Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26 results about "Water reducer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water reducers are special chemical products added to a concrete mixture before it is poured. They are from the same family of products as retarders. The first class of water reducers was the lignosulfonates which has been used since the 1930s. These inexpensive products were derived from wood and paper industry, but are now advantageously replaced by other synthetic sulfonate and polycarboxylate, also known as superplasticizers.

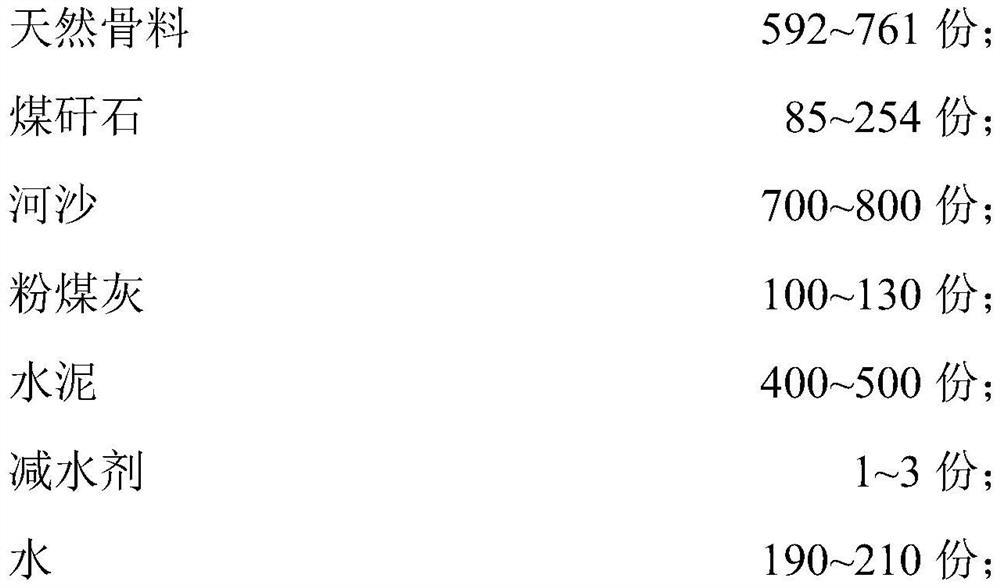

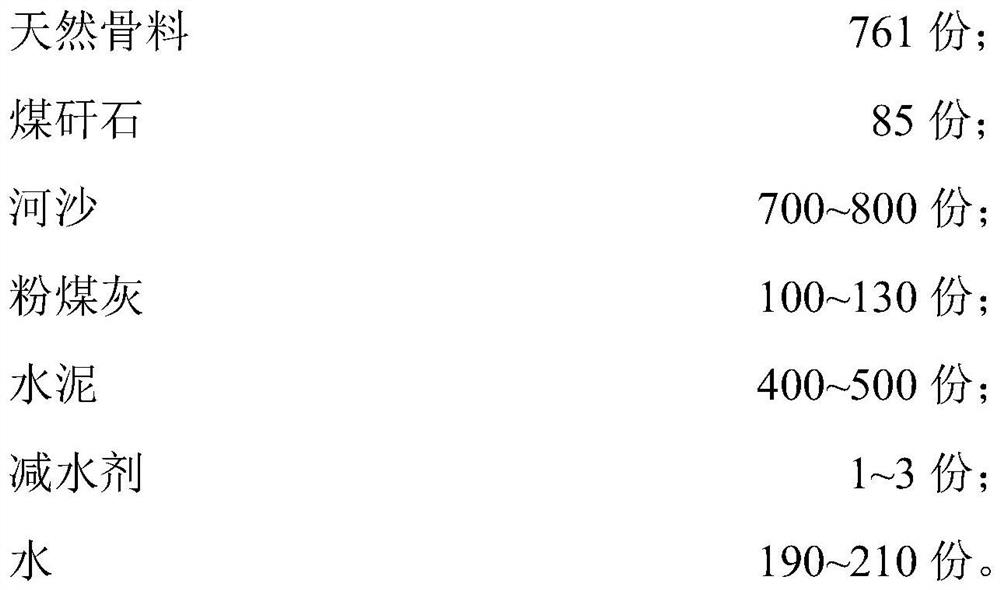

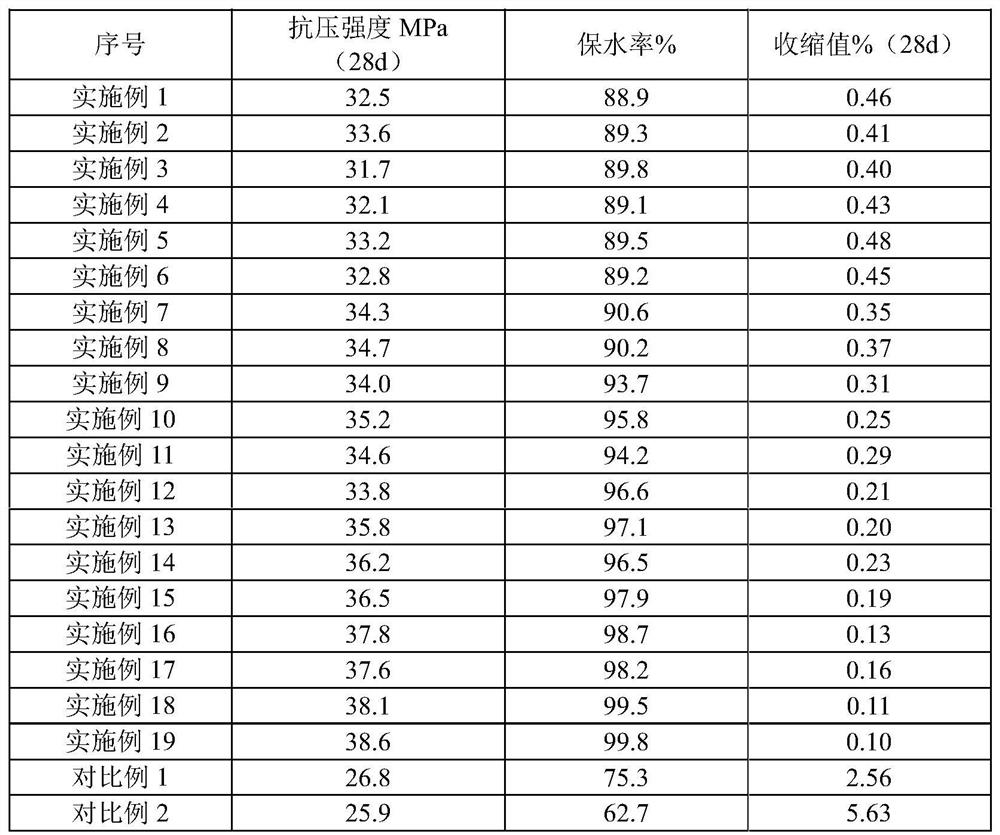

Recycled concrete and preparation method thereof

Owner:陕西金基石新型建材有限公司

Powdery polycarboxylic acid water reducing agent, preparation method therefor and application of powdery polycarboxylic acid water reducing agent

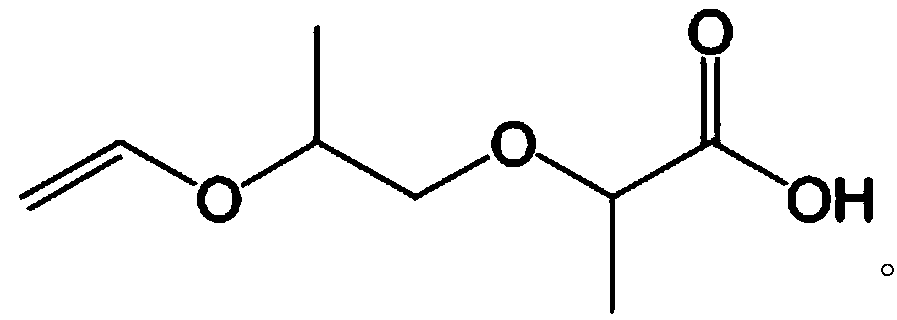

The invention discloses a powdery polycarboxylic acid water reducing agent and a preparation method therefor. The water reducing agent contains the following ingredients: 100 parts of macromonomer A, 10-20 parts of monomer B, 0.6-2 parts of initiator and 0.6-2 parts of chain transfer agent, wherein the macromonomer A is R1-O-[CH2-CH2O]m-[CH2-CH(CH3)O]n-R2; and the monomer B is liquid-state unsaturated carboxylic acid. The method comprises the steps: mixing the macromonomer A with 5% to 20% of the monomer B, heating the mixture to 50 DEG C to 70 DEG C, and adding 60% to 80% of the initiator into the mixture; dropwise adding a mixed solution of the chain transfer agent and the rest of the monomer B, wherein the time for dropwise adding is 2 to 4 hours, 60% to 85% of the mixed solution is dropwise added uniformly in first 1 / 2 to 2 / 3 of the time, and the rest of the mixed solution is dropwise added uniformly in remaining time; and carrying out a heat-preservation reaction for 1 to 2 hours, and then, carrying out cooling and crushing. The powdery polycarboxylic acid water reducing agent disclosed by the invention is good in dispersity, high in water reducing rate, small in blended amount and good in slump loss resistant performance.

Owner:SHANGHAI DONGDA CHEM

C50 high performance concrete prepared from fully-recycled fine aggregate

Owner:SOUTH CHINA UNIV OF TECH

Low-density foaming cement and preparation method thereof

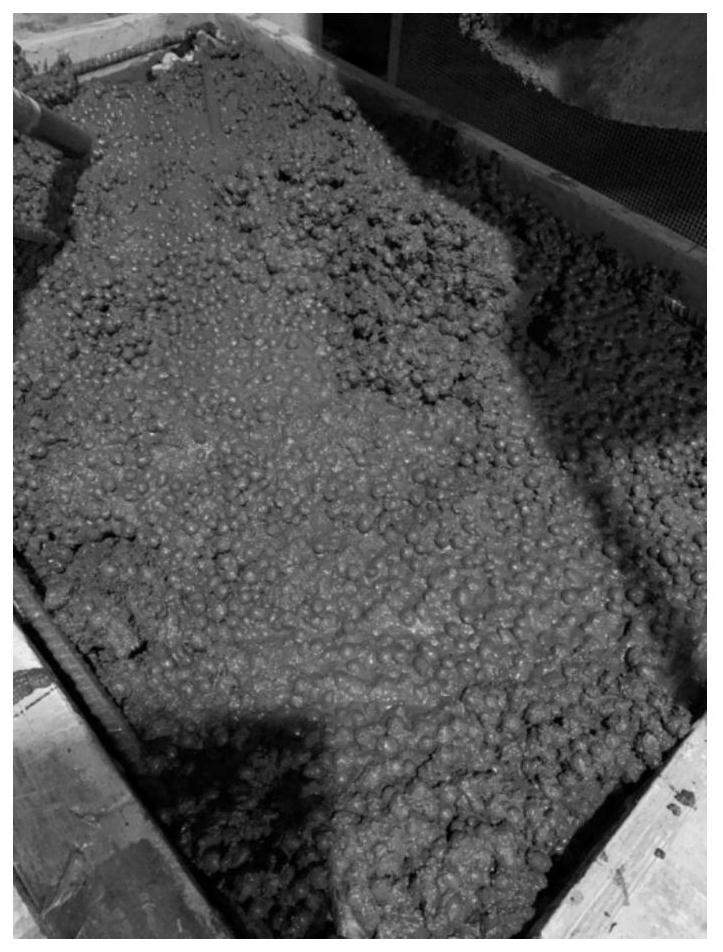

The invention discloses a low-density foaming cement, which comprises the following components in parts by weight: 60 to 120 parts of cement, 0.3 to 1.0 part of coagulant, 0.4 to 1.0 part of foam stabilizer, 0.5 to 1.2 parts of water reducer, 9 to 14 parts of foaming agent, 0.2 to 0.5 part of fiber, and 25 to 50 parts of water. The invention also discloses a preparation method of the low-density foaming cement. The low-density foaming cement is prepared through the following steps: evenly stirring dry powder, adding water to prepare cement slurry, adding a foaming agent under rapid stirring, casting to mould, and carrying out natural maintenance; and has the advantages of low dry density and low thermal conduction coefficient.

Owner:GUANGDONG JIANKE CONSTR CONSULTING CO LTD

Flexible waterproof mortar and production method thereof

The invention discloses flexible waterproof mortar and a production method thereof. The method comprises a liquid material component and a powder material component. The liquid material component comprises styrene-acrylic emulsion, acetic acid emulsion, water, a defoaming agent, and a bactericide. The powder material component comprises quartz powder, wollastonite powder, ash concrete, a water-reducing agent, a dispersing agent, and a leveling thixotropic agent. The waterproof mortar is prepared from the liquid material and the powder material according to a ratio of 1:2. The waterproof mortar has good extensibility and high elasticity. With the mortar, slight cracks on a base layer can be resisted. During vertical surface construction, the waterproof mortar is prevented from flowing and dropping, and has good construction performance. After coating, the mortar surface is smooth as mirror. The mortar is suitable for underground space water prevention, seepage prevention, and moisture prevention. The mortar is especially suitable for water prevention of buildings with waterproof exposed underground. Soaking of underground condensed water and dew condensation to the building can be effectively resisted for a long time.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL +3

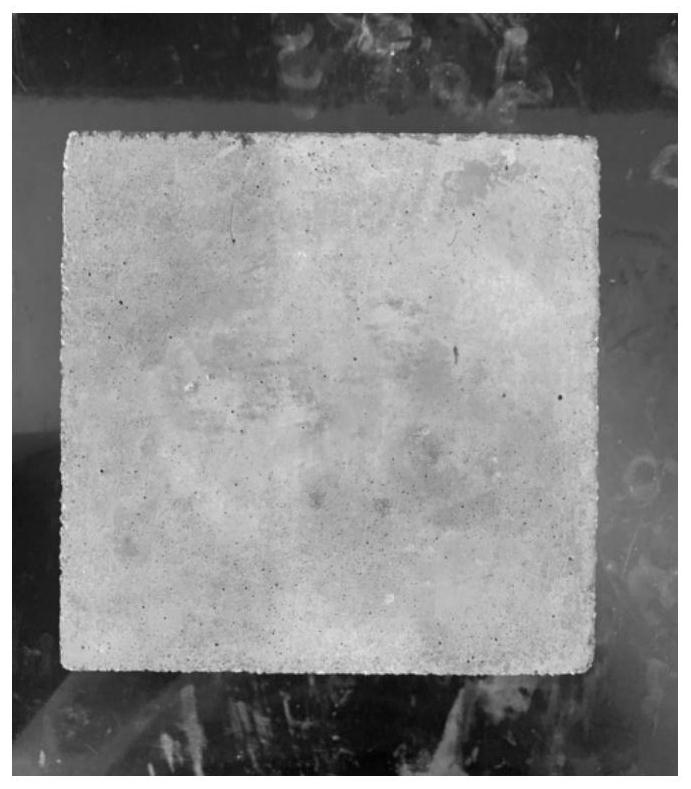

High-strength concrete formula and preparation method of high-strength concrete formula

InactiveCN102690126AHigh strengthImprove penetration resistanceCeramicwareHigh strength concreteLevel structure

The invention discloses a high-strength concrete formula. The high-strength concrete formula is characterized by comprising the following constituents by weight: 20-40% of cement, 3-5% of pulverized coal ash, 30-50% of fine aggregate, 20-40% of coarse aggregate, 3-5% of plant protein foaming agent, 1-10% of water reducer and 1-10% of water. Above materials are mixed and uniformly stirred to obtain the concrete. The concrete disclosed by the invention has the advantages of fewer holes in interior of the concrete, compact microstructure and meso-level structure and excellent anti-permeability performance by mutual interaction of various ingredients, so that the high-performance concrete is good in durability, and the strength can be up to over 280MPa.

Owner:LANGFANG RONGSHENG CONCRETE

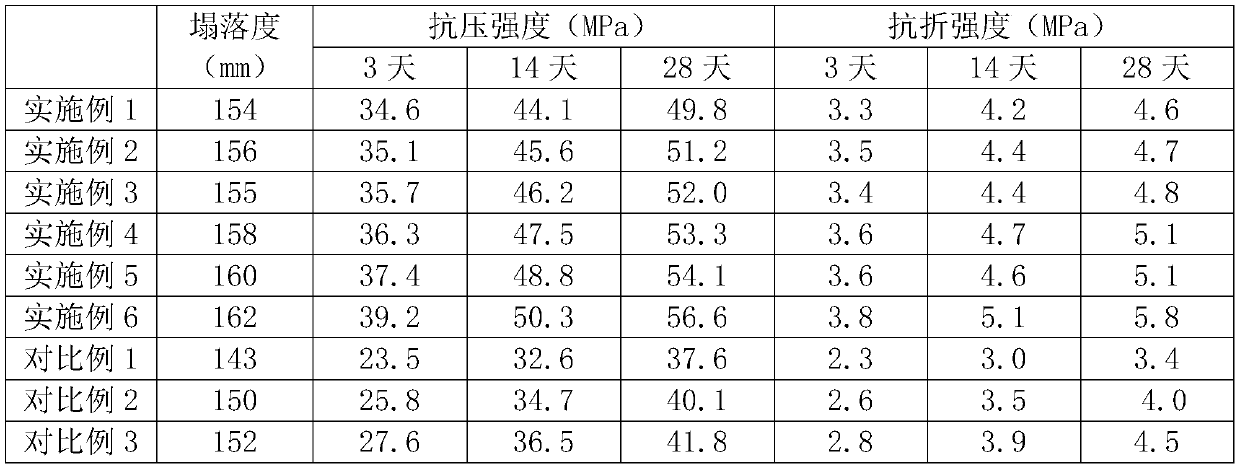

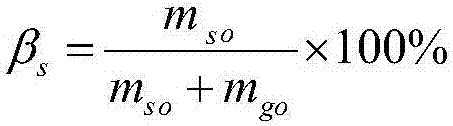

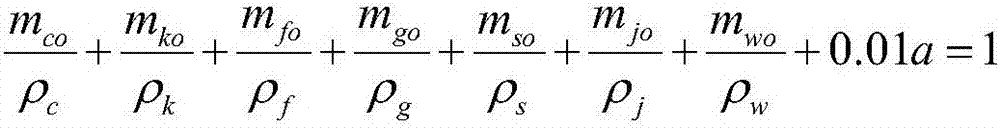

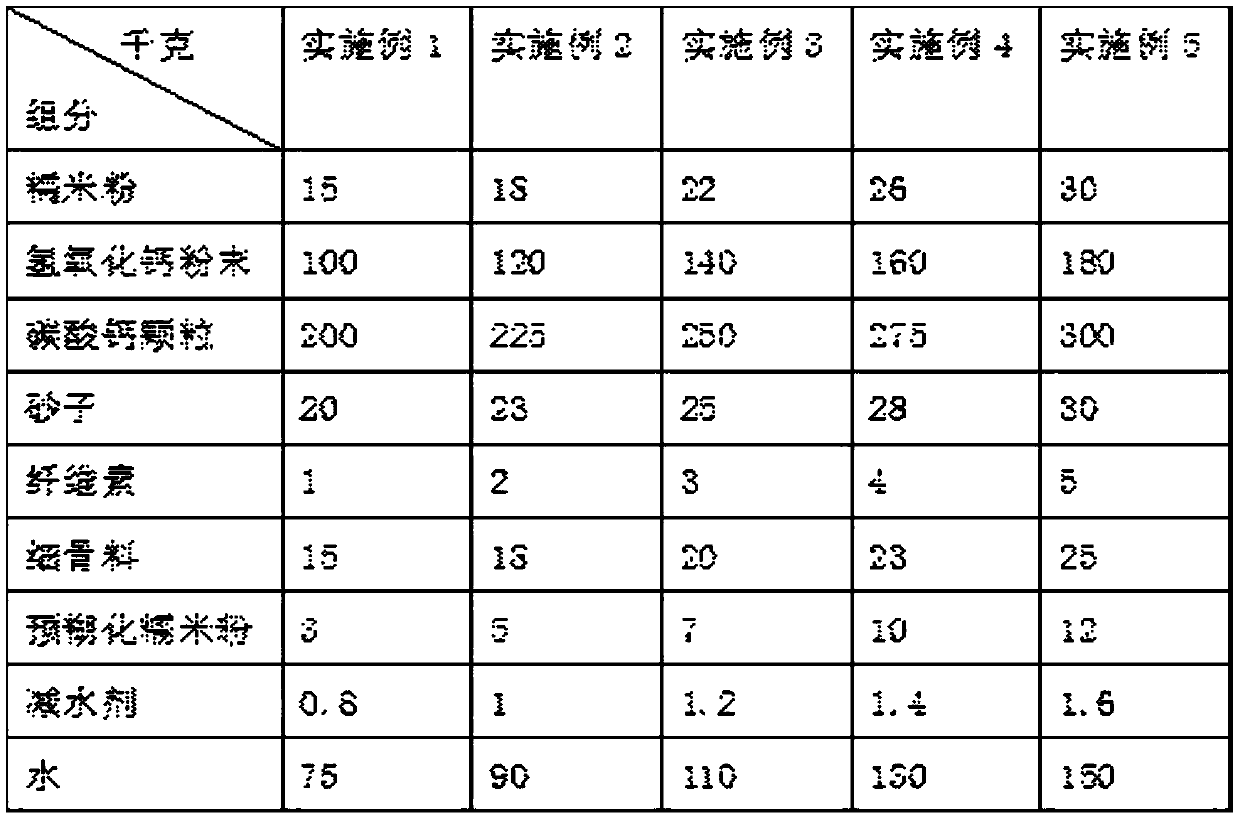

Sticky-rice mortar and preparation method thereof

Owner:中兴文建工程集团有限公司

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

Photocatalytic concrete prepared with phosphogypsum-based hydraulic composite binding material and preparation method of photocatalytic concrete

Owner:TONGJI UNIV

Concrete high-efficiency water reducer and preparation method thereof

Owner:KUNMING ANXIA NEW MATERIAL SCI & TECH CO LTD

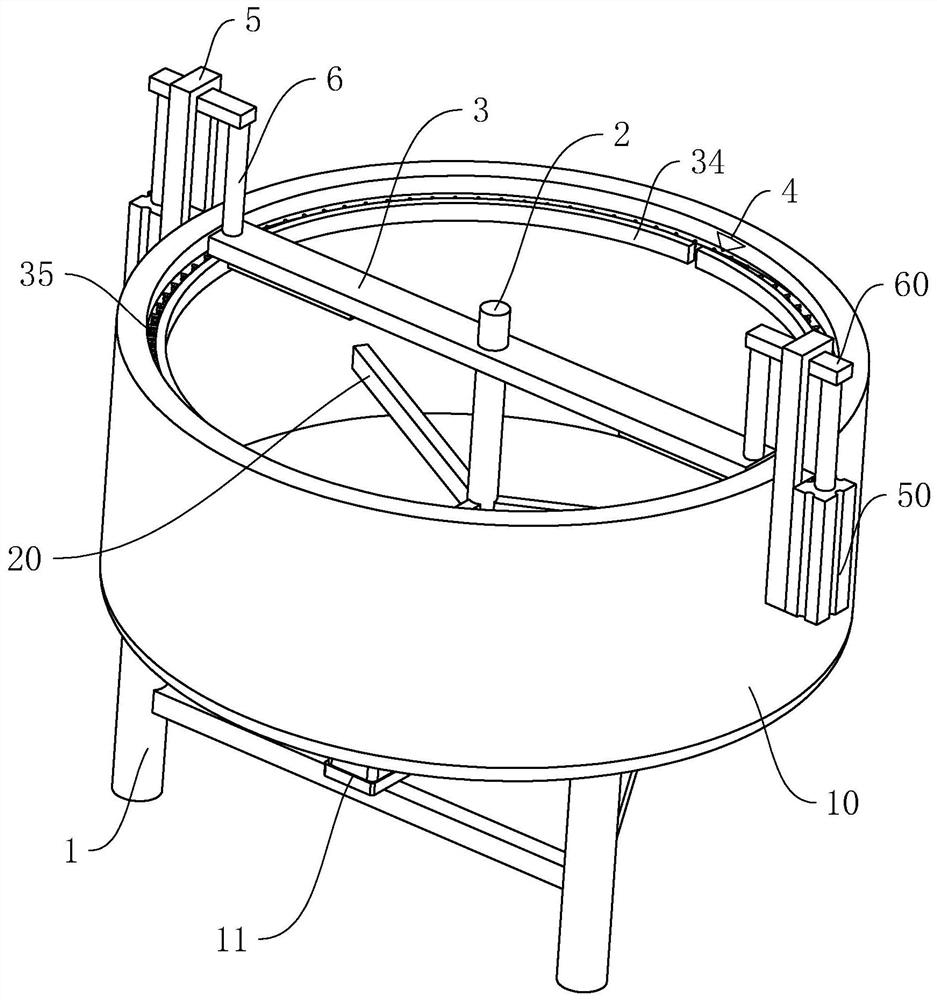

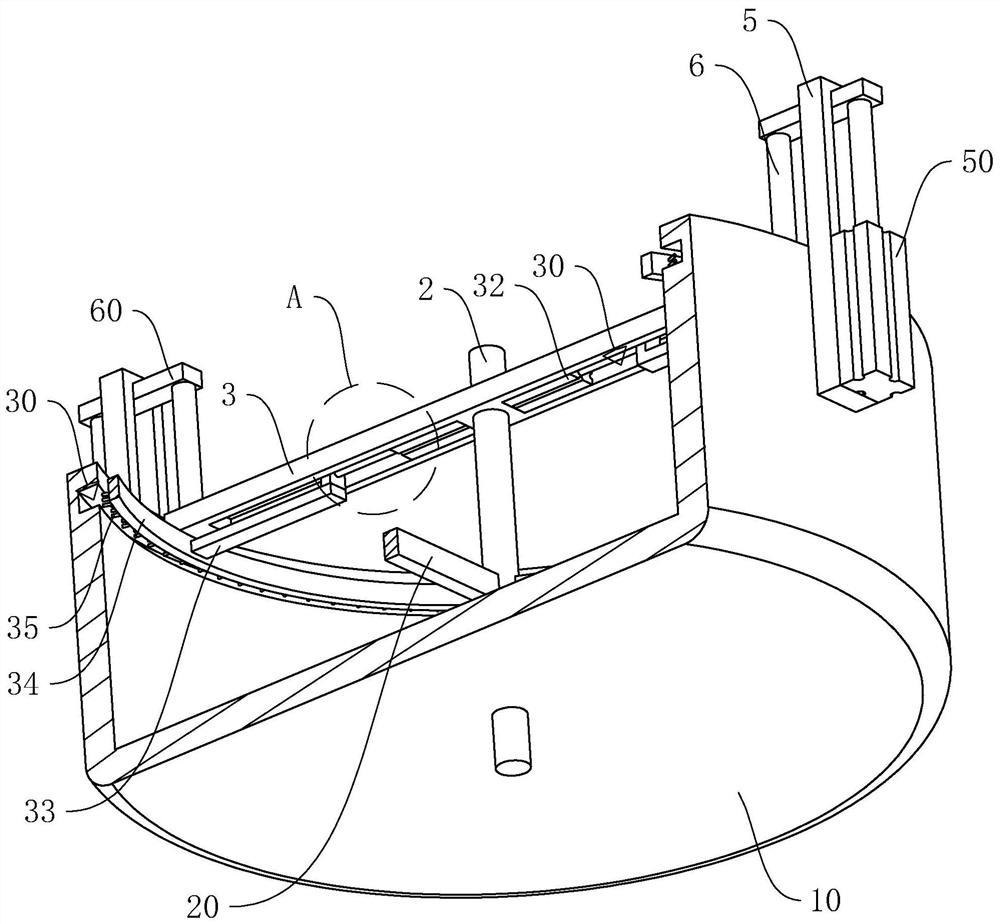

High-ductility concrete as well as preparation method and equipment thereof

Owner:佛山市高明明建混凝土配送有限公司

Environmental-friendly water-resistance high-strength ceramic gum and preparation method

Owner:WUHAN UNIV OF SCI & TECH

Nuclear power plant containment concrete

ActiveCN108059405AIncreased durabilityReduce porosityNuclear energy generationContainmentFiberCrack resistance

The invention relates to nuclear power plant containment concrete. The concrete consists of the following components in parts by mass: 130-200 parts of cement with strength of 52.5 or 42.5, 60-120 parts of slag, 50-100 parts of metakaolin, 50-150 parts of boron glass sand, 600-800 parts of nickel slag, 600-800 parts of barite, 200-400 parts of limonite, 100-300 parts of ceramsite, 20-50 parts of lead fibers, 130-160 parts of water, 4-6 parts of a water reducing agent and 4-6 parts of an early strength agent. After 28 days of curing of the concrete, the inner surface of the concrete is coated with a layer of anti-radiation coating. The nuclear power plant containment concrete provided by the invention has a good anti-radiation property, can well shield alpha, beta and gamma rays and neutronrays, and has good crack resistance, high-temperature resistance and durability, and simultaneously solid wastes such as nickel slag, glass powder and the like are utilized, so that the problems of resource waste and environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

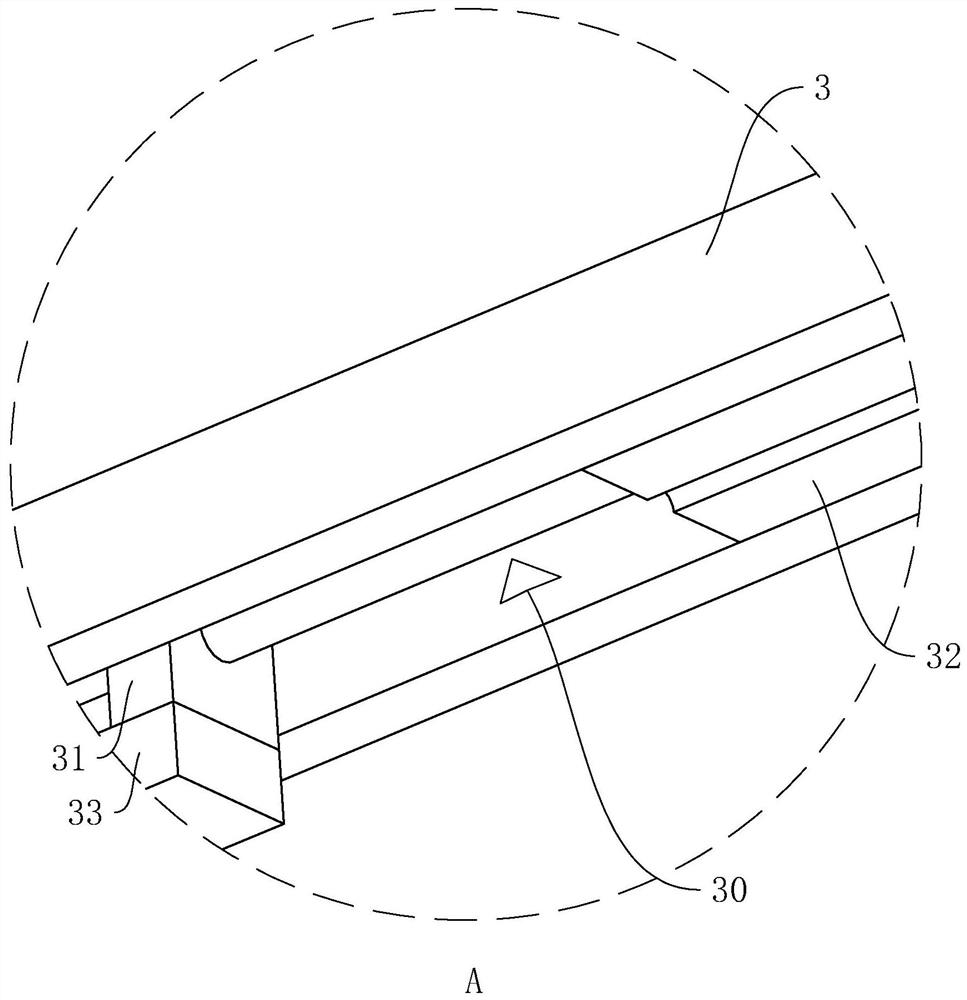

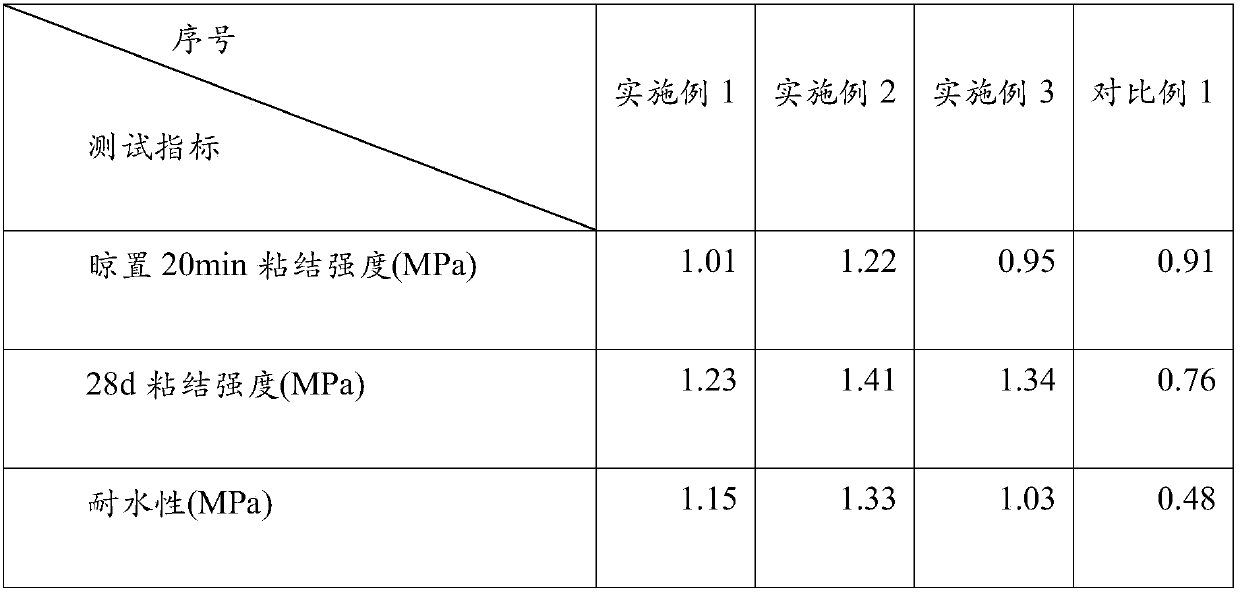

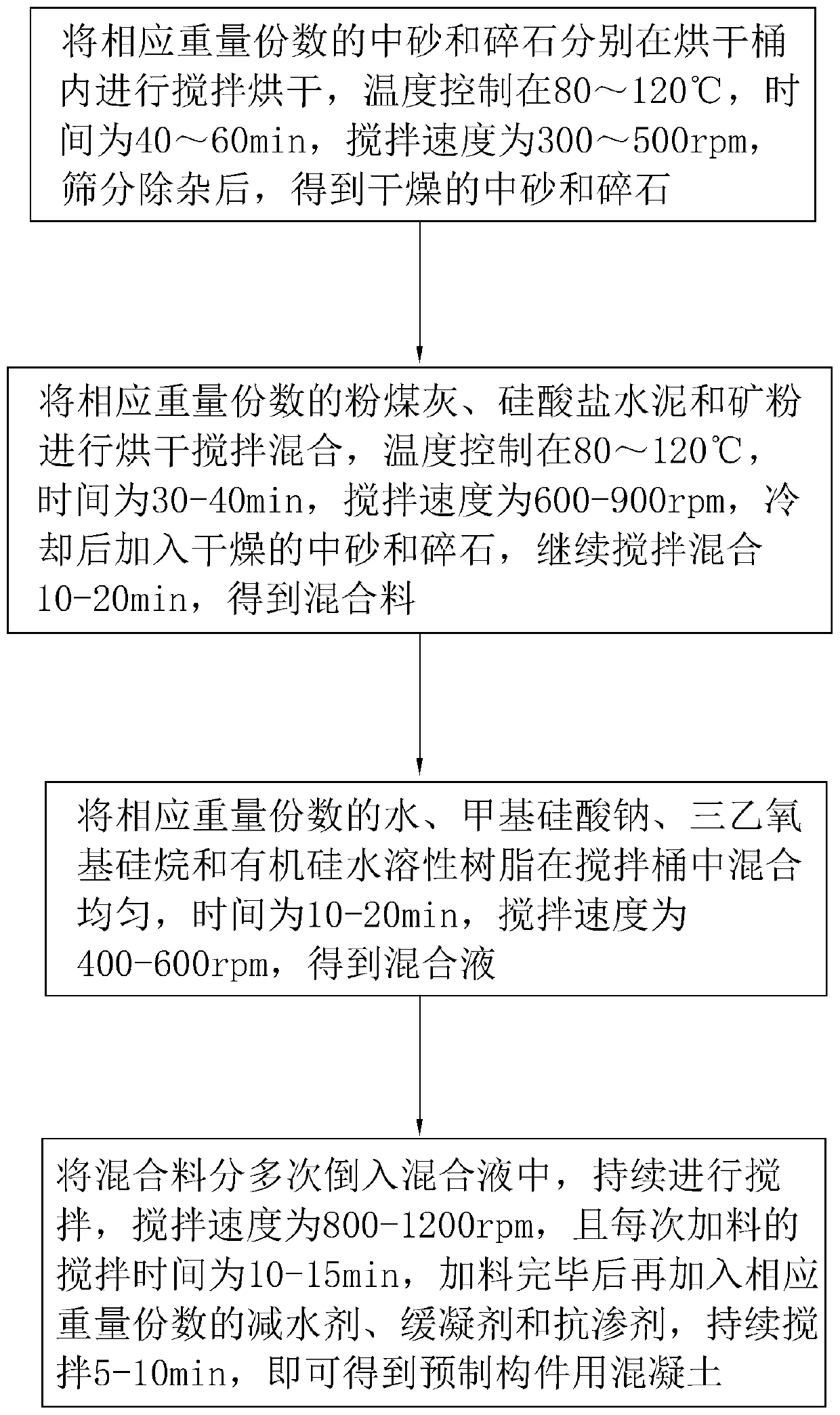

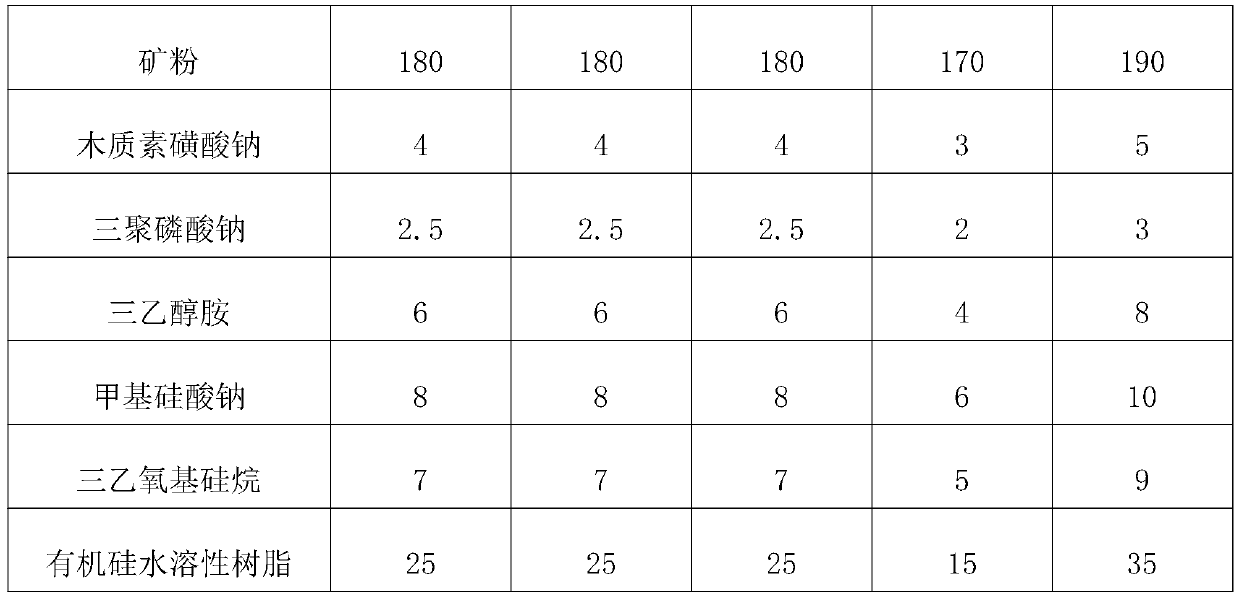

Concrete for prefabricated part and preparation method thereof

Owner:上海石化安东混凝土有限公司

Shield grouting material and preparation method thereof

Owner:北京华阳众信建材有限公司

Quick-setting self-leveling mortar

The invention provides a quick-setting self-leveling mortar. The quick-setting self-leveling mortar is prepared from, by mass, 16-18% of 42.5-strength ordinary Portland cement, 7-10% of stone powder,42% of 0-1.2 mm machine-made sands, 5-15 % of 1.2-2.4 mm machine-made sands, 18-28% of 2.4-4.75 mm machine-made sands, 0.02-0.03 % of cellulose ether, 0.02% of a thixotropic lubricant and 0.1% of a water reducing agent. All the components are mixed; when the mortar is used, 14-16% of water is added, and uniform mixing is performed for instant use; components adopting the machine-made sands, gradation has good regulation performance, and the stability of the product can be ensured; the stone powder is ash powder sucked out by a dust collection system in the limestone crushing process, and the stone powder is used as an additive, so the stone powder is absorbed to prevent the ash powder from causing air pollution and improve the crushing environment, the resource utilization rate is increased, and the stone powder is prevented from being stacked at will; and the magnesium aluminum silicate thixotropic lubricant has high hydrophilicity, and the thixotropic lubricant forms non-Newtonian liquid type thixotropic gel in an aqueous solution, so that the self-leveling mortar is easy to flow.

Owner:HANGZHOU MOTAI TECH CO LTD

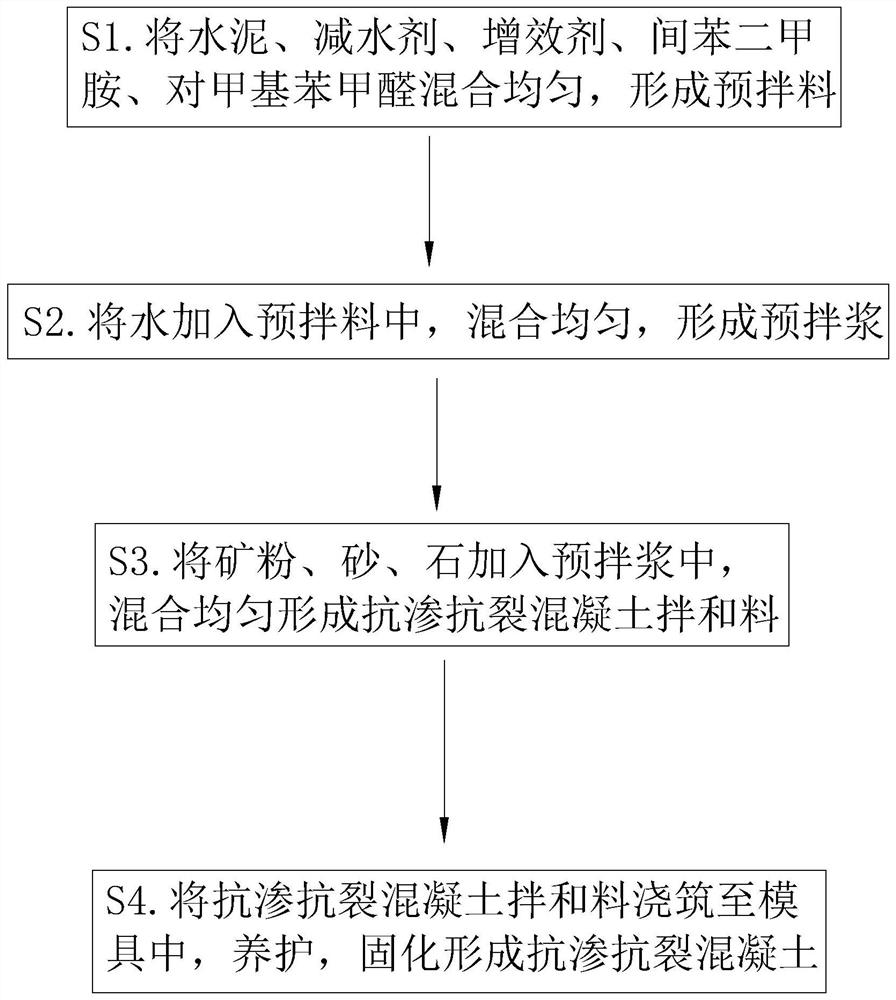

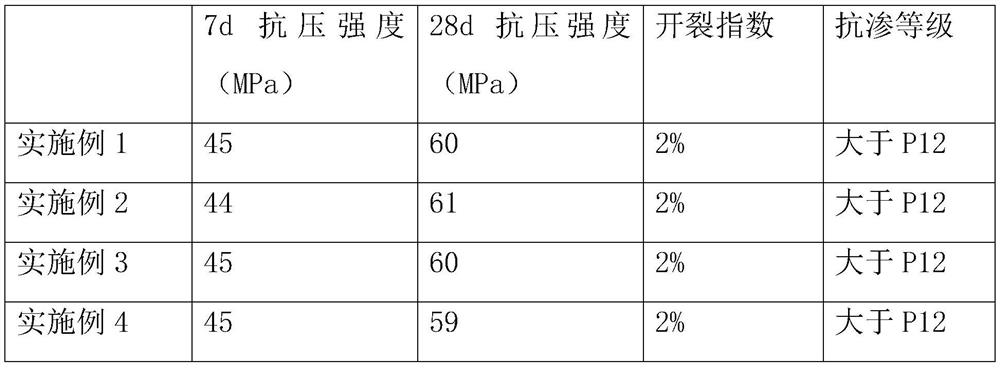

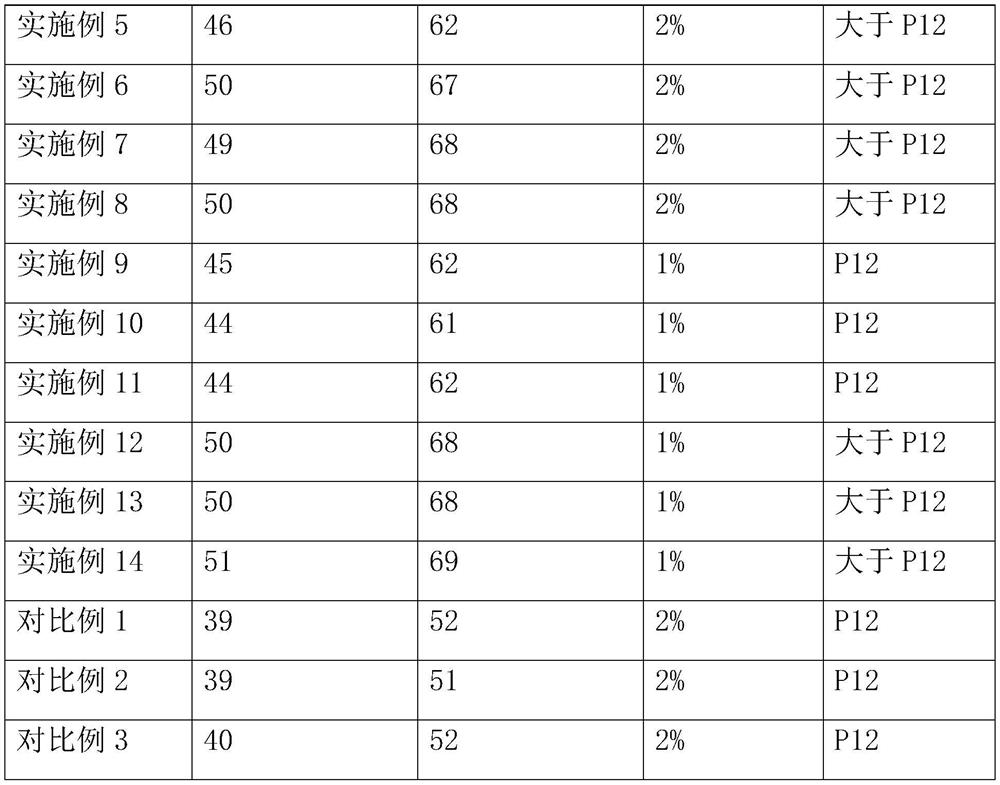

Impermeable and anti-crack concrete and preparation method thereof

ActiveCN112745073AHigh compressive strengthCounteracts defects in compressive strength lossSolid waste managementSlurryCompressive strength

Owner:广州市长运预拌混凝土有限公司

Mud-resistant early-strength enhanced polycarboxylate superplasticizer and preparation method thereof

Owner:安徽海螺材料科技股份有限公司 +1

Light-weight middle-high pressure mold and preparation method thereof

ActiveCN112142408AAffect productionAvoid deformationCeramic shaping apparatusPortland cementWater reducer

Owner:JOMOO KITCHEN & BATHROOM

Non-flowable quick-setting phosphate cement repair material with strong cohesive forces and preparation method thereof

ActiveUS11339092B2Quick SetupImprove crack resistanceSolid waste managementCarboxylic acidP phosphate

The present invention belongs to the field of composite materials, and particularly to a non-flowable quick-setting phosphate cement repair material with strong cohesive forces and the preparation method thereof. The material comprises the following raw materials in percentage by weight: 20% to 40% of sand, 5% to 12% of ammonium dihydrogen phosphate, 10% to 25% of magnesium oxide, 2% to 8% of fly ash, 30% to 60% of rubber powder, 6% to 10% of silica fume, 0.35% to 0.6% of a polycarboxylate high efficiency water-reducing agent, 1% to 5% of sodium silicate, 1.5% to 2% of a polypropylene fiber, 0.5% to 2% of a retarder, and 8% to 10% of water. The material is used as the repair material for the special positions of bottom boards of bridges or facades of buildings which are damaged, and the repair effect thereof is remarkable.

Owner:YU JIAHUAN +1

Concrete glue reducing agent and preparation method thereof

The invention relates to a concrete glue reducing agent and a preparation method thereof. The concrete glue reducing agent is prepared by adding a quaternary ammonium salt surfactant and silicone oilinto raw material components according to a proper proportion. During preparation, a methyl allyl polyoxyethylene ether polycarboxylic acid water reducing agent is added into water firstly, then organic amine and organic alcohol are added for a stirring reaction, cellulose ether is added, a stirring reaction is performed for certain time, a mixture of a quaternary ammonium salt surfactant and silicone oil is added, and a stirring mixing reaction is performed to finally prepare a concrete glue reducing agent. According to the invention, the concrete glue reducing agent is used for concrete, thehydration degree of the cement is enhanced, the cement consumption is lowered, the mechanical properties and compactness of the concrete are effectively enhanced, and the workability and the volume stability of the concrete are also improved; and according to the concrete glue reducing agent, the manufacturing cost can be effectively reduced, 30 kg of cement can be saved for each cubic meter of concrete with C30 or above, and the concrete glue reducing agent is compatible with a conventional additive and has no side effect.

Owner:BEIJING FURUILES TECH DEV CO LTD

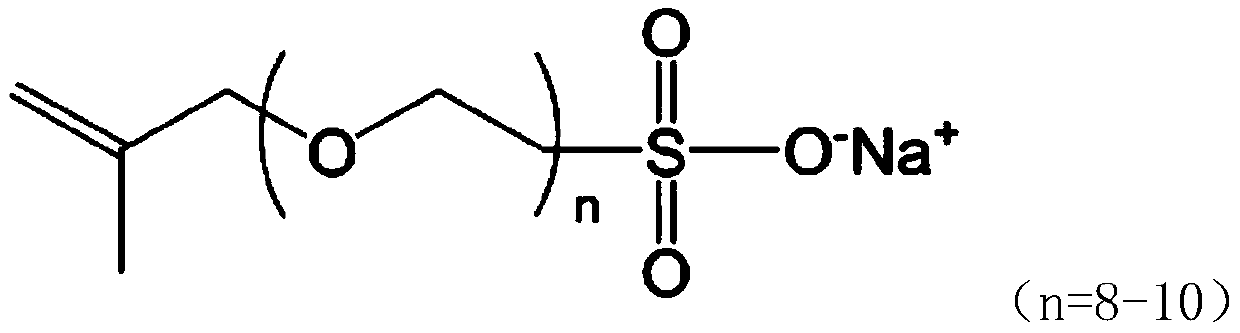

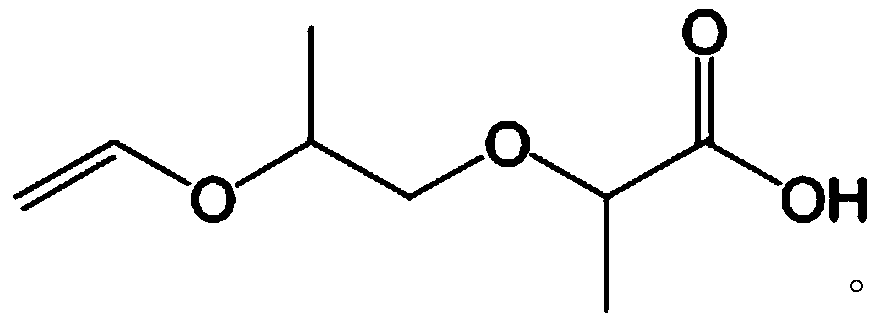

Polycarboxylic acid high-performance water reducing agent and preparation method thereof

The invention discloses a polycarboxylic acid high-performance water reducing agent which comprises the following components in parts by weight: 200-300 parts of methallyl polyoxyethylene ether, 150-250 parts of deionized water, 100-150 parts of a liquid A and 85-100 parts of a liquid B. The invention further discloses a preparation method of the polycarboxylic acid high-performance water reducingagent. The polycarboxylic acid high-performance water reducing agent disclosed by the invention is small in raw material type, simple in preparation method, short in time and low in temperature; in addition, the prepared water reducing agent is relatively high in water reduction rate and excellent in property, and construction of multiple projects can be met.

Owner:YUNNAN SHENGBIAO BUILDING MATERIALS CO LTD

Concrete water reducer

Owner:朱新峰

Single-size-fraction coal gangue self-compacting concrete

PendingCN112707700APromote post-hydrationHigh strengthSolid waste managementMining engineeringSorptivity

Owner:张家港市华诚混凝土构件有限公司

High-strength anti-crack masonry dry-mixed mortar and production process thereof

ActiveCN113387657AReduce autogenous shrinkageGood structural strengthSolid waste managementCelluloseCrack resistance

Owner:河南融之科建材有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap