Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Control devices for washing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

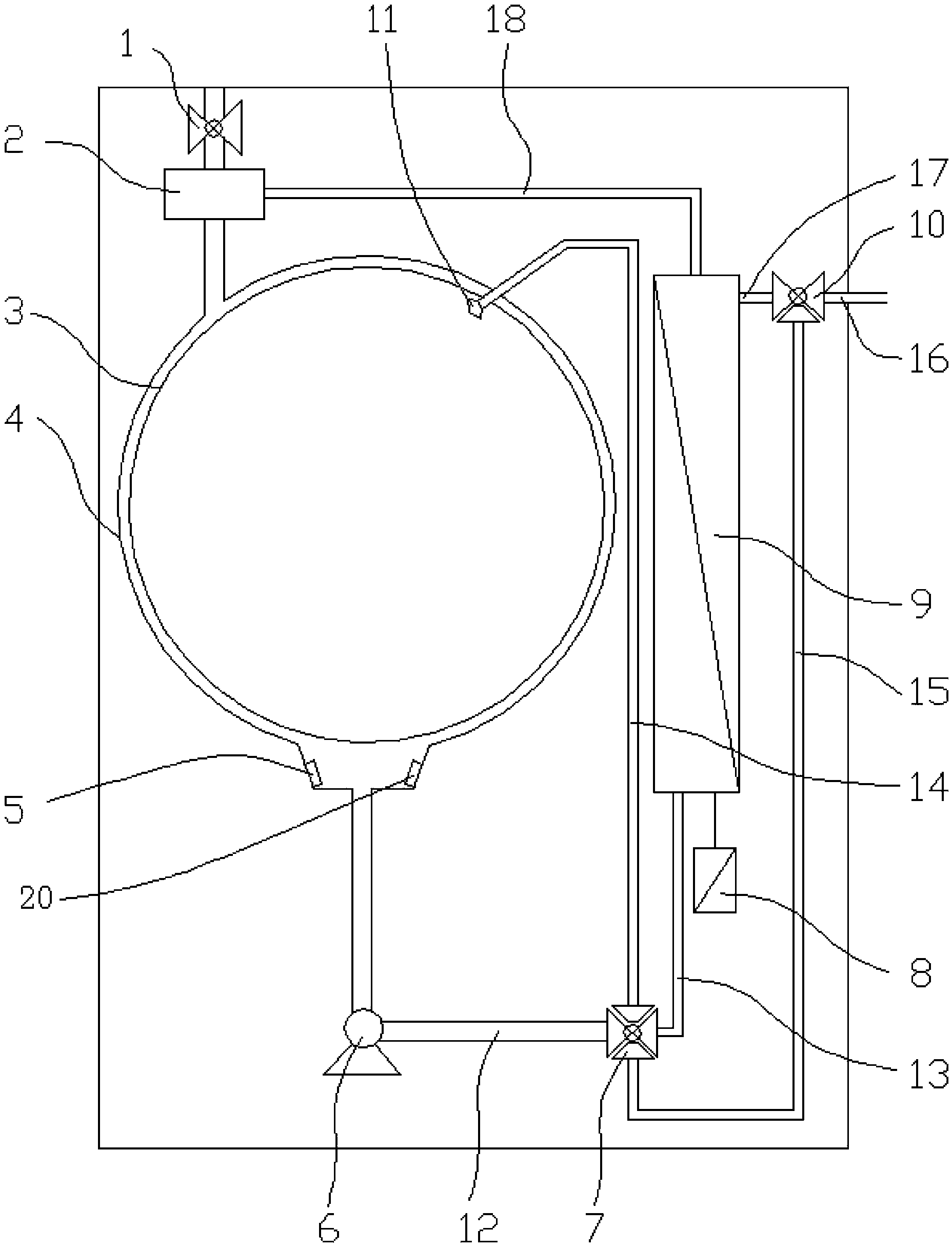

Washing machine and washing method thereof

InactiveCN103343436AOther washing machinesControl devices for washing apparatusInlet channelEngineering

The invention discloses a washing machine and a washing method thereof. The washing machine comprises an inner barrel, a water inlet channel, a storage box and a liquid pump, wherein the water inlet channel is communicated with the inner barrel so that water can be provided for the inner barrel, a plurality of chambers which are mutually separated are arranged in the storage box, each chamber is used for accommodating one kind of liquid agent and is communicated with the inner barrel to put a proper amount of the liquid agent in the chamber into the inner barrel, and the liquid pump is arranged between the storage box and the inner barrel through an on-off piece and is used for controlling the storage box to put the liquid agents into the inner barrel. According to the washing machine, the storage box provided with the chambers is arranged, various kinds of liquid agents can be stored in the storage box, and therefore, different kinds of liquid agents can be put into the inner barrel according to different requirements of users; due to the arrangement of the on-off piece, connection and disconnection between the chambers of the storage box and the inner barrel can be controlled, corresponding liquid agents can be put into the inner barrel according to the actual requirements of the users, and various kinds of liquid agents can be put into the inner barrel within one washing cycle.

Owner:WUXI LITTLE SWAN CO LTD

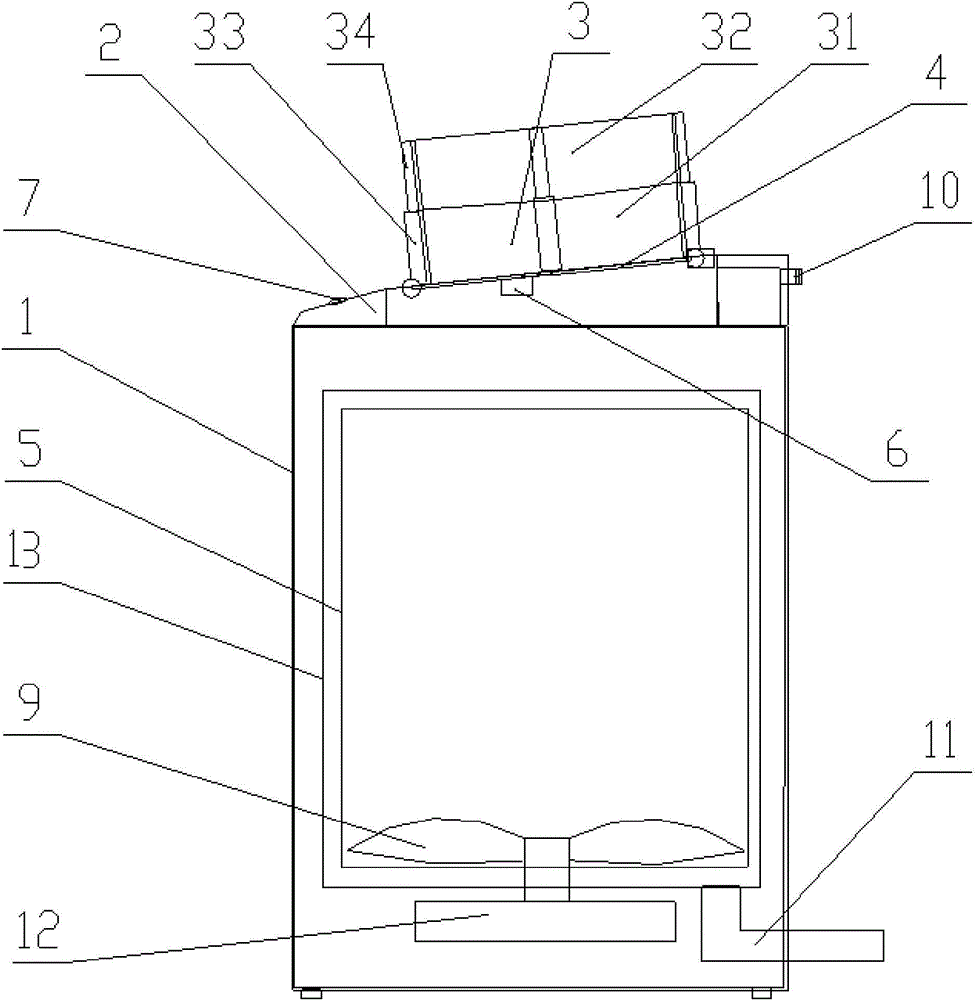

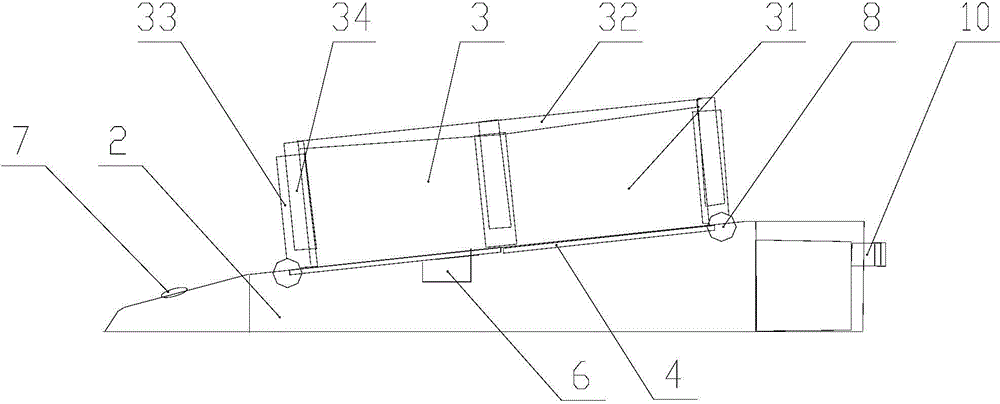

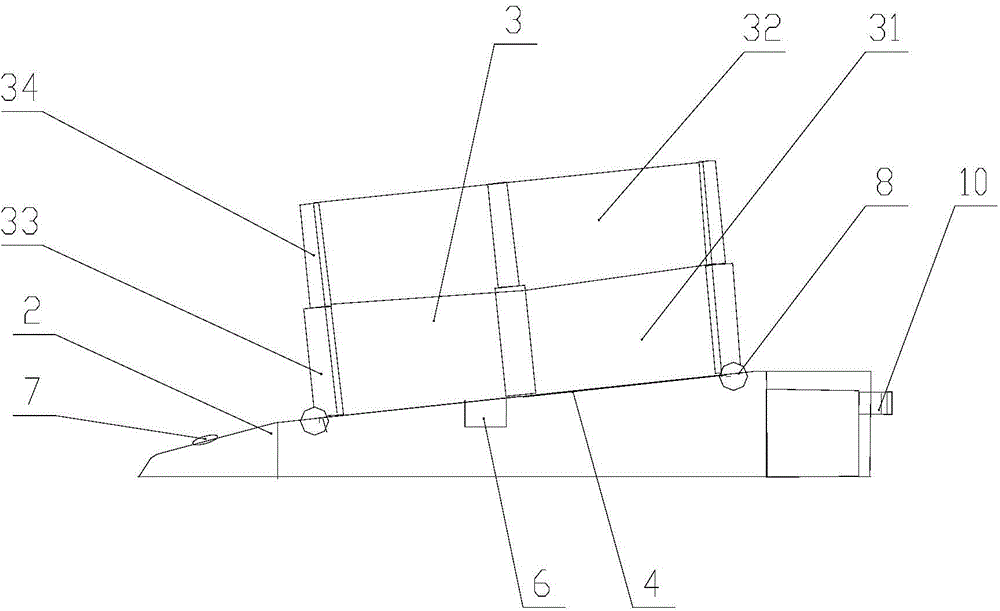

Washing machine having clothes releasing function and control method thereof

ActiveCN106032627ARealize the automation of feeding and washingImprove experienceOther washing machinesControl devices for washing apparatusMachine controlMechanical engineering

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

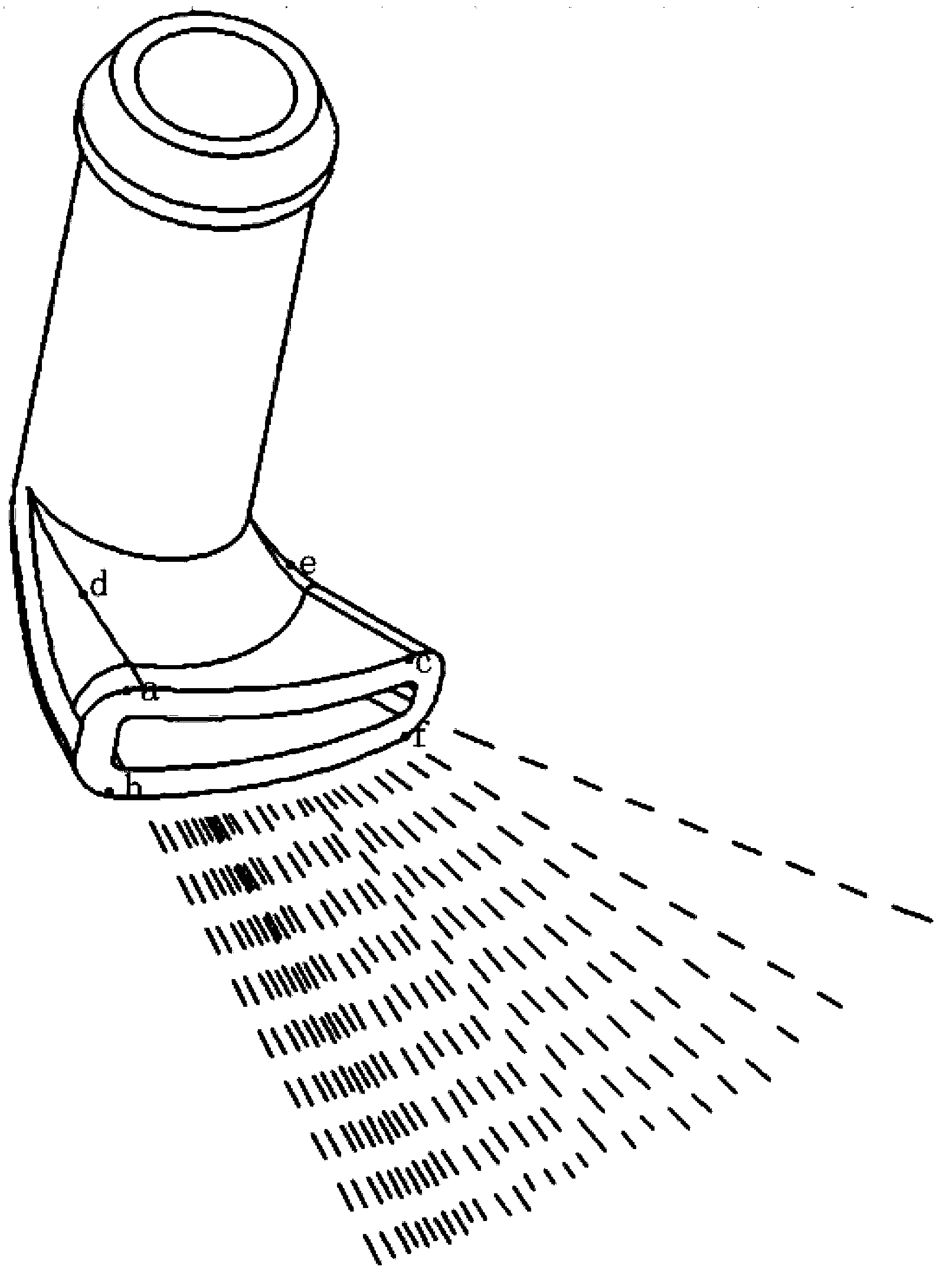

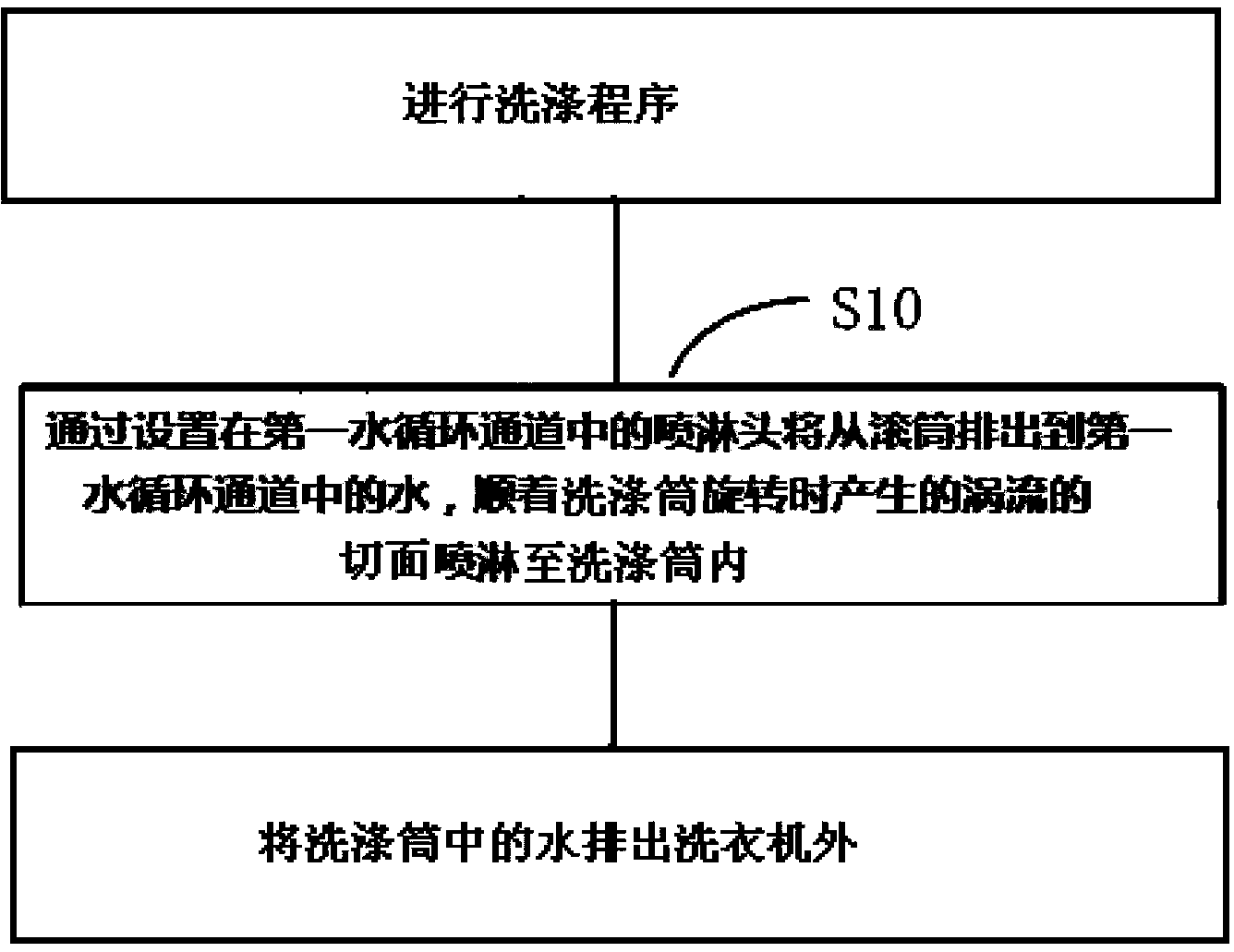

Washing machine and clothes washing control method

ActiveCN104074023AFast water seepageIncrease contact areaOther washing machinesControl devices for washing apparatusEngineeringEddy current

Owner:HAIER GROUP TECHN R&D CENT +1

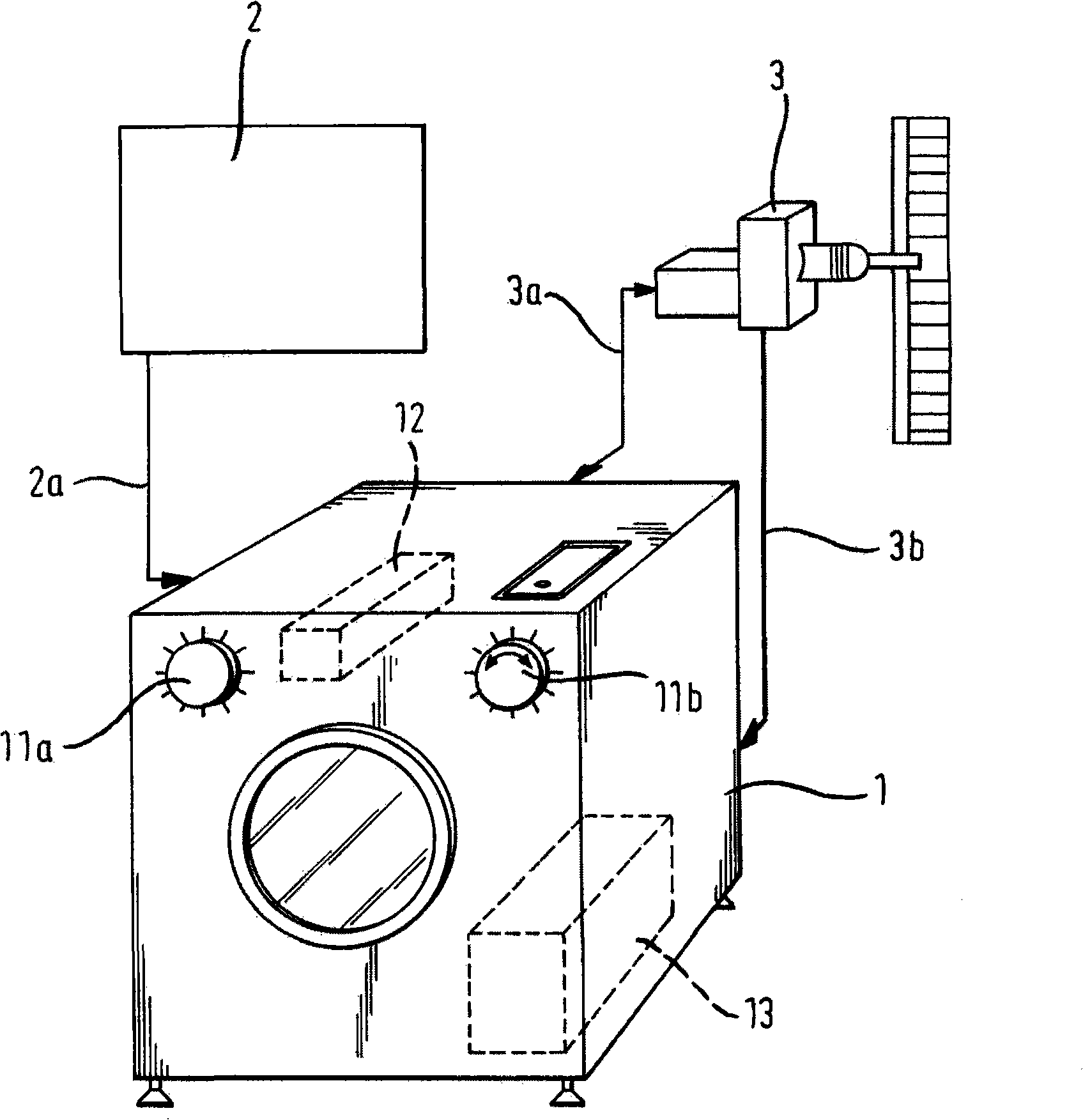

Washing machine

InactiveCN101313101AOther washing machinesControl devices for washing apparatusCommunication unitProcess engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

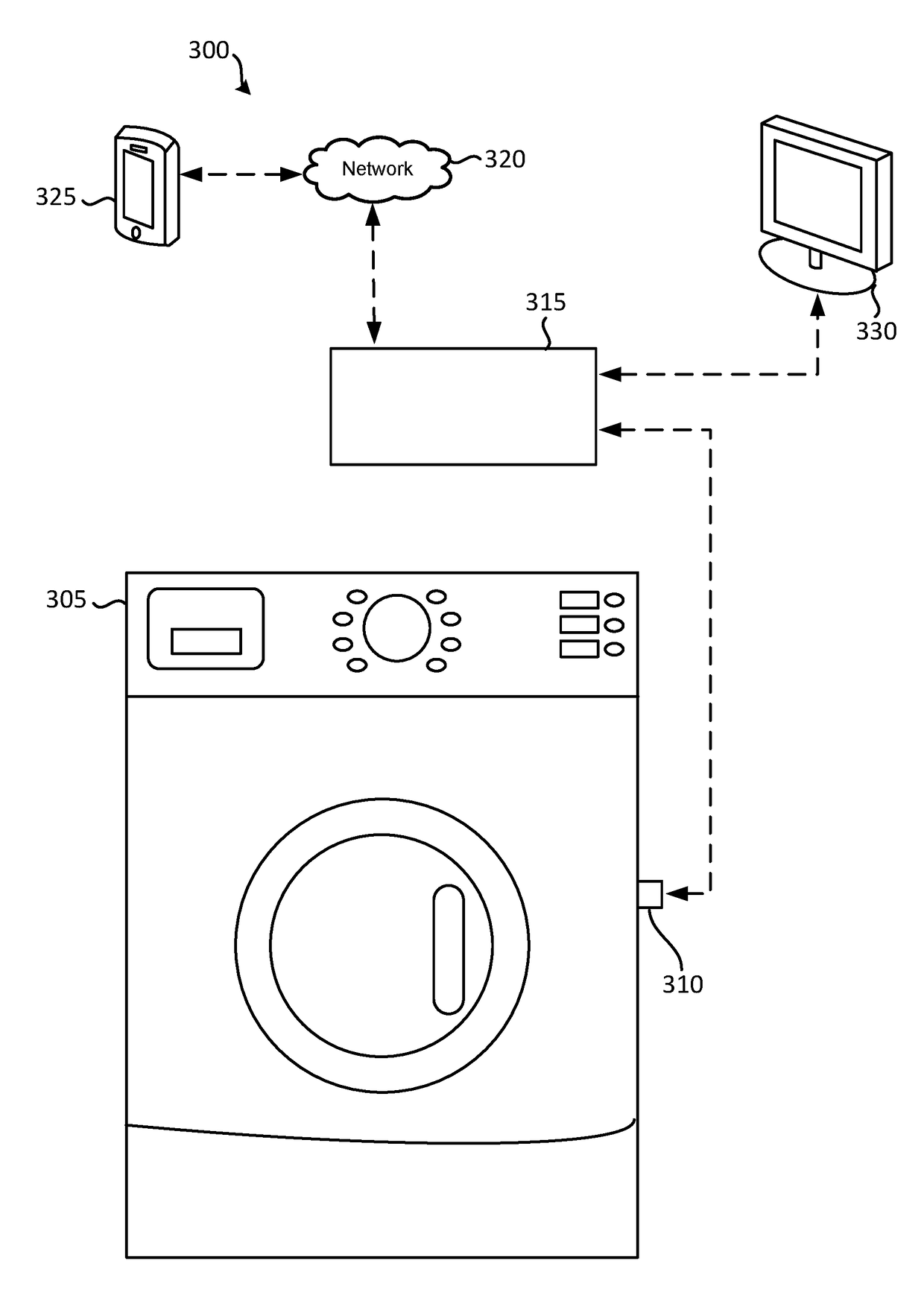

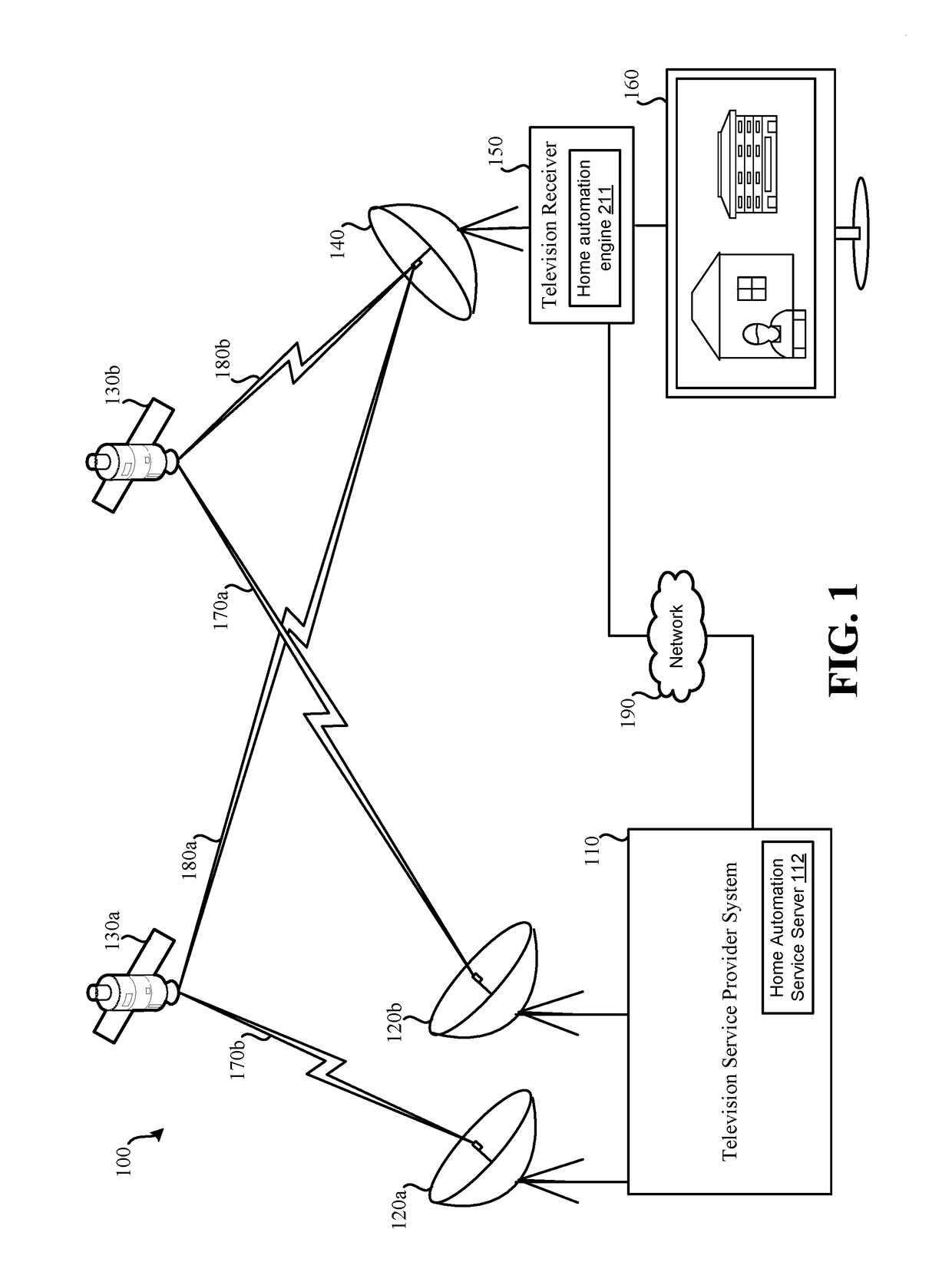

Automated detection of washer/dryer operation/fault condition

ActiveUS20180038029A1Computer controlControl devices for washing apparatusProcess engineeringMems sensors

Owner:ECHOSTAR TECH INT CORP

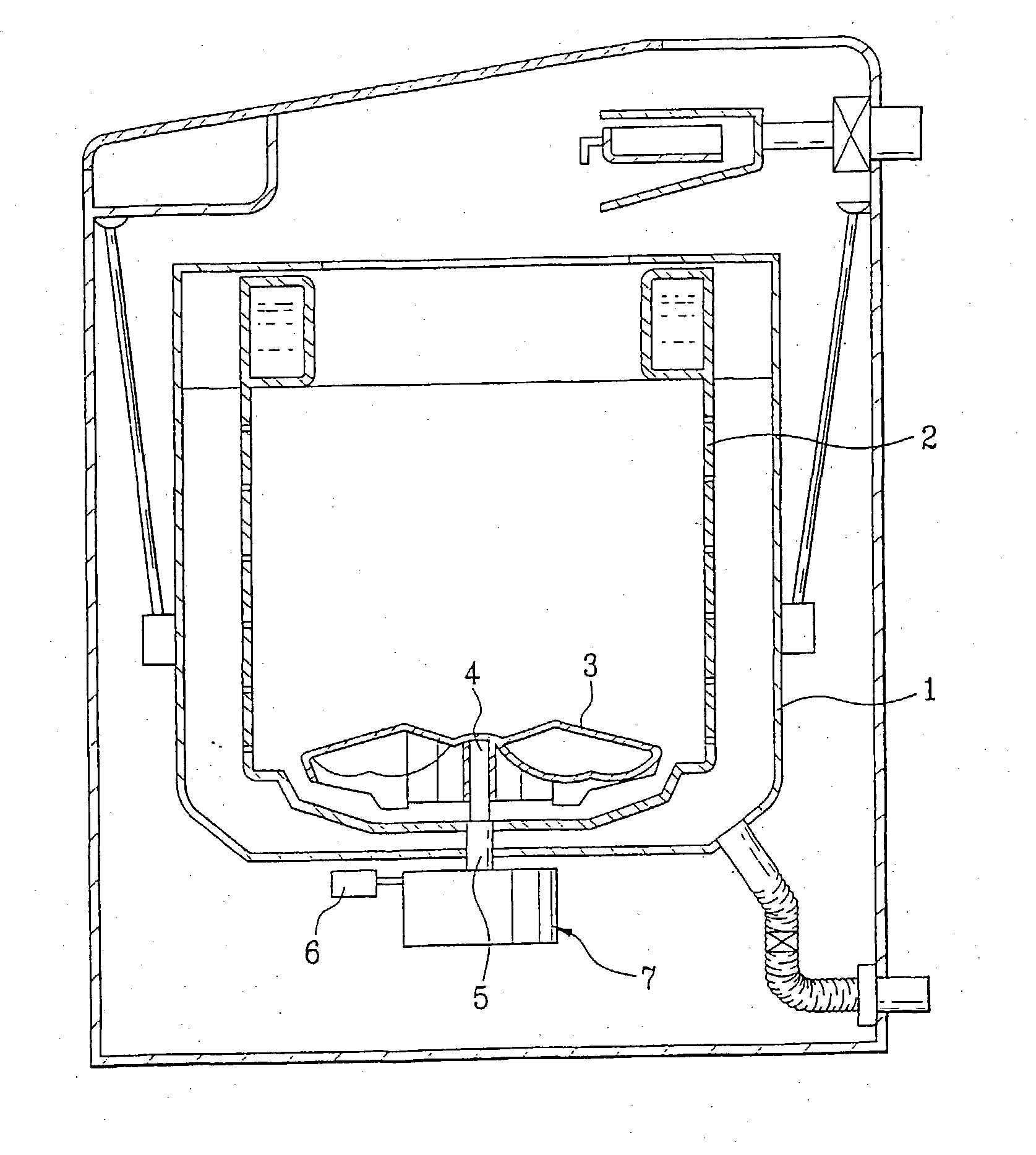

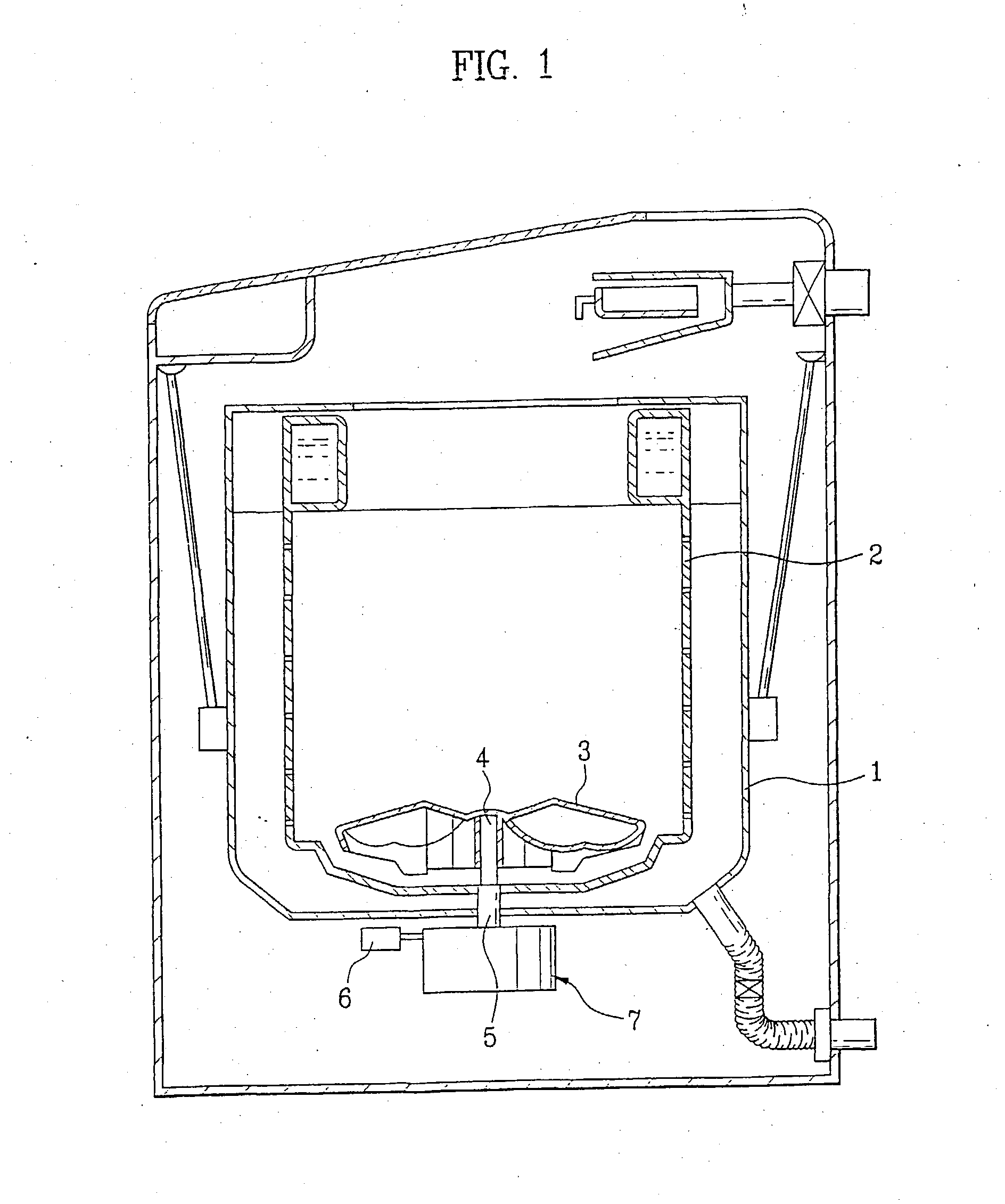

Full automatic washing machine and method for controlling the same

InactiveUS20030177794A1Short timeOther washing machinesControl devices for washing apparatusEngineeringClutch

Owner:LG ELECTRONICS INC

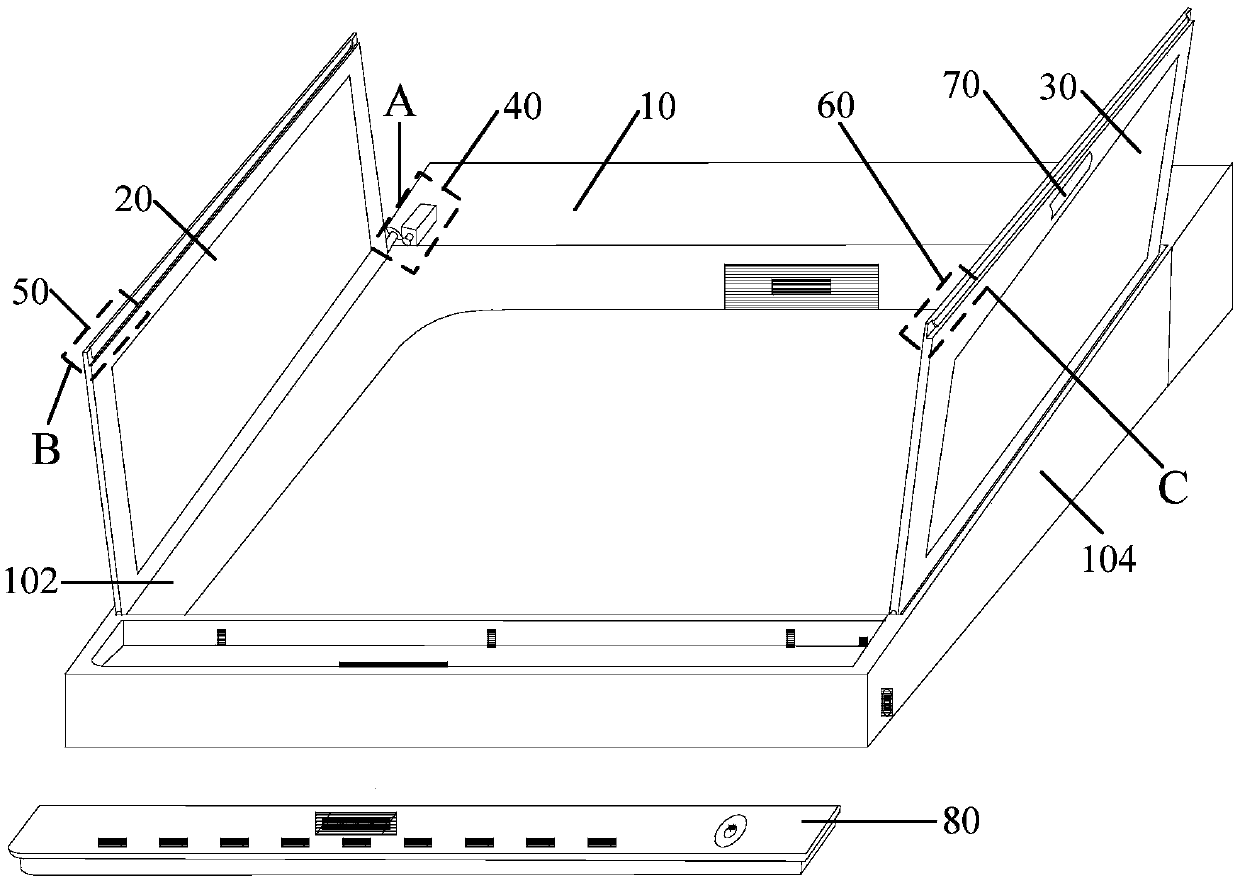

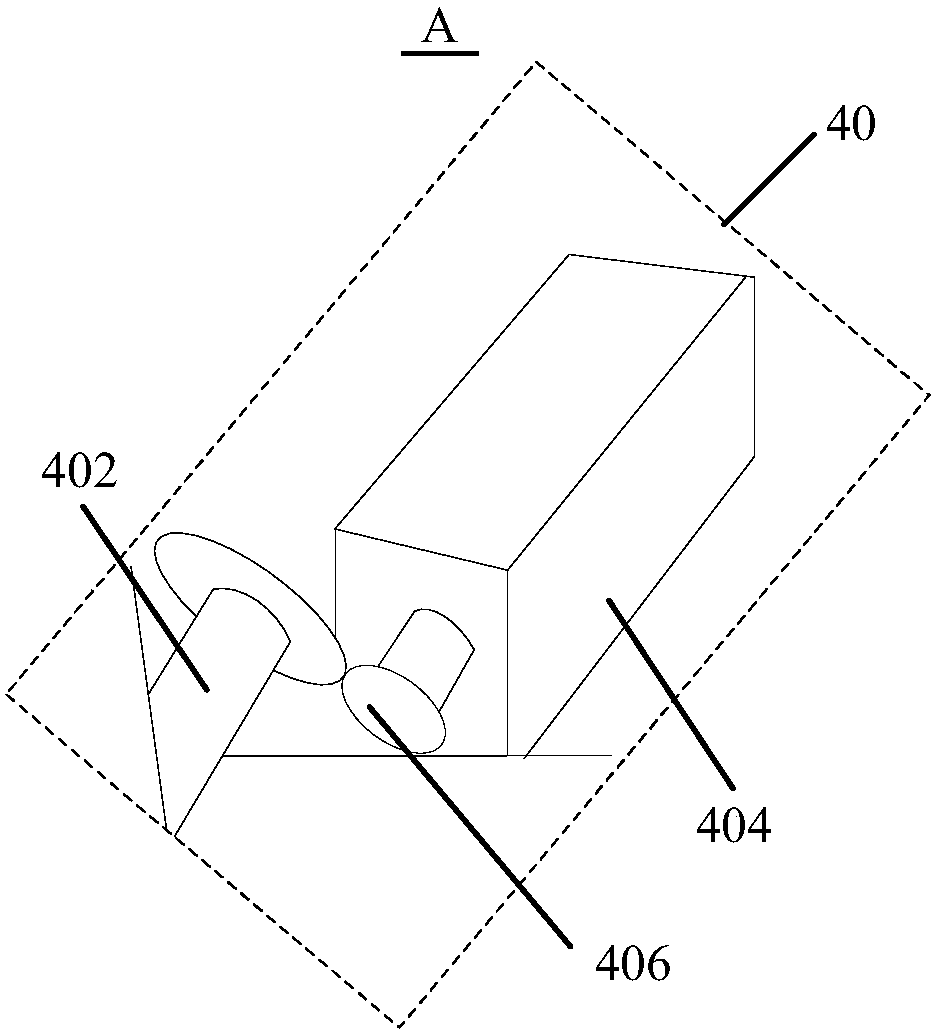

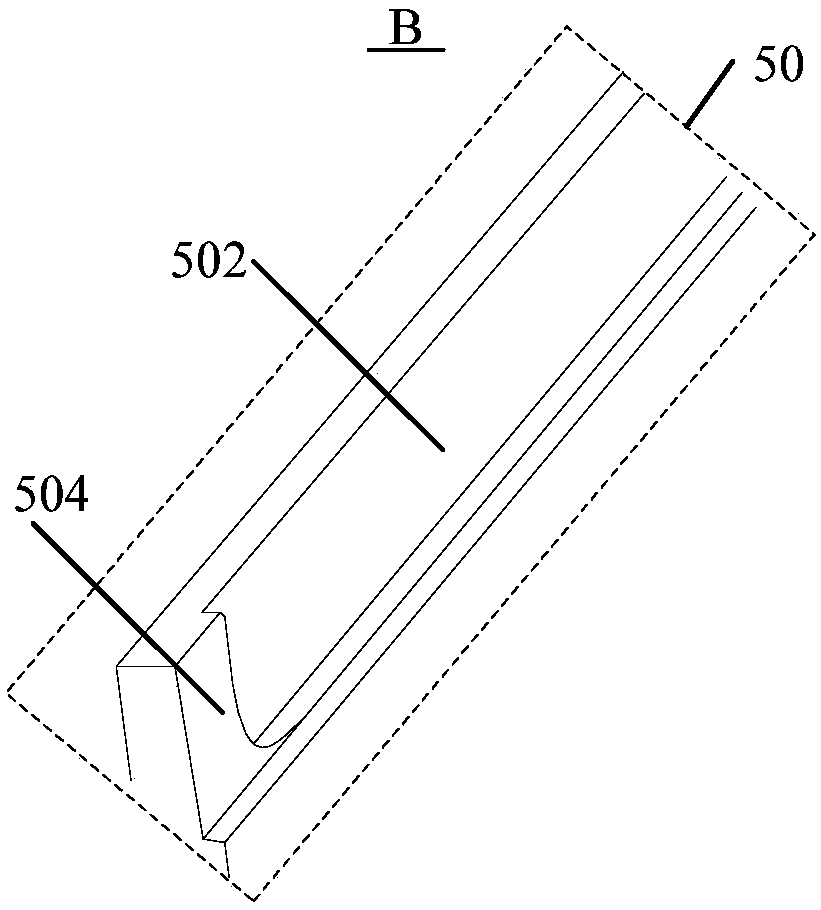

Washing machine and door body assembly control method for same

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

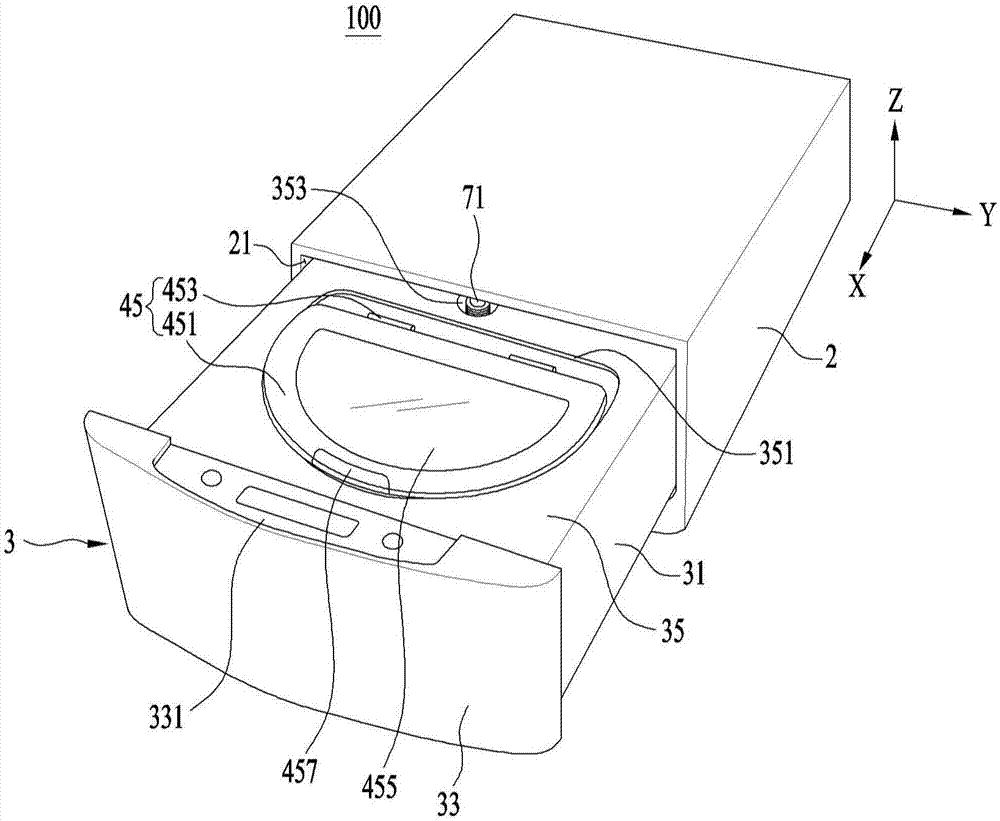

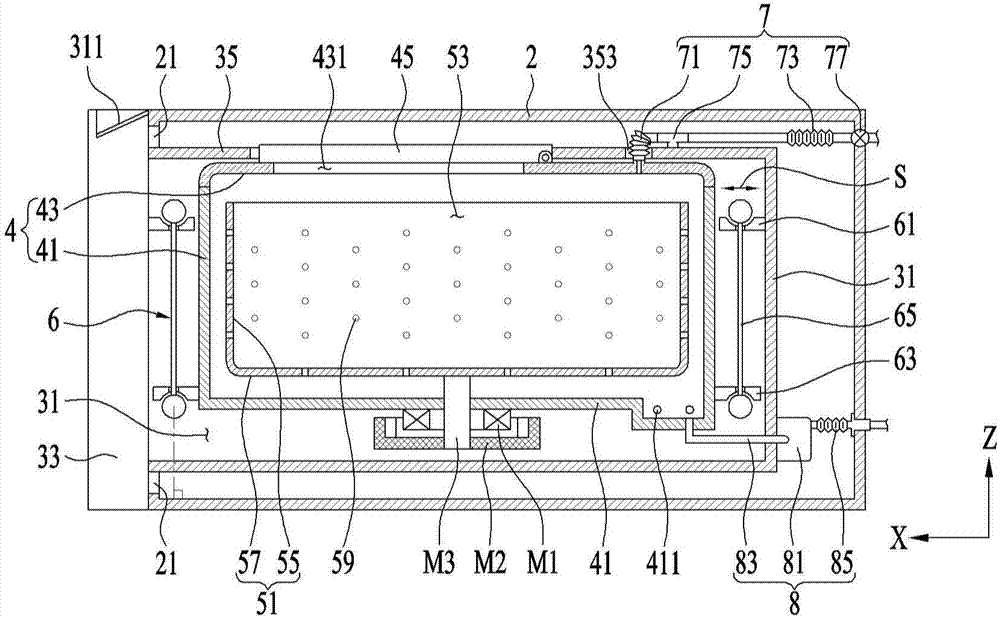

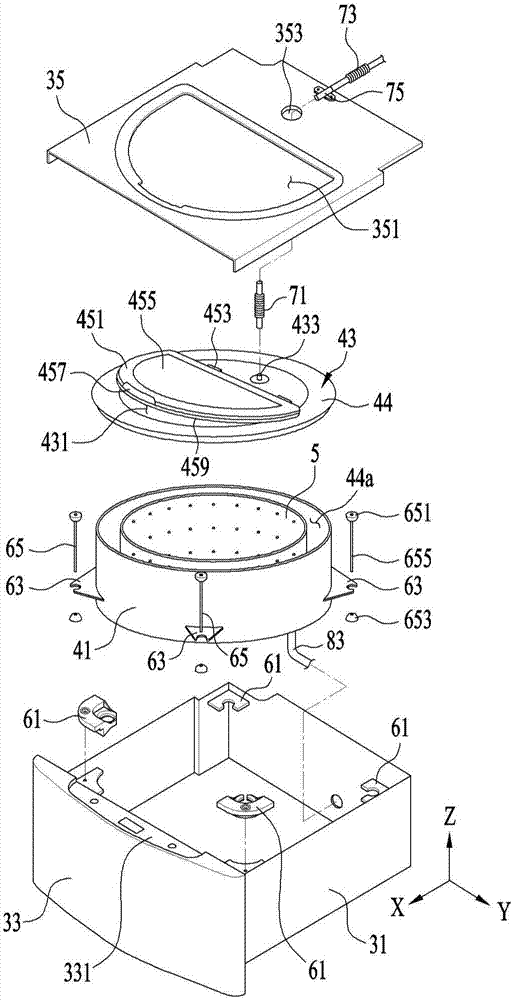

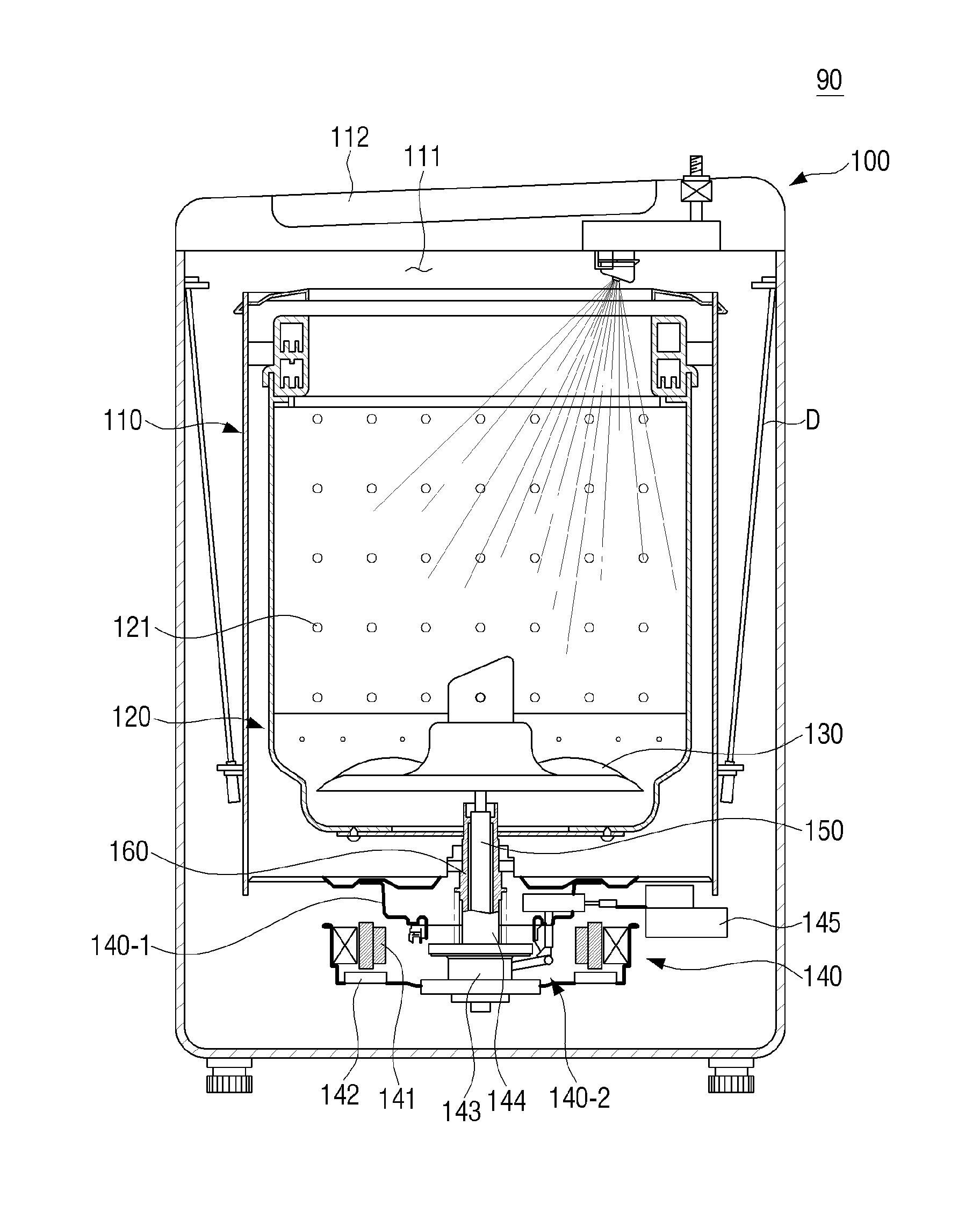

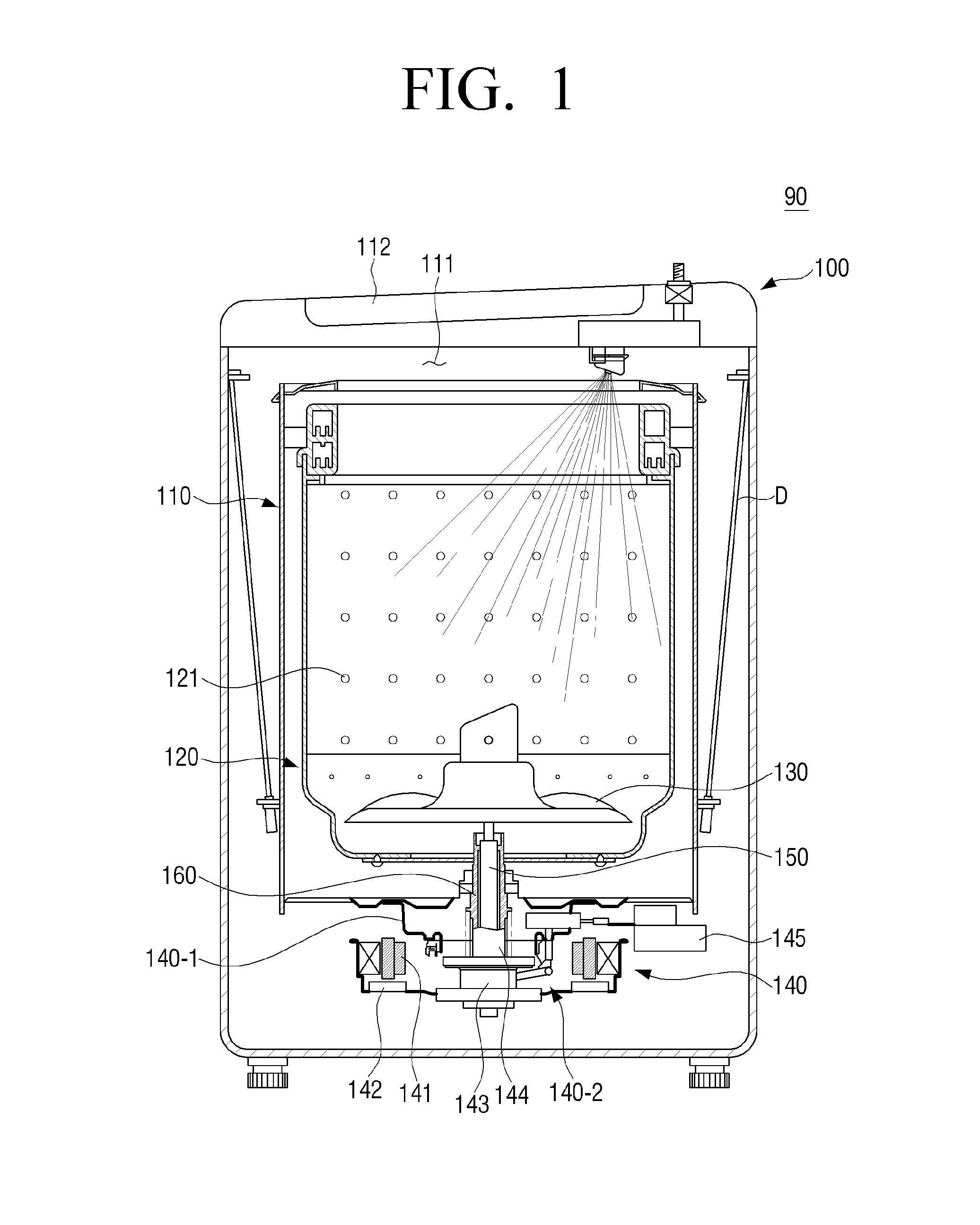

Laundry Treatment Apparatus And Method Of Controlling The Same

ActiveCN107447432APrevent negative pressureAvoid negative pressureOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

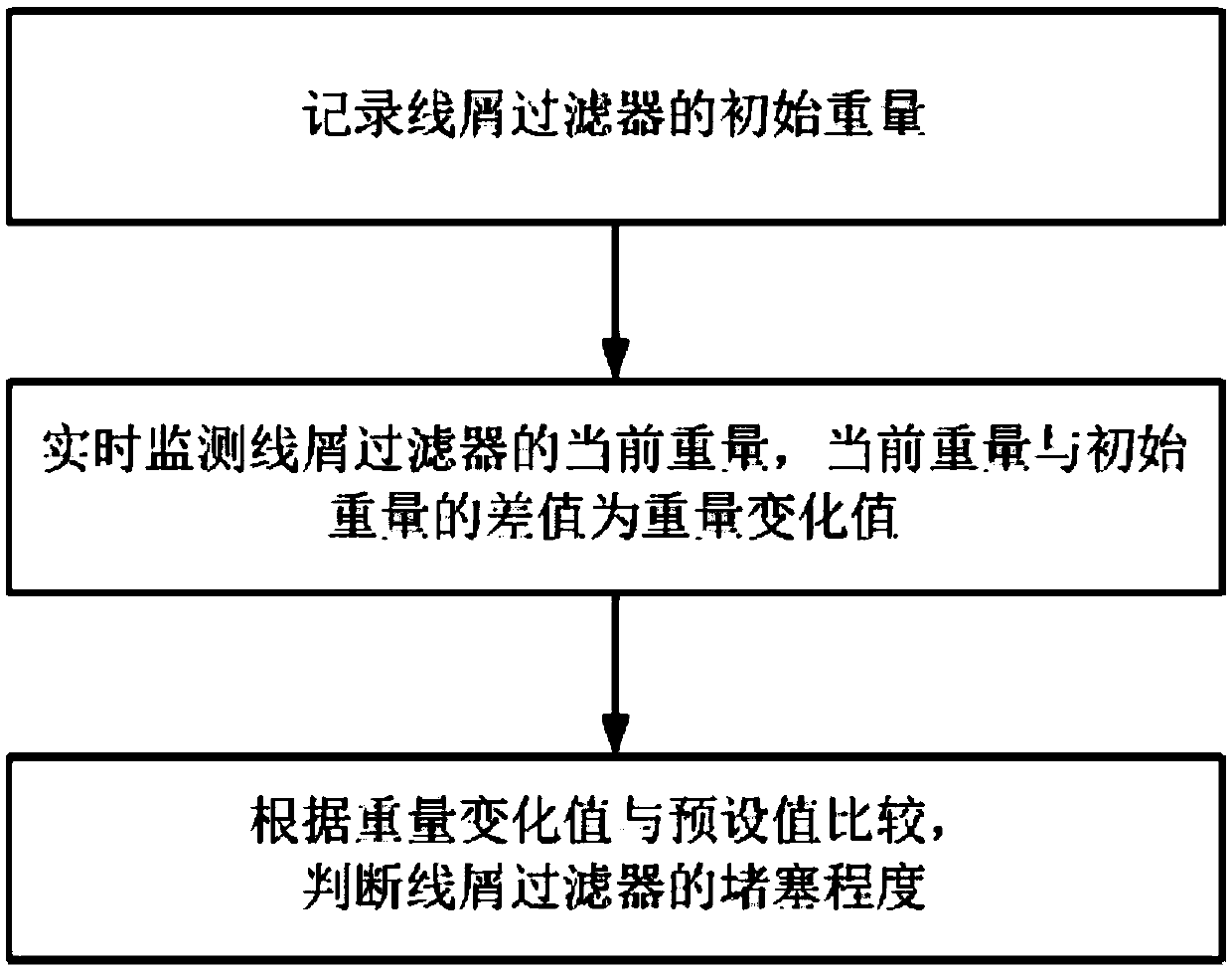

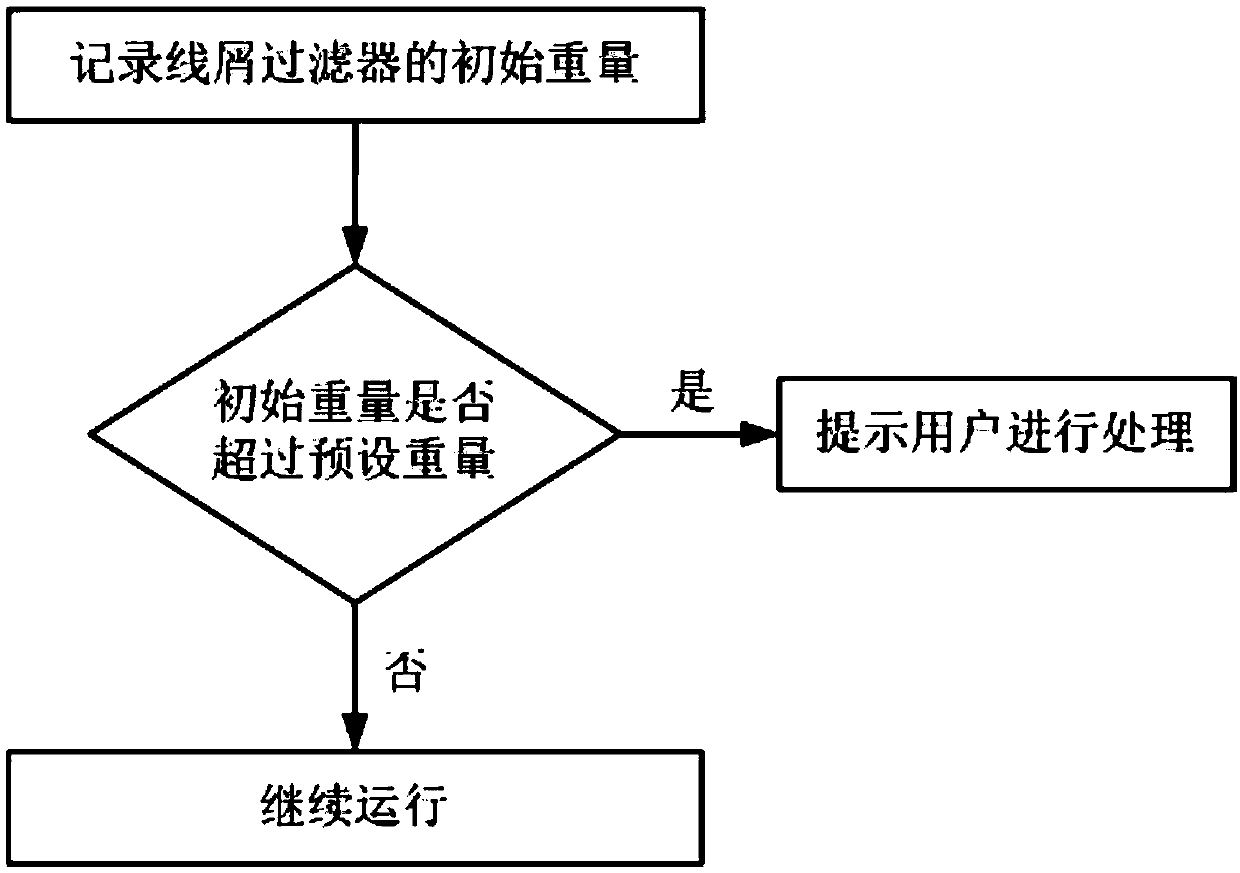

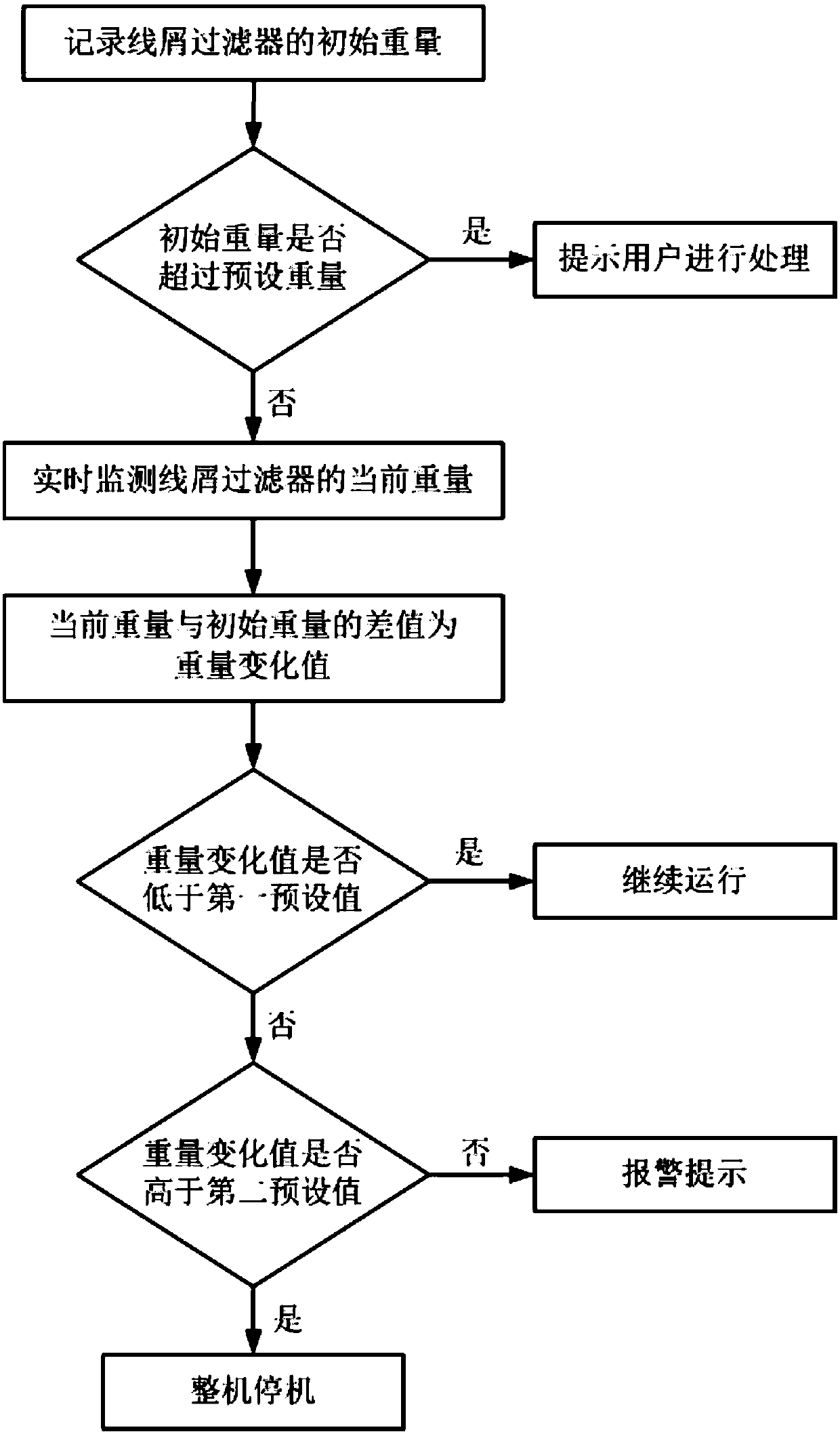

Method for judging blockage of lint filter and clothes dryer

PendingCN110804849AJudging the degree of congestionWeight monitoringControl devices for washing apparatusTextiles and paperProcess engineeringIndustrial engineering

Owner:QINGDAO HAIER DRUM WASHING MACHINE

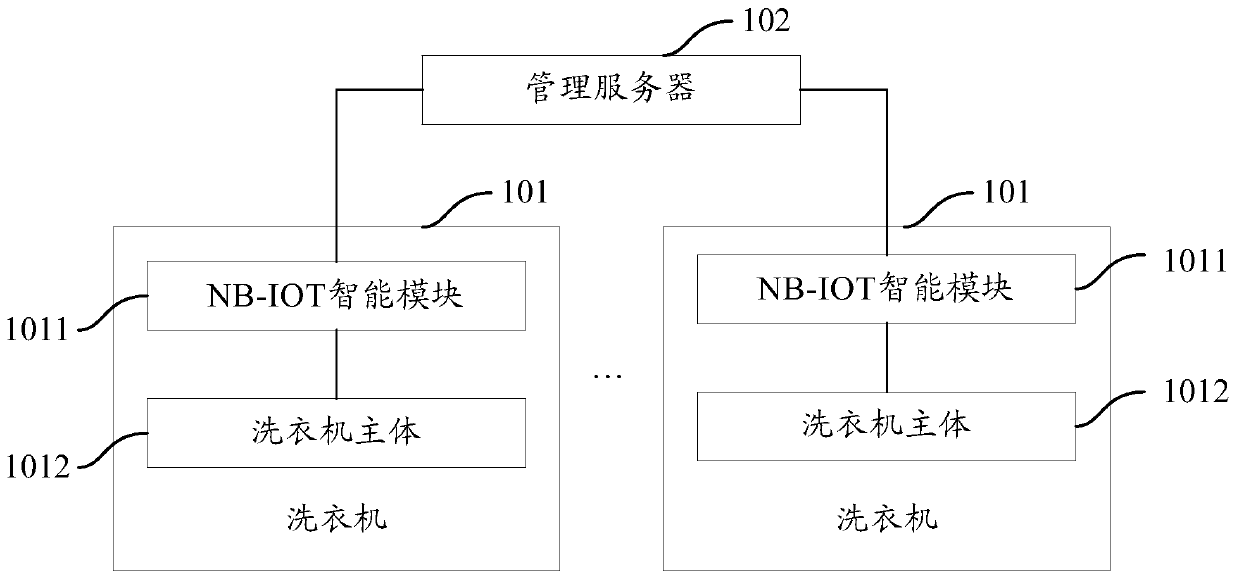

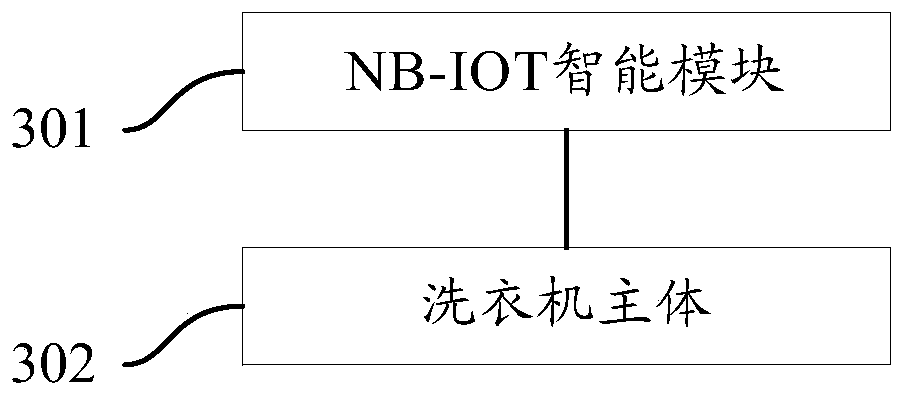

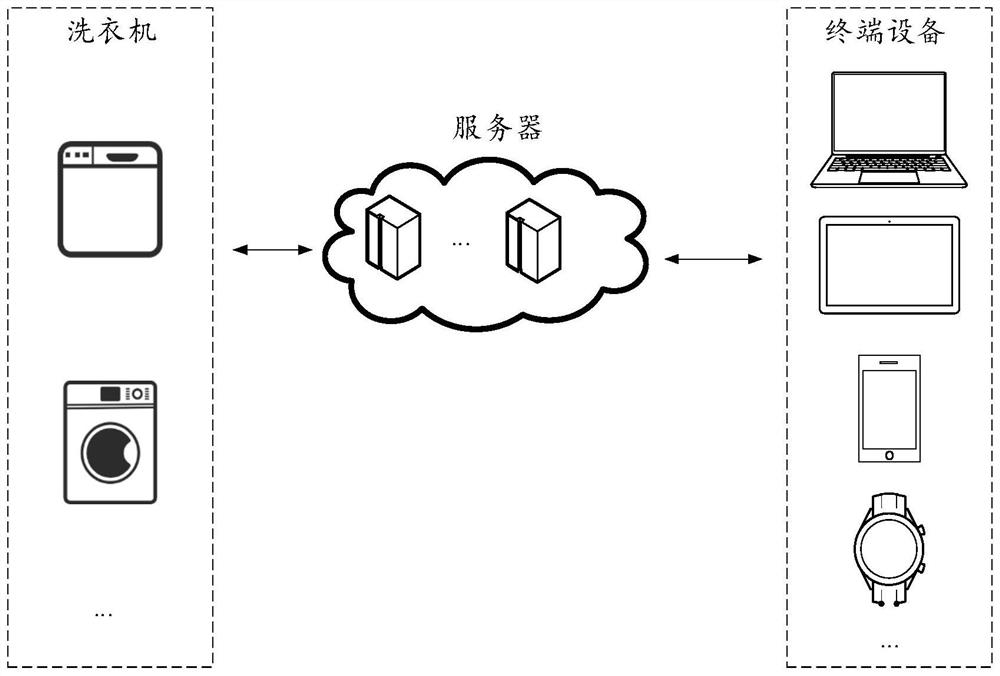

Washing machine system and washing machines

InactiveCN109811507AControl devices for washing apparatusTextiles and paperManufacturing engineeringMachining system

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

Washing machine and control method

ActiveCN108729123AAvoid collisionExtended service lifeOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention belongs to the field of washing machines and particularly relates to a washing machine and a control method. The washing machine comprises a box body, an inner barrel disposed in the boxbody and a driving device for driving the inner barrel to rotate, wherein the inner barrel is a water containing barrel; the washing machine further comprises a main control device, a detected end and a detecting end for detecting the position of the detected end, wherein the detected end and the detecting end are disposed on the inner barrel and the box body respectively, and the detecting end is electrically connected to the main control device. The washing machine has the advantages that the detecting end and the detected end are disposed on the inner barrel and the box body respectively;when the detected end is detected by the detecting end, a detection signal is transmitted to the main control device, and the main control device controls the washing machine to prevent the inner barrel from colliding with the box body, so that damage is reduced, and the service life of the inner barrel and the box body are both prolonged; at the same time, automatic monitoring and control are achieved, and more convenience is provided for users during use.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

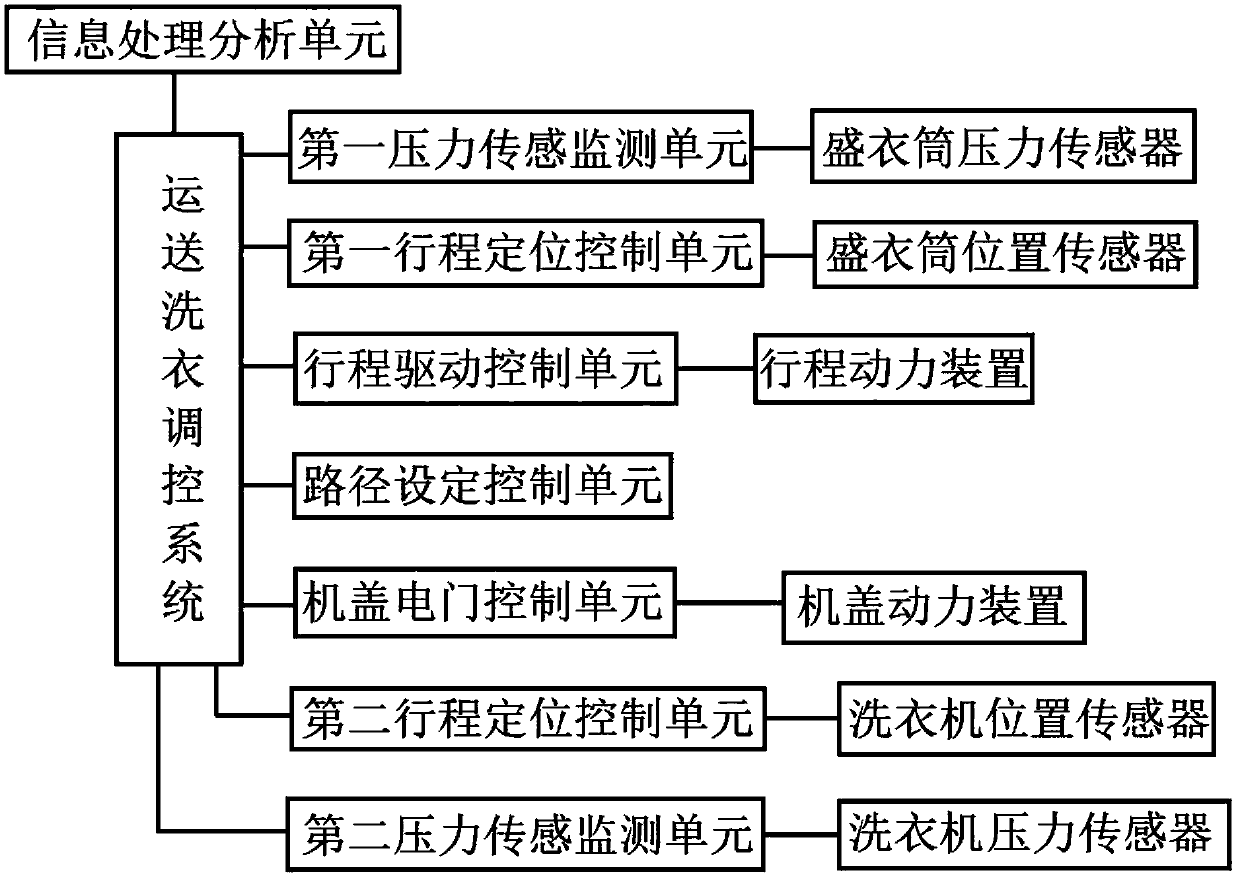

Laundry robot control system based on directional transport

InactiveCN108677456AControl devices for washing apparatusIroning apparatusRobot control systemPosition control

Owner:WUHU LE CHUANG ELECTRONICS TECH CO LTD

Controlling water levels and detergent concentration in a wash cycle

ActiveUS20200248385A1Easy to cleanOther washing machinesControl devices for washing apparatusSoil scienceLaundry washing machine

Systems, apparatuses and methods for controlling the various phases and in particular in a wash cycle of a wash machine are provided. In particular, the present application relates to controlling the water levels and detergent composition concentrations in order to reduce the amount of water and composition required to provide improved soil removal. The systems, apparatuses and methods provided allow for the use of less water and lower quantities of more concentrated detergent compositions which are customized to the types of soil to be removed.

Owner:ECOLAB USA INC

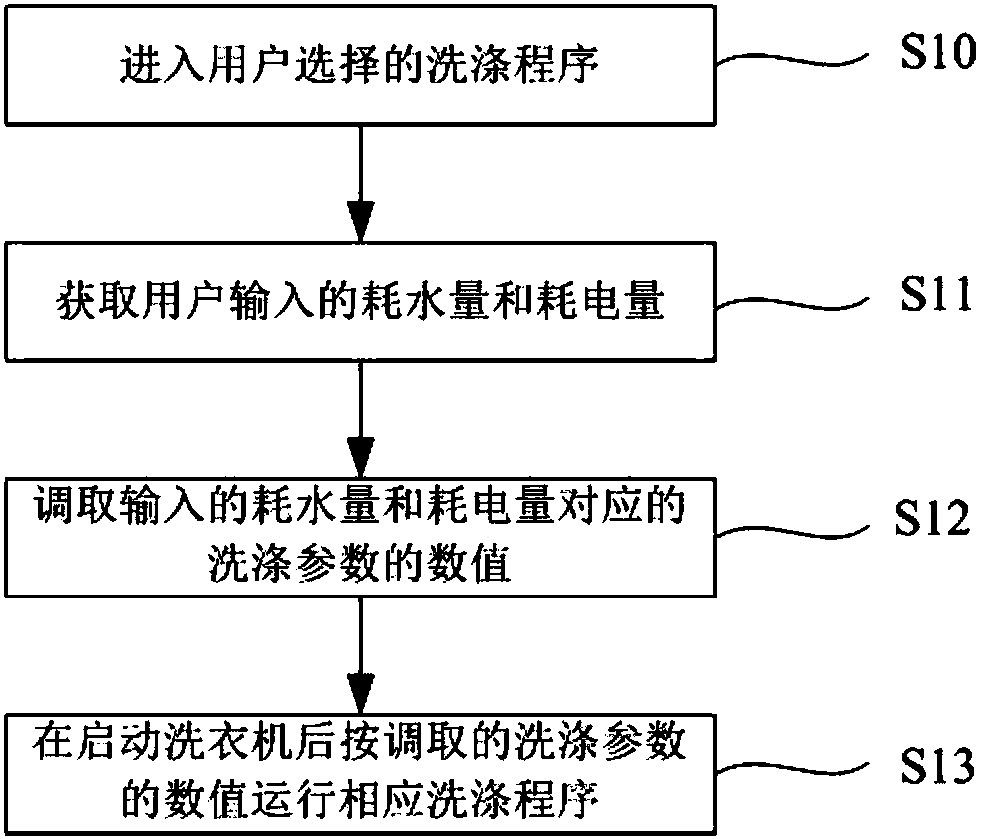

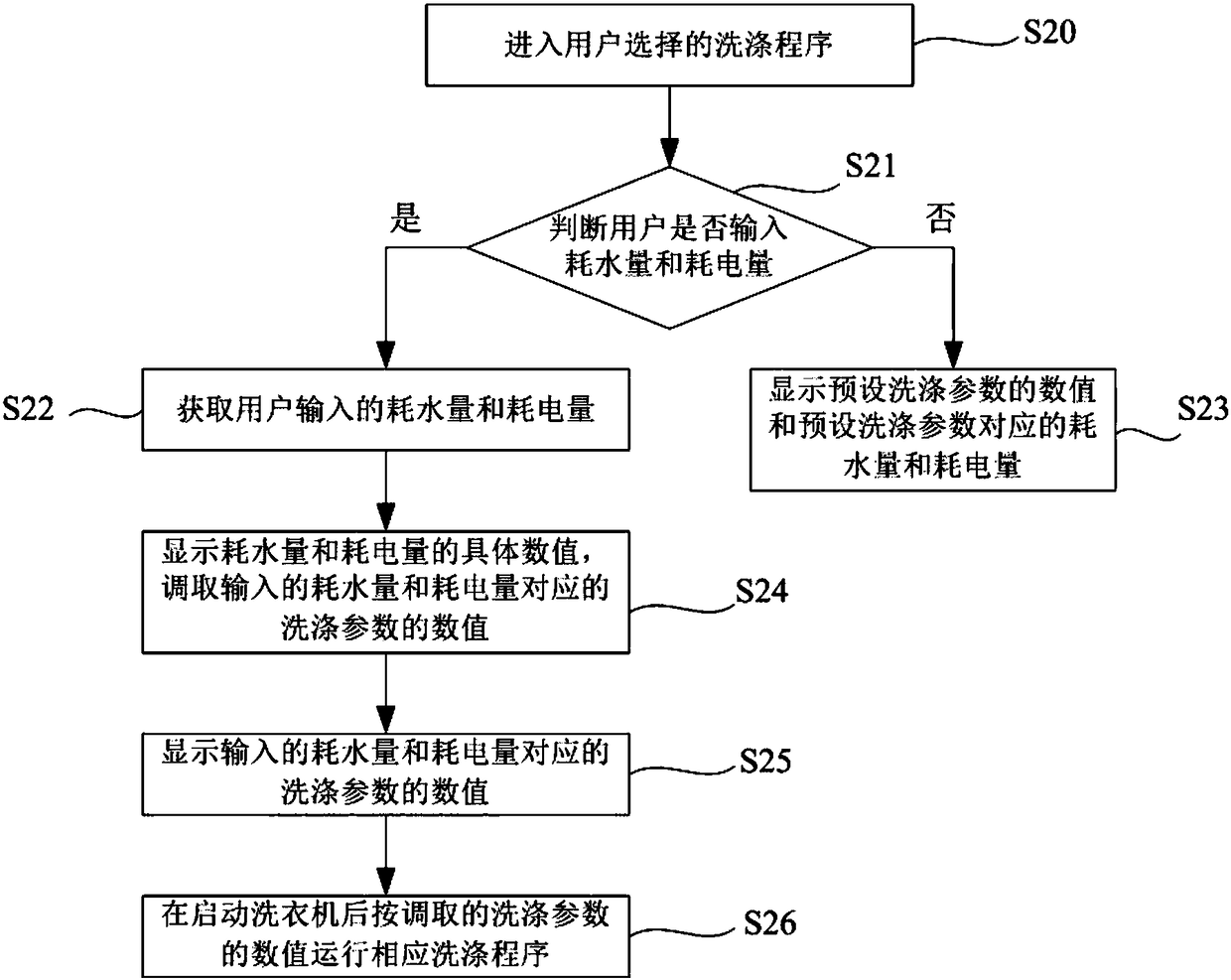

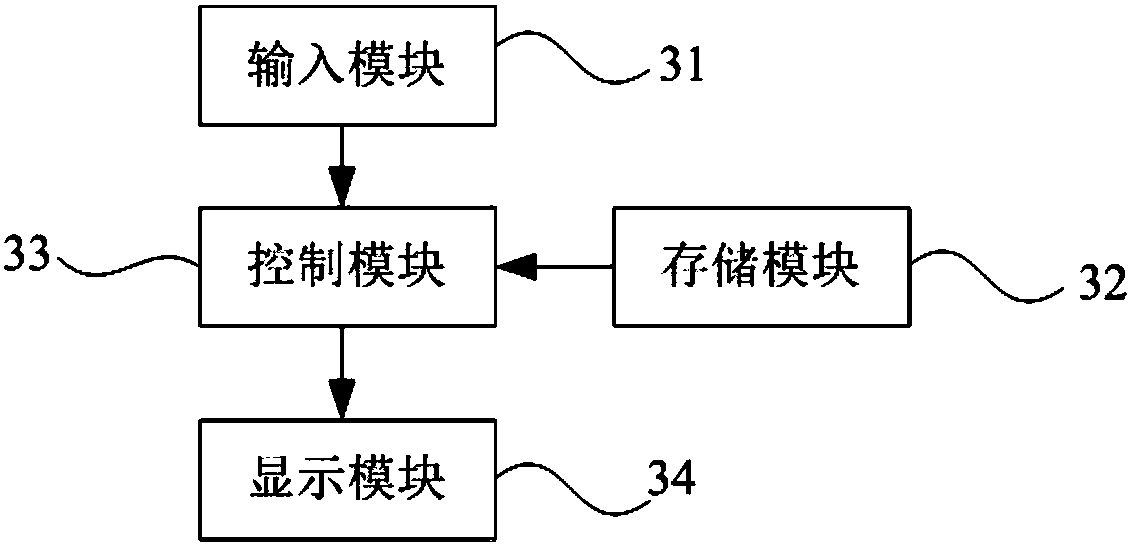

Energy consumption adjusting method, energy consumption adjusting device and clothes washing machine

InactiveCN109385814AControl devices for washing apparatusTextiles and paperProcess engineeringEnergy consumption

Owner:QINGDAO HAIER WASHING MASCH CO LTD

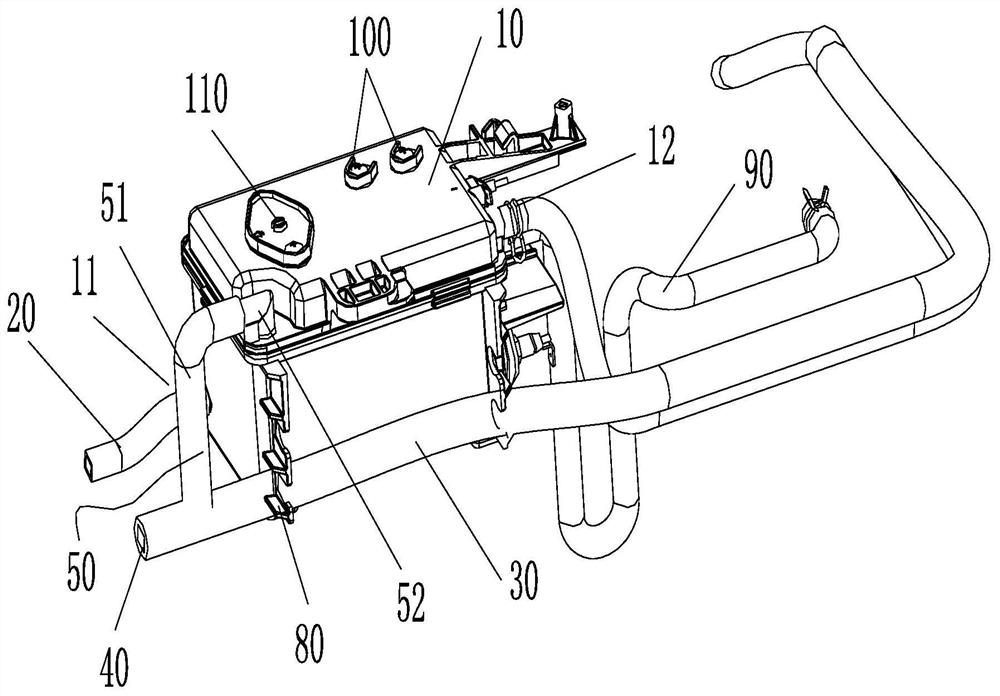

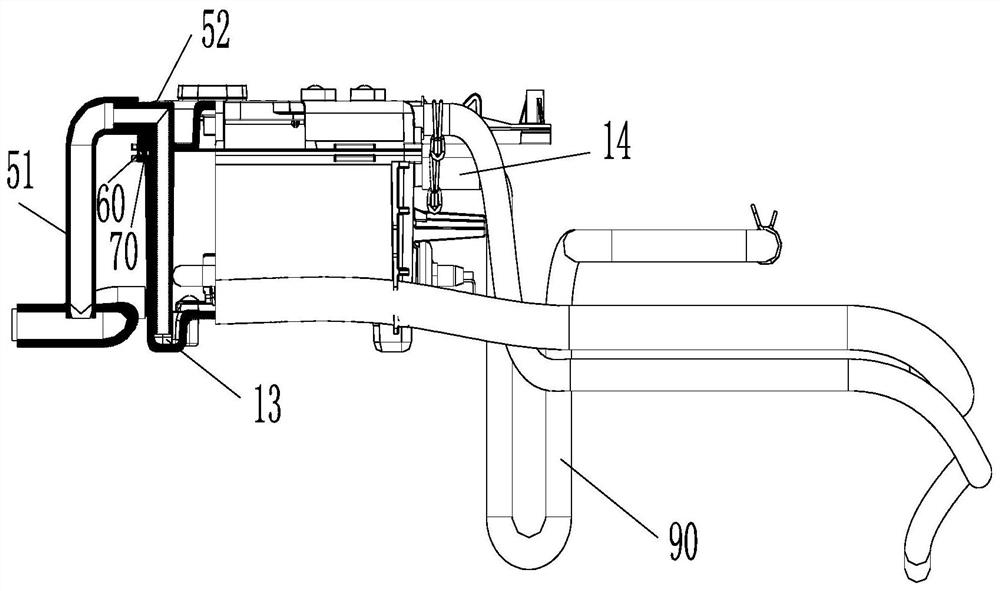

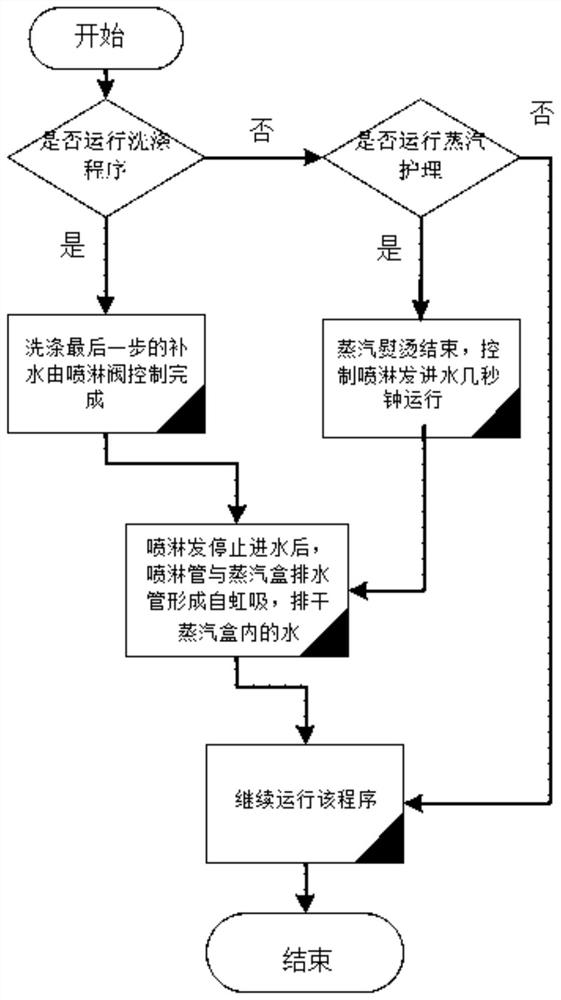

Steam generating device, washing machine and drainage method

PendingCN111648095ASolve the technical problem that it is not convenient to discharge the residual water in the steam boxEasy dischargeOther washing machinesControl devices for washing apparatusThermodynamicsLaundry washing machine

Owner:GREE ELECTRIC APPLIANCES INC

Washing machine, method for controlling washing machine, and computer readable recording medium

ActiveUS20160108575A1Reduce manufacturing costSolve quality problemsOther washing machinesControl devices for washing apparatusDrive motorEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Method for Treating Laundry with Improved Wetting Phase, and Washing Machine Suitable for This Purpose

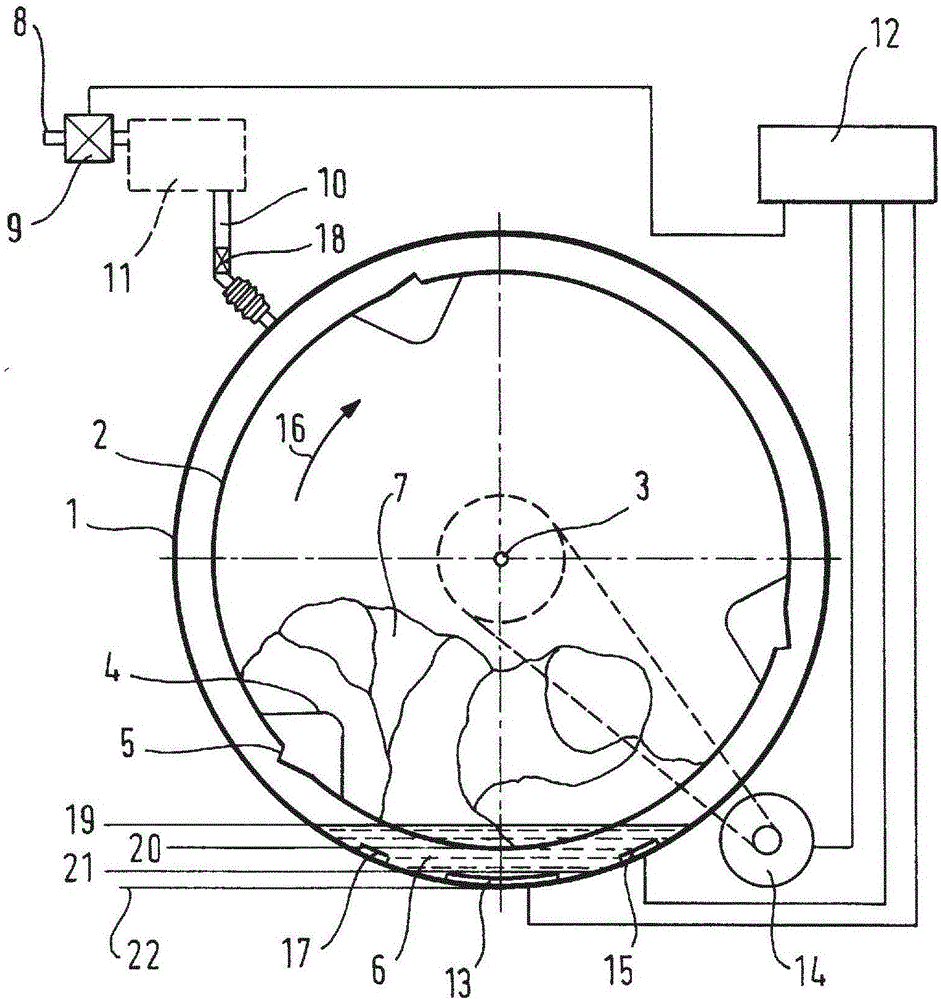

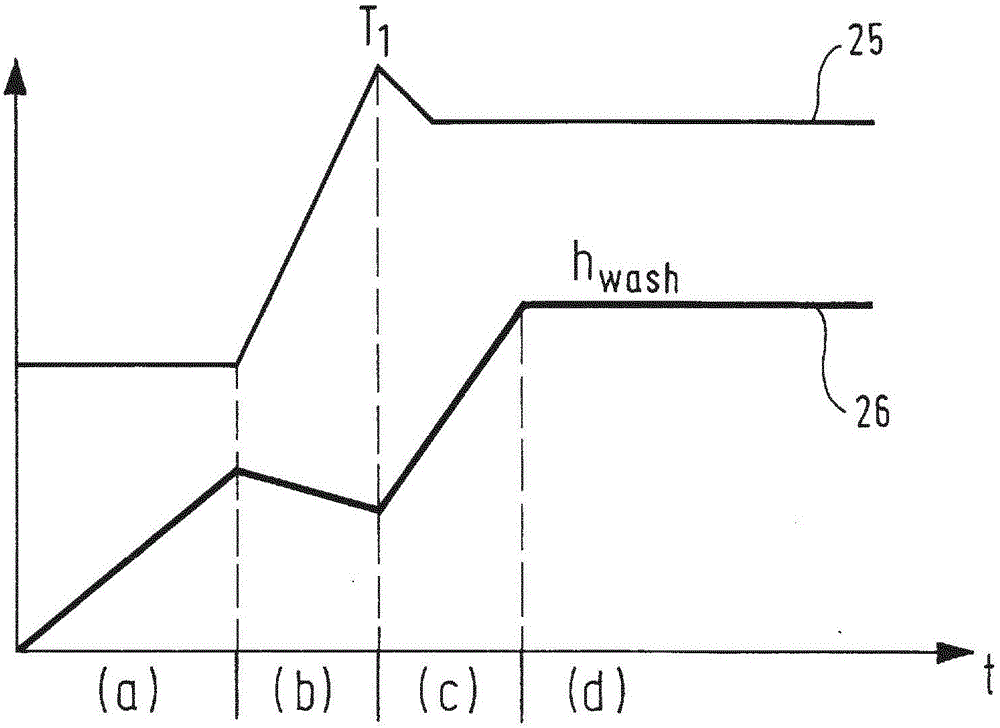

ActiveCN105829596APrevent incomplete wettingImprove uniformityOther washing machinesControl devices for washing apparatusDrive motorProcess engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

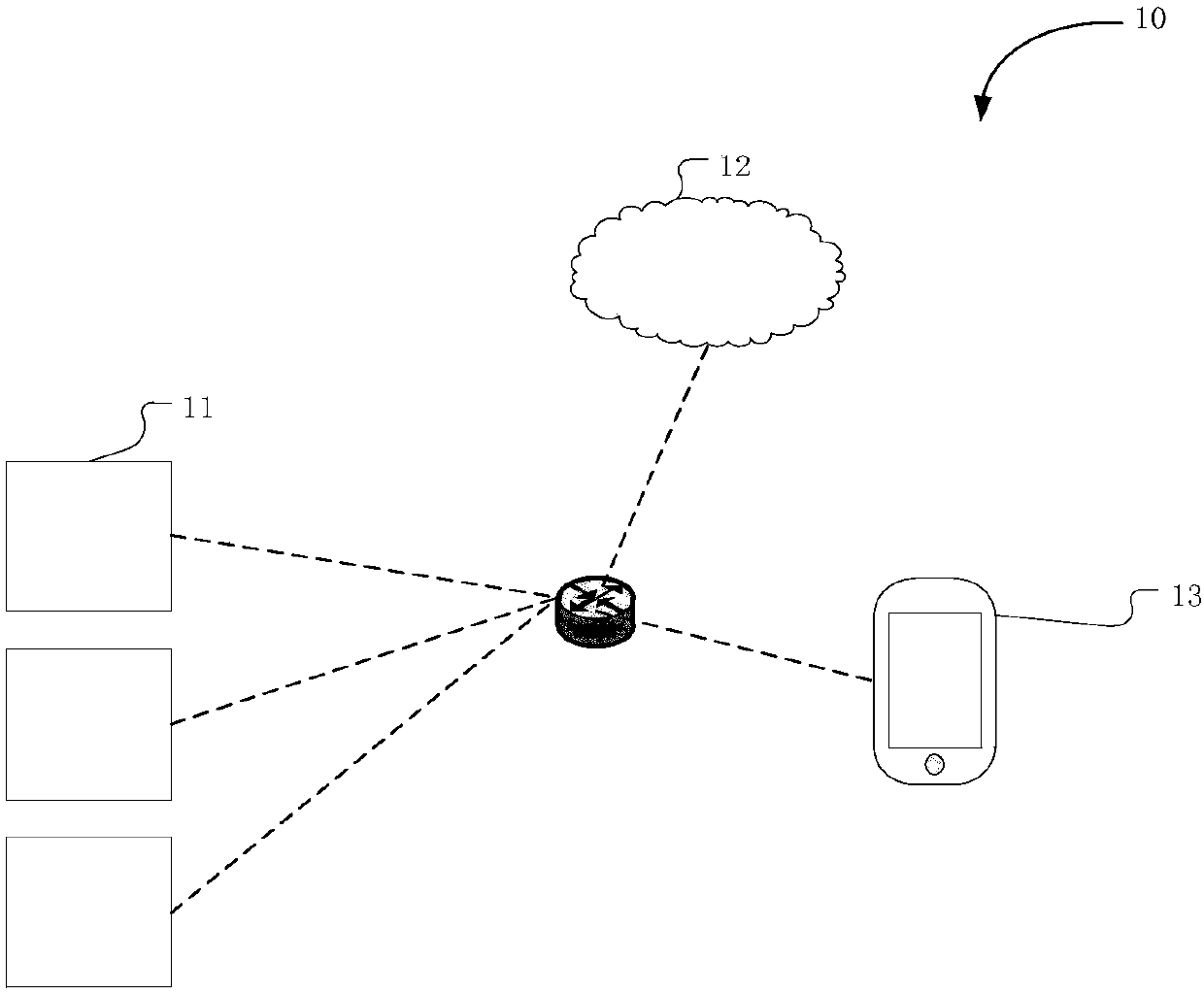

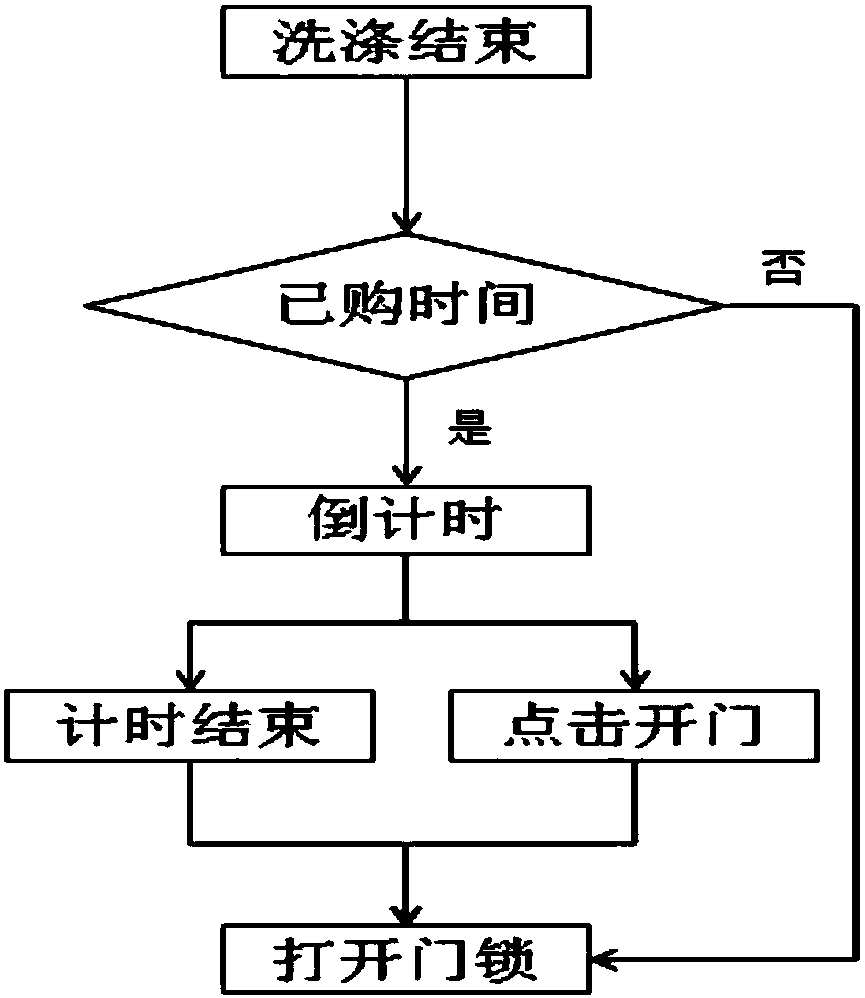

Control method and device of self-service washing machine door lock and computer storage medium

ActiveCN109750444AReduce lossOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

The invention provides a control method of a self-service washing machine door lock. The control method is applied to a server, and includes the following steps: the delay time of door opening sent bya client is received, wherein the delay time of door opening refers to the time after the washing process is finished; after a washing event is finished, whether the delay time of door opening expires or not is judged; if not, an unlocking instruction sent by the client is received, and a washing machine is controlled to open the door lock according to the instruction. According to the control method of the self-service washing machine door lock, washing machines in a washhouse can be efficiently utilized, and if users fail to take out clothes in time after washing is finished, the users needto reserve the delay time and pay for continued occupation of the washing machine.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

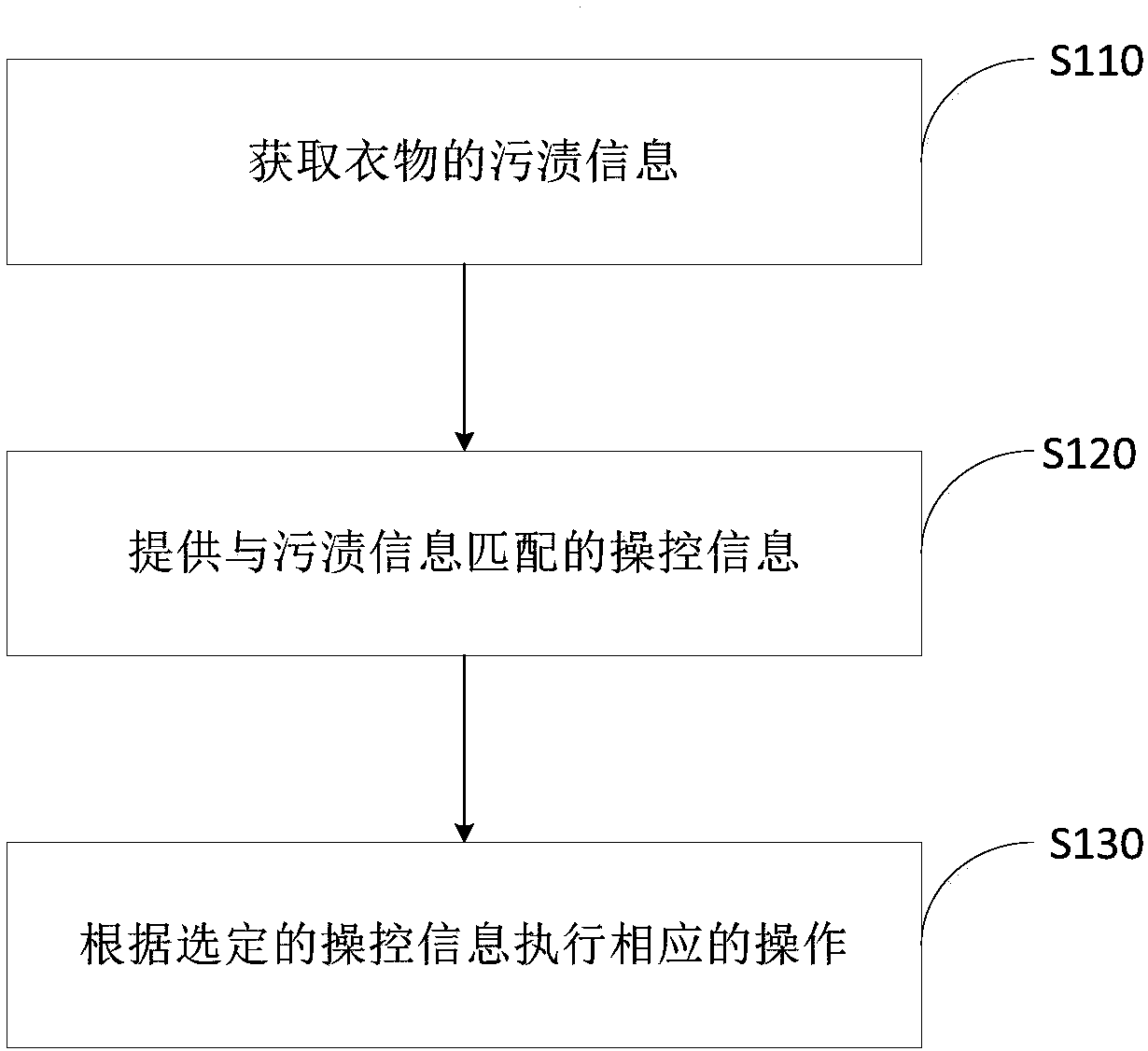

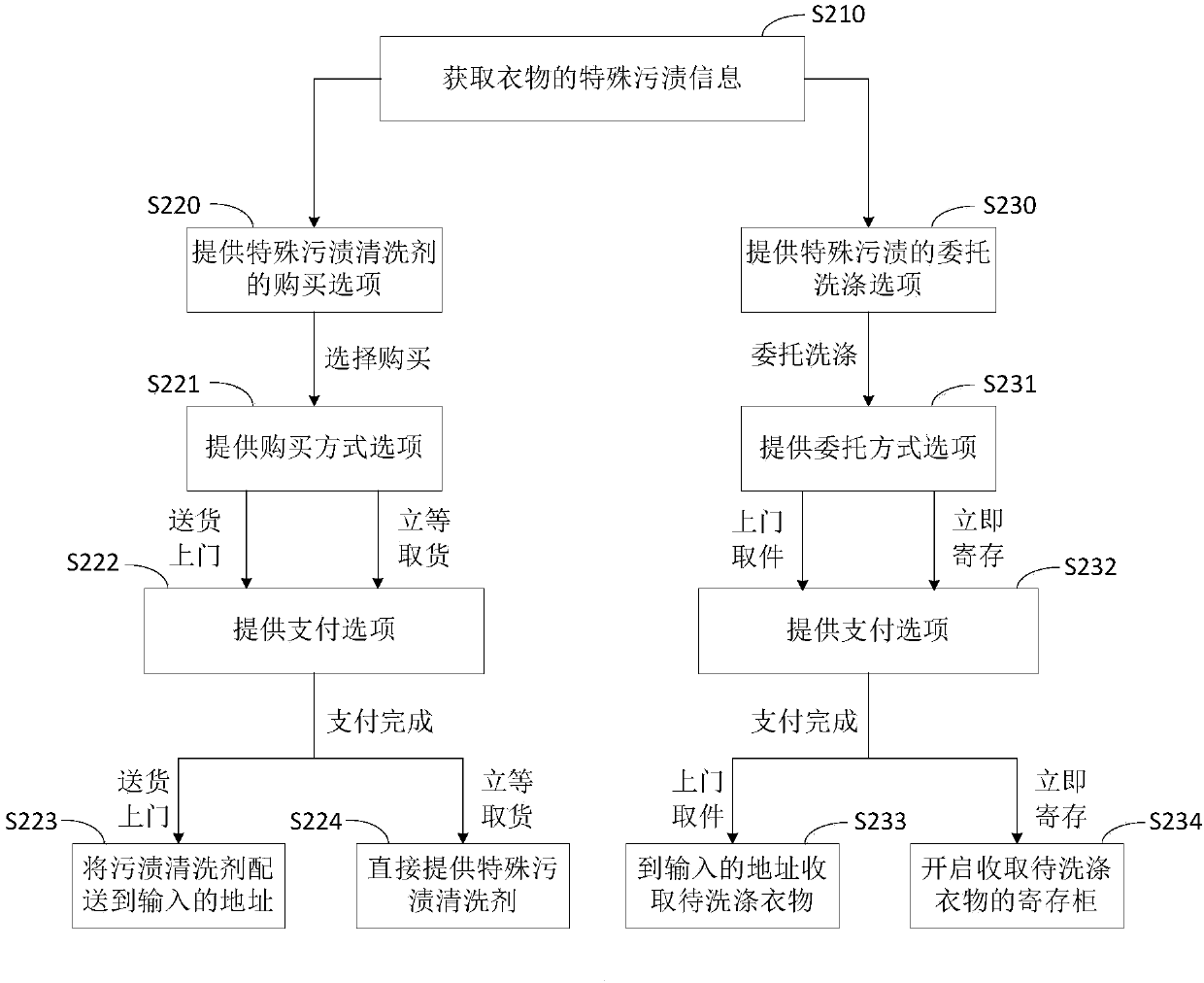

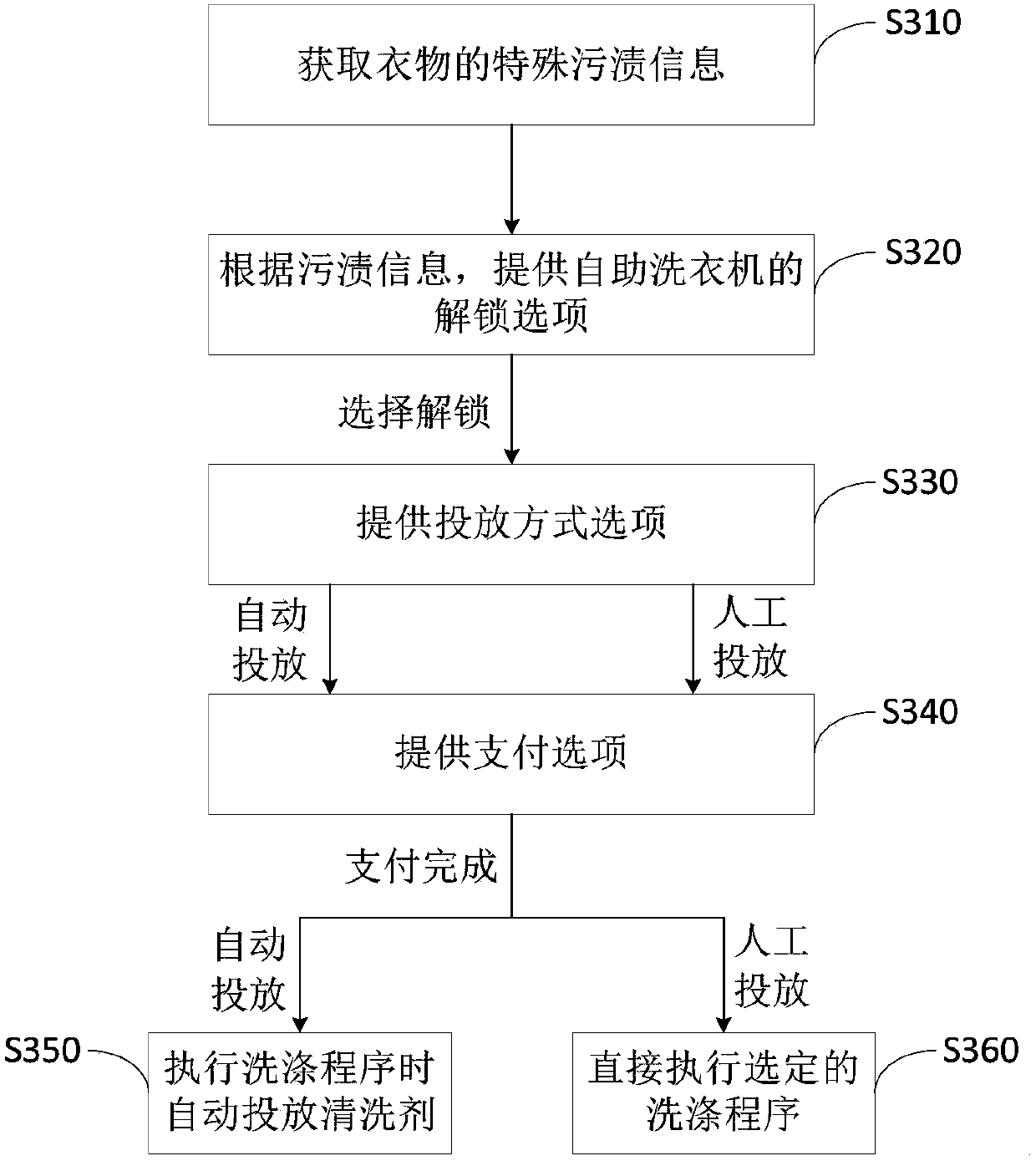

Method for treating clothing stains

ActiveCN109957912AAvoid unnecessary lossesControl devices for washing apparatusPayment architectureCleansing AgentsComputer science

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

Clothes washing program sharing method, terminal and storage medium

ActiveCN114059265AReduce inconvenienceImprove experienceControl devices for washing apparatusTextiles and paperLaundry washing machineProcess engineering

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Water level frequency self-calibration method of washing machine and washing machine

ActiveCN113073445AEasy to controlEliminate errorsOther washing machinesControl devices for washing apparatusLaundry washing machineControl system

The invention discloses a water level frequency self-calibration method of a washing machine. The washing machine comprises a control system, and a drainage pump and a water level sensor electrically connected with the control system respectively. The method comprises the following steps: a, the control system controls the drainage pump to start working; b, the control system obtains a water level frequency value F measured by a water level sensor; and c, the control system calibrates a reference water level frequency value F0 according to the obtained water level frequency value F. According to the water level frequency self-calibration method, an error between a set water feeding quantity and an actual water feeding quantity can be eliminated without additionally adding other devices, and thus the water feeding quantity of the washing machine can be controlled more accurately.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

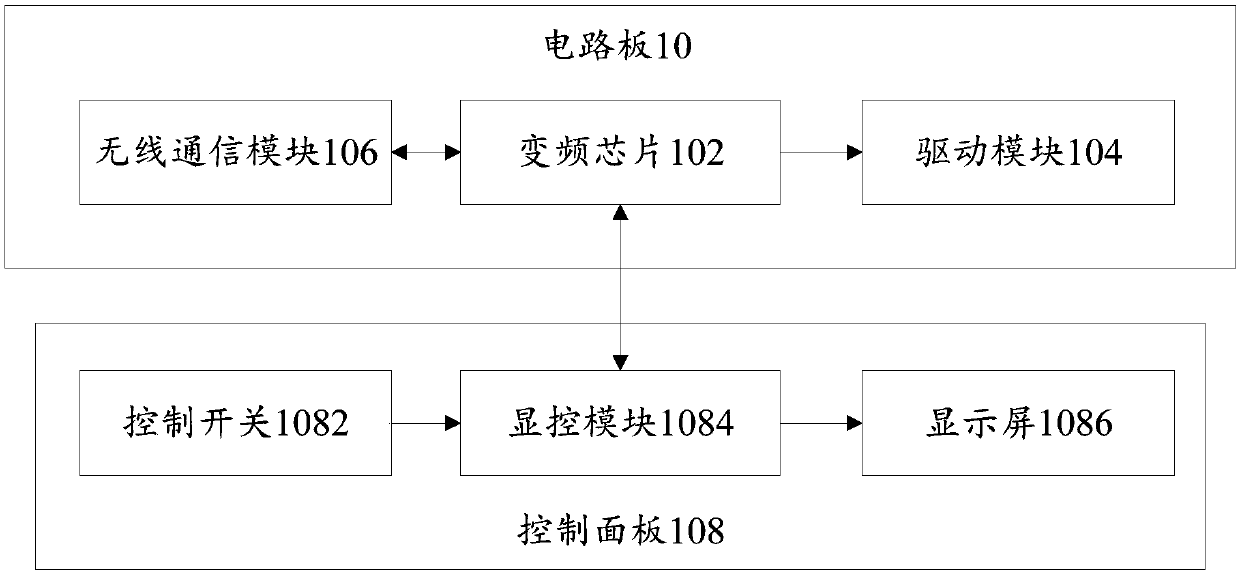

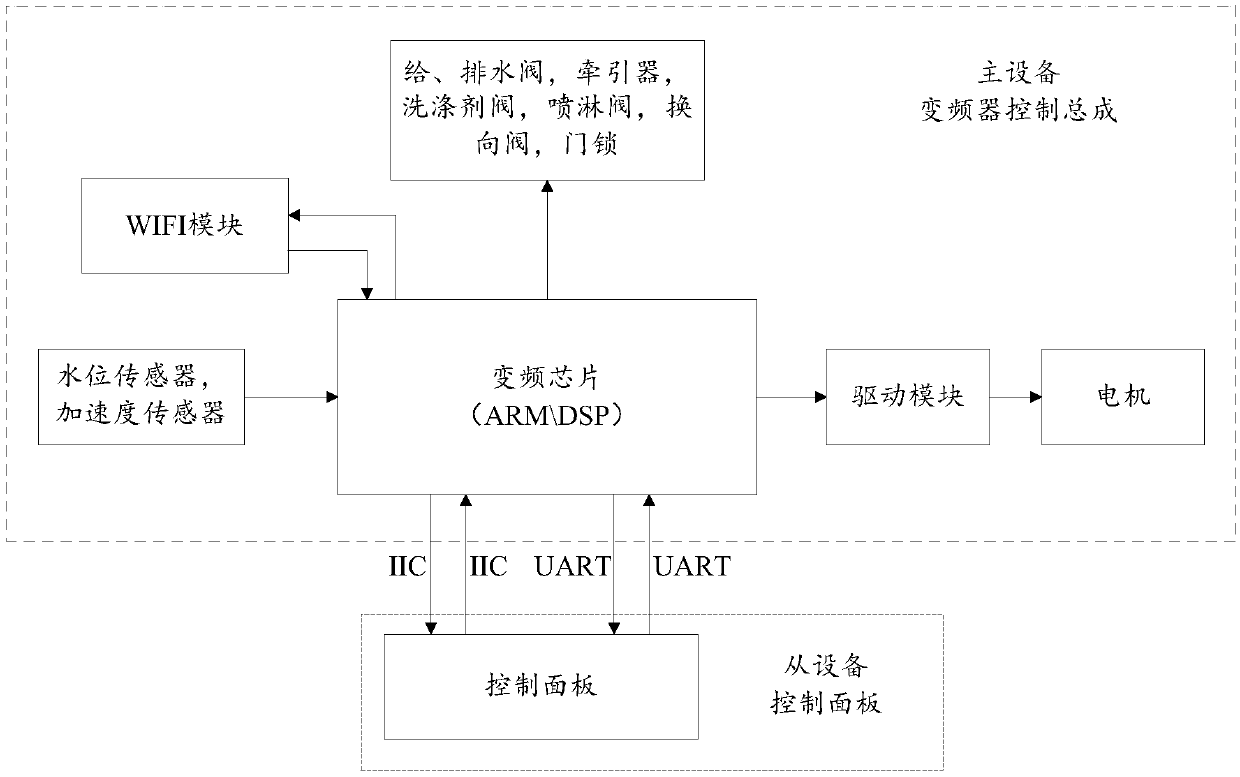

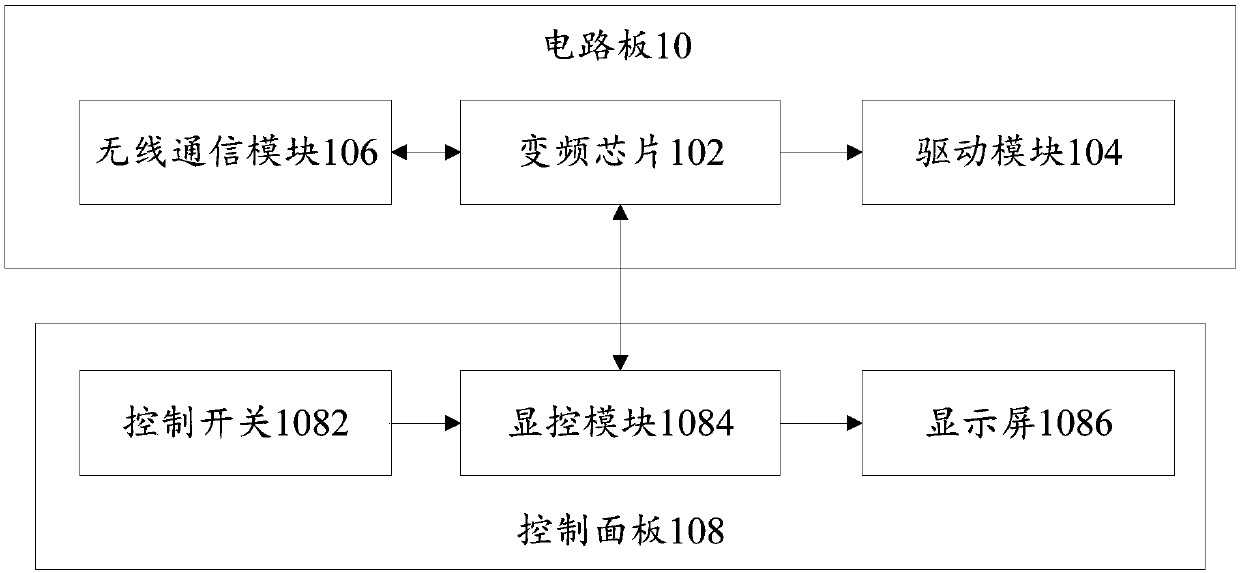

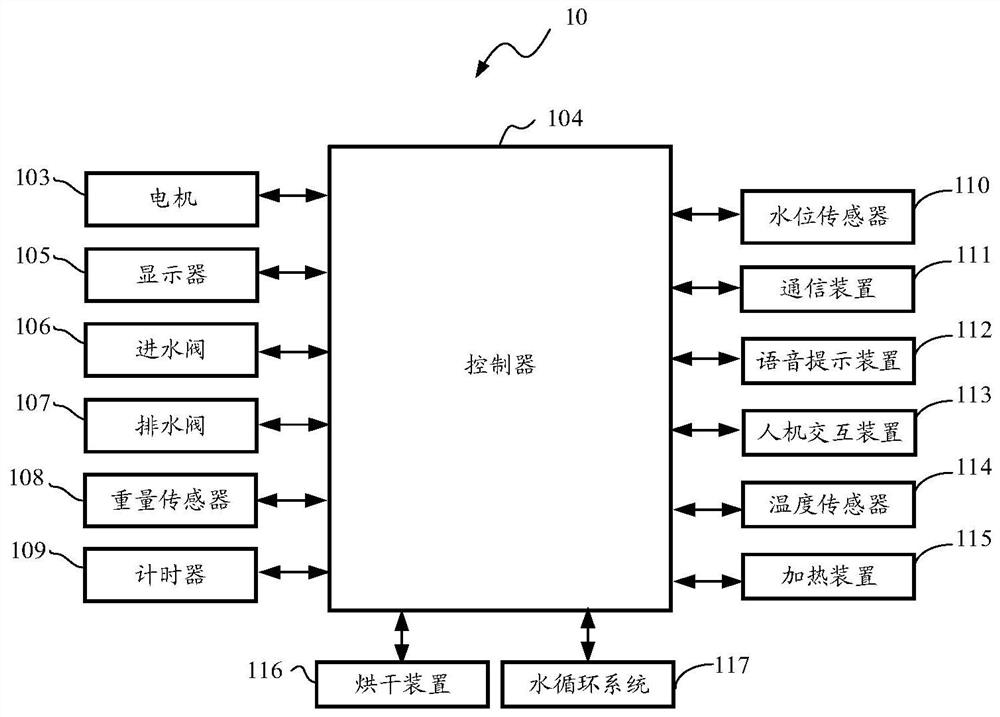

Control device and washing machine

PendingCN111118822AOther washing machinesControl devices for washing apparatusLaundry washing machineFrequency conversion

Owner:WUXI FILIN ELECTRONICS CO LTD

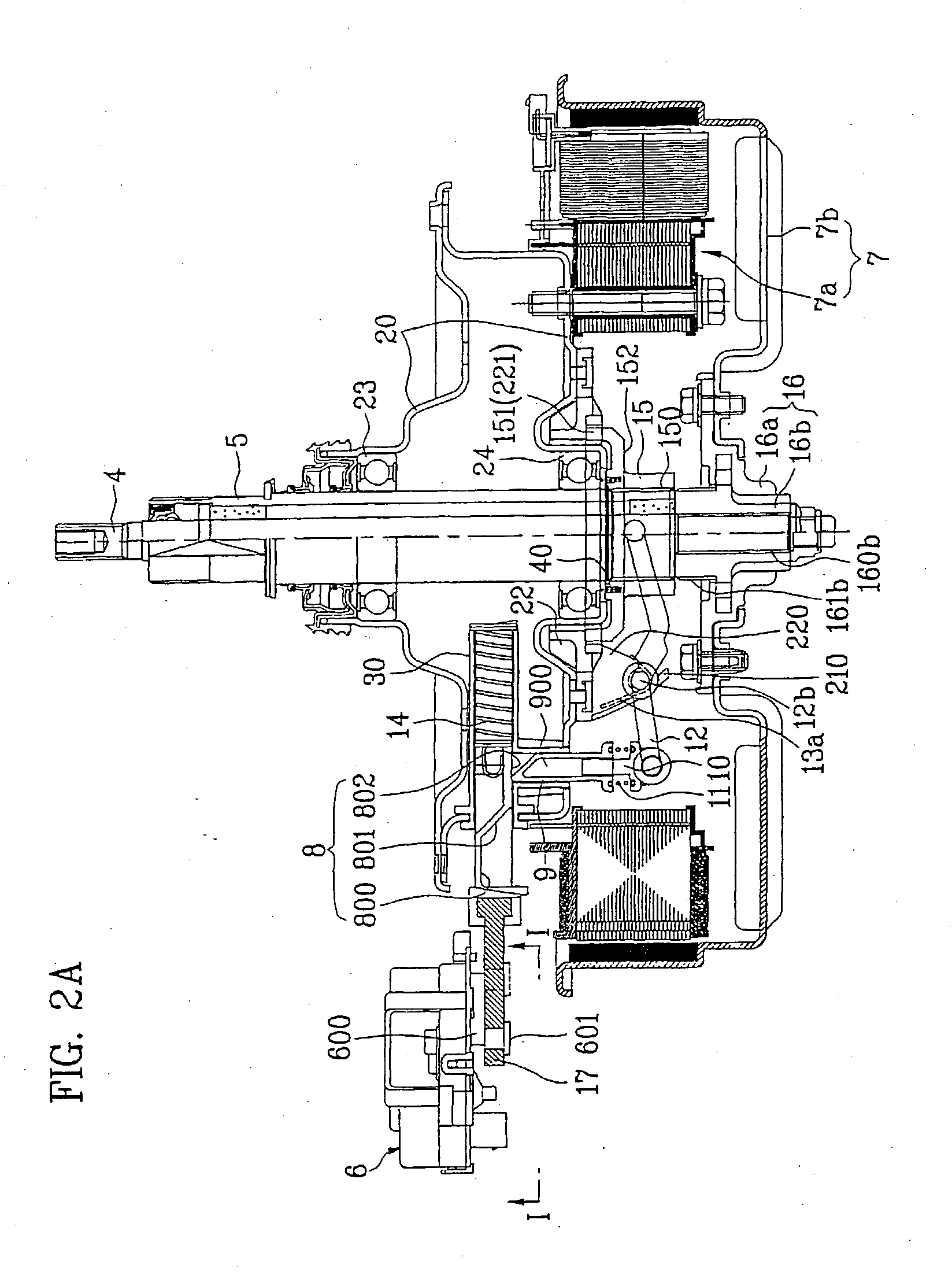

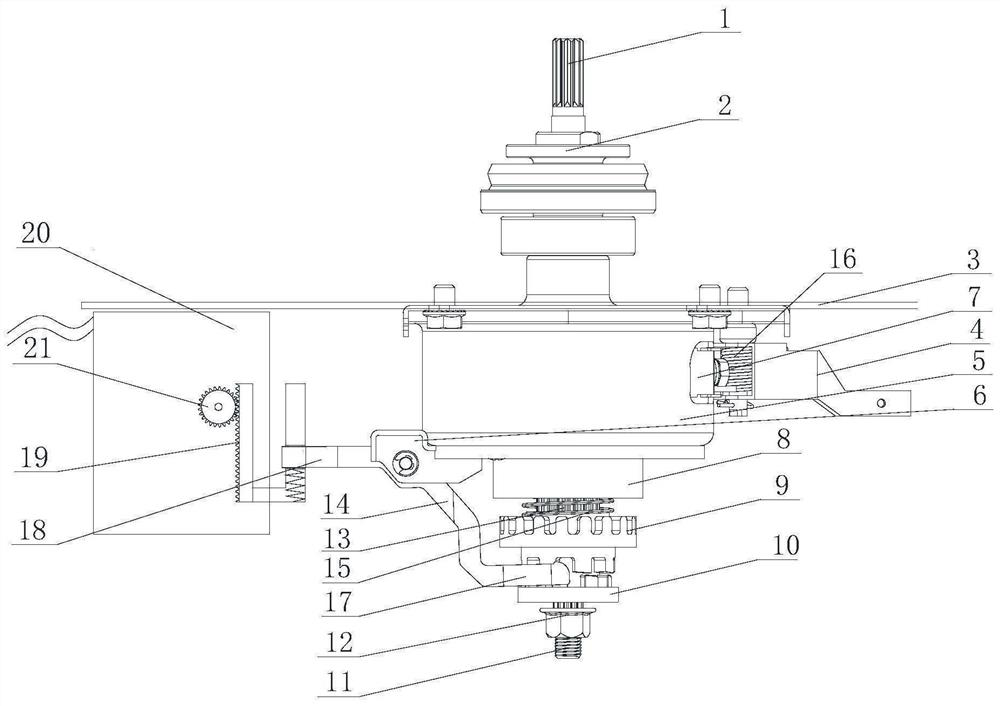

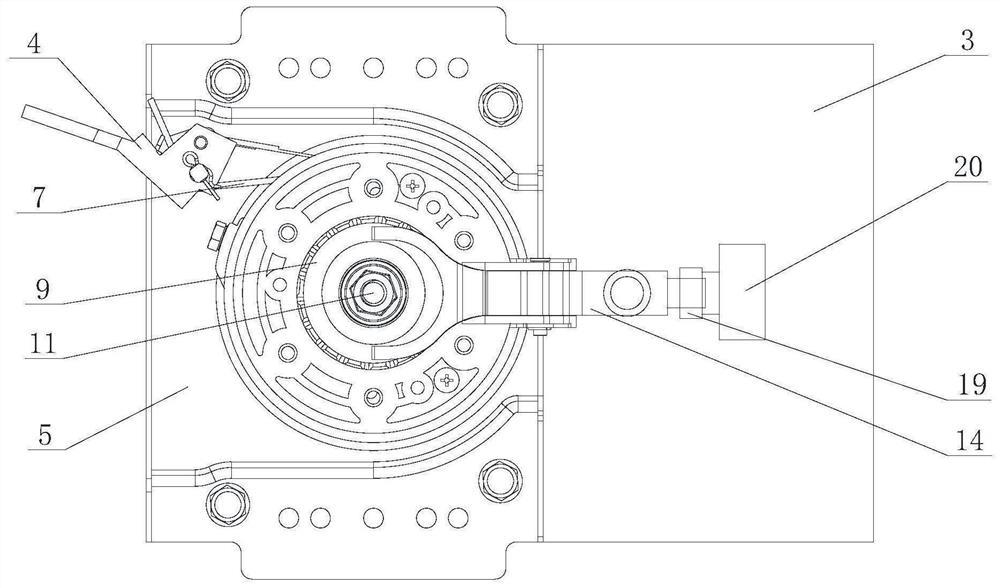

Washing machine speed reduction clutch device, washing machine and control method of washing machine

PendingCN114108255AAccurateImprove reliabilityOther washing machinesControl devices for washing apparatusClutchPower component

The invention provides a washing machine speed reduction clutch device, a washing machine and a control method thereof.The washing machine speed reduction clutch device comprises a clutch mechanism, the clutch mechanism comprises a clutch sleeve and a shifting fork assembly, the clutch sleeve can reciprocate to conduct clutch switching, the shifting fork assembly drives the clutch sleeve to move, and the shifting fork assembly comprises a shifting fork and a shifting fork driving device; one end of the shifting fork is connected to the clutch sleeve in a forked mode, the shifting fork driving device comprises a power component and a gear and rack transmission mechanism, and the rotating output end of the power component is in transmission connection with the other end of the shifting fork through the gear and rack transmission mechanism. And the power part drives the shifting fork to shift the clutch sleeve to do reciprocating motion through the gear and rack transmission mechanism to perform clutch switching. The rotation output of the power part of the washing machine speed reduction clutch device is converted into reciprocating motion in the vertical direction through the gear and rack transmission mechanism to drive the shifting fork to stir the clutch sleeve to do reciprocating motion for clutch switching, and the stability of the washing machine speed reduction clutch device in the working process is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Clothing wrinkle-removing method and system, as well as storage medium and washing machine

ActiveCN111607936AImprove wrinkle removal effectImprove wrinkle removal efficiencyControl devices for washing apparatusTextiles and paperThermodynamicsLaundry washing machine

The invention provides a clothing wrinkle-removing method which comprises the following steps: judging a washing state of the washing machine after receiving a wrinkle-removing program instruction; while the washing state is at a final stage of dehydrating, obtaining current water level position of the washing machine; while the water level information is within a first set threshold value range,enabling the washing machine to stop draining away water to store part of water at the dehydrating stage; while the washing state is that dehydrating is accomplished, enabling a heating assembly in the washing machine to perform heating for heating part of residual water until water steam is generated, thereby removing wrinkles on clothing in an inner barrel of the washing machine. The invention further relates to a clothing wrinkle-removing system, a storage medium and a washing machine. The water steam generated by washing water at the heating dehydrating stage is utilized to remove wrinkles, so that operations are simple, and the cost is reduced; and moreover, a shaking and scattering mode is performed while the heating assembly heats, so that the wrinkle-removing effect on the clothingin the rotary inner barrel is improved, and therefore, wrinkle-removing efficiency is improved.

Owner:YUNMI HULIAN TECH (GUANGDONG) CO LTD

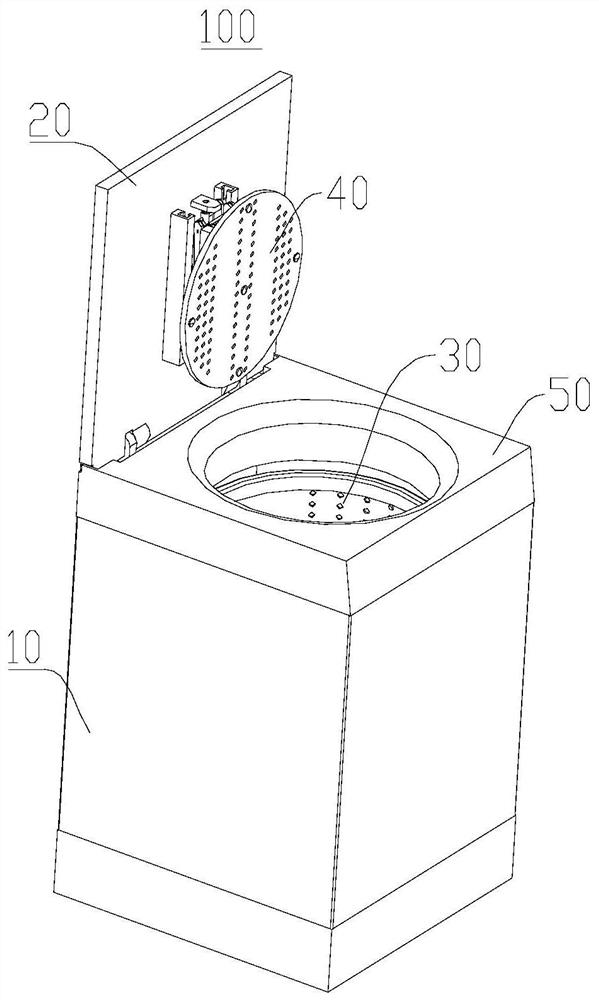

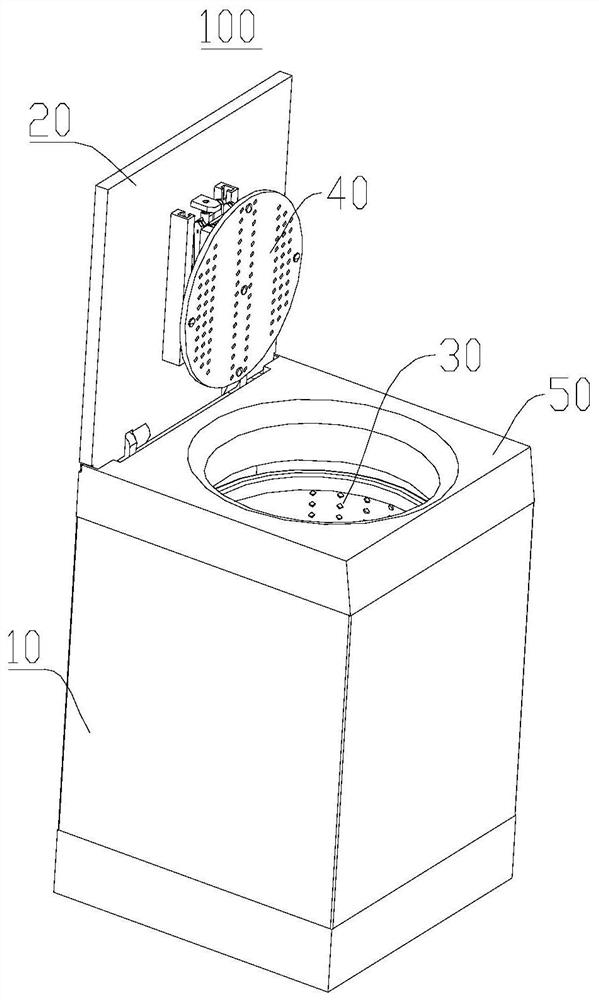

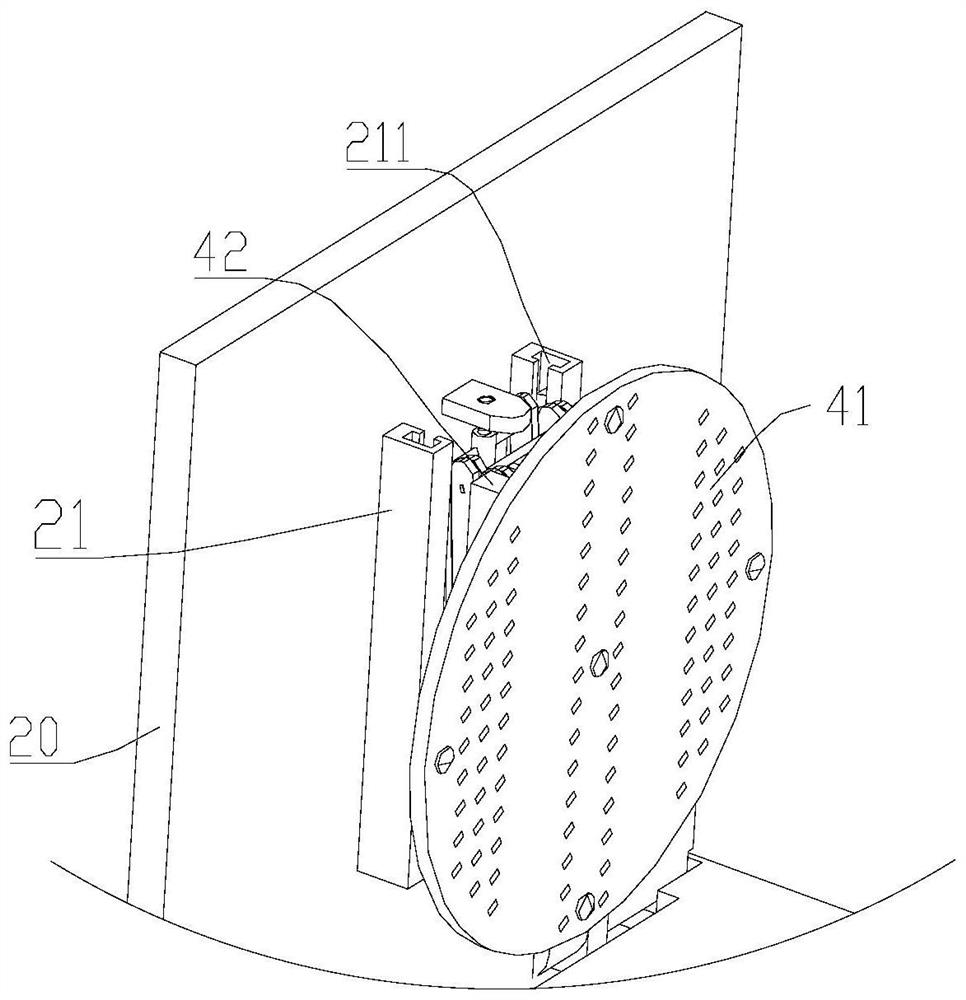

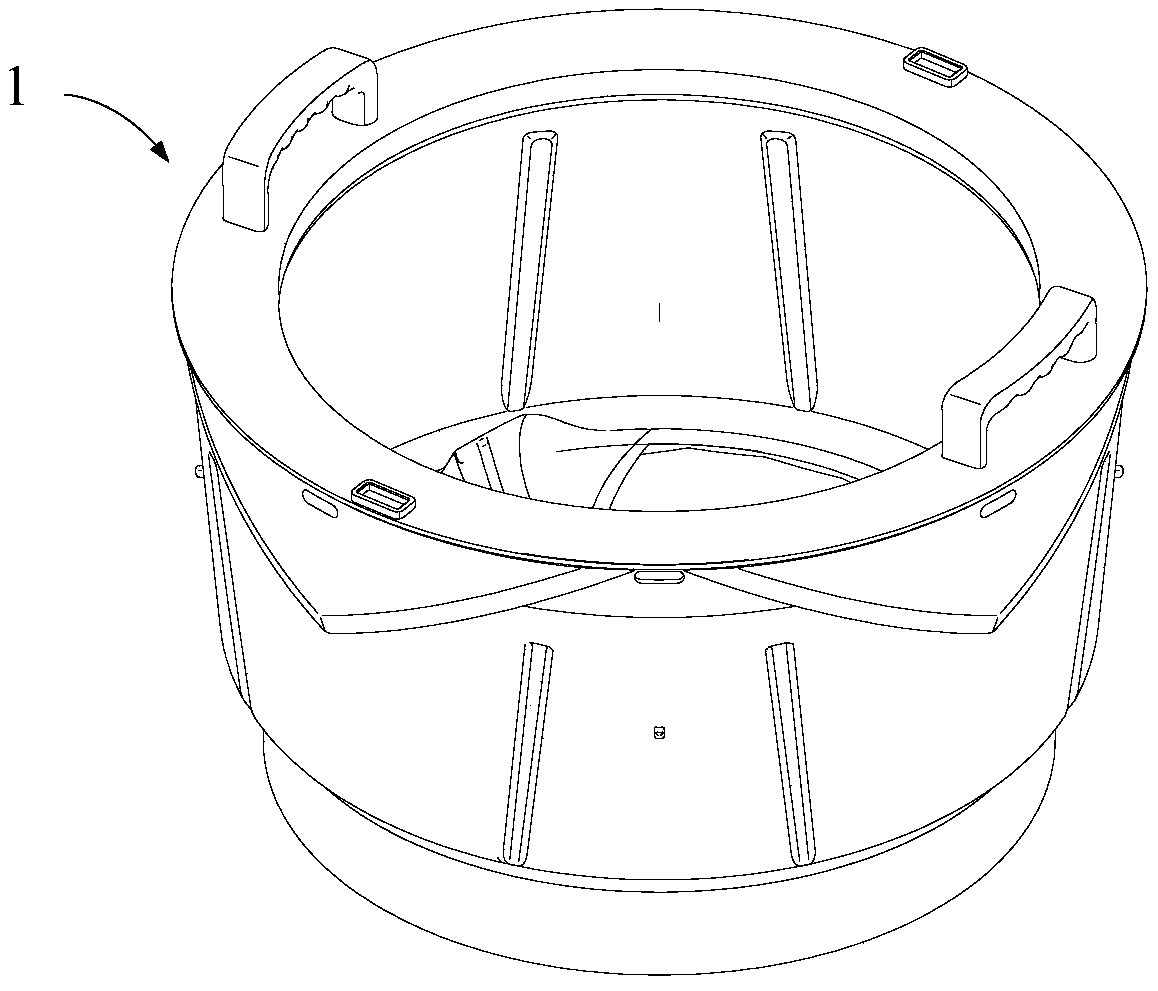

Washing machine with pressing plate assembly and anti-floating control method

PendingCN113957674AImprove washing effectIncrease contactOther washing machinesControl devices for washing apparatusLaundry washing machineEngineering

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

Washing machine, washing machine control method and readable storage medium

ActiveCN111206372AOther washing machinesControl devices for washing apparatusProcess engineeringMechanical engineering

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

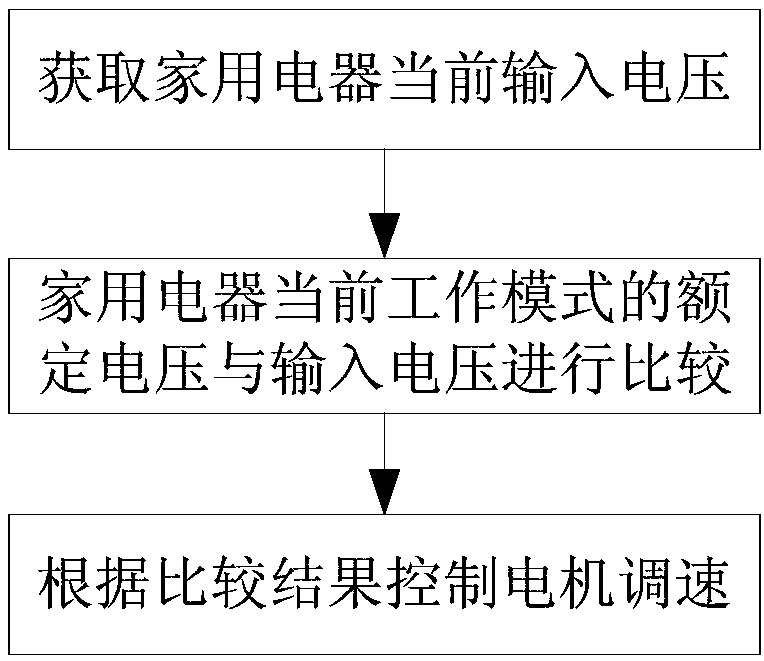

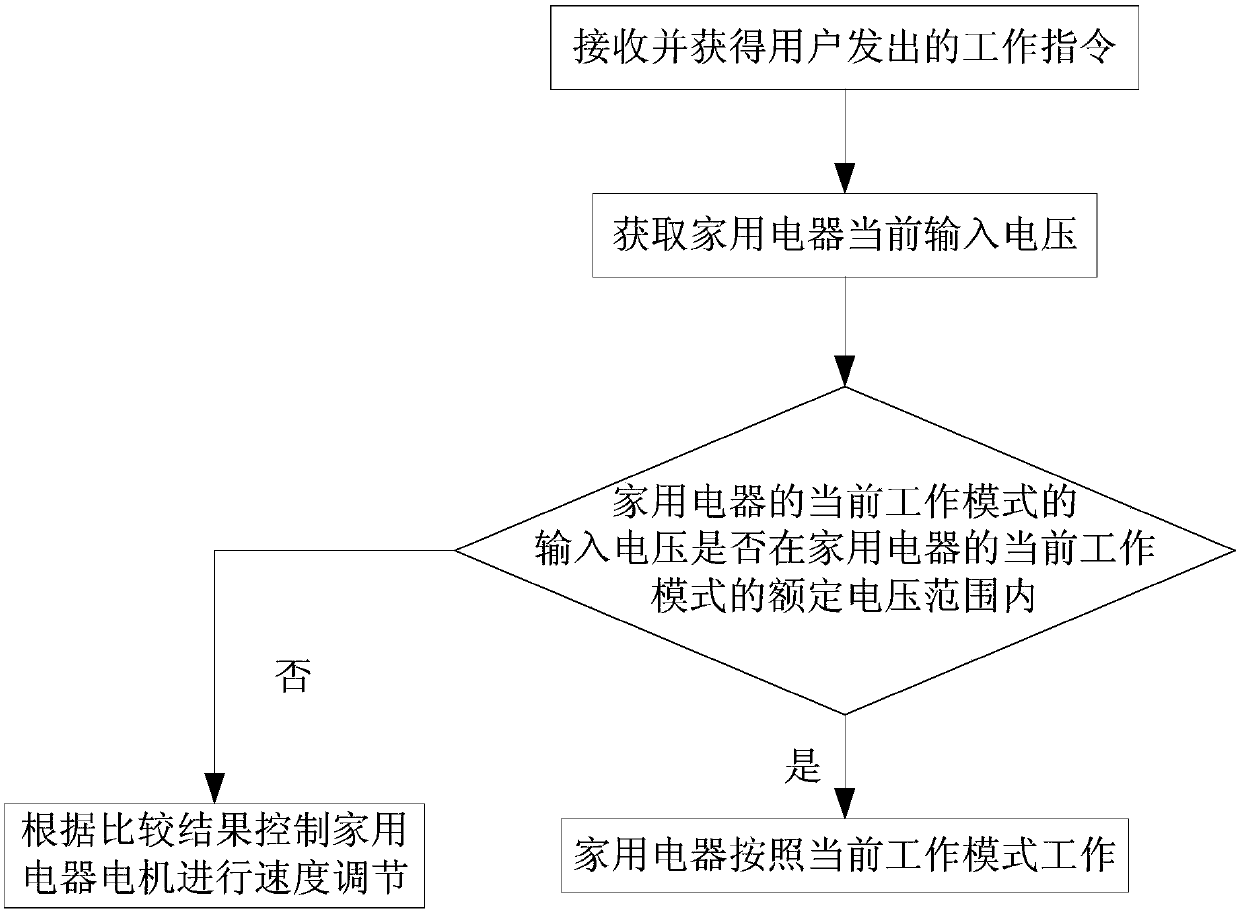

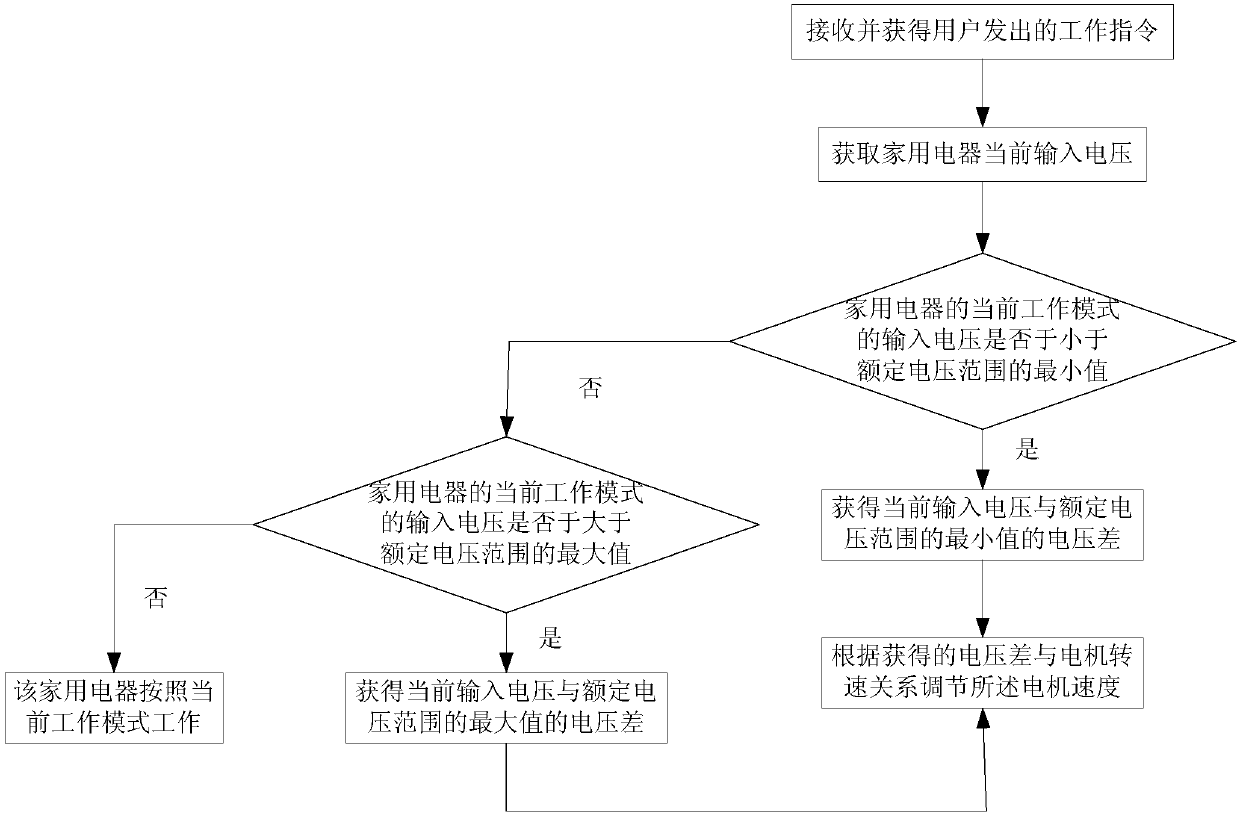

Household appliance control method and household appliance

InactiveCN110318208AReduce manufacturing costAdjust speedTableware washing/rinsing machine detailsControl devices for washing apparatusEngineeringControl theory

Owner:QINGDAO HAIER DISHWASHER

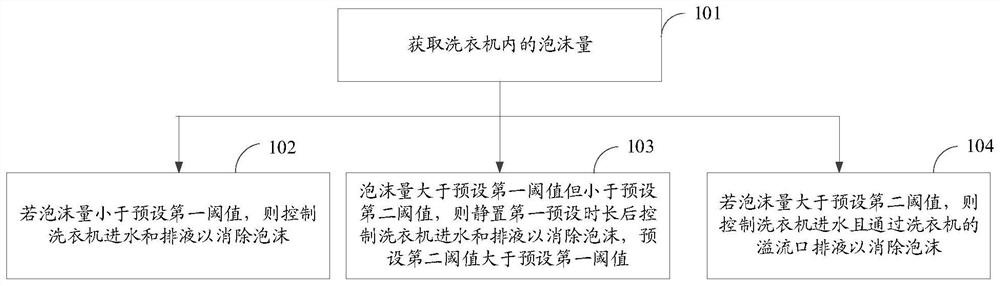

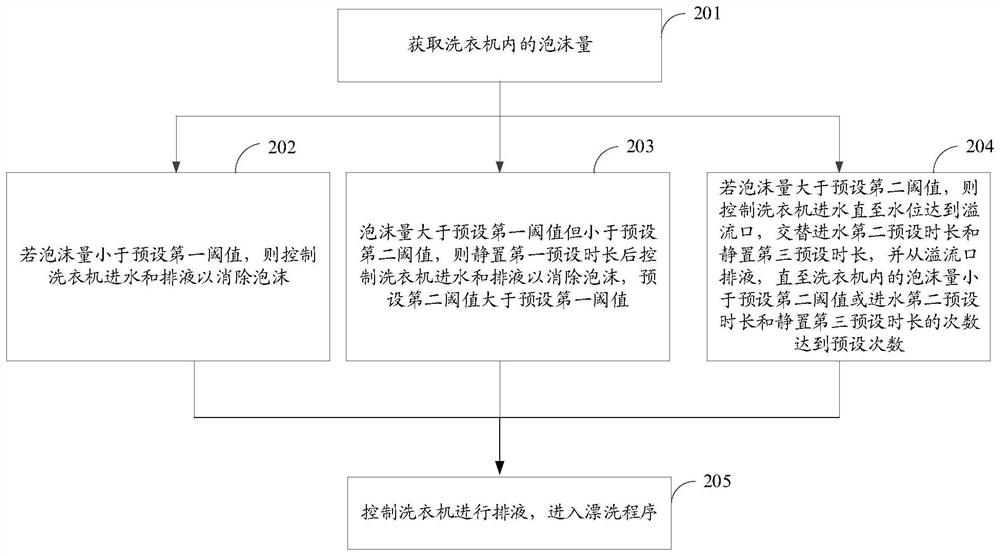

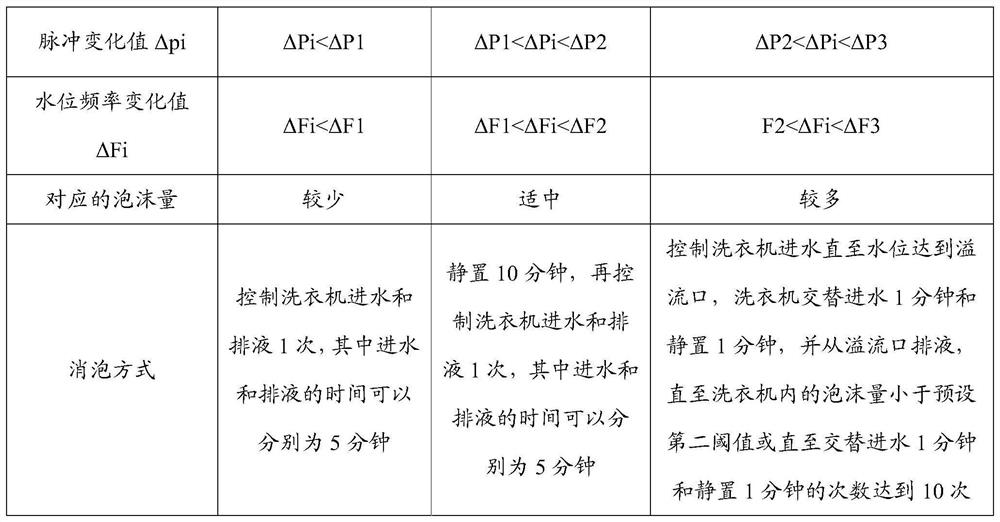

Foam eliminating method and device, storage medium and washing machine

PendingCN114481530AImprove the anti-foaming effectReduce foam volumeControl devices for washing apparatusTextiles and paperLaundry washing machineEngineering

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

Washing machine and control method thereof

PendingCN114687145ASpeed up the flowBrought out in timeOther washing machinesControl devices for washing apparatusLaundry washing machineSuction force

The invention provides a washing machine and a control method thereof, and the washing machine comprises an inner barrel, the bottom of which is provided with an inner barrel water outlet; the water collecting device is coaxially arranged outside the inner barrel; the drainage assembly comprises a communicating structure which is fixedly arranged in the water collecting device and is rotatably communicated with the inner barrel drainage opening in a sealing manner, and a first drainage pipeline connected with the communicating structure; and the air extractor is arranged on the first drainage pipeline and can apply suction force to air in the inner barrel through the first drainage pipeline, and the air is discharged through the first drainage pipeline. According to the washing machine provided by the invention, the air in the inner barrel is sucked through the air suction device and is discharged through the first water discharge pipeline, so that not only can the humid air in the inner barrel be brought out of the inner barrel and the humidity in the barrel be reduced, but also the separation of clothes and water in the inner barrel can be accelerated, and the dewatering efficiency and the clothes drying effect of the washing machine are further improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Washing machine and control method thereof

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap