Photocatalytic concrete prepared with phosphogypsum-based hydraulic composite binding material and preparation method of photocatalytic concrete

A composite cementitious material and photocatalytic technology, which is applied in the field of photocatalytic concrete and its preparation, to achieve the effects of improving indoor air quality, excellent sound insulation, and broad market economic prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

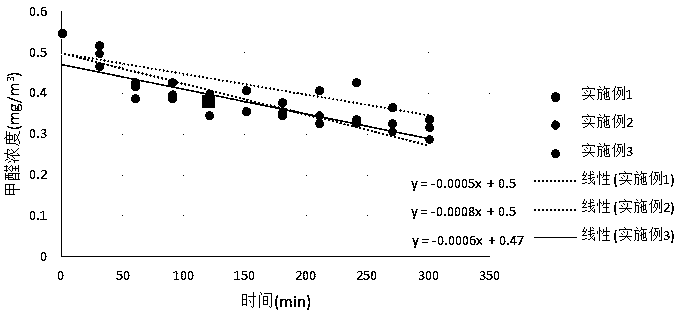

[0058] Embodiment 1, a kind of photocatalytic concrete prepared with phosphogypsum-based hydraulic composite cementitious material Press phosphogypsum 100, slag powder 70, limestone powder 50, Portland cement 10, particle diameter is (0-3) mm Crushed glass slag 158, cullet slag 282 with a particle size of (3-8) mm, aeolian sand 168, foaming agent 0.09, foam stabilizer 0.02, water reducing agent 0.04 in mass ratio, mix after weighing, add gelling 30% of the material mass is mixed with water to make a concrete slab evenly, and the nitrogen-doped TiO 2 The mass ratio of powder 1, polyacrylamide 24, and double distilled water 222 is weighed and mixed uniformly to make an organic binder for loading photocatalytic powder, and evenly spread on the concrete board with a brush to obtain the desired product. For performance test results, see figure 1 .

Embodiment 2

[0059] Embodiment 2, a kind of photocatalytic concrete prepared with phosphogypsum-based hydraulic composite cementitious material Press phosphogypsum 100, slag powder 80, limestone powder 57.7, Portland cement 20, particle diameter is (0-3) mm Crushed glass slag 167.3, cullet slag with a particle size of (3-8) mm 312.1, aeolian sand 176.5, foaming agent 0.42, foam stabilizer 0.10, water reducing agent 1.1 by weight, mix and add gelatin Water with a material quality of 34.8% is stirred evenly to make a concrete slab, and the nitrogen-doped TiO 2 The mass ratio of powder 1, polyacrylamide 25, and double distilled water 225 is weighed and mixed evenly to make an organic binder for loading photocatalytic powder, and evenly spread on the concrete with a brush to obtain the desired product. For performance test results, see figure 1 .

Embodiment 3

[0060] Embodiment 3, a kind of photocatalytic concrete prepared with phosphogypsum-based hydraulic composite cementitious material Press phosphogypsum 100, slag powder 95, limestone powder 63, Portland cement 21, particle diameter is (0-3) mm Crushed glass slag 177, cullet slag 365 with a particle size of (3-8) mm, aeolian sand 185, foaming agent 0.8, foam stabilizer 0.2, water reducing agent 1.8 in mass ratio, mix after weighing, add gelling Water with 40% of the mass of the material is stirred evenly to make a concrete slab, and the nitrogen-doped TiO 2 The mass ratio of powder 1, polyacrylamide 26, and double distilled water 227 is weighed and mixed uniformly to make an organic binder for loading photocatalytic powder, and evenly spread on the concrete board with a brush to obtain the desired product. For performance test results, see figure 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap