Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about "Supports/enclosures/casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

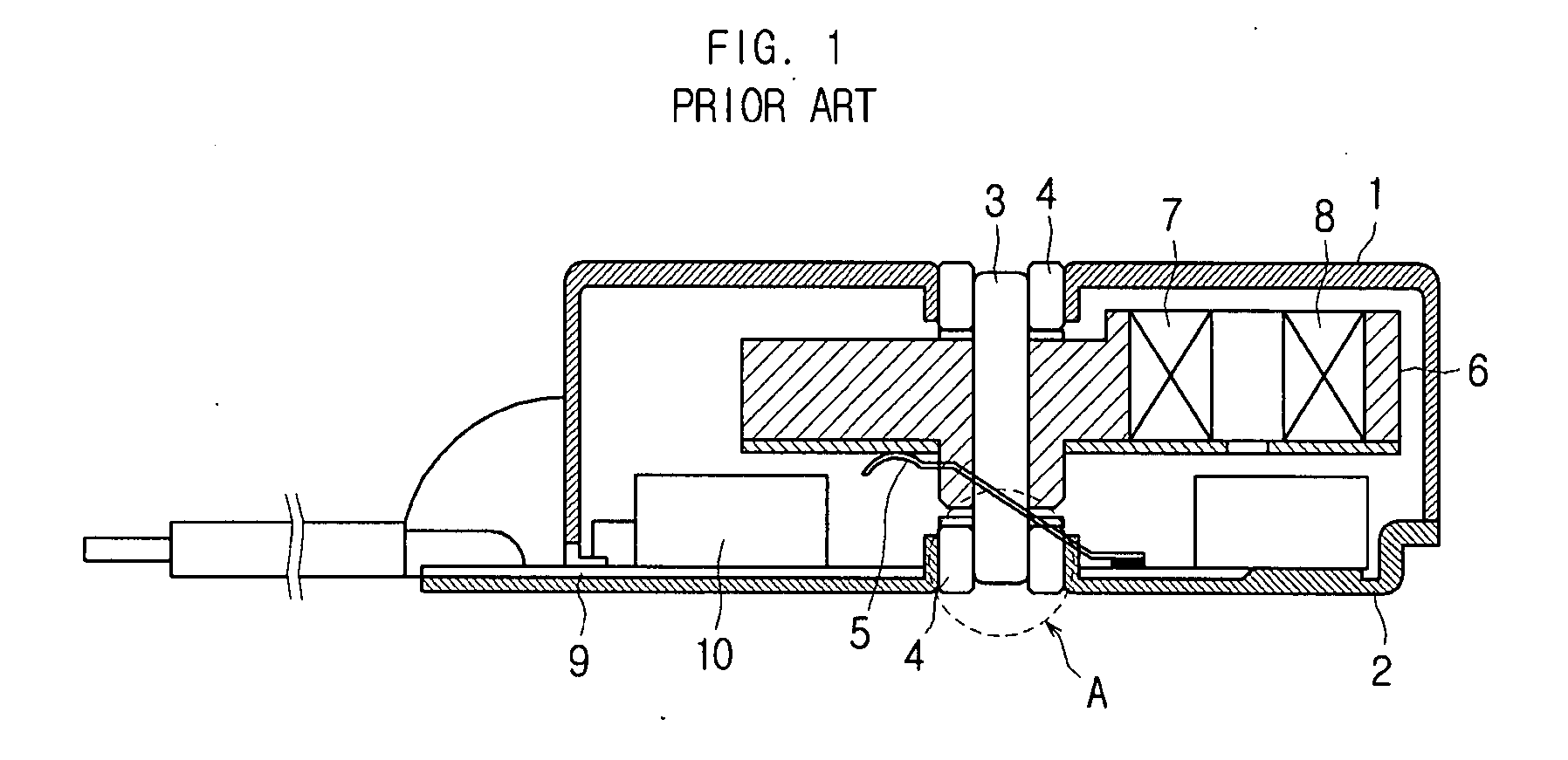

Low cost electrical motor components manufactured from conductive loaded resin-based materials

InactiveUS20050206270A1Characteristic can be alteredRotary current collectorTransformers/inductances coolingElectrical conductorMetal fibers

Owner:INTEGRAL TECHNOLOGY INC

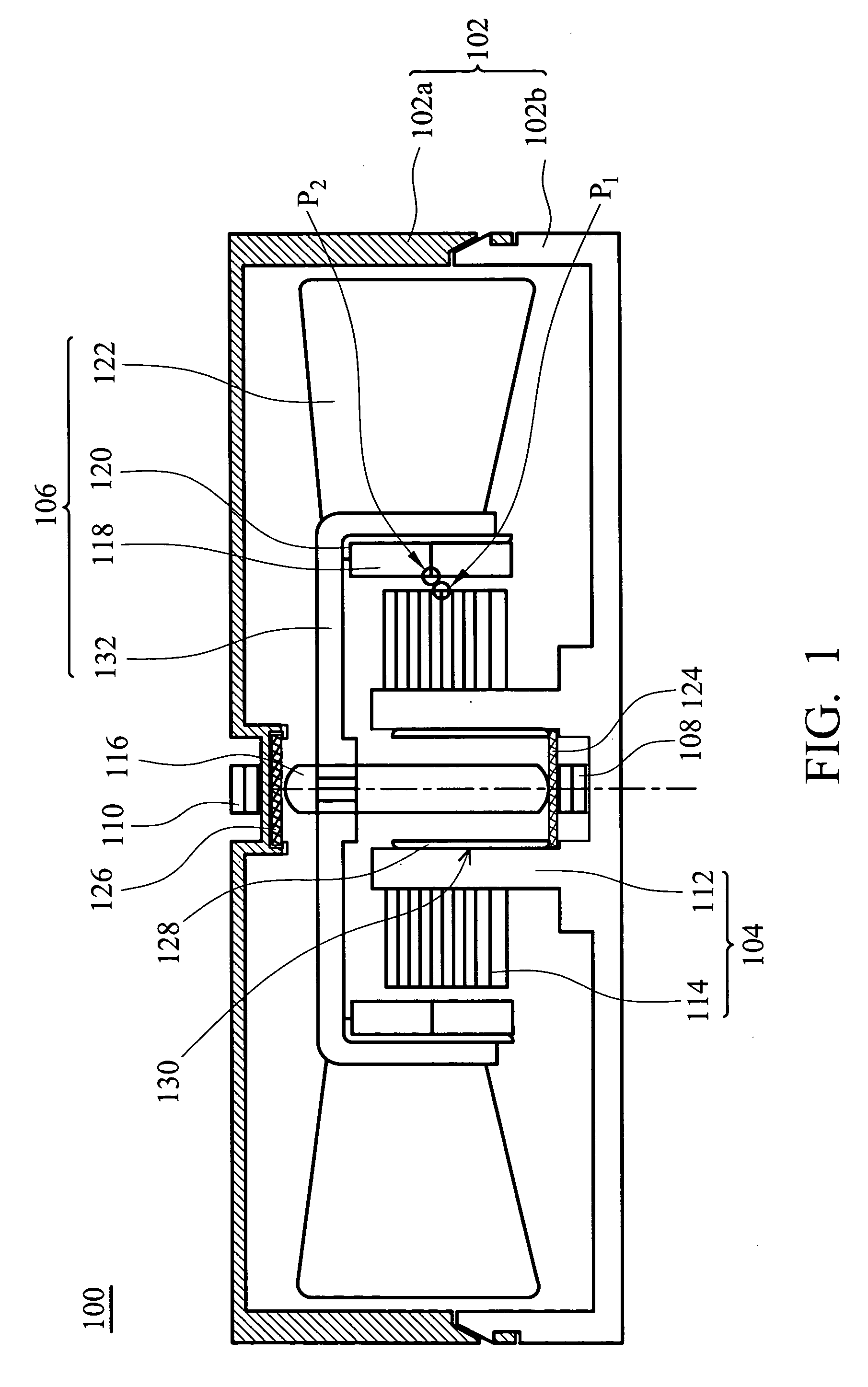

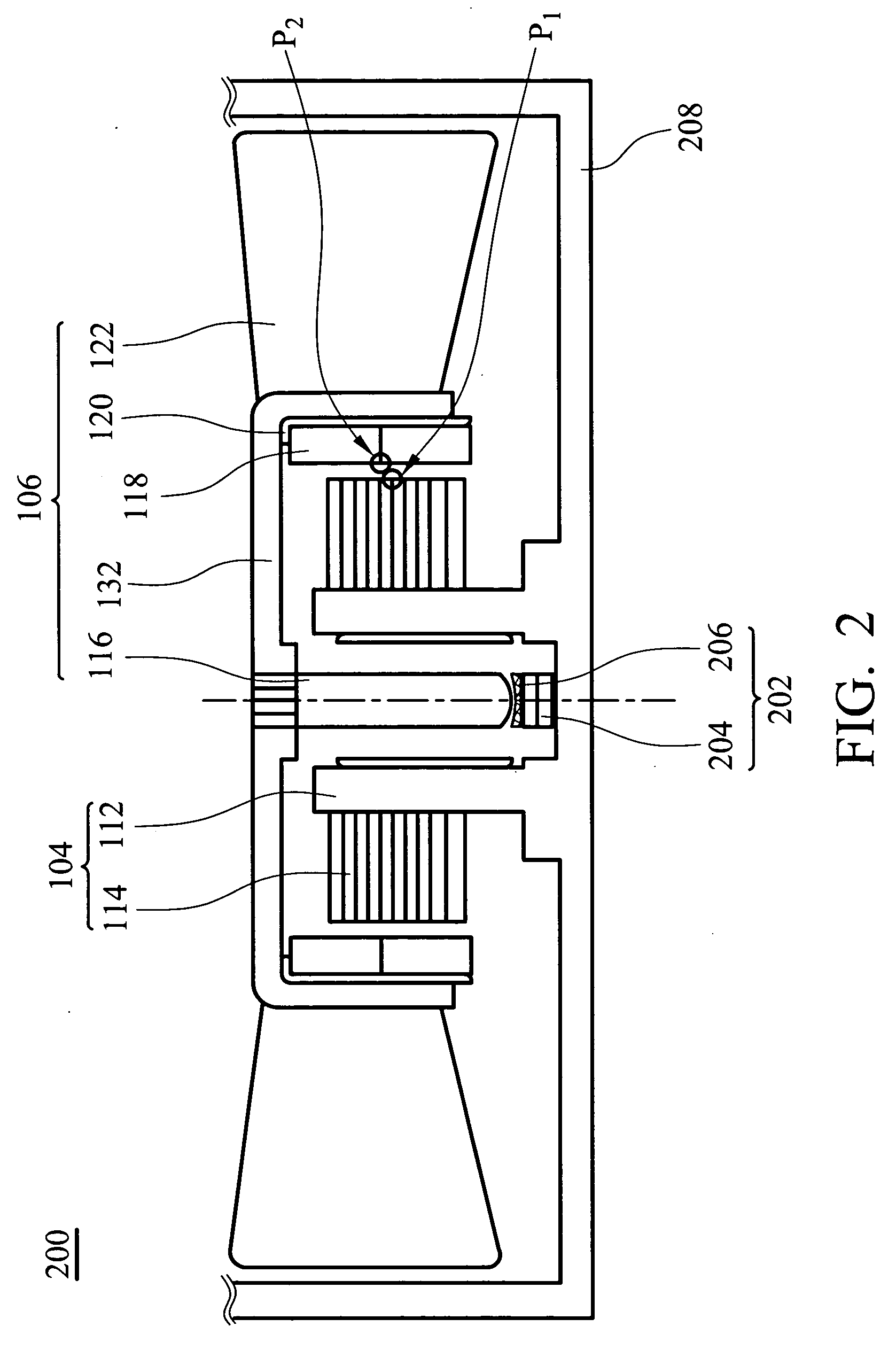

Motor

InactiveUS20050035670A1Reduce noiseExtended service lifePump componentsMagnetic circuitPhysicsMagnetic structure

Owner:DELTA ELECTRONICS INC

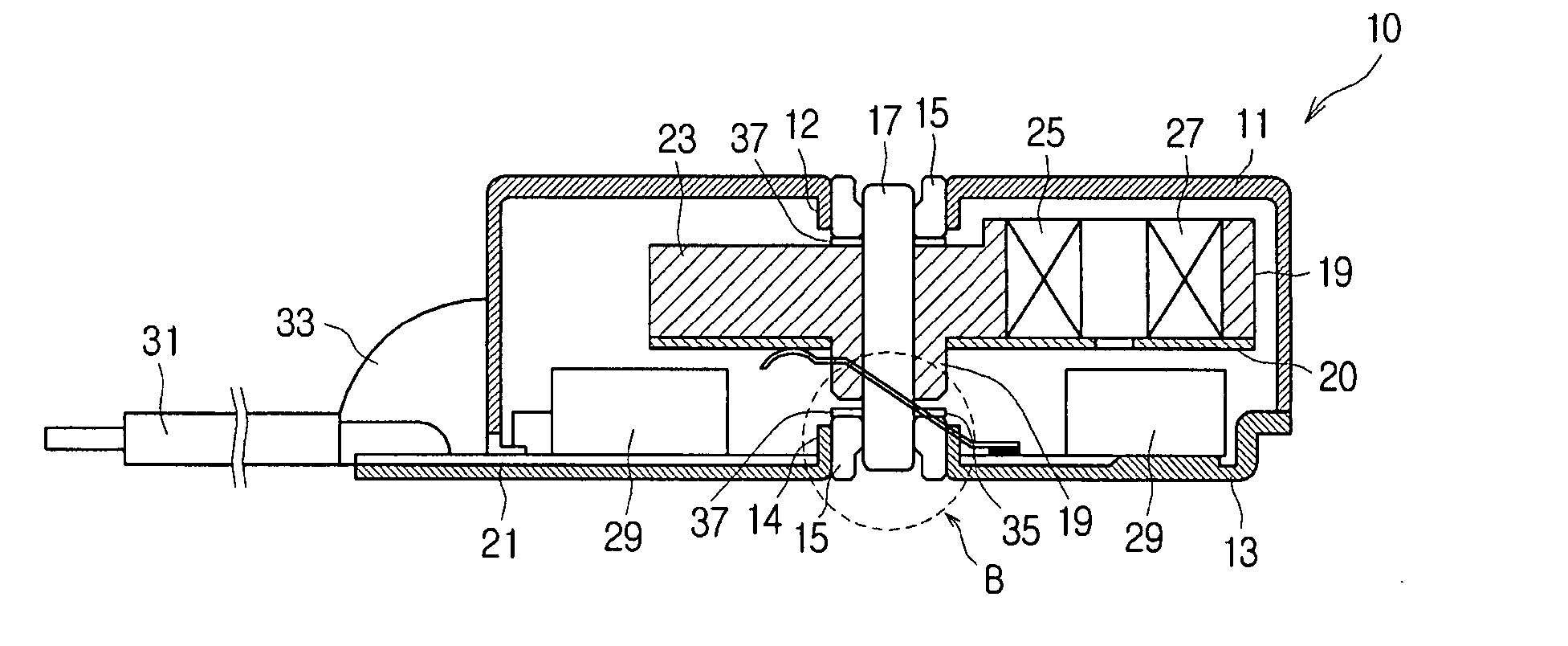

Brushless motor

ActiveUS20100133935A1High positioning accuracyProlonging permanent magnetWindingsMechanical energy handlingBrushless motorsMagnetic poles

Owner:MITSUBISHI ELECTRIC CORP

Motor

InactiveUS20100127588A1Prevent disengagementMagnetic circuit rotating partsPump componentsEngineeringSingle component

Owner:SUNONWEALTH ELECTRIC MACHINE IND

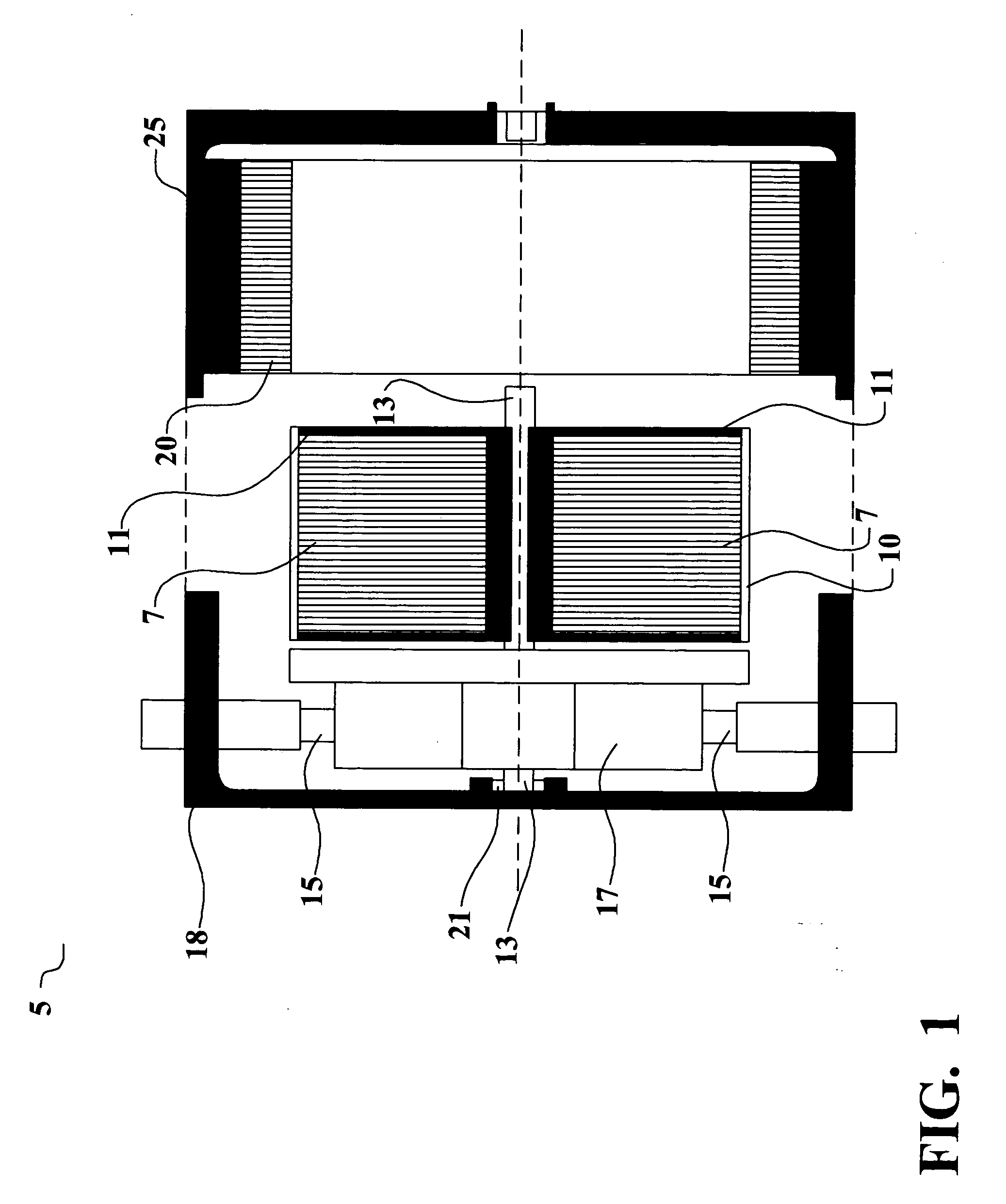

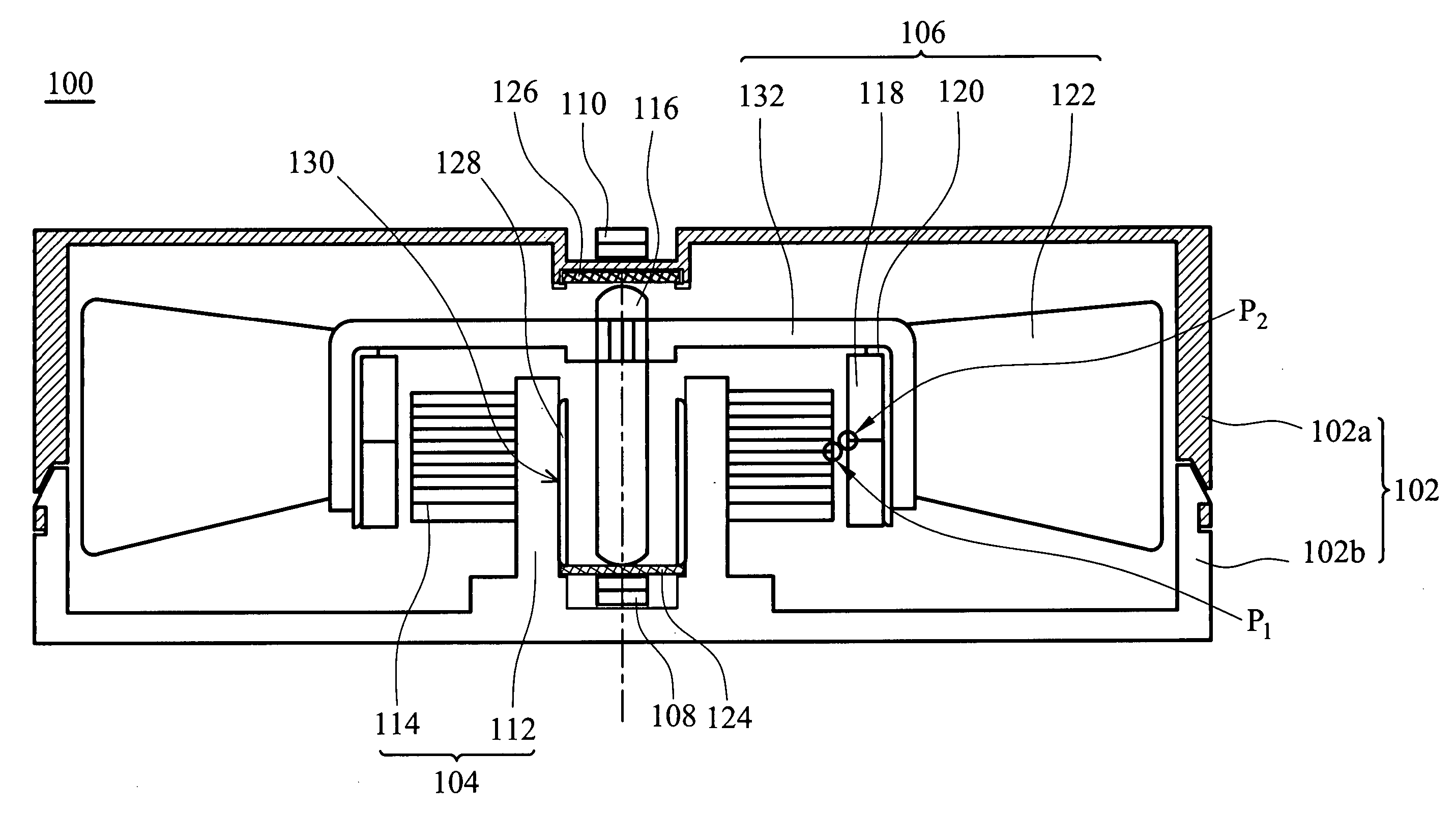

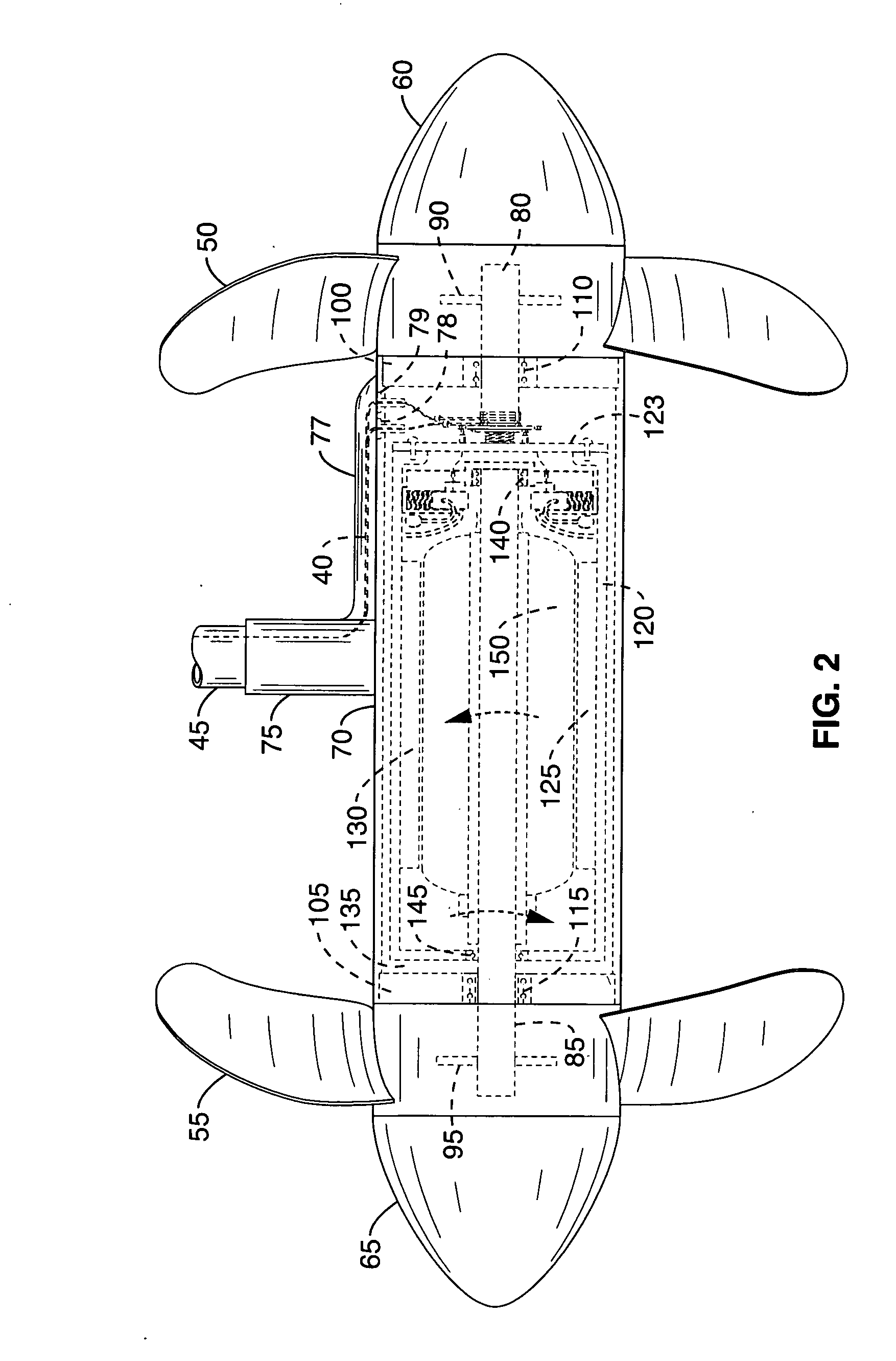

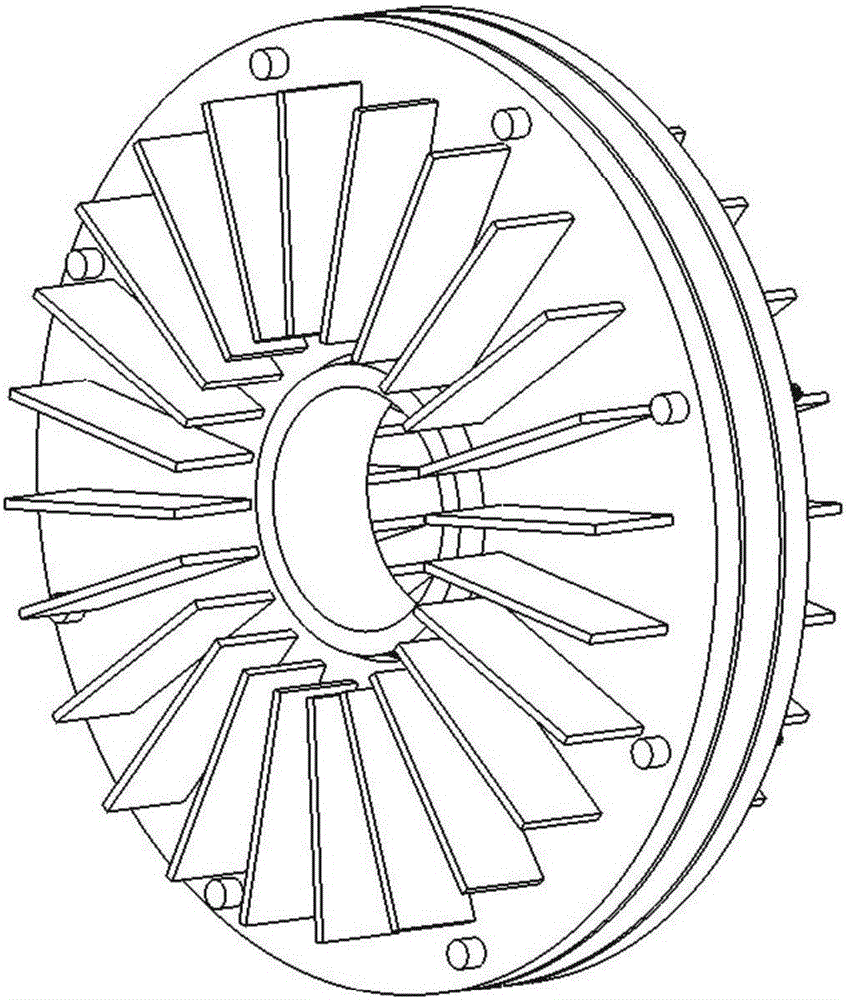

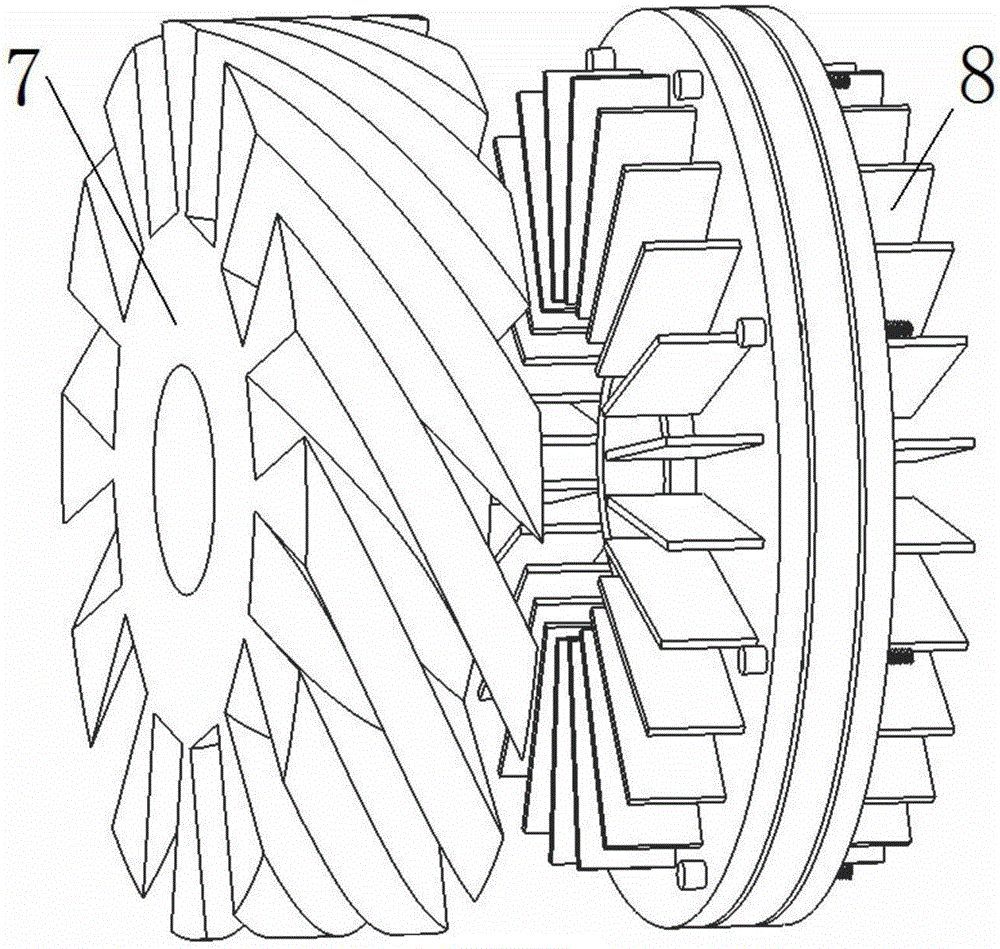

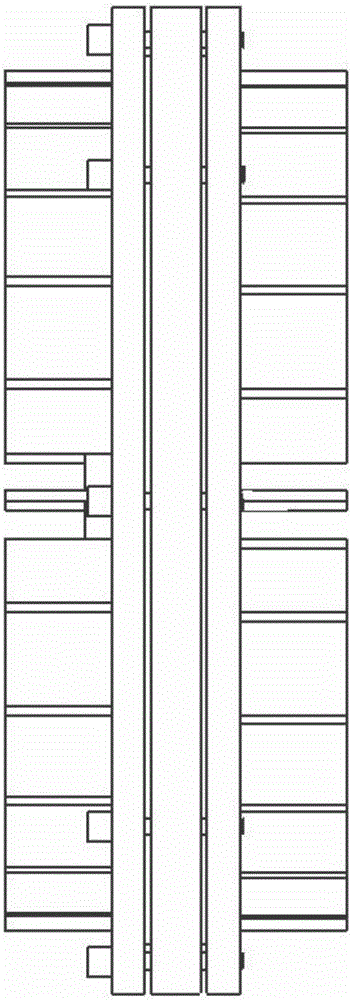

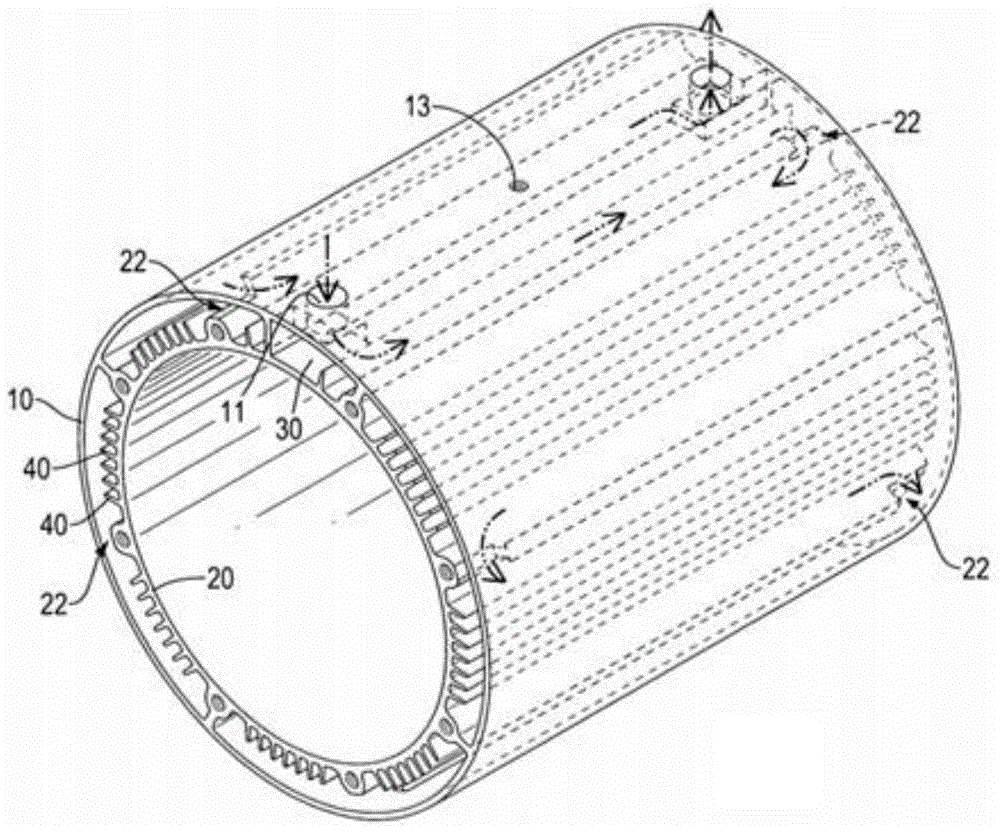

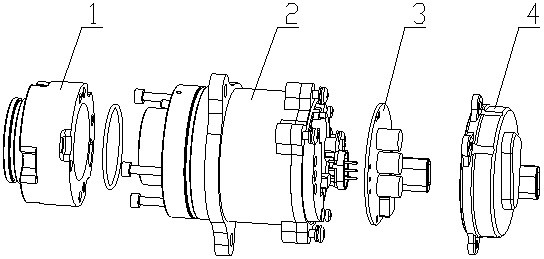

In-wheel actuator and in-wheel assembly comprising the same

An in-wheel assembly is provided, and the in-wheel assembly includes an in-wheel actuator and a wheel. The in-wheel actuator includes a driving motor; a decelerator which is disposed inside the driving motor and configured to reduce a rotational speed of the driving motor; and a hollow shaft which is disposed inside the driving motor and configured to transfer a rotational force of the driving motor to the decelerator, which is accommodated in a hollow of the hollow shaft, and circulates fluid inside of the driving motor with respect to a surface of the decelerator when driven to rotate by the driving motor. The wheel accommodates the in-wheel actuator and receives a rotational speed reduced by the decelerator to rotate.

Owner:SAMSUNG ELECTRONICS CO LTD

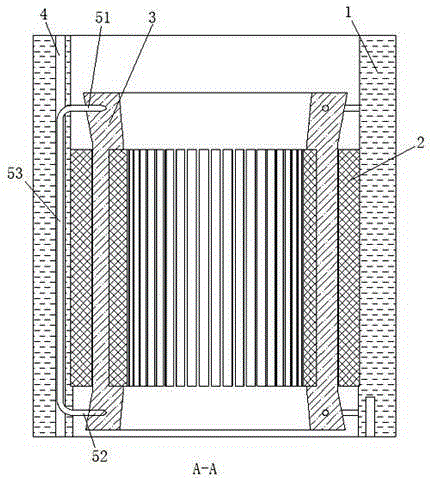

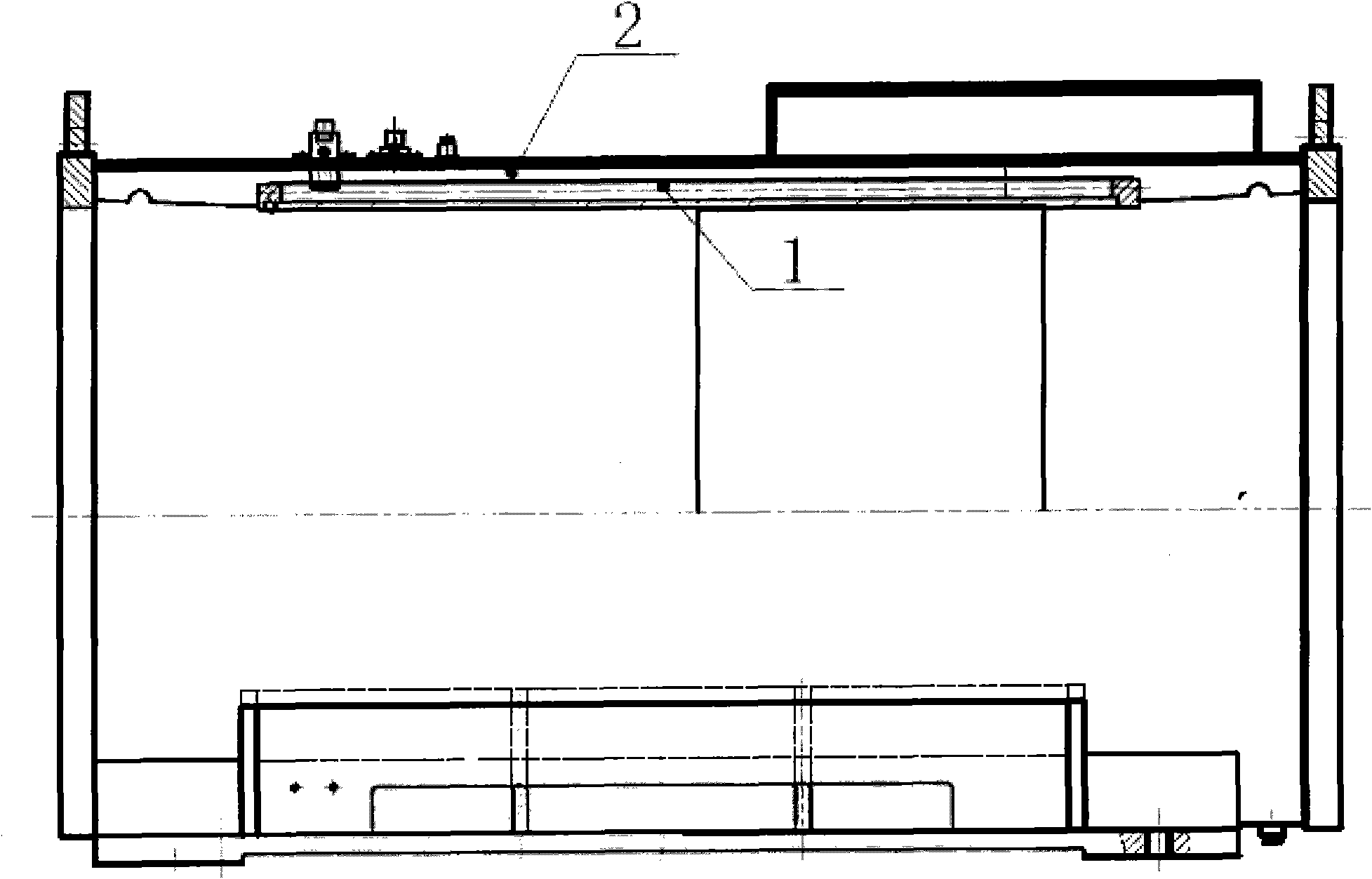

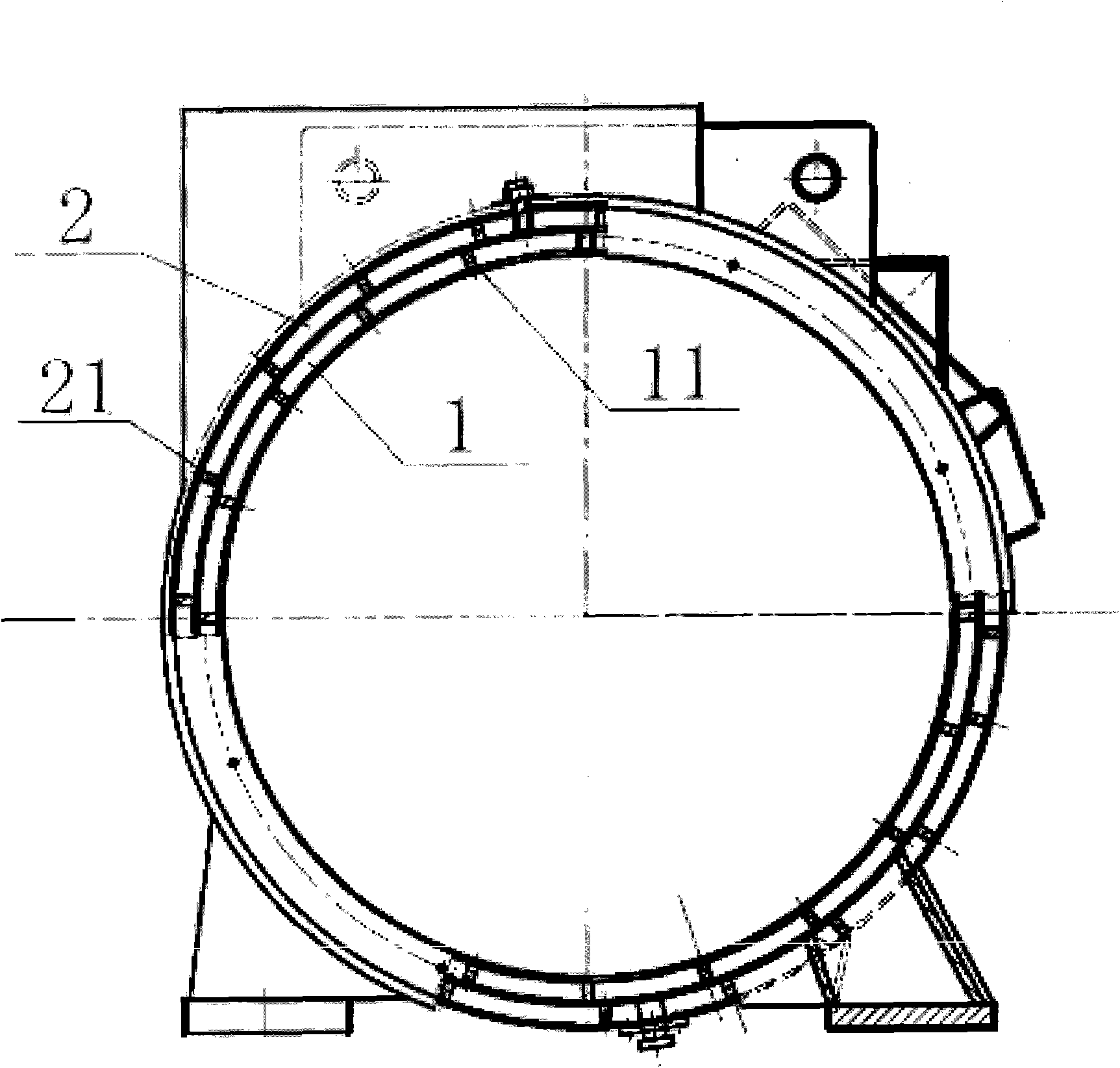

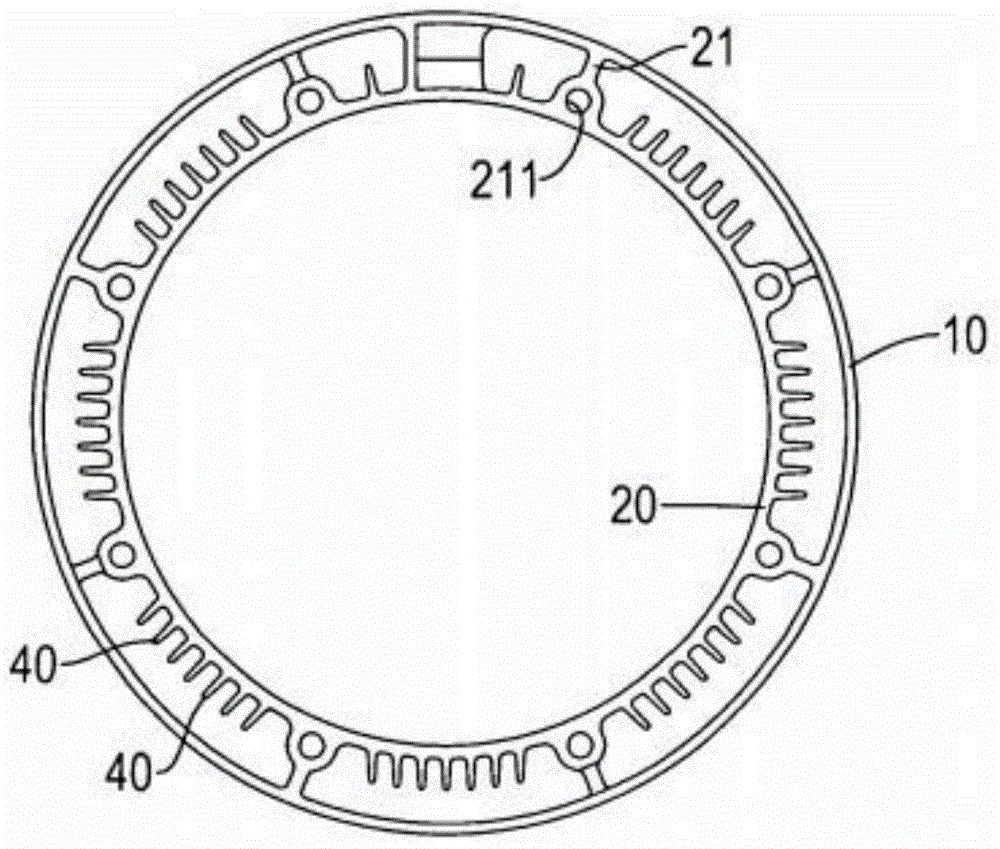

Motor stator heat radiation structure

InactiveCN105356671AGuaranteed cooling effectImprove thermal conductivityCooling/ventillation arrangementSupports/enclosures/casingsConductor CoilCooling pipe

Owner:HEFEI JUYI POWER SYST CO LTD

Slotless Ac Induction Motor

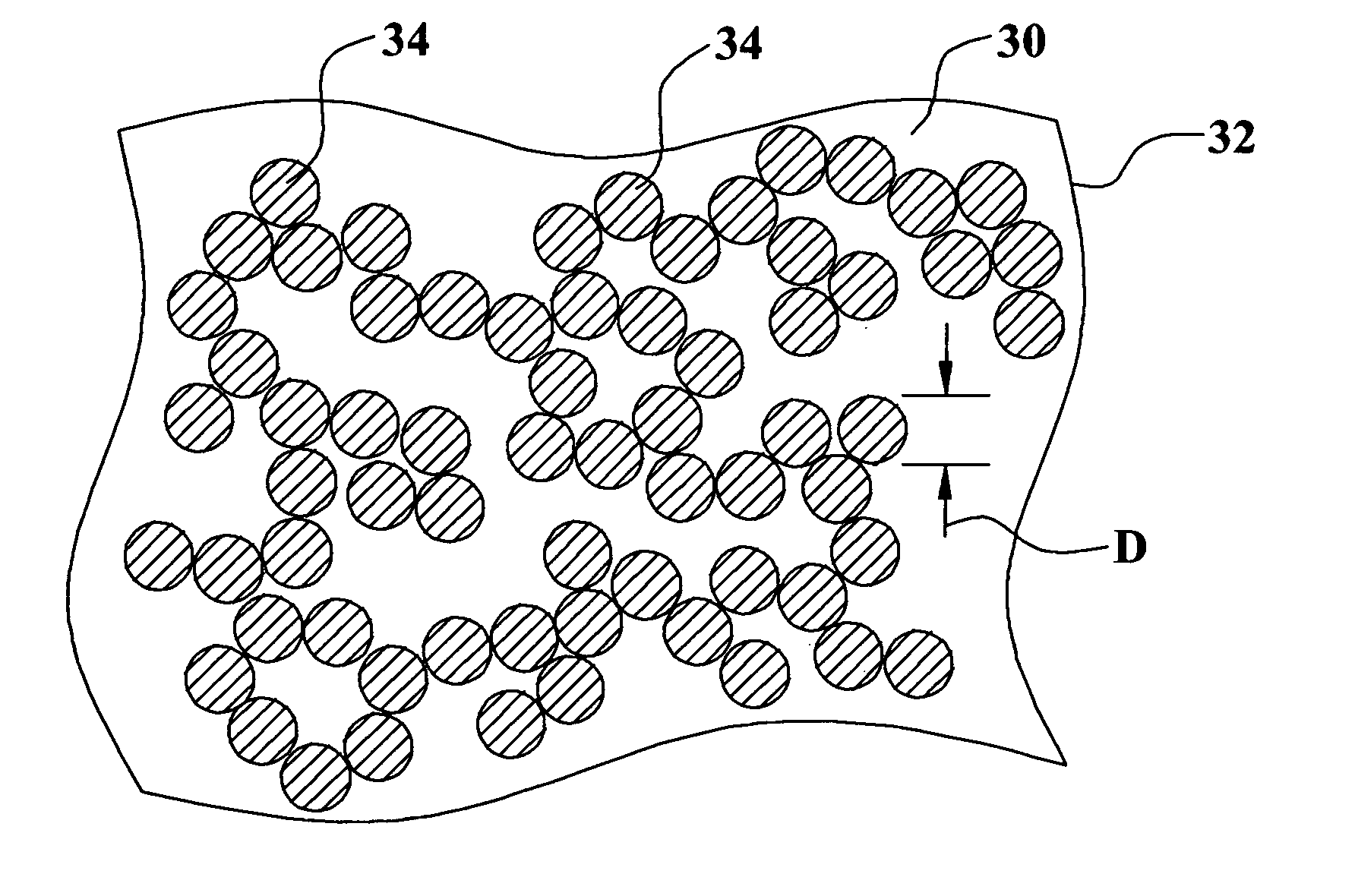

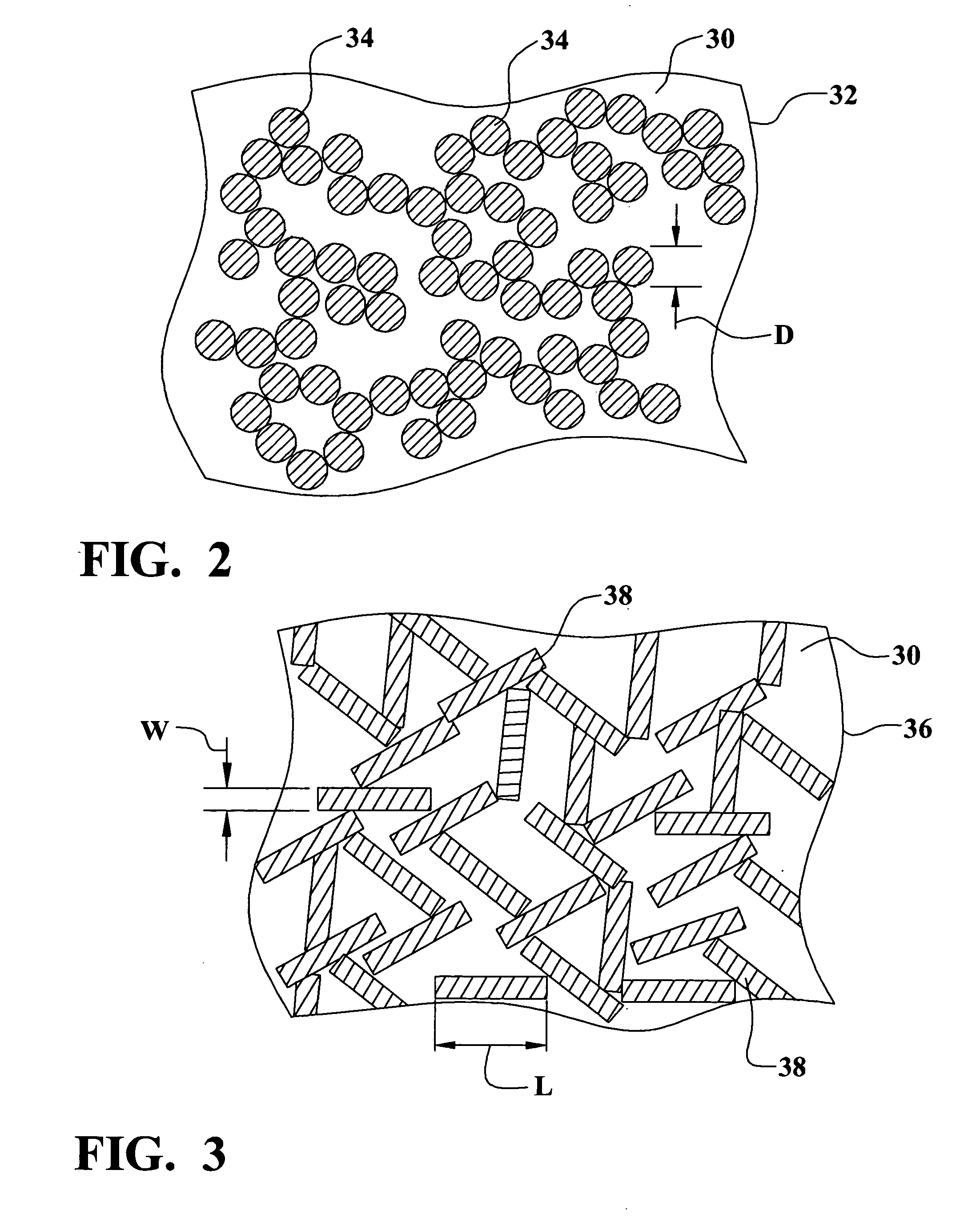

InactiveUS20080054733A1Increase in sizeIncrease currentWindings insulation shape/form/constructionMagnetic circuit rotating partsElectrical conductorInduction motor

The present invention is a rotating induction motor that is capable of providing higher peak torque than a conventional design, which achieves the shortcomings of the prior art by in regard to iron saturation by a slot-less design; removing the iron slot provides more space for the conductor. The motor comprises a stator and a concentric rotor, separated from the stator by an air gap. The rotor has rotor bars and rotor windings. The stator is slot-less and comprises surface mounted conductors separated from each other by suitable insulation. An advantage of this design is that the motor does not exhibit typical behavior at high currents; there is no saturation effect.

Owner:BOREALIS TECH LTD

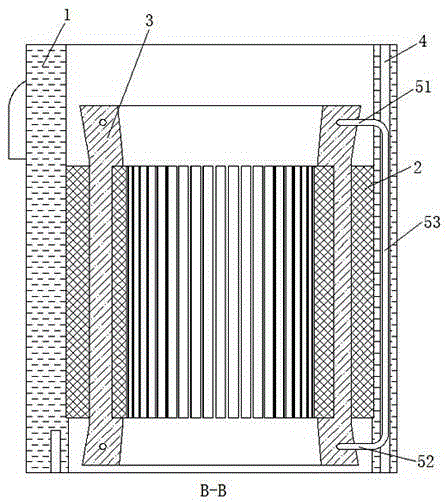

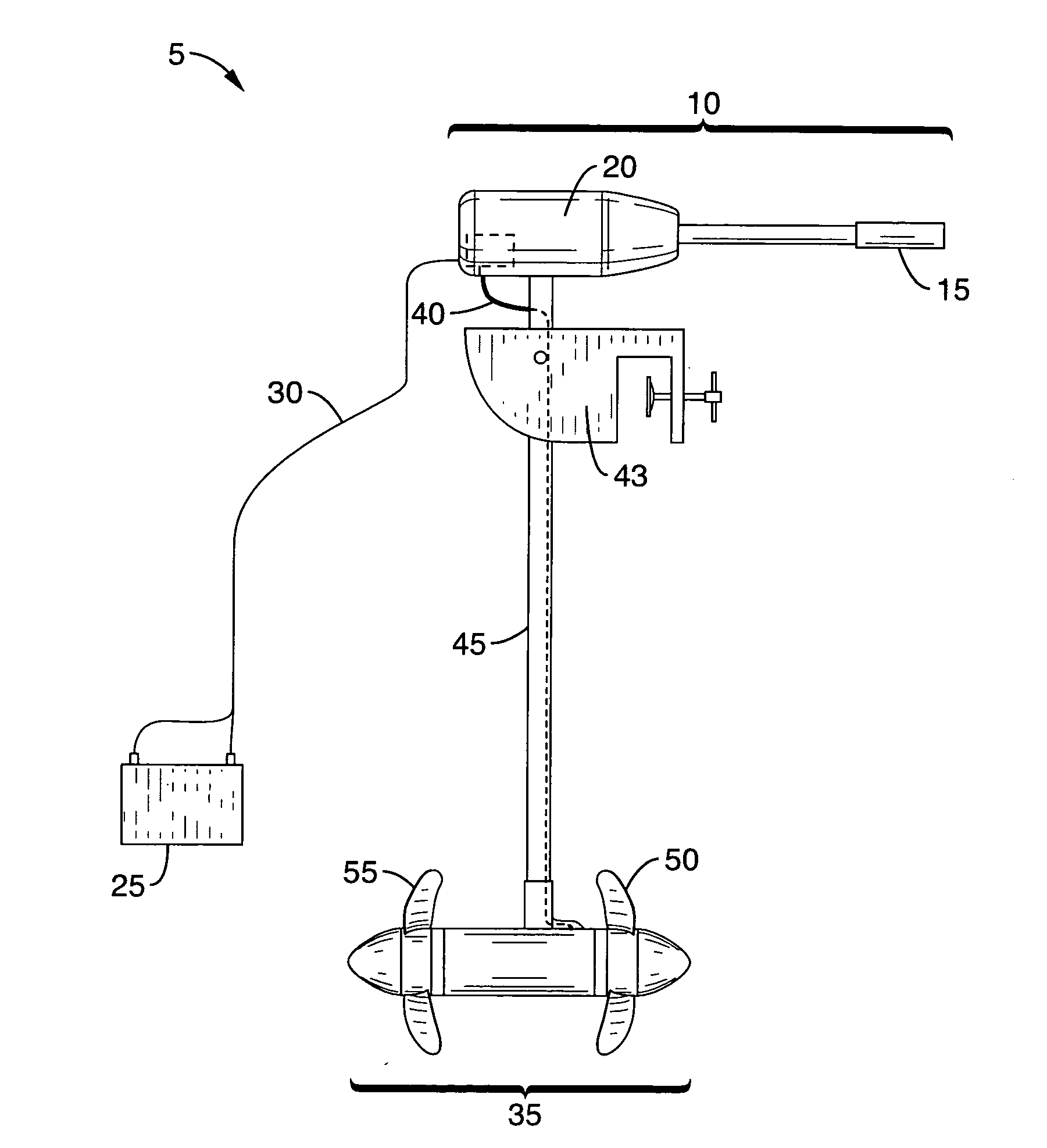

Increased efficiency counter-rotating electric motor for propelling a boat

ActiveUS20100003871A1Improve abilitiesReduce windRotary current collectorPropulsion power plantsElectricityElectrical connection

Owner:E WISH TECH

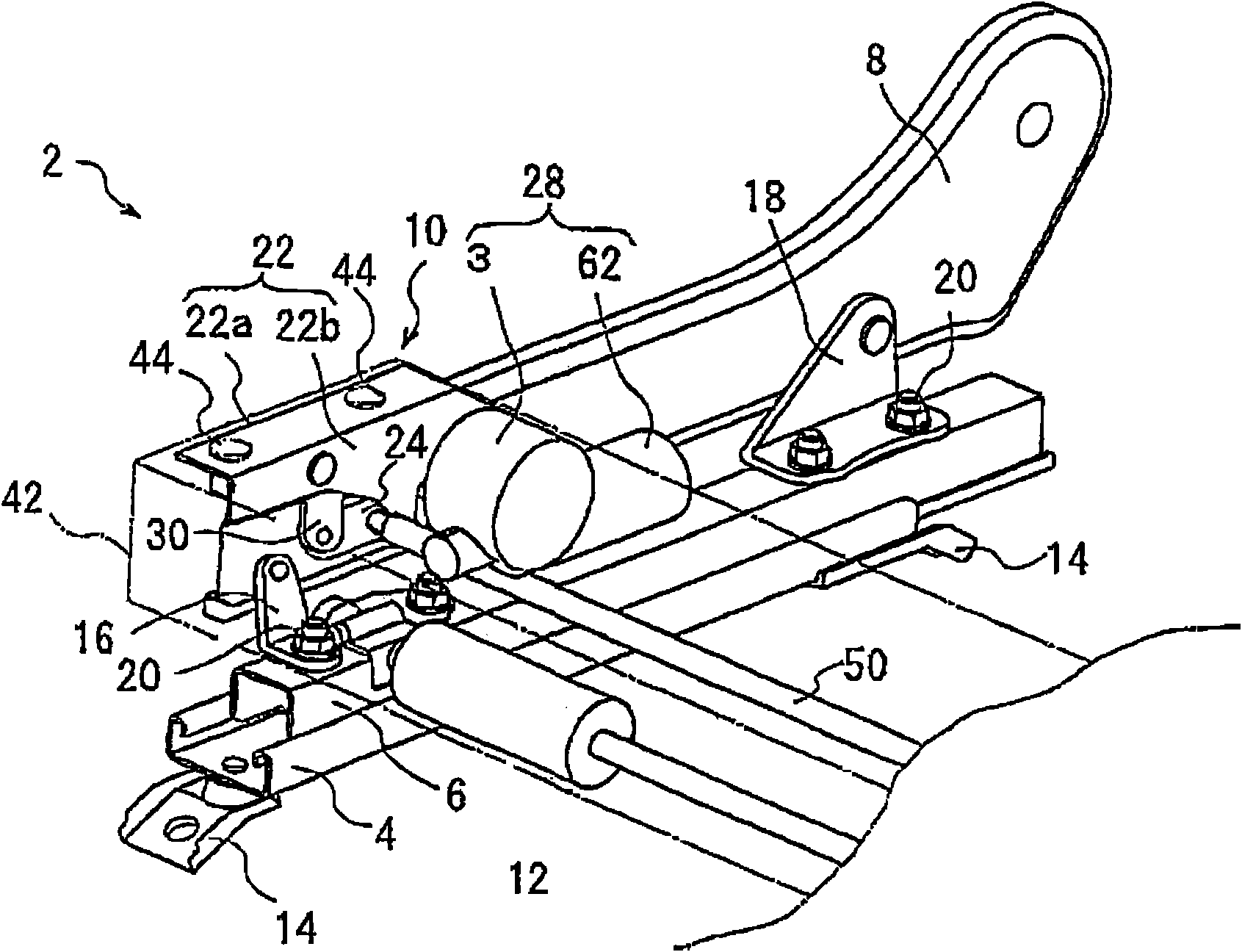

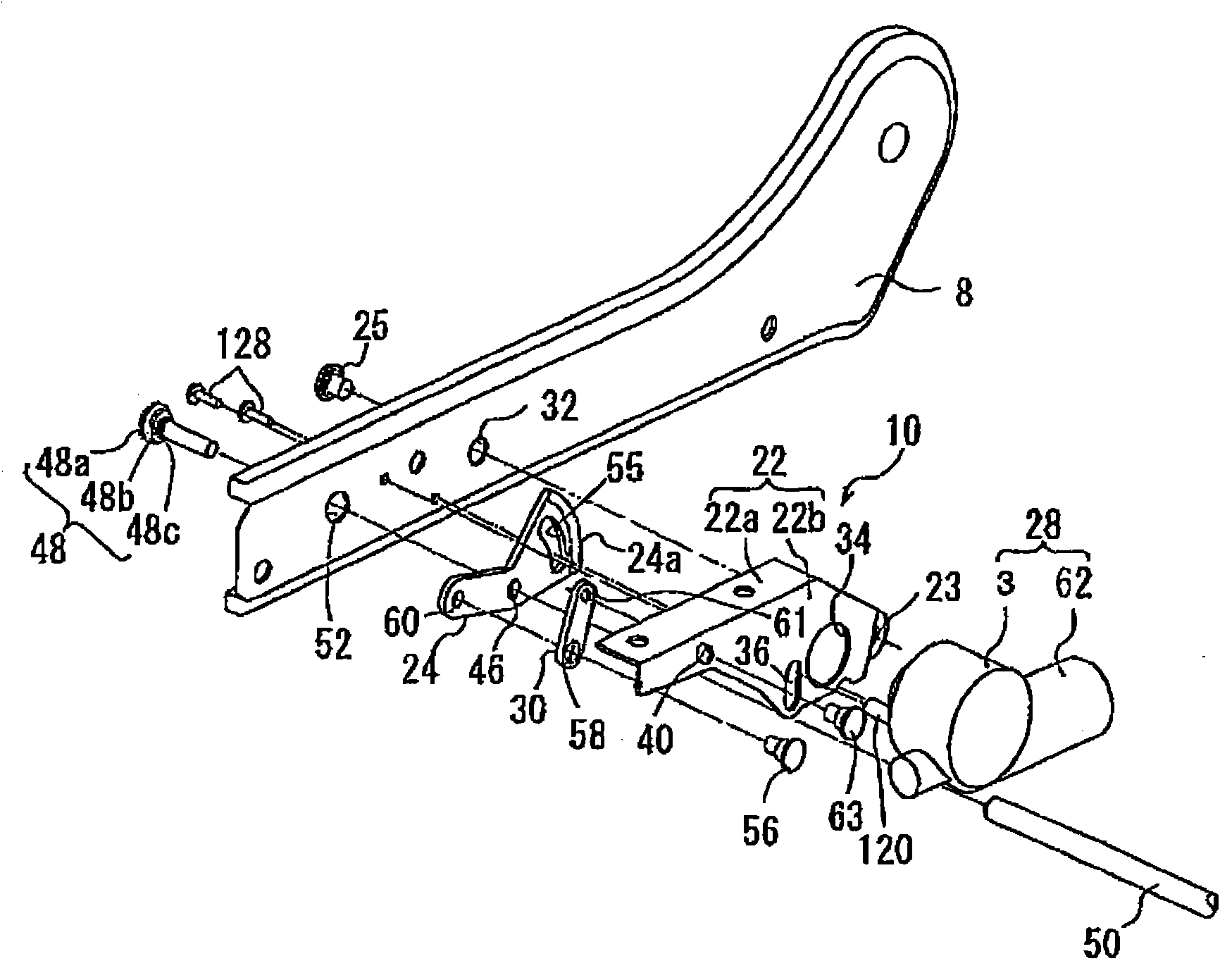

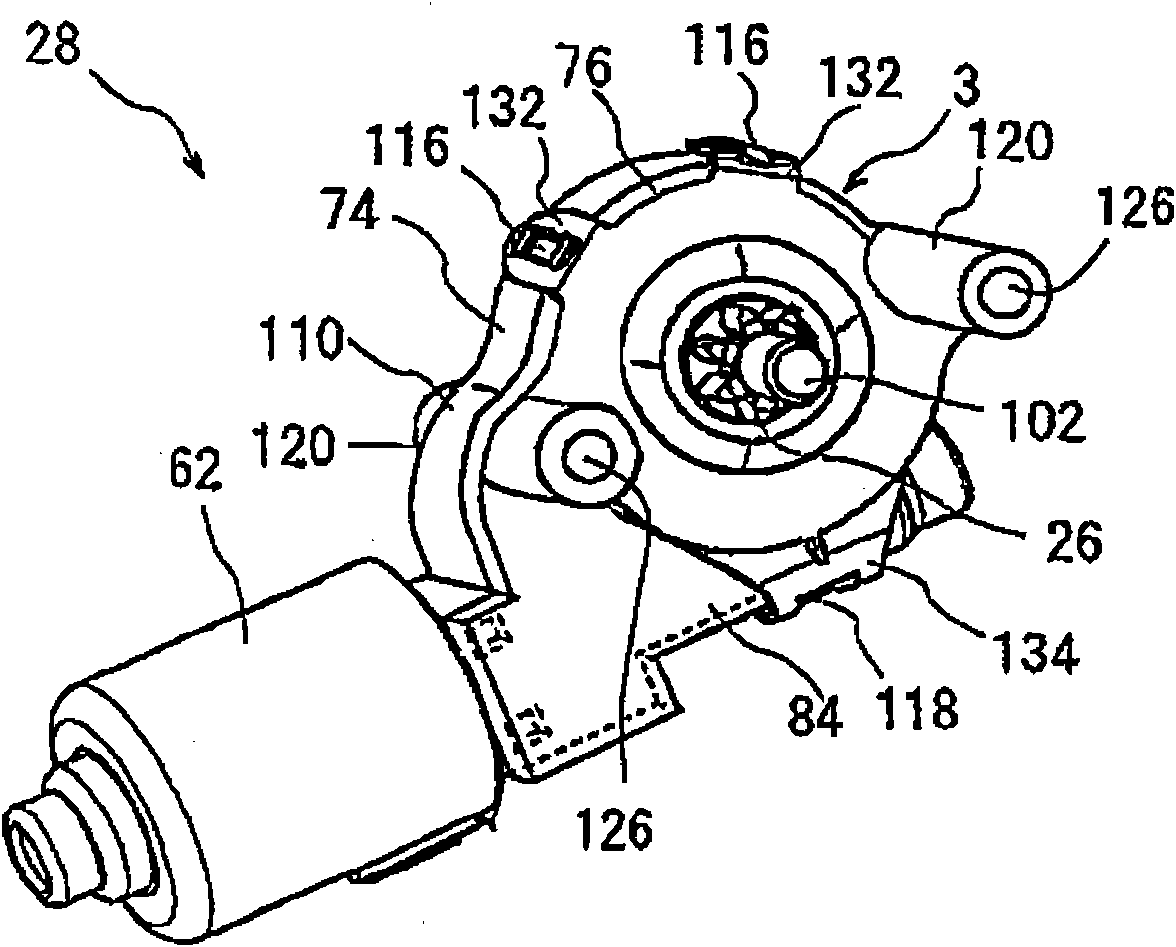

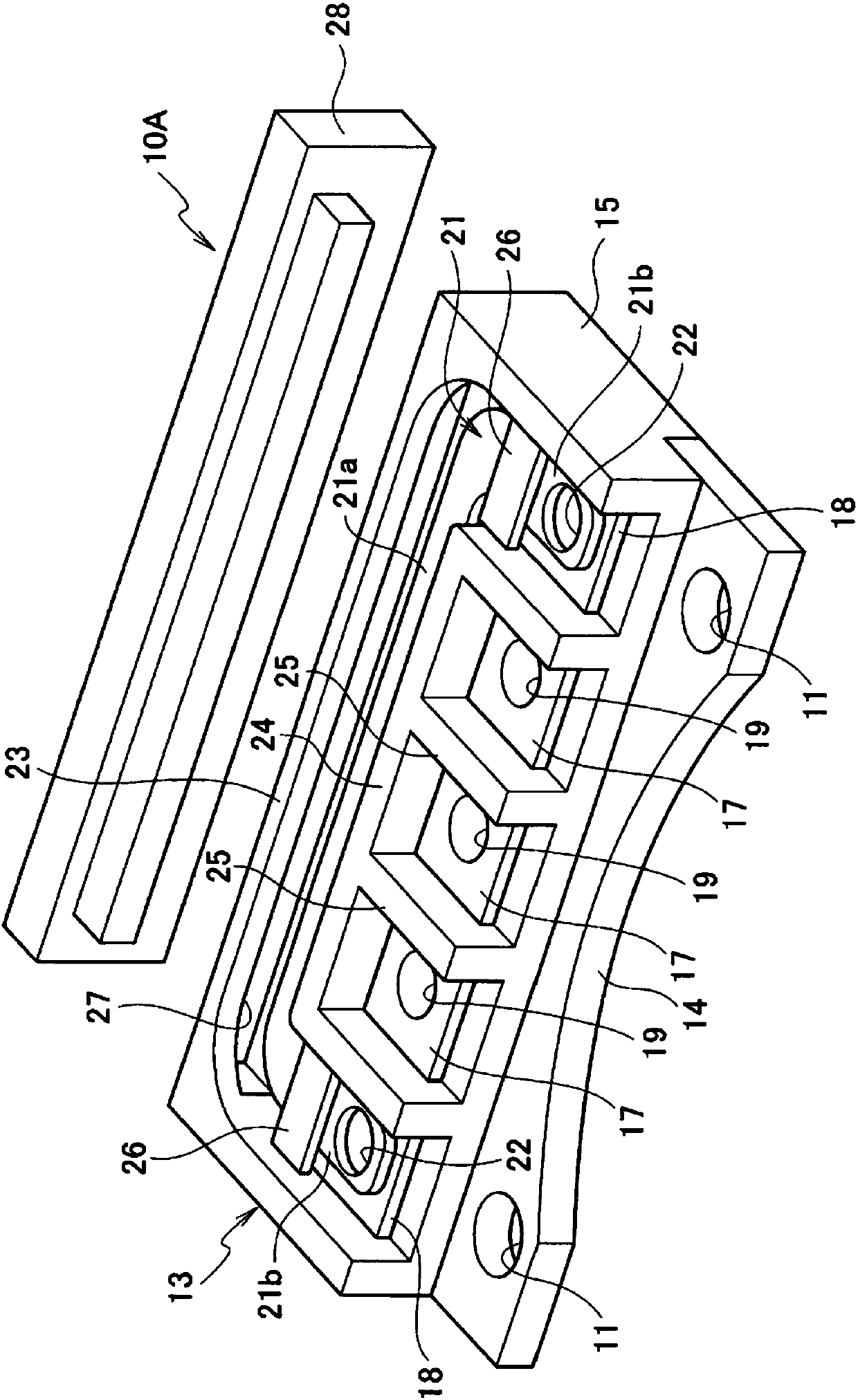

Seat slide apparatus for vehicle

Owner:AISIN SEIKI KK

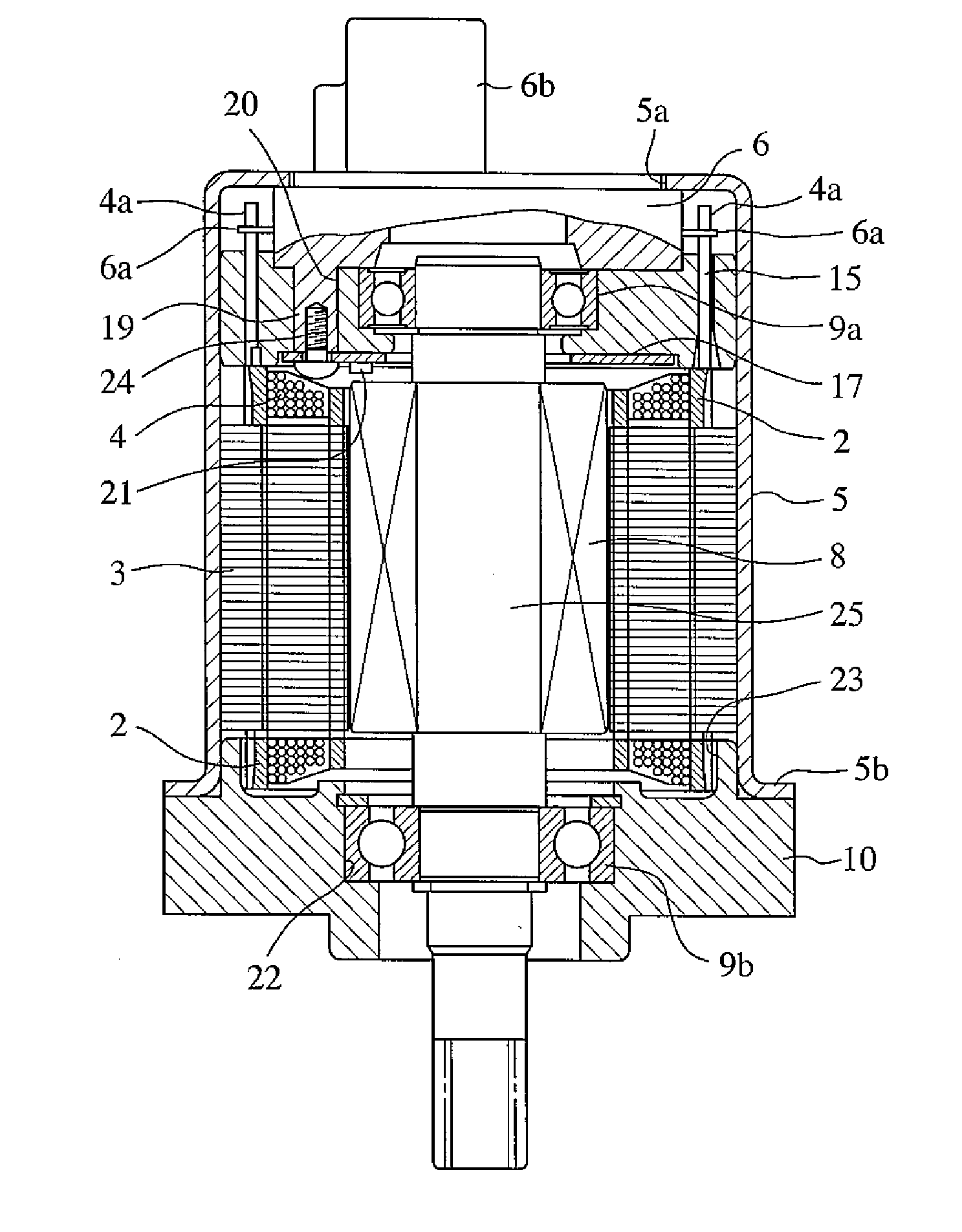

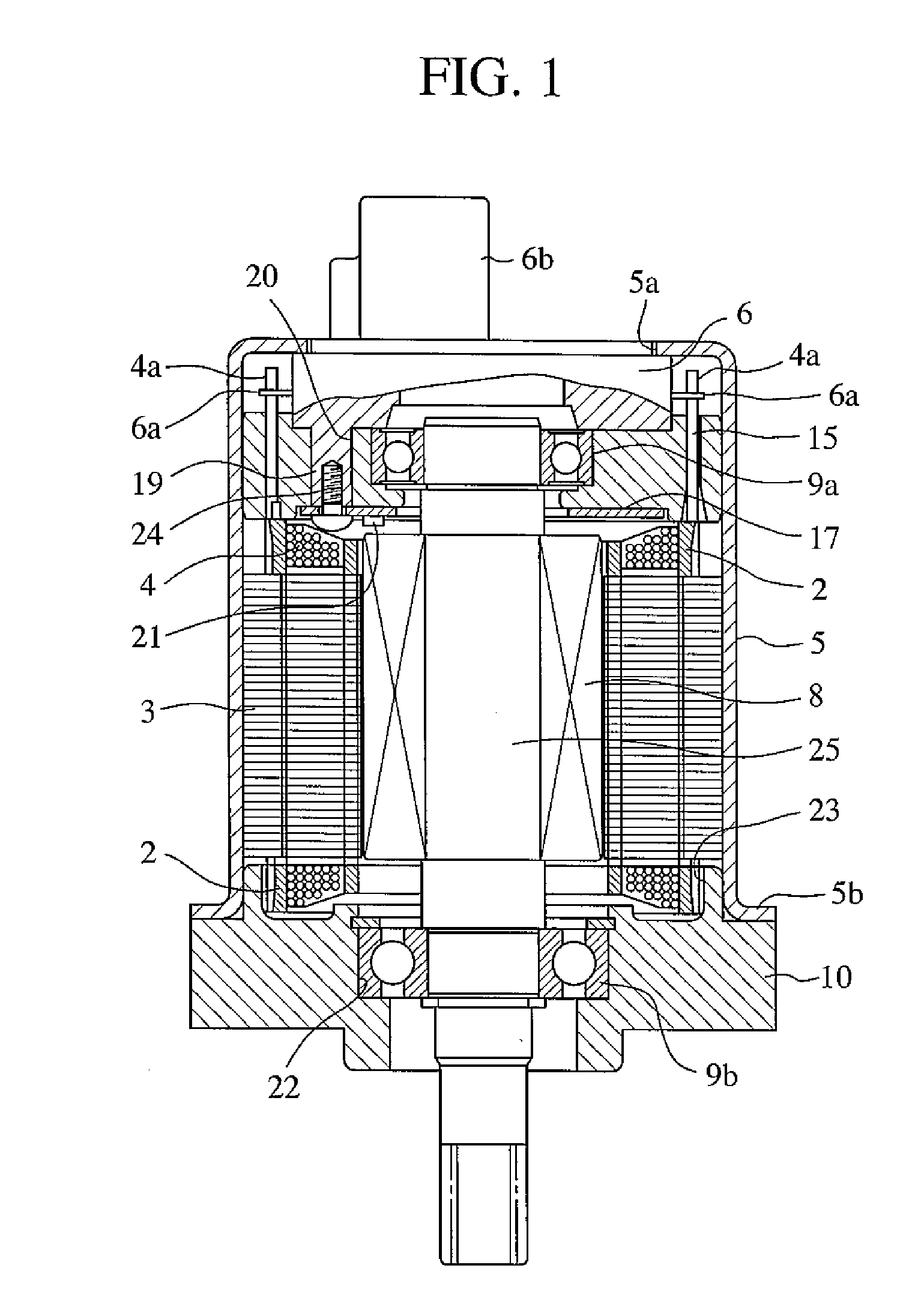

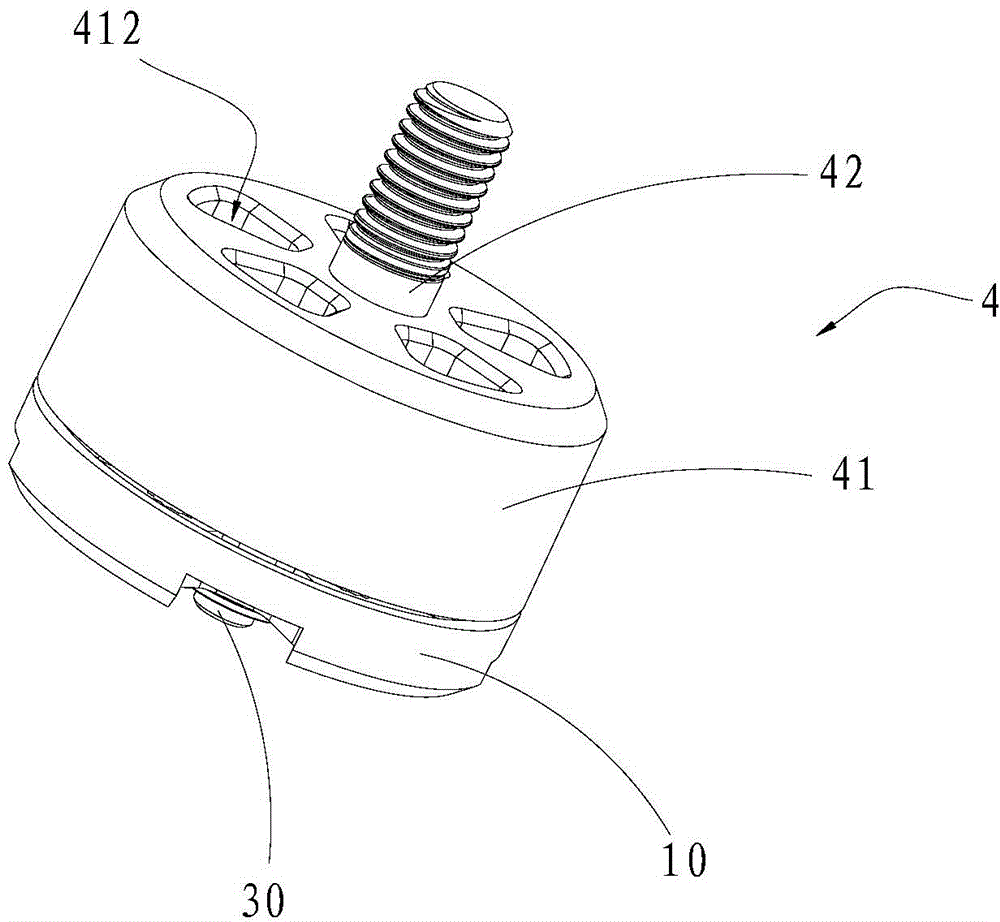

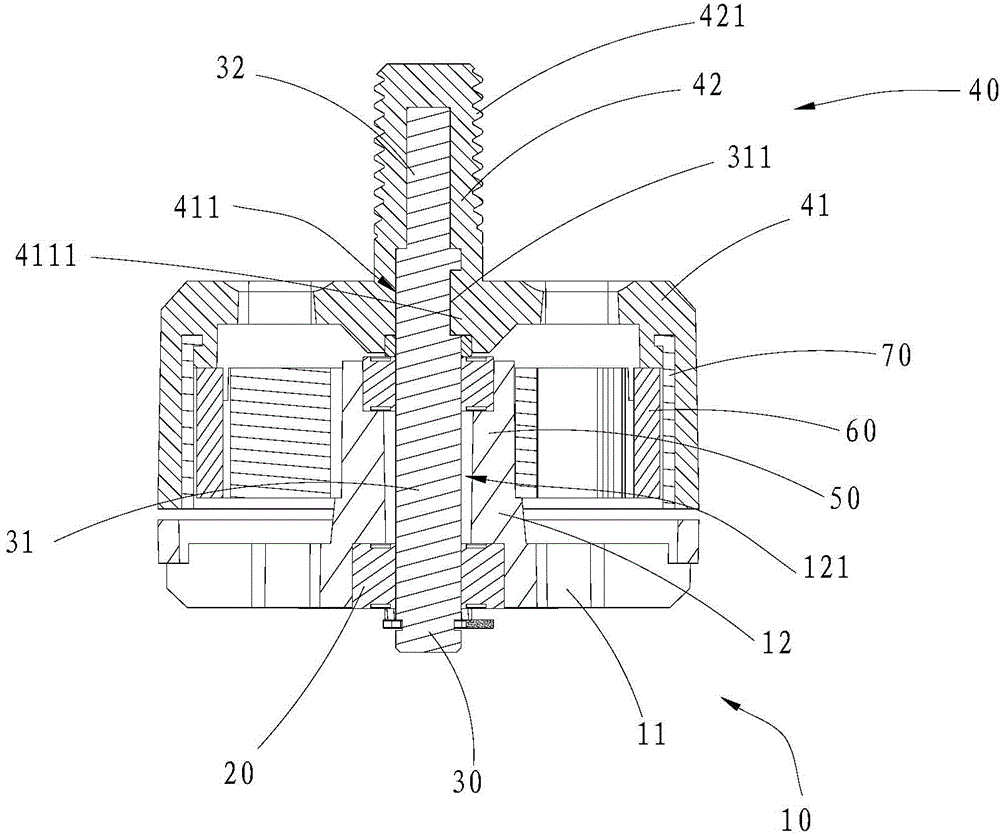

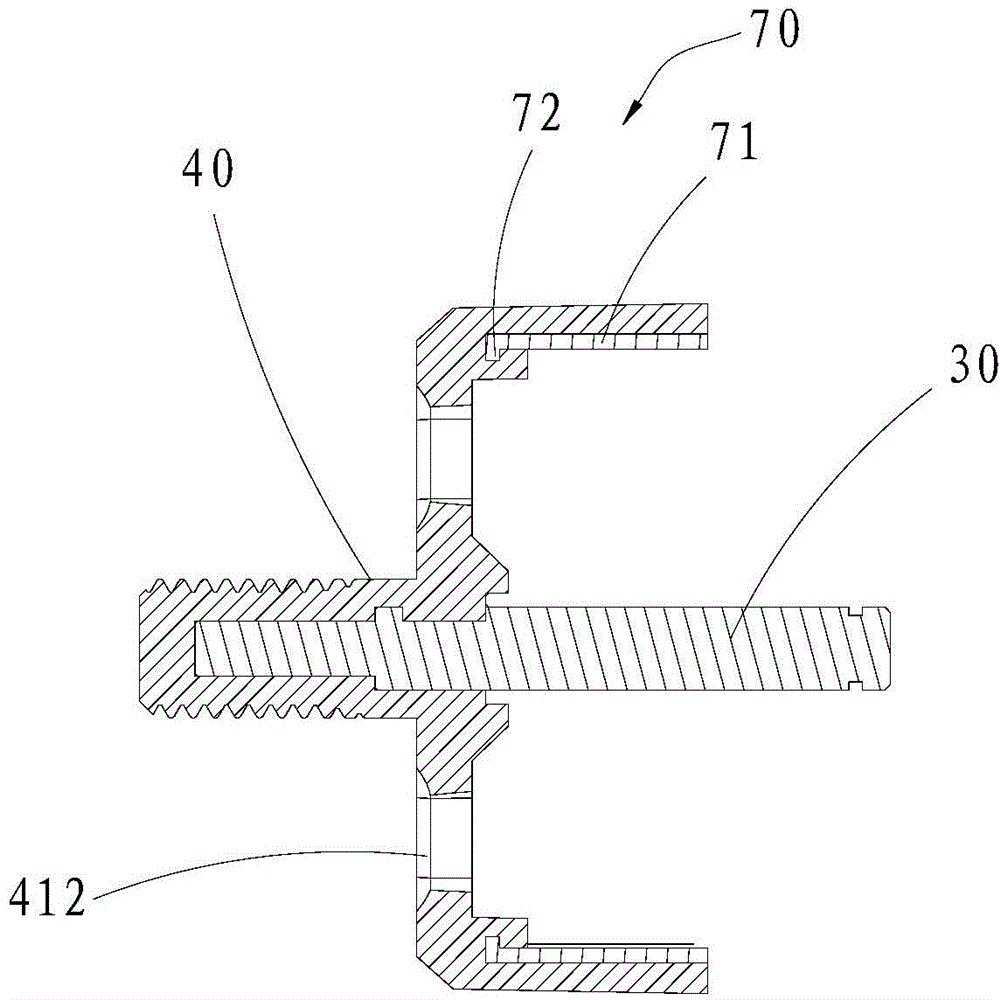

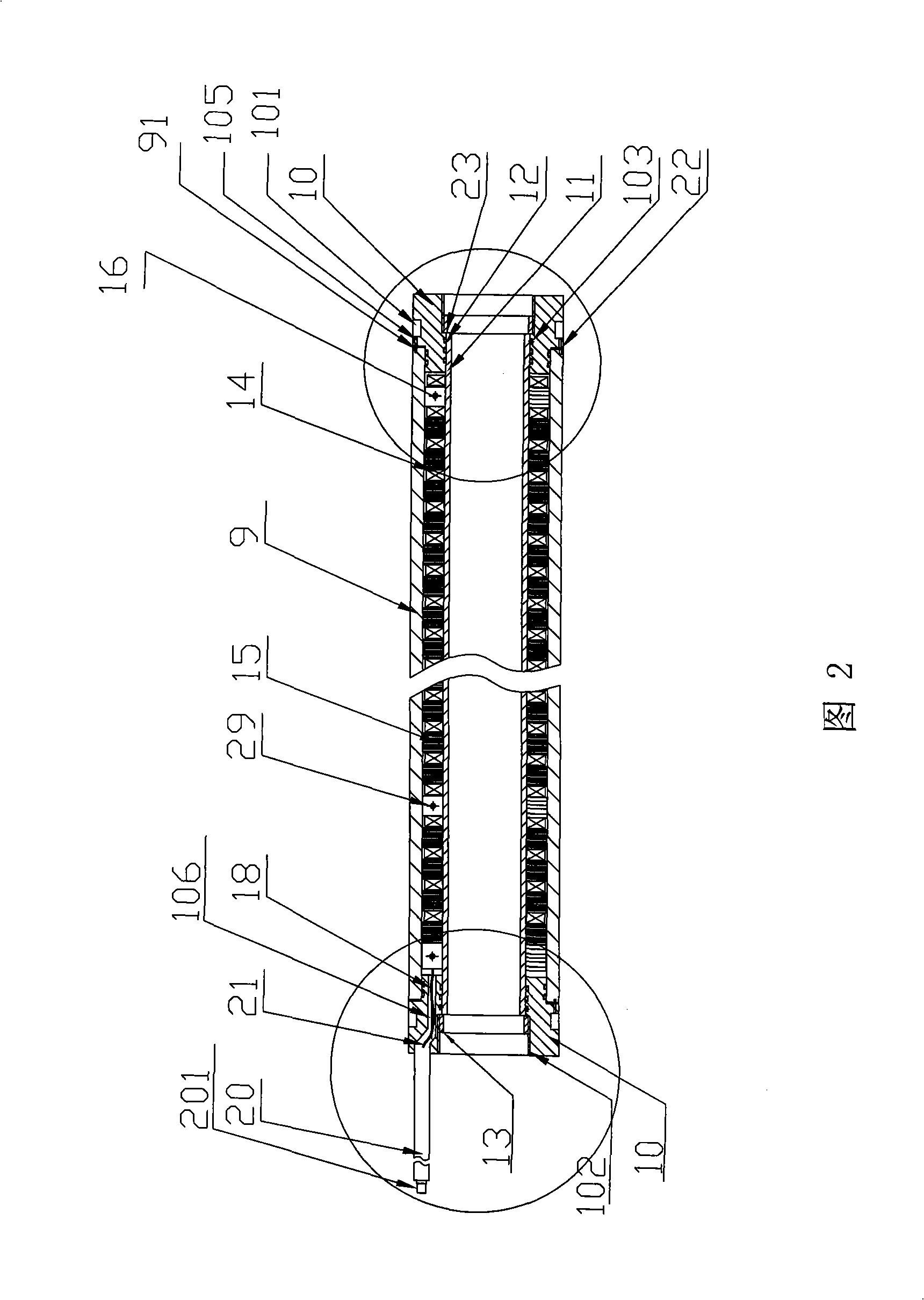

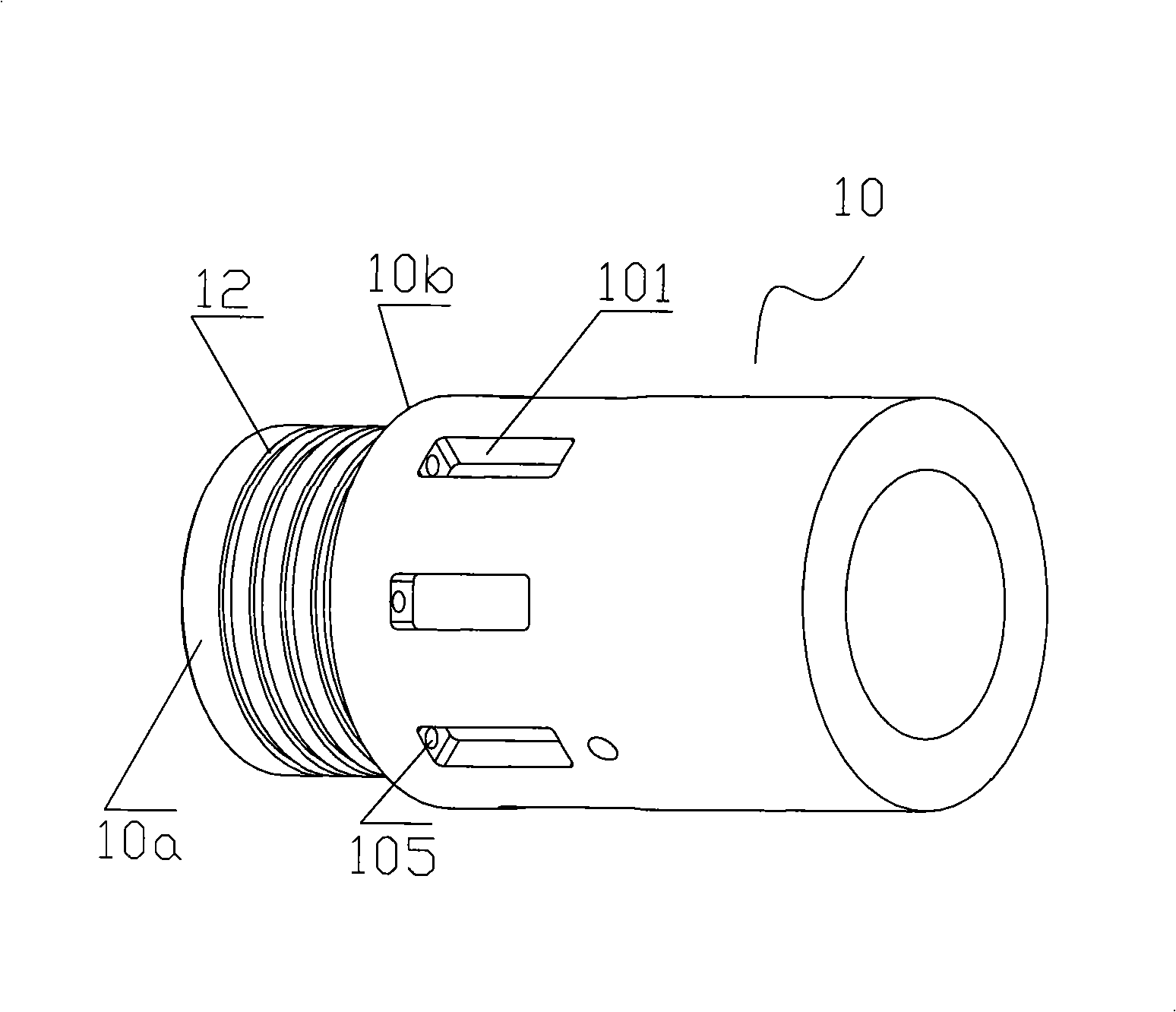

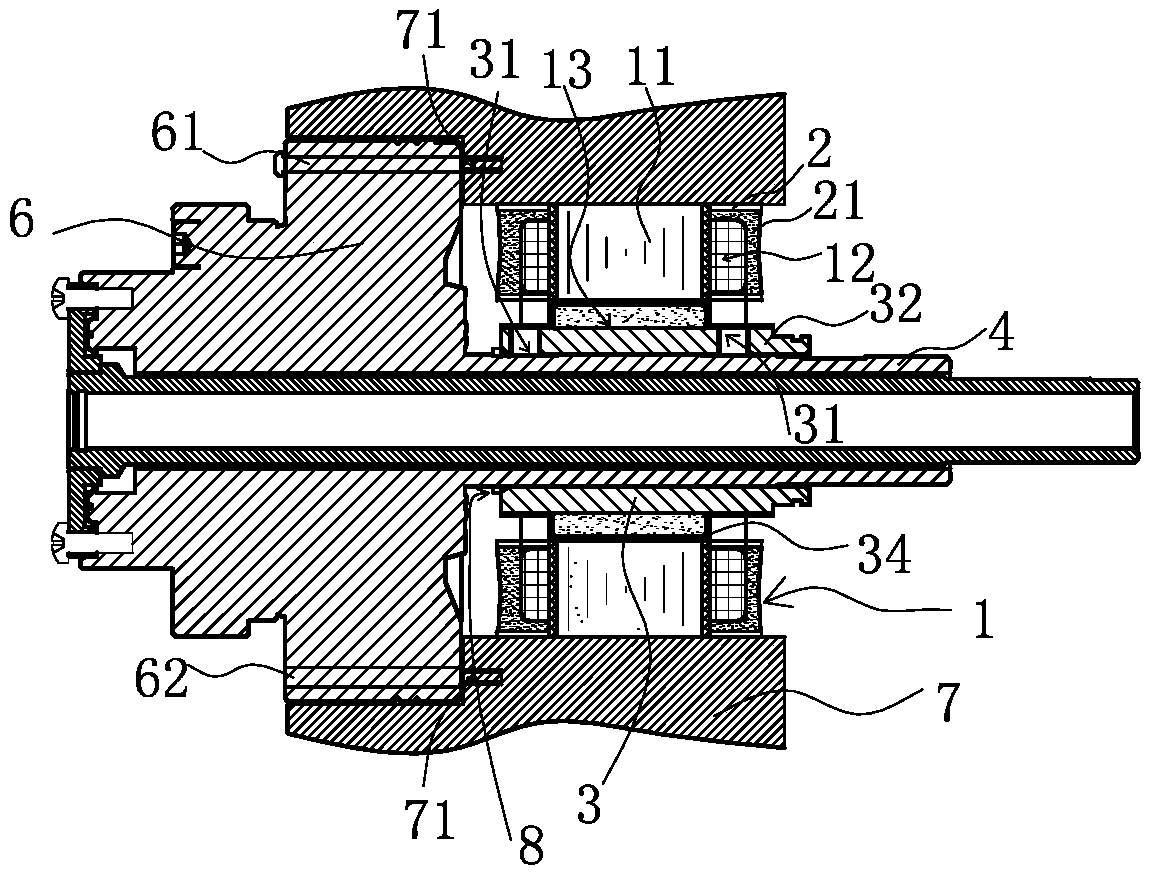

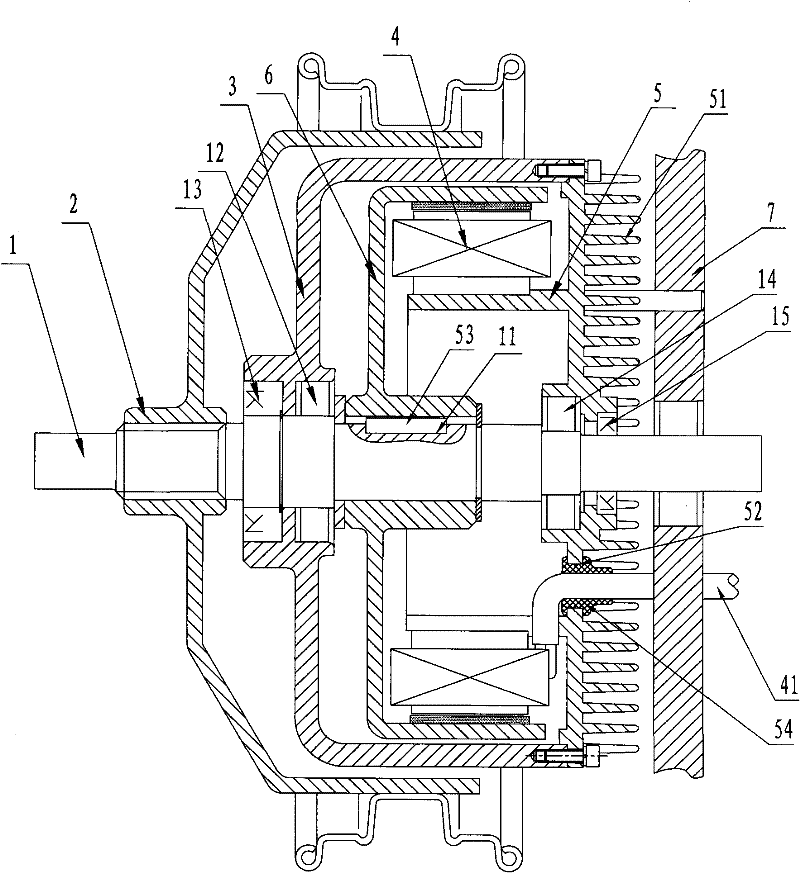

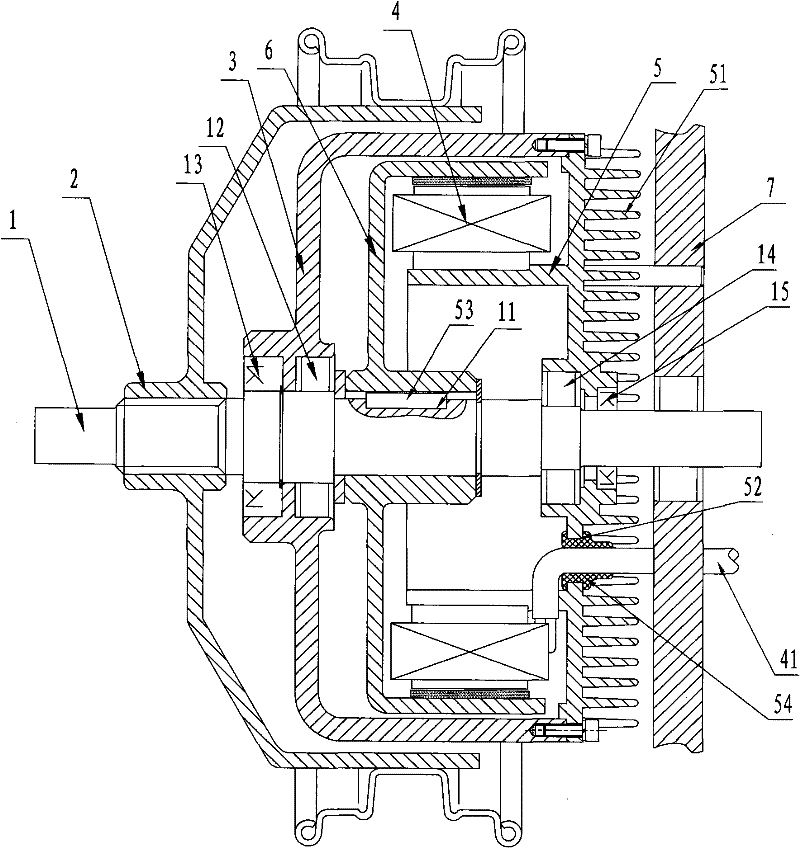

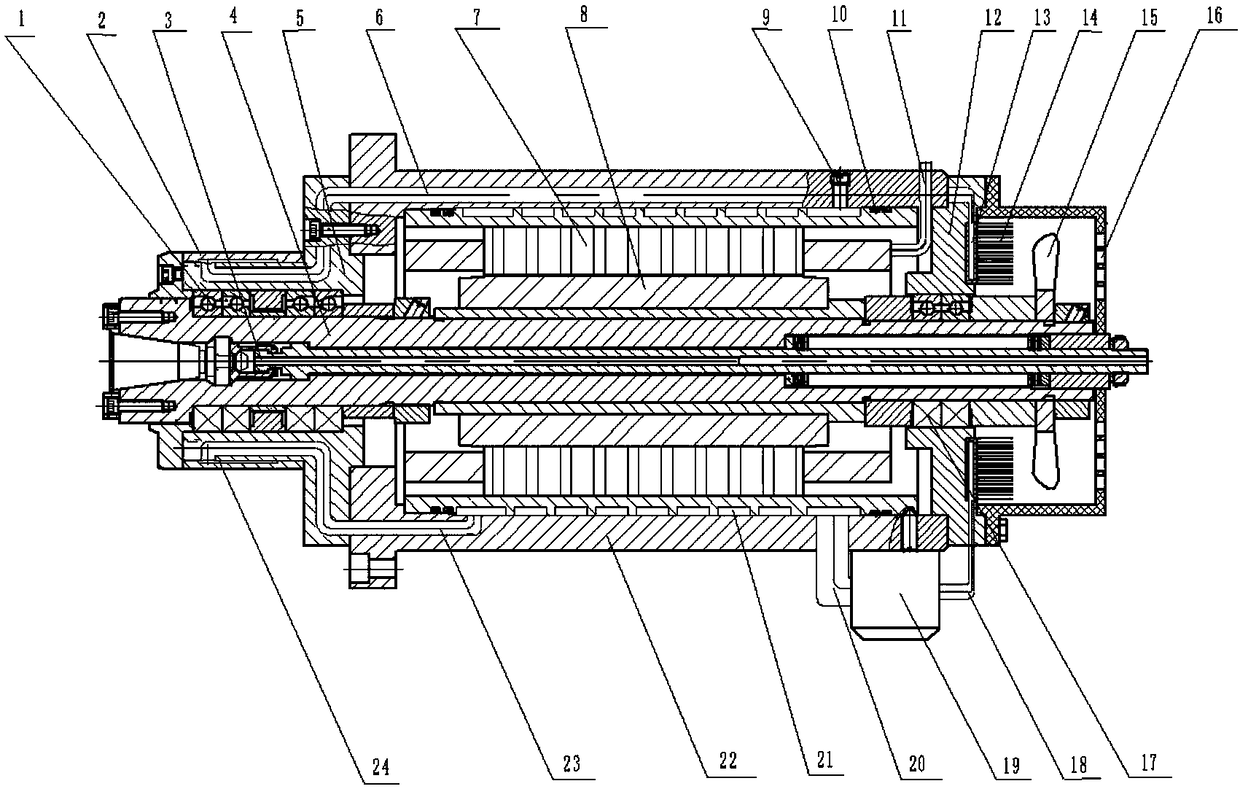

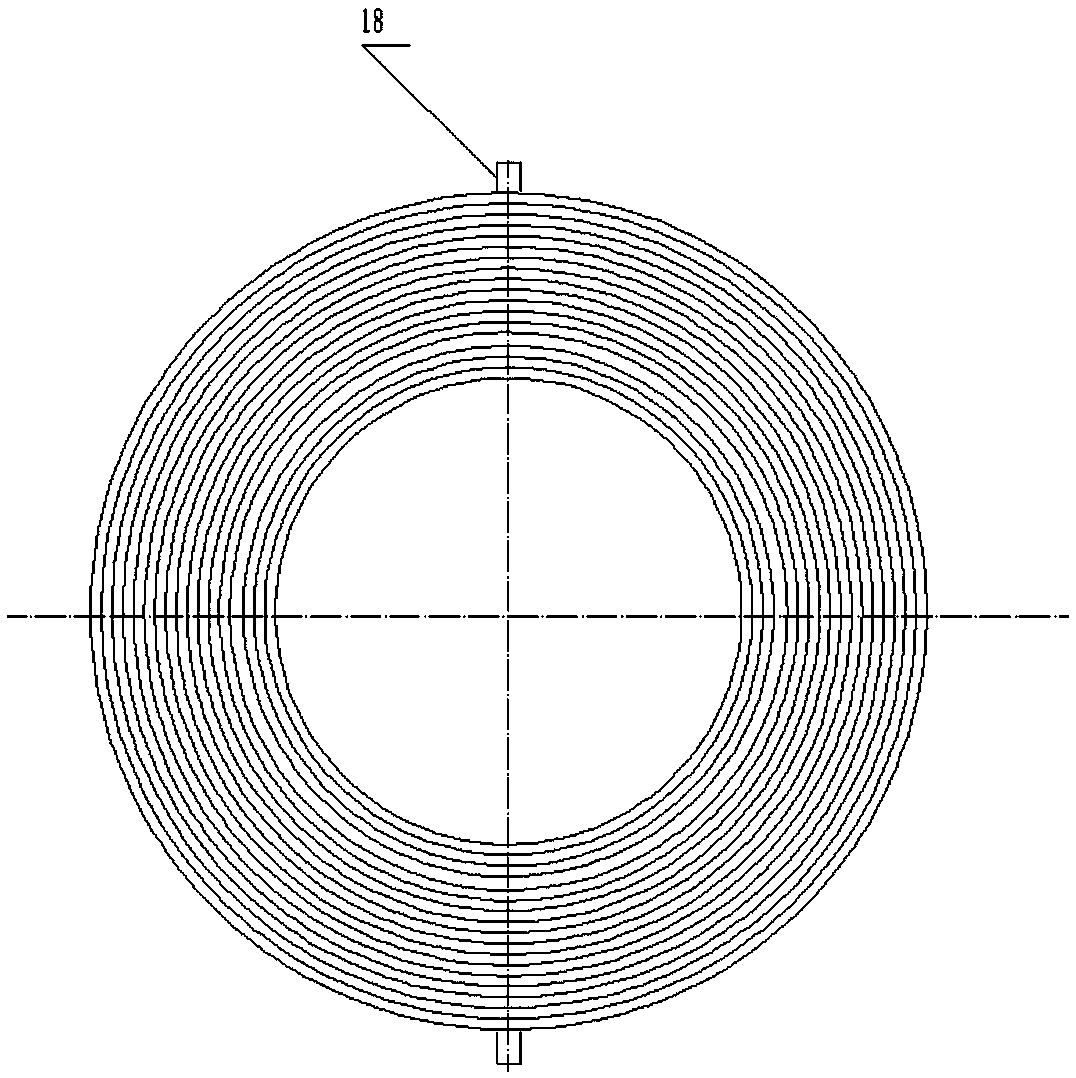

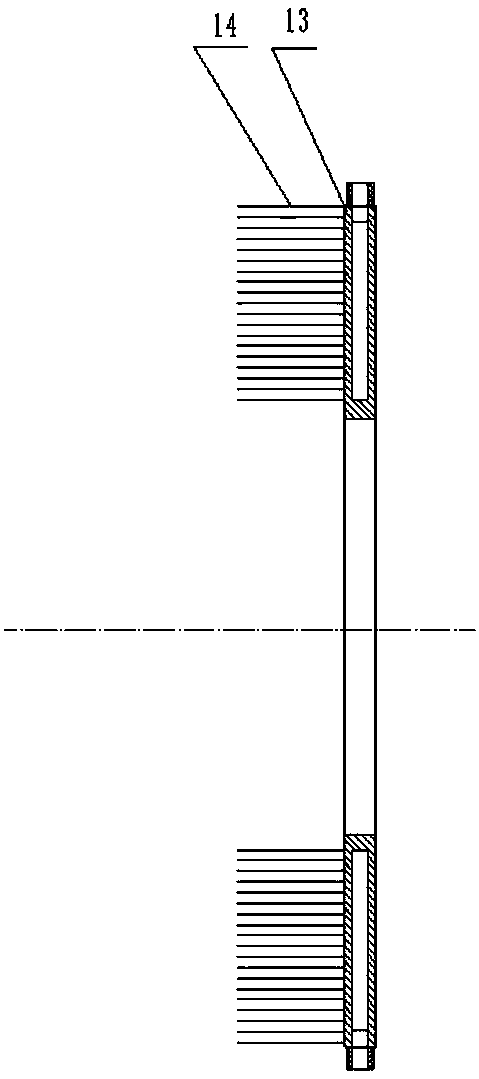

Pan-tilt motor and pan-tilt

ActiveCN104756373AShooting stabilityEnsure consistencyAircraft componentsMechanical energy handlingEngineeringMotor shaft

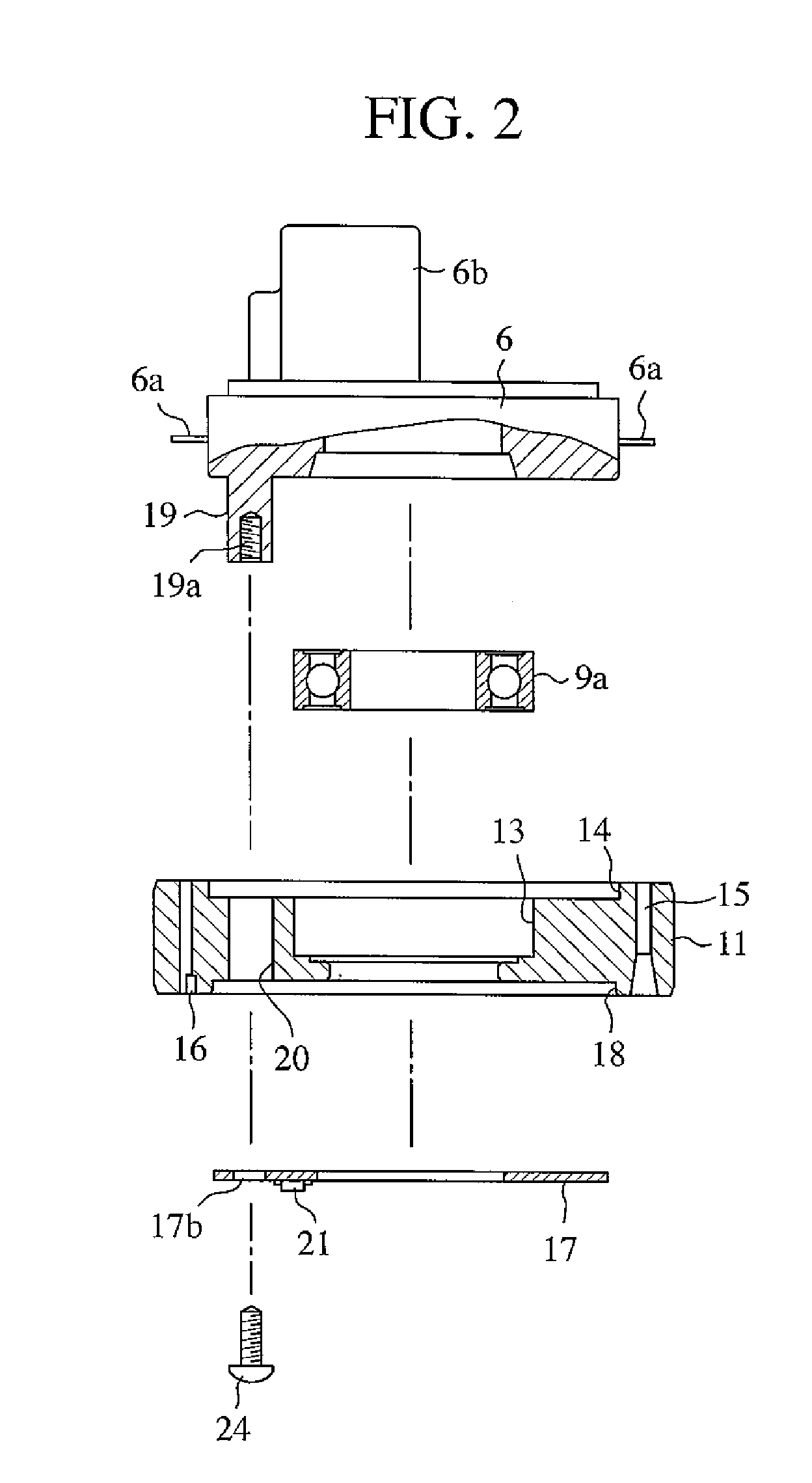

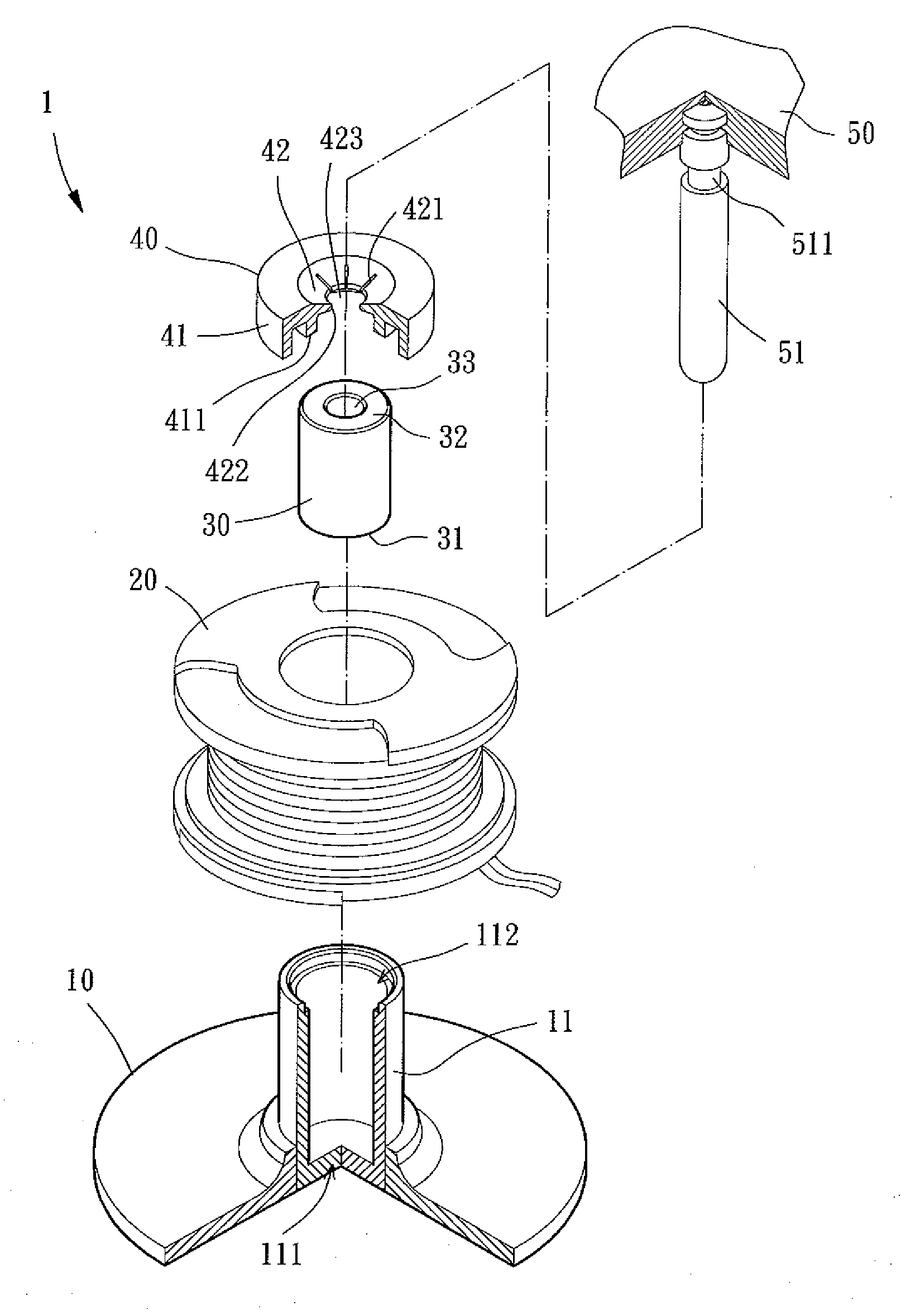

The invention discloses a pan-tilt motor (10), comprising a rotor component (11), a motor shaft (12) and a stator component (13). The motor shaft (12) comprises a shaft body (122), a first end (124) and a second end (126). The first end (124) if fixedly connected to the rotor component (11). The stator component (13) sleeves the periphery of the shaft body (122) and is connected to the motor shaft (12) in a rotating manner through a pair of bearings (15). The pair of bearings (15) are disposed near the first end (124) and the second end (126). The pan-tilt motor (10) also comprises a compressing piece (16) and an elastic body (18). The compressing piece (16) matches with the second end (126), and thereby the stator component (13) is positioned at the motor shaft (12) in an axial direction. The elastic piece (18) and a bearing pad (152) are both disposed between the compressing piece (16) and the bearing (15) adjacent to the second end (126). The bearing pad (152) clings to the bearing (15). The elastic piece (18) is disposed between the bearing pad (152) and the compressing piece (16). The elastic body (18) is elastically deformed through the compressing piece (16), and thereby the axial pretightening force of the pan-tilt motor (10) can be ensured.

Owner:SZ DJI OSMO TECH CO LTD

Brushless plastic motor and manufacturing method thereof

ActiveCN104135101AManufacturing dynamo-electric machinesSupports/enclosures/casingsMagnetEngineering

Owner:DONGGUAN YINYAN ELECTRICAL SCI & TECH CO LTD

Vibration motor and oilless bearing

InactiveUS20070273224A1Improve propertiesReduce mechanical noiseManufacturing dynamo-electric machinesMechanical vibrations separationMotor vibrationElectric machinery

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

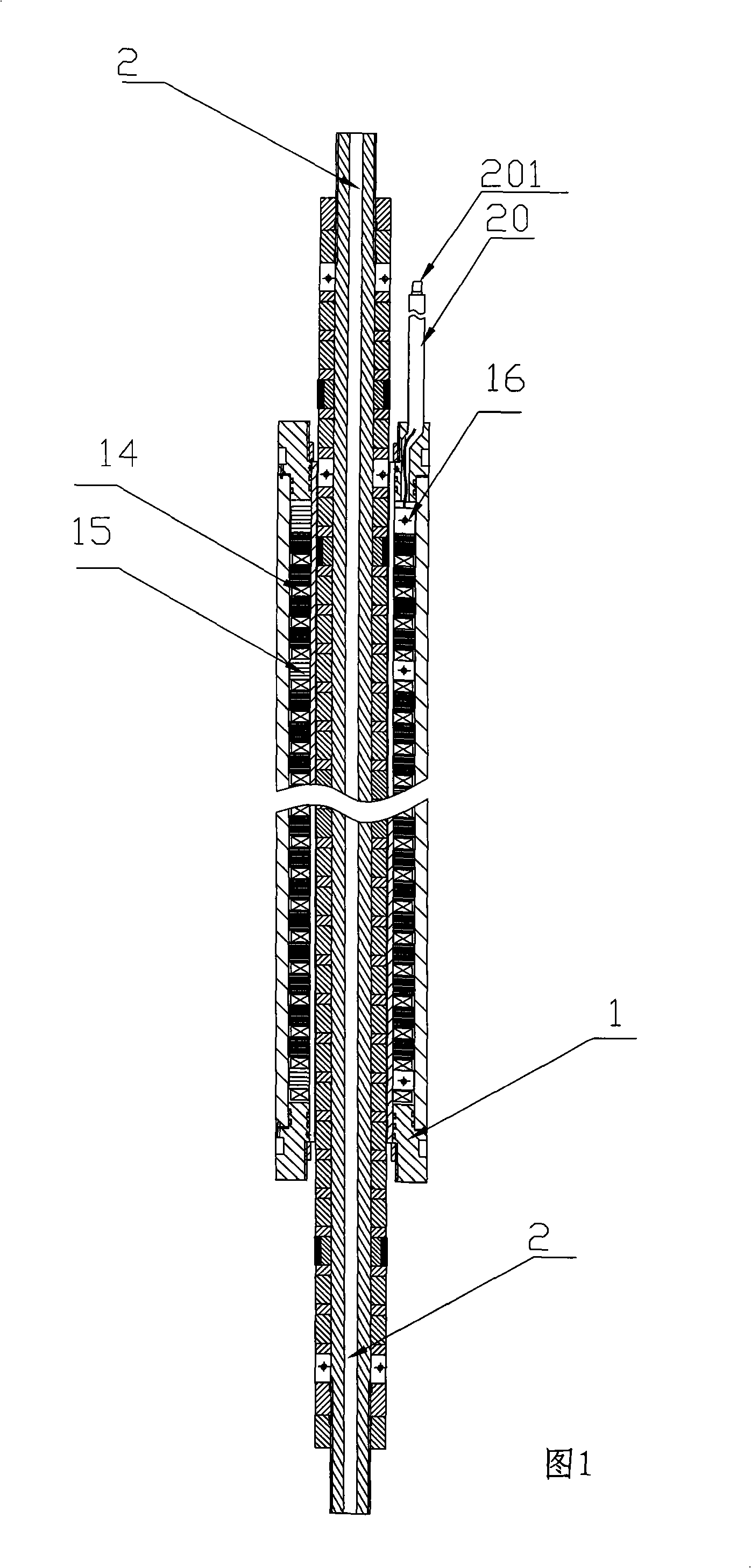

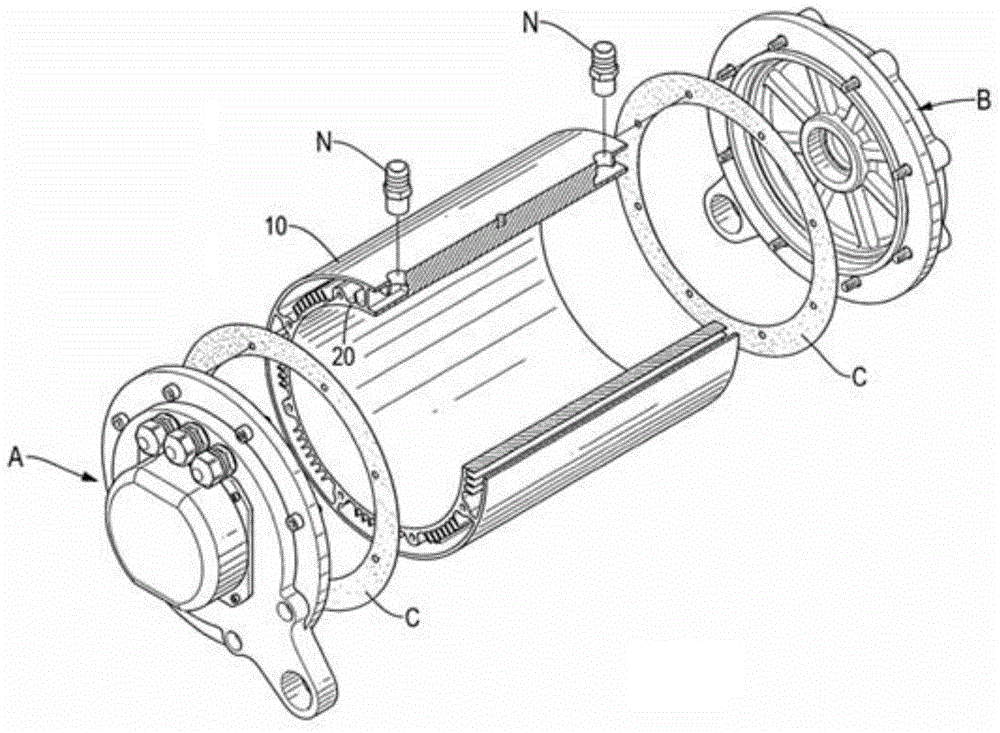

Oil-submersible linear motor

ActiveCN101409495AGuaranteed up and down linear motionGuaranteed tightnessPropulsion systemsSupports/enclosures/casingsLinear motionLinear motor

Owner:SHENZHEN HANS MOTOR S&T

Cooling end cover of permanent magnet motor

Owner:GUANGXI UNIV

Motor device

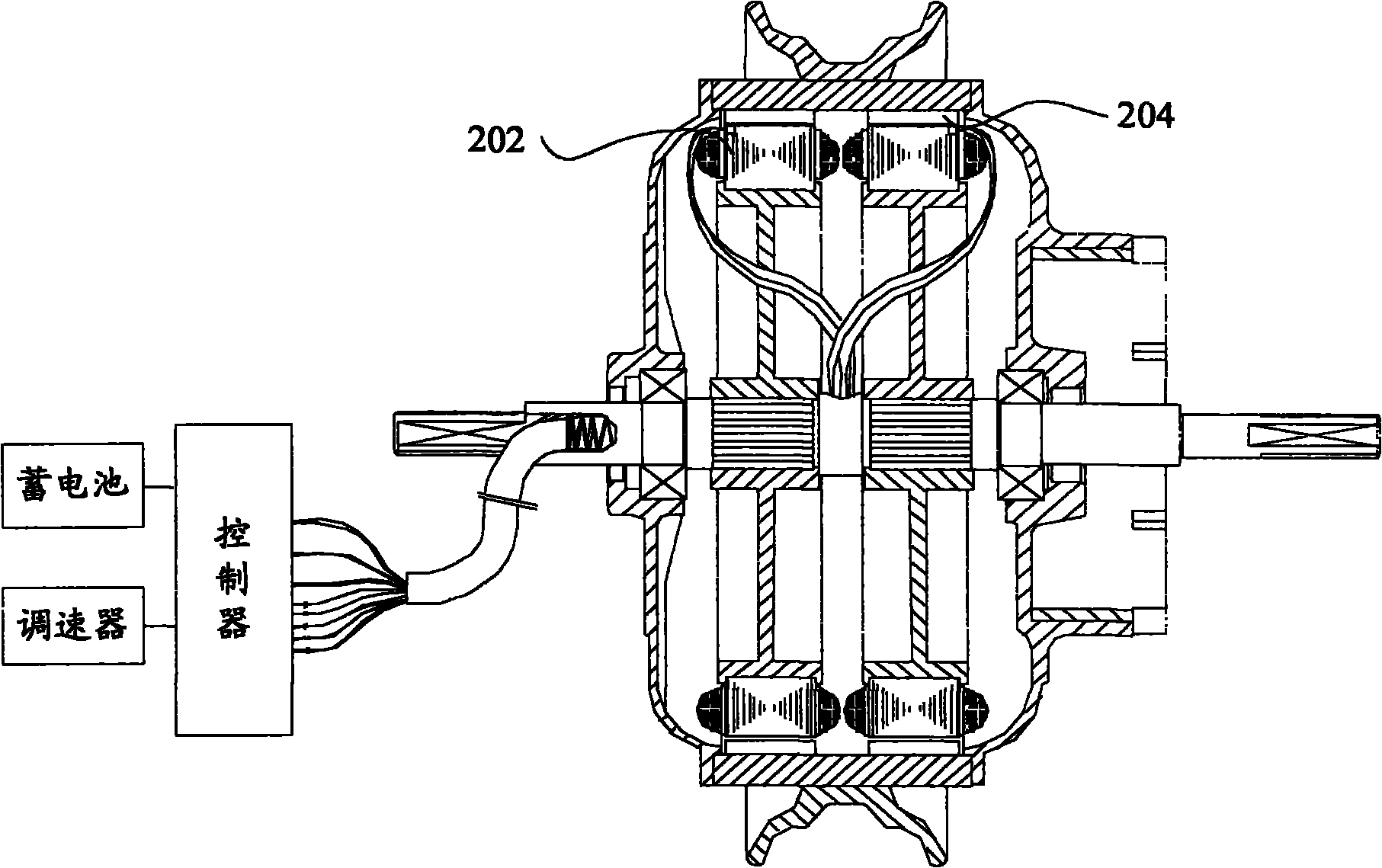

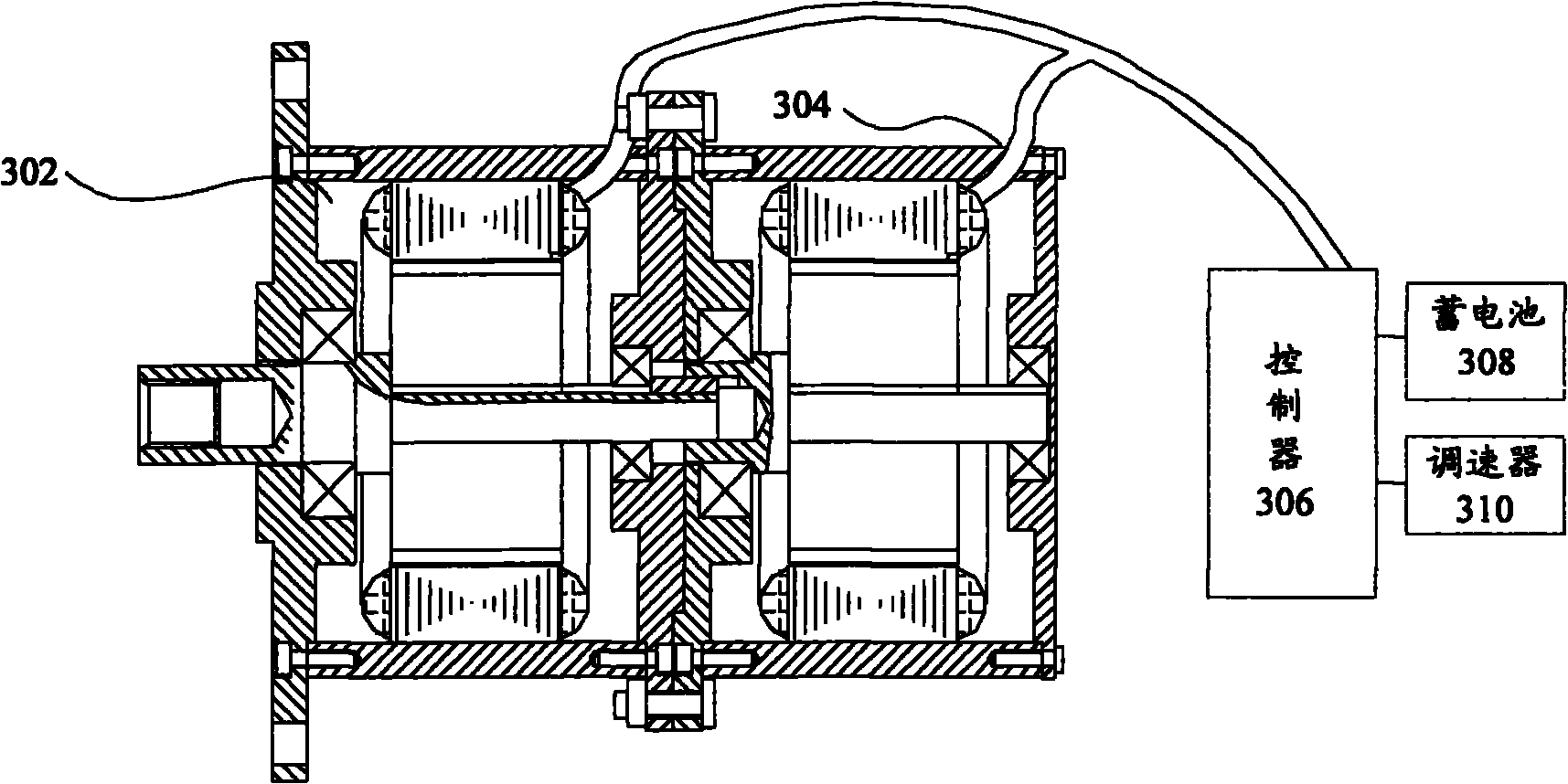

ActiveCN101917086AReduce manufacturing costBatteries circuit arrangementsMultiple motor speed/torque controlControl theoryEffective energy

Owner:ZHEJIANG LUYUAN ELECTRIC VEHICLE

Oil pollution prevention motor

Owner:杨庆华

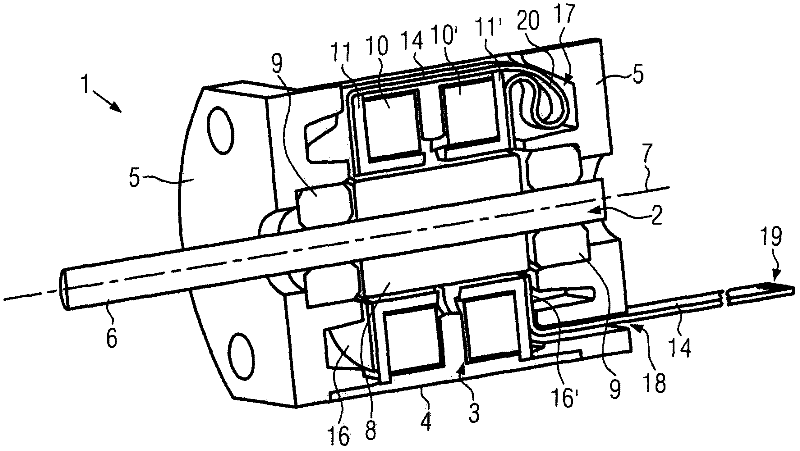

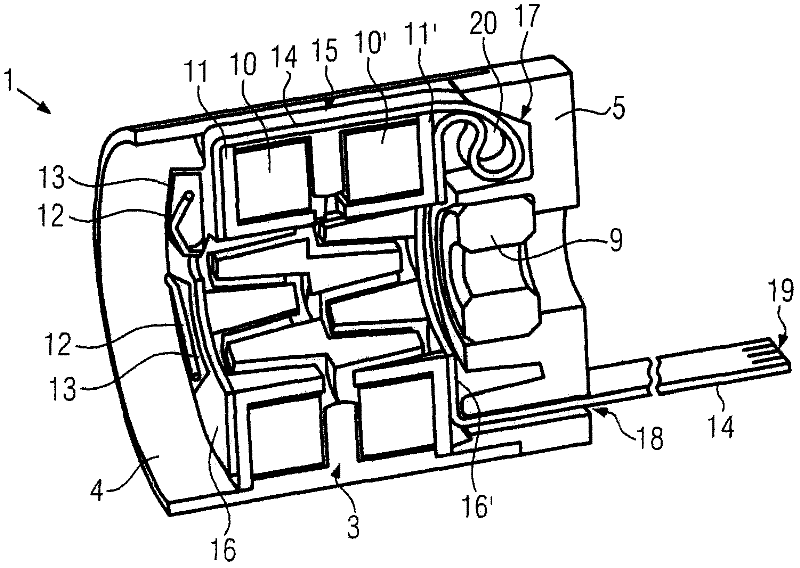

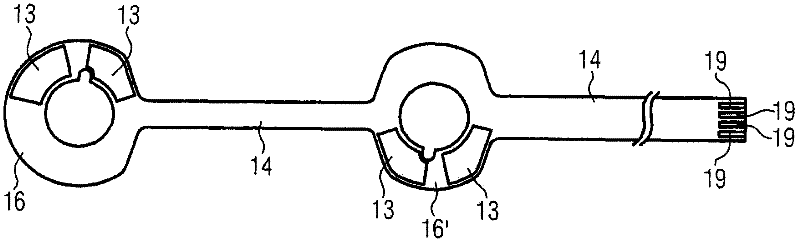

Small electric motor and method for manufacturing the same

ActiveCN102340202AReliable jointEasy to assembleWindingsManufacturing dynamo-electric machinesRotational axisElectrical conductor

Owner:MAXON MOTOR AG

Structure for motor of electric vehicle

InactiveCN102457119AReduce the temperatureReduce power lossElectric machinesMagnetic circuit stationary partsEngineeringElectric vehicle

Owner:上海苗湃信息技术服务中心

Liquid metal temperature control system for electric spindle

ActiveCN108199533AMagnetic circuit stationary partsCooling/ventillation arrangementTemperature controlElectricity

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

Rotor assembly for motor

A rotor assembly for a motor includes a rotor shaft having a journal portion formed in an axial direction and having a predetermined radius about an axis, and a center shaft portion extending along the axial direction from the journal portion and having a radius smaller than a radius of the journal portion about the axis; a cylindrical, integral permanent magnet inserted into the center shaft portion to surround an outer circumferential surface of the center shaft portion and being supported by the journal portion; and a sleeve inserted into the rotor shaft to surround an outer circumferential surface of the journal portion and an outer circumferential surface of the integral permanent magnet, supporting the integral permanent magnet in the axial direction, and supporting the outer circumferential surface of the center shaft portion in the radial direction.

Owner:HYUNDAI MOTOR CO LTD +1

Aerogenerator machine base

InactiveCN101527478ALow costImprove cooling effectSupports/enclosures/casingsCooling effectEngineering

Owner:上海电气集团上海电机厂有限公司

Liquid-cooled motor

InactiveCN104578518ASimple structureEasy to operateCooling/ventillation arrangementSupports/enclosures/casingsEngineeringFront cover

Owner:CHENGDU ZHONGYUANXIN ELECTRONICS TECH

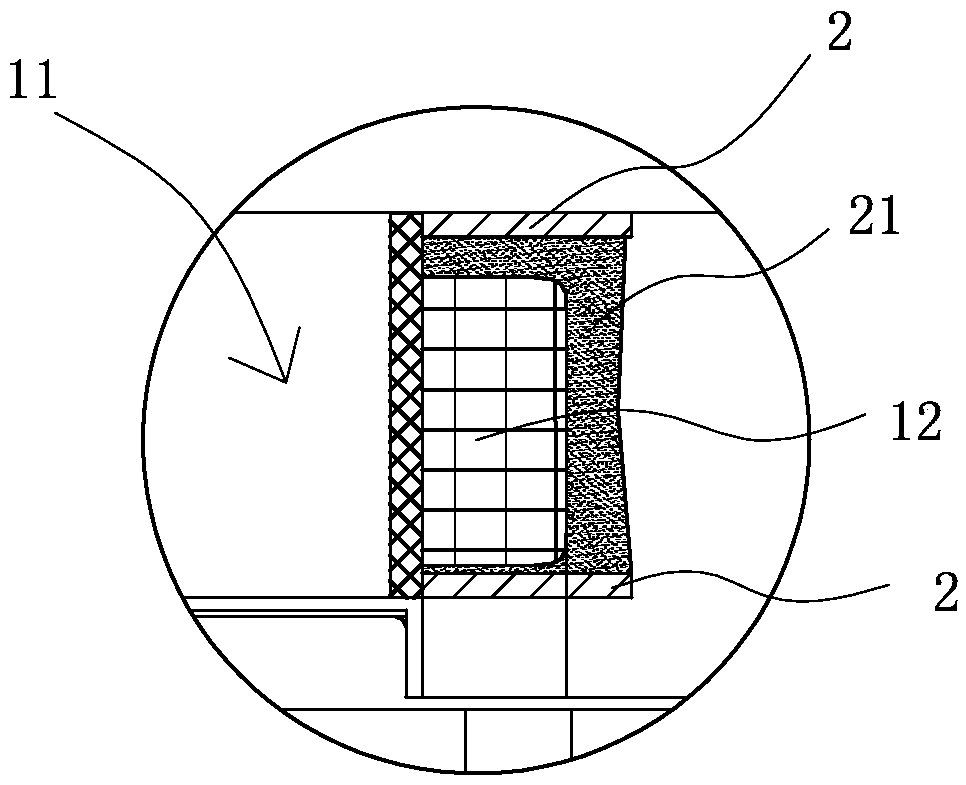

Permanent magnet double-stator synchronous machine

InactiveCN101154863AReduce volumeReduced responseCooling/ventillation arrangementSupports/enclosures/casingsEngineeringMoment of inertia

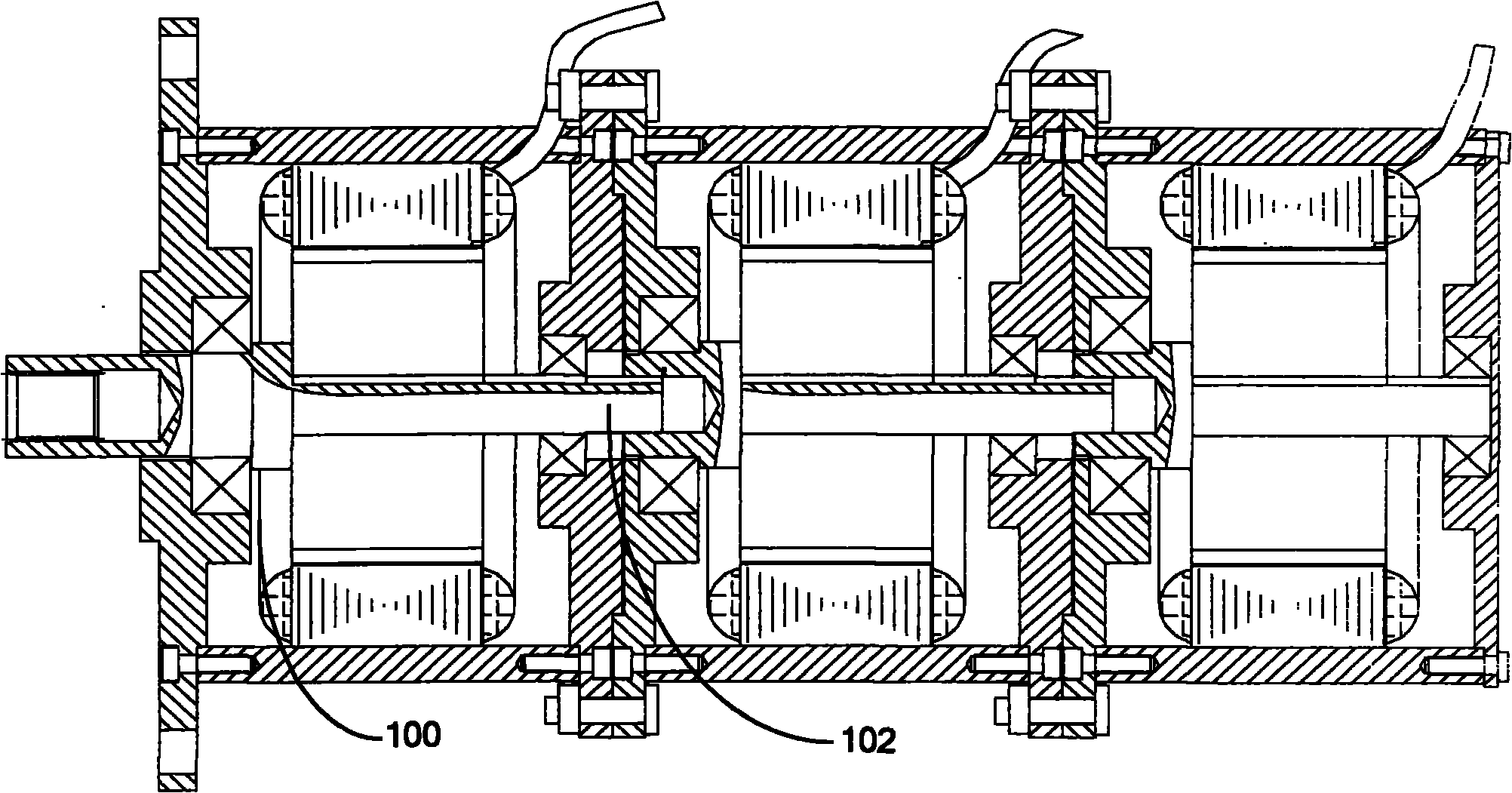

A permanent magnetism double-stator synchronous machine is provided, wherein, a rotor is a multipolar drag cup rotor consisting of a tegular permanent magnetic steel, a non-magnetic bracket and a rotating shaft; the inner annulus and the outer annulus of the magnetic steel of the rotor are respectively provided with a bushing and a lantern ring; the single end of the drag cup rotor is fixed on the rotating shaft, and a fan is arranged on the rotor; an air passage is arranged on the bracket and between the bushing and the rotating shaft; the four corners of a square housing fixing an outer stator core are provided with air chutes; a left end closure and a right end closure are provided with vents correspondingly. The invention has the advantages of small cubage of the machine, minimal armature reaction and moment of inertia, convenient manufacturing and simple structure.

Owner:TIANJIN DEXIN ELECTRIC MACHINERY

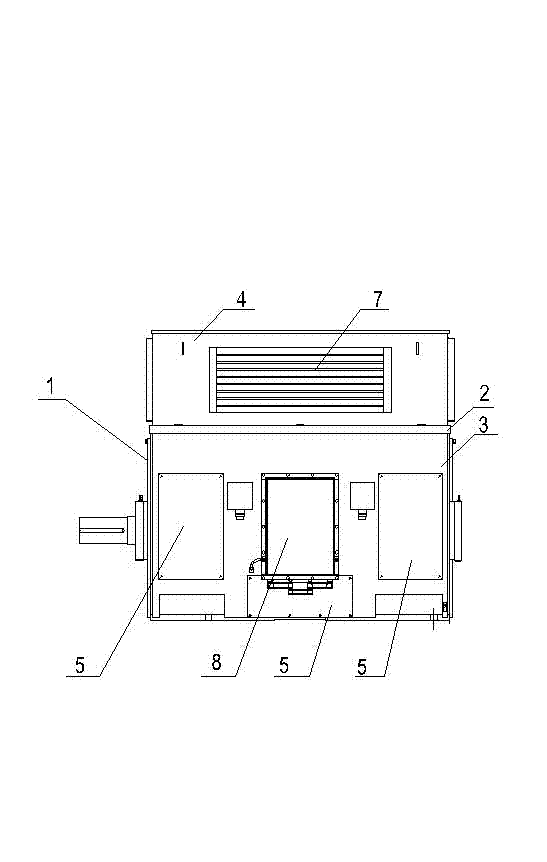

Base of Y-series three-phase asynchronous motor

InactiveCN102790495AImprove cooling effectReduce volumeAsynchronous induction motorsSupports/enclosures/casingsThree phase asynchronous motorCooling effect

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

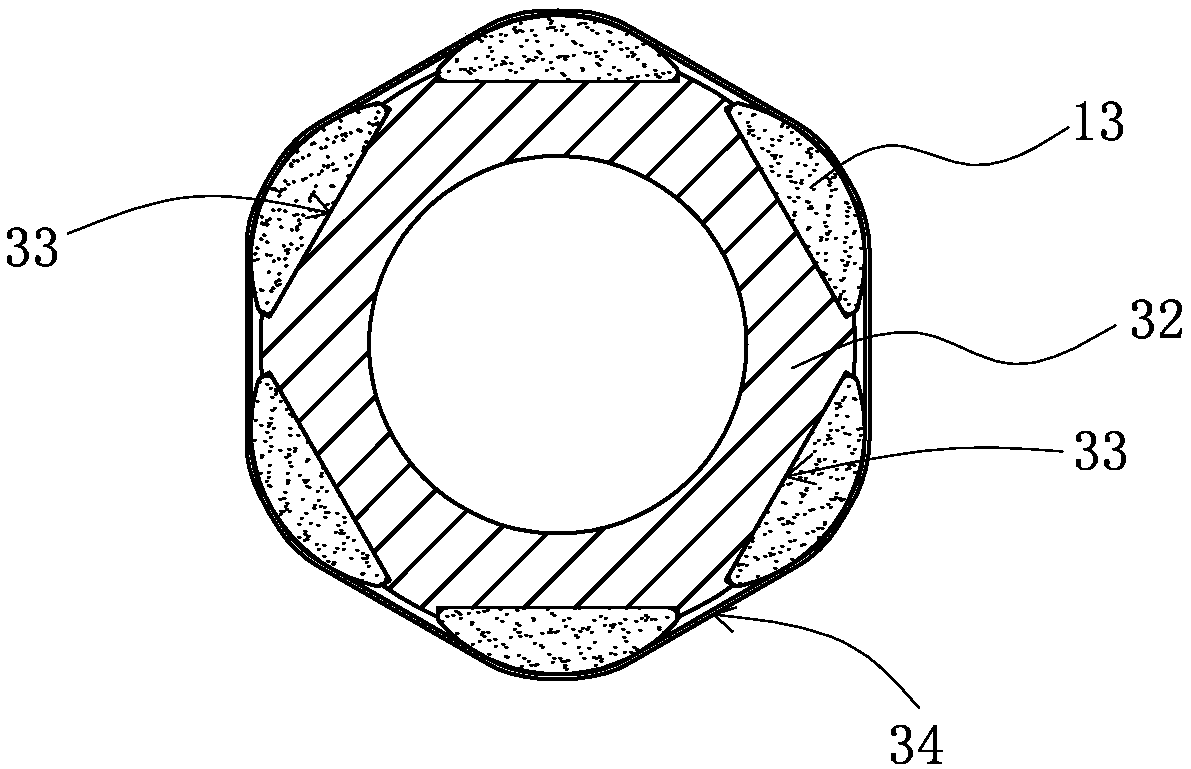

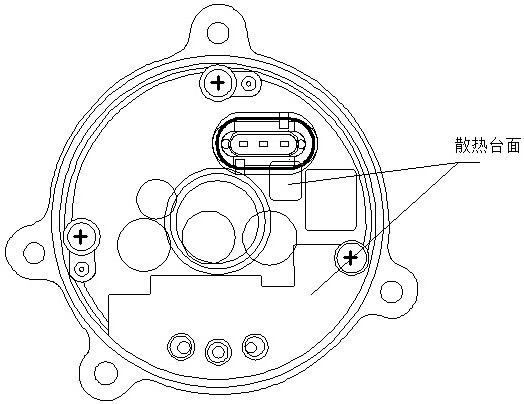

Motor end cover bearing chamber structure

InactiveCN103490550ASimple structureImprove cooling effectSupports/enclosures/casingsEngineeringMachining

The invention discloses a motor end cover bearing chamber structure and relates to the field of fan manufacturing and machining. The bearing chamber structure comprises a motor end cover, a bearing chamber body and a bearing, and is characterized in that a plurality of protruding rivet points are arranged on the motor end cover and located on the circumference of the bearing chamber body, the bearing chamber structure further comprises a locating unit provided with plum-blossom-shaped holes, and the locating unit is used for locating the bearing in the bearing chamber body. The motor end cover bearing chamber structure is simple, and good in heat dissipation, and the plum-blossom-shaped riveting mode saves mounting space and enhances firmness of the bearing chamber.

Owner:SUZHOU SHUANGHANG ELECTRICAL CO LTD

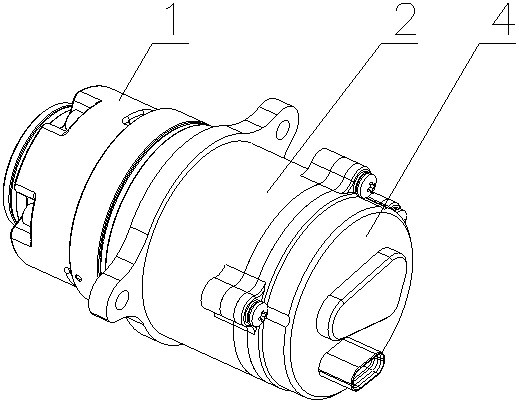

Automobile electronic oil pump driving system

PendingCN112165281AReduce dependenceReduce connectionsAssociation with control/drive circuitsSingle motor speed/torque controlBrushless motorsElectric machine

Owner:湖南东嘉智能科技有限公司 +1

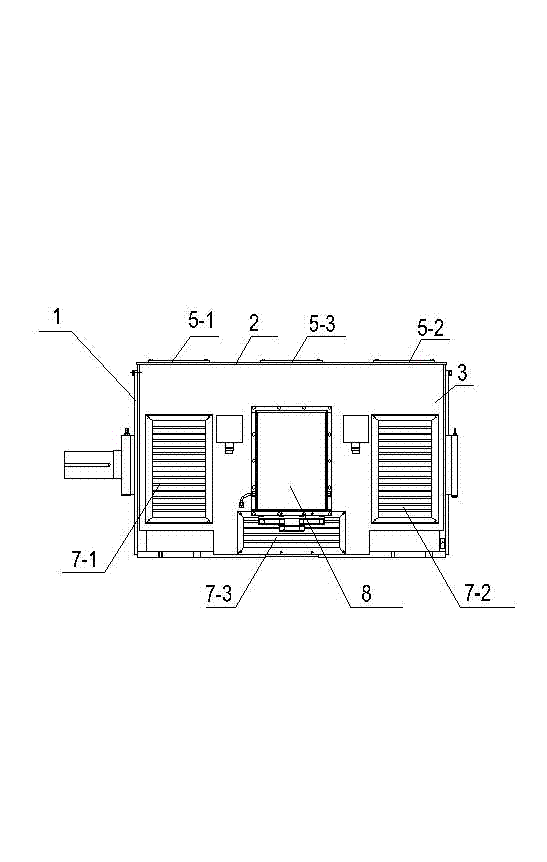

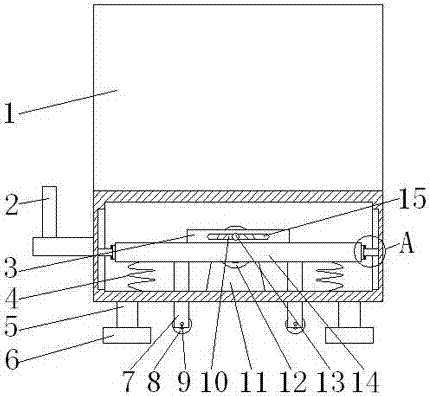

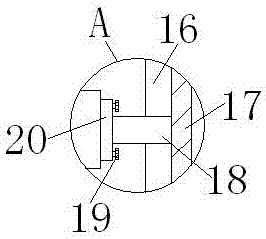

Movable generator box

InactiveCN107994713AEasy to moveAvoid situations that require a lot of manpower and material resourcesMachine framesSupports/enclosures/casingsComputer engineeringPulley

Owner:王腾蛟

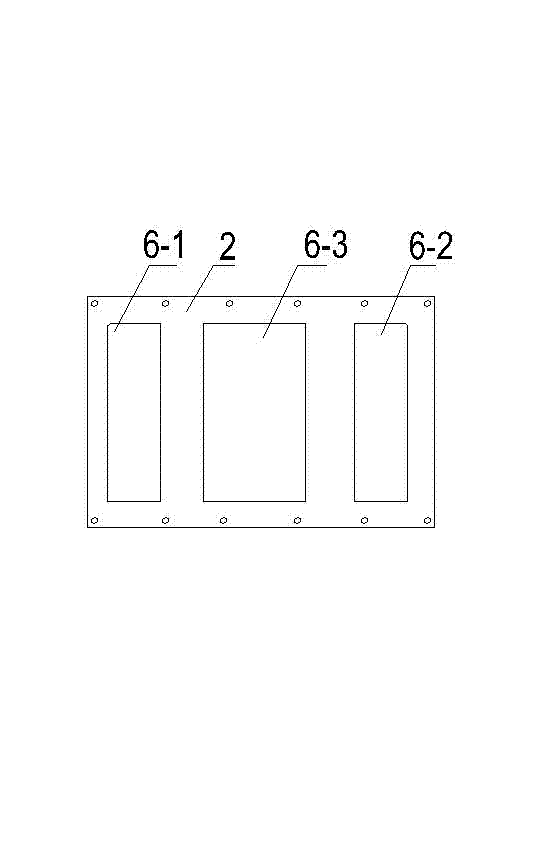

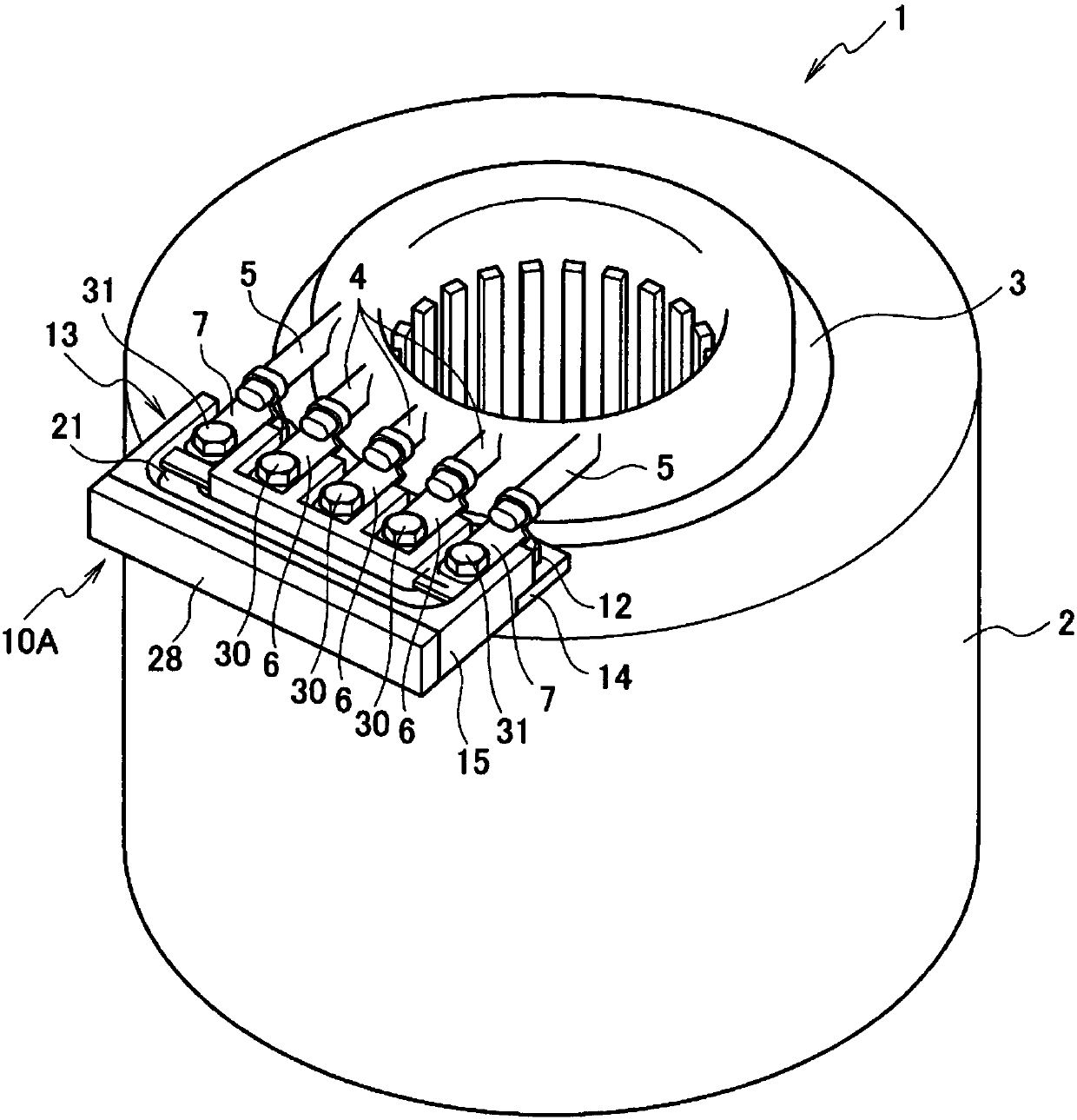

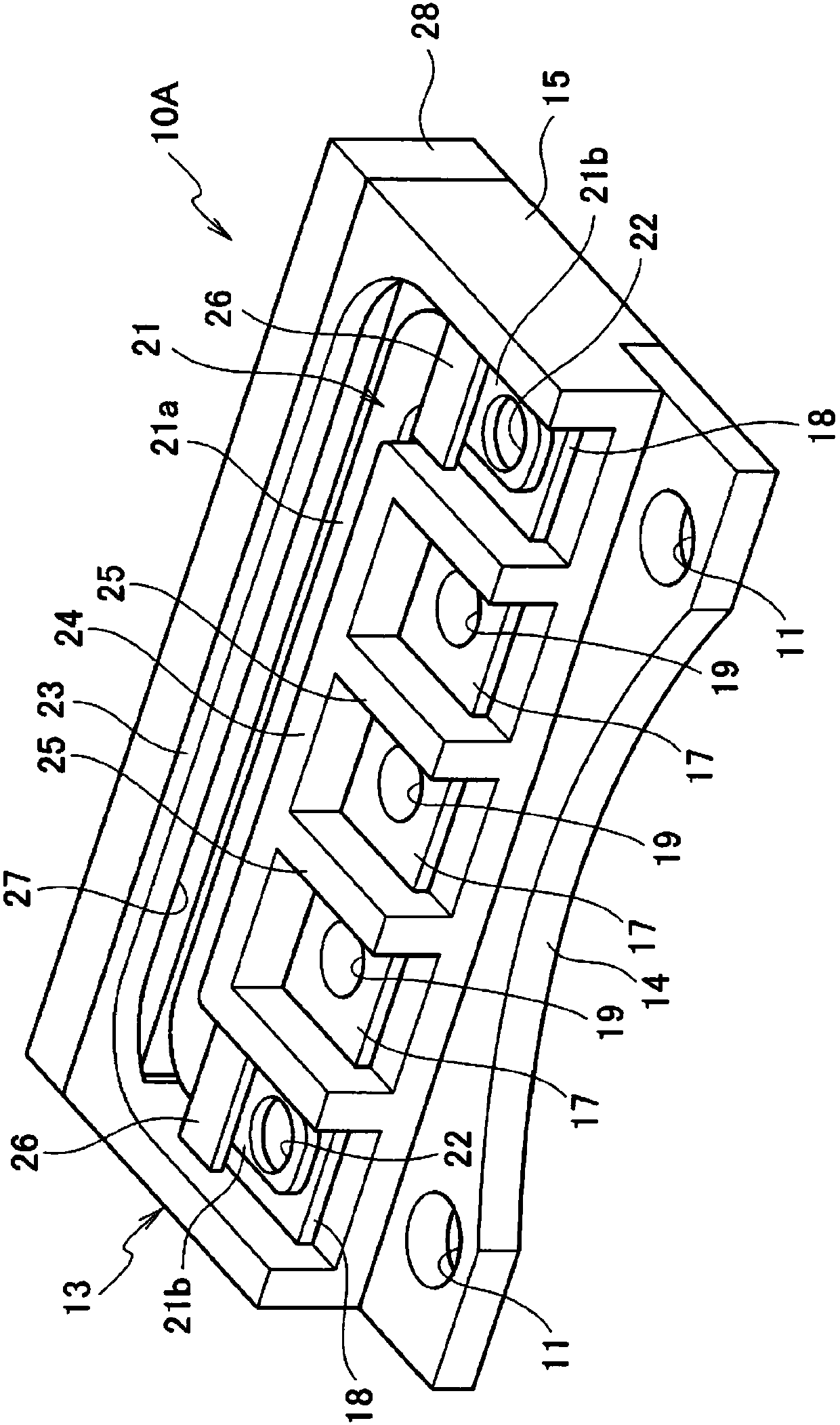

Terminal block of rotating electric machine

ActiveCN107925307AElectrically conductive connectionsSupports/enclosures/casingsHigh currentElectric machine

Owner:NISSAN MOTOR CO LTD

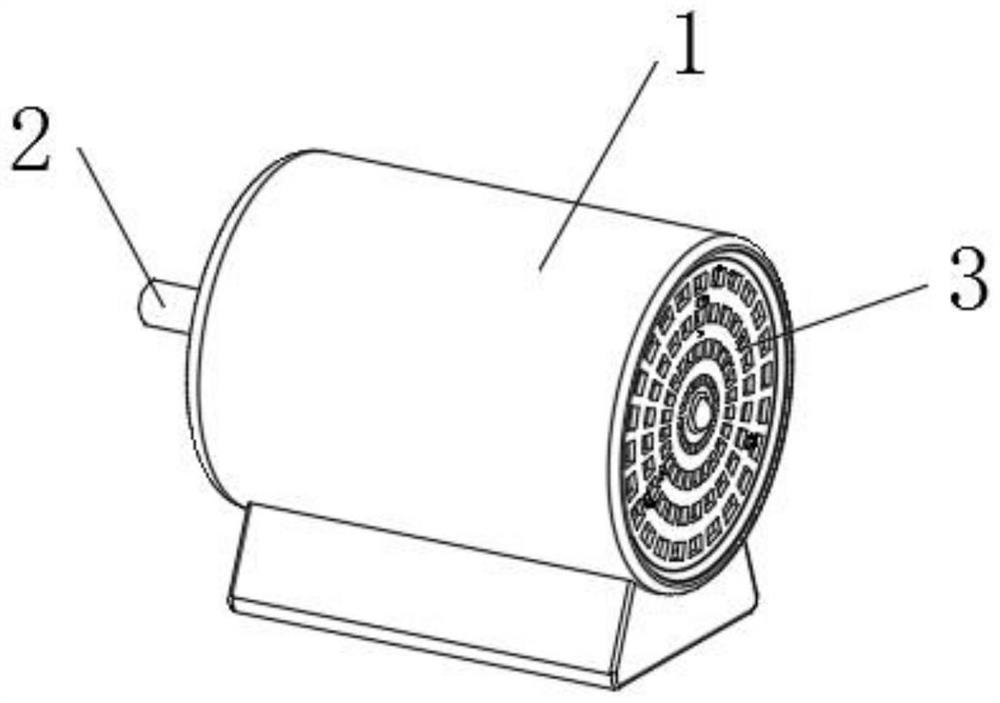

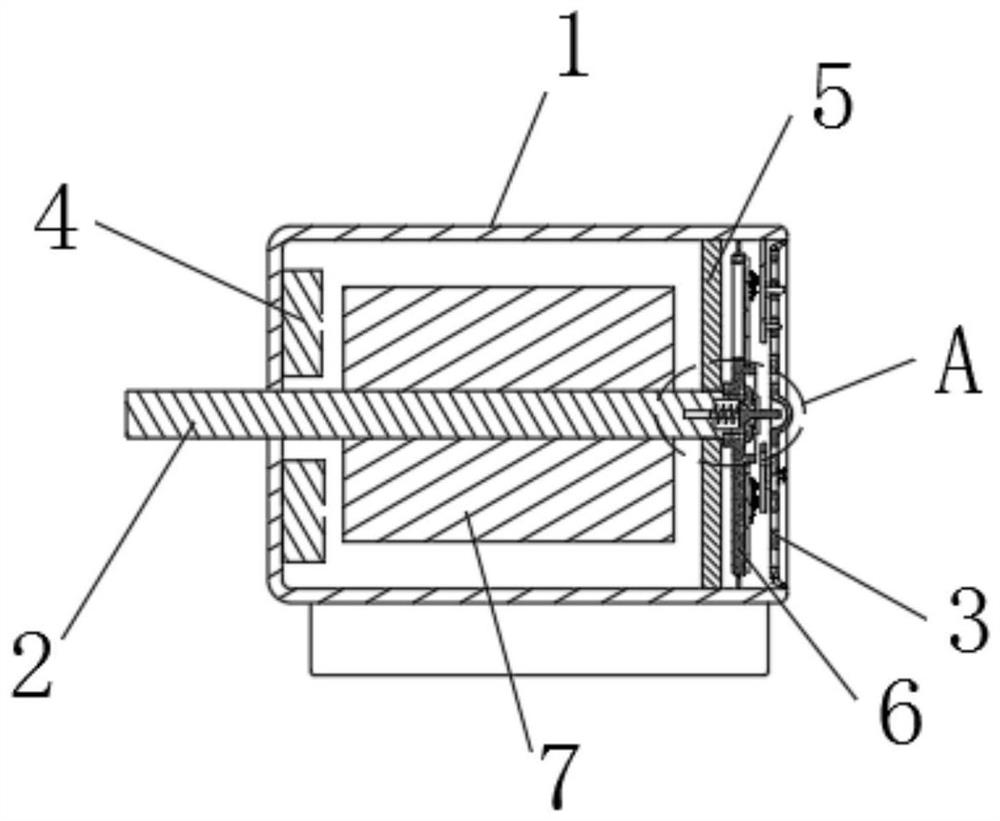

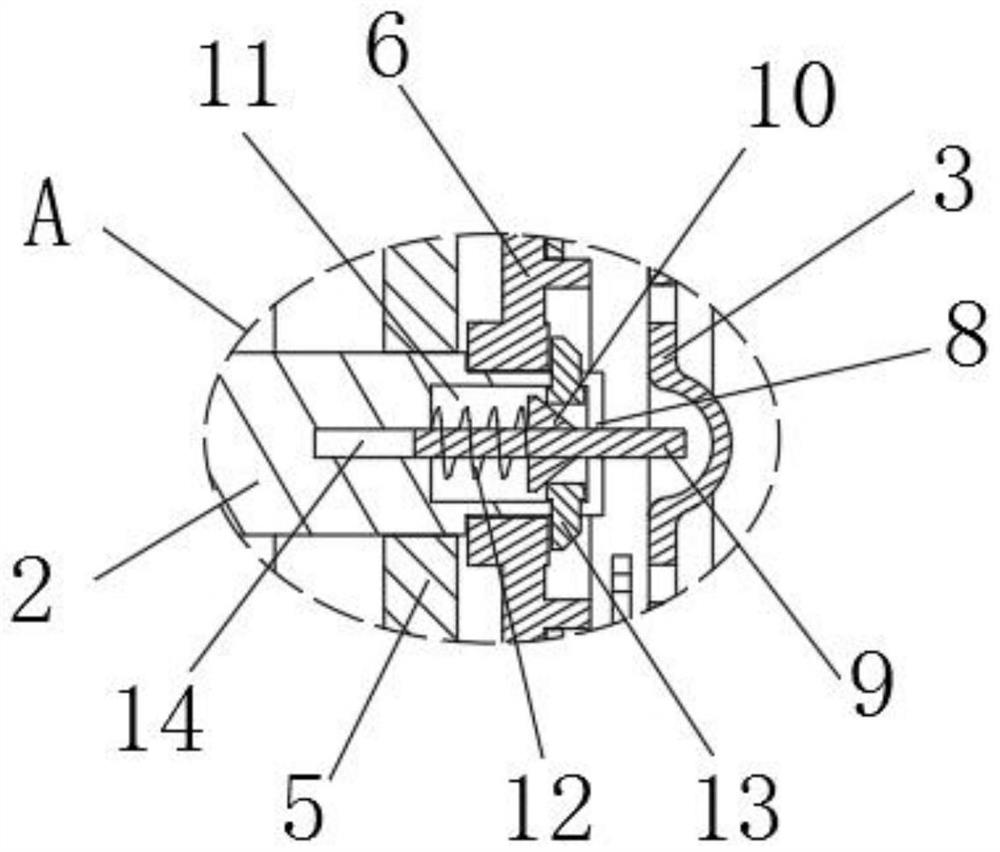

Dustproof motor

PendingCN114301211AAvoid enteringNormal coolingDispersed particle filtrationMechanical energy handlingElectric machineMotor shaft

Owner:陈明芮

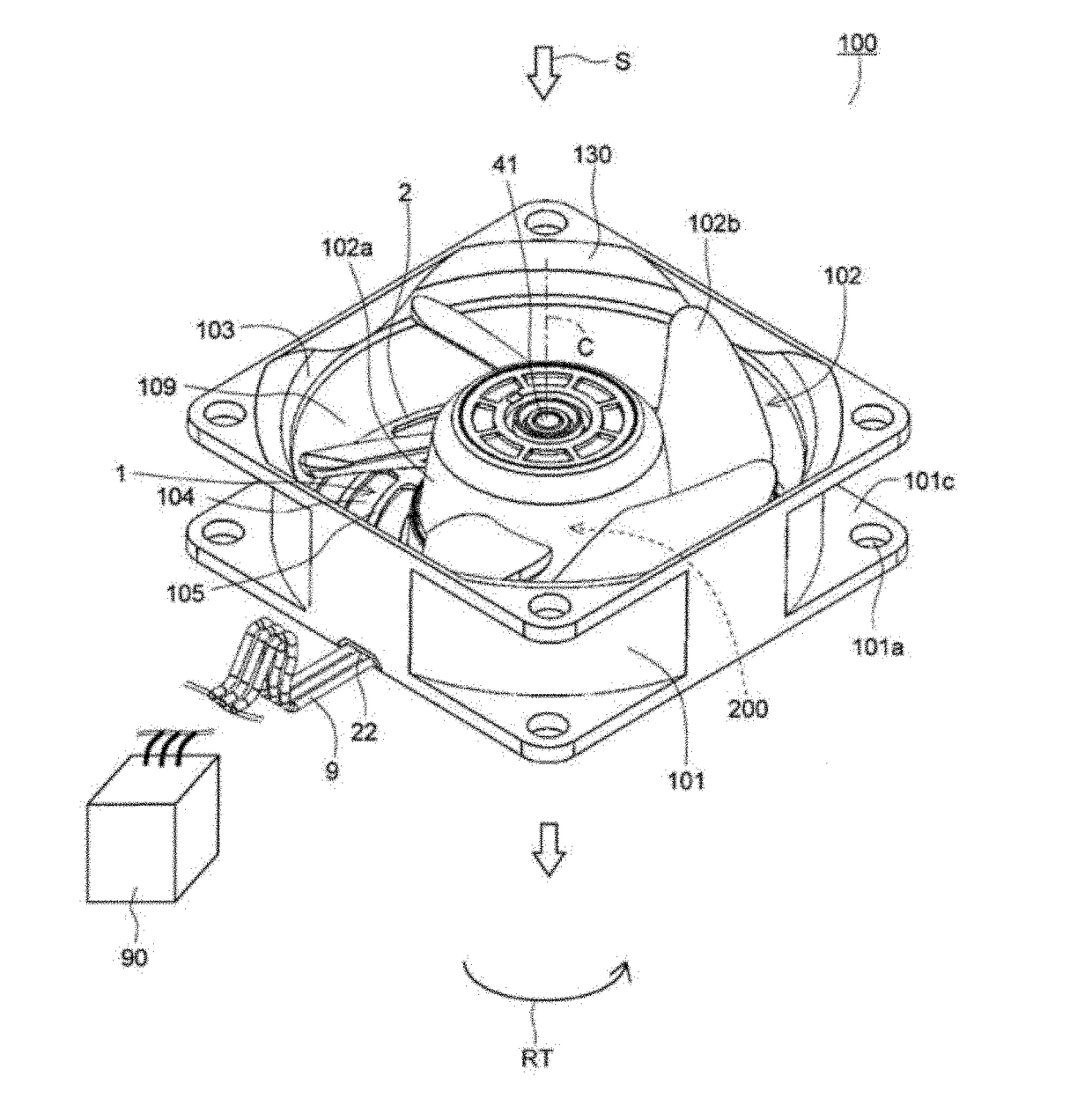

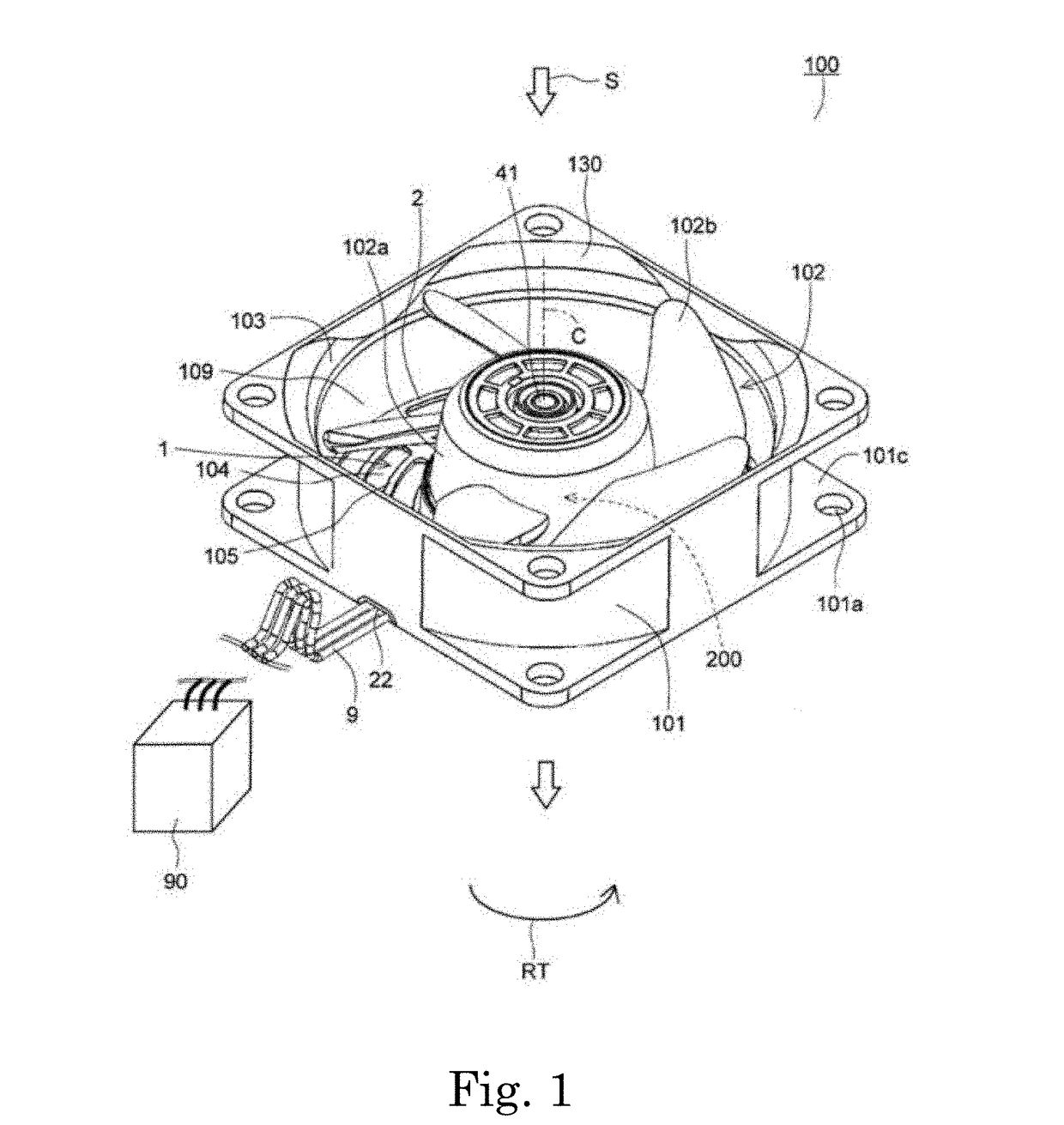

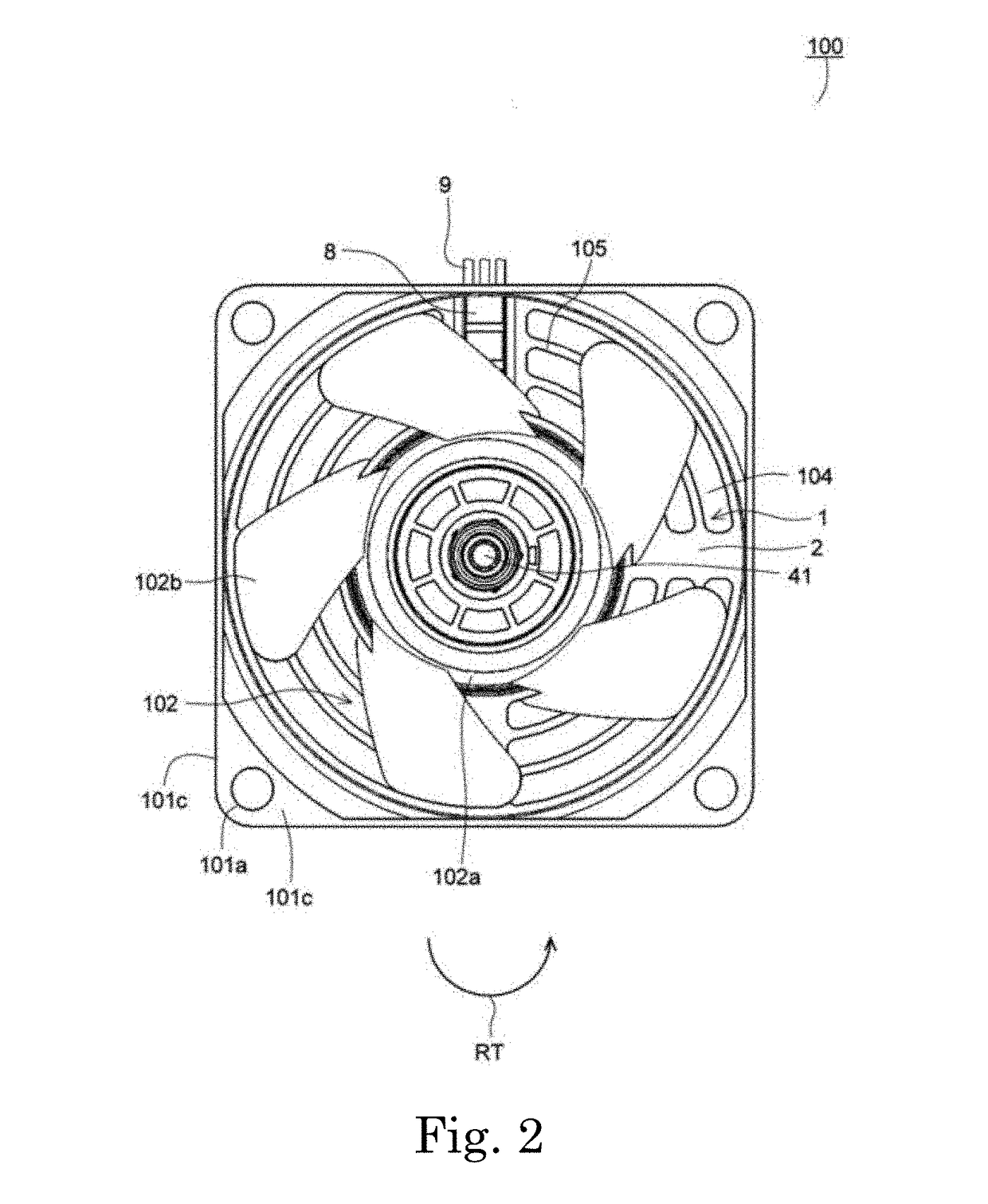

Base unit, motor, and air blowing device

Owner:NIPPON DENSAN CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap