Hydraulic geotextile bag dewatering box

A dehydration box and geotechnical bag technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of difficult on-site operation, pollution, and low dehydration efficiency, so as to reduce secondary pollution, shorten operation time, and improve dehydration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

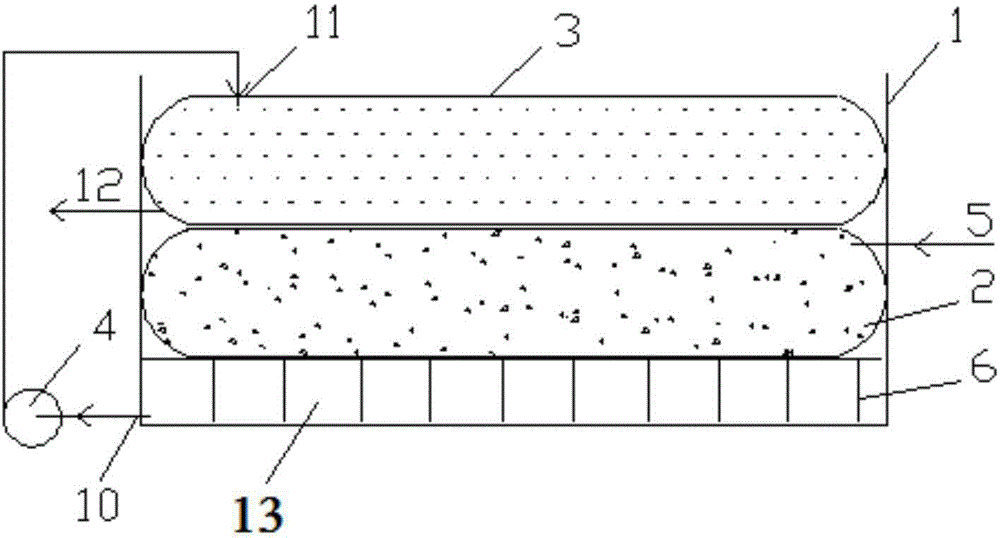

[0015] Such as figure 1 As shown, the dehydration box 1 is placed on a flat and relatively hard ground or platform, and the seepage pool 13 is formed between the platform brackets arranged at the bottom of the dehydration box 1, and the dehydration bag 2 is placed on the bracket 6 at the bottom of the box body 1, and then Put the hydraulic bag 3 flat on the dehydration bag 2, then connect the mud injection port 5 of the dehydration bag, and pass the pipeline and the water pump 4 between the water injection port 11 of the hydraulic bag and the water outlet 10 of the seepage tank 13 connect. When working, first inject the slurry to be dehydrated into the dewatering bag 2 through the mud injection port 5, and during the pouring process, water will continuously escape into the seepage pool 13 at the bottom of the box body 1, and start the water pump 4 to collect this part of the dehydrated water from the water outlet 10 And inject it into the water pressure bag 3 through the water i

Embodiment 2

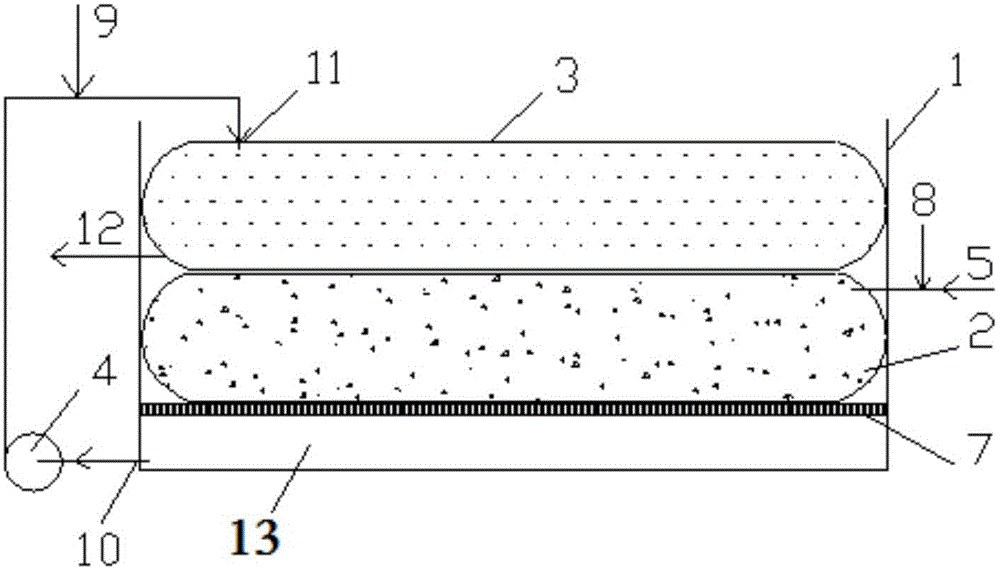

[0017] Such as figure 2 As shown, the dehydration box is placed on a flat and relatively hard ground or platform, and the seepage pool 13 is formed between the partitions arranged at the bottom of the dehydration box 1, and the dehydration bag 2 is placed on the partition 7 at the bottom of the box body 1, and then Put the hydraulic bag 3 flat on the dehydration bag 2, then connect the mud injection port 5 of the dehydration bag, and pass the pipeline and the water pump 4 between the water injection port 11 of the hydraulic bag and the water outlet 10 of the seepage tank 13 connect. Connect dehydration agent 8 (polyferric sulfate, etc.) to the mud injection pipeline, and connect water purification agent 9 (polyaluminum chloride, etc.) to the pipeline at the rear end of the water pump. When working, first inject the mud to be mixed with dehydrating agent into the dehydration bag 2 through the mud injection port 5, during the pouring process, water will continuously escape into t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap