Motor stator heat radiation structure

A technology of heat dissipation structure and motor stator, which is applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as hidden safety hazards and restrict motor performance, and achieve the effects of improving stability and safety, simple structure, and improving heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

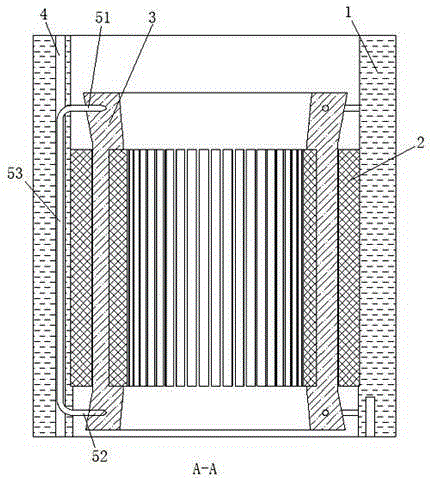

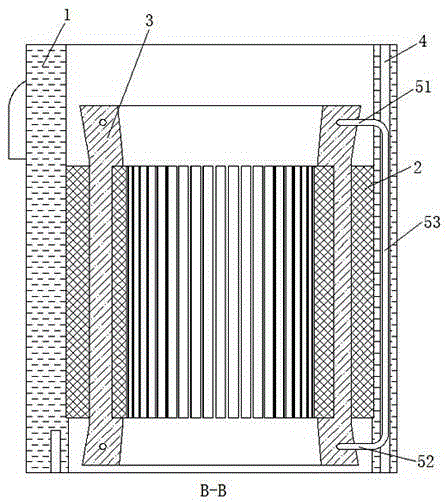

[0016] See Figure 1-Figure 3 , a motor stator heat dissipation structure, the motor includes a housing 1, a stator core 2 located in the housing 1, and a motor winding 3 wound on the stator core 2, and the housing 1 is provided with two closed ends The heat pipe 5 is provided with eight vertical cooling passages 4 on the housing, and the cooling liquid inlet 6 and the cooling liquid outlet 7 respectively connected to the two ends of the eight cooling passages are provided on the housing 1, and each heat pipe 5 all include an upper horizontal radiating pipe 51 with one end closed, a lower horizontal radiating pipe 52 with one end closed, and a vertical cooling pipe 53 connected between the upper horizontal radiating pipe 51 and the lower horizontal radiating pipe 52, and the upper horizontal radiating pipe 51 and the lower horizontal heat pipe 51 are embedded in the motor winding 3, and the cooling pipe 53 is located in the cooling channel 4; see Figure 4 , the upper horizontal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap