Oil-submersible linear motor

A linear motor, submersible technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems affecting system efficiency, coil components can not work normally, crude oil pollution, etc., to achieve the effect of improving system work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

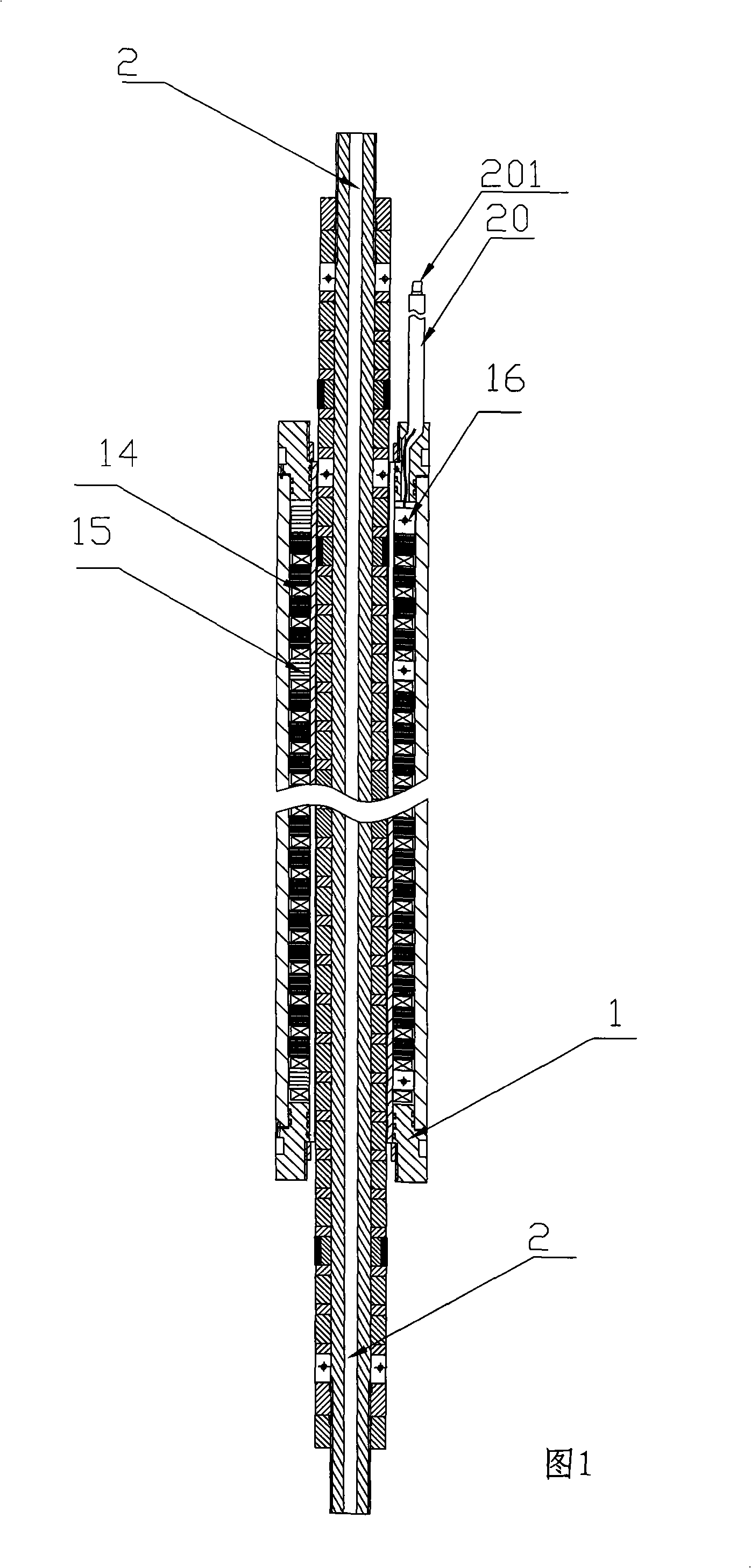

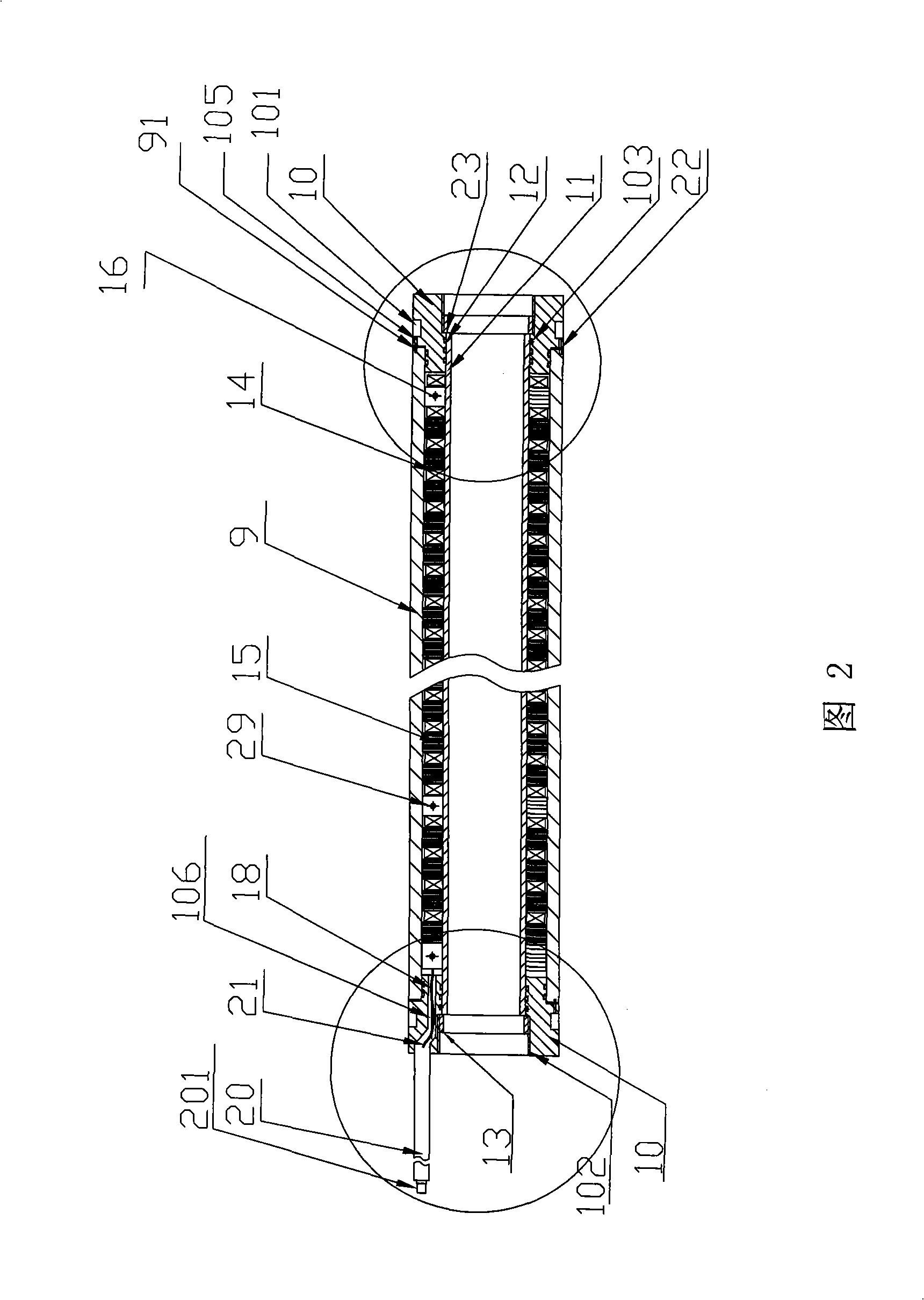

[0037] As shown in Figures 1 and 2, the present invention mainly relates to a submersible linear motor for working in an oil well, which can pump crude oil located underground to the ground. The linear motor includes a stator 1 (generally primary) and a The mover 2 (generally the secondary) that moves up and down in a straight line in 1.

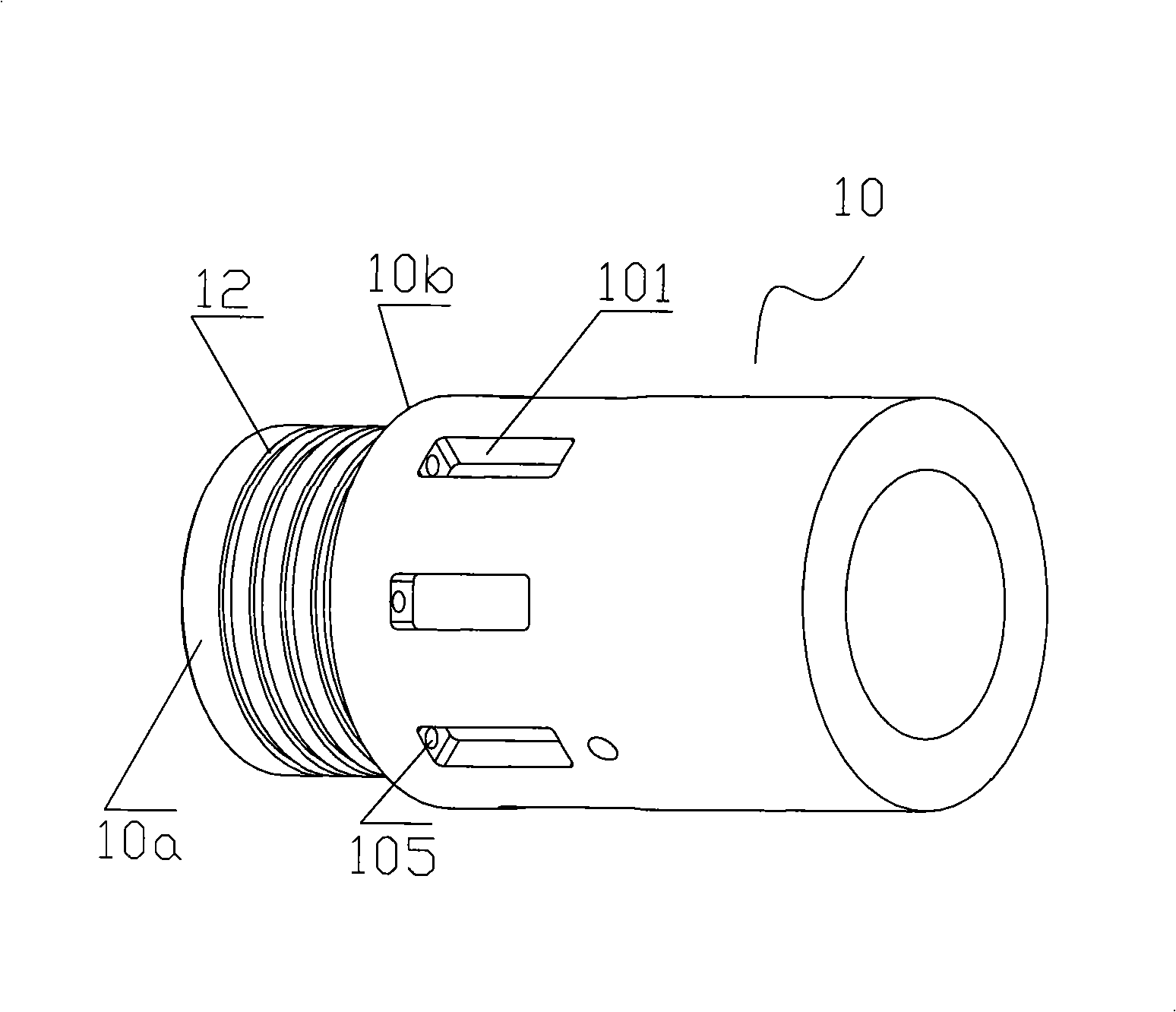

[0038] The stator 1 includes a stator outer tube 9, a stator inner tube 11, a plurality of silicon steel rings 15 arranged in an array, a plurality of coils 14, and two annular joints 10, wherein the stator outer tube 9 and the stator inner tube 11 can be steel pipe, the coil 14 is annular.

[0039] The multi-section silicon steel rings 15 and multiple coils 14 arranged in an array are axially sleeved between the stator outer tube 9 and the stator inner tube 11, and are looped on the stator in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap