Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Improve uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

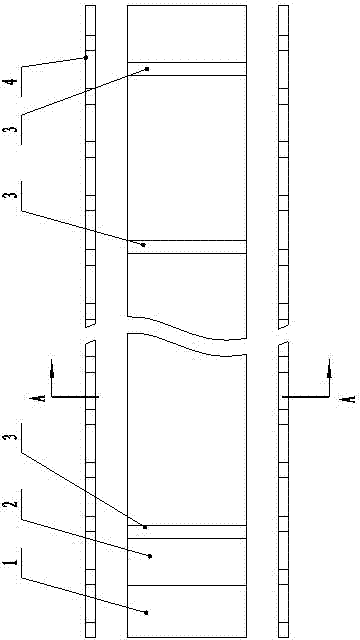

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

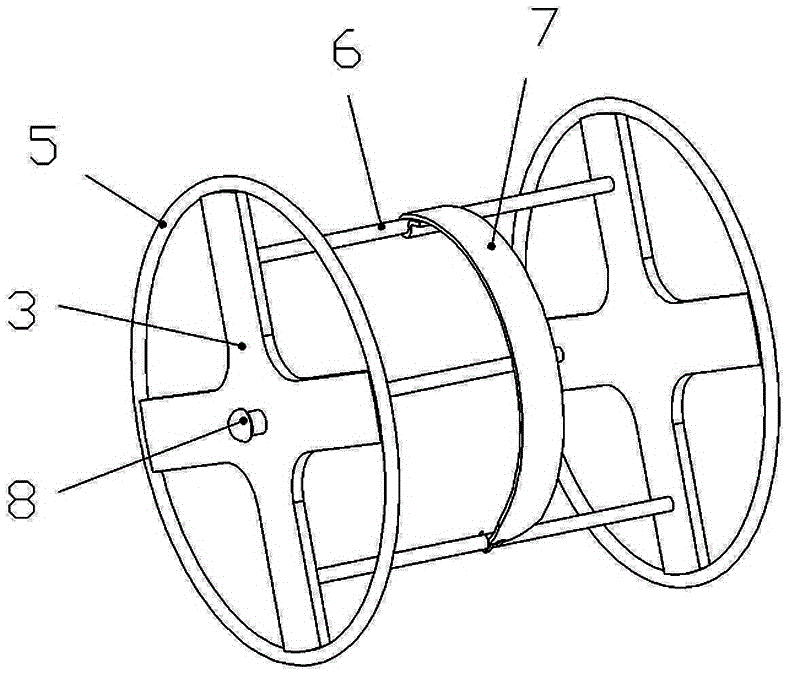

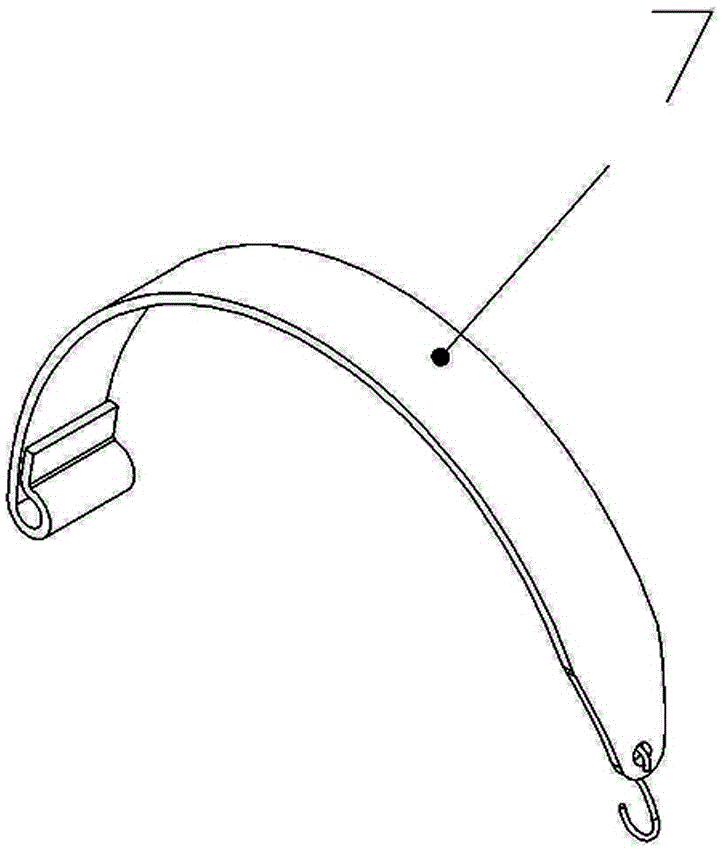

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

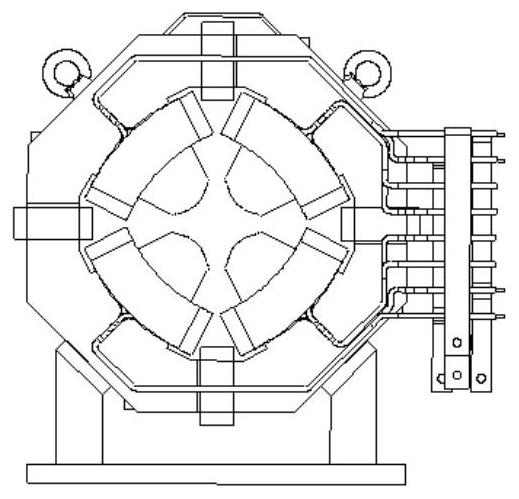

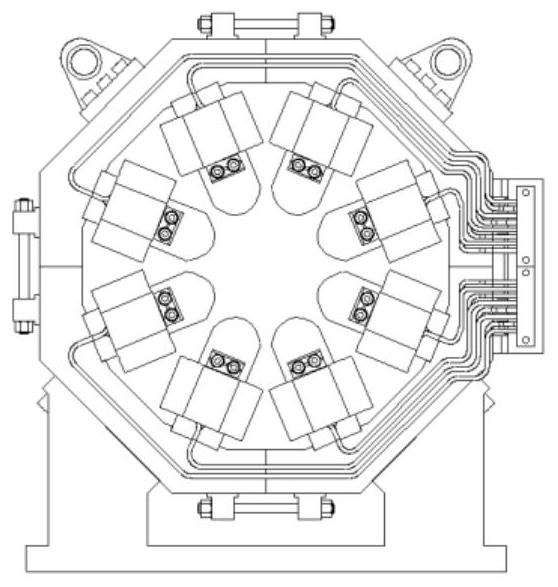

High-power plasma microwave resonant cavity

ActiveCN105244251AImprove efficiencyImprove uniformityElectric discharge tubesClassical mechanicsDeposition rate

Owner:YANGTZE OPTICAL FIBRE AND CABLE JOINT STOCK LIMITED COMPANY

Photoresist composition for multi-micro nozzle head coater

ActiveUS7378230B2Improve uniformityImprovement in productivity and product qualityCoatingsDecorative surface effectsActive compoundChemistry

Owner:SAMSUNG DISPLAY CO LTD +1

Method for producing rare earth ion doped yttrium aluminum garnet nano phosphor powder

InactiveCN101602944AImprove uniformityOvercoming phenomena such as reunionLiquid spraying apparatusGrain treatmentsHigh concentrationRare-earth element

The invention discloses a method for producing a rare earth ion doped yttrium aluminum garnet nano phosphor powder. The general formula of the nano powder is (Y1-xLnx)3Al5O12, wherein Ln is one of rare earth elements Ce and Eu, x is more than or equal to 0.0 and less than or equal to 0.1, mixed solution of nitrates or acetates of Al, Y and Ln is used as a mother liquor of salt, and mixed solution of NH4HCO3 and NH3.H2O is used as solution of compound precipitator; the ammonia water is used for adjusting the pH value of the solution of compound precipitator to 10; and the mother liquor of salt undergoes ultrasonic atomization and then is sprayed in the solution of compound precipitator which is continuously stirred, and after complete reaction, the mixed solution if filtered, washed, dried, repeatedly ball-milled and calcined to obtain uniform and dispersed rare earth ion doped YAG nano phosphor powder. The method has the advantages that the produced nano phosphor powder is uniform and dispersed, the granularity is small (between 50 and 70 nanometers), and the generated phase is unitary; and the high-concentration uniform doping of the rare earth ions is realized, so that the rare earth ion doped yttrium aluminum garnet nano phosphor powder can be obtained in high efficiency.

Owner:NINGBO UNIV

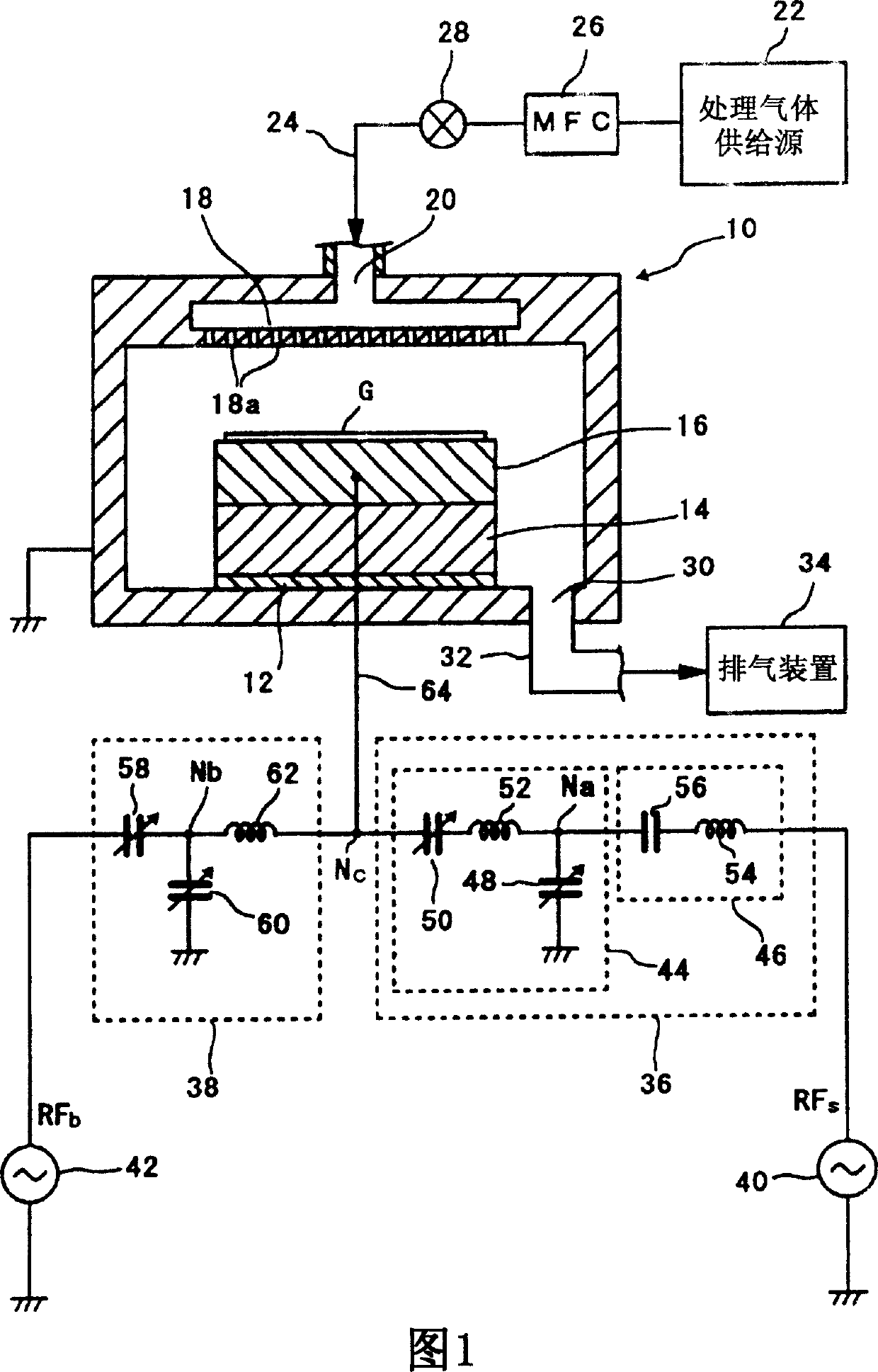

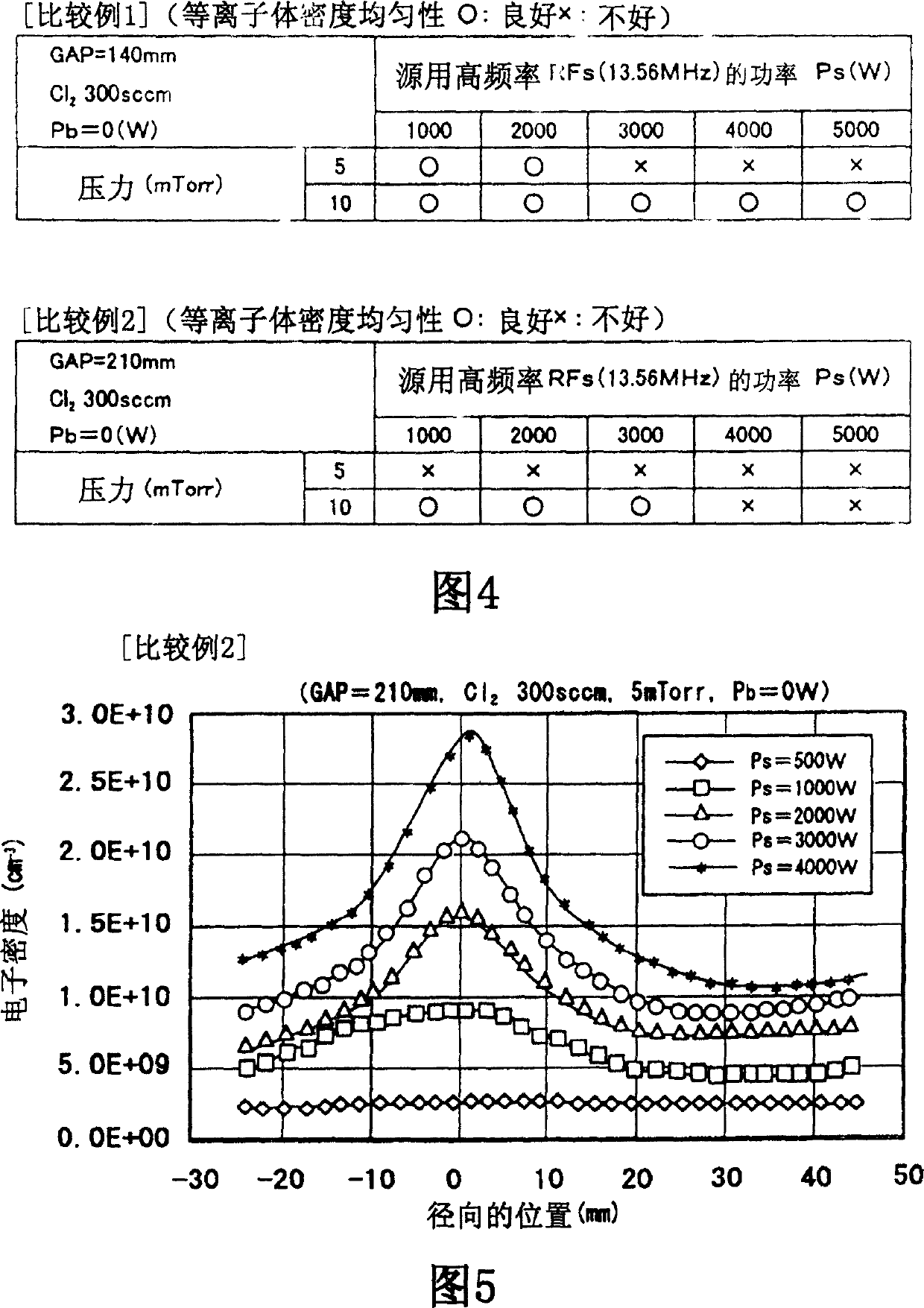

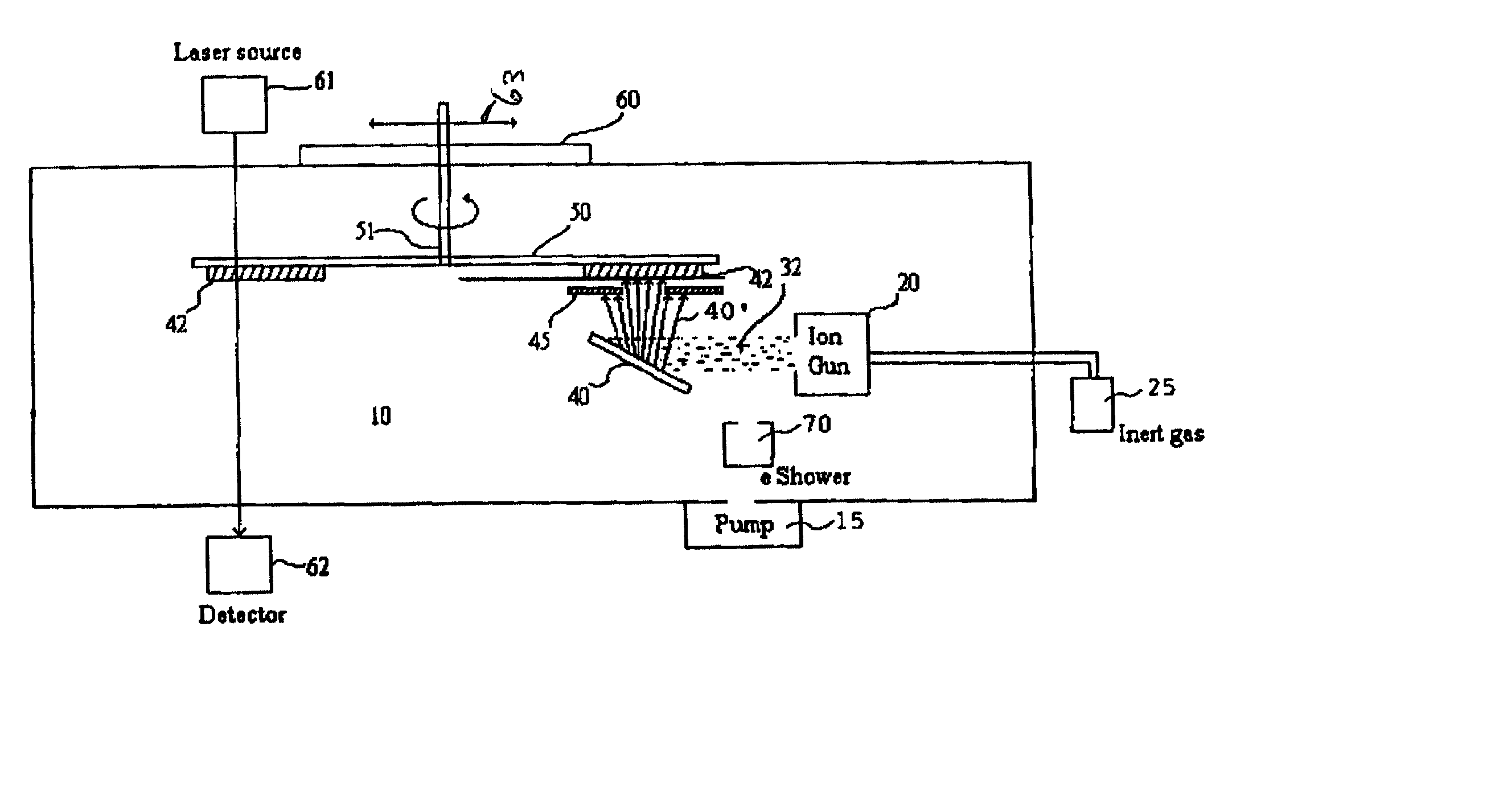

Plasma etching method and plasma treatment apparatus

ActiveCN1581445AMiniaturizationImprove etching effectElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyPhysics

To realize reduction in size and low cost of a matching circuit in the double-frequency superimposing and impressing system. In this plasma etching apparatus, an upper electrode 18 is connected (grounded) to the ground potential via a chamber 10, while a lower electrode 16 is electrically connected to a first radio frequency power source 40 (for example, 13.56 MHz) and a second radio frequency power source 42 (for example, 3.2 MHz) via a first matching unit 36 and a second matching unit 38. The second matching unit 38 in the lower frequency side is formed of a T-type circuit in which a coil 62 is provided in the final output stage and the coil 62 is also operated as a high-cut filter for shielding the radio frequency (13.56 MHz) from the first radio frequency power source 40.

Owner:TOKYO ELECTRON LTD

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

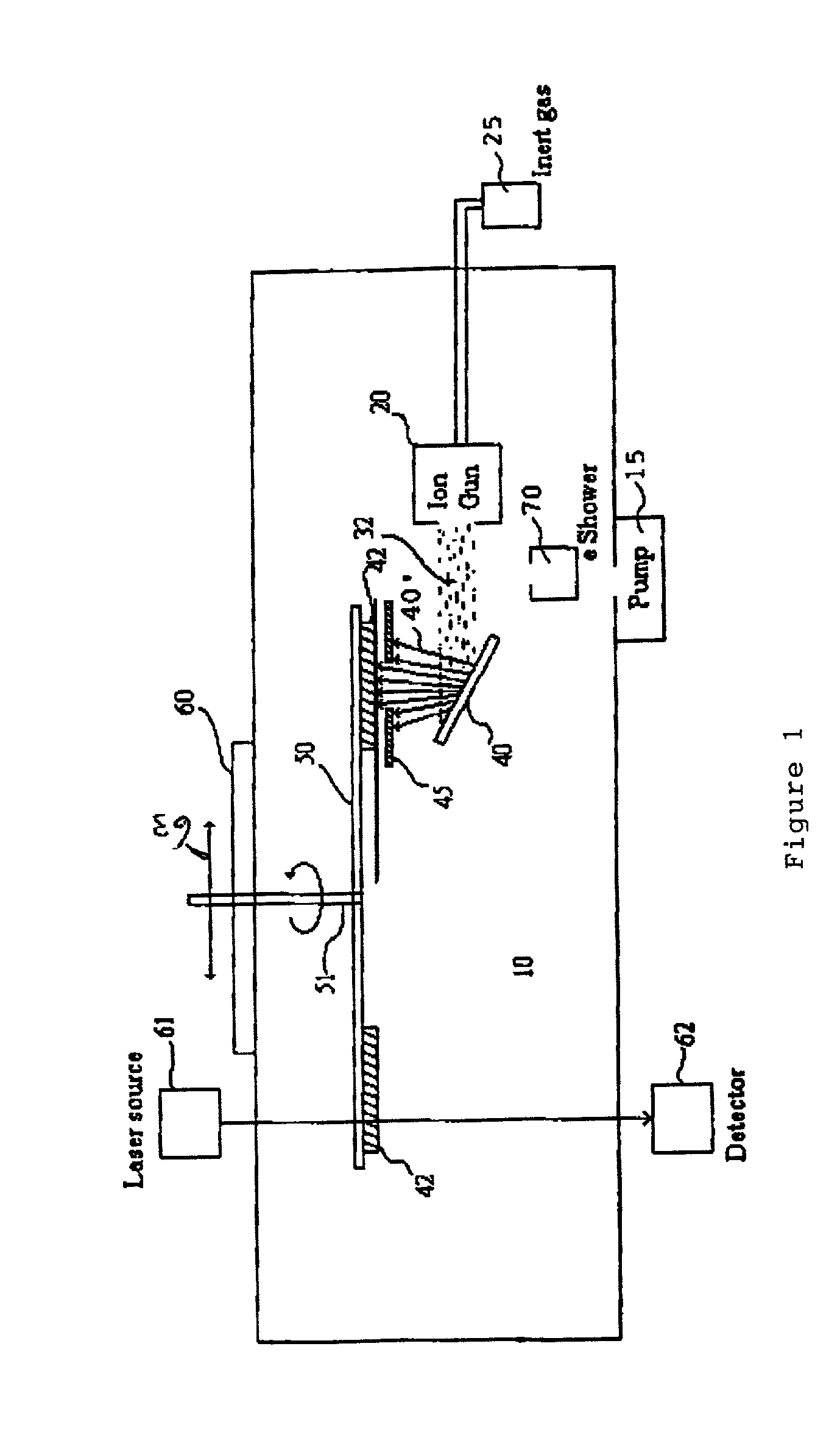

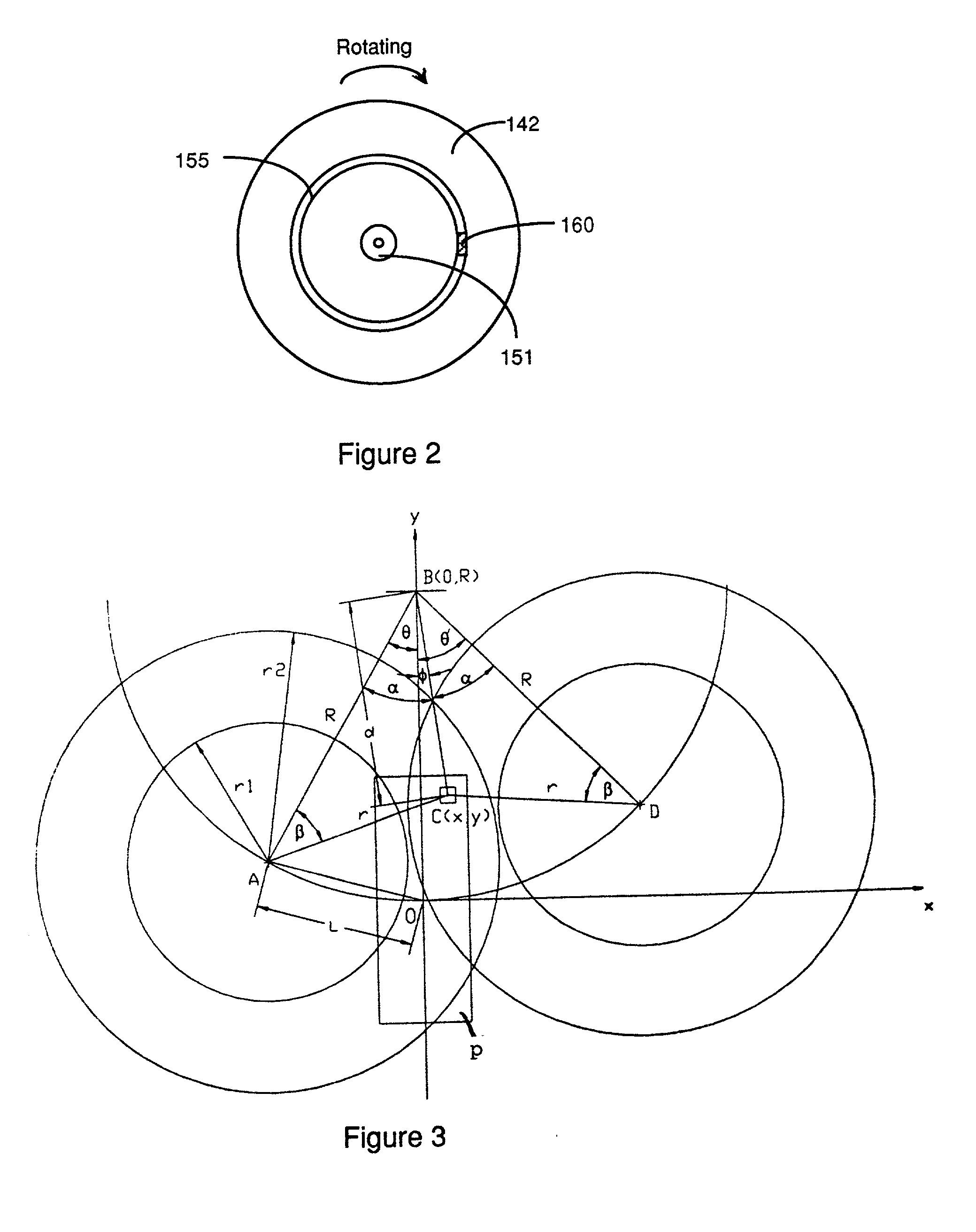

Apparatus and method for uniformly depositing thin films over substrates

InactiveUS20020134668A1High over substrate surfaceImprove uniformityCellsVacuum evaporation coatingPhysicsParticle beam

Owner:ADVANCED OPTICS SOLUTIONS

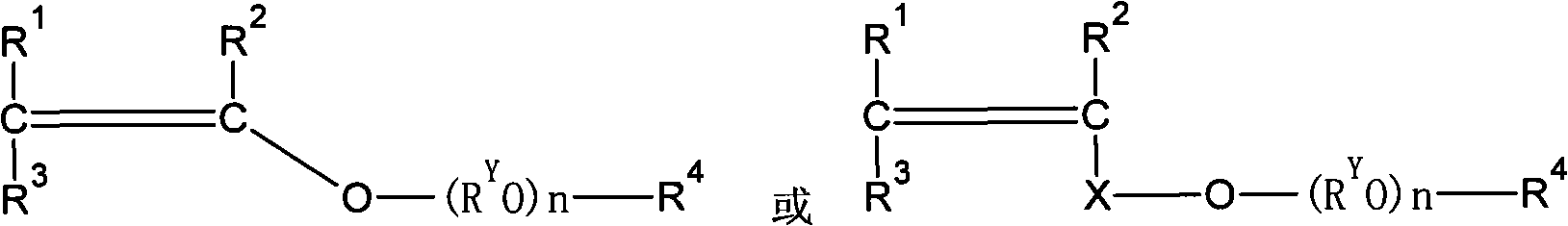

Preparation method of concrete water reducer

The invention provides a preparation method of a concrete water reducer, comprising the following steps: 1) letting MPEG and unsaturated acid be subject to esterification to obtain a mixture of MPEG unsaturated fatty acid and unsaturated acid (salt); 2) dissolving nonsaturated polyether; 3) adding an initiator, and adding the mixture of MPEG unsaturated fatty acid and unsaturated acid (salt), a chain transferring agent and a promoter dropwisely; and 4) keeping warm and aging, neutralizing with alkali, and discharging. By using a copolymerization method to copolymerize the ester unsaturated monomer and the ether unsaturated monomer, the water reducer with good adaptability is prepared.

Owner:SHANGHAI TAIJIE CHEM

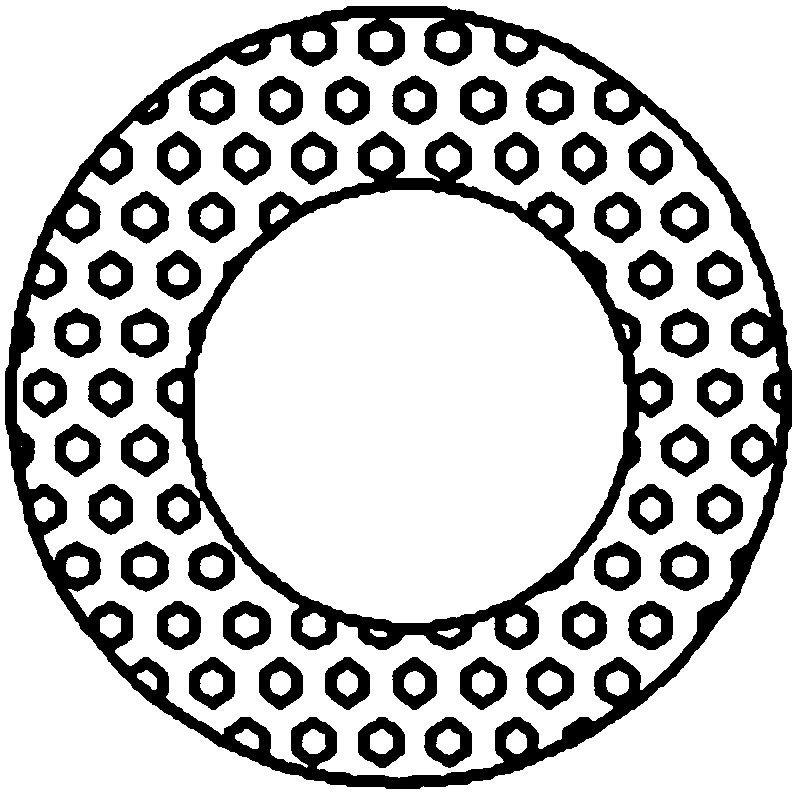

Fly ash ceramsite and preparation method thereof

The present invention relates to fly ash ceramsite and a preparation method thereof, wherein the fly ash ceramsite has a cavity structure, uniform gas pores are distributed in the area outside the cavity, and the inner wall of the cavity is obtained by carrying out high temperature decomposition on low melting point solid waste containing crystal water, structural water or hydroxyl. The preparation method comprises: nucleating by utilizing the raw materials of a nucleating agent to obtain a spherical nucleating agent; mixing fly ash and other auxiliary materials according to a formula ratio; coating the nucleating agent by utilizing the mixture; granulating to obtain pellets; and drying the pellets, roasting, and cooling to obtain the fly ash ceramsite. According to the invention, the prepared fly ash ceramsite has a ceramsite stacking density of 400-600 kg / m<3>, a water absorption rate of 0.5-2.5% and a numerical tube pressure of 3-6 MPa; and with the method, in the case of the ensuring of the strength of ceramsite, the prepared fly ash ceramsite has characteristics of low bulk density, light weight, low water absorption rate and the like, can meet the market requirements on lightweight high-strength fly ash ceramsite, and has good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

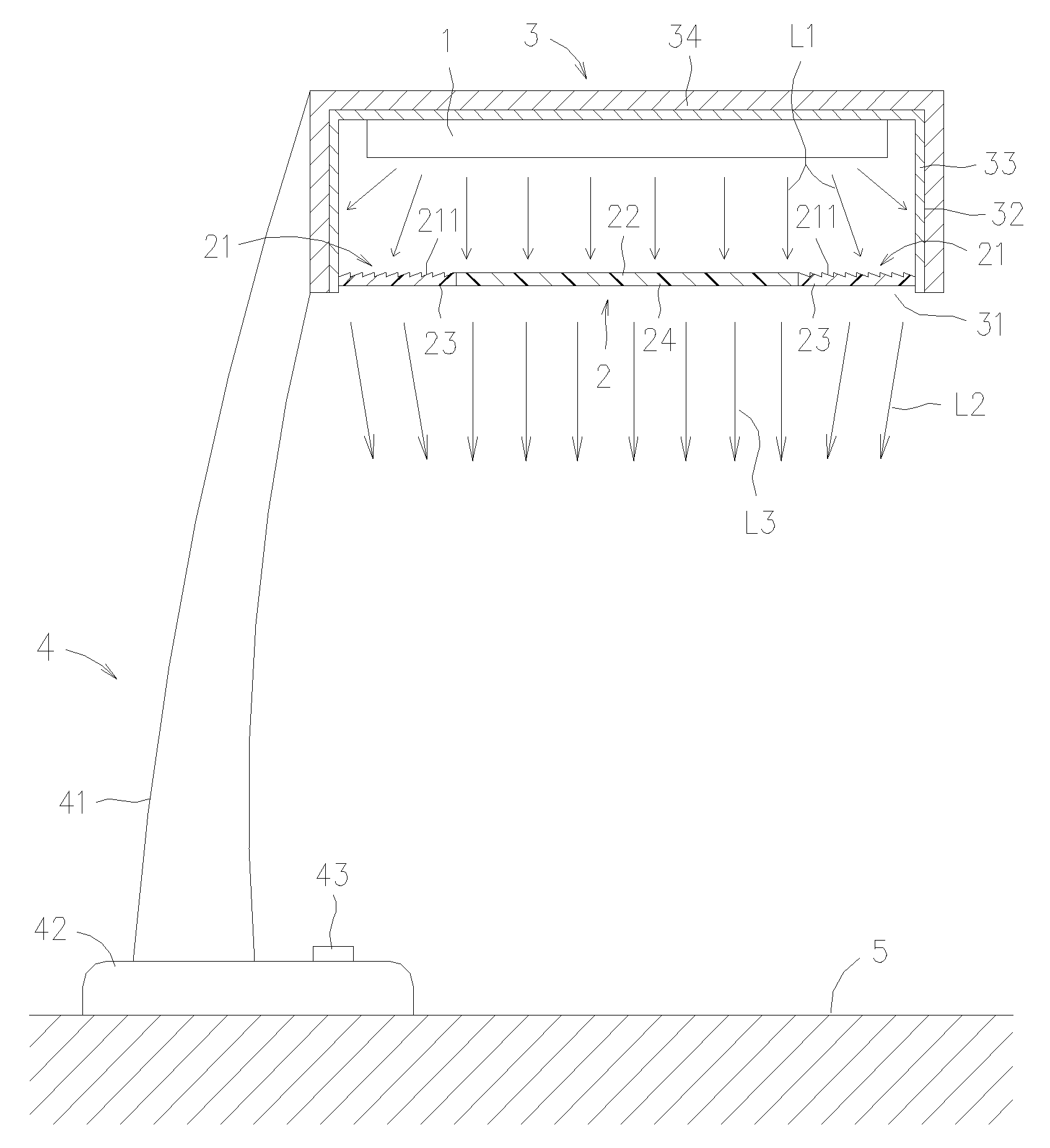

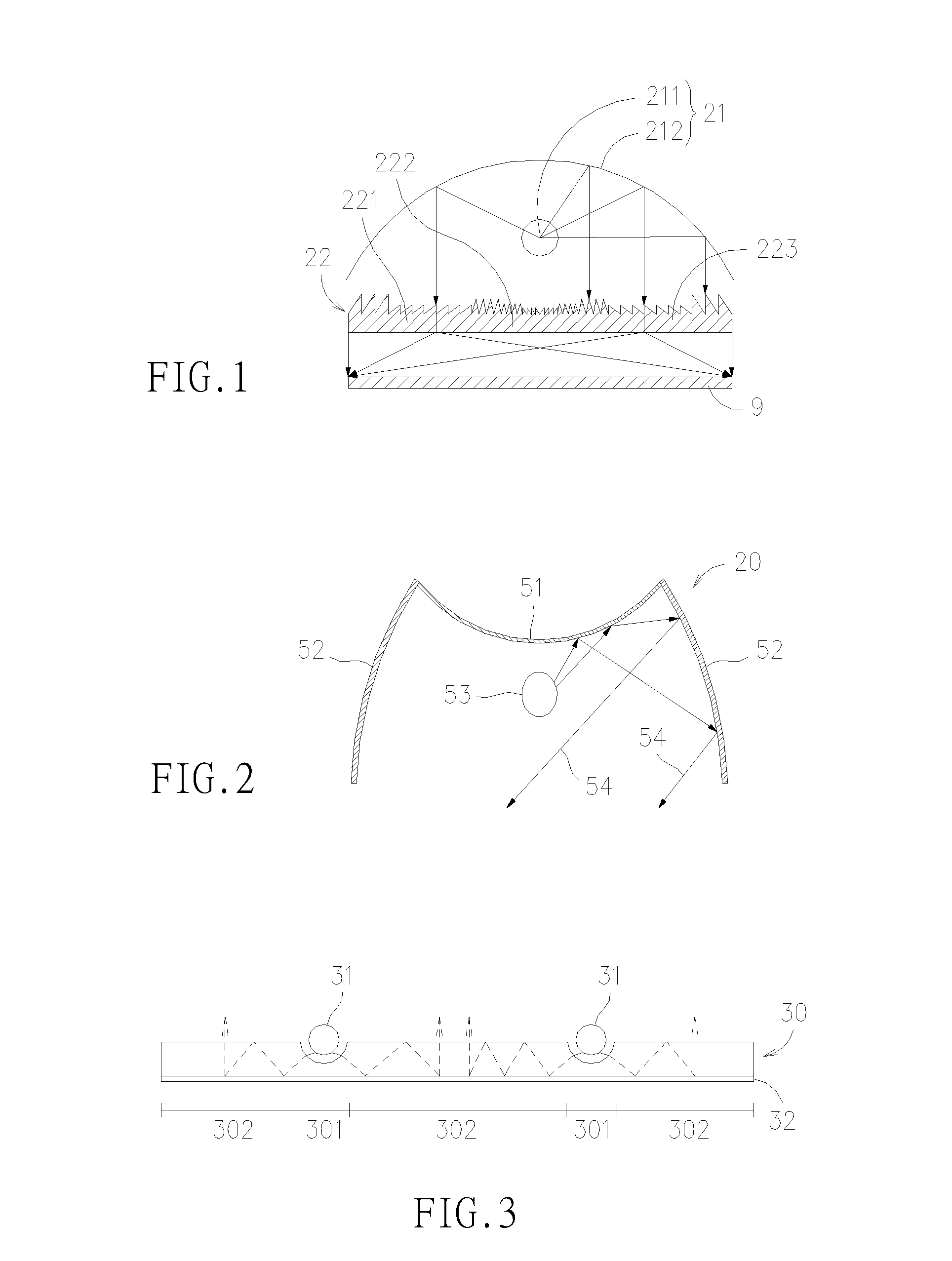

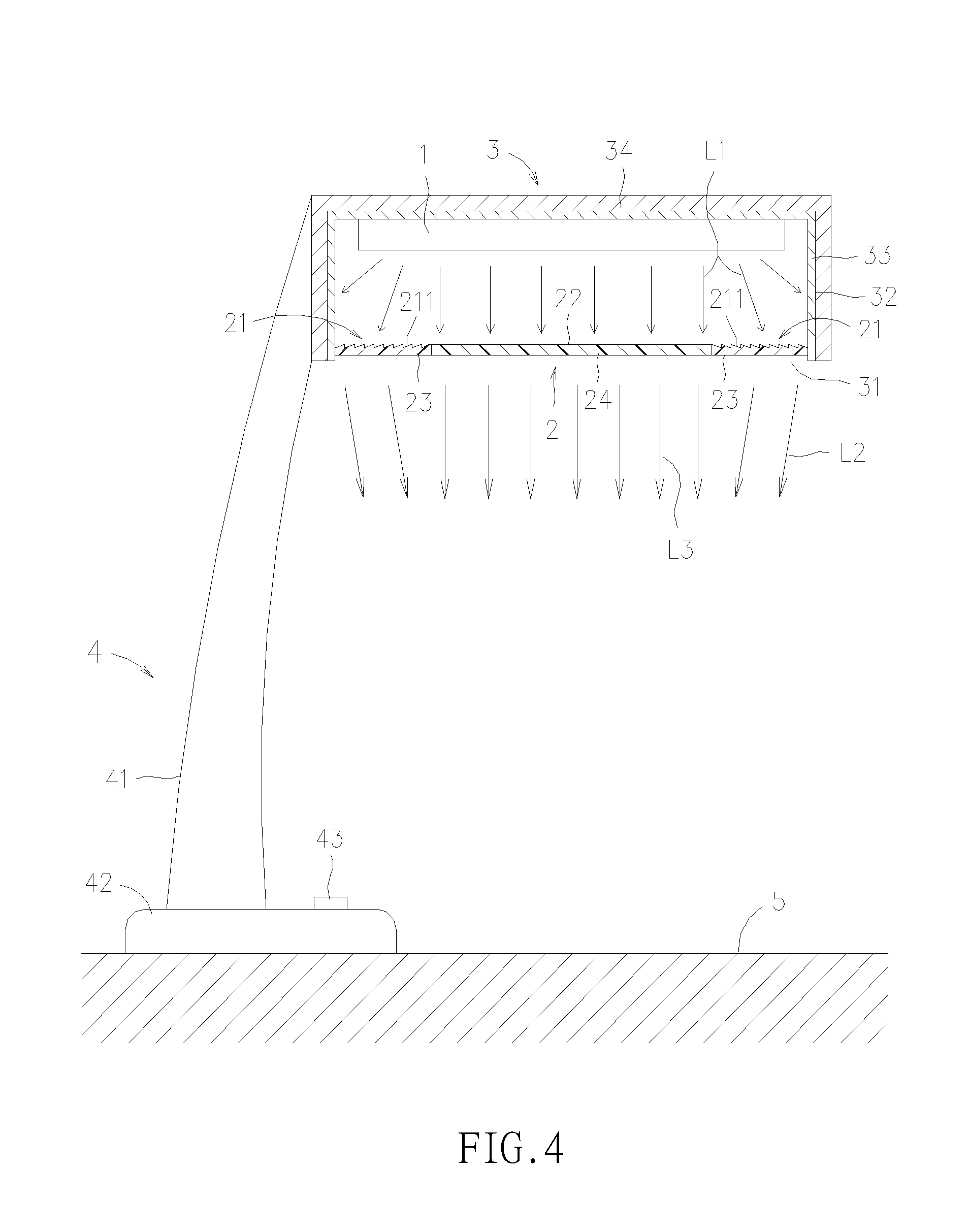

Lamp fixture

ActiveUS20080253129A1Prevent glareImprove uniformityNon-electric lightingElectric circuit arrangementsMicrostructureLight source

Owner:IND TECH RES INST

Planar Optical Waveguide Based on Two-Dimensional Optical Gratings

ActiveUS20200264367A1Maximum flexibilityEnhanced visible areaOptical light guidesGratingParallel plate

A planar optical waveguide based on two-dimensional grating includes an optical waveguide substrate which is a transparent plane-parallel plate, and a functional grating element which includes a two-dimensional grating having two grating directions with an angle of 60° in between. The two-dimensional grating is either protruded or recessed into the top surface of the optical waveguide substrate. The output image from a micro-projector can enter the optical waveguide and then gets projected to cover the entire area of the functional grating element, enabling a human eye to view the output image across a large eye-box.

Owner:SHANGHAI NORTH OCEAN TECH CO LTD

Liquid-cooled LED (light-emitting diode) lamp

ActiveCN104896342AGuaranteed thermal performanceImprove uniformityElectric lightingLight fasteningsHeat capacityHeat spreader

Owner:DONGGUAN WENYU IND

Down hole impacting rotary jetting mixing pile construction technology and device

ActiveCN106996105ASimple structureNo need to disassembleSolid waste managementBulkheads/pilesArchitectural engineeringHigh pressure

The invention provides a down hole impacting rotary jetting mixing pile construction technology and device. The down hole impacting rotary jetting mixing pile construction device includes a drill rod, a down hole impacting device arranged at the bottom end of the drill rod, a mixing device connected to the lateral side of the drill rod or the down hole impacting device, and a nozzle arranged on the lateral side of the down hole impacting device. A communicating high-pressure air passageway is arranged among the drill rod, the nozzle and the down hole impacting device. The above down hole impacting rotary jetting mixing pile is adopted in the down hole impacting rotary jetting mixing pile construction technology. By means of the down hole impacting rotary jetting mixing pile construction technology and device, the stratum adaptability is high, and pollution and influences of industrial production to the environment are reduced.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

Pulse type spray-dyeing system for dyeing machine and control method of pulse type spray-dyeing system

ActiveCN105624948AGood economic and social benefitsImprove uniformityLiquid/gas/vapor treatment of definite length materialsTextile treatment by spraying/projectingAgricultural engineeringControl unit

Owner:高勋绿色智能装备(广州)有限公司

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

Hanger assembly and equipment assembly

PendingCN113668039AAvoid gloss or color differenceImprove uniformityAnodisationCellsAppliance componentManufacturing engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Backlight module and display device

ActiveCN109557720AImprove the display effectImprove uniformityNon-linear opticsDisplay deviceEngineering

Owner:XIAMEN TIANMA MICRO ELECTRONICS

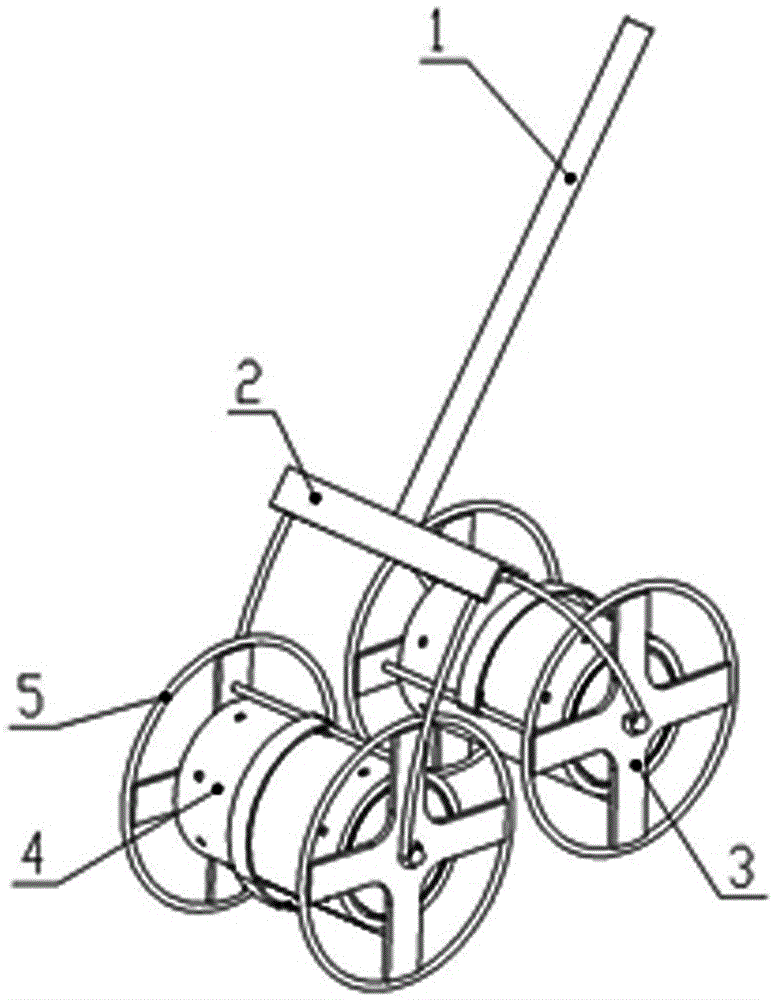

Dandelion sowing device

InactiveCN105746052AImprove seeding efficiencyImprove uniformityRegular seed deposition machinesEngineeringSowing

Owner:长子县生贵大棚技术推广有限公司

Mixing technology for lead, boron and polyethylene

A process for mixing lead-boron polyethylene related to the material mixing process of radioactive masking material comprising the steps of, mixing lead and boron evenly, high speed mixing and plasticizing of polyethylene in heated mixer, and mixing the lead-boron mixture with polyethylene in heated mixer evenly. The process according to the invention realizes simple operation process, less pollution, even product mixing, thus can be widely applied into the mixing process for lead-containing material.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Display screen brightness adjusting method and system

Owner:BOE TECH GRP CO LTD

Laser acceleration proton beam homogenization method and device

Owner:PEKING UNIV +1

Device and method for improving finishing temperature of oriented silicon steel

ActiveCN103331302BRaise the finishing temperatureImprove uniformityMetal rolling arrangementsEngineeringHot rolled

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

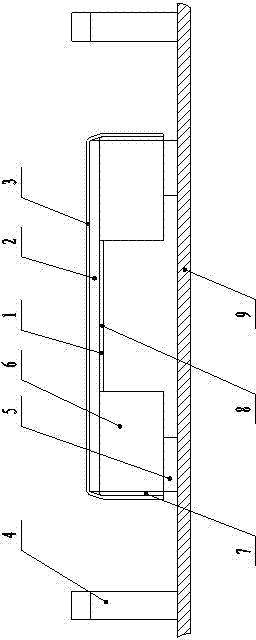

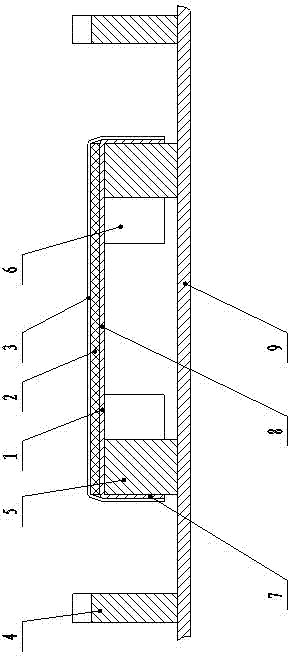

LED lamp with water-circulating heat dissipation function

ActiveCN105221970AEven heat absorptionImprove heat absorption efficiencyPoint-like light sourceLighting heating/cooling arrangementsWater flowEngineering

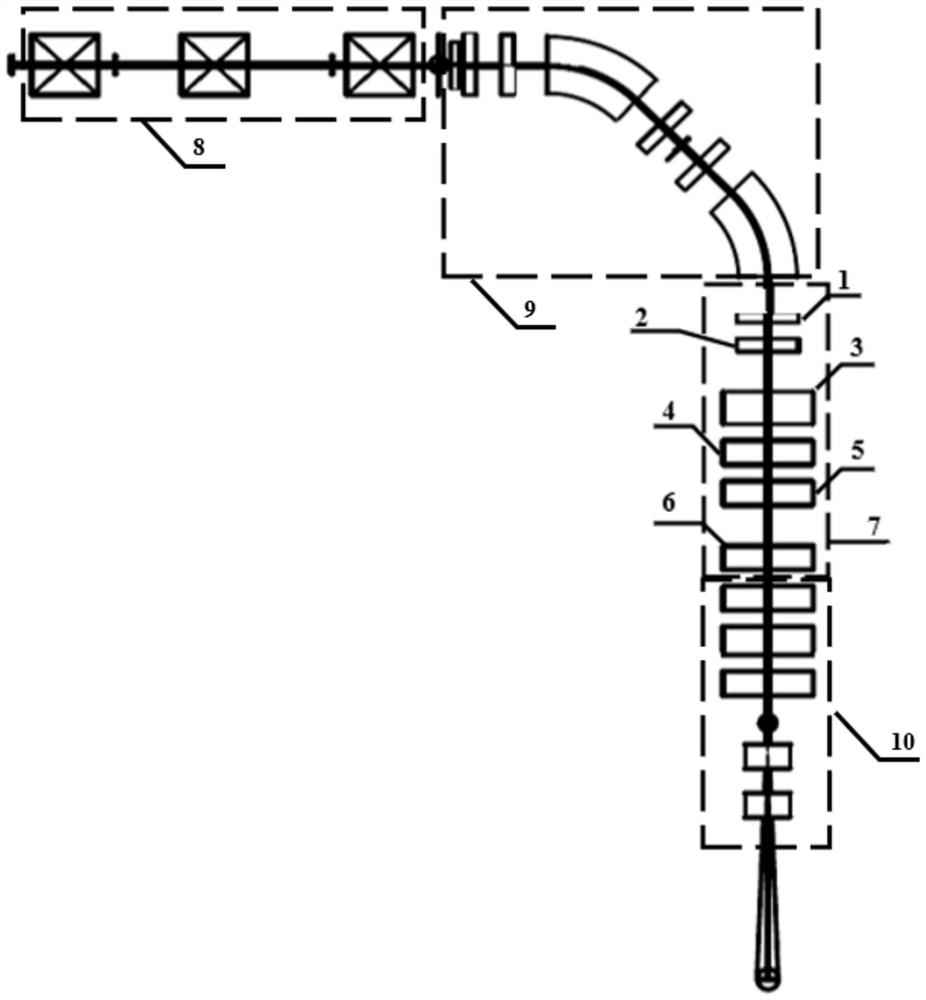

The invention discloses an LED lamp with a water-circulating heat dissipation function. The LED lamp comprises an LED wafer (1), a connecting wire (2), a lens (3), an LED wafer substrate (5), a system circuit board (6) and a heat dissipation fin (7), wherein a heat dissipation device (8) used for heat dissipation is arranged below the heat dissipation fin (7); the water inlet (9) of the heat dissipation device (8) is positioned under the heat dissipation device (8); and two or more water outlets (10) are arranged the heat dissipation device (8) and uniformly distributed on the side surface of the heat dissipation device (8). The LED lamp has the beneficial effects that the water inlet is arranged under the heat dissipation device and the water outlets are arranged on the side surface of the heat dissipation device, and water flows in from below and flows out from the surroundings, so that water flow of relative low temperature is formed from the middle to both sides of the heat dissipation fin, heat on the heat dissipation fin is brought away, uniform heat absorption of the water flow is achieved, heat absorption efficiency of the water flow is improved, and all regions of the heat dissipation fin can keep the same and stable temperature.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

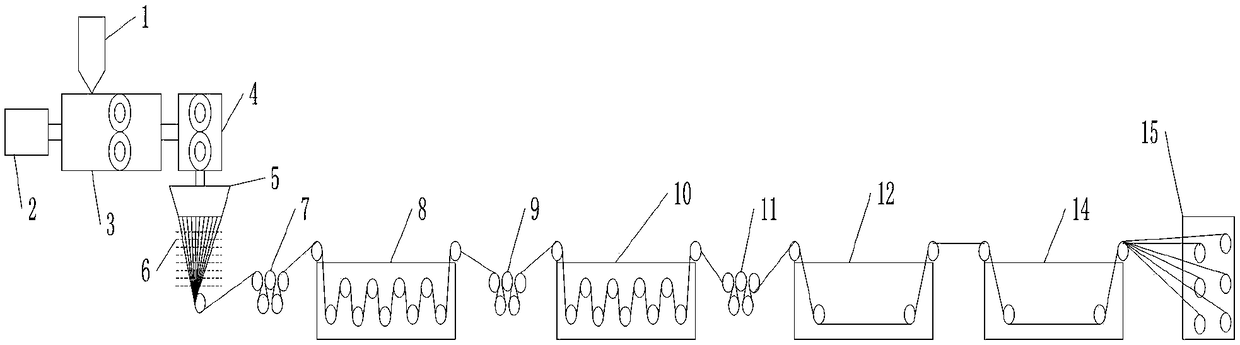

Preparation method of ultrahigh molecular weight polyethylene monofilament

InactiveCN109487349AHigh strengthImprove uniformityFilament forming substance formingSpinning head liquid feederEnvironmentally friendlyThermal treatment

The invention discloses a preparation method of an ultrahigh molecular weight polyethylene monofilament. The preparation method comprises the following steps that an ultrahigh molecular weight polyethylene composite agent obtained through melting and kneading treatment is adopted, a special screw extruding device is adopted for performing sufficient melting and mixing on the composite agent, and extrusion and conveying are performed; furthermore, a booster pump is adopted for improving pressure of a fusion system, meanwhile, a melt is quantitively pressed into a spinning die head or a spinningbox to perform extrusion spinneret, after water bath or oil bath or air bath cooling is performed, primary monofilaments are obtained, the obtained primary monofilaments are subjected to doffing, after multi-heating stretching is performed, the primary monofilaments can be directly and continuously subjected to water bath drafting, multi-stage heat roller drafting and hot air stretching and thensubjected to thermal treatment, and oiling is performed to obtain the high-strength high-modulus polyethylene monofilaments. The problems that molecules are nested and arranged difficultly, and macromolecule winding is series, so that melt flowability and uniformity are poor are well solved, and the monofilaments are high in strength, good in uniformity, simple in production technology, high in efficiency and environmentally friendly.

Owner:郭海洋

Backflow type high temperature hot wind tunnel structure

ActiveCN105509929AImprove uniformityReduce energy consumption and calibration costsThermometer testing/calibrationAir compressorControl valves

Owner:AECC SICHUAN GAS TURBINE RES INST

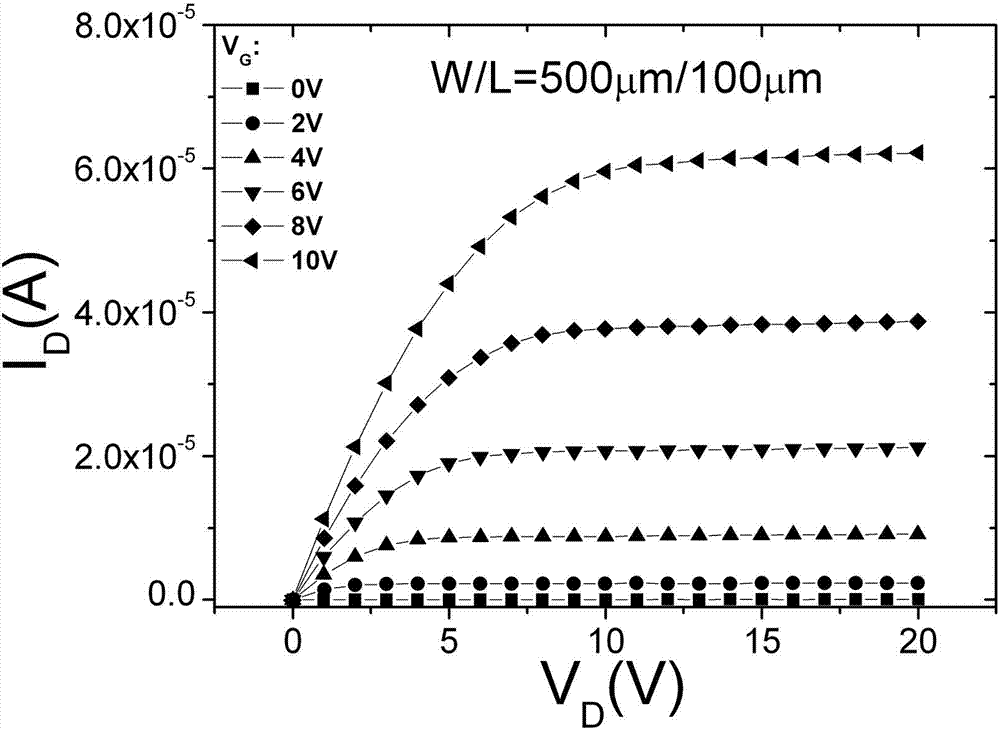

On-line atomic layer deposition device and deposition method

InactiveCN102644062ASimple structureEasy loading and unloadingChemical vapor deposition coatingBatch processingAtomic layer deposition

The invention discloses an on-line atomic layer deposition device, which comprises a substrate feeding system, a processing chamber, a precursor feeding system, at least one loading and unloading element, a lifting element, a control and detection system and an exhaust system, wherein a substrate is fed into the processing chamber by the substrate feeding system; the precursor feeding system is arranged on the side face of the processing chamber; the loading and unloading element is arranged at the inlet and outlet position of the processing chamber; the lifting element is arranged just below the processing chamber and is in contact with a substrate carrying device through an open groove on the processing chamber; and the control and detection system and the exhaust system are connected with the processing chamber respectively. According to the on-line atomic layer deposition device, the problem of the complex loading element and substrate carrying device can be solved, and atomic layer deposition on the surface of a substrate can be realized in a batch processing mode.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Composite quality control product of liver function, and preparation method and application thereof

ActiveCN112063686AAvoid inactivationHigh purityMicrobiological testing/measurementDisease diagnosisNucleotidaseUltrafiltration

The invention relates to a composite quality control product of a liver function, and a preparation method and application thereof, wherein the composite quality control product comprises alpha-L-fucosidase, adenosine deaminase and 5'-nucleotidase; and the preparation method comprises the following steps of: taking a fresh pork liver as a raw material, and obtaining the composite quality control product of the liver function simultaneously containing three kinds of enzymes through processes of grinding, homogenizing, crushing, centrifuging, salting-out, purifying, ultrafiltration, freeze-drying and the like. By optimizing preparation process parameters, enzyme inactivation in the preparation process is avoided; meanwhile, impurities in the finished product are reduced; therefore, the purity of the target enzyme is improved; furthermore, the freeze-dried powder of the composite quality control product with better stability is obtained through a freeze-drying process; furthermore, a protective agent of enzyme solution is optimized, so that the thermal stability and long-term stability of the freeze-dried powder of the composite quality control product are enhanced; and thus, the composite quality control product of the liver function, which is simple and rapid in preparation method, low in cost and high in enzyme activity, uniformity and stability, is obtained.

Owner:WUHAN LIFE ORIGIN BIOTECH LTD

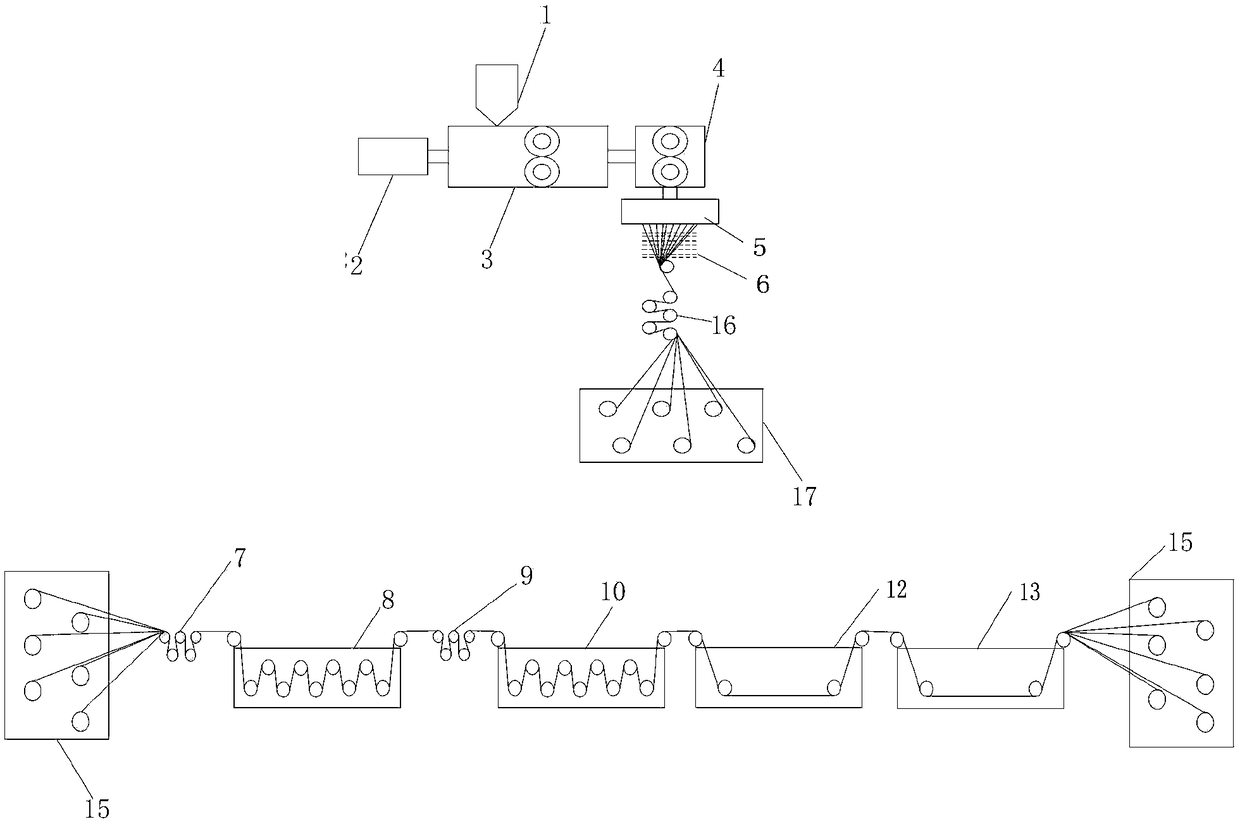

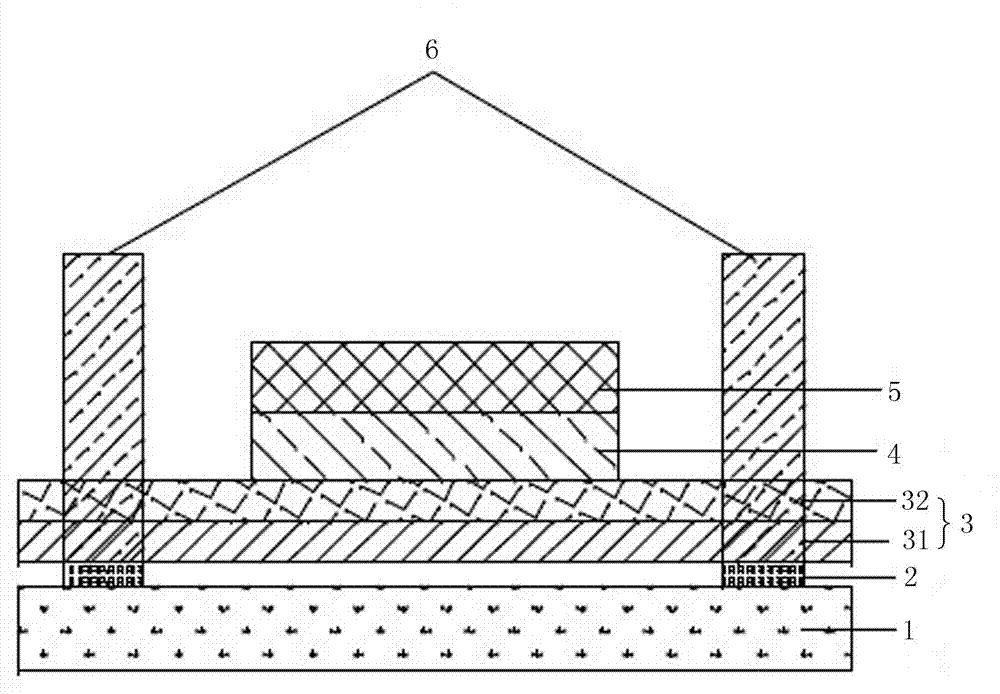

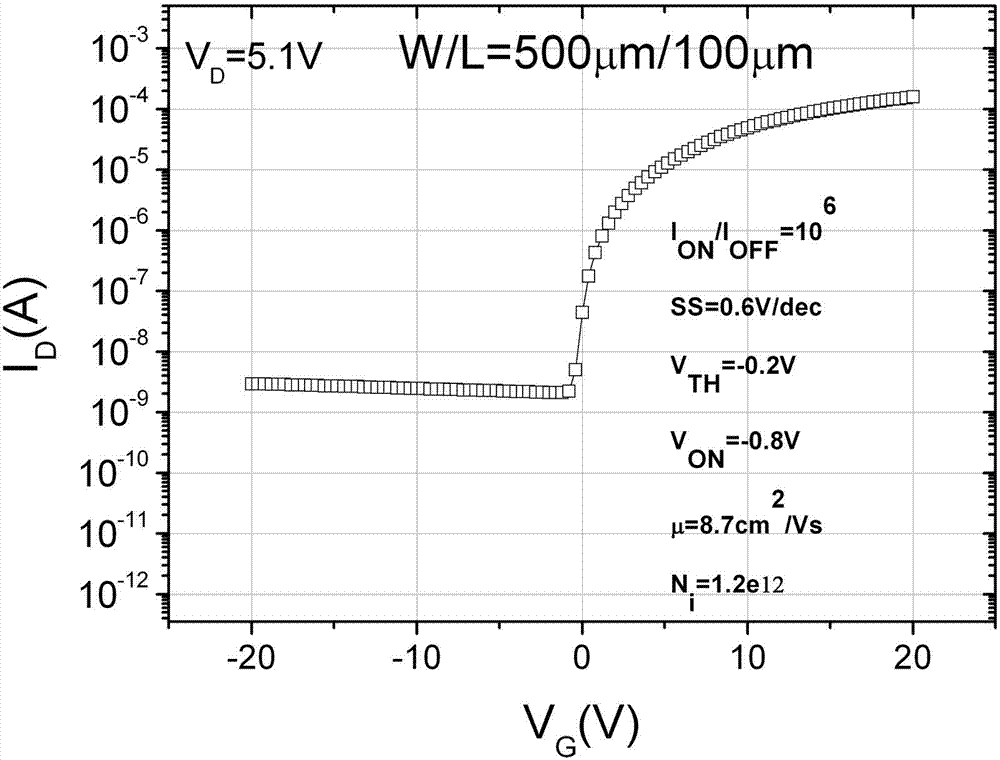

Top gate structure metallic oxide thin film transistor for improving device uniformity and manufacture method thereof

InactiveCN102969364AReduce contact resistanceImprove uniformityTransistorSemiconductor/solid-state device manufacturingPhysicsThin membrane

Owner:东莞有机发光显示产业技术研究院 +1

Method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions

ActiveCN106316397AHigh purityQuality improvementLayered productsCooling/ventilation/heating modificationsHeat conductingGranularity

The invention discloses a method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions. The method includes the steps of raw material preparing, pre-crushing, pre-screening, deironing, secondary crushing, secondary screening, mixing, profiling and heating, graphitizing at high temperature, back film preparing, heat conducting tank pressing and cutting. The machining process is scientific and reasonable in step, the machining process in the prior art is improved, the raw material is processed in a refined mode, the granularity of the graphite flakes is more uniform, the qualification rate of the finished product is increased, and electrical conductivity and heat conductivity of the heat conducting graphite flakes are improved; by means of the process, the chemical stability of the graphite flakes can be improved, thermal expansion is reduced, and the graphite flakes are easy to machine and shape.

Owner:DONGGUAN KAIDI CARBON CO LTD

Super absorbent resin and preparation method thereof

The invention provides super absorbent resin and a preparation method thereof. The preparation method comprises the steps of: mixing and heating a dispersion medium, a surfactant and a dispersing agent to obtain a substrate solution; mixing the substrate solution with a certain amount of an initiator-based mixed solution A and an acrylic acid solution A, heating, carrying out primary polymerization reaction, and evaporating out part of water; and then mixing the substrate solution with a certain amount of an initiator-based mixed solution B and an acrylic acid solution B to carry out secondary polymerization reaction, then evaporating out part of water, and carrying out post-crosslinking, distillation treatment, solid-liquid separation and drying to obtain spherical resin particles. According to the preparation method, complete interface fusion or partial interface fusion among the spherical resin particles can be avoided, the particle size of the synthesized spherical resin particles can be controlled within a certain distribution range, meanwhile, the synthesized resin does not have a special shape, and the water absorption effect of the resin is improved.

Owner:YANKUANG COAL WATER SLURRY GASIFICATION & COAL CHEM NAT ENG RES CENT CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap