Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Mechanical machines/dredgers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

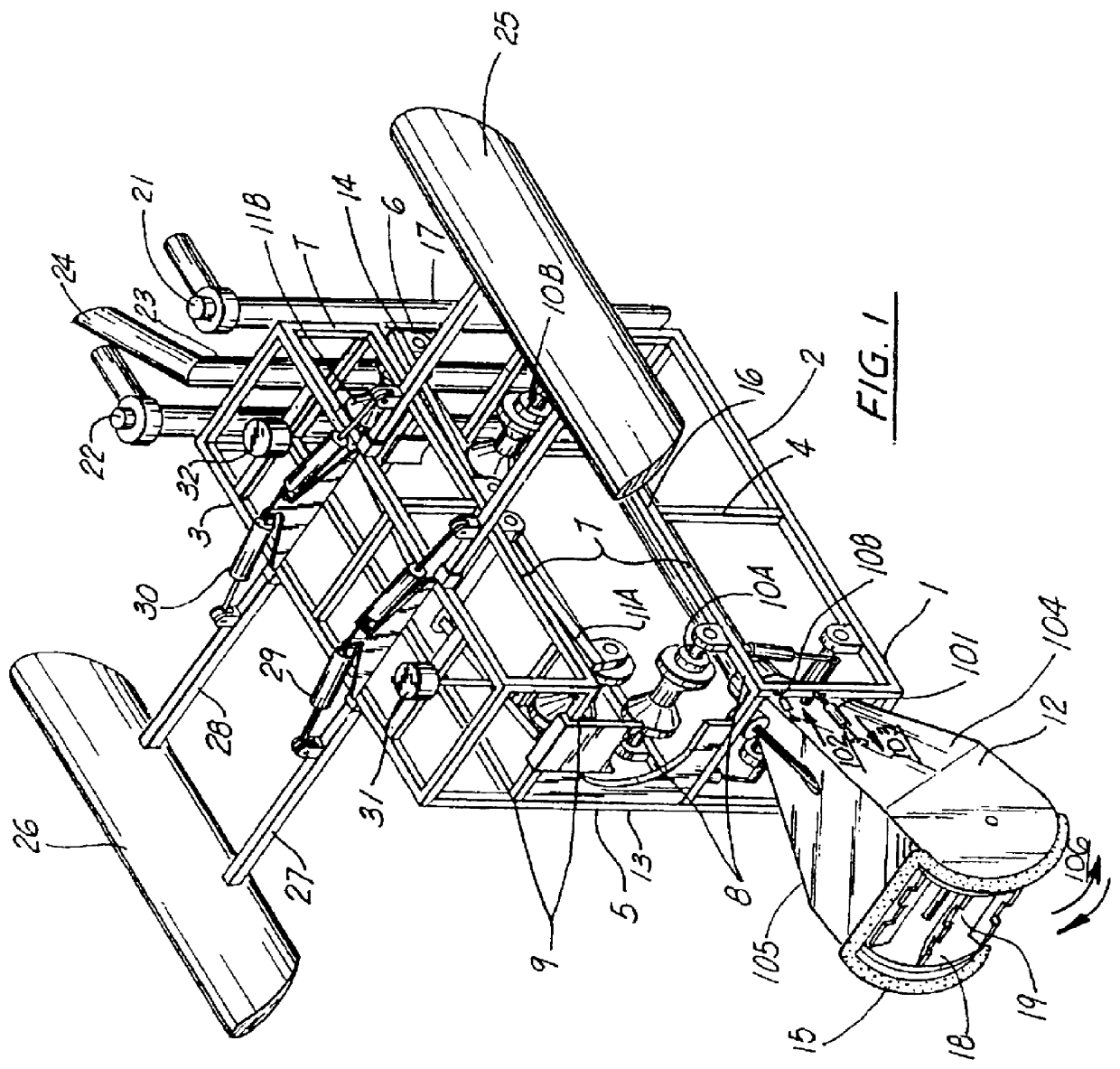

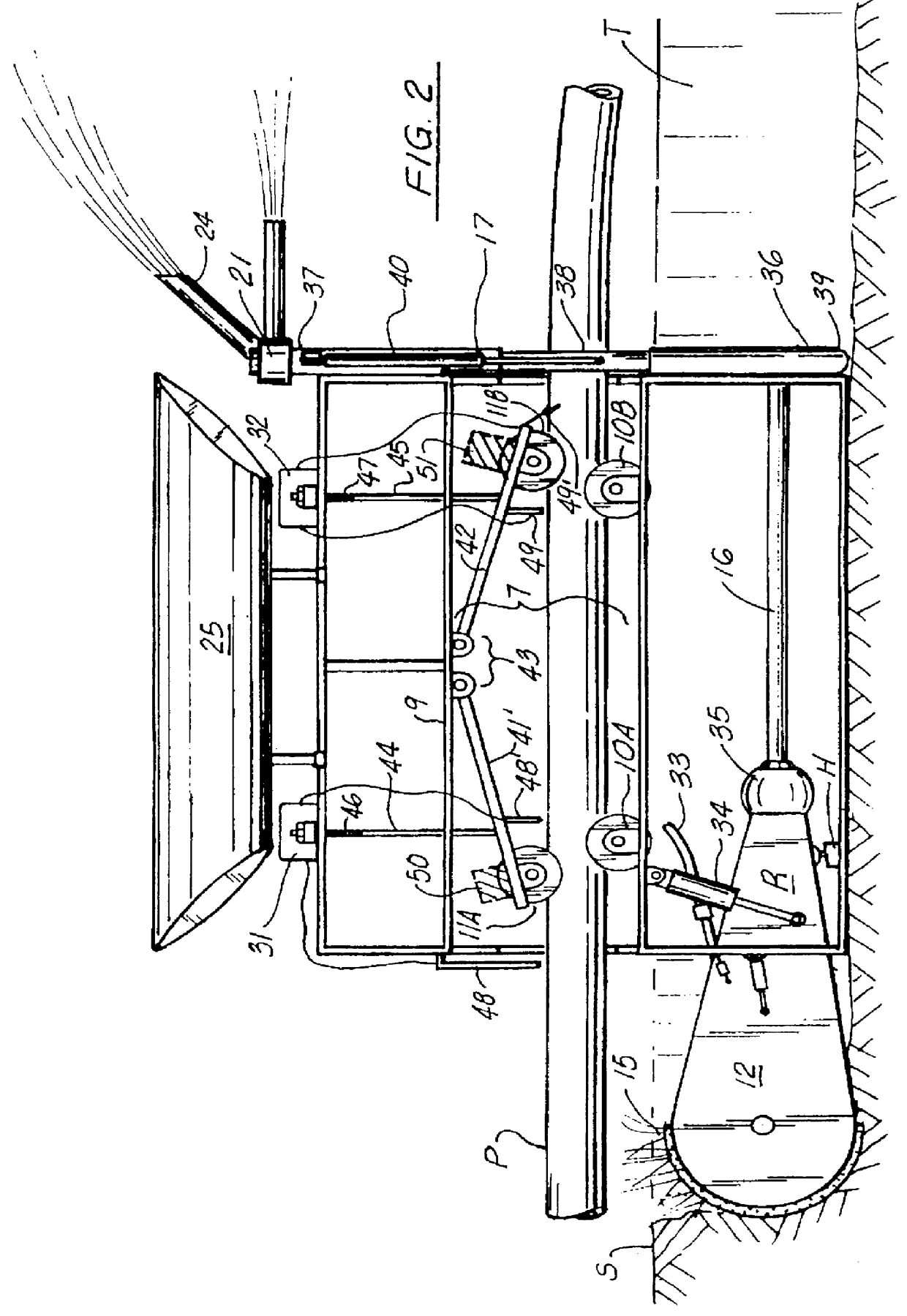

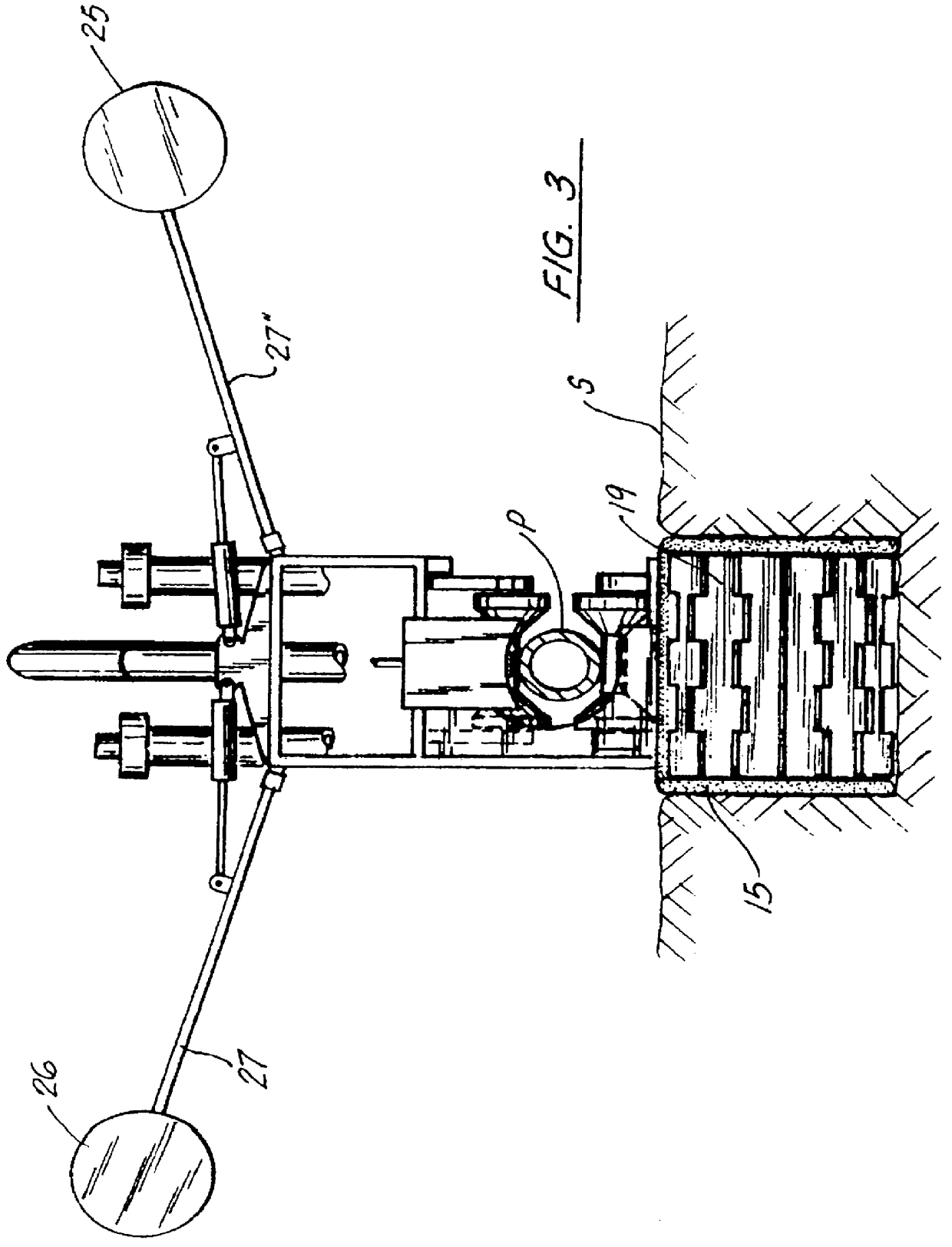

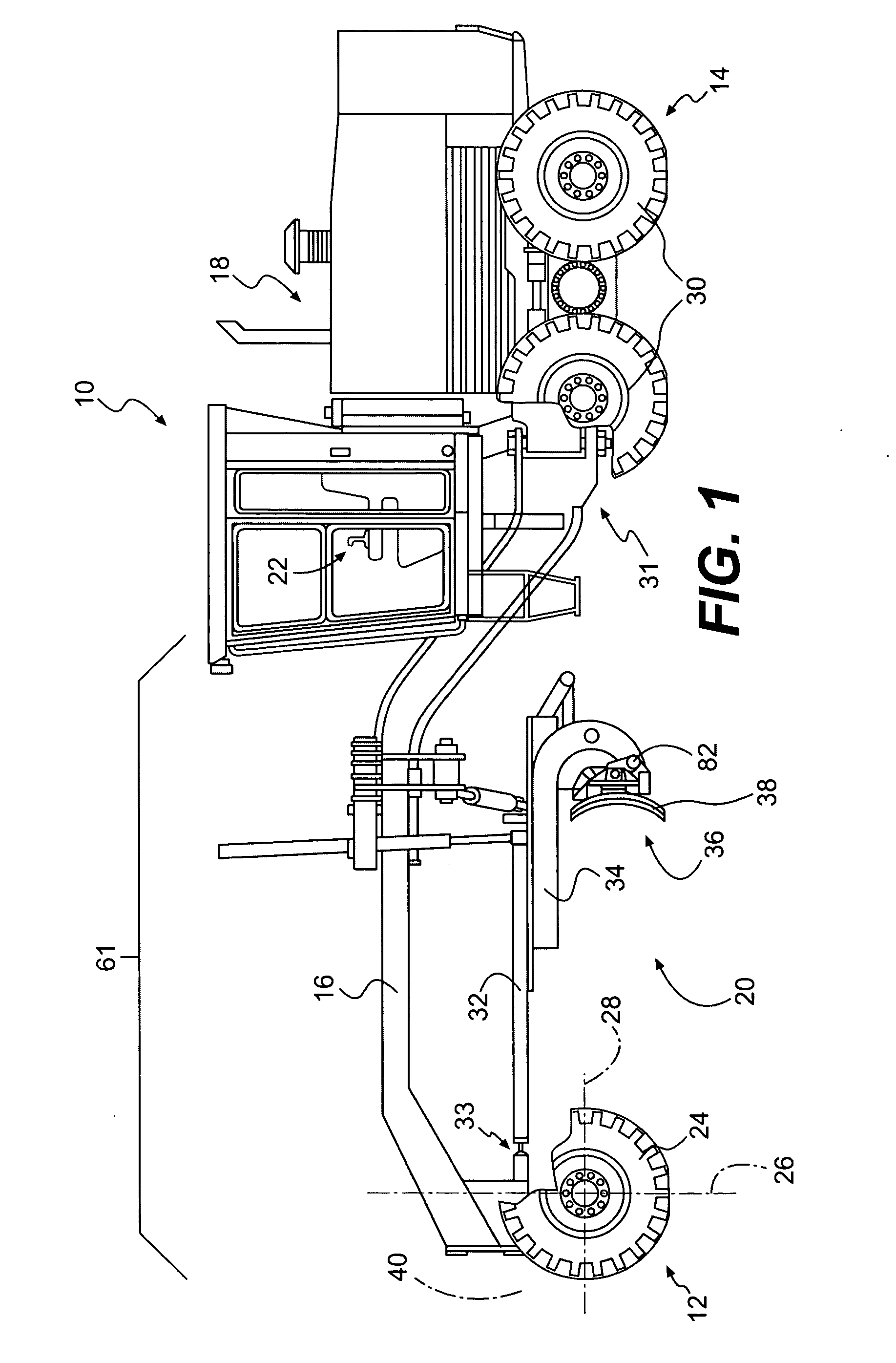

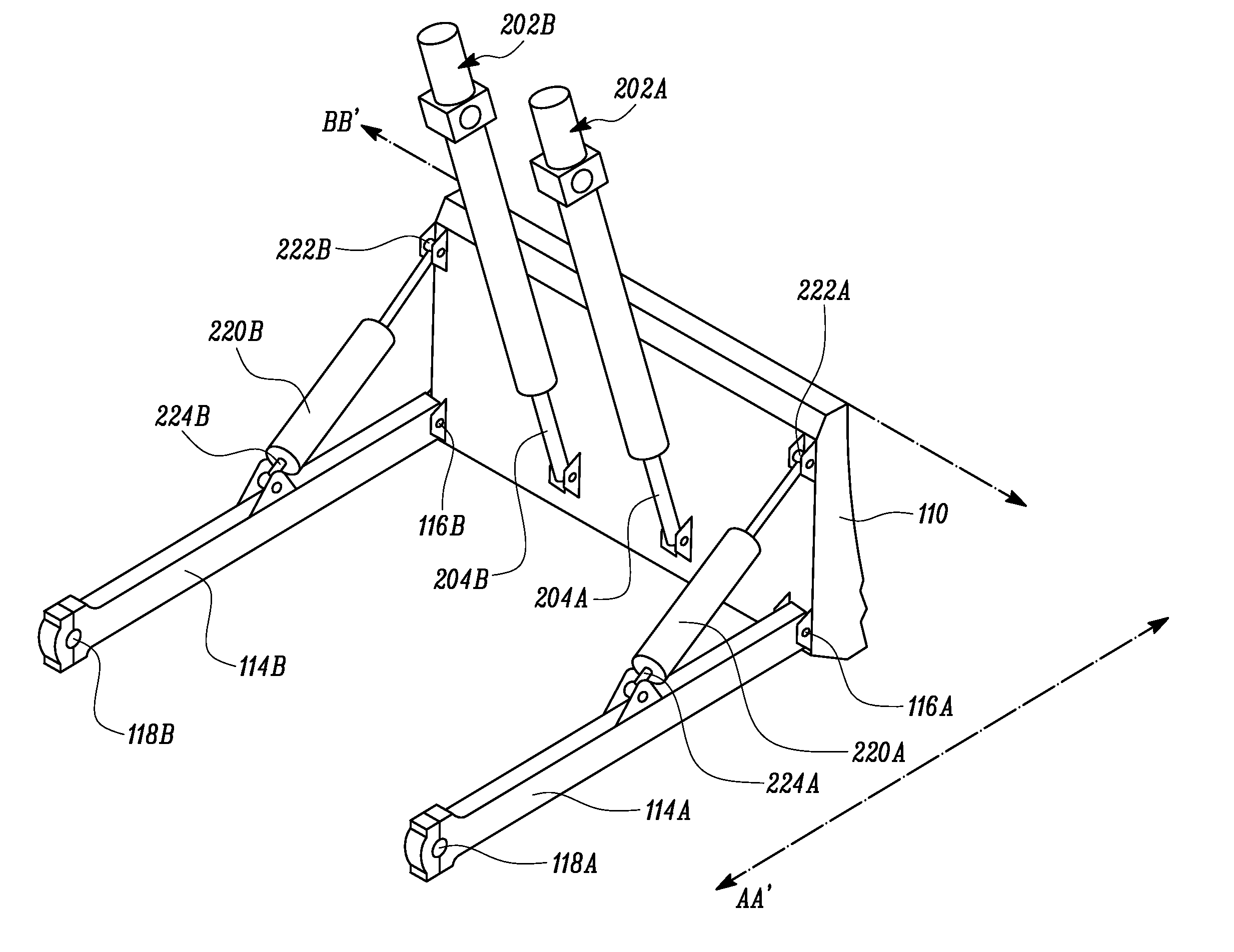

Underwater trenching system

InactiveUS6022173AImprove reliabilityProcess economyPipe laying and repairMechanical machines/dredgersData transmissionSelf guided

Owner:SAXON SAINT E

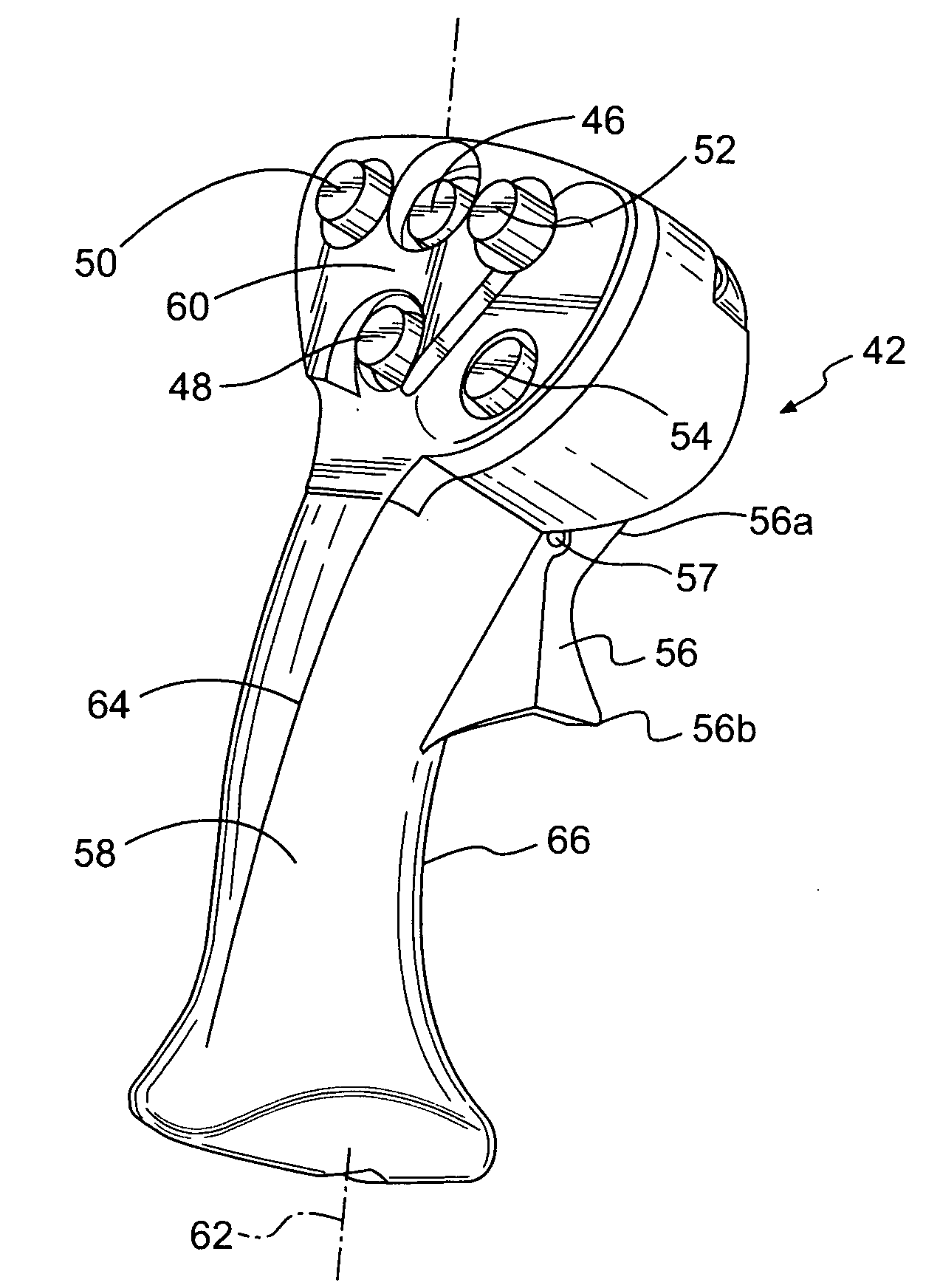

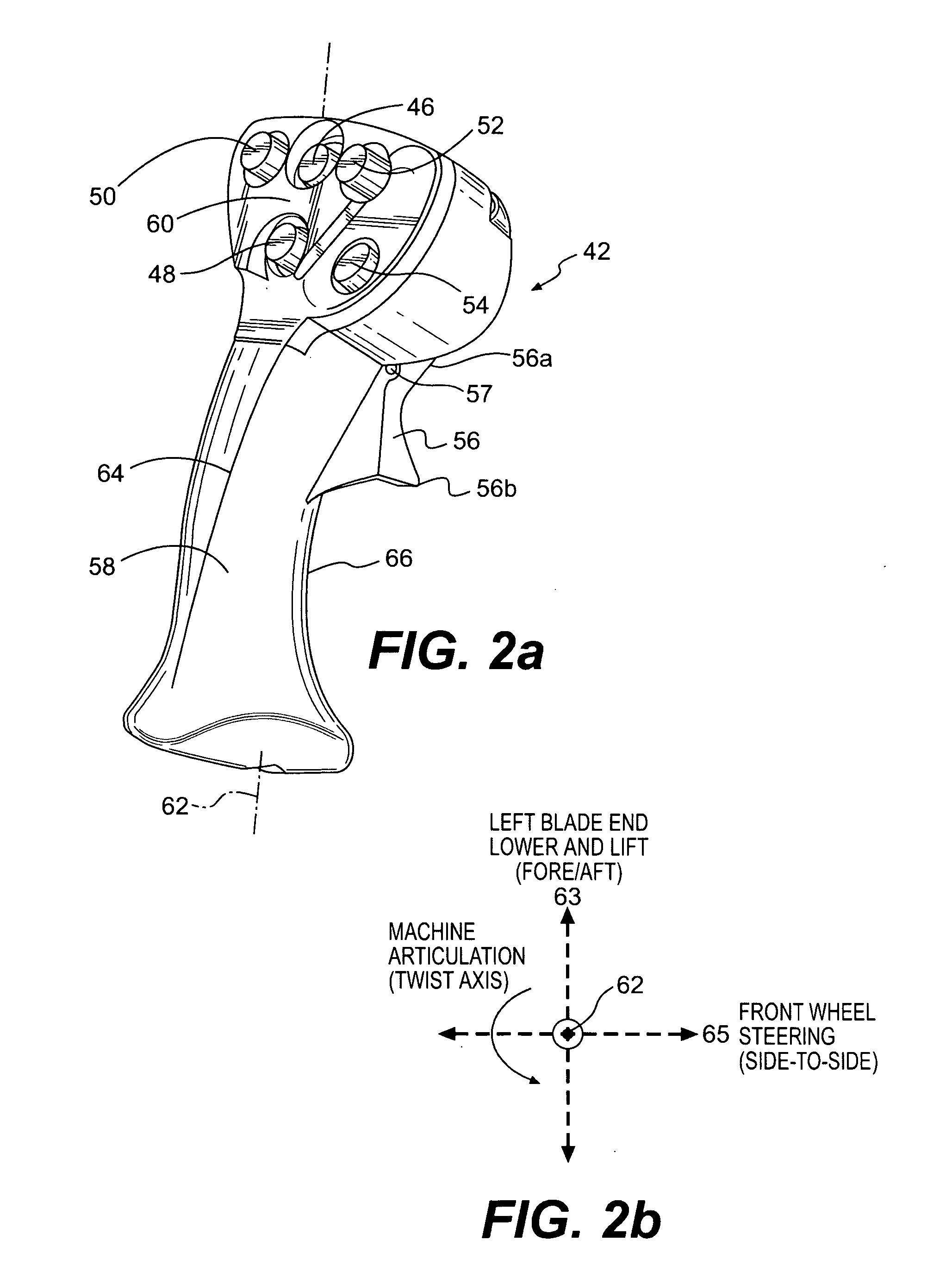

Work machine joystick control system

ActiveUS20050279561A1Controlling membersManual control with multiple controlled membersJoystickControl system

Owner:CATERPILLAR INC

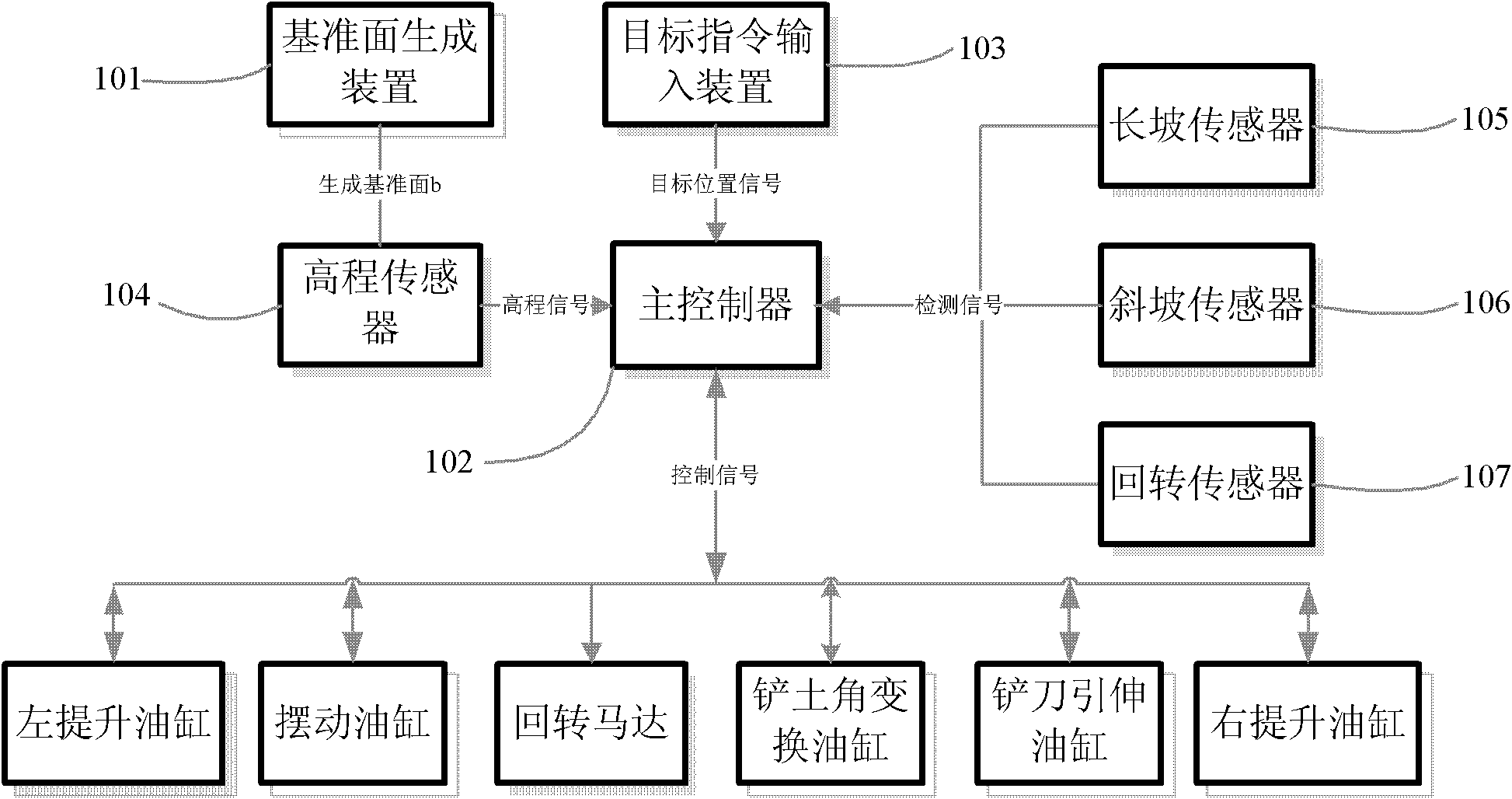

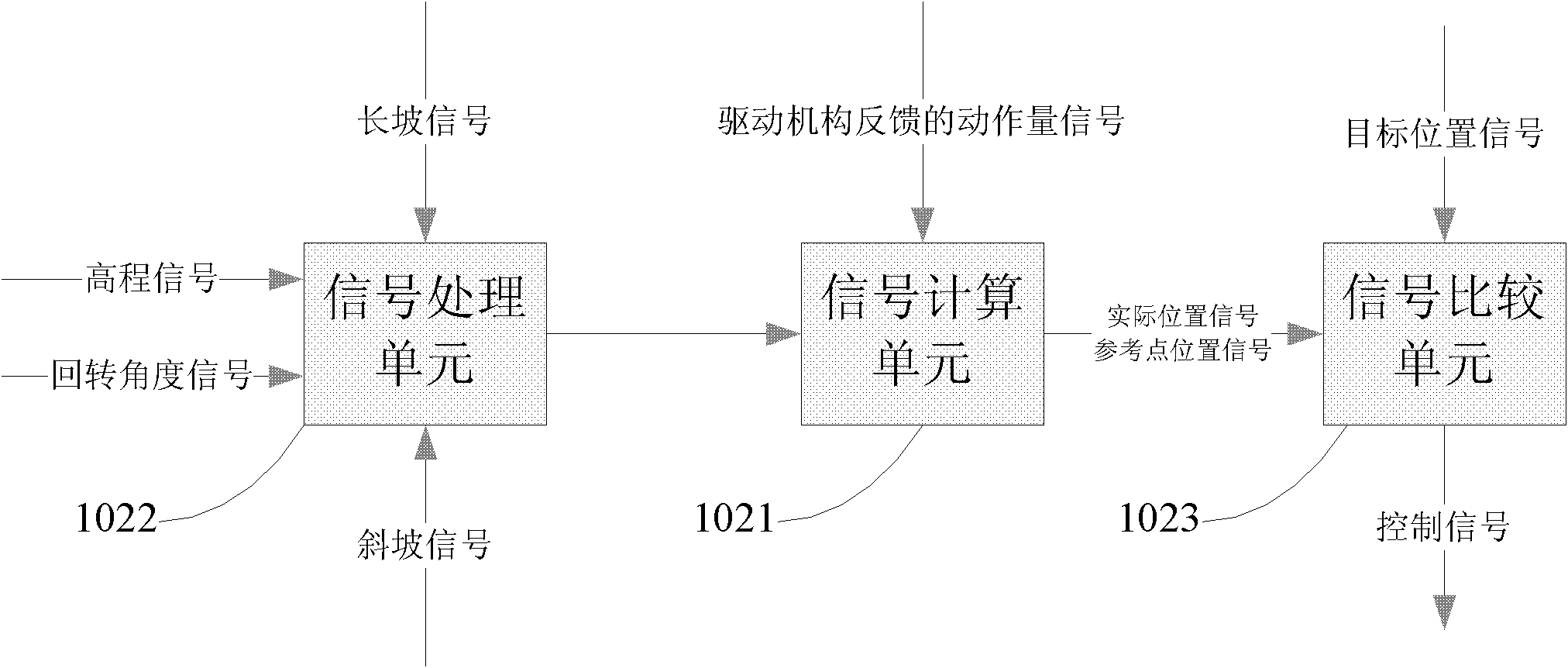

Land leveler leveling control system, control method and land leveler

Owner:SANY HEAVY IND CO LTD (CN)

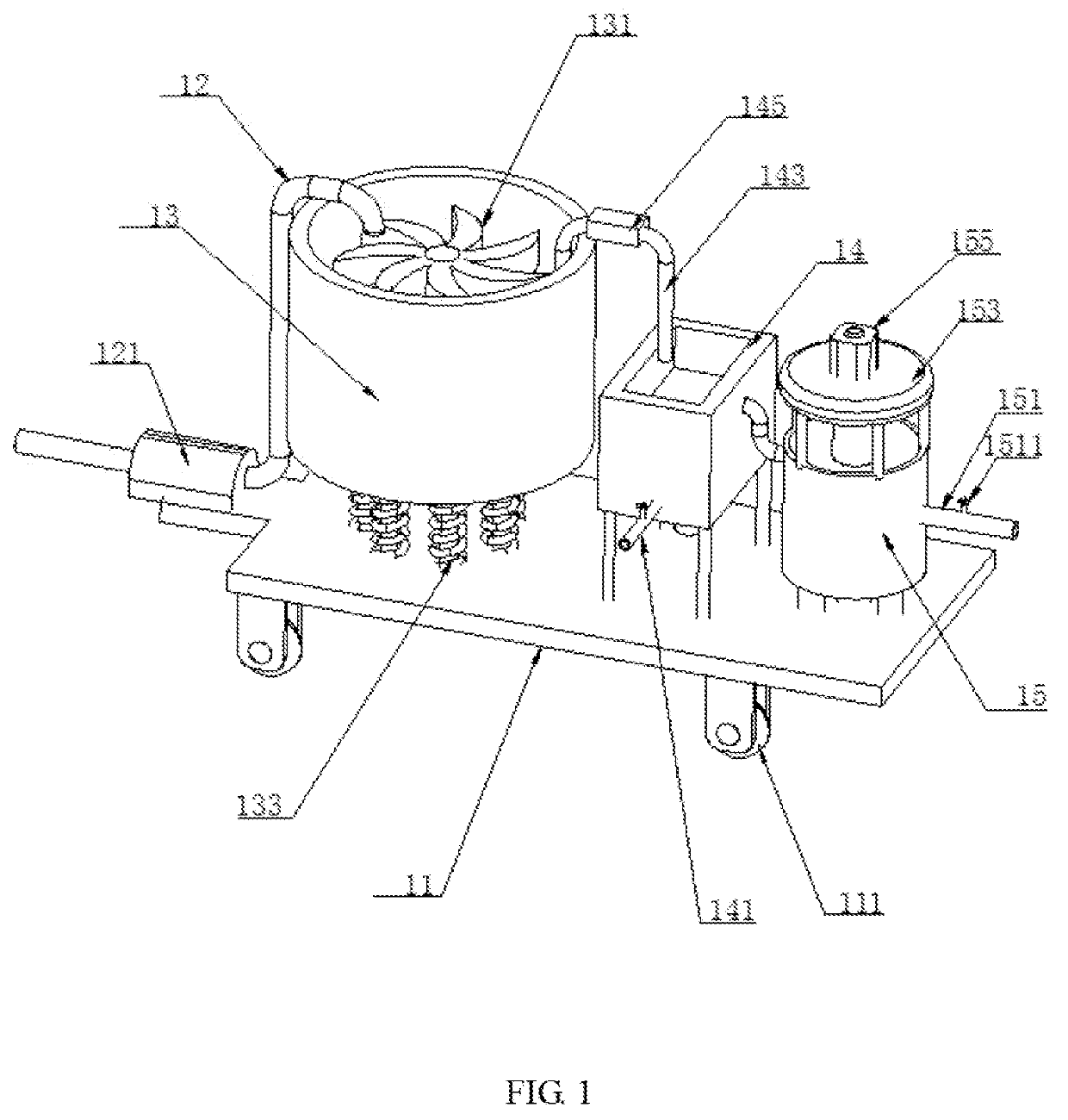

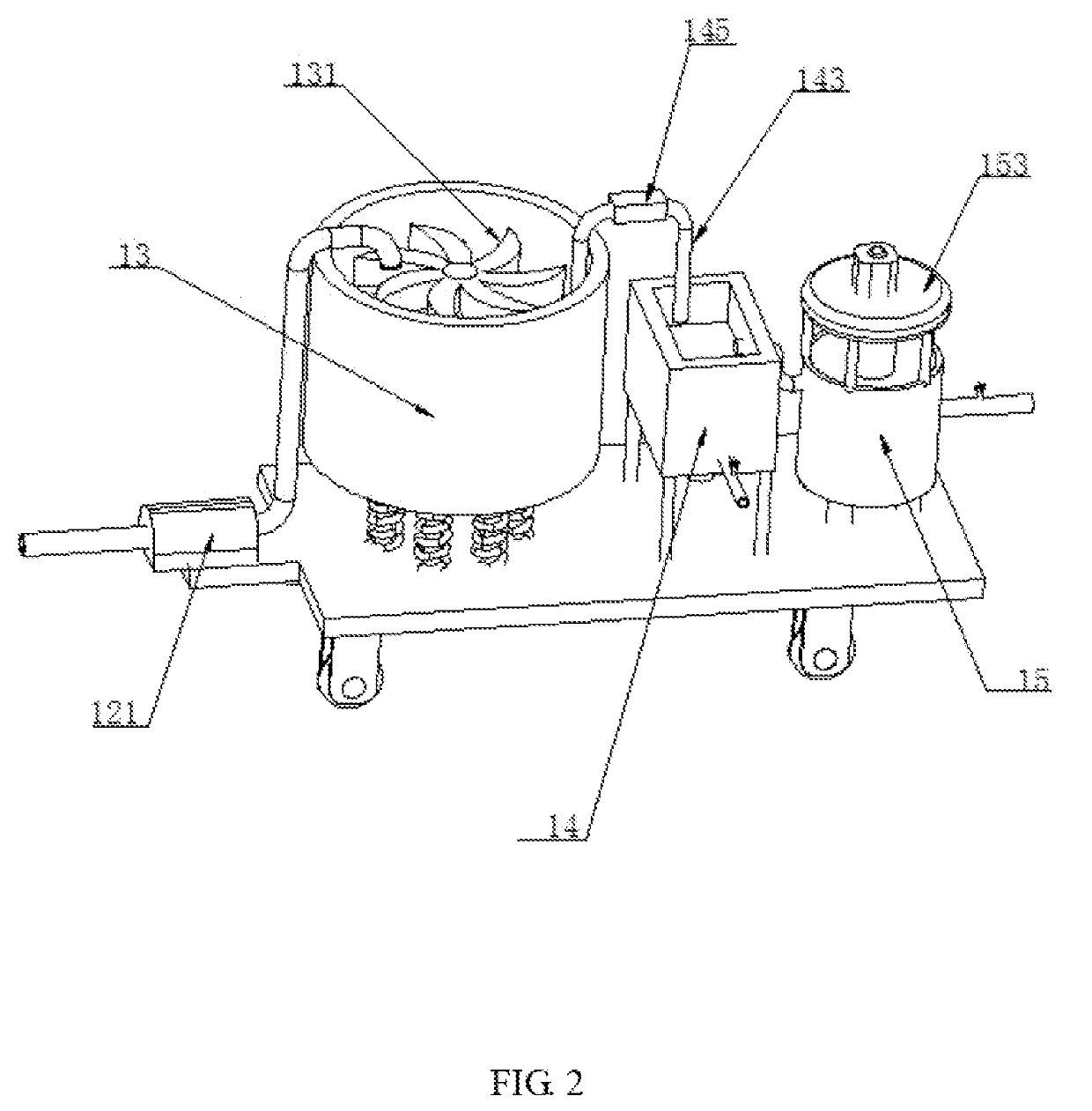

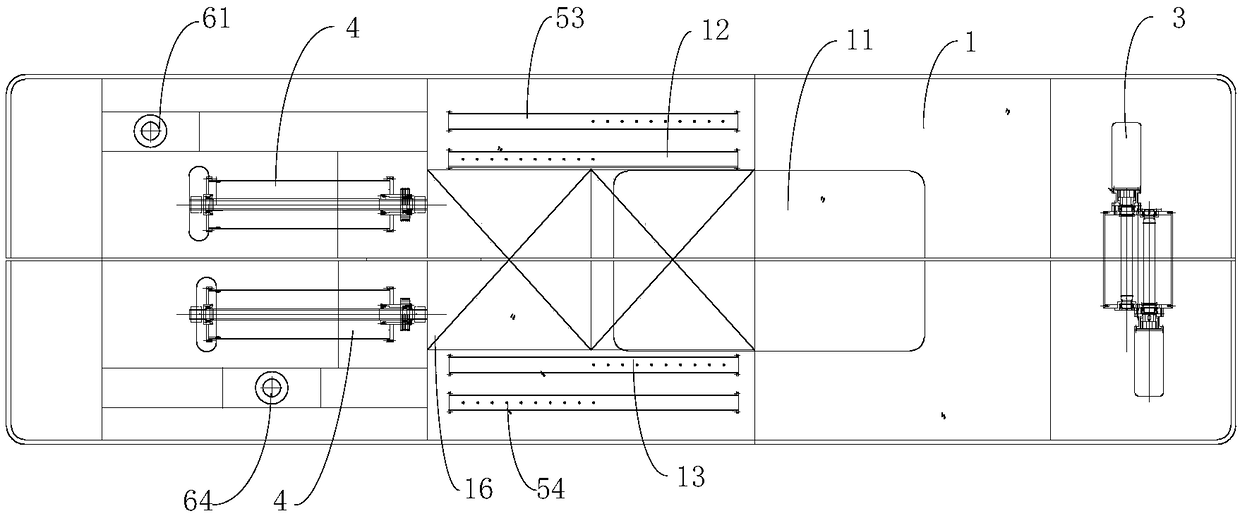

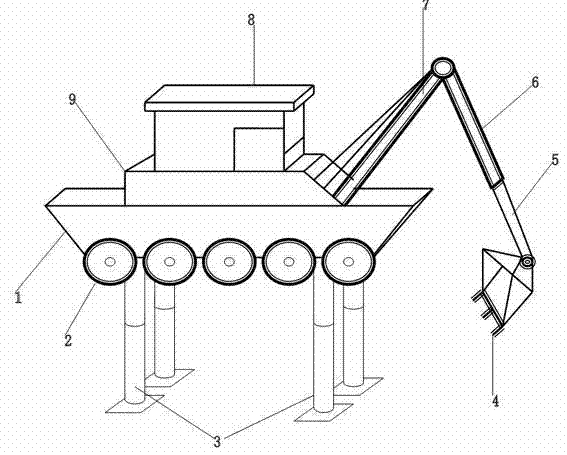

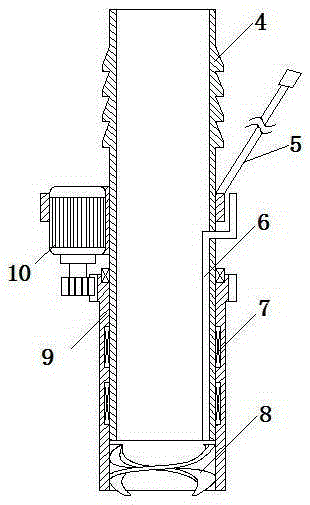

Suction sludge dewatering sand dredger

InactiveCN102121256AAdaptableEasy to operateWaterborne vesselsMechanical machines/dredgersWastewaterDewatered sludge

The invention relates to a suction sludge dewatering sand dredger which is characterized in that a sludge processing device is arranged on a boat body and comprises an extracting unit, a sieving unit, a heavy metal processing unit, a dewatering unit, a deodorizing unit, a dewatered sludge collecting unit and a wastewater processing and discharging unit. In the invention, the integral design of sediment dewatering processing device for urban landscape water pollution is realized; the sludge is immediately dried and dewatered while dredging; and the processed sludge can be directly used in the agricultural field, therefore, the pollution on the environment is avoided.

Owner:TIANJIN UNIV OF SCI & TECH

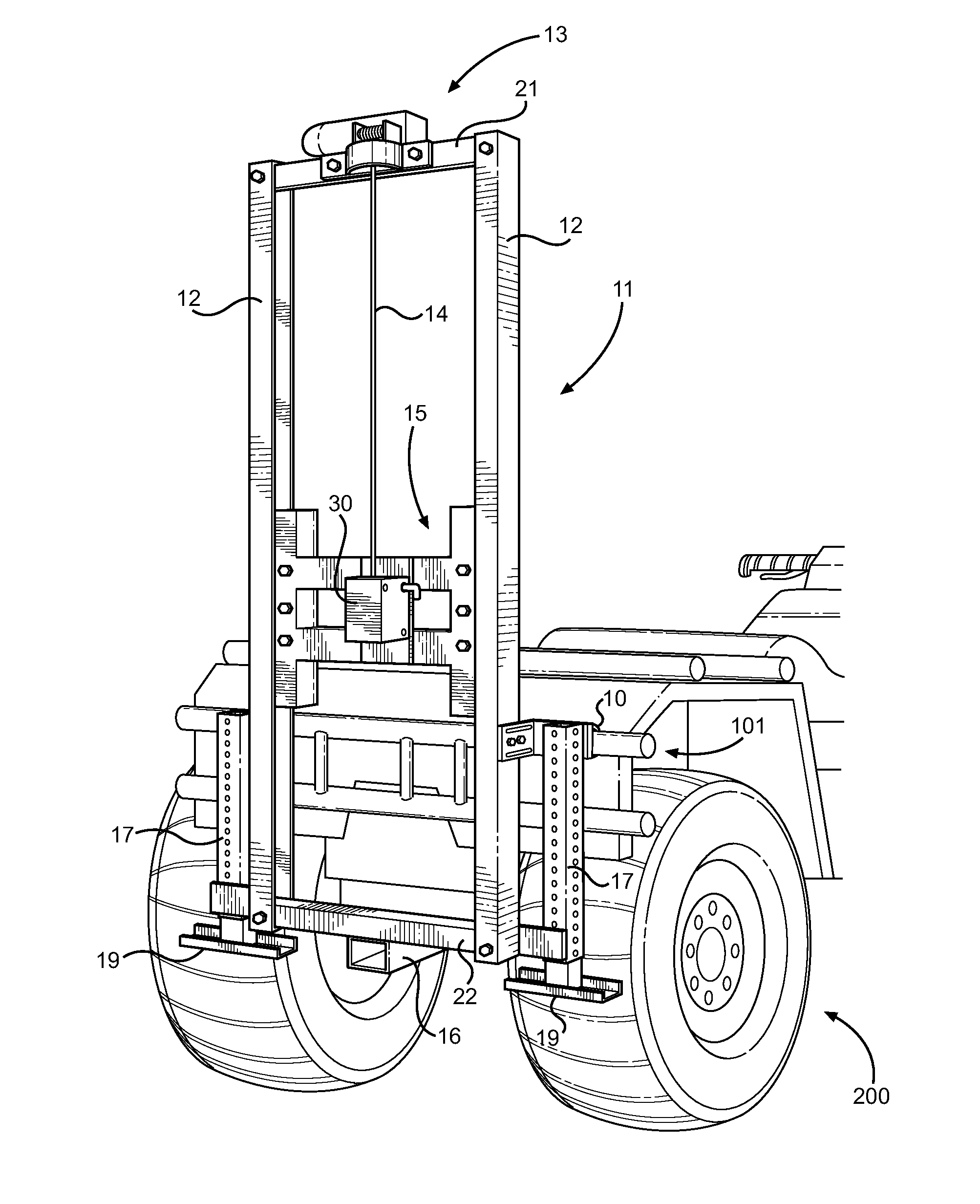

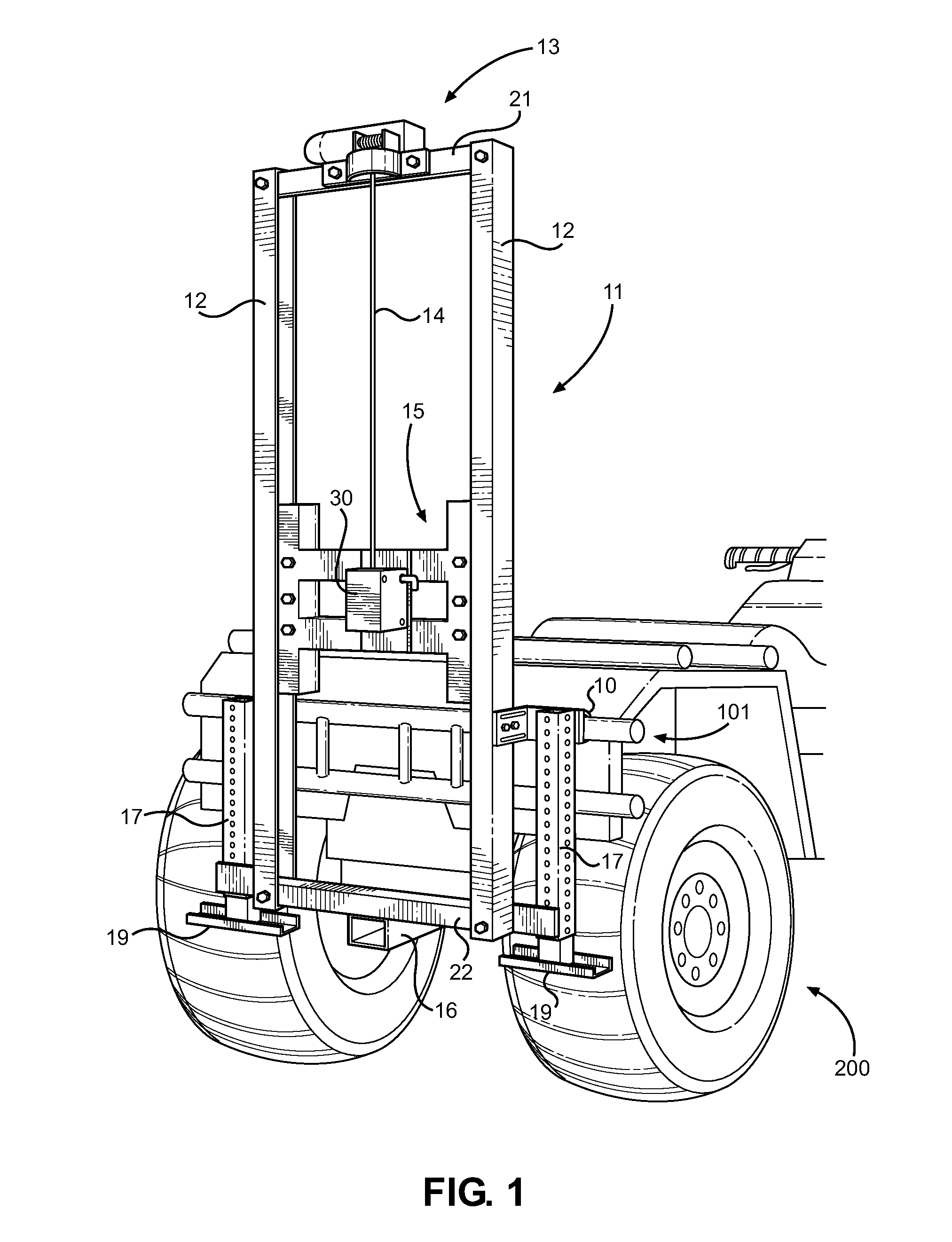

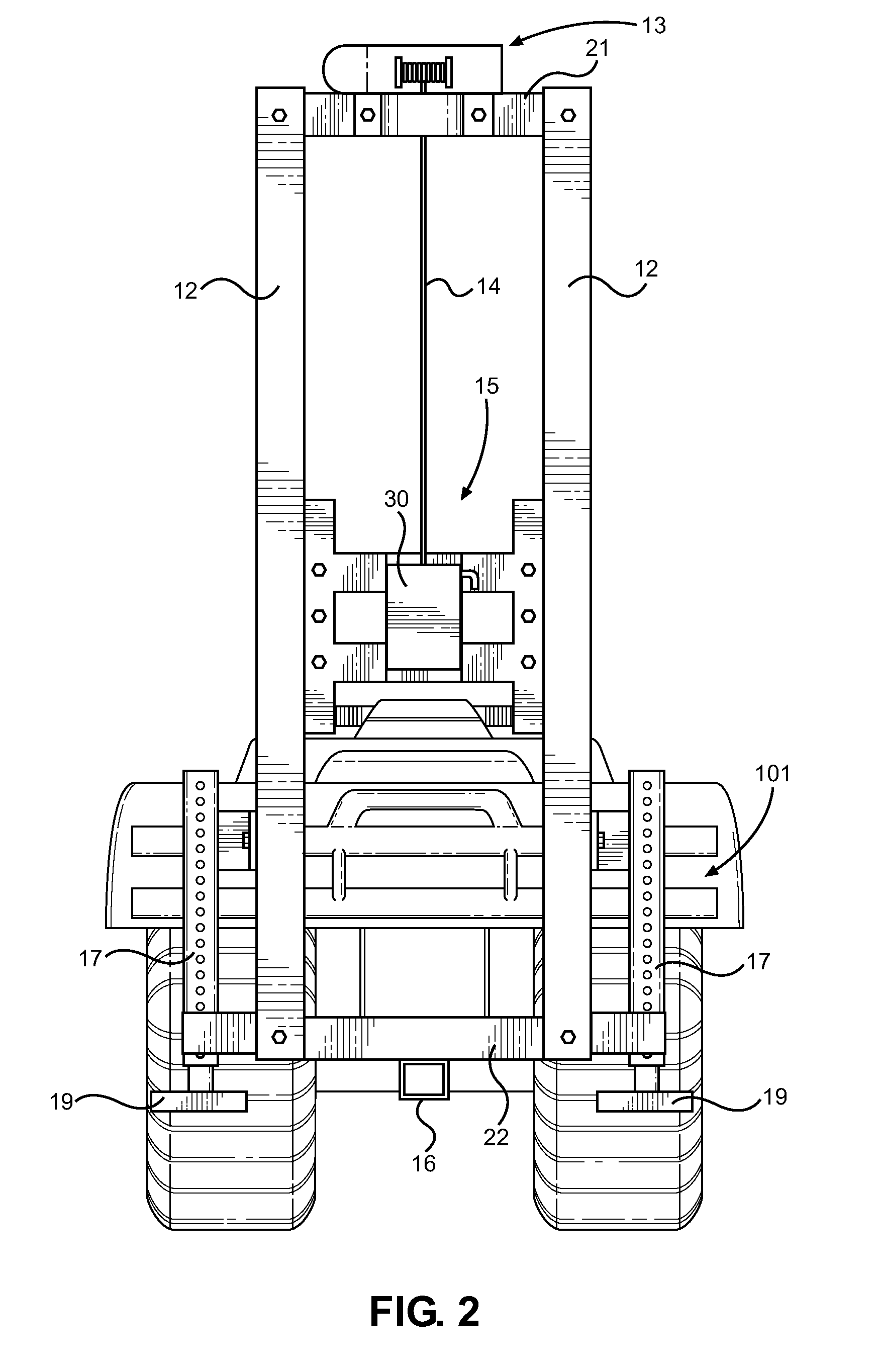

Vehicle-Attached Lifting and Tool Support Device

Owner:ROBINSON JAMES ALLEN +1

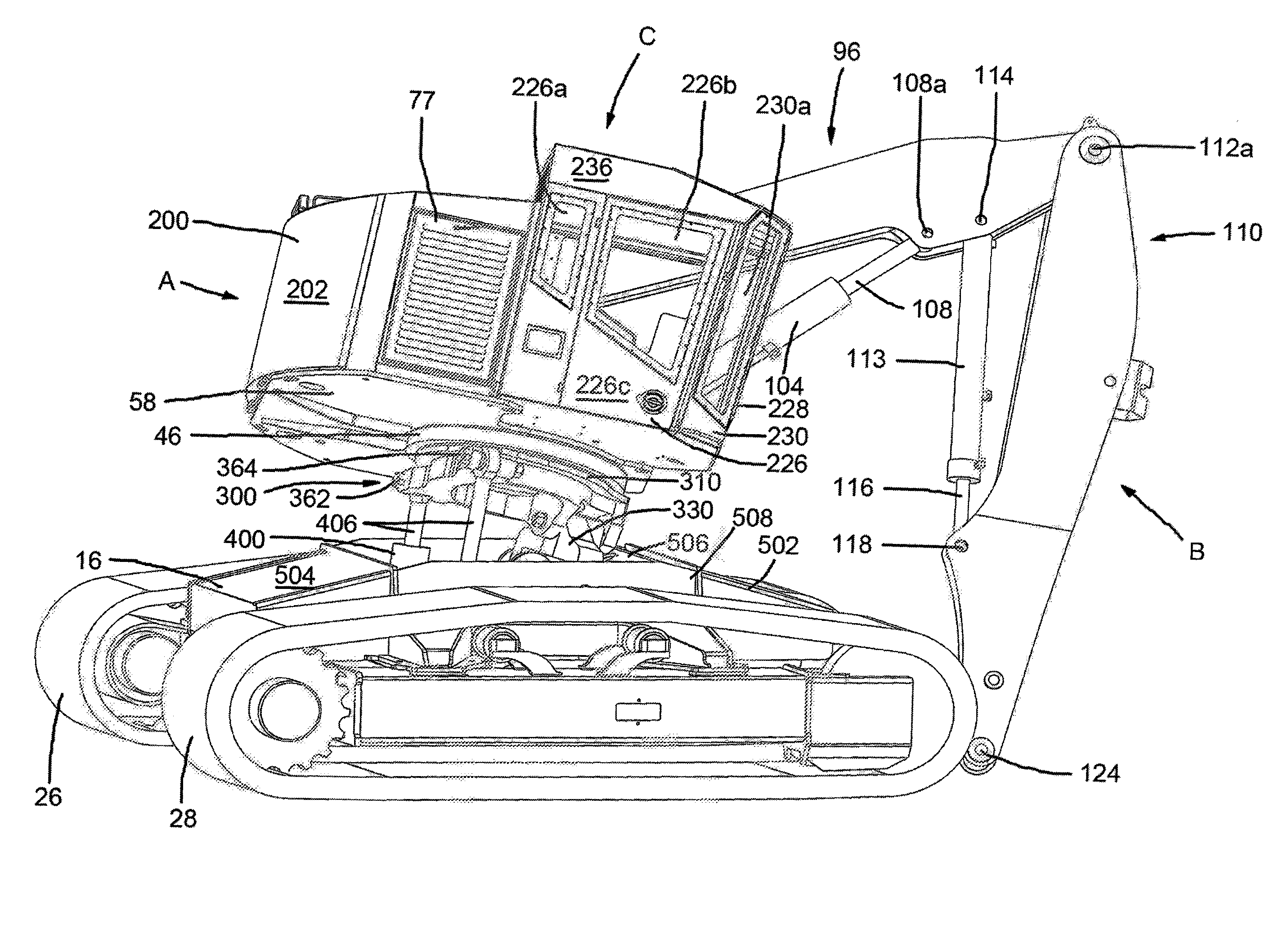

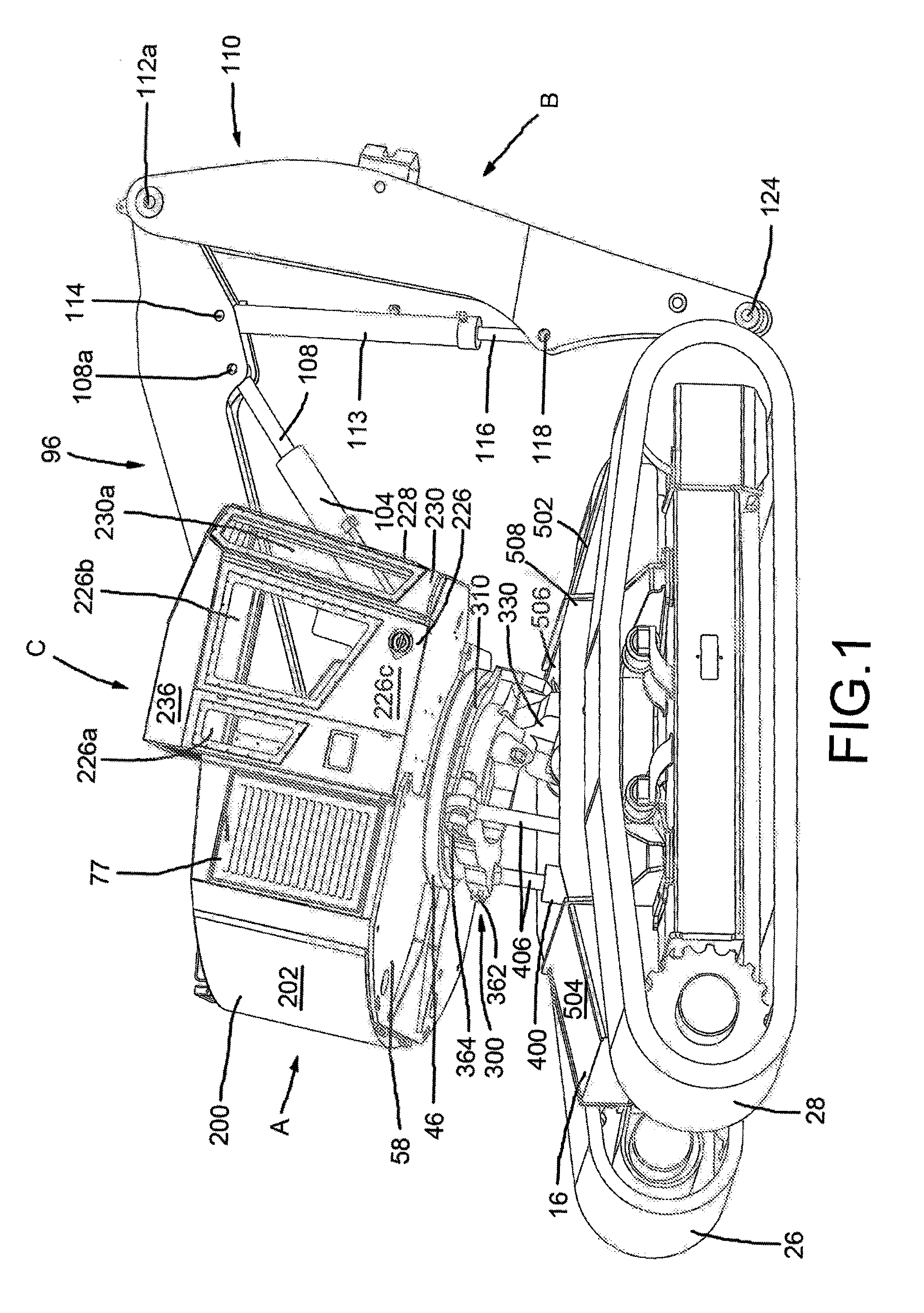

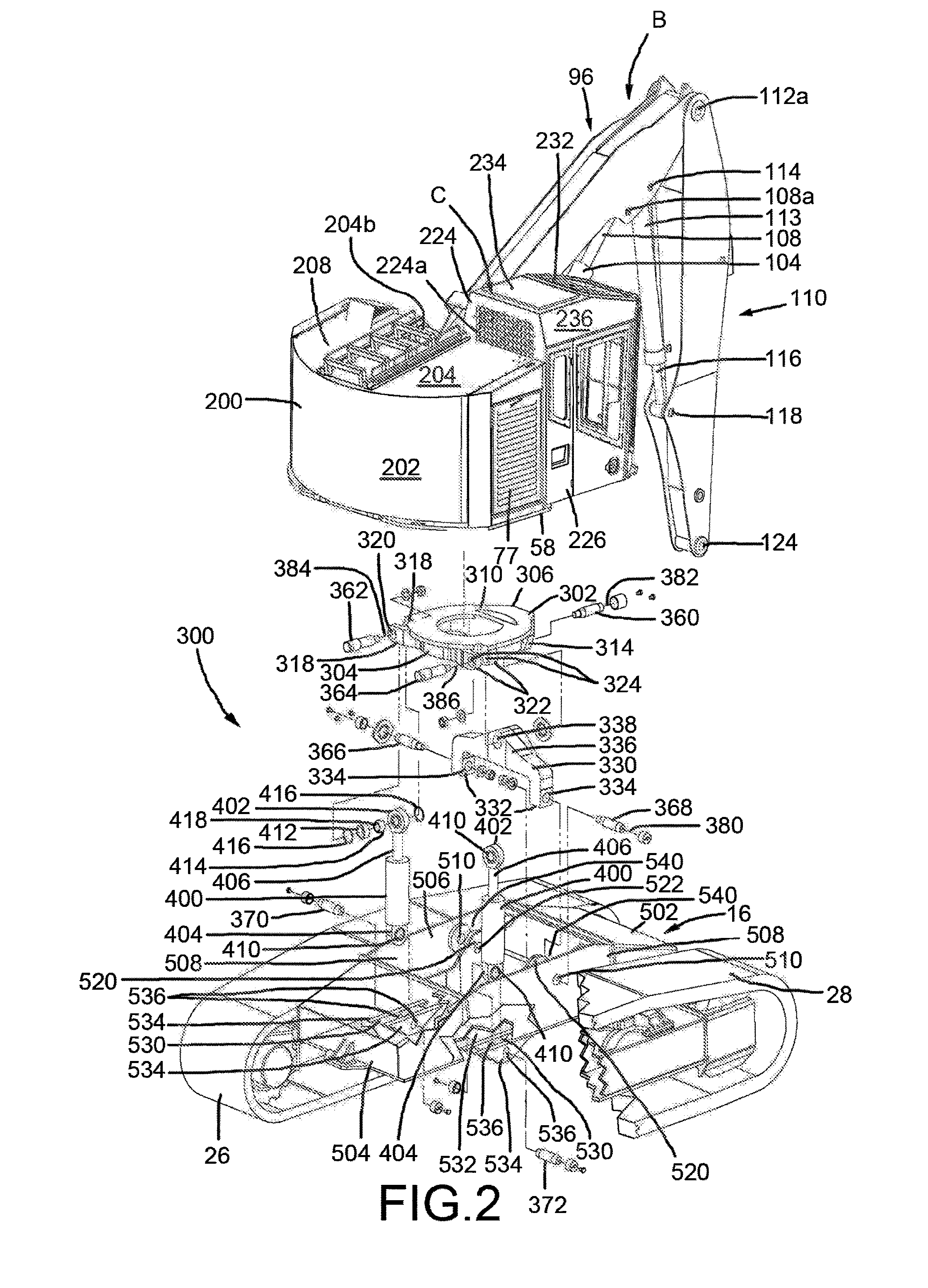

Tilt Device for a Material Handling Machine

ActiveUS20100264694A1Reduce the overall heightLess limitationVehicle seatsMechanical machines/dredgersEngineeringMechanical engineering

Owner:TIMBERPRO

Water conservating silt discharging device

ActiveUS20190242091A1Reasonable structural designEasy to useMechanical machines/dredgersFiltration circuitsHigh definitionSilt

A water conserving silt discharging device includes a moving bottom plate. A first material conveying water pump, a stirring box, a filler box and a compression box are sequentially arranged on an upper portion of the moving bottom plate. And a roller mechanism is arranged on each of four diagonal portions of a lower portion of the moving bottom palate. A controller, an infrared sensor and a high-definition camera assembly are arranged on the upper portion of the moving bottom plate. The first material conveying water pump conveys silt material to the stirring box through a convey pipe. A jitter mechanism assembly is arranged at a bottom portion of the stirring box to generate jittering. The jitter mechanism assembly comprises a plurality of identically shaking spring bodies and a driving cylinder arranged on the shaking spring bodies.

Owner:LIU XIAOJUN

Production process of steel pile structure of cutter suction dredger

InactiveCN101812856AImprove manufacturing precisionEasy to manufactureMechanical machines/dredgersEngineeringMechanical engineering

The invention discloses a production process of the steel pile structure of a cutter suction dredger. The production process comprises the following steps: blanking boards, preparing a jig, machining and bending, performing sectionalized assembly of round tubes, performing integral-type assembling, measuring pin holes, positioning and installing, coating, removing the jig, etc. the invention has the advantages of high production precision, convenient preparation and good operational effect.

Owner:NAN TONG GANG ZHA CHUAN BO ZHI ZAO YOU XIAN GONG SI

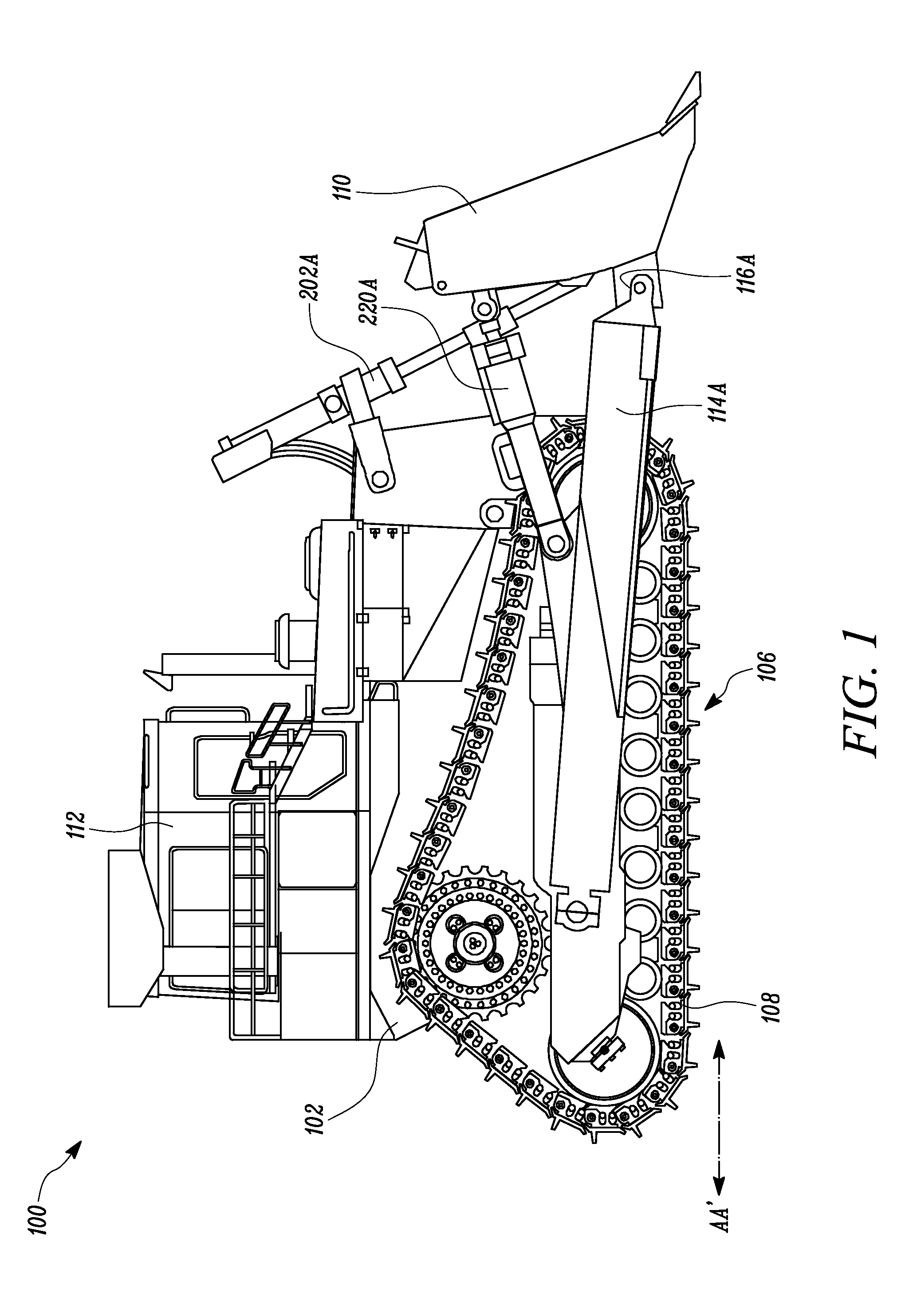

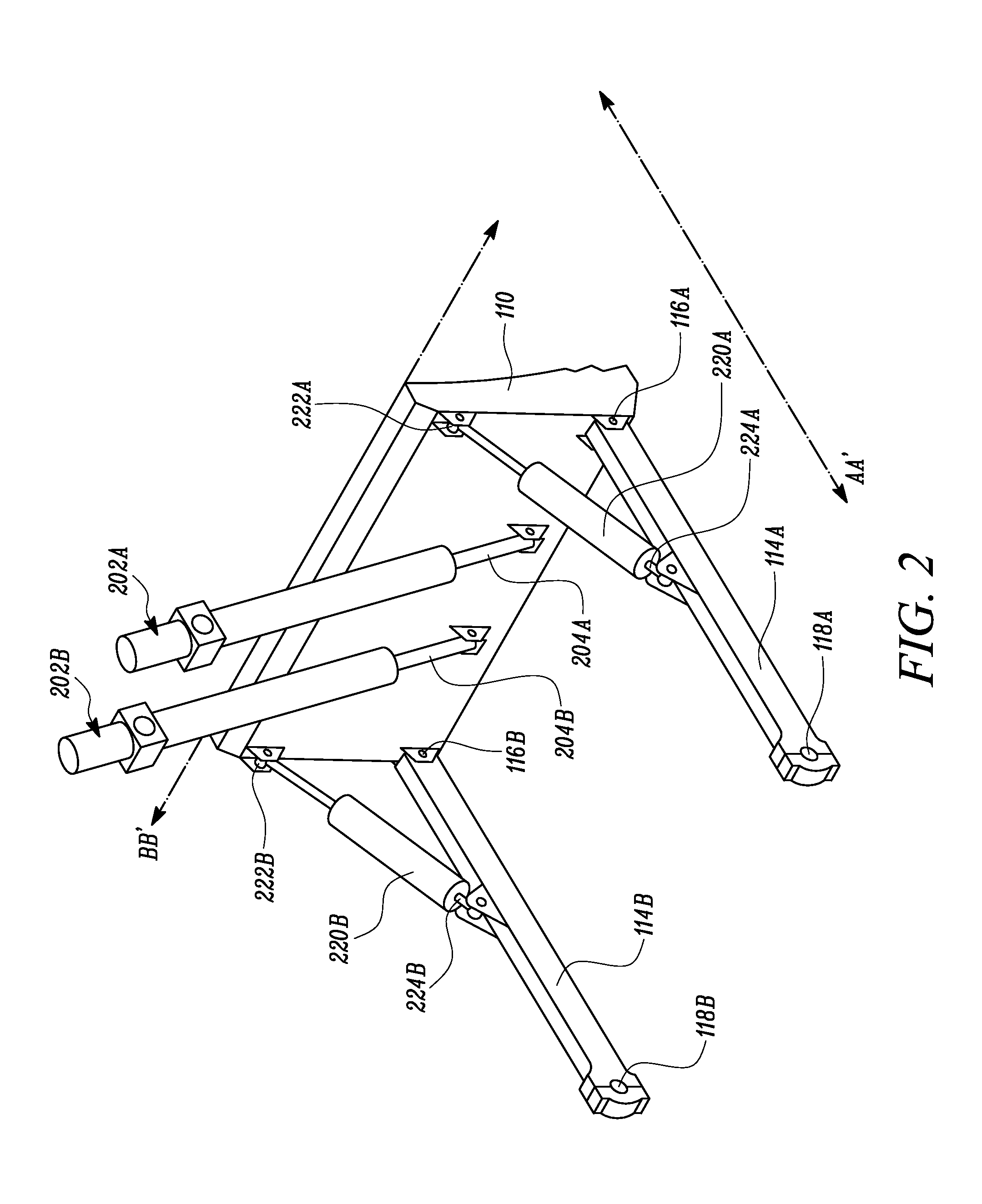

System and method for controlling a machine implement

Owner:CATERPILLAR INC

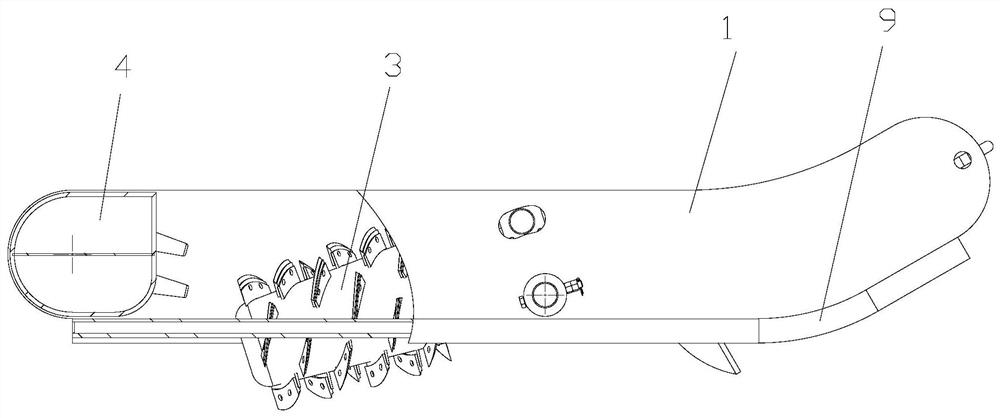

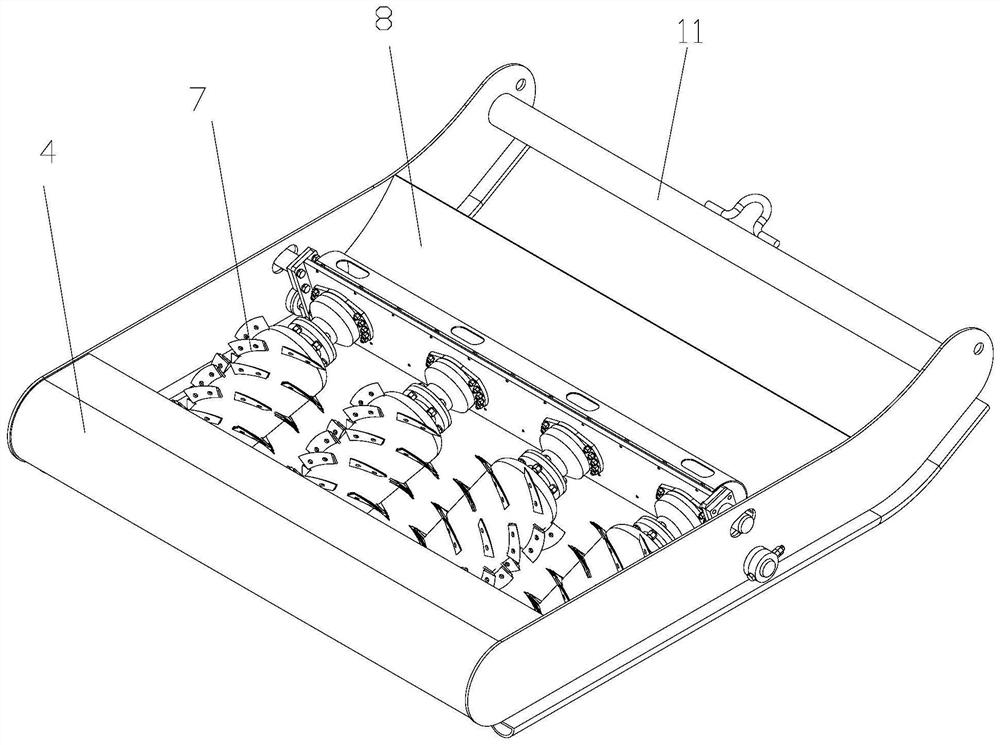

Milling excavation device and dredger with milling excavation device

PendingCN108166555ARealize continuous milling and diggingHigh milling efficiencyMechanical machines/dredgersGrain treatmentsEngineering

Owner:广州市昊力工具有限公司

Amphibious efficient excavator

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Small-sized bowing grass mower

ActiveCN102433903AReasonable structureEasy to useMechanical machines/dredgersAgricultural engineeringTurning radius

The invention discloses a small-sized bowing grass mower, which comprises a front vertical column seam, a rear girder seam, an engine, a front axle assembly, a rear axle and a large arm of a small-sized tractor. The rear end of the large arm is hinged with the front vertical column seam, a large arm oil cylinder is hinged between the large arm and the front vertical column seam, the front vertical column seam is fixedly connected with the front axle assembly, the rear girder seam is fixedly connected with the rear axle of the small-sized tractor, the front vertical column seam and the rear girder seam are hinged through a vertical shaft part and a balance shaft part, a steering oil cylinder is arranged on the rear girder seam, and the other end of the steering oil cylinder is hinged with the vertical column seam. The small-sized bowing grass mower has the advantages of being reasonable in structure, flexible and convenient in use, small in turning radius, not easy to turn over during turning and high in safety, particularly meeting the requirements of small-sized factories and mines and indoor loading, and the like.

Owner:LINYING COUNTY YING MACHINERY MFG

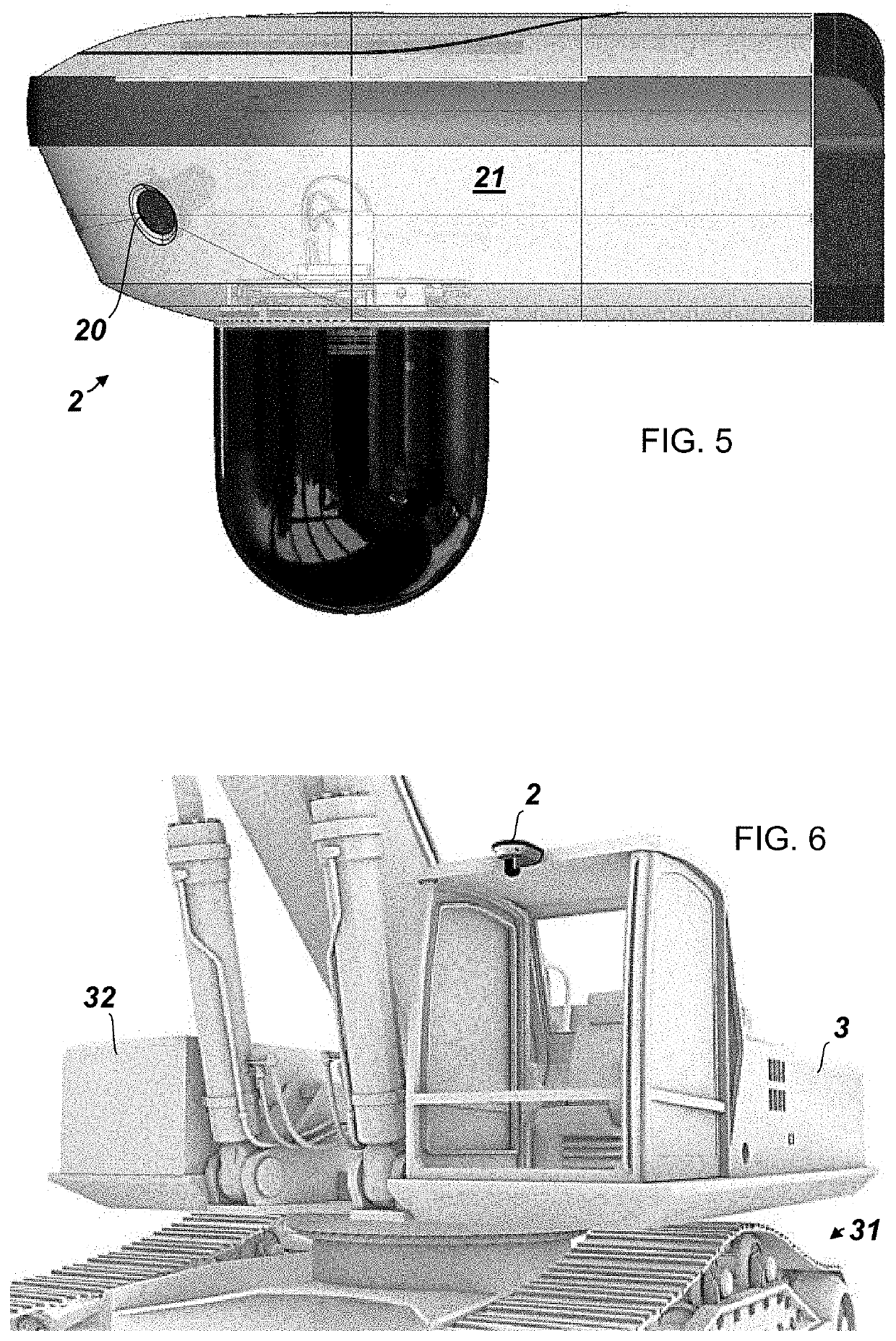

Energy-saving type bulldozing engineering machine capable of realizing convenient and fast observation of front and rear

InactiveCN106801444AIncrease light receiving areaIncrease production capacityPhotovoltaic supportsMechanical machines/dredgersCouplingPersonal computer

The invention discloses an energy-saving type bulldozing engineering machine capable of realizing convenient and fast observation of front and rear. The machine comprises a bulldozer body, wherein the middle-upper end of the bulldozer body is fixedly connected with an operation cab; the left-upper end of the bulldozer body is fixedly connected with a motor; a rotating end of the motor is fixedly connected with an air cylinder end of an electric telescopic rod; a telescopic rod end of the electric telescopic rod is fixedly connected with one end of a support shaft by a coupler; a first solar panel, a second solar panel and a third solar panel are arranged on the support shaft; the left end of the bulldozer body is fixedly connected with a storage battery; a tablet PC (personal computer) is fixed in the operation cab; a first support rod is fixed on the operation cab; a first camera is fixed on the first support rod; a second support rod is fixed on the bulldozer body; a second camera is fixed on the second support rod. The machine has the beneficial effects that observation is convenient in operation, and energy saving and environment protection are realized.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

Sludge suction system of sewage suction truck

Owner:HUNAN JINSONG AUTOMOBILE CO LTD

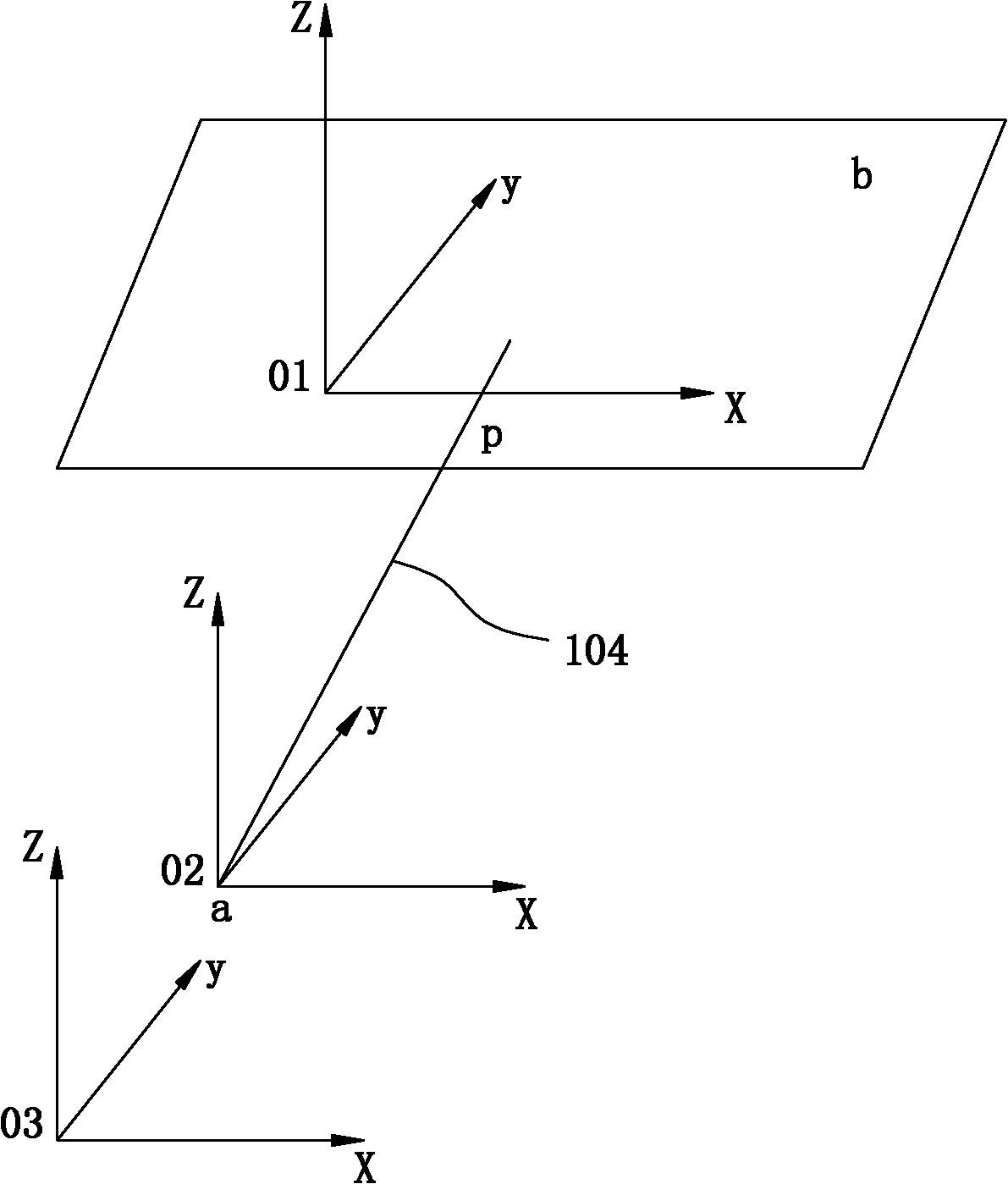

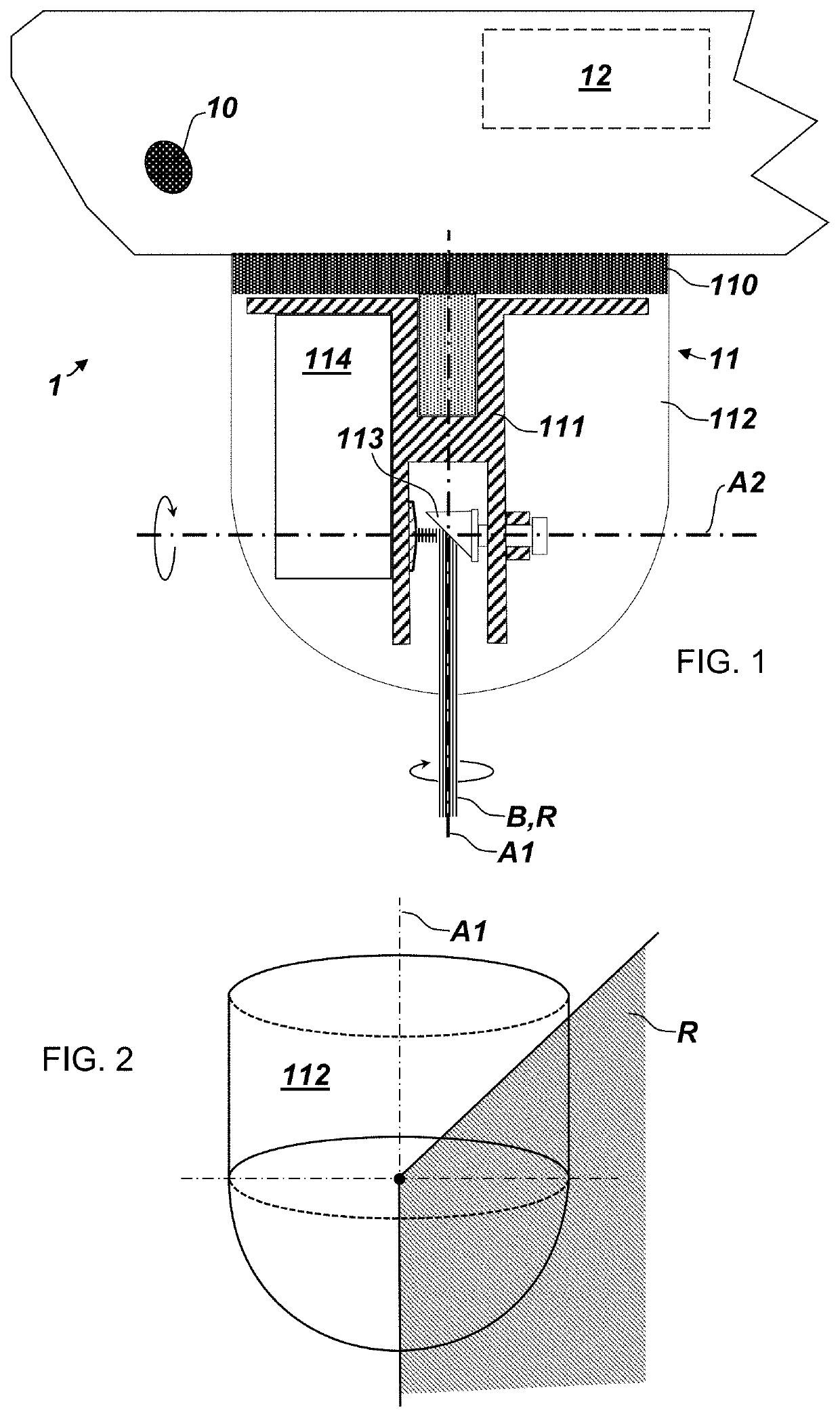

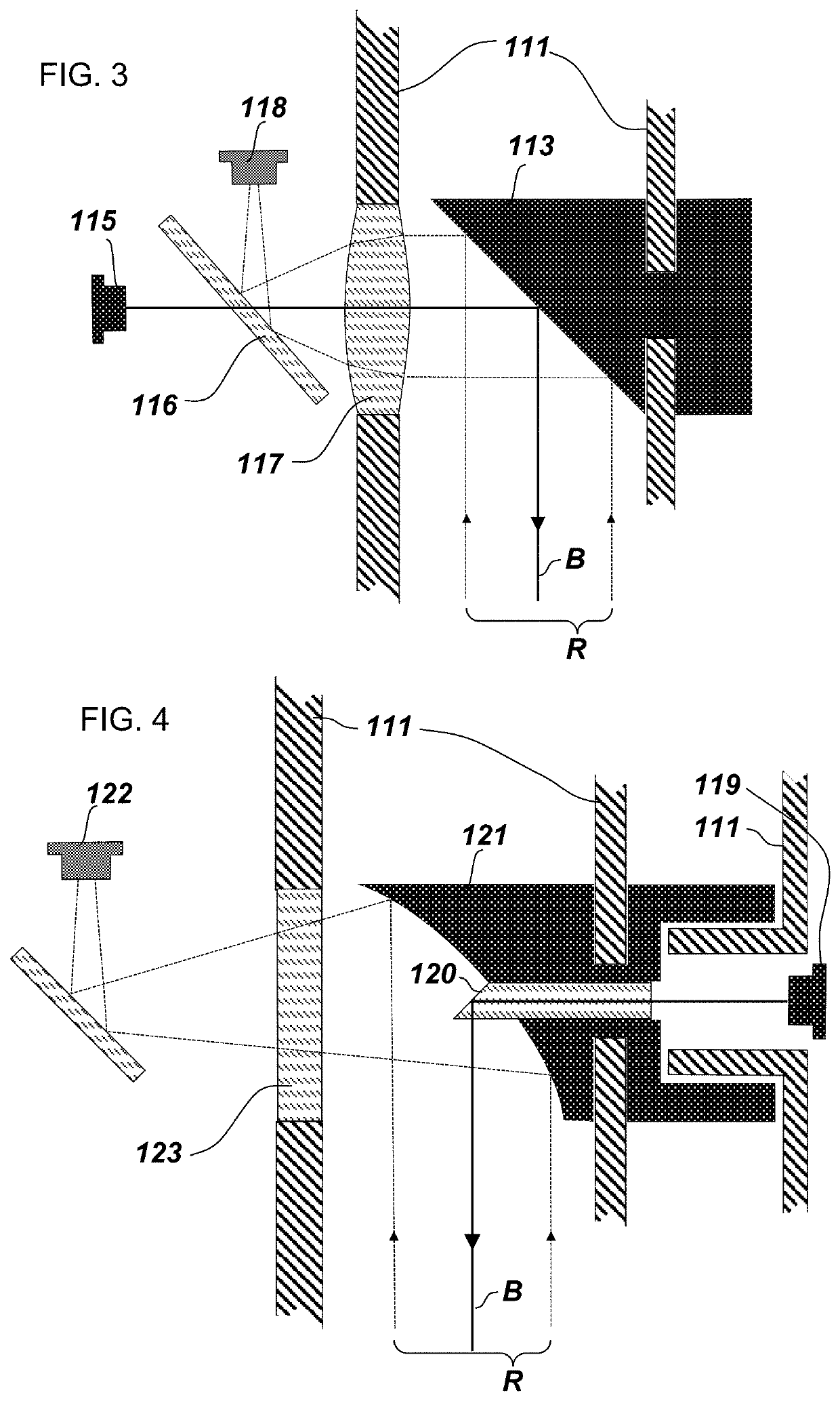

Construction machine with measuring system and construction site measuring system

PendingUS20210254308A1Mechanical machines/dredgersSatellite radio beaconingThree dimensional modelPowertrain

Owner:LEICA GEOSYST TECH +2

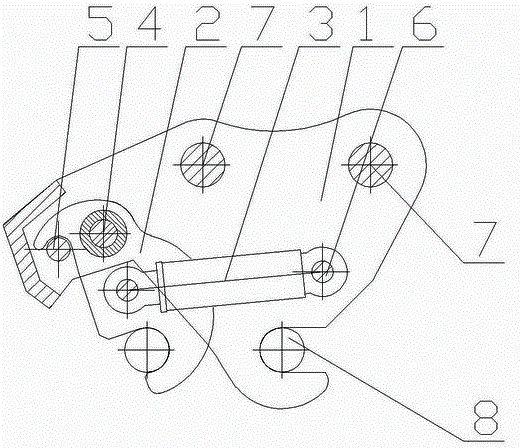

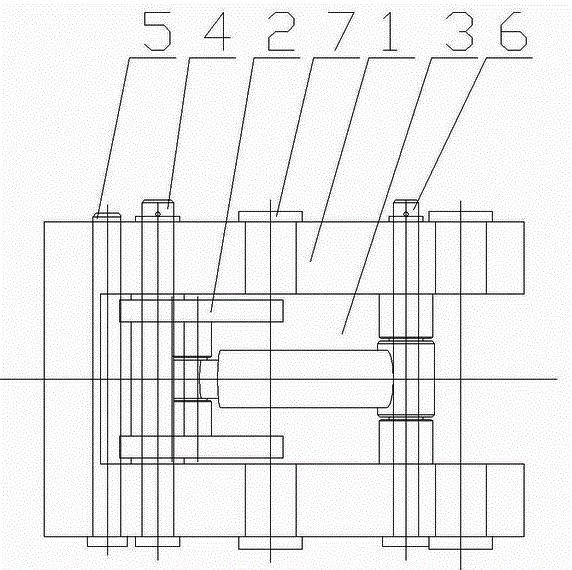

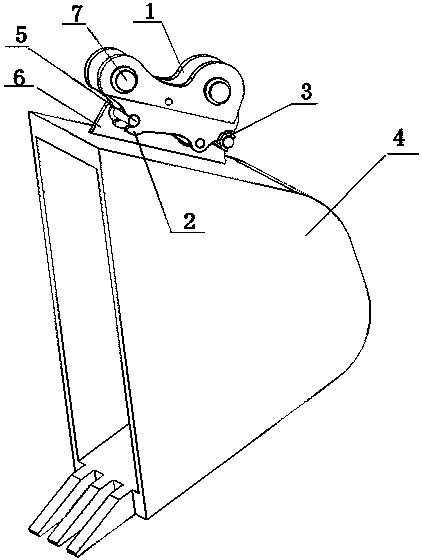

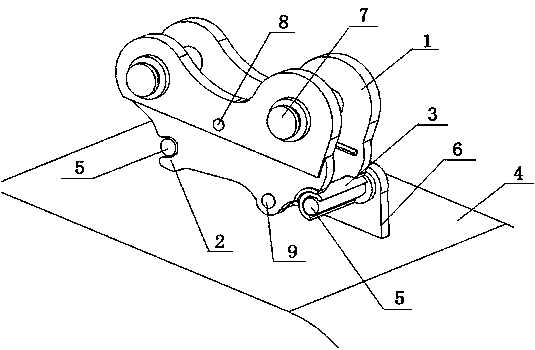

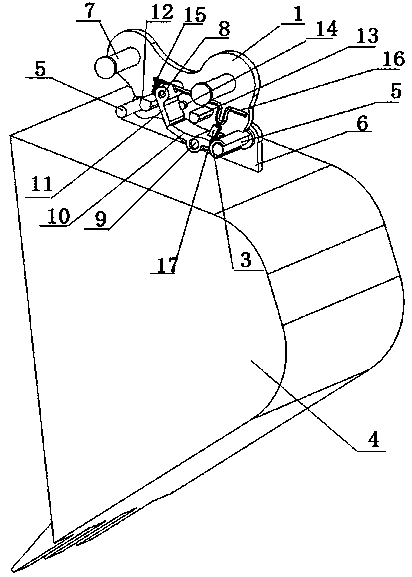

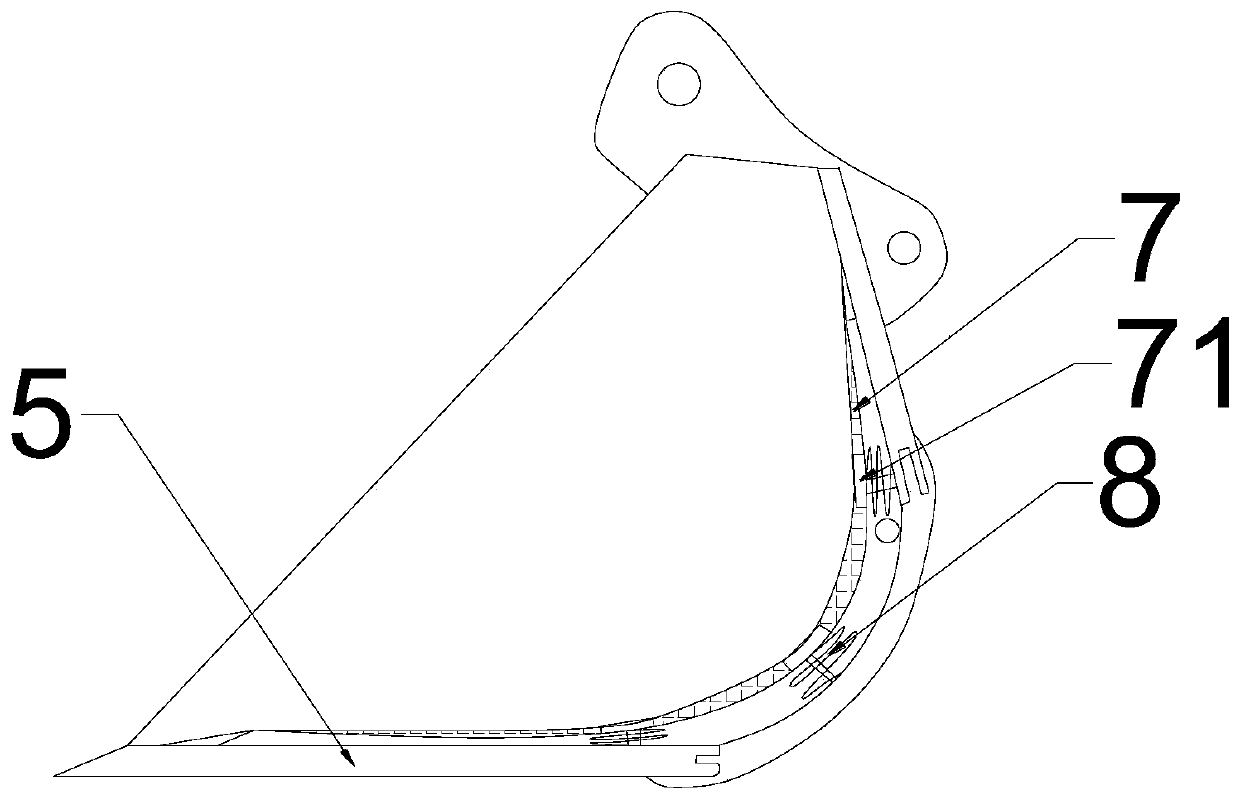

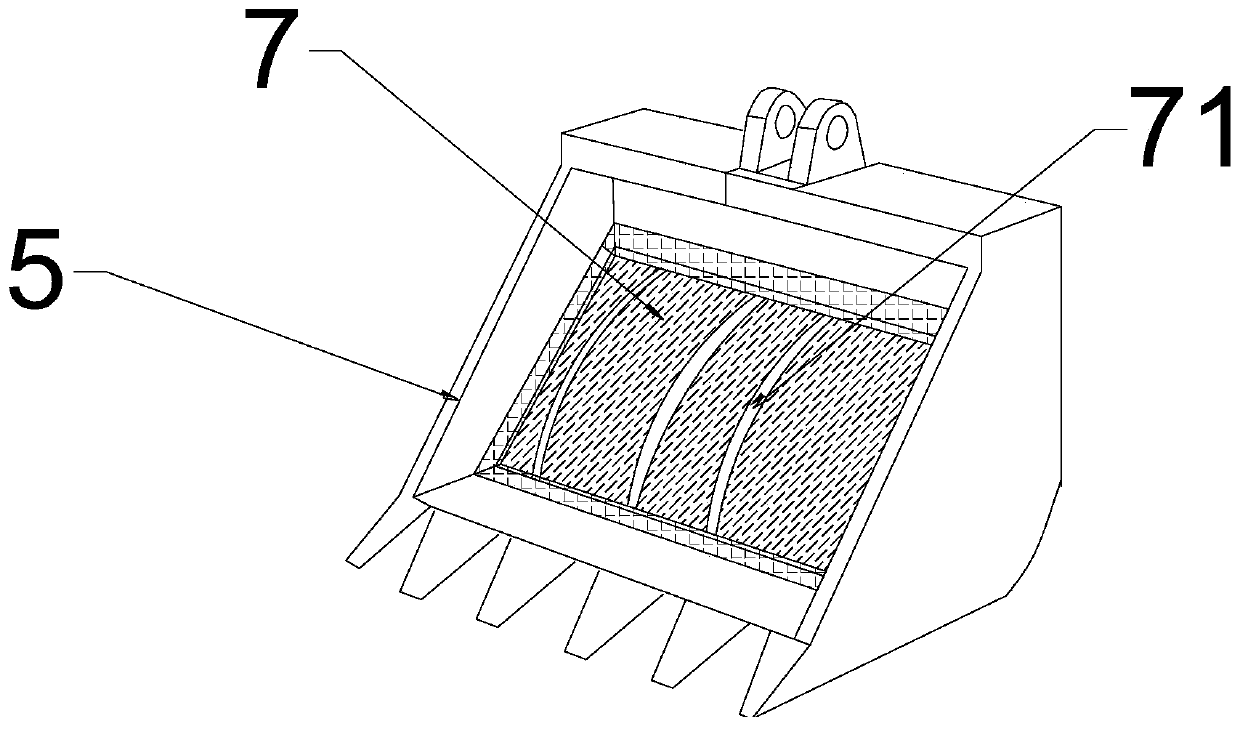

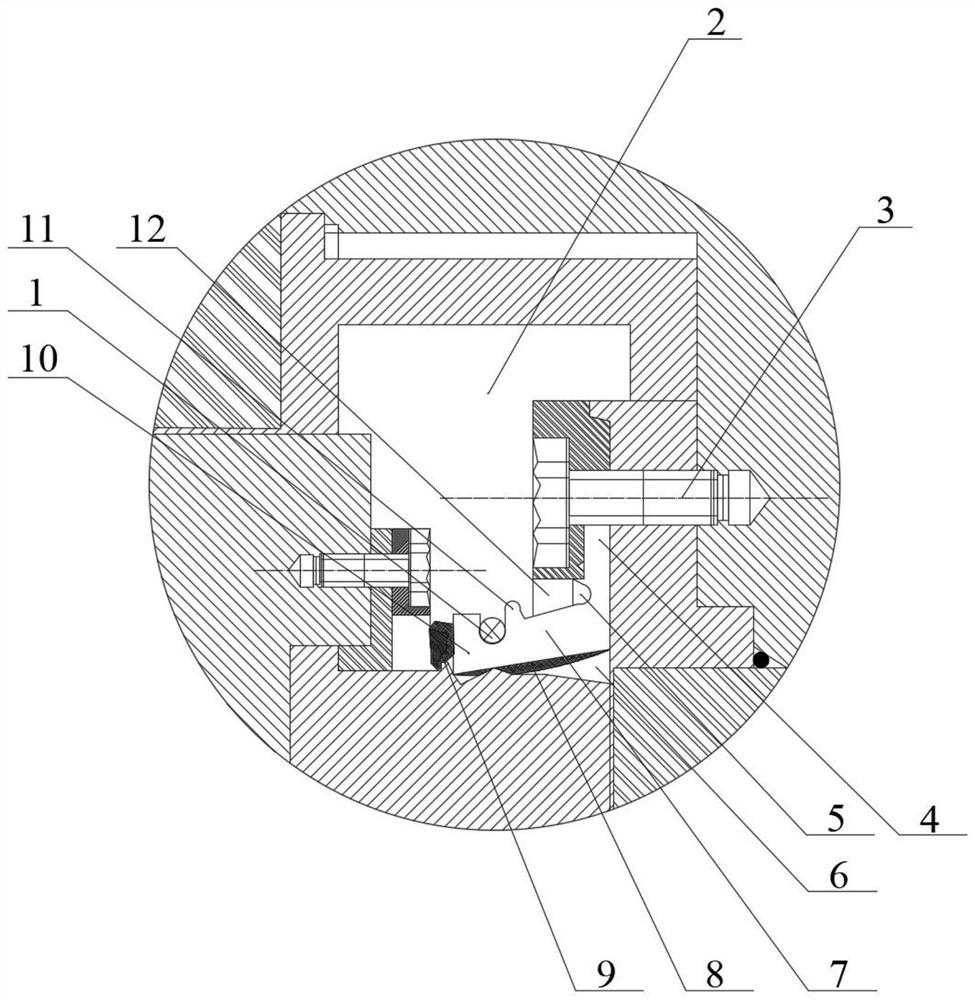

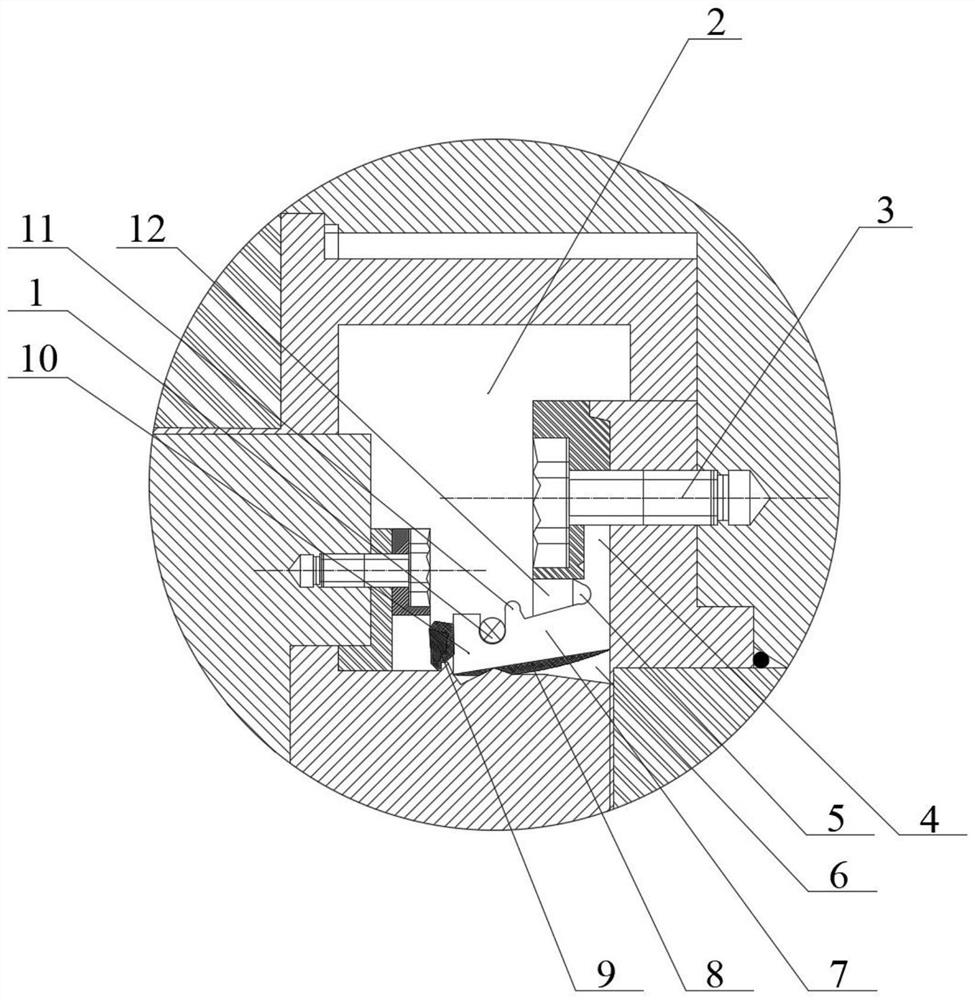

Quick connector

ActiveCN114809154AAchieve releaseSimple structureMechanical machines/dredgersRotational axisEngineering

The quick connector comprises a cavity, a connecting shaft connected with a working device is arranged at the top of the cavity, a fixed hook claw is arranged at one end of the bottom of the cavity, a clamping opening is formed in the other end of the bottom of the cavity, and a movable hook claw rotating around the clamping opening is arranged at the clamping opening. The cavity and the movable hook claw are connected in a sliding mode through track structures which are meshed with each other, and the movable hook claw is positioned on the cavity through a safety pin. According to the quick connector, the movable hook claw slides in a reciprocating mode through rail structures which slide in a mutually-meshed mode, hooking and releasing of a machine tool are achieved, the structure is simple, labor is saved, reliability is achieved, the rear shaft of the machine tool serves as a rotating shaft in the sliding process, large-amplitude reciprocating swing is not needed, and operation is convenient. The axis along which the movable claw slides in a reciprocating mode coincides with the axis of a rear shaft of a machine tool to be hooked, interference with the machine tool is avoided, and when the machine tool shaft is hooked and released, the safety pin is always in an inserted state and is prevented from being lost.

Owner:XCMG EXCAVATOR MACHINERY CO LTD

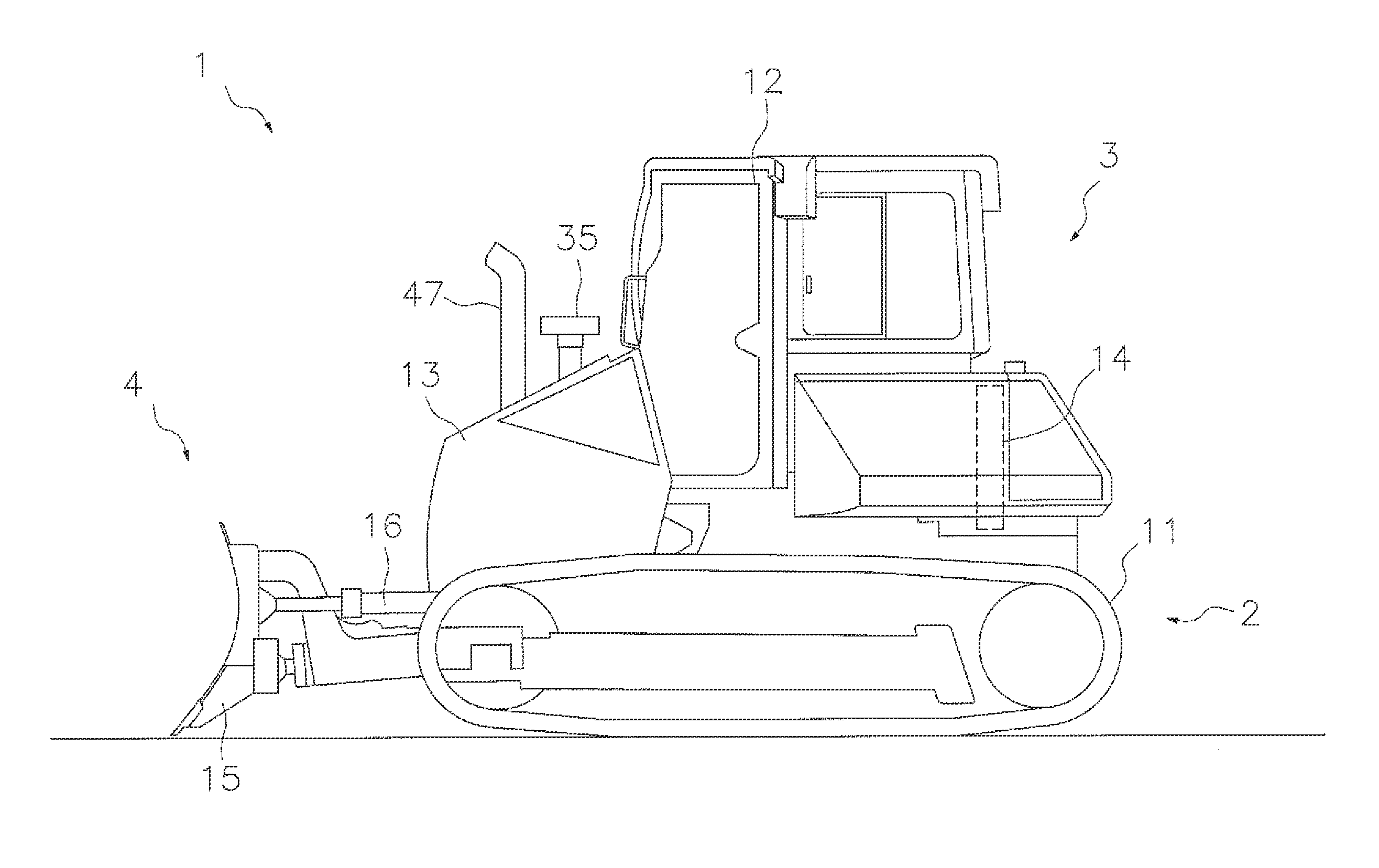

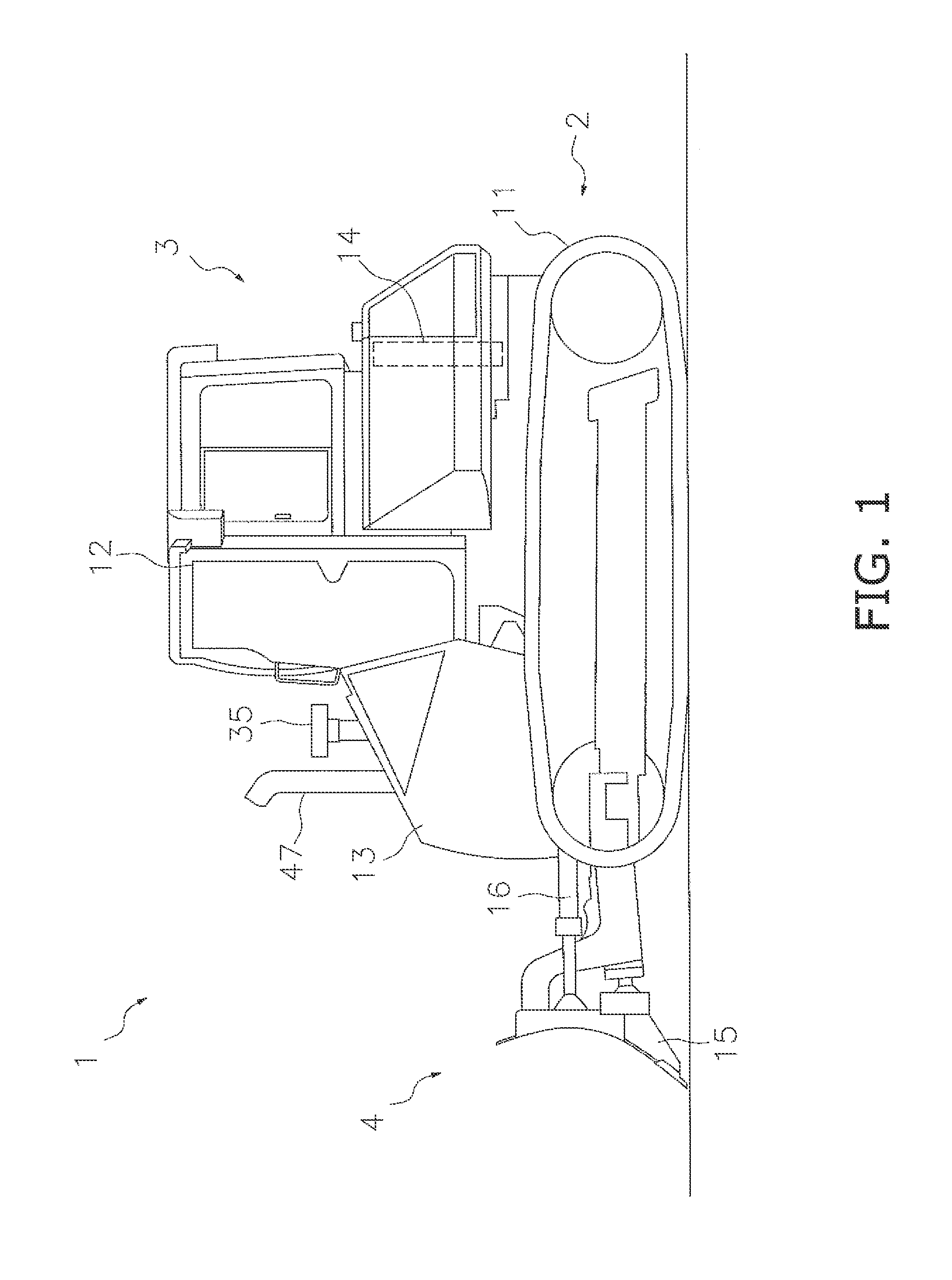

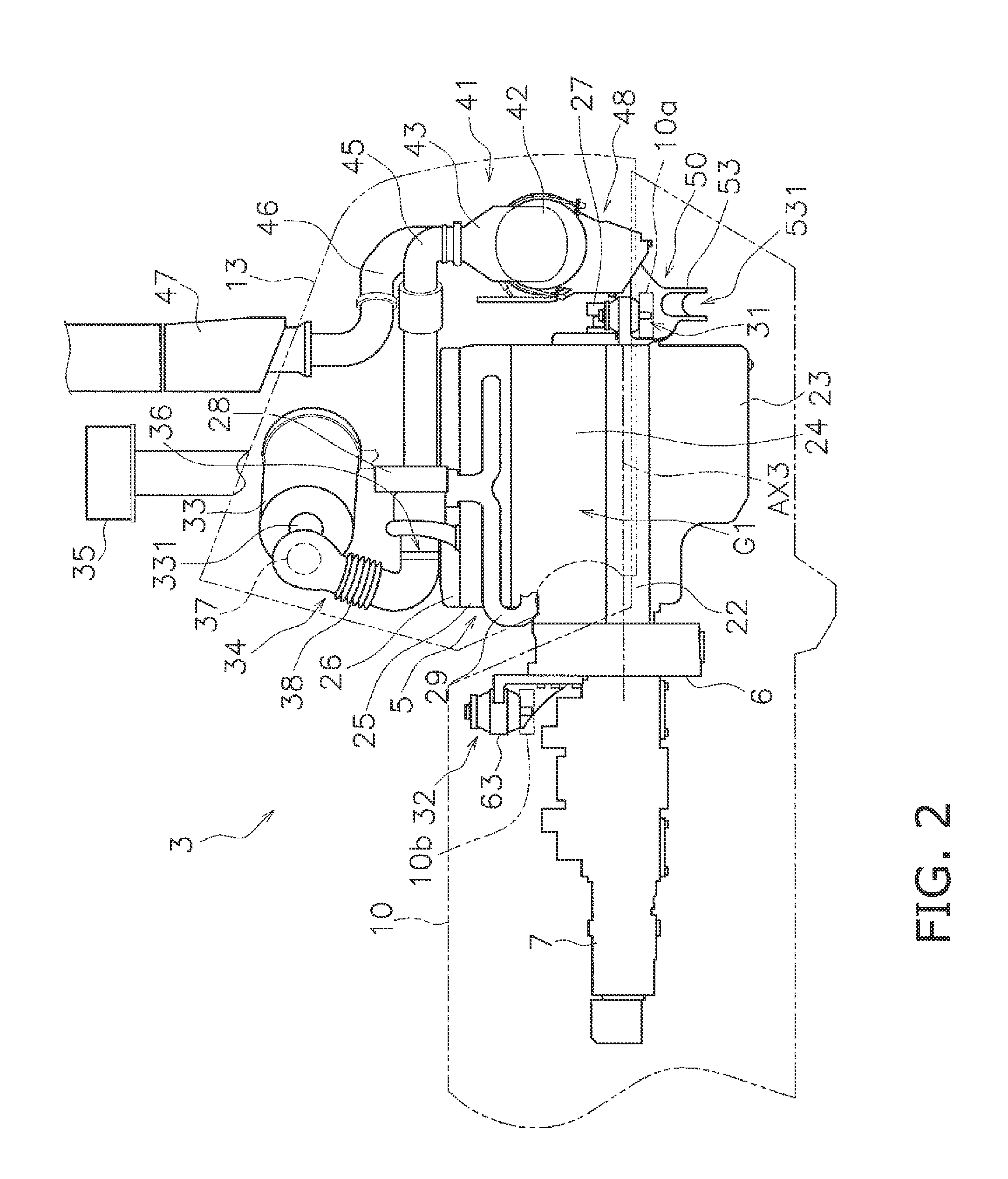

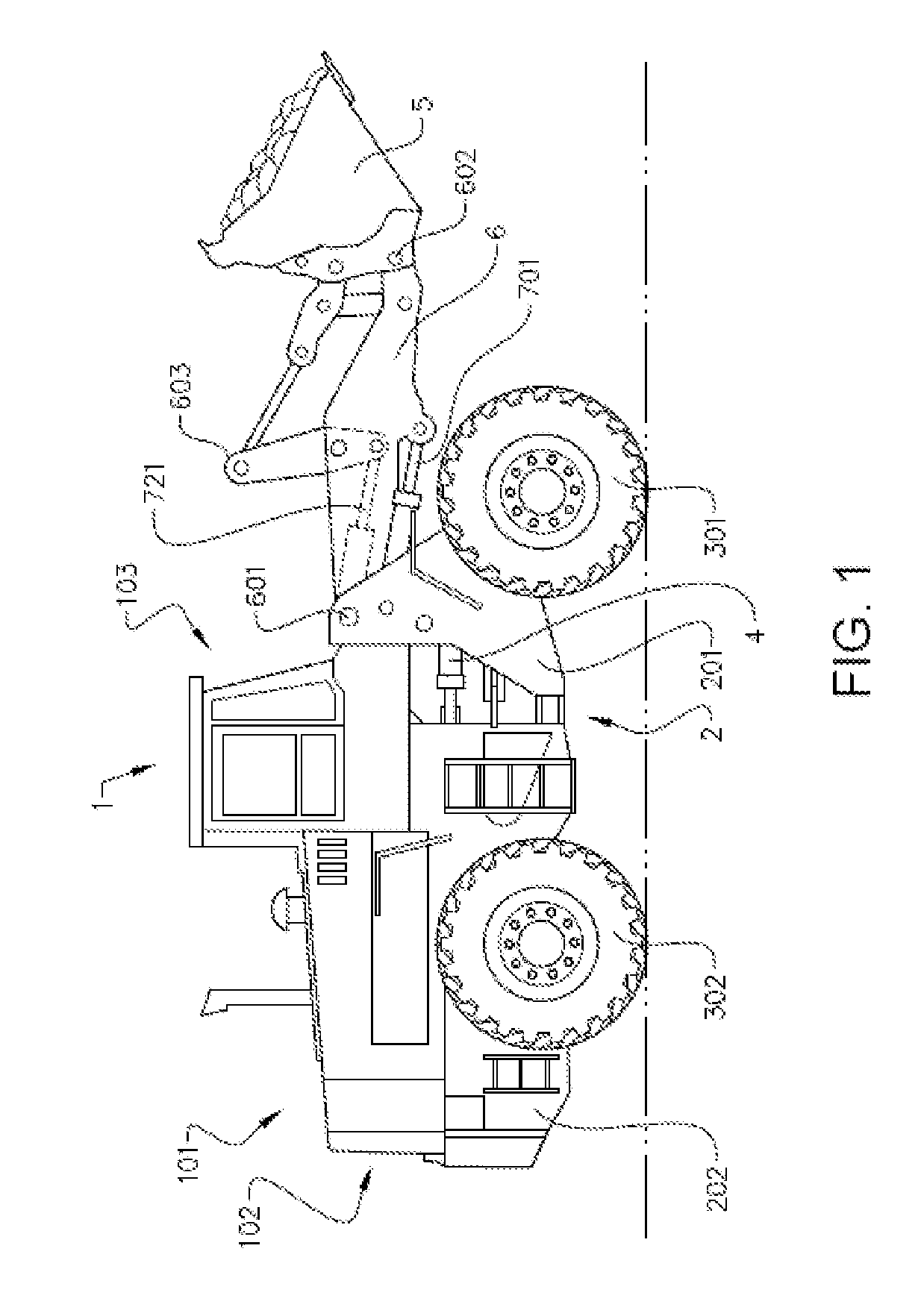

Bulldozer

ActiveUS20130277129A1Vertical distanceReduce loadMechanical machines/dredgersUnderstructuresAir cleanersVehicle frame

Owner:KOMATSU LTD

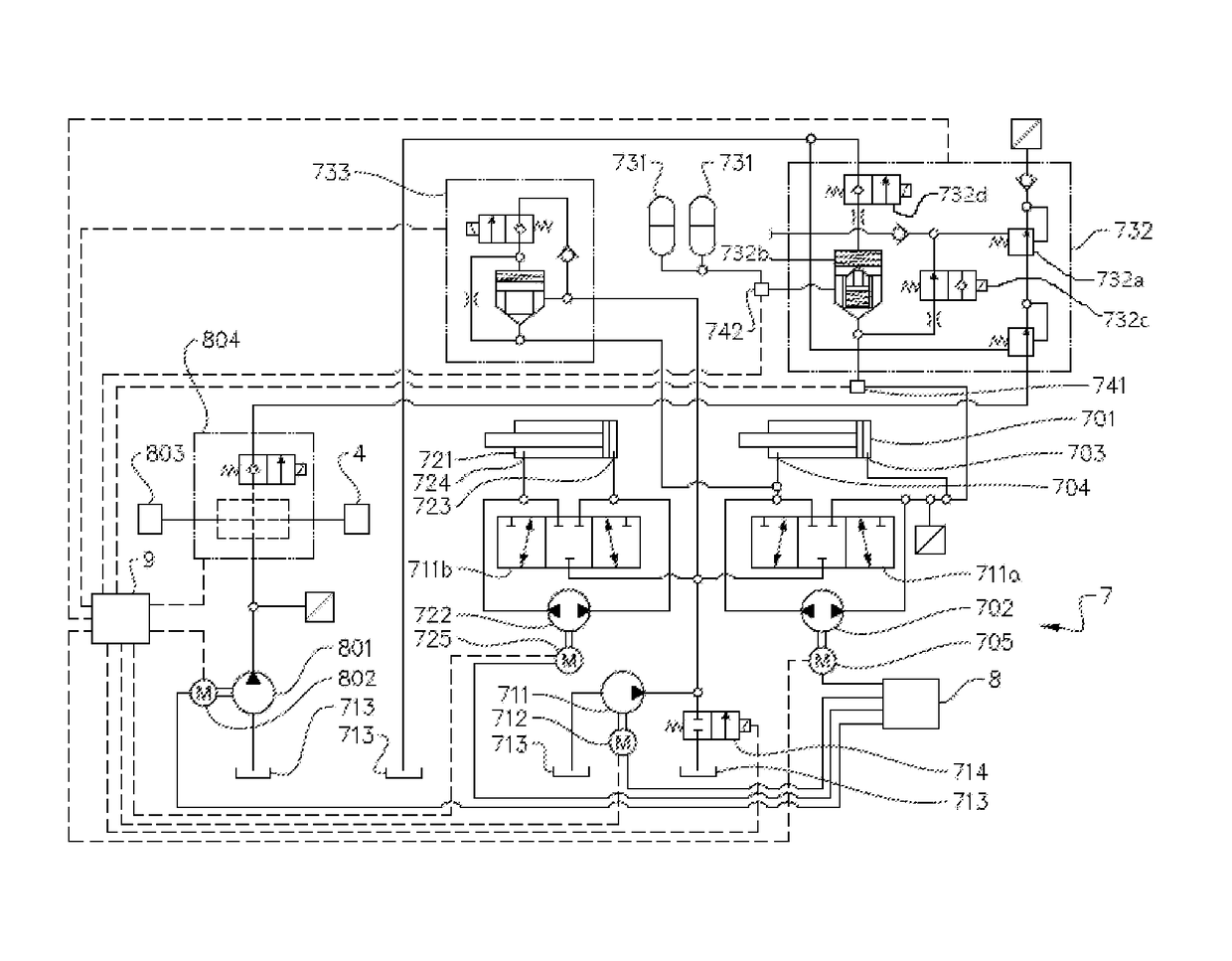

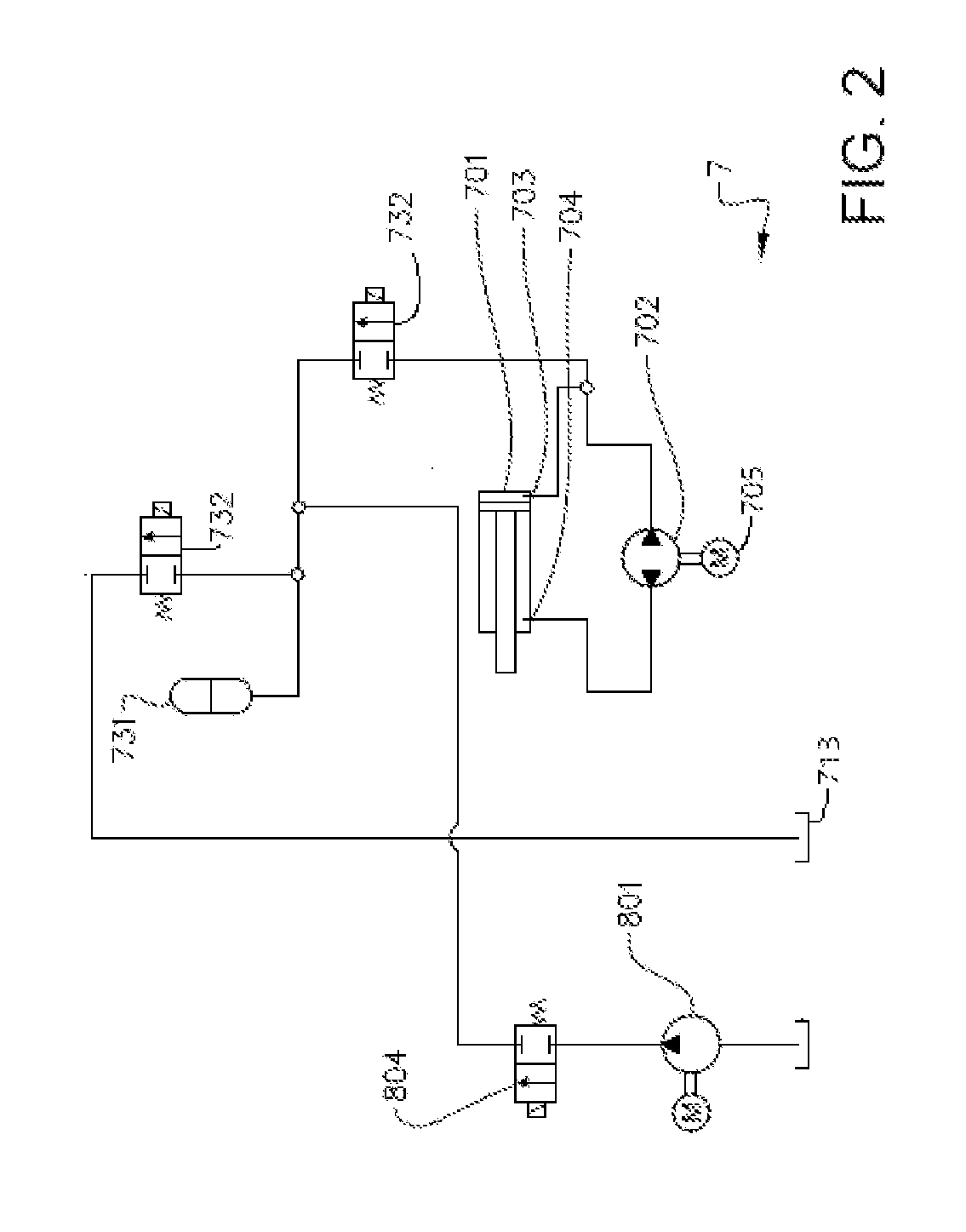

A hydraulic system and a method for moving an implement of a working machine

ActiveUS20180230669A1Prevent movementMechanical machines/dredgersAccumulator installationsPistonHydraulic accumulator

Owner:VOLVO CONSTR EQUIP

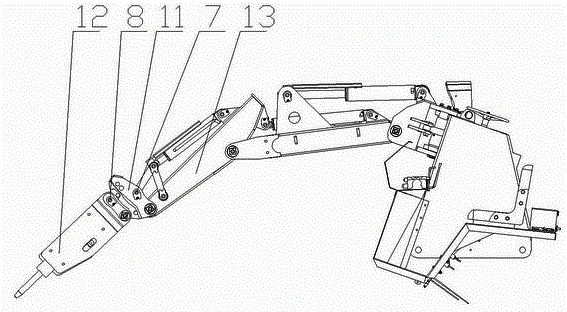

Bucket and hammer quickly-replacing device

Owner:襄阳忠良工程机械有限责任公司

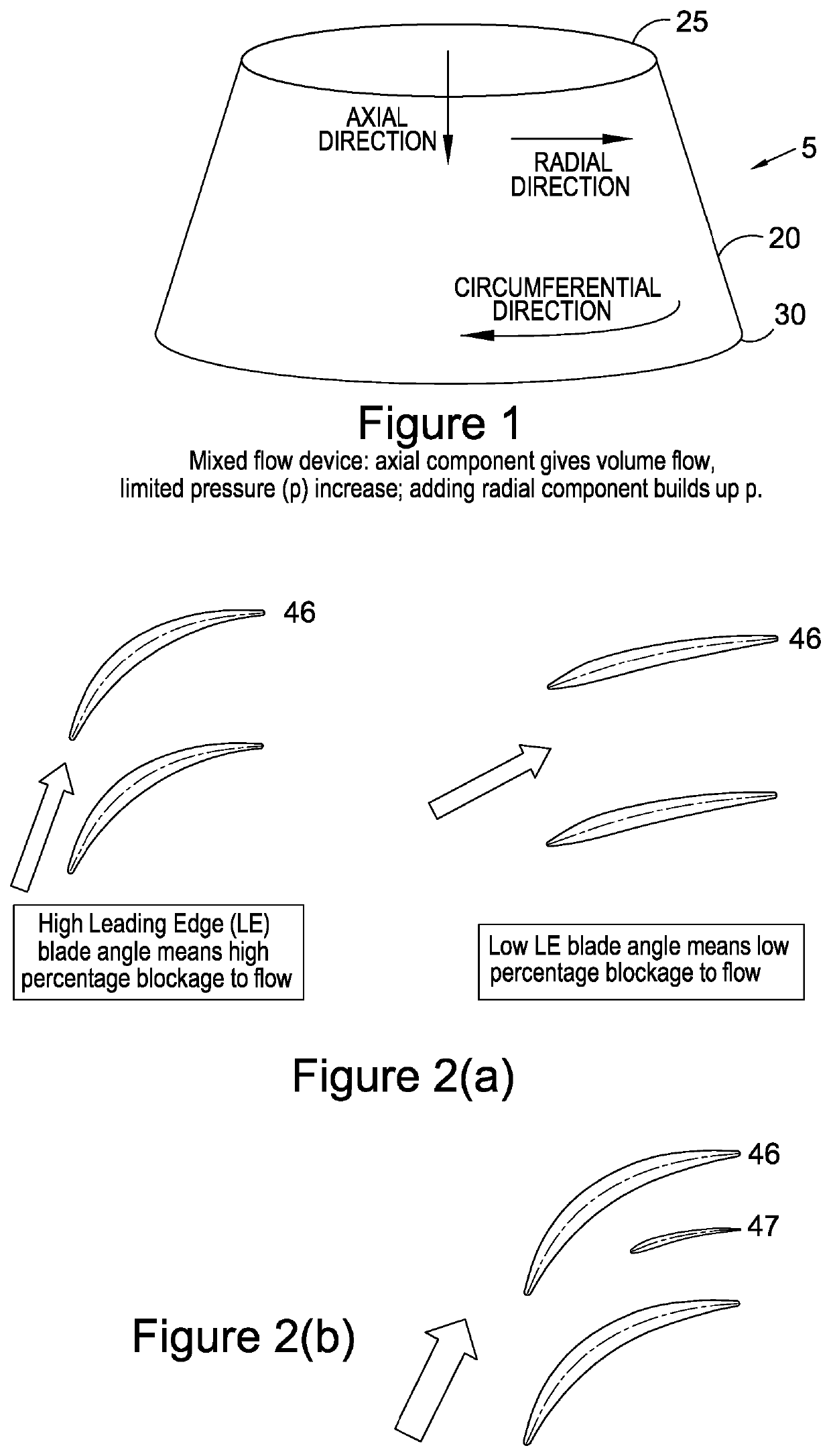

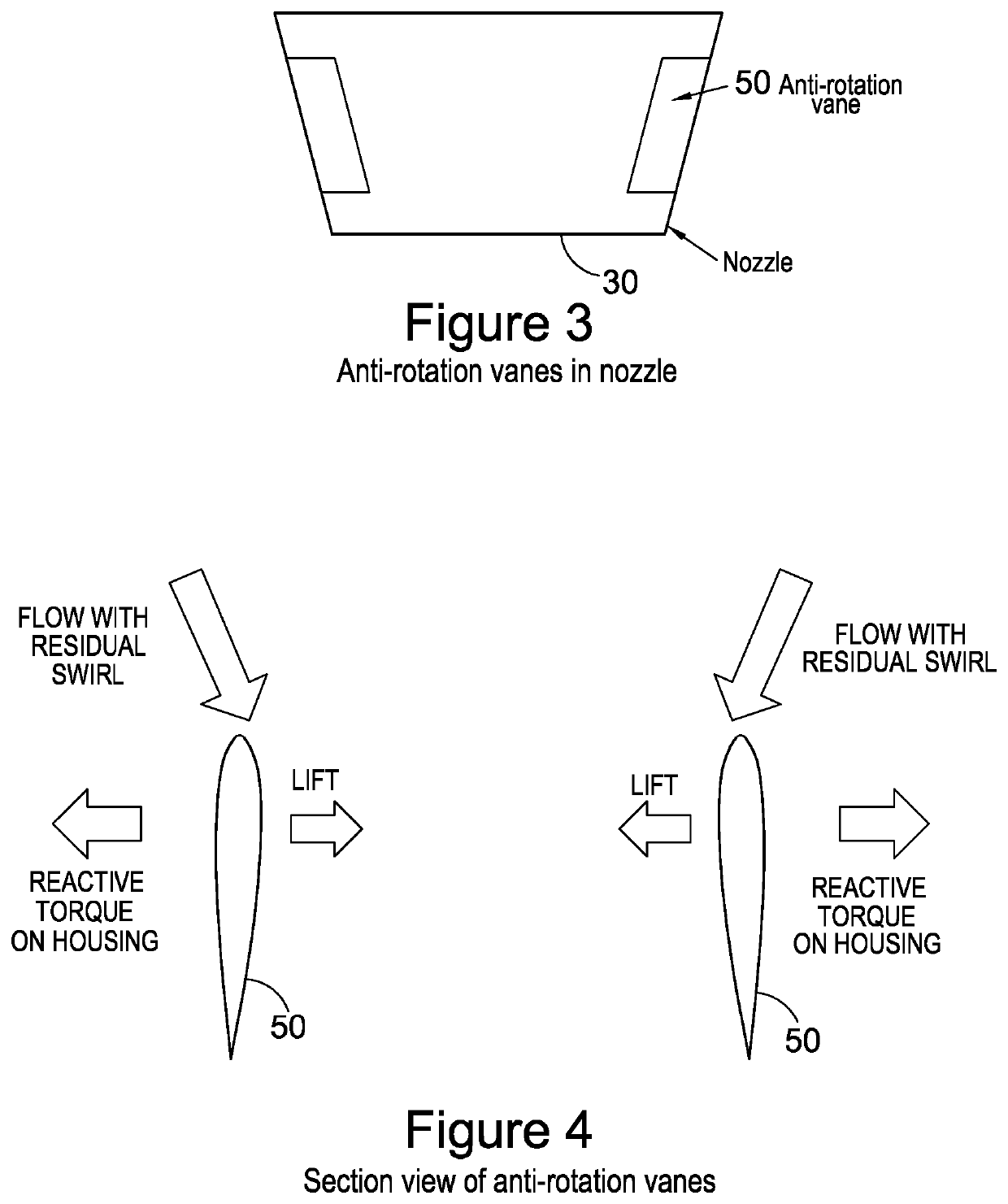

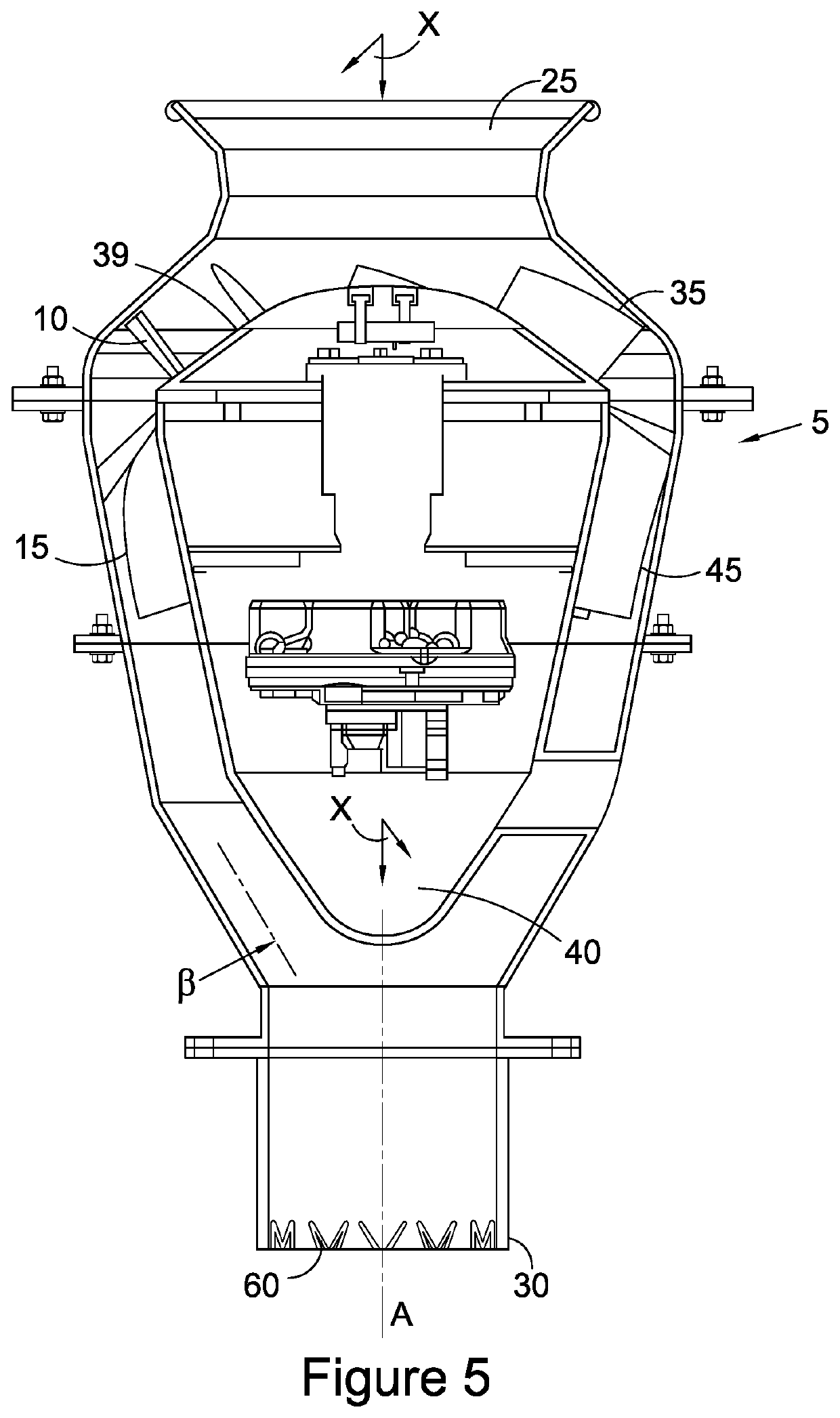

Improvements in and relating to underwater excavation apparatus

Owner:ROTECH HLDG

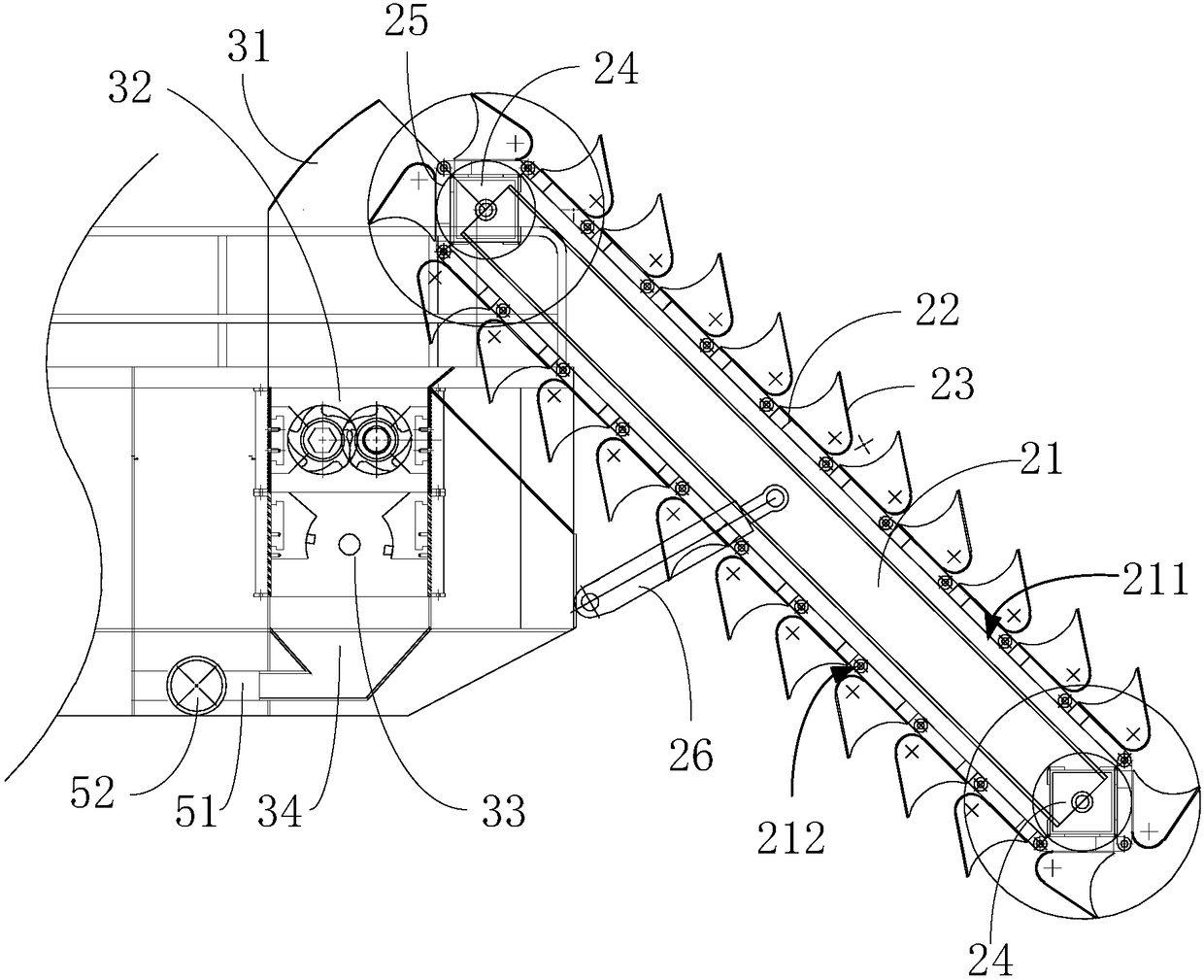

Composite underwater power dredging drag harrow

PendingCN113175016AEasy to processHigh strengthMechanical machines/dredgersEnvironmental geologyStructural engineering

The invention discloses a composite underwater power dredging drag harrow. The invention relates to the field of water conservancy environmental protection, in particular to a mechanical disturbance type dredging harrow tool which can be used in muddy coast coastal tidal estuaries, silt-laden rivers and channels. The invention provides a composite underwater power dredging drag harrow which is simple in structure, reliable in layout and capable of improving efficiency. The composite underwater power dredging drag harrow comprises a harrow frame and further comprises a fixed harrow, a power harrow and a gas water tank which are sequentially arranged from front to back, wherein the harrow frame comprises a pair of side plates arranged in parallel, the fixed harrow is fixedly connected between the pair of side plates, the power harrow is movably connected between the pair of side plates, and the gas water tank is fixedly connected between the pair of side plates. The power rake comprises a motor mounting plate, vertical plates are symmetrically arranged at the two ends of the motor mounting plate, limiting shafts are arranged on the upper portions of the vertical plates, rotating shafts are arranged on the lower portions of the vertical plates, arc-shaped holes and rotating holes are formed in the side plates, the limiting shafts are located in the arc-shaped holes, and the rotating shafts are located in the rotating holes. The composite underwater power dredging drag harrow is convenient to install and reliable in desilting.

Owner:THE JIANGSU GENERAL FACTORY OF WATER CONSERVANCY MACHINERY

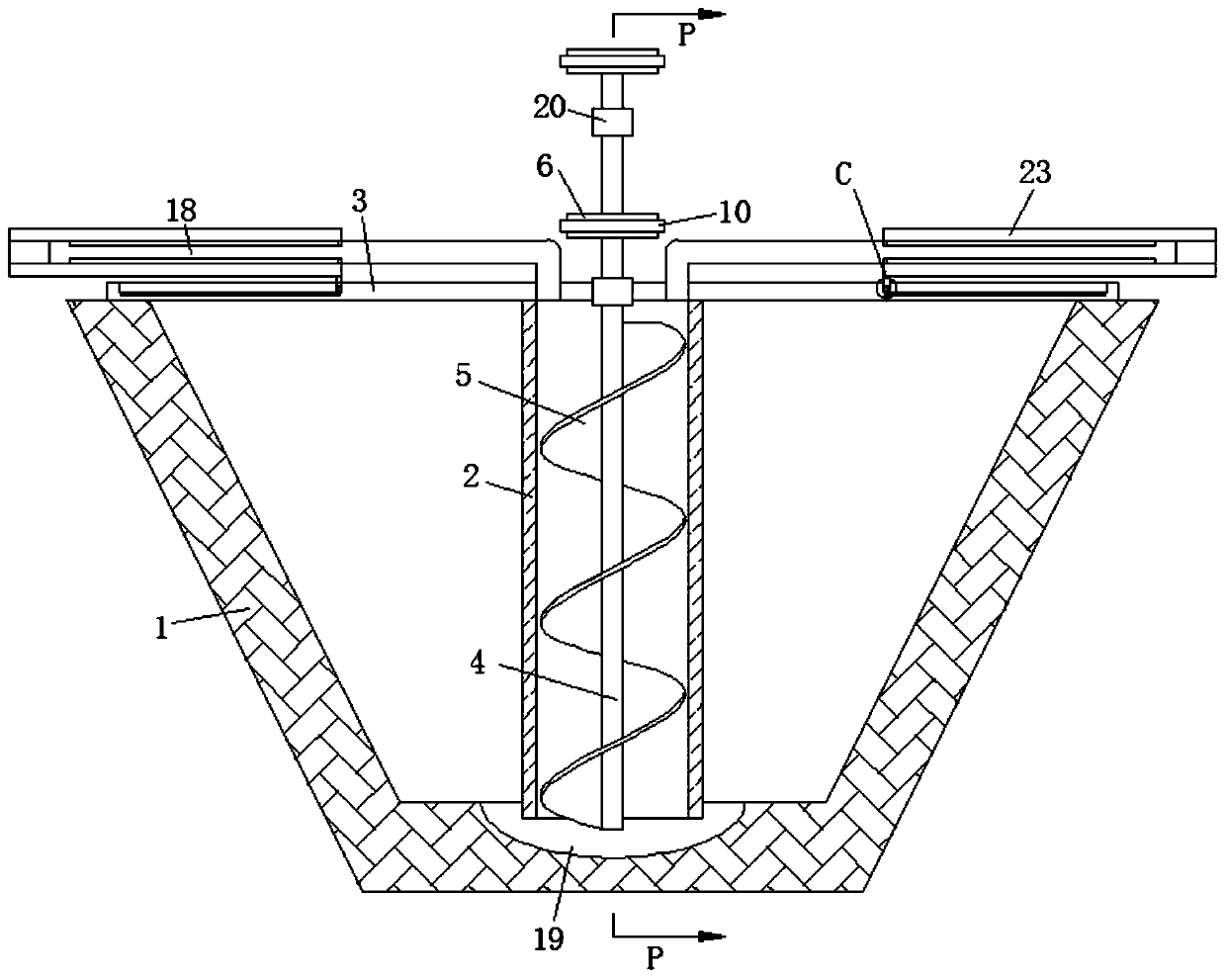

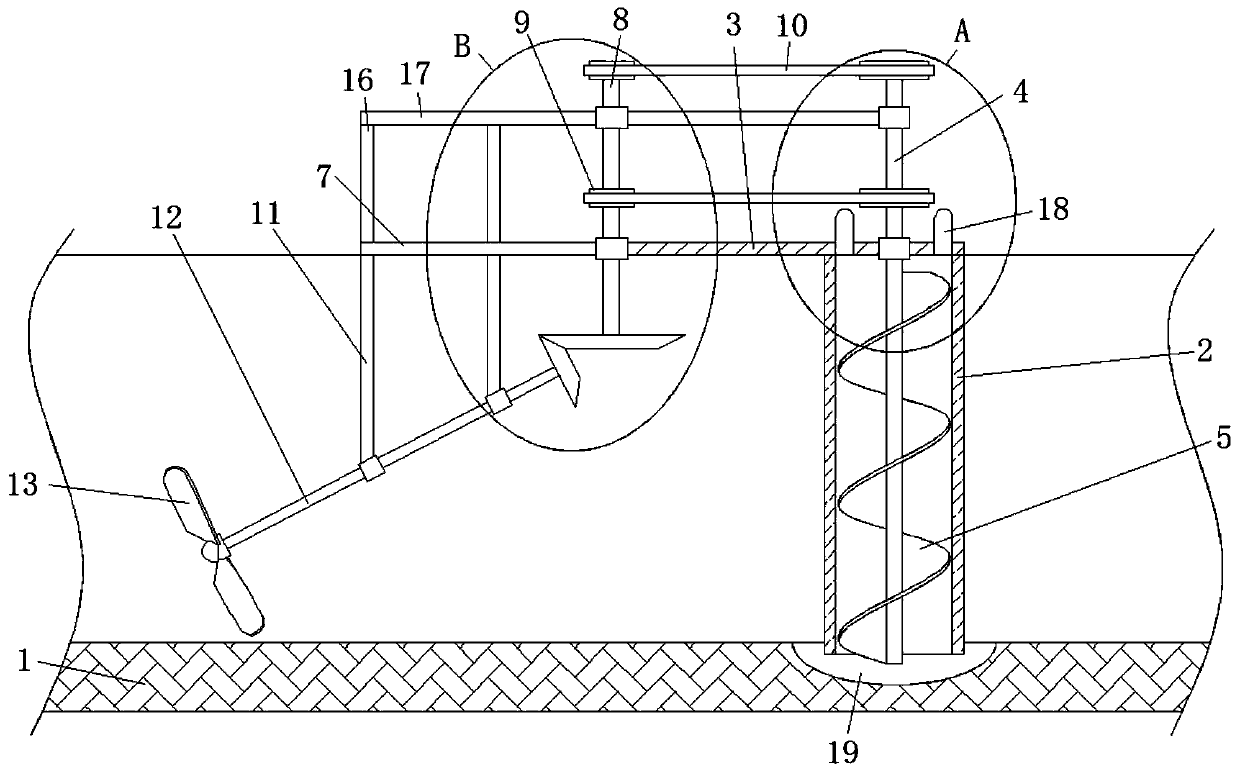

Ecological drainage channel

InactiveCN111560925AMeet the needs of useAvoid cloggingMechanical machines/dredgersSoil drainageSludgeSpiral blade

Owner:陈文娟

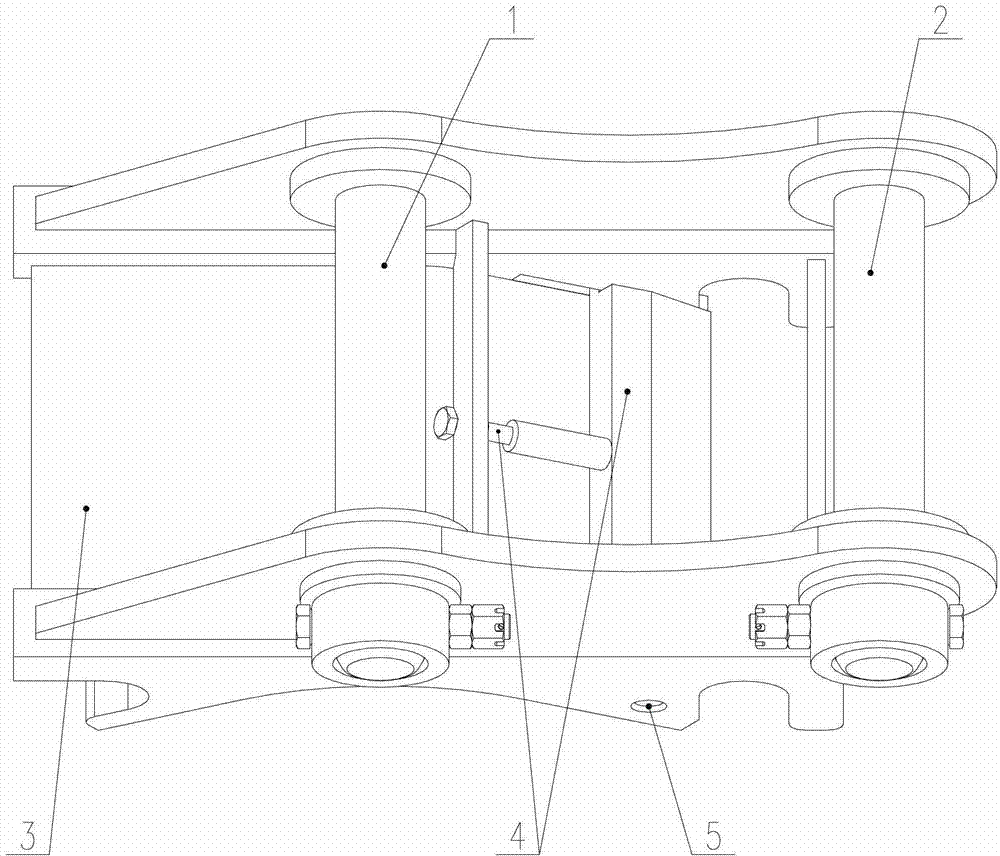

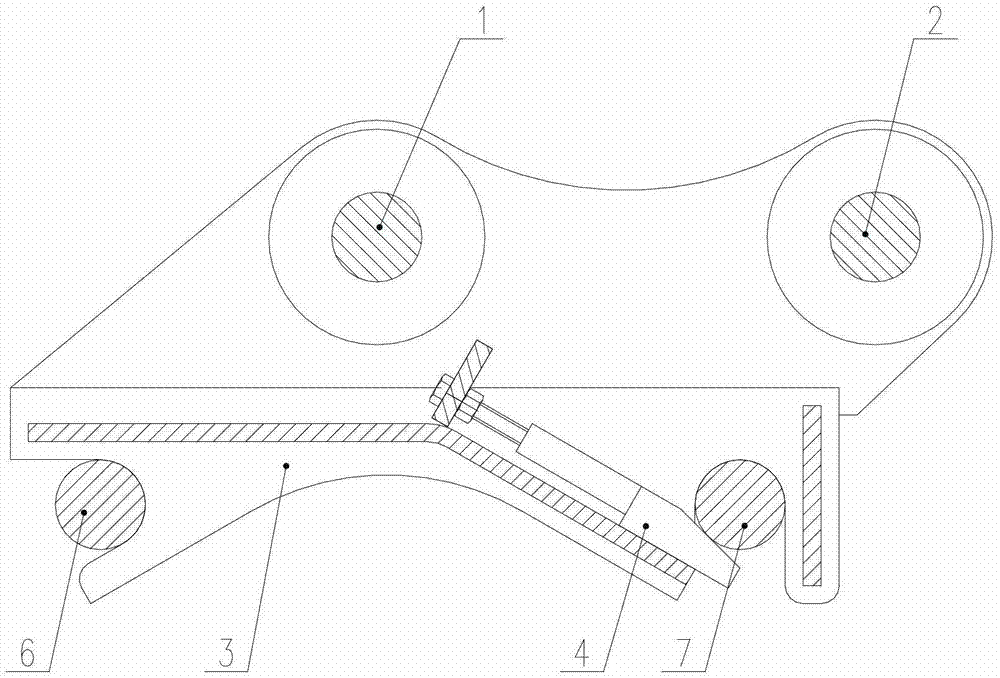

Quick-changing device for accessories of hydraulic excavator working device

InactiveCN102926420AQuick installation and removalLow costMechanical machines/dredgersEffective solutionExcavator

Owner:GUANGXI YUCHAI HEAVY IND

Sandy soil excavating equipment

Owner:CHENGDU HUANMEI GARDEN ECOLOGICAL CO LTD

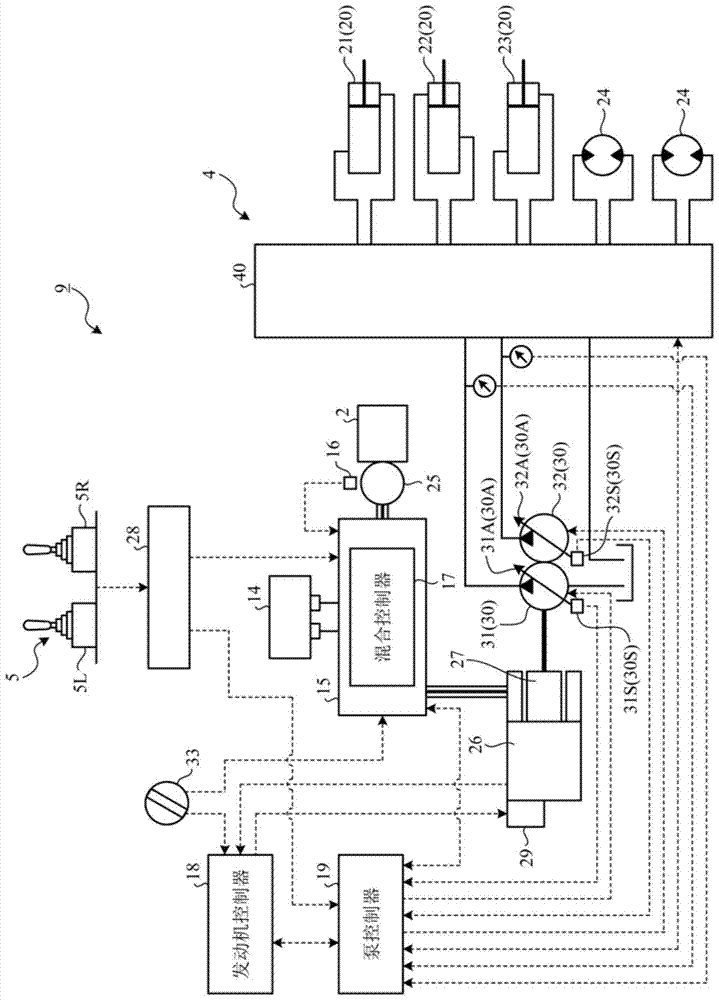

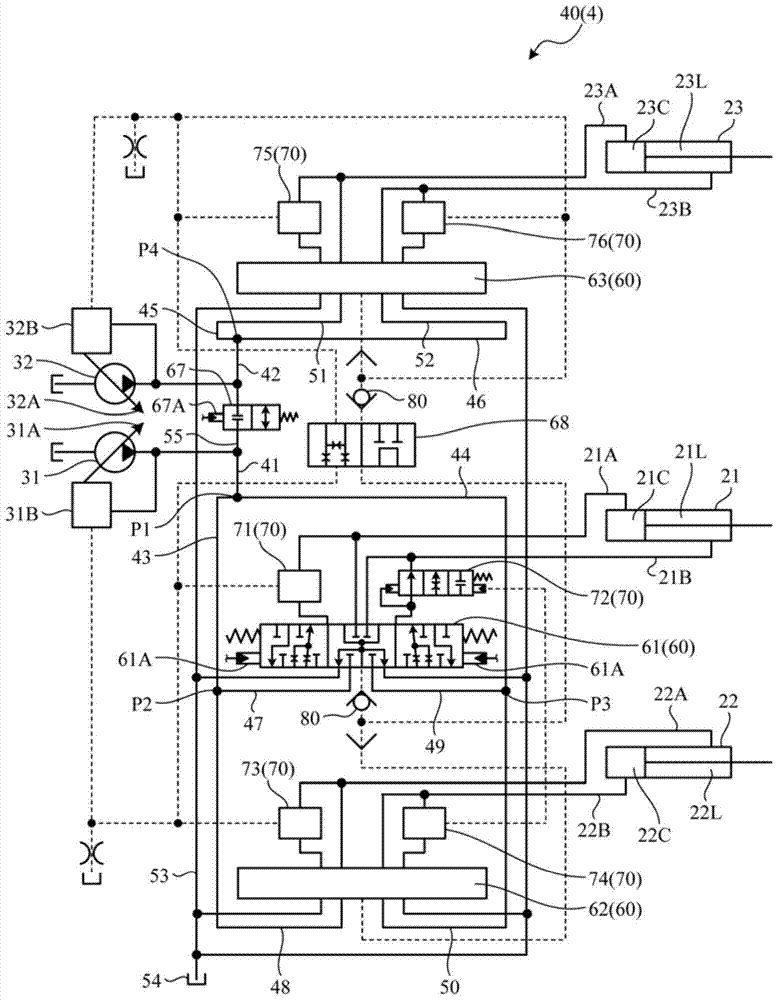

Drive device for construction equipment

ActiveCN107250560ASuppress fuel consumption deteriorationServomotor componentsMechanical machines/dredgersHydraulic pumpEngineering

Owner:KOMATSU LTD

Self-cleaning slurry suction inlet sealing structure of trailing suction hopper dredger

ActiveCN112695824ACushion torsion damageGuaranteed stabilityMechanical machines/dredgersMechanical engineeringRigid structure

Owner:TIANJIN BAOBOTE SEALING TECH

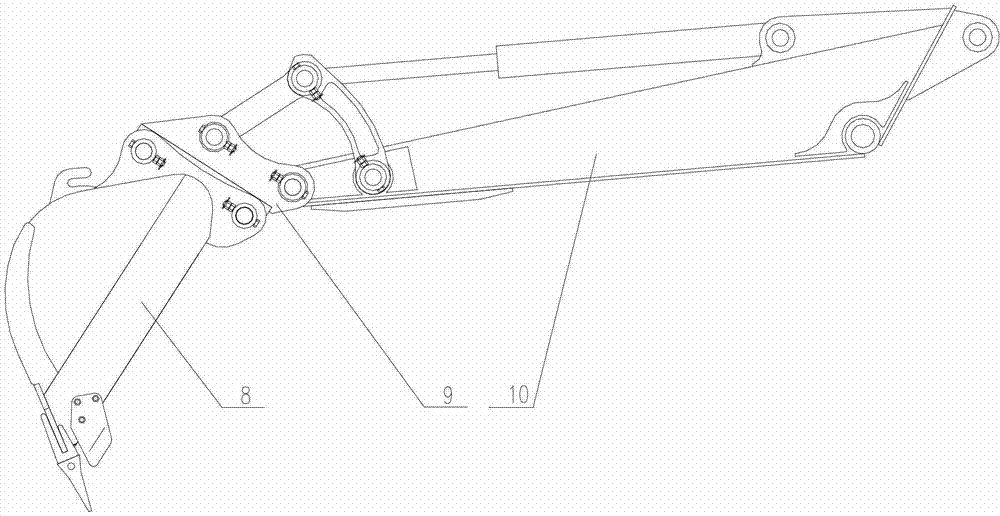

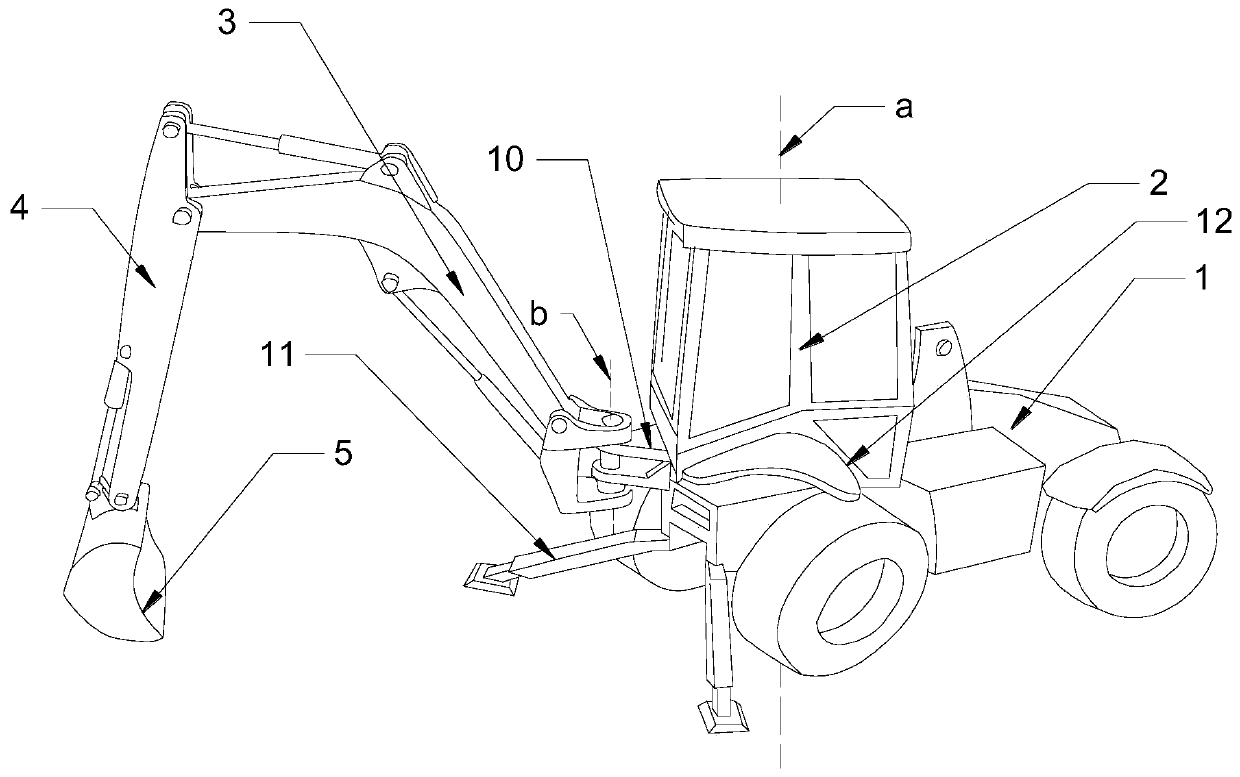

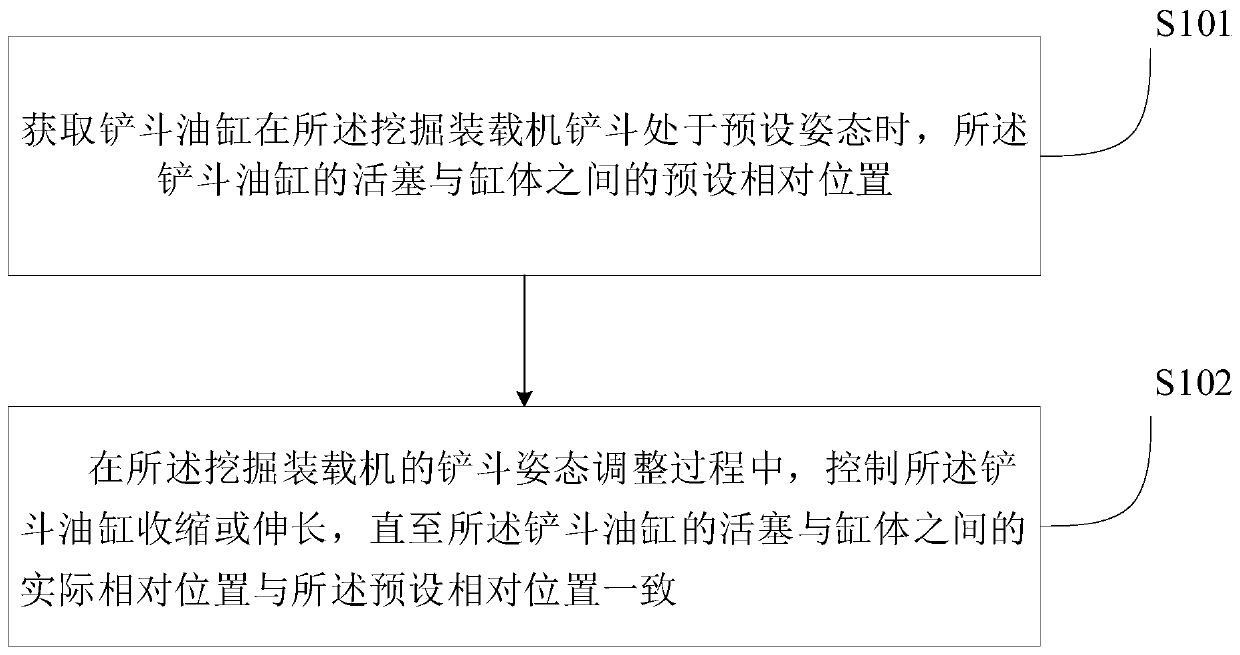

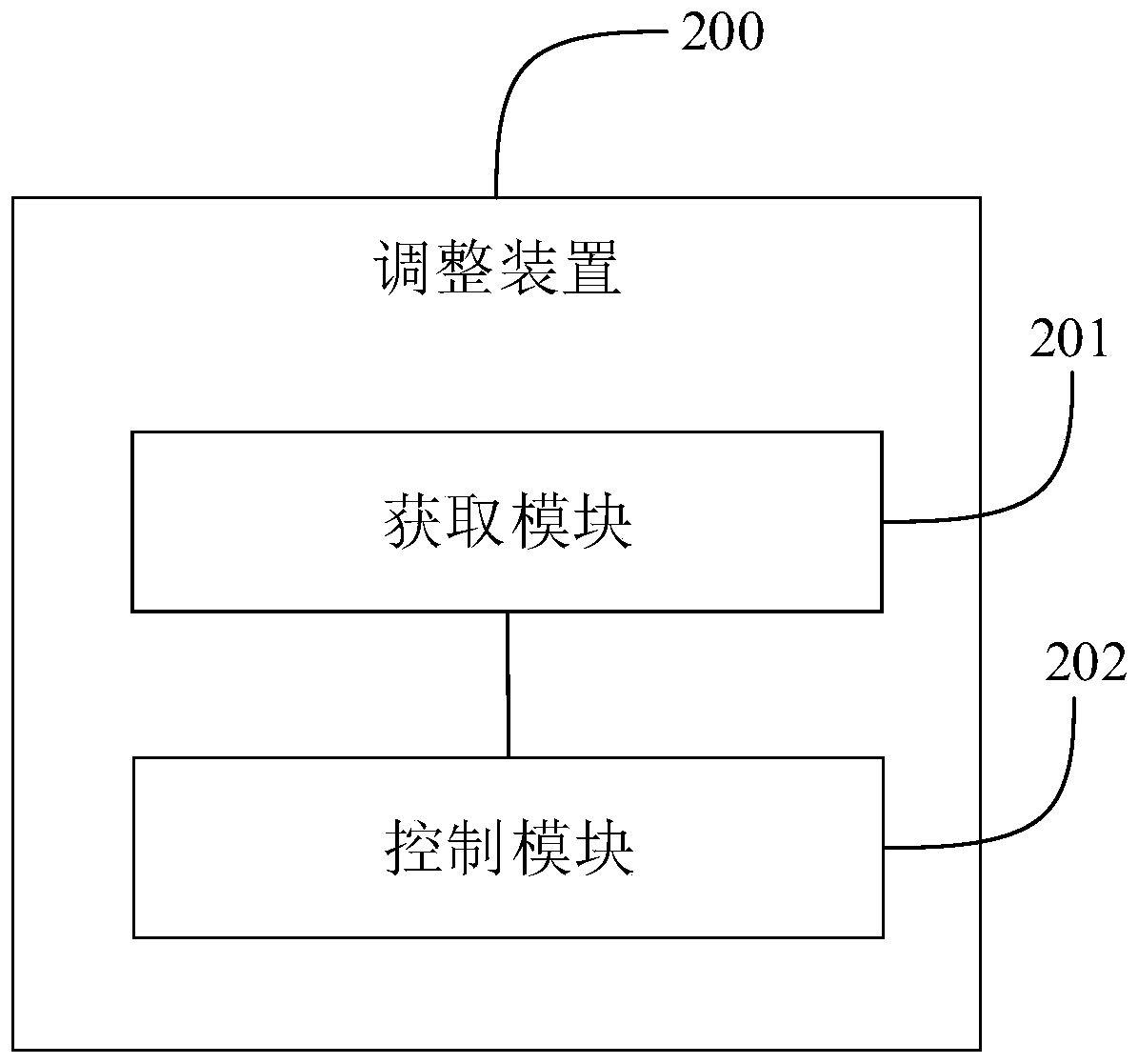

Loader-digger bucket posture adjusting method and device and loader-digger

PendingCN110924459AAccurate adjustmentReduce mistakesMechanical machines/dredgersCylinder blockMechanical engineering

The invention provides a loader-digger bucket posture adjusting method and device and a loader-digger. The adjusting method comprises the steps of obtaining the preset relative position between a piston and a cylinder block of a bucket oil cylinder when the loader-digger bucket is in a preset attitude; and in the loader-digger bucket posture adjusting process, controlling the bucket oil cylinder to contract back or extend out until the actual relative position between the piston and the cylinder block of the bucket oil cylinder is coincident with the preset relative position. By means of the adjusting method, loader-digger bucket posture accurate adjustment can be realized, errors are effectively reduced, and the operation efficiency is improved.

Owner:SANY HEAVY MACHINERY

Building construction device

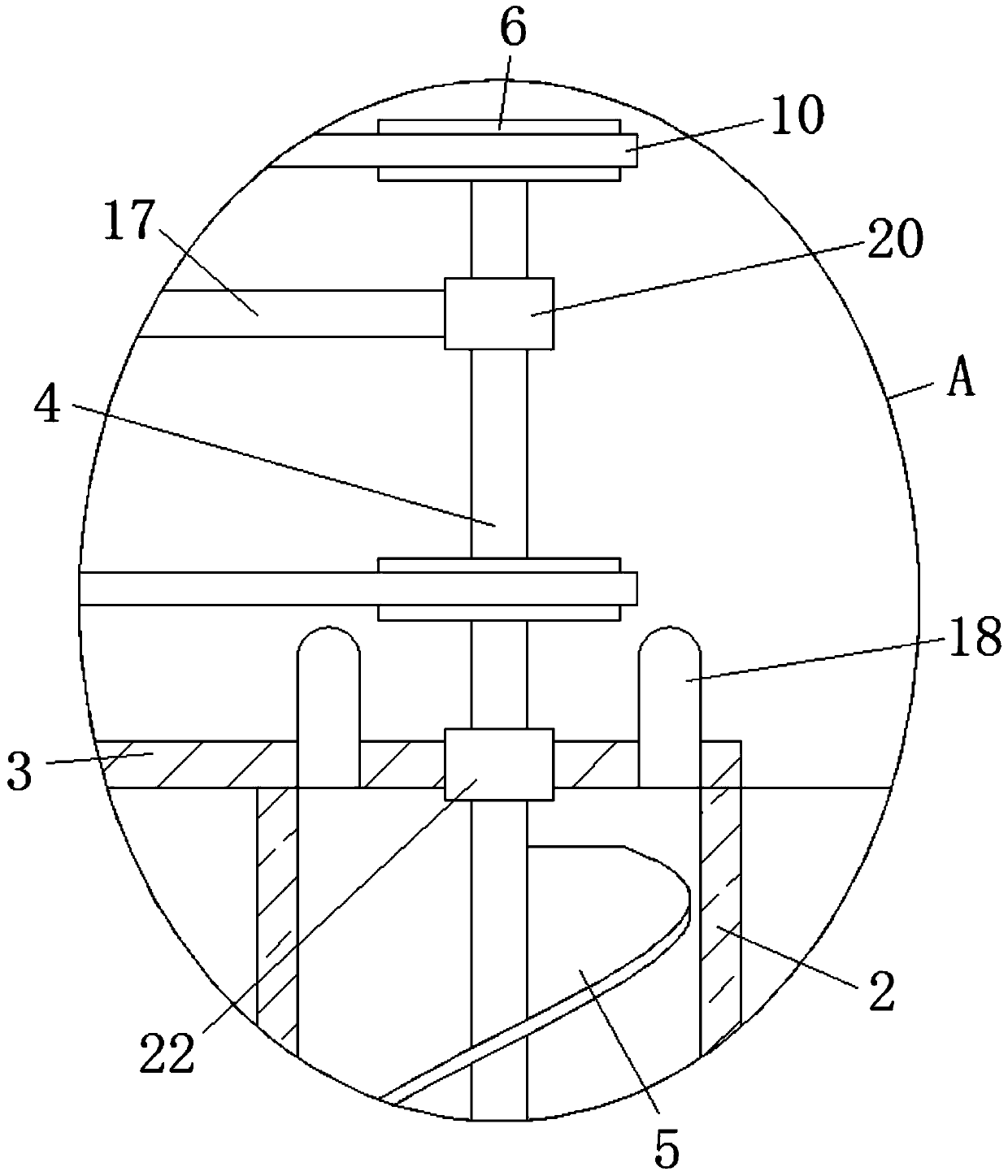

InactiveCN108360594AEasy to installEasy maintenanceMechanical machines/dredgersArchitectural engineeringCooperative work

The invention discloses a building construction device. The device comprises a containing box, a plurality of rolling wheels driven by electric rotating machines are fixedly arranged on the lower endsurface of the containing box, a rotating connecting cavity with a rightward through opening is formed in the containing box, a partition plate is fixedly arranged on the rear end wall of the rotatingconnecting cavity, the right side of the partition plate is fixedly provided with a containing cavity which is located in the containing box and provided with an upward through opening, the electricrotating machine A is fixedly arranged in the rear end wall of the rotating connecting cavity, a rotating connecting block is fixedly arranged on the outer surface of the rotating connecting shaft ofthe electric rotating machine A, the upper end face and the lower end face of the rotating connecting block are fixedly provided with a swing rod with the upper part equal to the lower part, the outersurface of the swing rod is in sliding connection fit with a sliding connecting sleeve A, the front end face of the sliding connecting sleeve A is fixedly provided with a rotating connecting column A, and a rod shaft which extends rightwards is arranged on the outer surface of the rotating connecting column A in a rotatable mode. According to the device, the structure is simple, the use is convenient, the multi-mechanism cooperative work is adopted, so that efficient treatment of solid waste is realized, the labor intensity of workers is effectively reduced, and the construction efficiency isimproved.

Owner:GUANGZHOU FANGGE CONSTR ENG TECH DEV CO LTD

Work machine

A work machine including a front control section configured to calculate a limit command value for restricting an operation of a front work implement includes: for example, a bypass line that bypasses, for example, the proportional solenoid valve in, for example, the pilot line; for example, a bypass valve disposed in, for example, the bypass line; a switch configured to output a signal to turn on or off control by the front control section; an on / off determining part configured to determine whether the signal from the switch is an on signal that brings front control into an on state or an off signal that brings the front control into an off state; an open / close command part configured to generate an open / close command signal to open the bypass valve when the signal is determined to be the off / off signal.

Owner:HITACHI CONSTRUCTION MACHINERY CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap