Preparation method of concrete water reducer

A technology of concrete water reducing agent and solvent, which is applied in the field of preparation of concrete additives, can solve the problems of difficult control of cement adaptability, poor cement adaptability, and large difference in cement performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing a concrete water-reducing agent. The ester-type unsaturated monomer and the ether-type unsaturated monomer are organically combined by means of copolymerization, thereby preparing a water-reducing agent with good adaptability. The preparation method is as follows:

[0019] Step 1, unsaturated organic acid is esterified with MPEG to obtain MPEG unsaturated organic acid ester (or MPEG unsaturated organic acid ester and unsaturated organic acid (salt) mixture); wherein, the MPEG molecular weight is preferably 500-2500 ; The unsaturated organic acid is preferably acrylic acid.

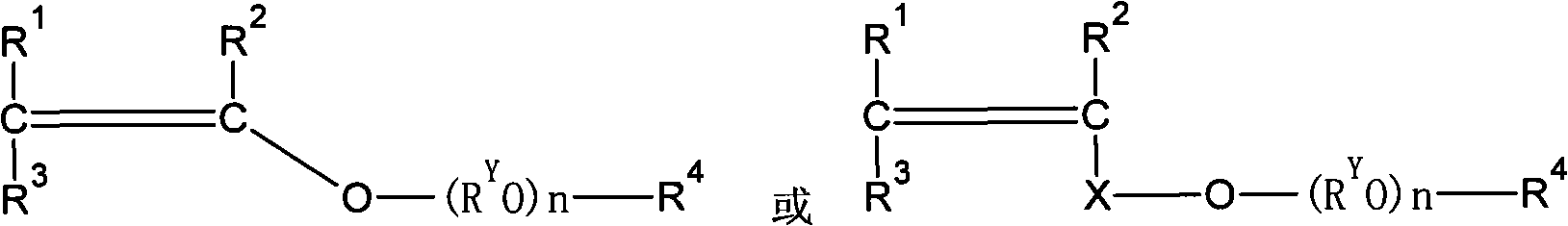

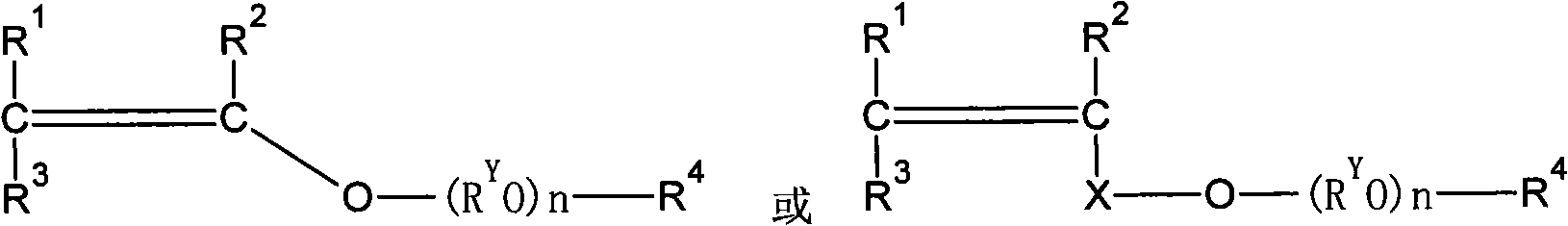

[0020] Step 2, adding the unsaturated alcohol polyether into the solvent, heating and dissolving; preferably, the structural formula of the unsaturated alcohol polyether is:

[0021]

[0022] Among them, R 1 , R 2 , R 3 Alkyl or hydrogen atom; R 4 is a hydrogen atom or C 1 ~C 20 Hydrocarbyl; R Y for C 2 ~C 18 Alkenyl; n is a natural number f...

Embodiment 1

[0030] Put 600 parts of MPEG1200, 245 parts of acrylic acid, 1 part of hydroquinone, and 1.5 parts of concentrated sulfuric acid into a flask with a stirring and heating device as a catalyst, heat up to 110°C and keep warm for 10 hours for esterification, then cool down to 50°C and add 30 parts Triethanolamine, 110 parts of water and 110 parts of 30% aqueous caustic soda, neutralized for 20 minutes. MPEG acrylate and acrylate mixtures were obtained.

[0031] In a flask equipped with a stirring and heating device, 220 parts of bottom water and 225 parts of isobutenol polyoxyethylene (50) ether were added, and the temperature was raised to dissolve. Raise the temperature to 50±2°C and add 0.8 parts of ammonium persulfate. At the same time, 250 parts of MPEG acrylate and acrylate mixture were added dropwise; 65 parts of an aqueous solution containing 0.5 parts of mercaptopropionic acid, 0.1 octyl mercaptan, and 0.5 parts of sodium formaldehyde sulfoxylate. Control 2.5 hours to ...

Embodiment 2

[0033] In a flask with a stirring and heating device, 218 parts of bottom water and 245 parts of isobutenol polyoxyethylene (25) ether were added, and the temperature was raised to dissolve. Heat up to 55±2°C and add 1 part of hydrogen peroxide (35%). At the same time, 226 parts of MPEG acrylate and acrylate mixture of Example 1, 67 parts of aqueous solution containing 0.4 part of mercaptopropionic acid, 0.1 octyl mercaptan, and 0.3 part of sodium formaldehyde sulfoxylate were added dropwise. Control 2.5 hours to drop. Then add 30 parts of 1% ammonium persulfate aqueous solution dropwise within 0.5 hour, and continue to heat-preserve and ripen for 0.5 hour after dropping. Properly lower the temperature and add 30% lye to neutralize for 10 minutes, then discharge. A polycarboxylate water reducer copolymerized with ether ester is obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap