Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Dewatering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dewatering /diːˈwɔːtərɪŋ/ is the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes, such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes.

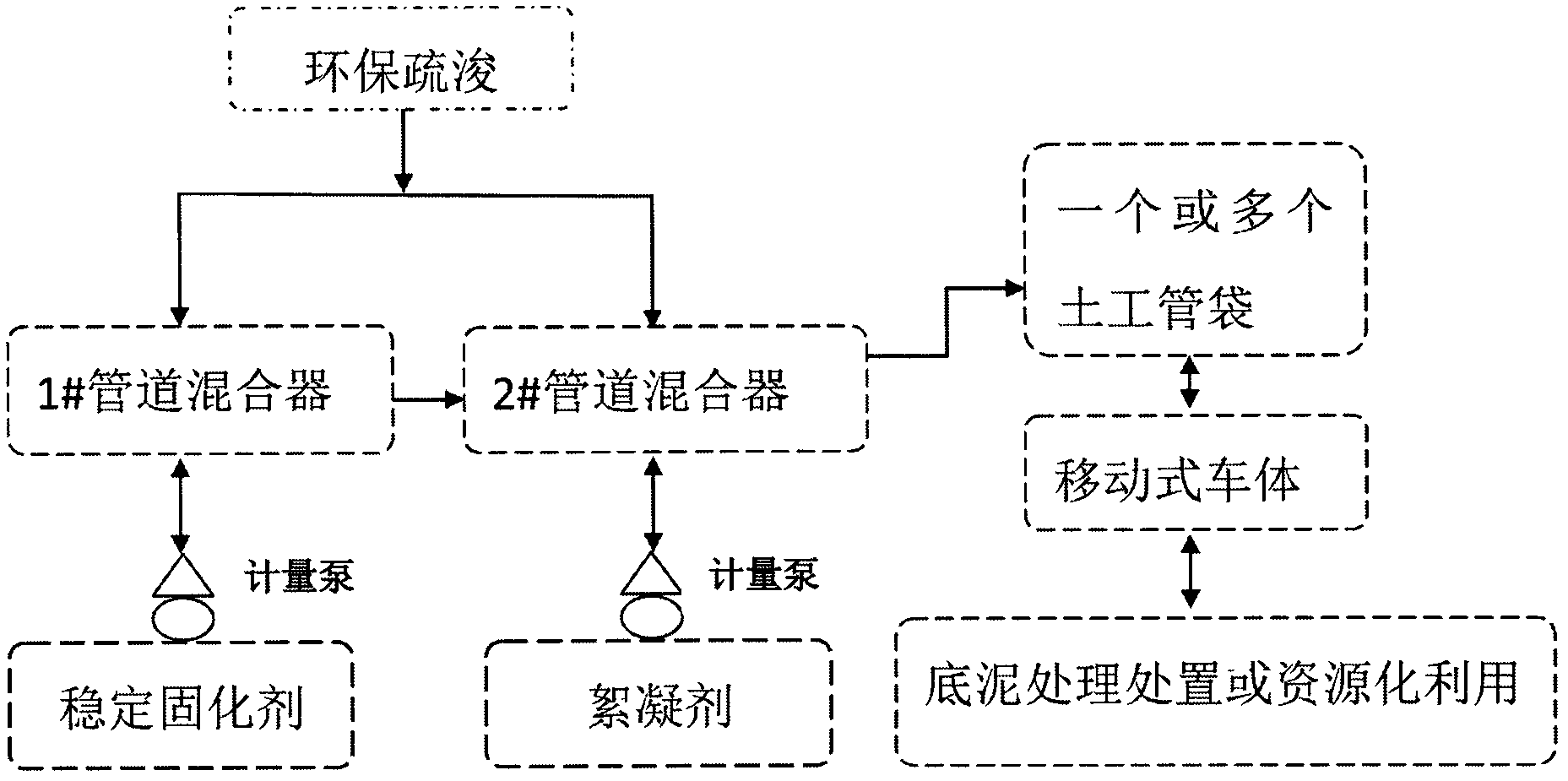

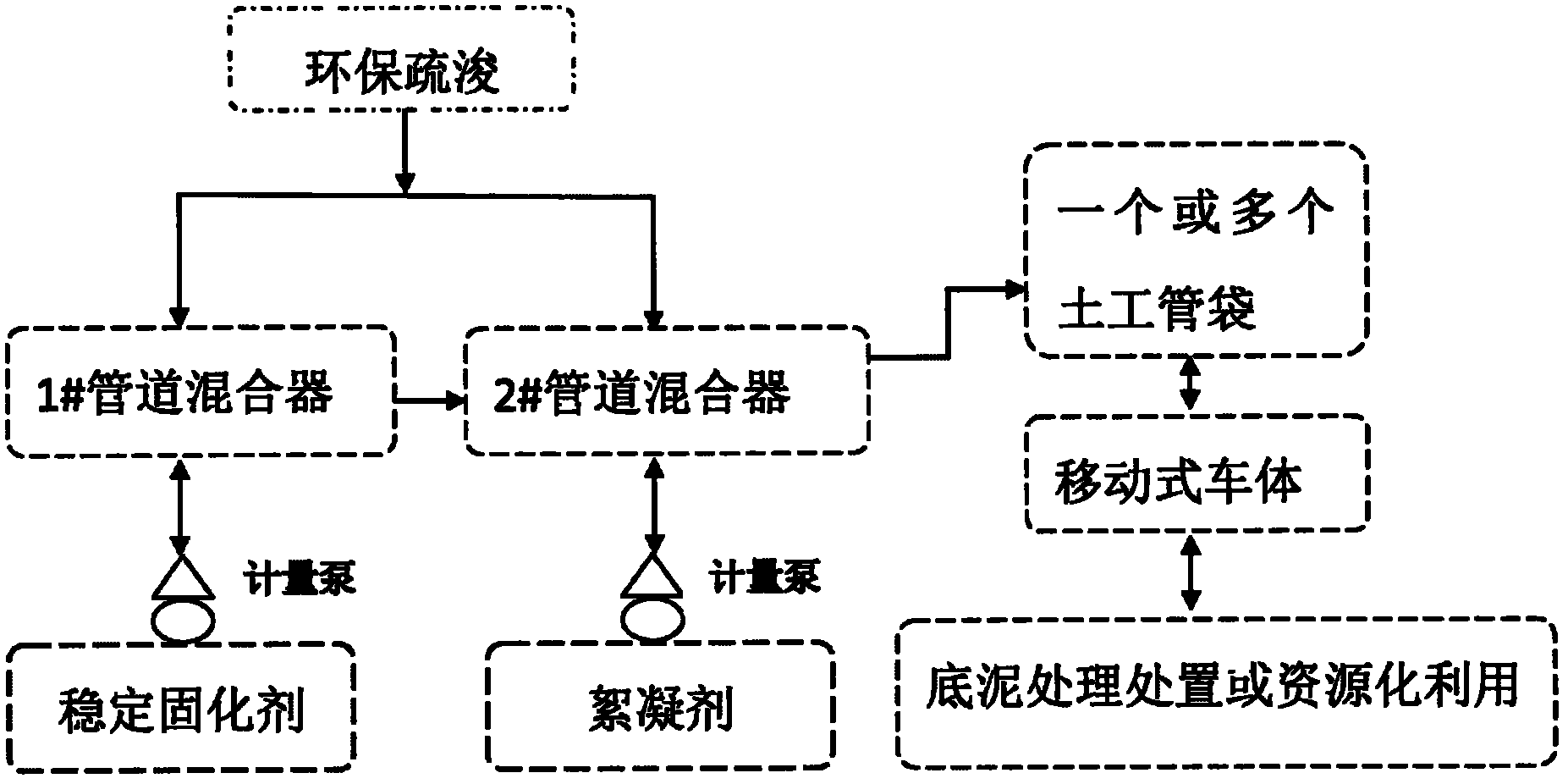

Mobile contaminated bottom mud bag pocket dewatering and volume reduction treatment method

InactiveCN102583950ASolve the problem of land occupationWill not cause secondary pollutionSludge treatment by de-watering/drying/thickeningSludgeResource utilization

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

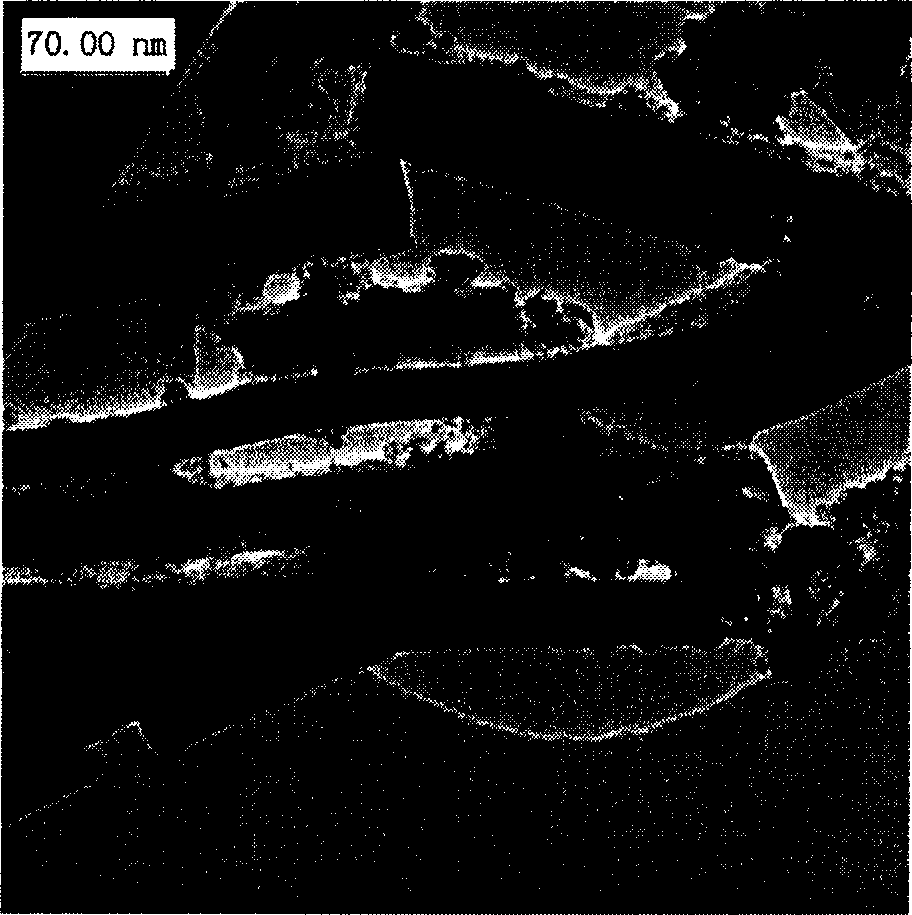

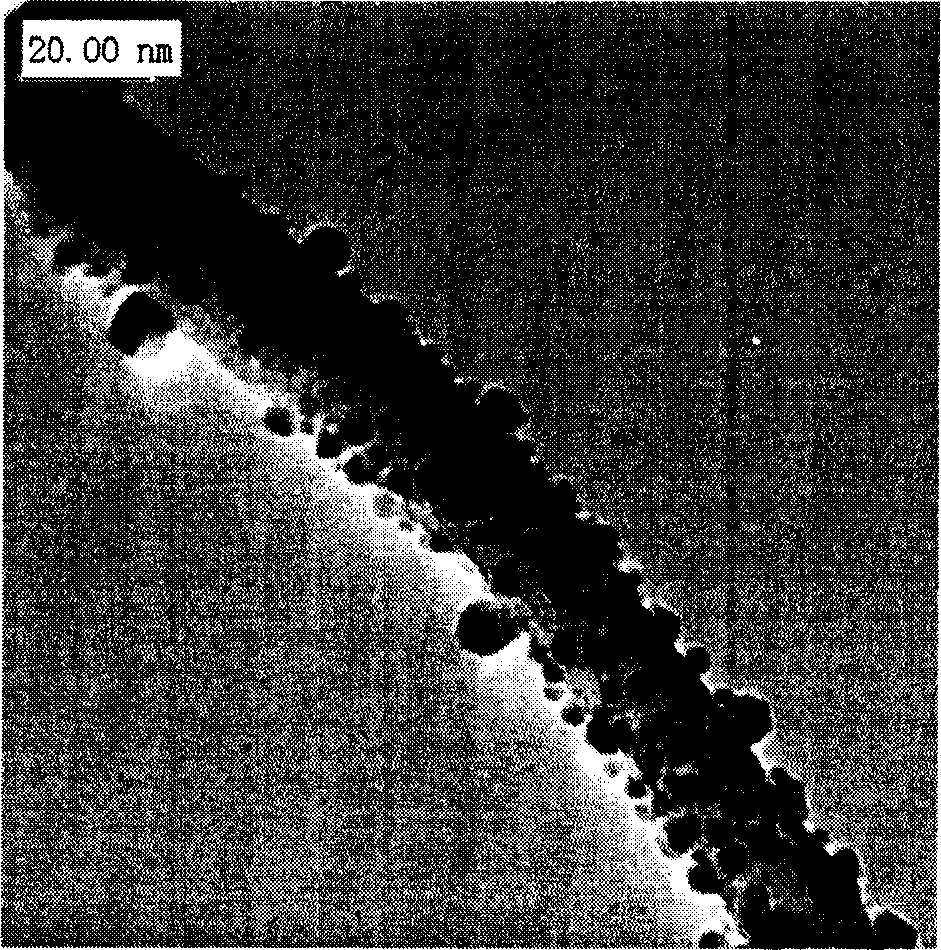

Magnetic granule and attapulgite nanometer composite material, and hydrolytic method for preparing its ferrous salts

InactiveCN1830884AWith characteristicsResolve separabilityWater/sewage treatment by sorptionClaywaresFerrous saltsMagnetite Nanoparticles

Owner:HEFEI UNIV OF TECH

Method for coloring and flavouring animal hide chewing gelatin for dog

InactiveCN1451270AThe process is simple and effectiveReliable colorOther apparatusFlavorFood colouring

Owner:WENZHOU ZHONGSHI PET FOOD CO LTD

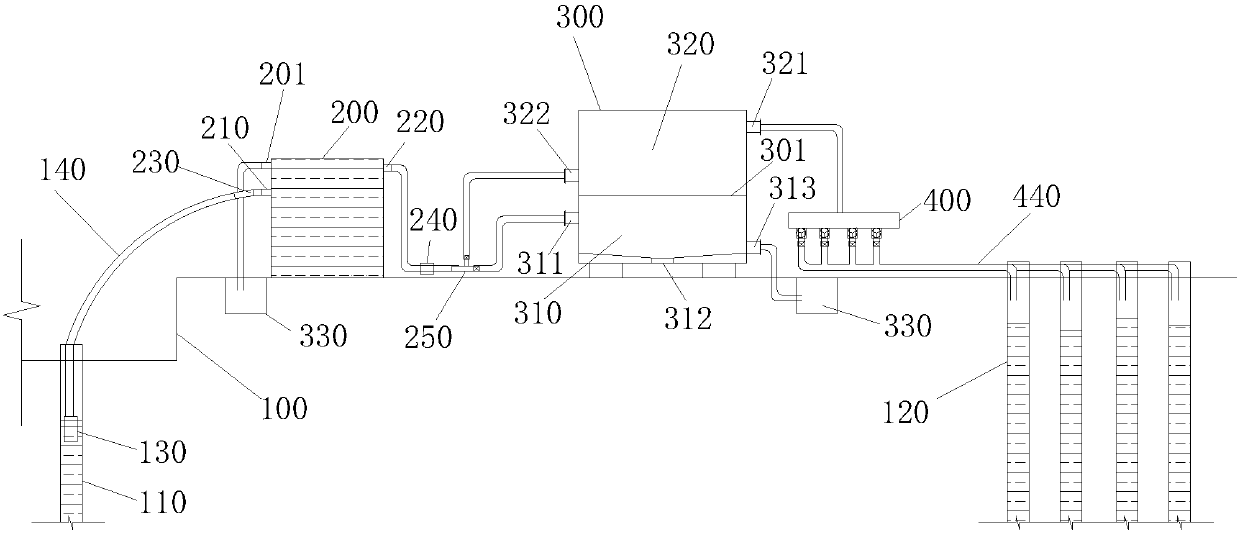

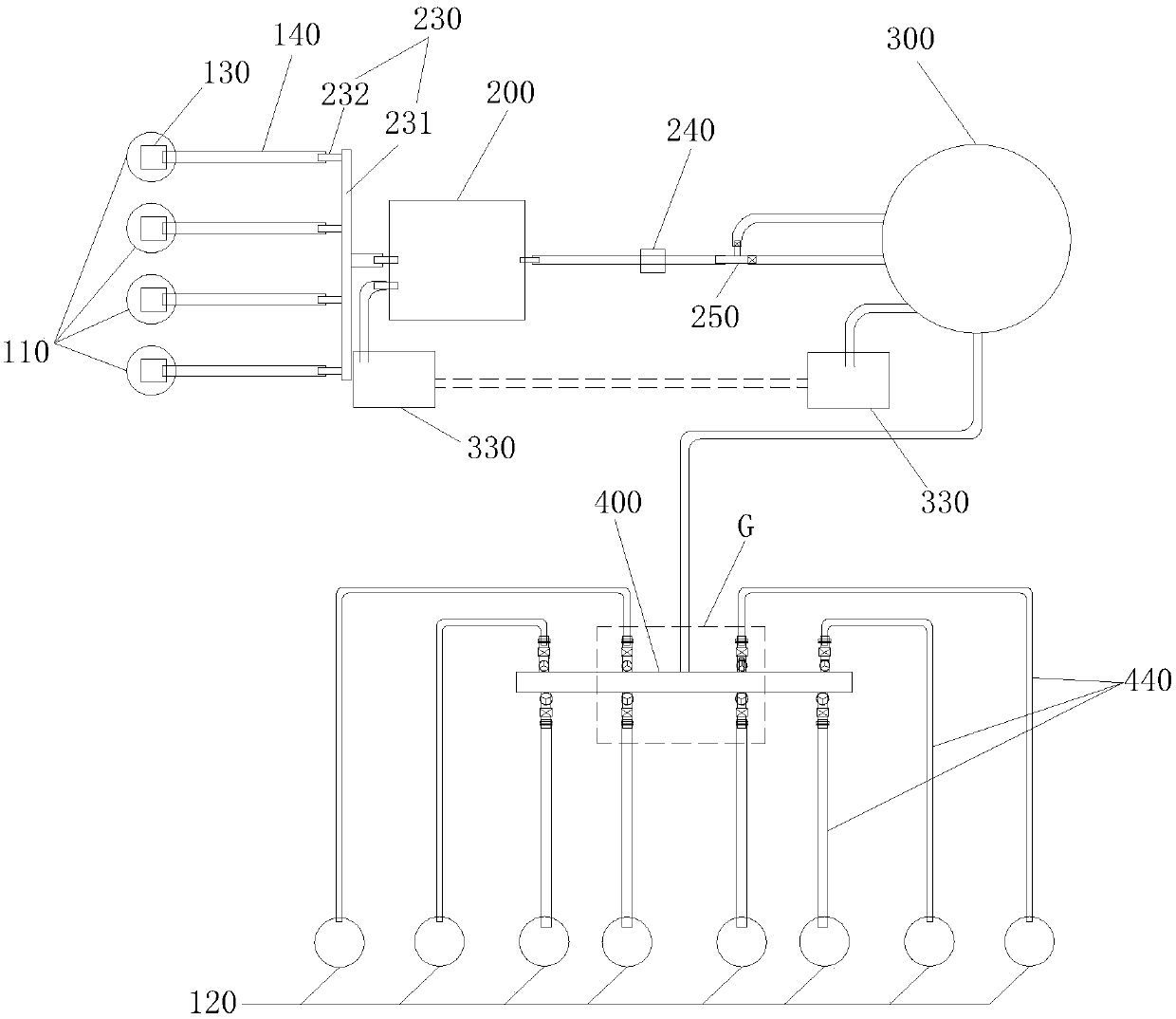

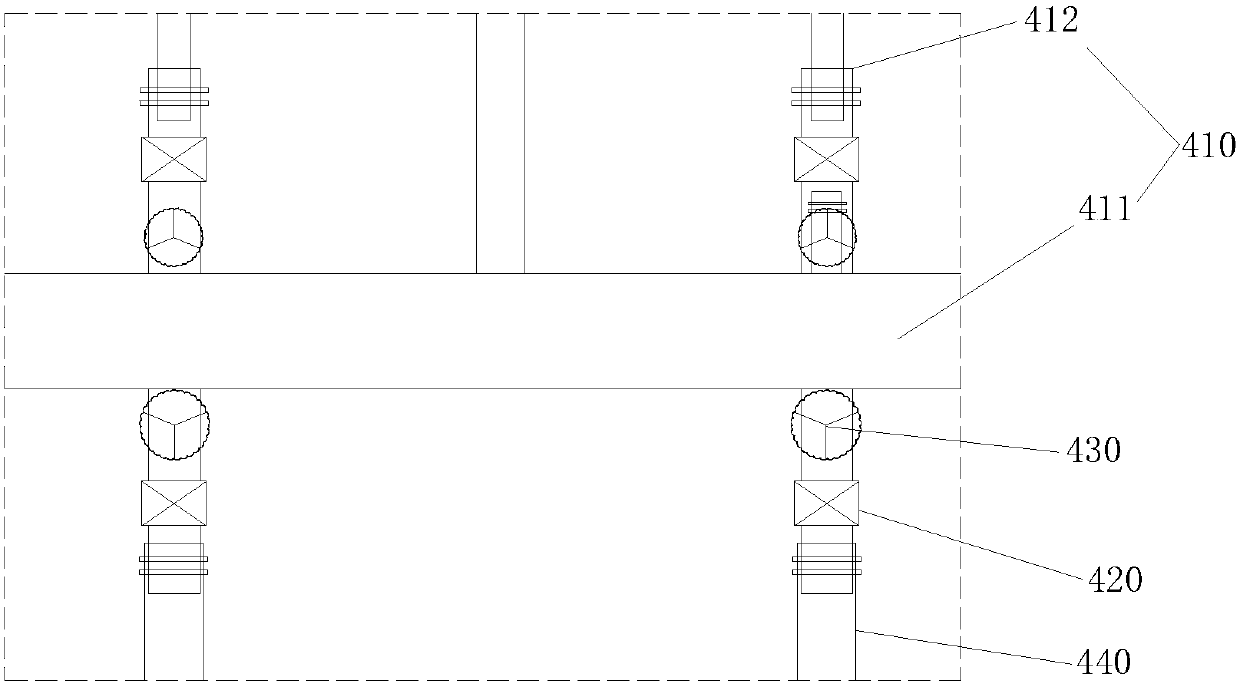

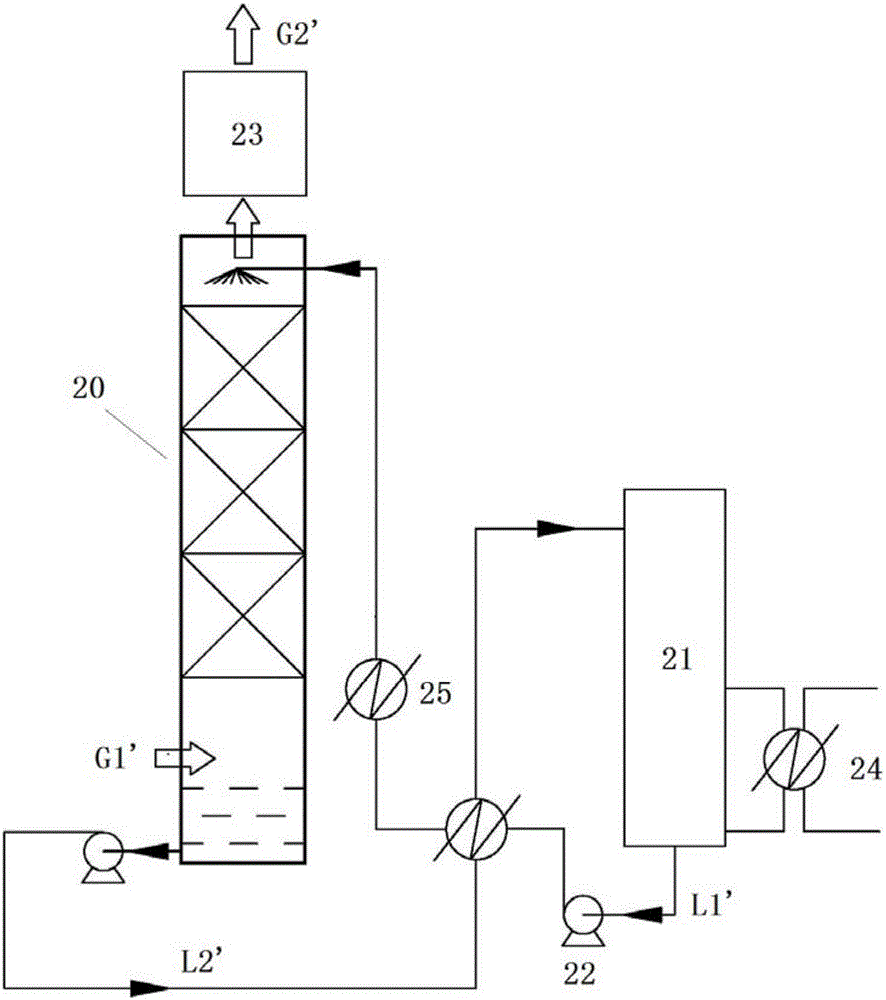

Deep foundation pit dewatering, purification and recharging all-in-one system and control method

Owner:SHANGHAI CONSTR NO 1 GRP

Ionic liquid dehumidifying method and system for regulating gas humidity

InactiveCN106076078AEfficient removalQuick removalGas treatmentDispersed particle separationHigh humidityIonic liquid

Owner:SUZHOU MOEWE ENVIRONMENTAL ENG CO LTD

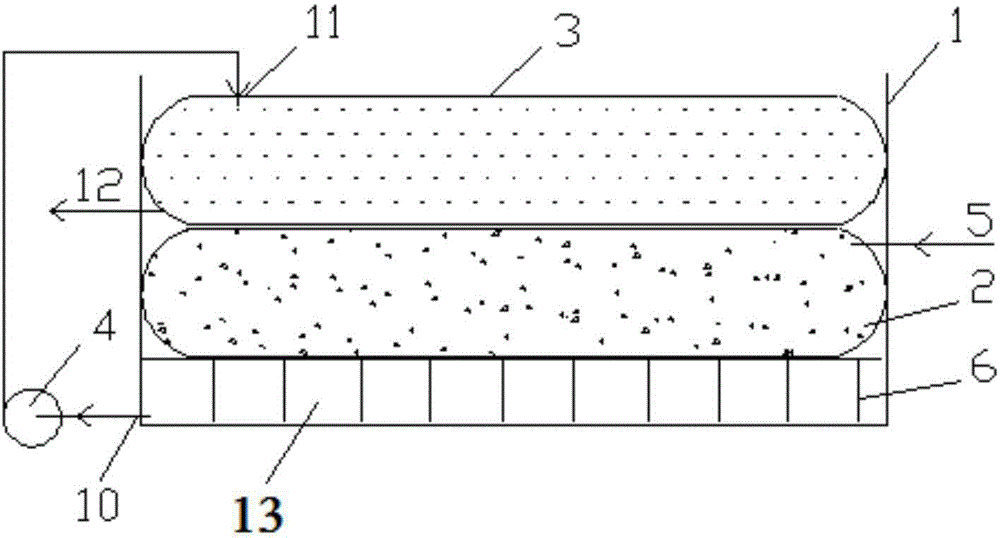

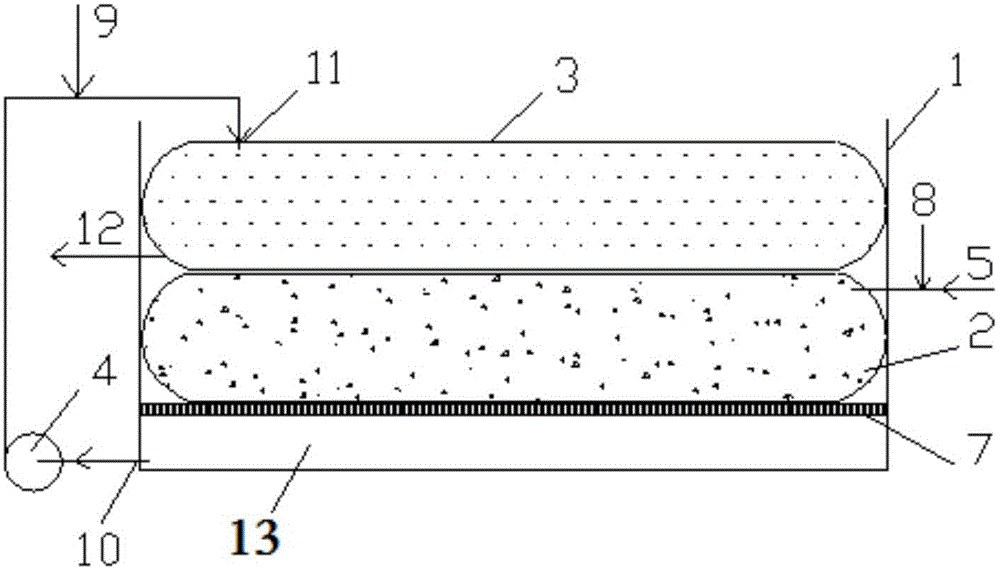

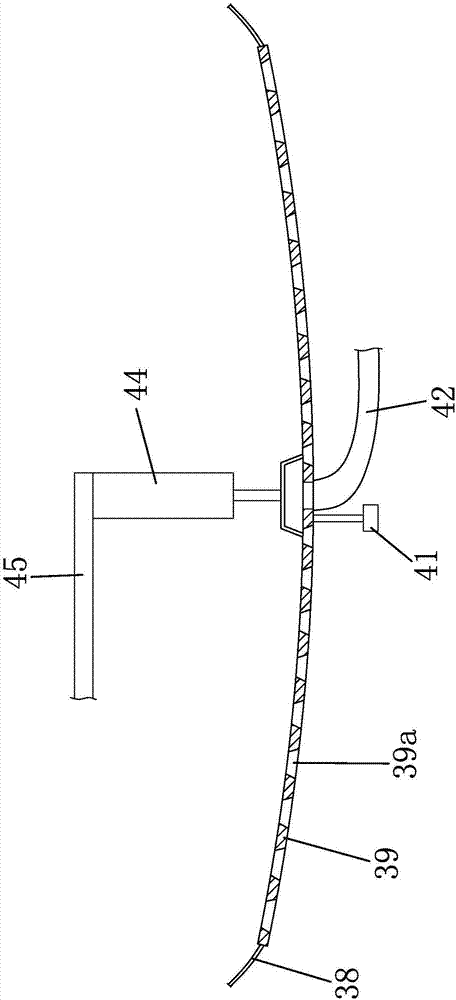

Hydraulic geotextile bag dewatering box

InactiveCN104860502AImprove dehydration effectImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningSludgeWater quality

Owner:天津市海顺交通工程设计有限公司 +1

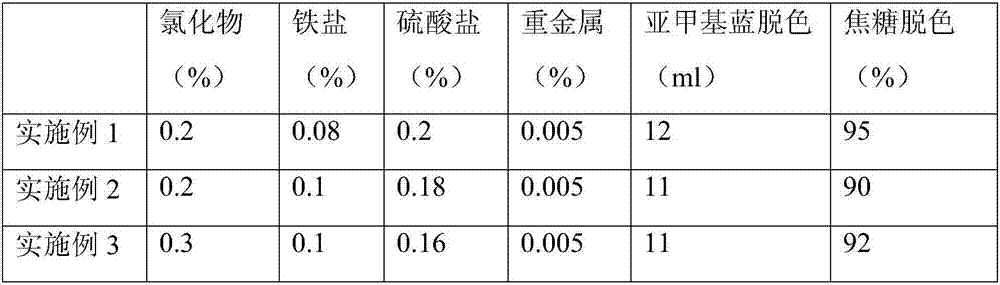

Preparation method of medicinal active carbon

InactiveCN106976873AFast decolorizationImprove adsorption capacityCarbon compoundsEcological environmentCarbonization

Owner:句容市盛达环保净化材料有限公司

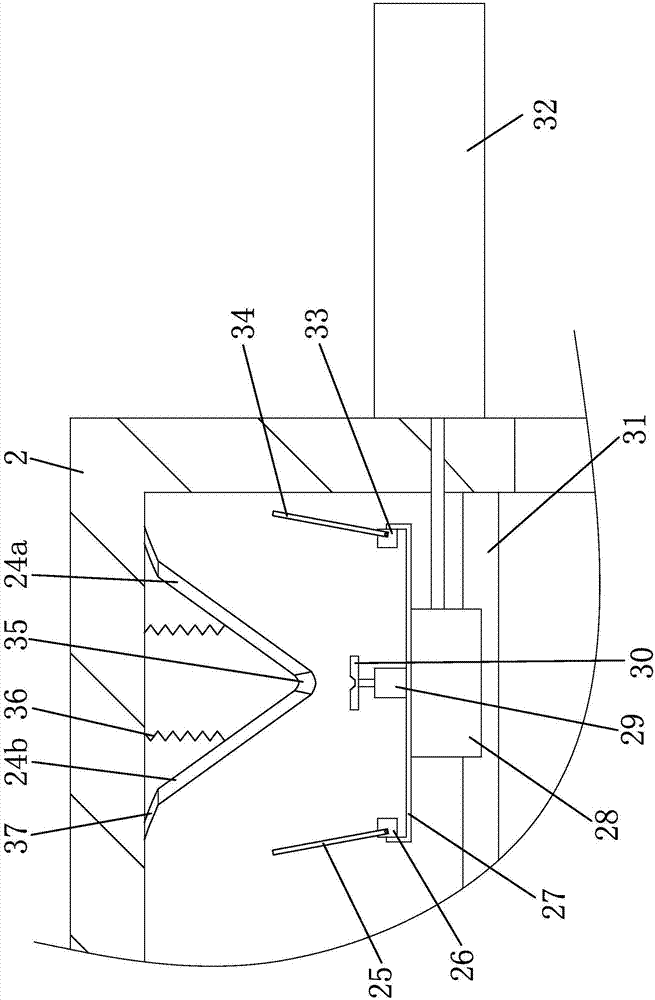

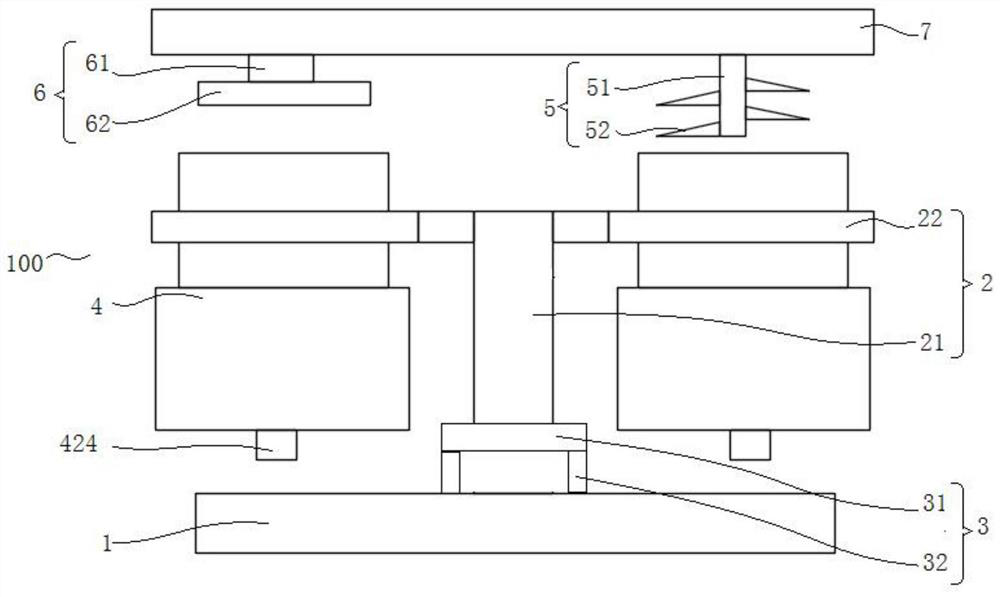

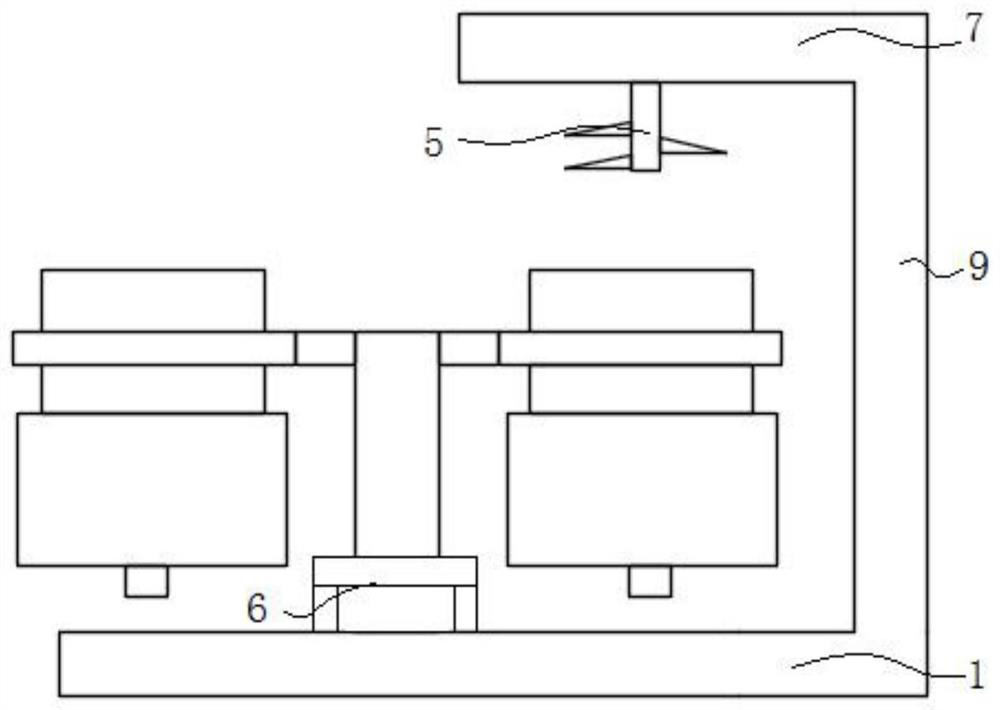

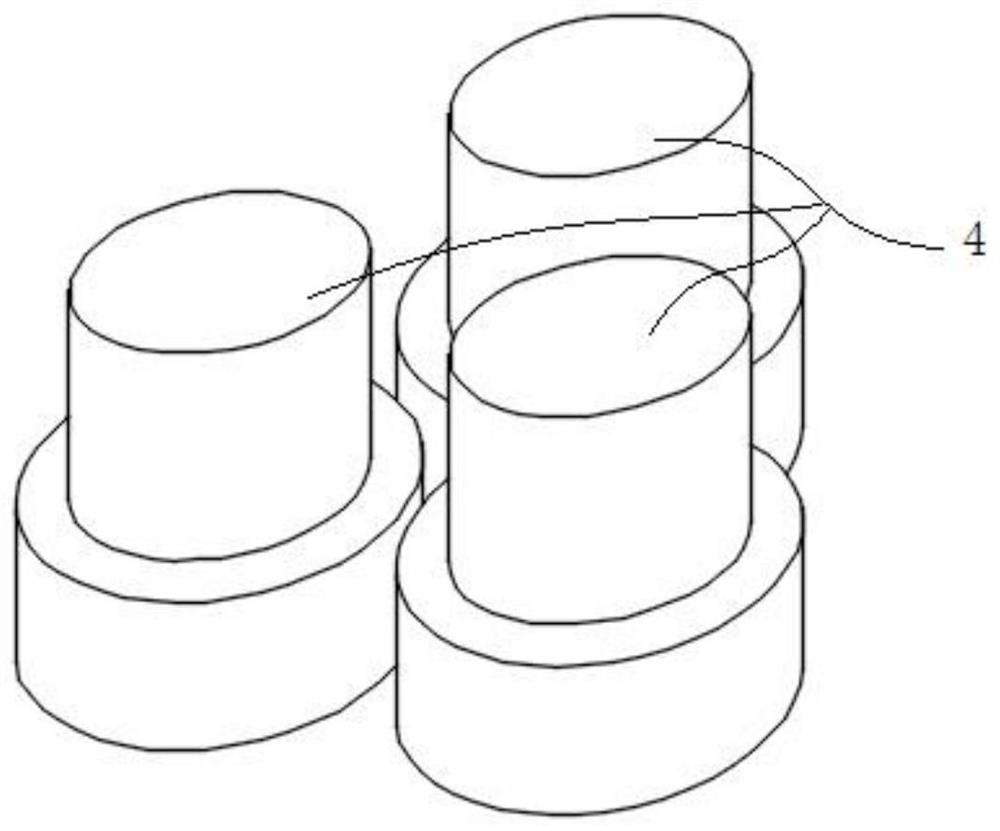

Fully automatic retarding clutch for washing machine

InactiveCN101195956ASmall opening forceReduce manufacturing costOther washing machinesToothed gearingsFully automaticDewatering

The invention discloses a fully automatic decelerating clutch of a washing machine, which relates to the washing machine technology field. The invention is composed of an input axle, an output axle, an output axle sleeve, an input axle sleeve, a braking wheel, and a double driving gear mechanism installed inside the braking wheel. The input axle, the output axle sleeve, the output axle are respectively connected with the double driving gear mechanism, the braking wheel and the output axle sleeve are mutually inverse, biaxially driven in proportion, repeatedly swung and rotated, and relatively rubbed and swung by strong force. When in dewatering working condition, the output axle and the output axle sleeve are caused to be automatically combined through the locking effect of the clutching device, simultaneously to perform high speed single direction continuous rotating for centrifugal dewatering. The structure is simple, the performance of decelerating clutching device of the normal washing machine is improved, the structure of the operation system is simplified, the noise of the washing machine is reduced, and the efficiency and the service life of the washing machine are enhanced.

Owner:NINGGUO JULONG IND

Denim fabric printing and dyeing process

ActiveCN107254786AFast coloringNot easy to fadeLiquid/gas/vapor removalTextile treatment machine arrangementsSodium bicarbonateDenim

Owner:上海宛林服装有限公司

Kitchen waste recycling system

PendingCN113732020AEffective interceptionAvoid enteringSolid waste disposalGrain treatmentsEnvironmental engineeringWaste treatment

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap