST CO LTD

Electromagnetic force engine

InactiveCN105186821ALower friction temperatureExtended service lifeMechanical energy handlingCooling/ventillation arrangementDrive motorControl switch

The invention discloses an electromagnetic force engine. The engine comprises a magnetic force driving device and a control box. A control circuit and a storage battery are arranged in the control box. The magnetic force driving device comprises a plurality of electromagnetic iron core driving pistons which are arranged side by side. Output shafts of the plurality of electromagnetic iron core driving pistons are connected to one output crankshaft respectively. The control circuit makes the magnetic force driving device generate an electromagnetic driving force so as to drive the output crankshaft to output power. One end of the output crankshaft is provided with a heat dissipation fan used for heat dissipation. A connection shaft of the output crankshaft and the heat dissipation fan is provided with a driven belt pulley. The driven belt pulley is connected to an active belt pulley through a belt. The active belt pulley is installed on an output shaft of an electric generator. The other end of the output crankshaft is provided with a driving motor. The driving motor drives the output crankshaft to rotate. An output power supply of the electric generator is connected to the storage battery. One side of the magnetic force driving device is provided with a power output shaft. By using the engine of the invention, through a control switch on the control box, on-key starting control is realized; electricity generation power can be rapidly provided; a usage scope is wide and a service life is long; and control is convenient and sensitive.

Owner:戢平

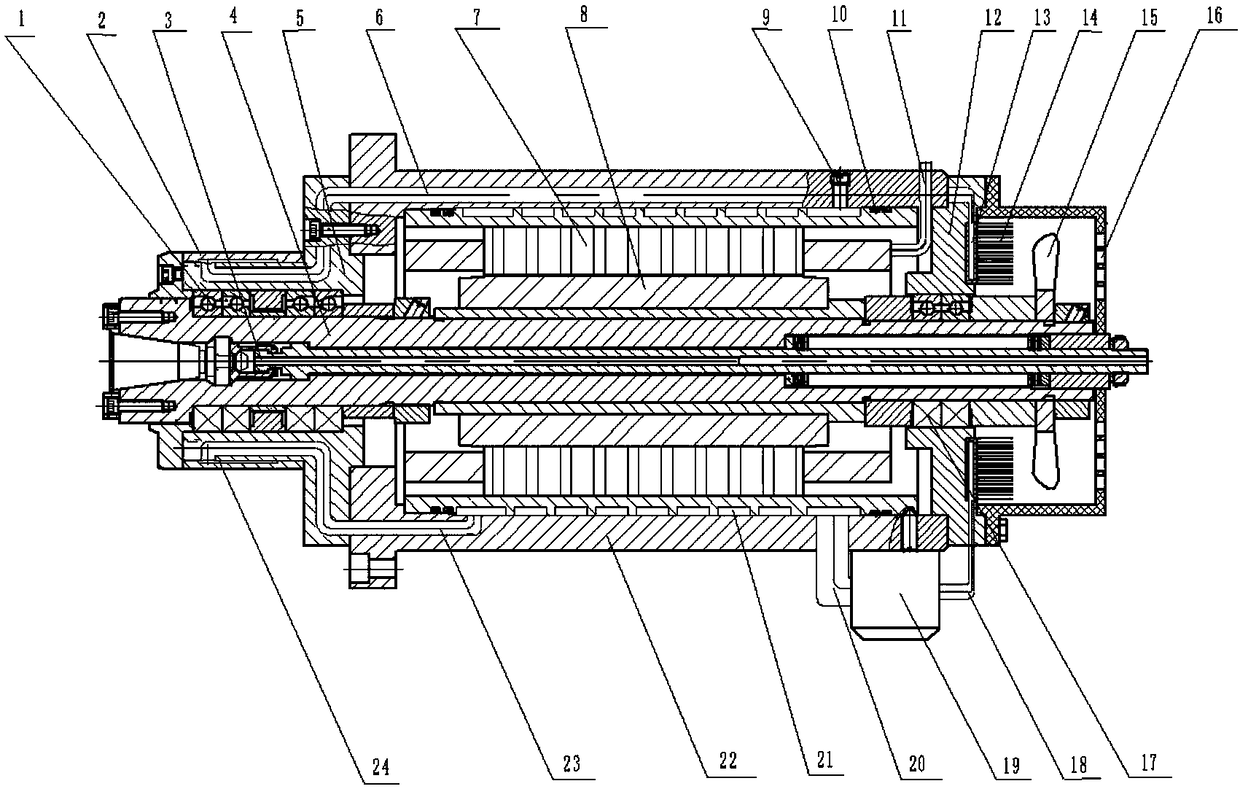

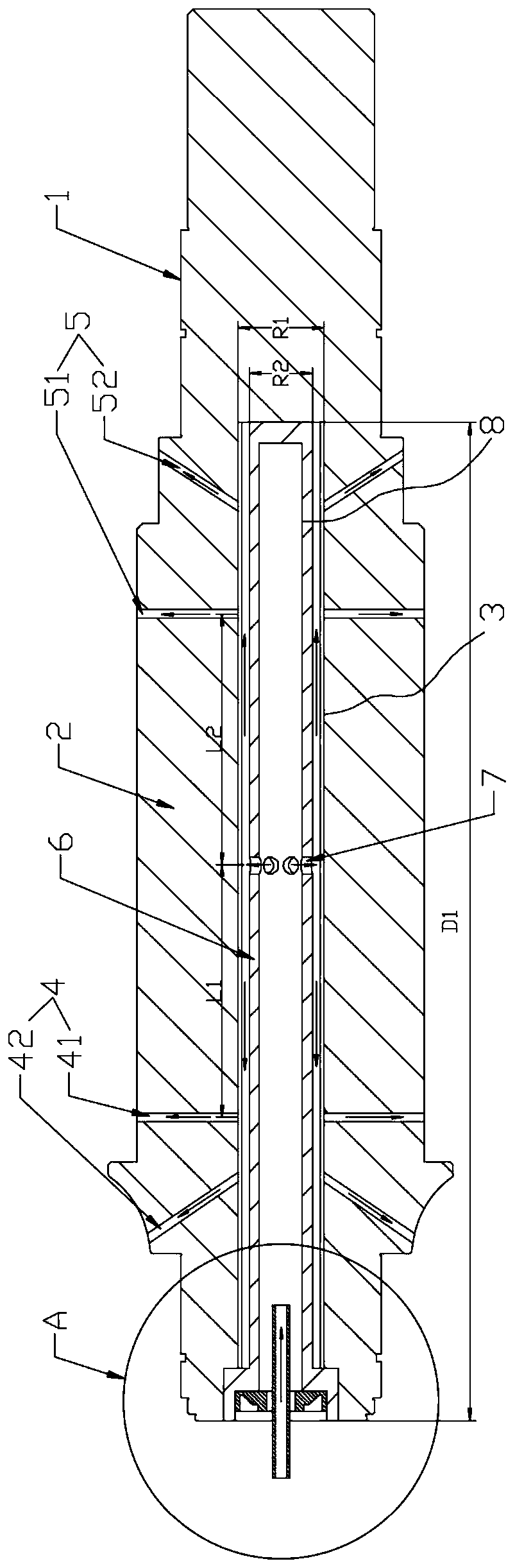

Liquid metal temperature control system for electric spindle

ActiveCN108199533AMagnetic circuit stationary partsCooling/ventillation arrangementTemperature controlElectricity

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

Liquid-cooled motor

InactiveCN104578518ASimple structureEasy to operateCooling/ventillation arrangementSupports/enclosures/casingsEngineeringFront cover

Owner:CHENGDU ZHONGYUANXIN ELECTRONICS TECH

Permanent magnet double-stator synchronous machine

InactiveCN101154863AReduce volumeReduced responseCooling/ventillation arrangementSupports/enclosures/casingsEngineeringMoment of inertia

A permanent magnetism double-stator synchronous machine is provided, wherein, a rotor is a multipolar drag cup rotor consisting of a tegular permanent magnetic steel, a non-magnetic bracket and a rotating shaft; the inner annulus and the outer annulus of the magnetic steel of the rotor are respectively provided with a bushing and a lantern ring; the single end of the drag cup rotor is fixed on the rotating shaft, and a fan is arranged on the rotor; an air passage is arranged on the bracket and between the bushing and the rotating shaft; the four corners of a square housing fixing an outer stator core are provided with air chutes; a left end closure and a right end closure are provided with vents correspondingly. The invention has the advantages of small cubage of the machine, minimal armature reaction and moment of inertia, convenient manufacturing and simple structure.

Owner:TIANJIN DEXIN ELECTRIC MACHINERY

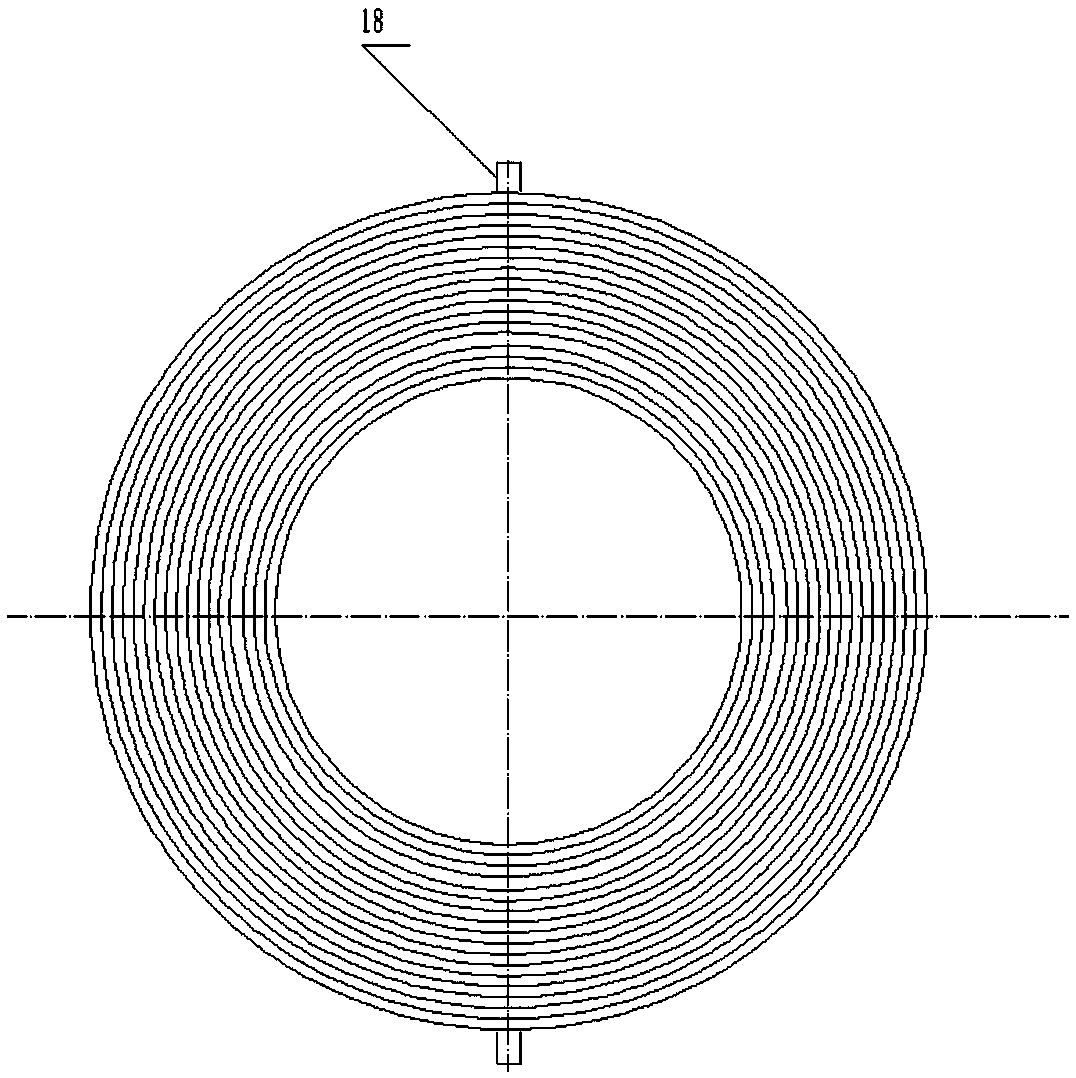

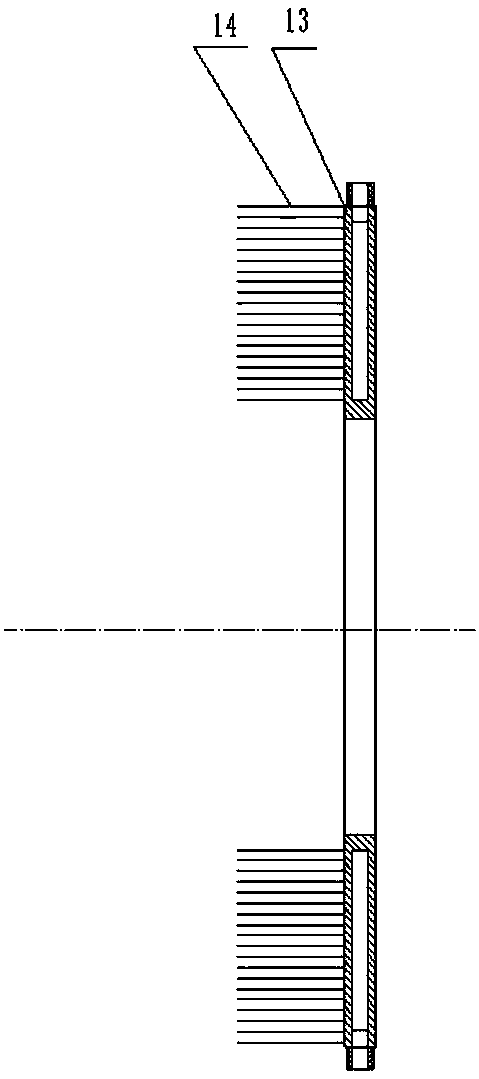

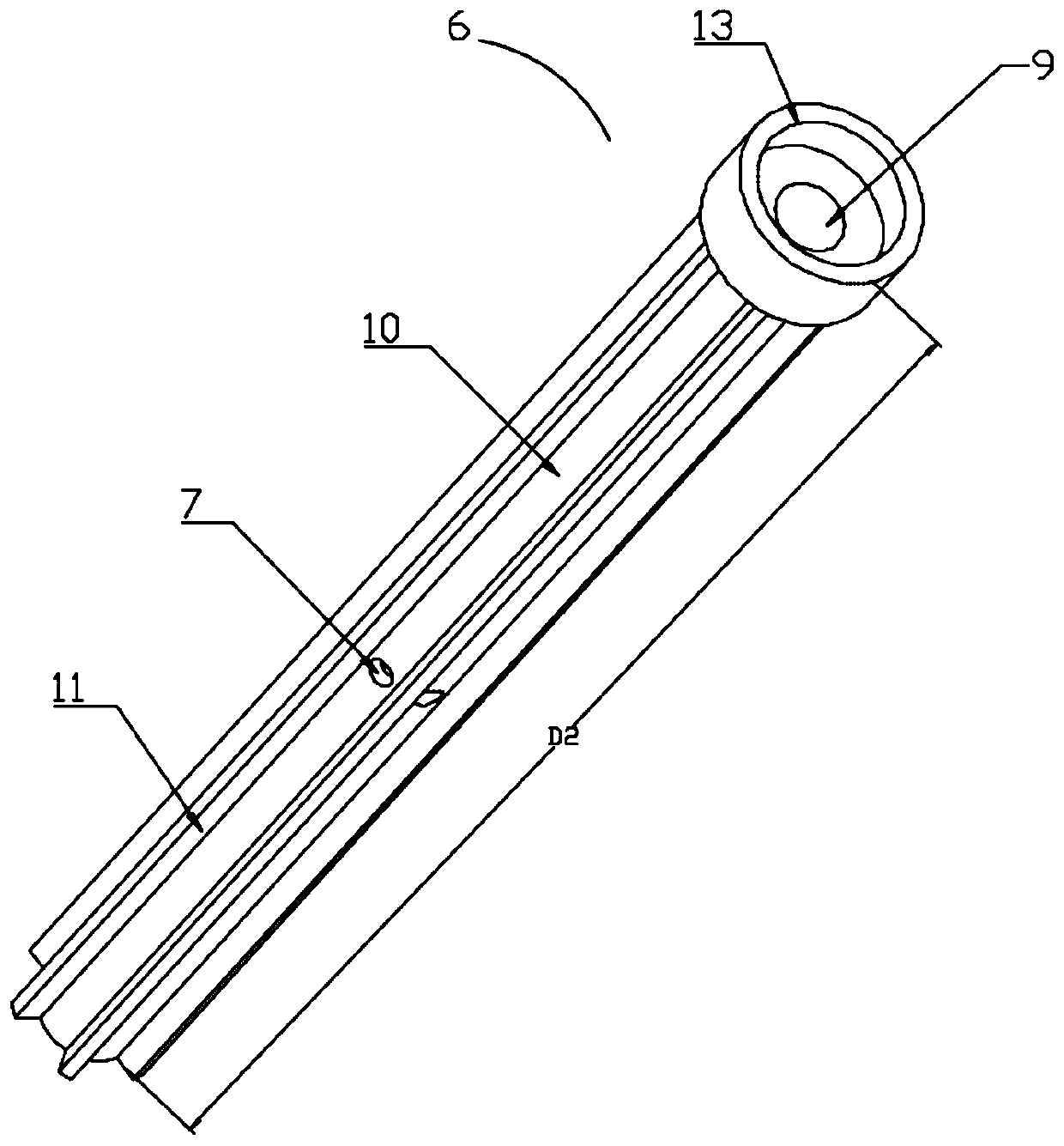

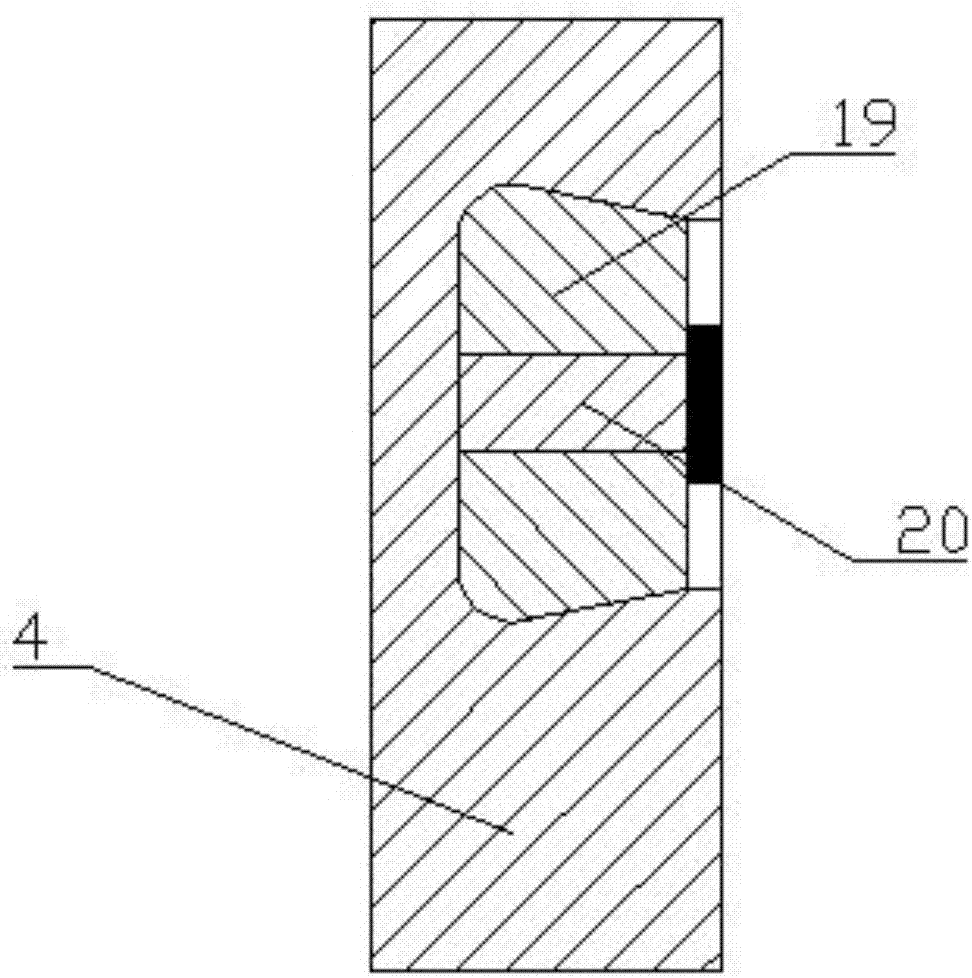

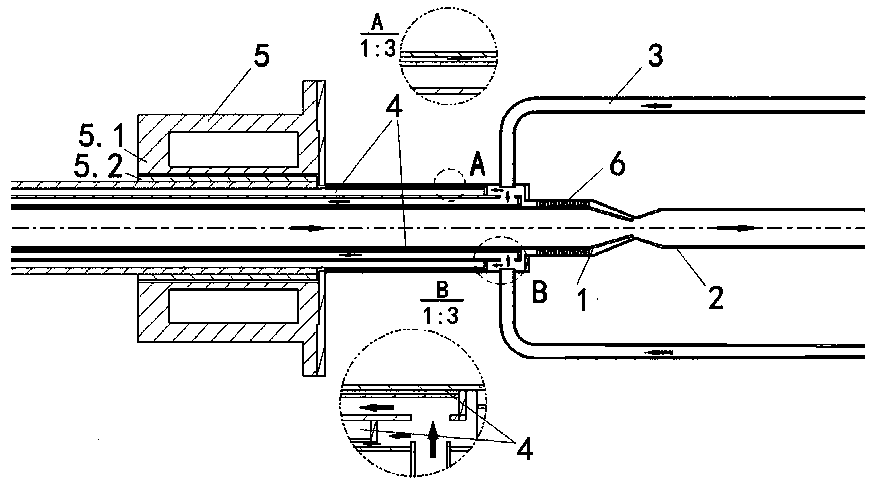

Cooling structure for ultraprecise linear motor

ActiveCN102882314ADo not change the ambient temperatureIncrease thrustCooling/ventillation arrangementCopper foilEngineering

The invention relates to a cooling structure for an ultraprecise linear motor and belongs to the technical field of linear motors. The cooling structure solves the problem of proneness to heat exchange with environment caused by high side temperature of two-side surface-mounted cooling structures of existing linear motors. The cooling structure comprises a winding supporting portion, a winding and a heat conductive portion, wherein the winding is fixed on the surface of the winding supporting portion, the heat conductive portion is arranged on the surface on the outer side and fixedly connected with the winding supporting portion, the heat conductive portion is a copper foil ring which fits the outer profile of the winding and is sleeved and fixed on the surface on the outer side of the winding, or the heat conductive portion is a copper foil heat conductive ring formed by arraying multiple copper foil sections in a dispersed manner, the copper coil heat conductive ring fits the outer profile of the winding, and each copper coil section is fixed on the surface on the outer side of the winding. The cooling structure for the ultraprecise linear motor is suitable for cooling of linear motors.

Owner:HARBIN INST OF TECH

Automobile electronic oil pump driving system

PendingCN112165281AReduce dependenceReduce connectionsAssociation with control/drive circuitsSingle motor speed/torque controlBrushless motorsElectric machine

Owner:湖南东嘉智能科技有限公司 +1

Electric air compressor with motor rotor cooling system

InactiveCN110145479AAchieve self-coolingReduce manufacturing costPump componentsPump installationsImpellerThrust bearing

Owner:DALIAN MARITIME UNIVERSITY

Dustproof motor

PendingCN114301211AAvoid enteringNormal coolingDispersed particle filtrationMechanical energy handlingElectric machineMotor shaft

Owner:陈明芮

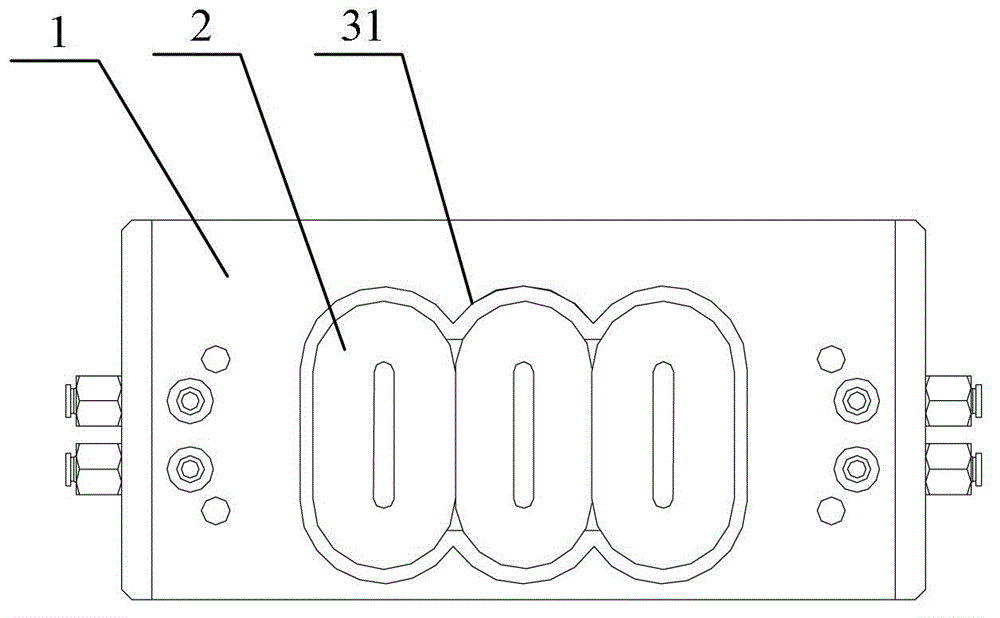

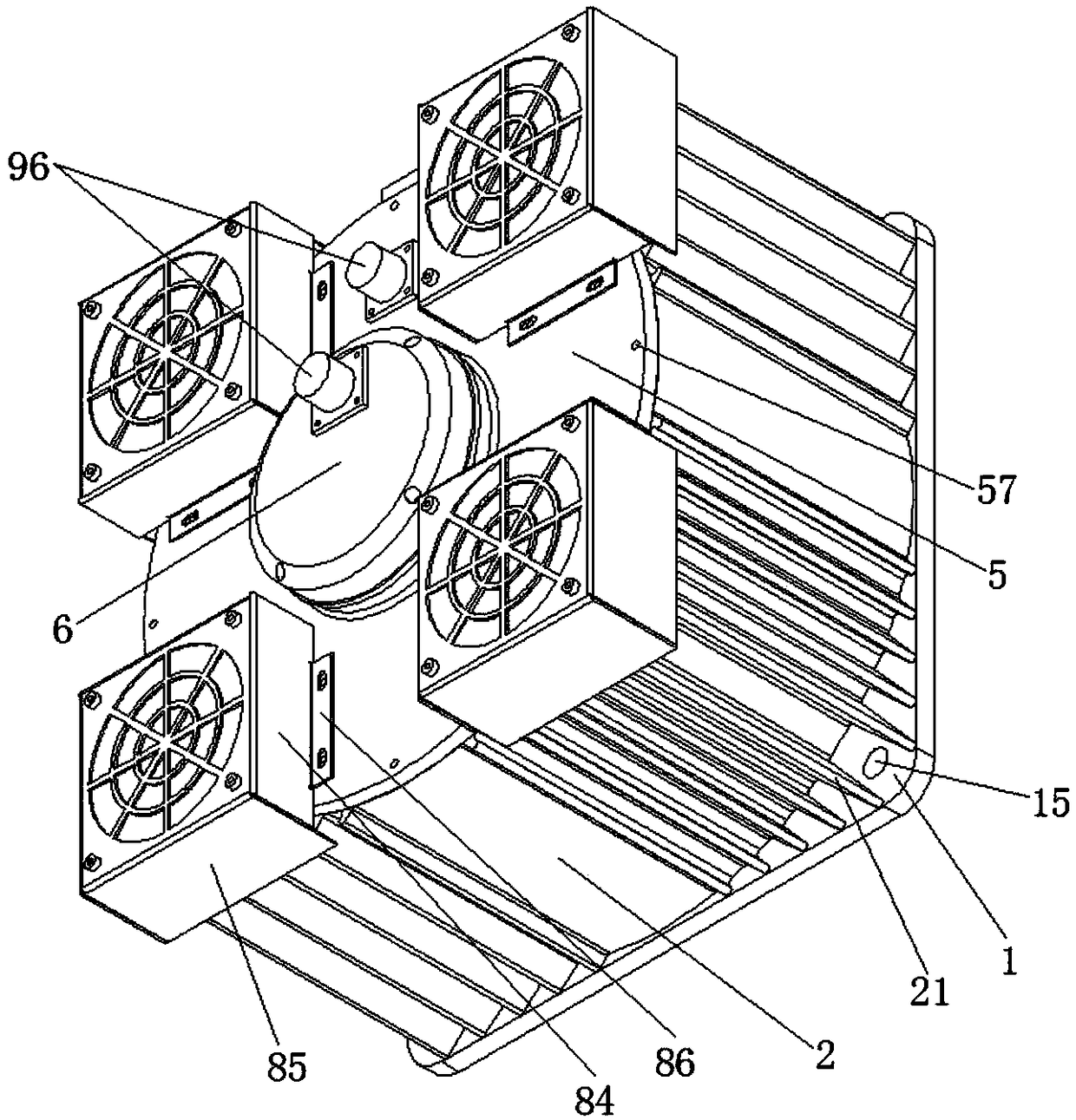

Compressor module for compressing gas and compressor equipped therewith

ActiveUS10704567B2Easy constructionPositive displacement pump componentsPiston pumpsEngineeringGas cooler

A compressor module for compressing gas composed of a compressor element with a housing with integrated compressor element cooler; a motor and a gas cooler for cooling the compressed gas originating from the compressor element. The gas cooler includes a primary section through which the gas to be cooled can be guided and a secondary section that is in heat-exchanging contact with the primary section. A first cooling circuit can guide a coolant through the secondary section of the gas cooler or through a section thereof and a second cooling circuit can guide a coolant through the compressor element cooler. The first cooling circuit and the second cooling circuit are joined together in series or in parallel and are guided to a common output.

Owner:ATLAS COPCO AIRPOWER NV

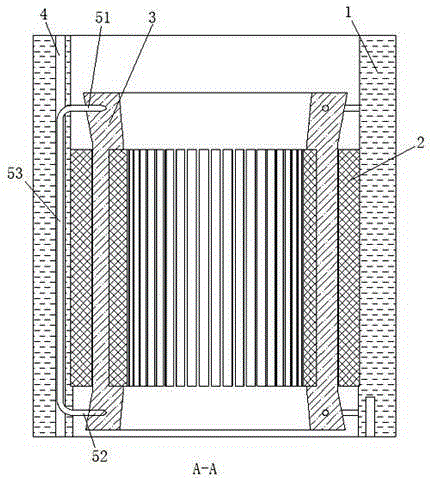

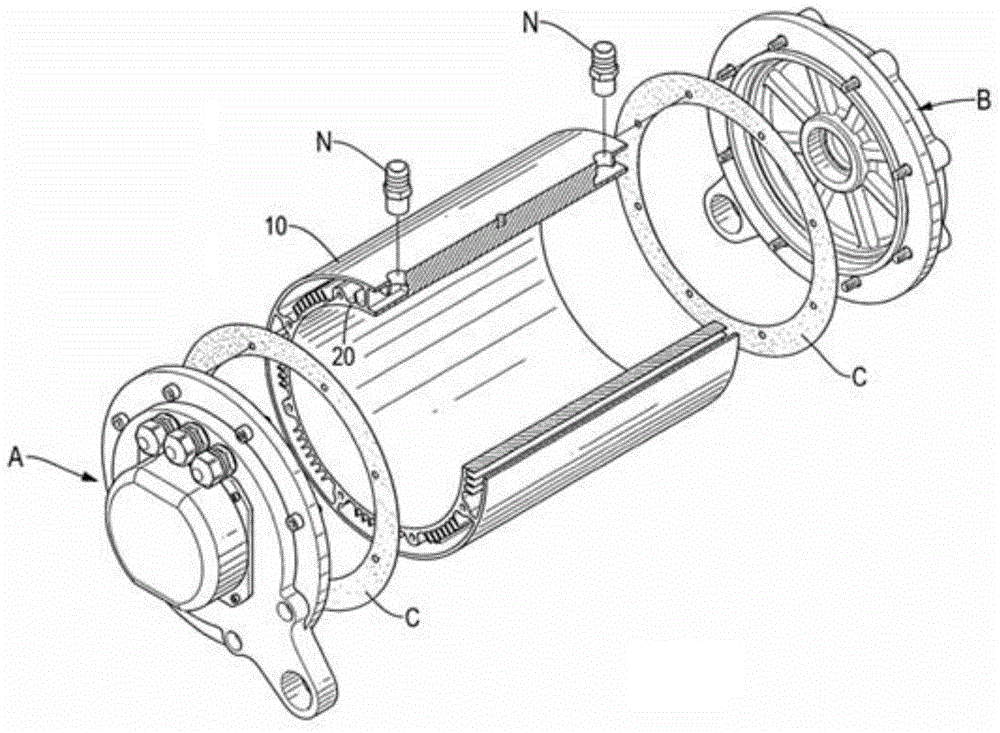

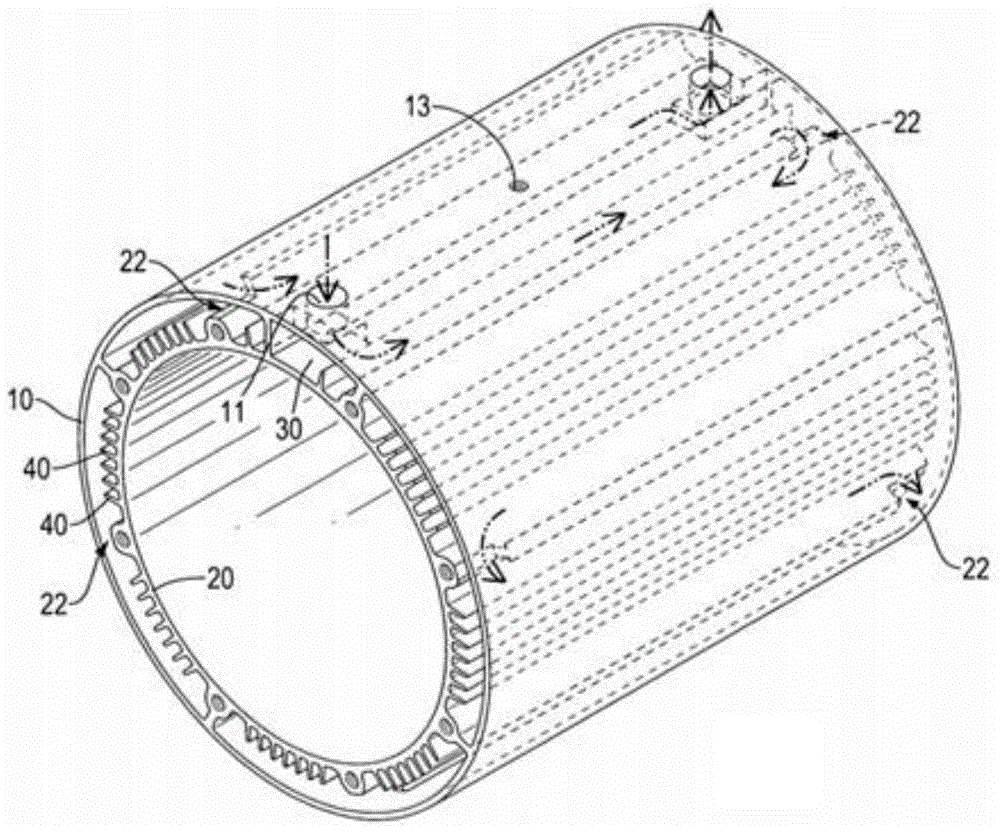

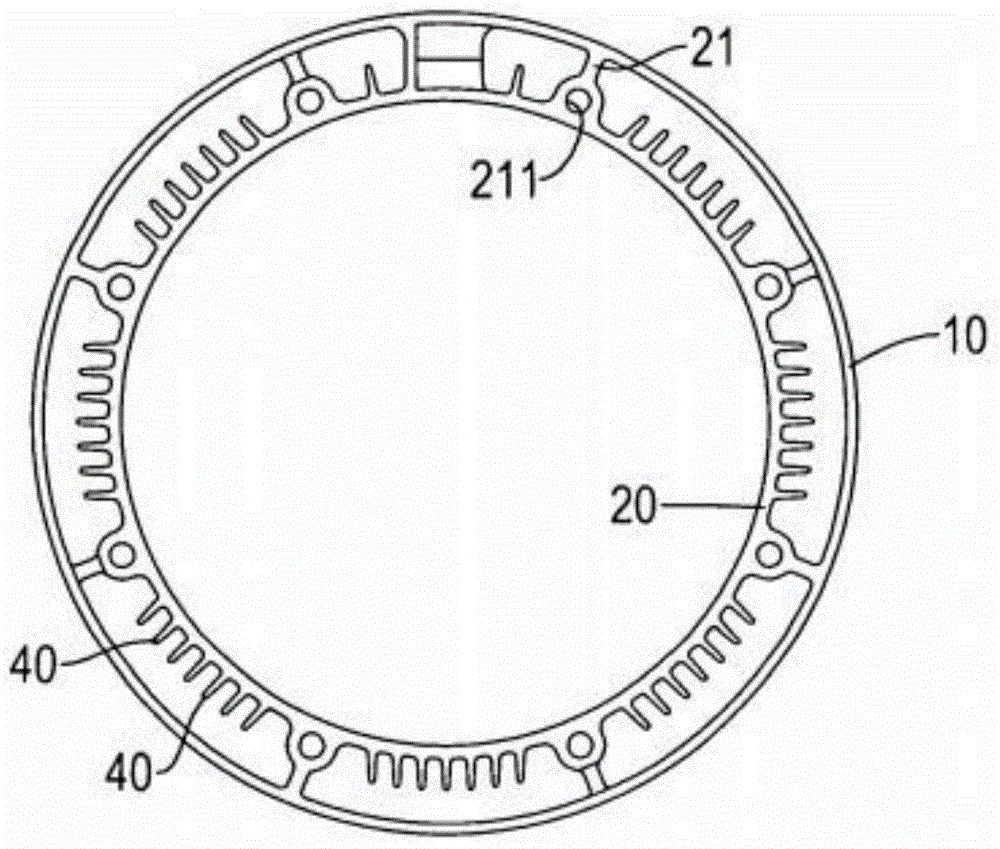

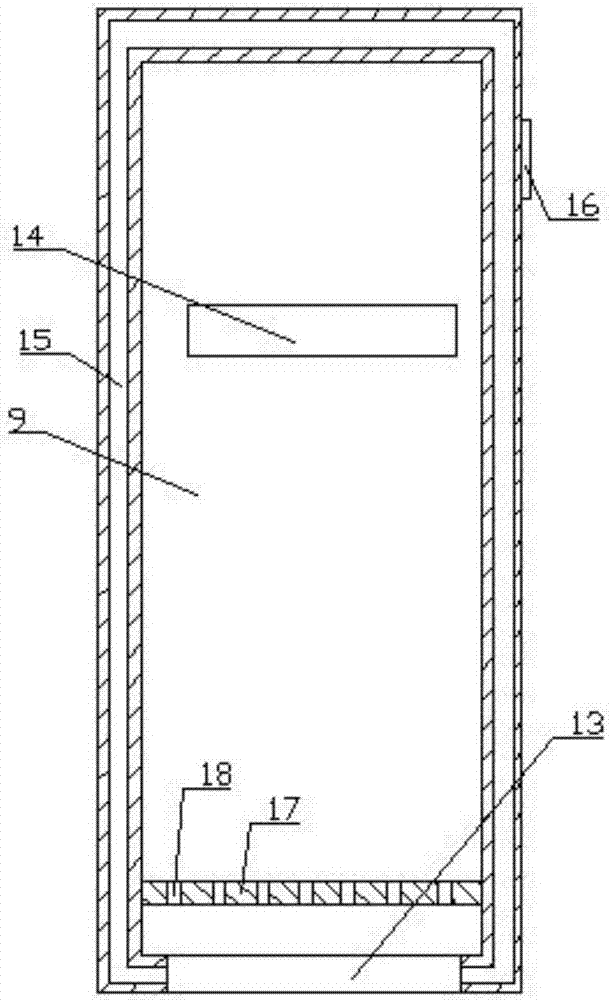

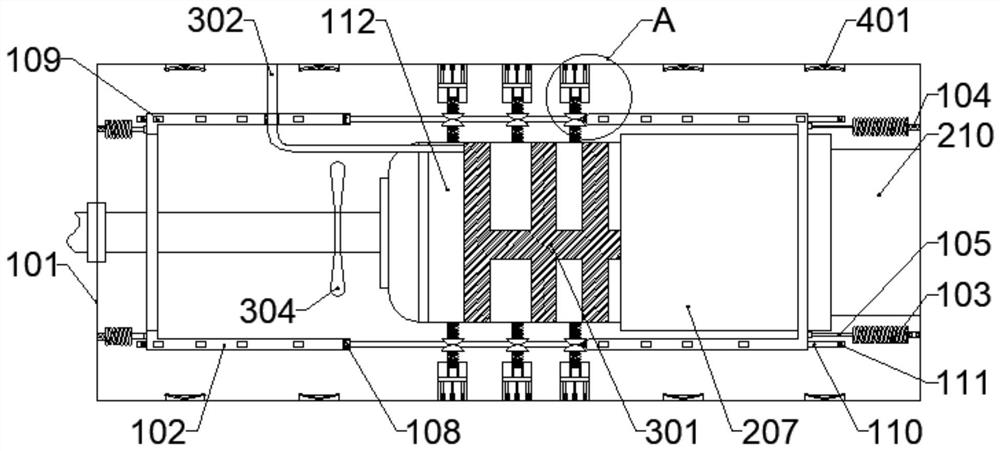

Internal circulation cooling structure of all-sealed motor

InactiveCN108649748AReduce processing costsReduce processing difficultyMagnetic circuit rotating partsMagnetic circuit stationary partsInternal heat transferEngineering

Owner:TIANJIN UNIV

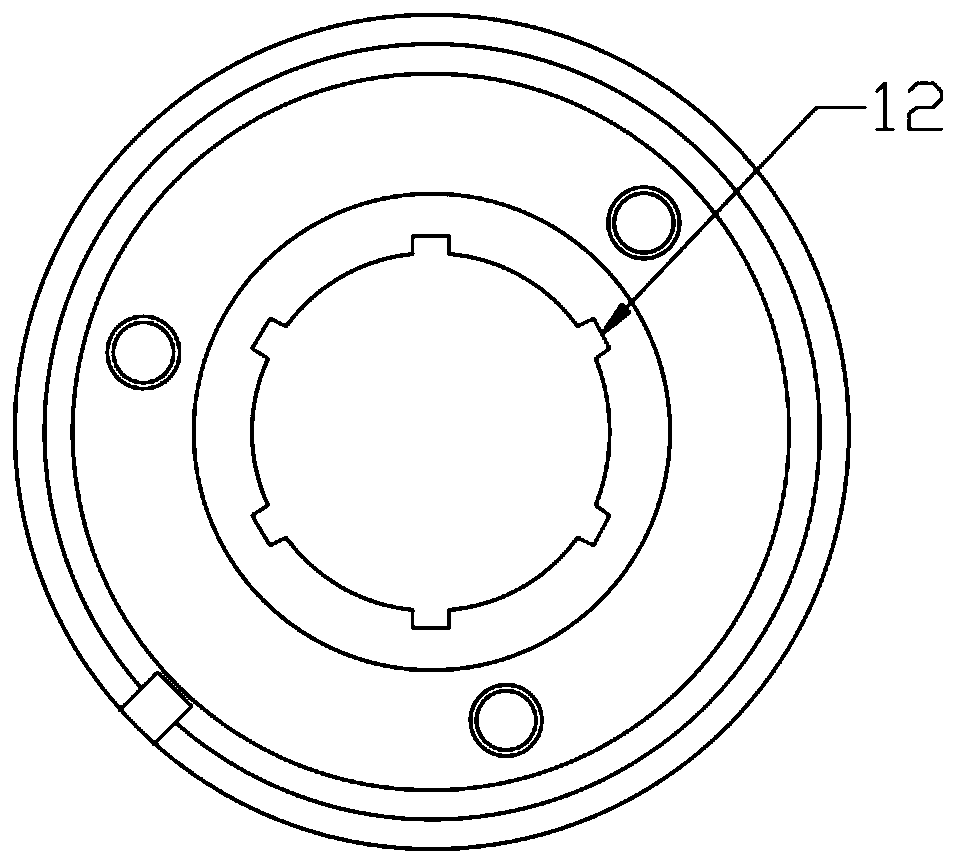

Hollow shaft sealing ring, hollow shaft, rotor structure, motor and electric vehicle

ActiveCN111564927APrevent leakageGuaranteed connectivityEngine sealsPiston ringsOil canElectric machinery

Owner:GREE ELECTRIC APPLIANCES INC

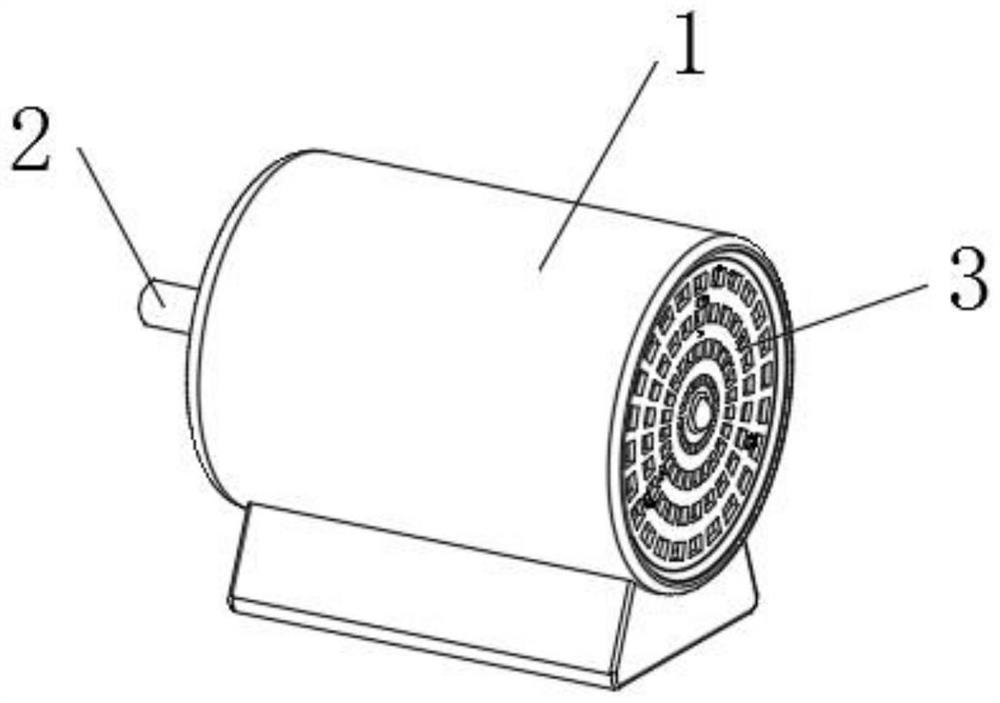

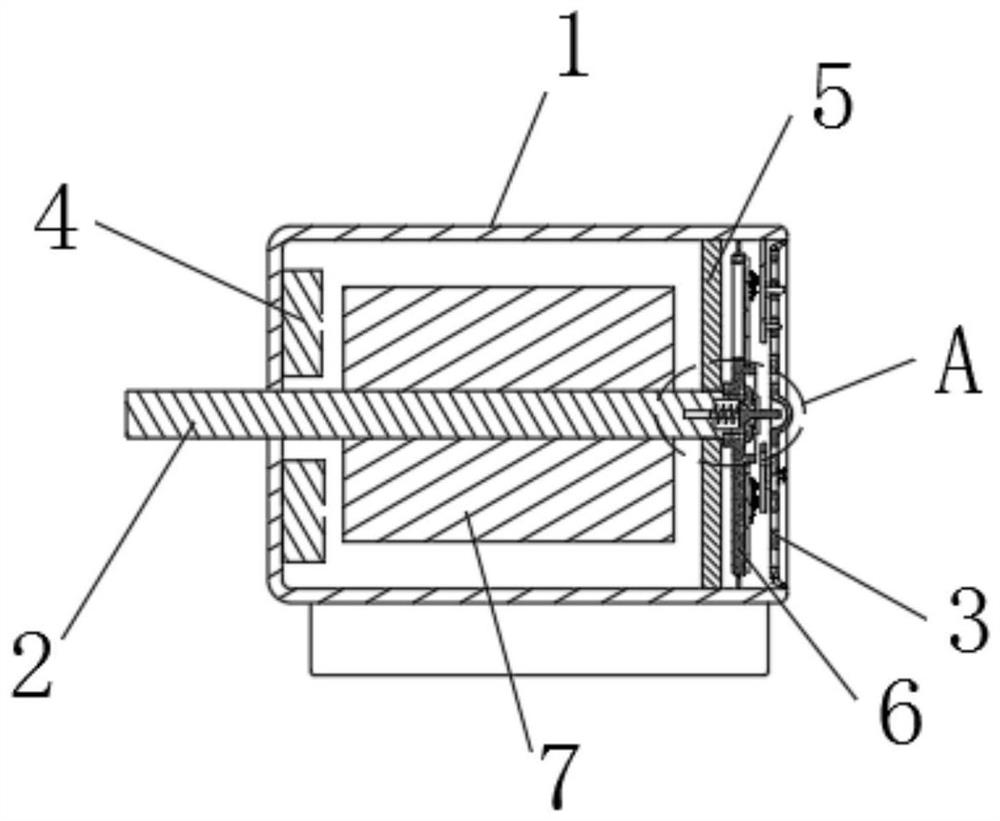

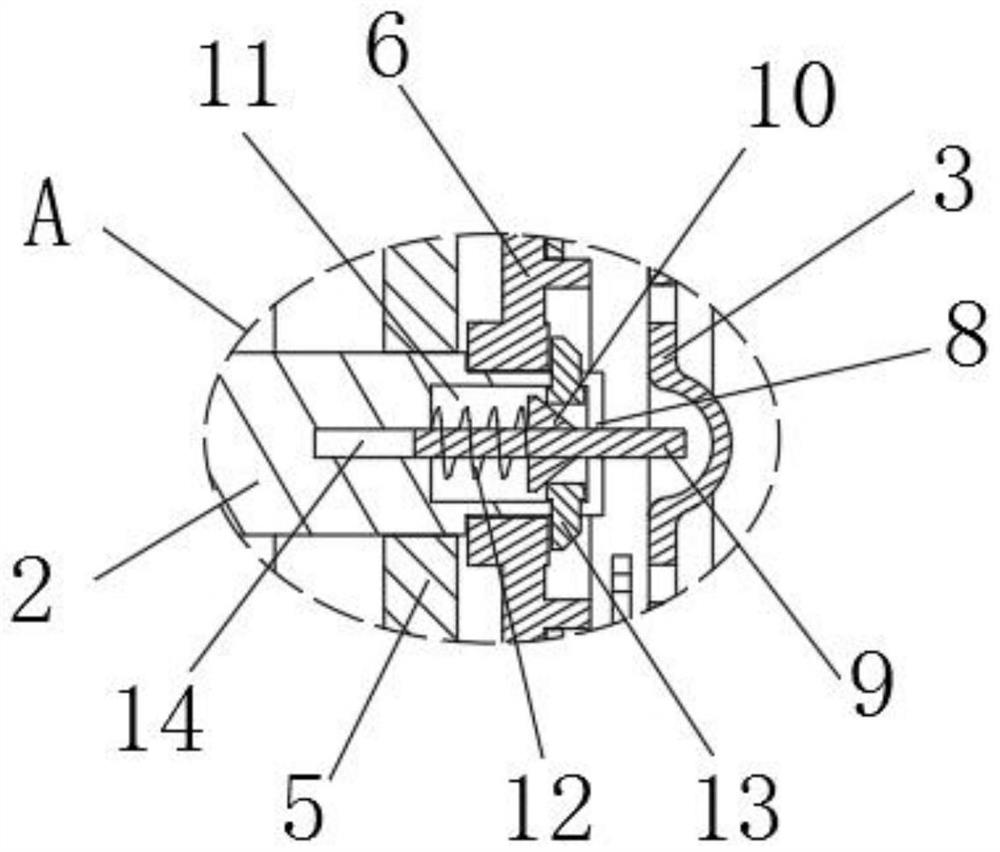

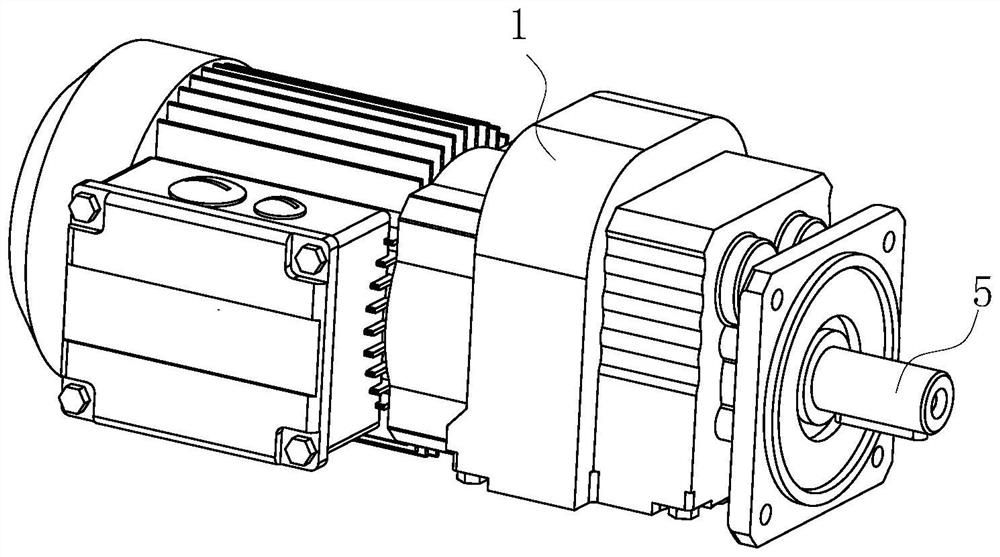

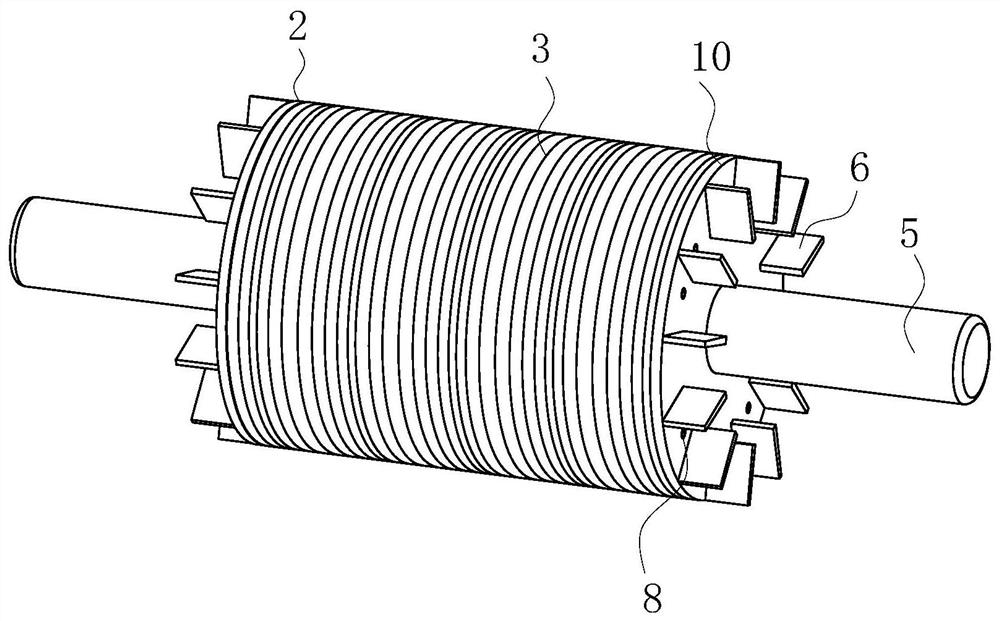

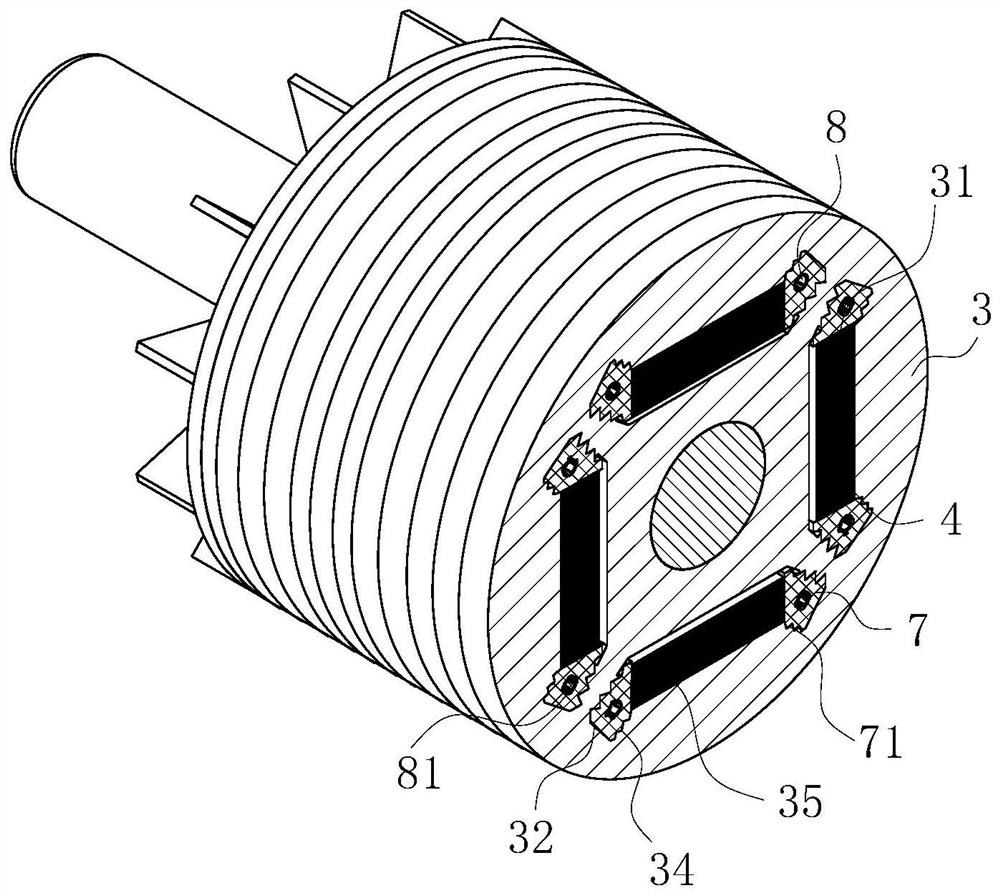

Permanent magnet electric roller with non-return device

PendingCN111835124ALarge sectionReduce wind resistanceMechanical energy handlingCooling/ventillation arrangementEngineeringMagnet

The invention relates to the technical field of electric transmission systems and discloses a permanent magnet electric roller with a non-return device. The electric roller comprises a rotor assembly,a first end cover assembly, a second end cover assembly, a backstop, a stator assembly, a fixed seat and a junction box assembly. The second end cover assembly is fixedly connected with the backstopthrough a flange ring and the second end cover assembly and the backstop are both located in one end of the rotor assembly cylinder. The stator assembly is located in the rotor assembly, and the two ends of the stator assembly are fixed to the first end cover assembly and the second end cover assembly respectively. According to the permanent magnet electric roller, the backstop is arranged in therotor assembly, the overall length of the permanent magnet electric roller is shortened, meanwhile, the inclined air inlet is adopted, the air guide effect in the permanent magnet electric roller is improved, and the heat dissipation effect of the permanent magnet electric roller is further improved.

Owner:JIANGSU JIAXUAN INTELLIGENT IND TECH CO LTD

Novel water cooling structure of water pump motor

ActiveCN113241881ACooling/ventillation arrangementSupports/enclosures/casingsEngineeringMechanical engineering

Owner:中擎电机有限公司

Three-phase permanent magnet synchronous variable frequency motor

ActiveCN111934455APrevent shakingHigh hardnessMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

Owner:ZHEJIANG XILING

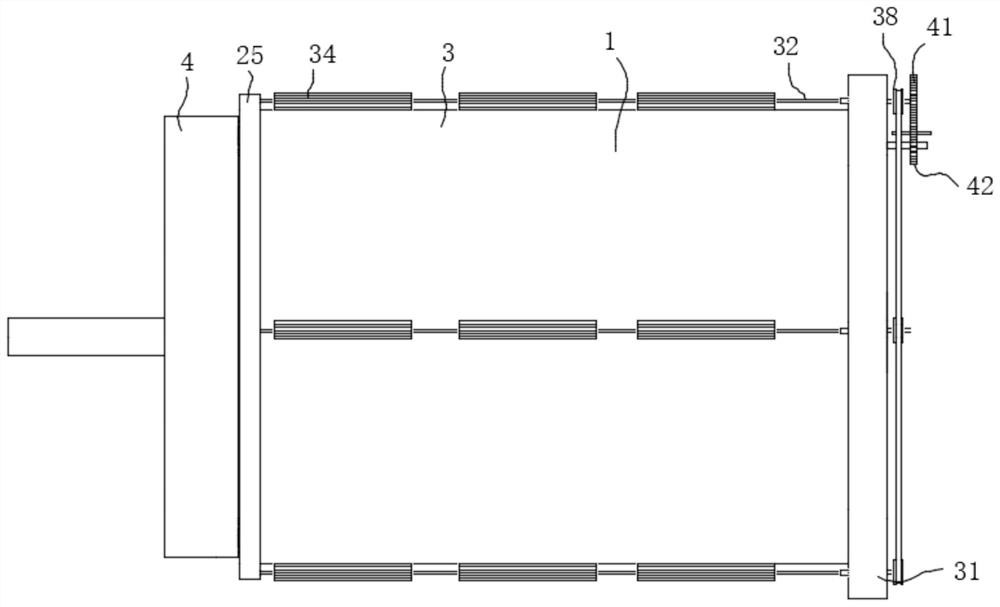

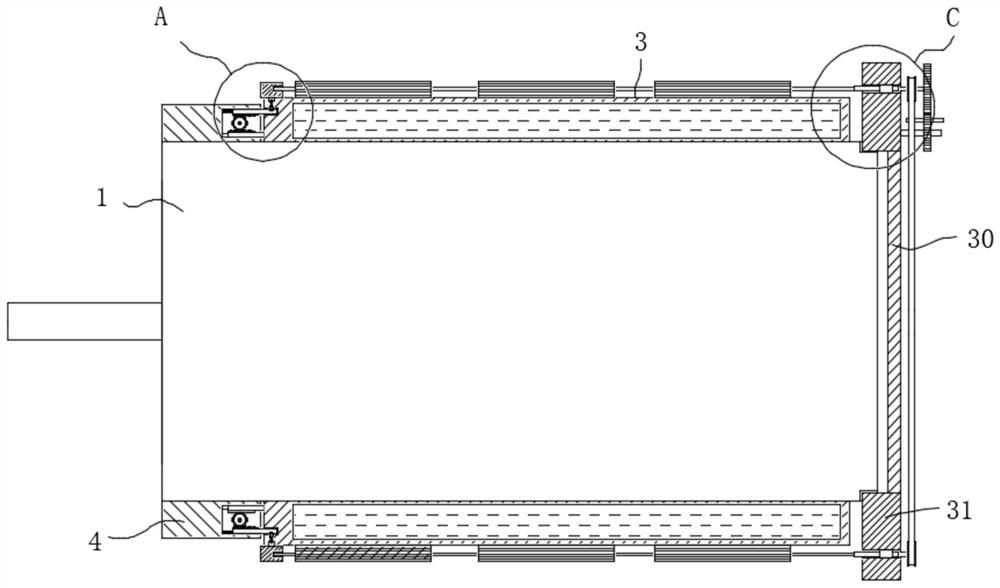

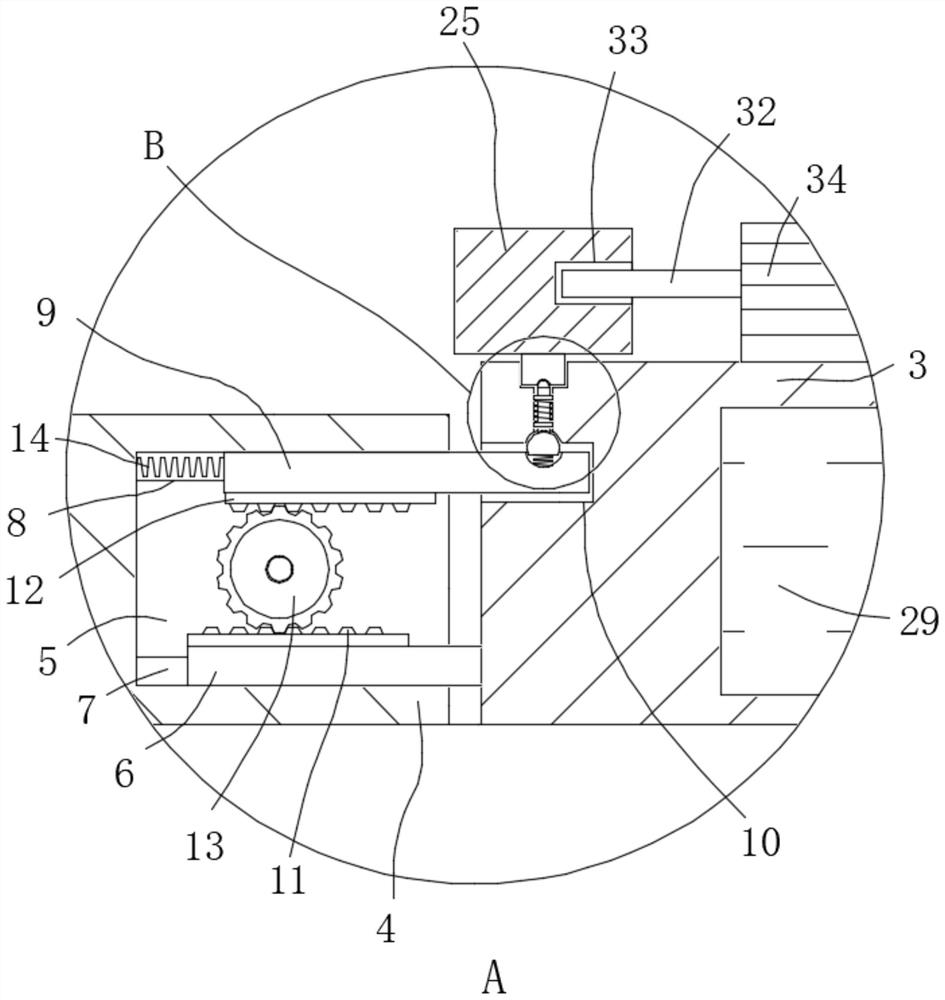

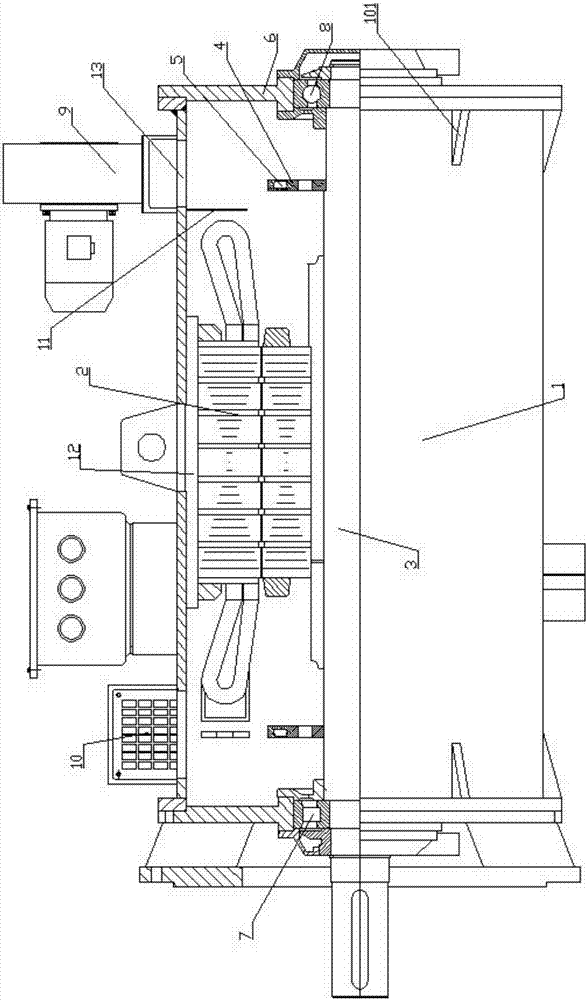

Cooling system for drive motor in twin-screw extruder

InactiveCN102832743AEffective coolingGuaranteed service lifeCooling/ventillation arrangementSupports/enclosures/casingsElectric machineEngineering

Owner:JIANGYIN LONGSHAN SYNTHETIC MATERIAL

Open-type suspension variable frequency motor and method for assembling the same

InactiveCN106992631AImprove the safety of useAchieve axial ventilation coolingManufacturing dynamo-electric machinesMechanical energy handlingEngineeringStator

Owner:PUYANG HUANAN HEAVY IND SCI & TECH CO LTD

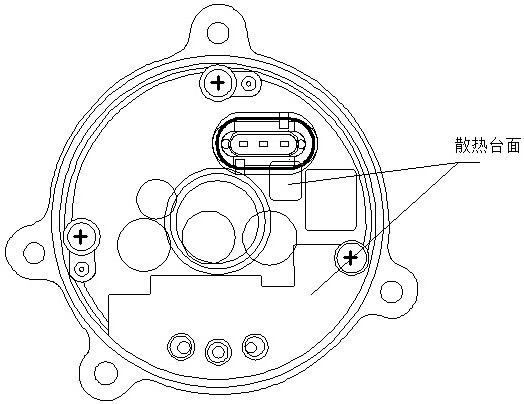

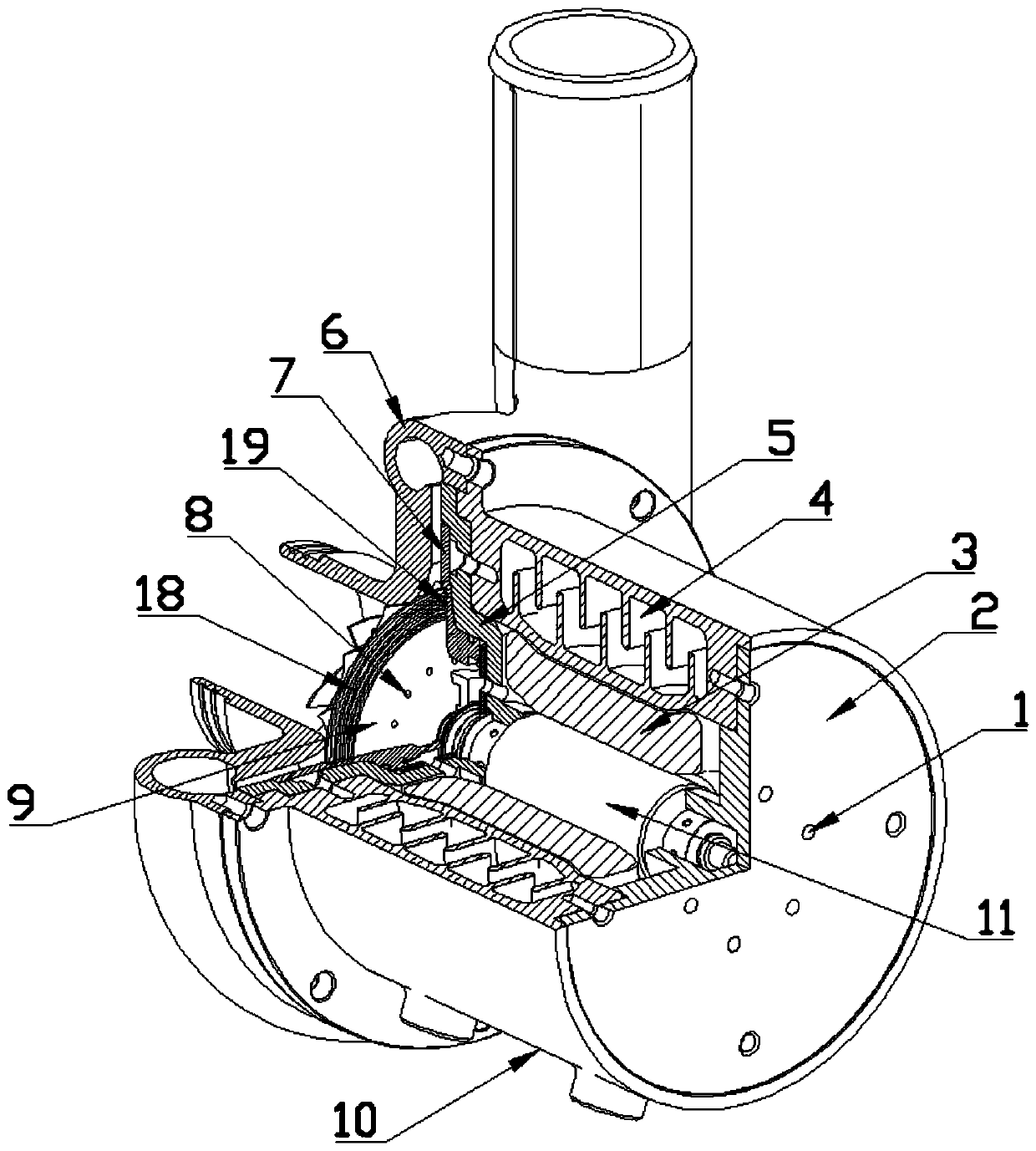

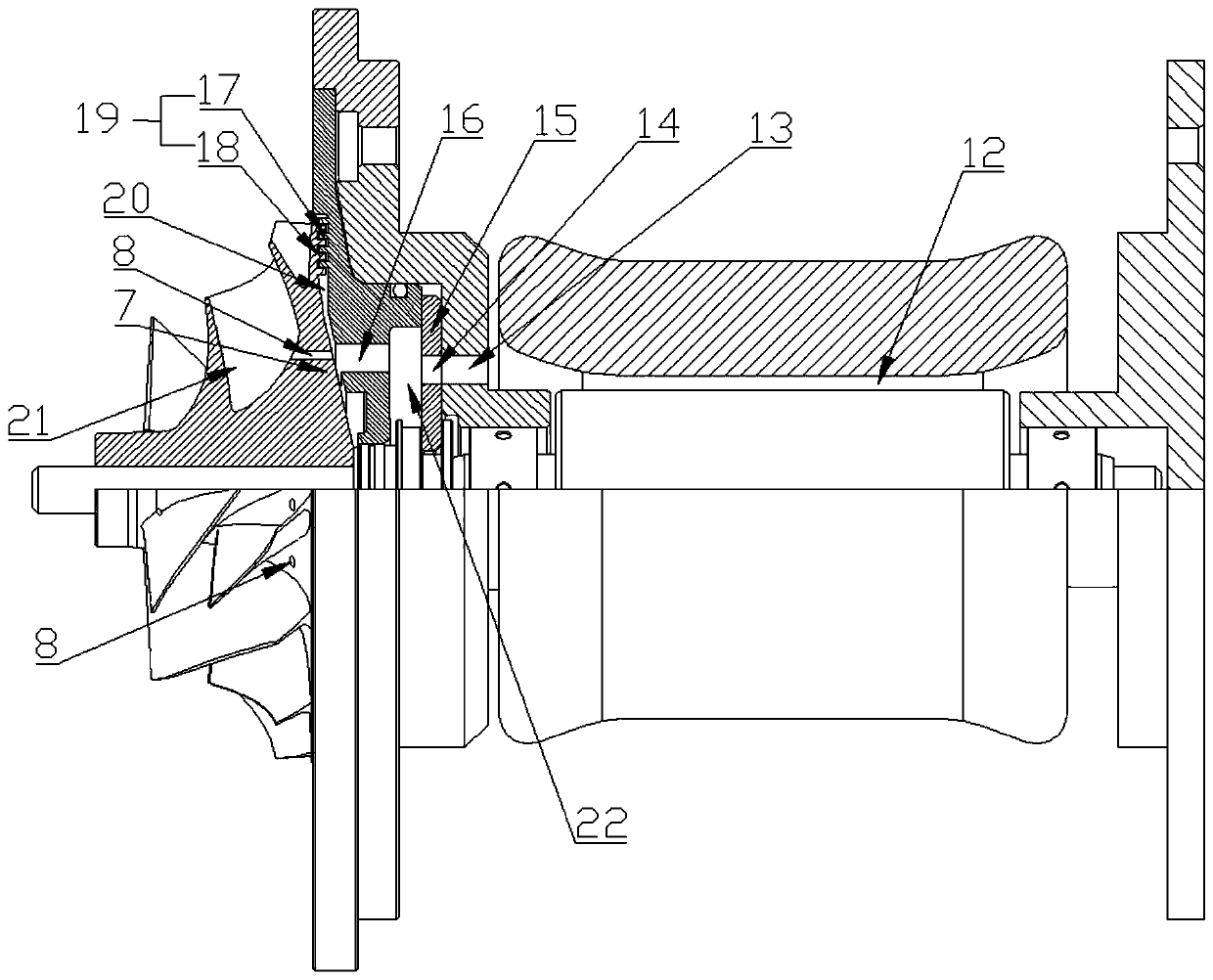

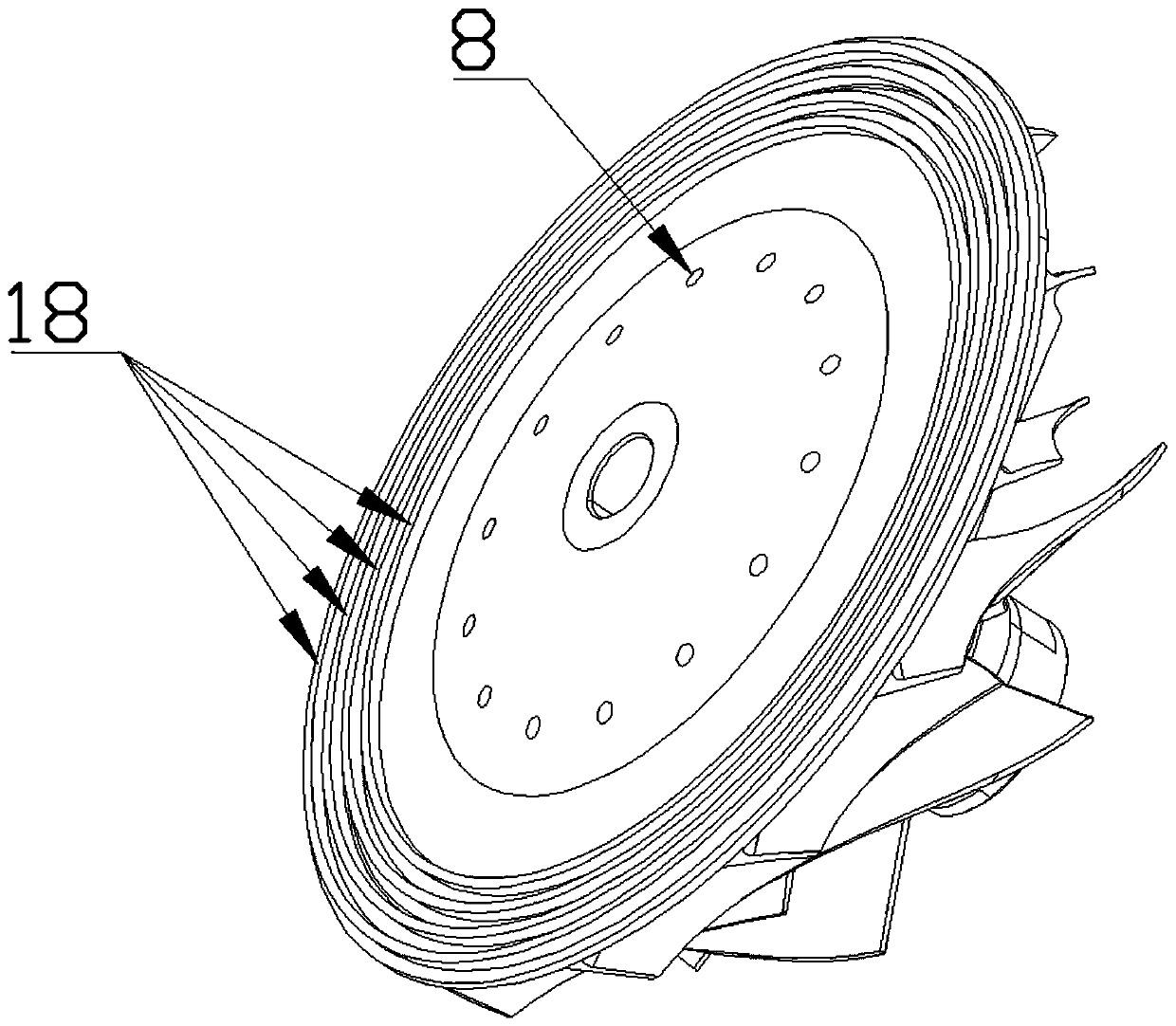

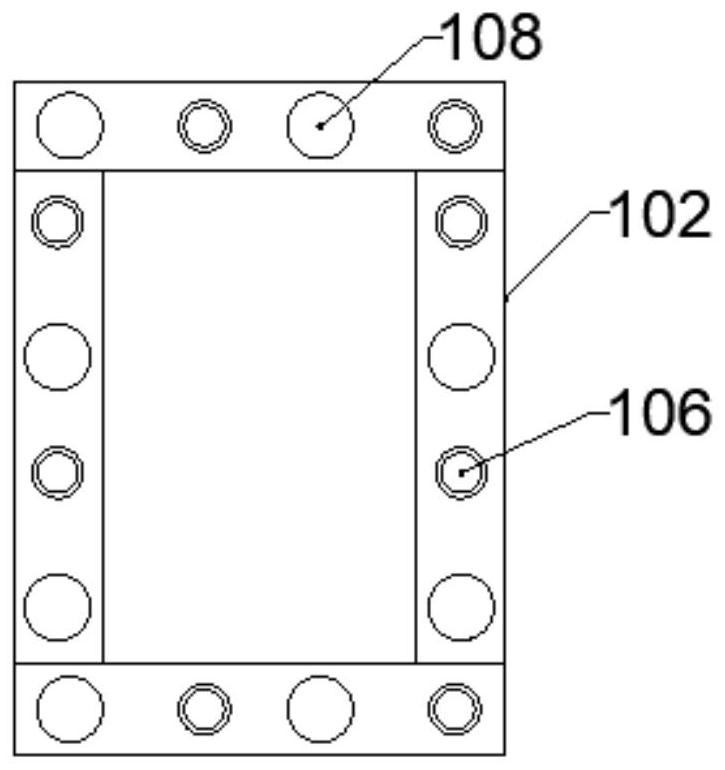

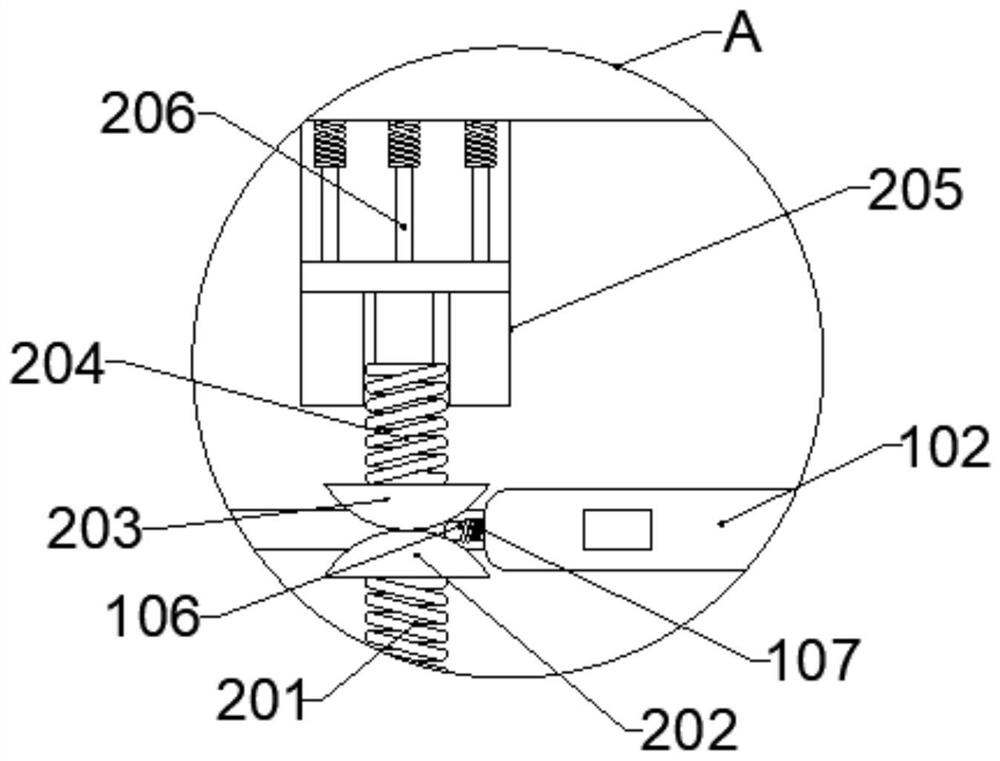

Novel wheel hub motor heat radiation controller

Owner:CHANGCHUN UNIV OF TECH

Motor for oil field drilling

InactiveCN106560984AImprove overload capacityImprove reliabilityStructural associationCooling/ventillation arrangementWell drillingEngineering

The invention relates to a motor for oil field drilling, and the motor comprises a pedestal and a motor main body. One side of the motor main body is provided with a wiring box, and the top of the motor main body is provided with an explosion-proof fan, and the wiring box and the explosion-proof fan are connected to the motor main body through explosion-proof pipes. The motor main body comprises a main shaft, an armature, a stator and a brush carrier. The brush carrier is disposed at one side of the armature, and the motor main body at the top of the brush carrier is provided with a cover plate. The motor main body at one side is provided with an end cover and a pressure plate, and two ends of the main shaft are respectively provided with a first rolling bearing assembly and a second rolling bearing assembly. The first rolling bearing assembly is sealed through a labyrinth bearing sealing structure. The interior of the motor main body also comprises a heater device and a bearing temperature measuring device. After the above structure is employed, the motor is strong in overload capability, is high in reliability, is easy to maintain, and maintains the same size as the size of a motor of the same type in a foreign country. Moreover, the performance index reaches the foreign level, and the motor can completely be used for replacing the motors of the same type in the foreign country, and is worthy of popularization in the whole industry.

Owner:JIANGSU JINHU ELECTRIC CO LTD

Winding type brushless doubly-fed motor with novel cooling function

ActiveCN113964996AEasy inspection and maintenanceTimely detection and maintenanceCooling/ventillation arrangementSupports/enclosures/casingsElectric machineDoubly fed electric machine

Owner:GUANGZHOU YIZHI ENVIRONMENTAL PROTECTION TECH CO LTD

Air duct assembly of motor and motor with air duct assembly

PendingCN108288889APrecise positioningEasy to assembleCooling/ventillation arrangementSupports/enclosures/casingsImpellerEngineering

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

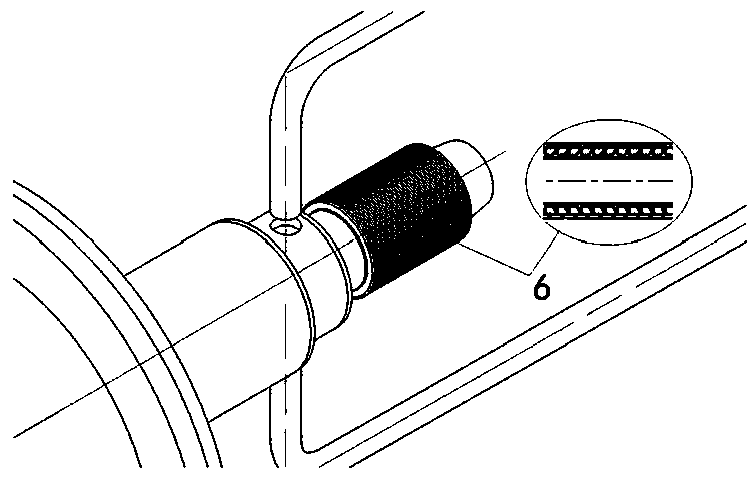

A refrigerant transmission sealing structure for superconducting motor

ActiveCN109742922BIncrease flow rateIncrease dynamic pressureCooling/ventillation arrangementSuperconducting electric machineElectric machine

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

New energy automobile driving motor protection shell

Owner:LUOHE VOCATIONAL TECH COLLEGE

Concrete mixing and transporting vehicle motor

InactiveCN107492976AImprove cooling effectMeet electricity demandBatteries circuit arrangementsElectric powerEngineeringMotor design

Owner:刘志运

Permanent-magnet direct-driving motor for sawing machine

PendingCN108347133ACompact structureNovel structureMagnetic circuit rotating partsMagnetic circuit stationary partsCooling effectHeat sink

Owner:孙建林

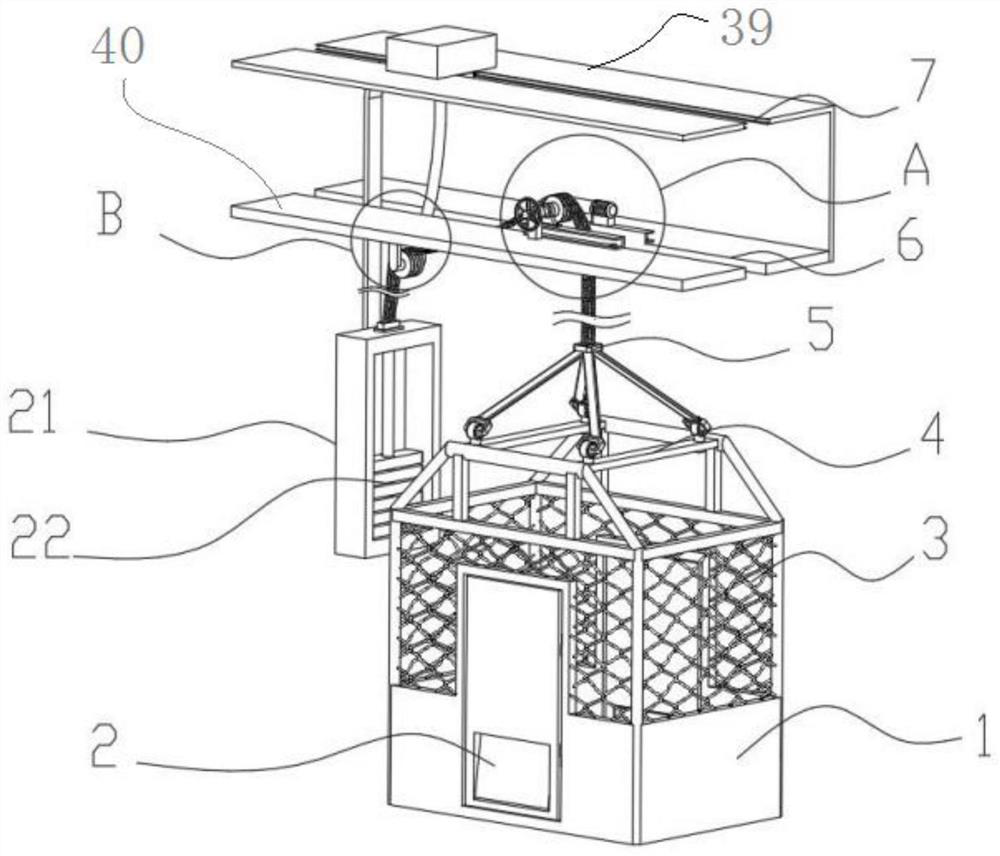

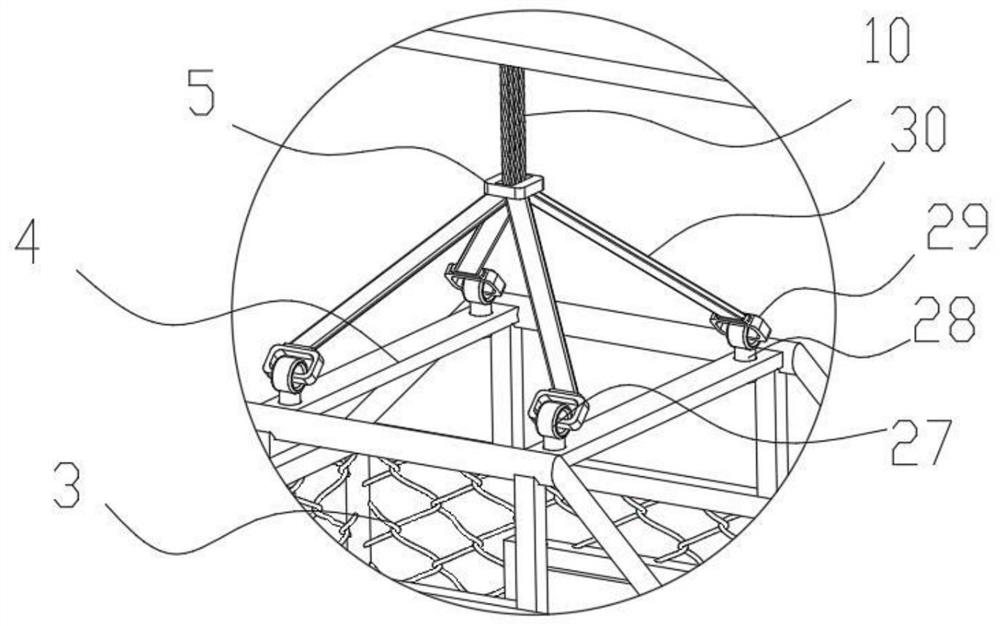

Vertical conveying device for maintenance personnel of wind power generation equipment

ActiveCN113636435AProtection securityExtended service lifeWind energy generationCooling/ventillation arrangementEngineeringWater spray

Owner:HUANENG CLEAN ENERGY RES INST

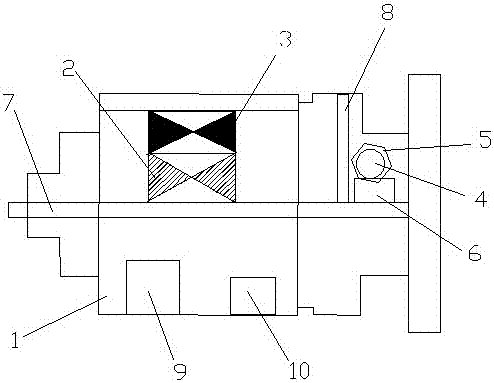

Industrial motor with good heat dispersion

InactiveCN109391082AImprove cooling effectGuaranteed to workCooling/ventillation arrangementSupports/enclosures/casingsControl engineeringScrew thread

The present invention relates to the technical field of industrial devices, and discloses an industrial motor with good heat dispersion. The motor comprises an engine body, a rotation shaft is fixedlyconnected with the inner cavity of the engine body in a penetrating mode, one end of the rotation shaft is fixedly connected with a fixed block, one side, far away from the rotation shaft, of the fixed block is fixedly connected with a threaded rod, the outer wall of the threaded rod is sleeved with a nut in a screw thread mode, the outer portion of the threaded rod is movably sleeved with a sleeve, the sleeve is located at the middle positions of the fixed block and the nut, the top portion and the bottom portion of the sleeve are fixedly connected with fans through a fixed rod. Through cooperation of a rotation shaft, a fixed block, the threaded rod, the sleeve, the fixed rod and the fans, the rotation shaft at the internal portion of the industrial motor is rotated to drive rotation ofthe fans to blow wind into the engine body to use wind to take away the heat in the engine body and allow the temperature in the engine body not to be too high so as to ensure that parts in the motorcannot be damaged by a high temperature, improve the service life of parts in the motor and ensure the normal work of the motor.

Owner:YANGZHOU MINGCHENG MASCH NEW TECH R & D SERVICE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap