Tee pipe connecting structure

A connection structure, three-way pipe technology, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, pipe, etc., can solve the problem of damage to anti-corrosion and wear-resistant materials, rigid connection of pipeline stress concentration, pressure-resistant hose adjustment range limited and other problems, to achieve the effect of ensuring sealing and large axial adjustment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] Example

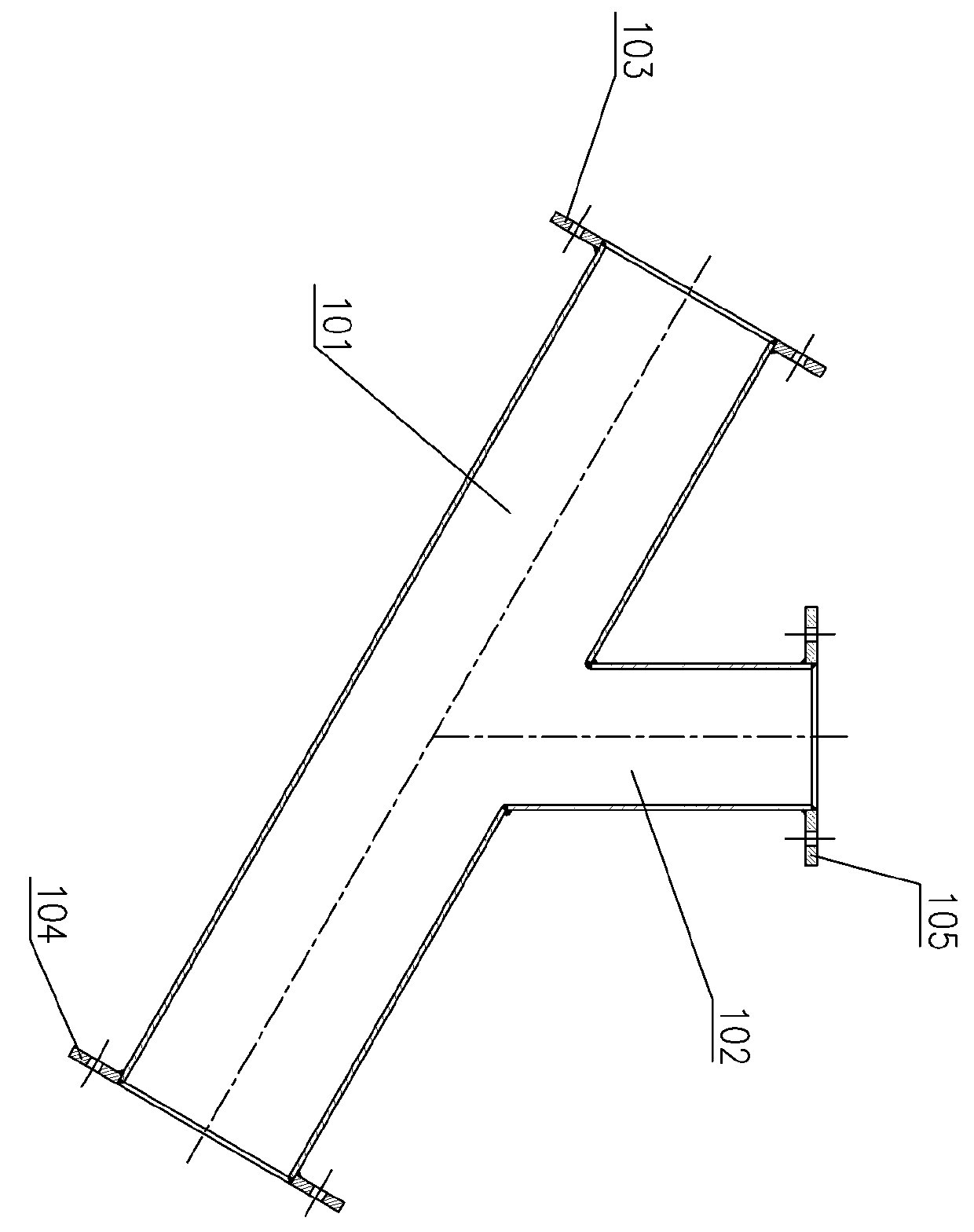

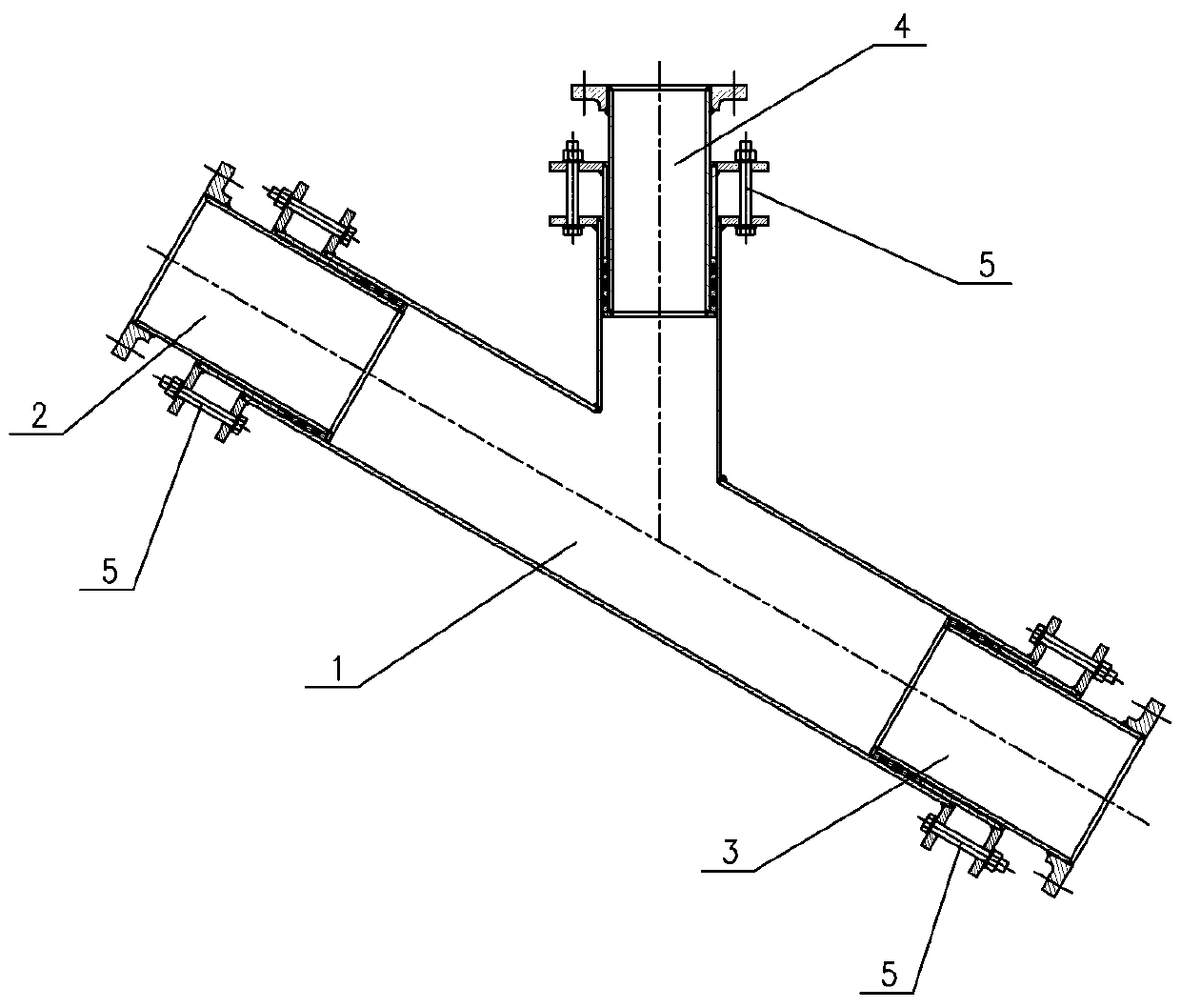

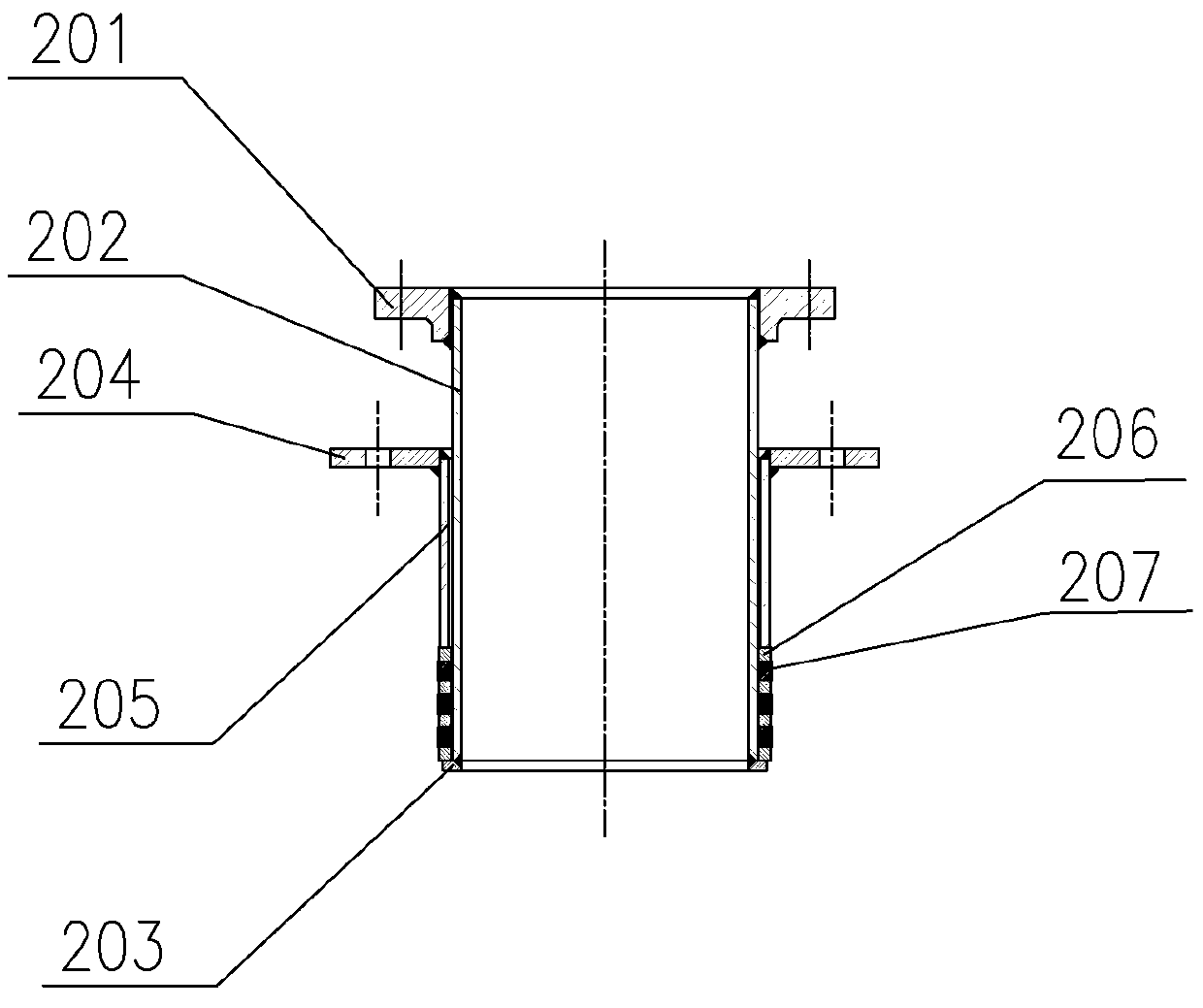

[0023] Such as Figure 4 As shown, the intersection of the center lines of the main steel pipe 101 and the secondary steel pipe 102 is set as the reference point, and the axial adjustment distance of each interface flange is ±50mm. Therefore, the reference point can be adjusted in the axial direction of the main steel pipe 101. It is ±100mm, and the adjustment distance in the axial direction of the secondary steel pipe 102 is ±50mm. In combination, the reference point can be adjusted within a parallelogram range. This performance feature can make the present invention have a great position adjustment in practical application Installation ability. For installed pipelines, the adjusting flange of the present invention can effectively eliminate the influence of the axial force generated by thermal expansion and contraction.

[0024] Installation operation of the present invention:

[0025] When installing the connecting pipe on site, first loosen the bolt assembly 5, ma

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap