Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used as an antiperspirant to treat feet that sweat or smell excessively. It is also used as a drying agent during wart treatment..

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

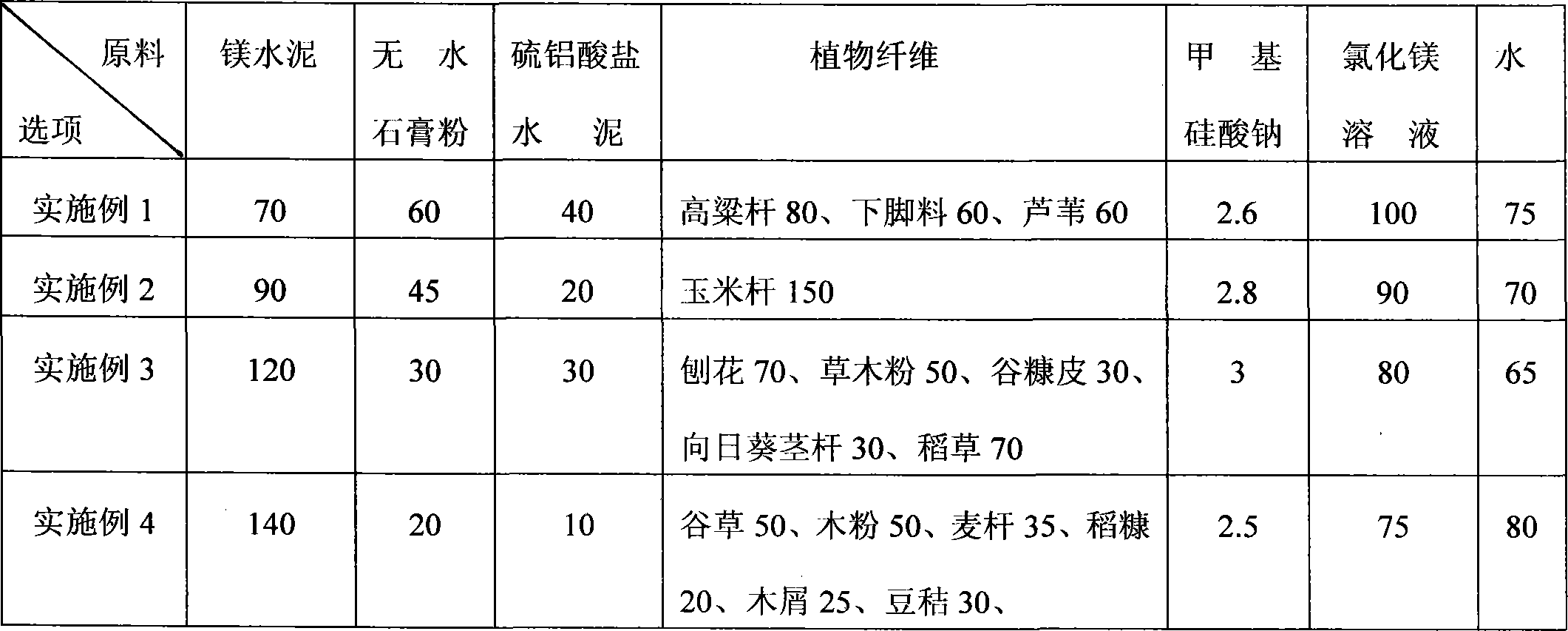

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

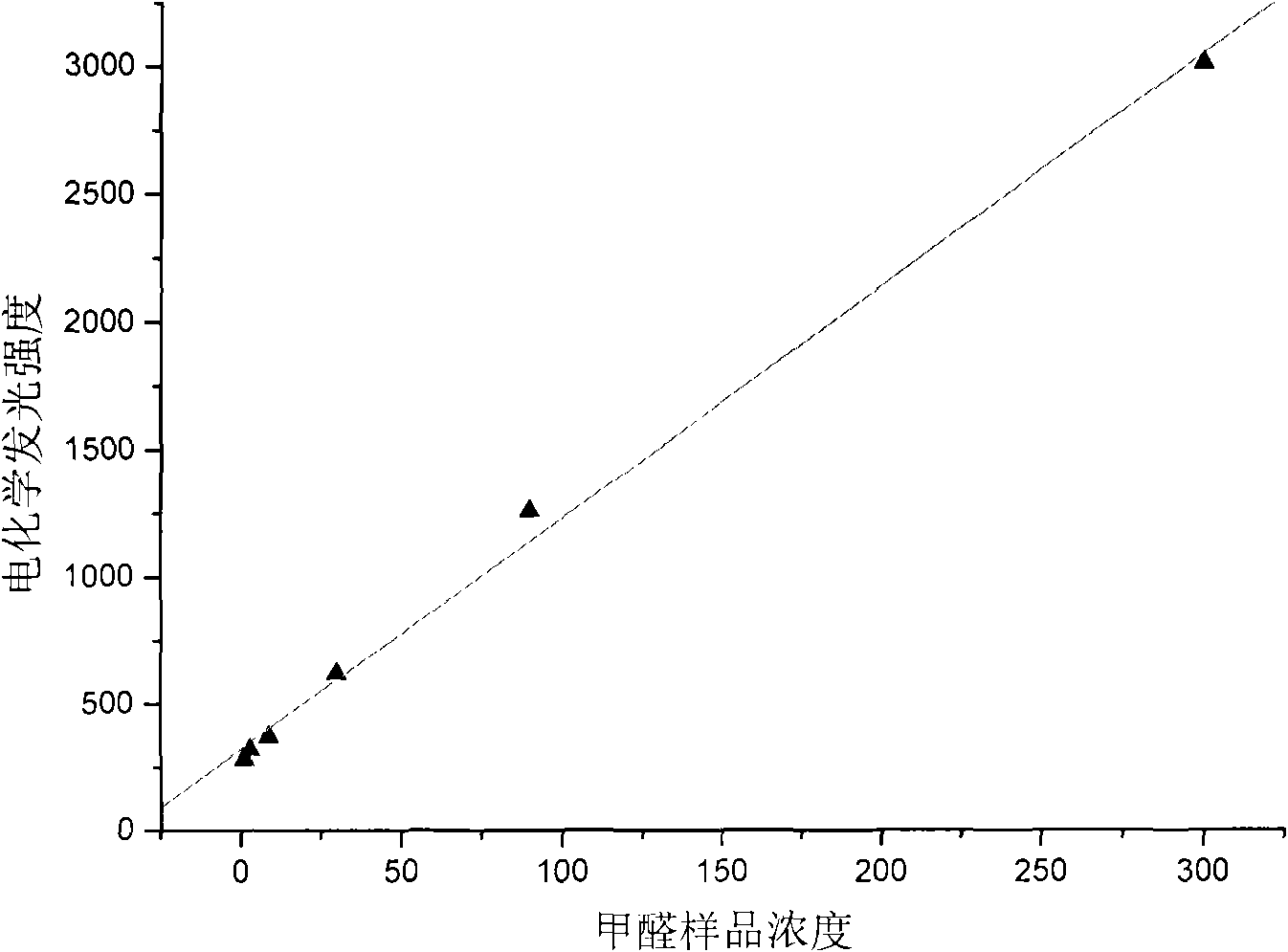

Method for measuring formaldehyde in aqueous solution by electrochemical luminescence of terpyridyl ruthenium

InactiveCN101539525AEasy to operateShort analysis timeChemiluminescene/bioluminescenceMaterial electrochemical variablesRutheniumElectrochemiluminescence

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Zirconium-molybdenum oxide catalyst for methane oxidation to synthesize formaldehyde and its preparation method

InactiveCN1394681AEasy to prepareHigh mechanical strengthMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureOxygen

The molecular formula of zirconium-molybdenum oxide catalyst for synthesizing formaldehyde by means of methane oxidation is (ZrO2)x(Zr(MoO4)2)y (MoO3)z, and its preparalcon method includes the following steps: using zirconium dioxide powder ammonium molbdate powder as raw material, metering and weighing ammonium molybdate powder according to the above-mentioned molecular formula, using deionized water to prepare ammonium modybdate aqueous solution with a certain concentration, adding said aqueous solution into zirconium dioxide powder, drying the mixture, high-temp. roasting, mechanical grinding, press-forming, screening granules so as to obtain the catalyst.

Owner:TSINGHUA UNIV

Preparation method of environment-friendly ecological board

ActiveCN105291540AImprove light resistanceReduce irradianceLaminationLamination apparatusHindered amine light stabilizersAdhesive

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Volcanic rock bound wooden plate

The invention relates to a volcanic adhesive wood plate. Wherein, it uses volcanic beehive plate and wood plate in same length and width; boiling the wood plate at 60Deg. C for 24h; boiling it at 80Deg. C for 76-100h; drying it at 40Deg. C for 3-15days; then coating adhesive on the connecting surfaces of beehive plate and wood plate, laying it for 3-6min, and combining, cold compressing at 70-80kg / m2 for 24h; then laying it at 15-35Deg. C for at least seven days. The invention uses the adhesive without formaldehyde, with flexibility, damp-proof, fireproof, etc.

Owner:黄茂景

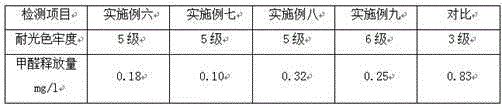

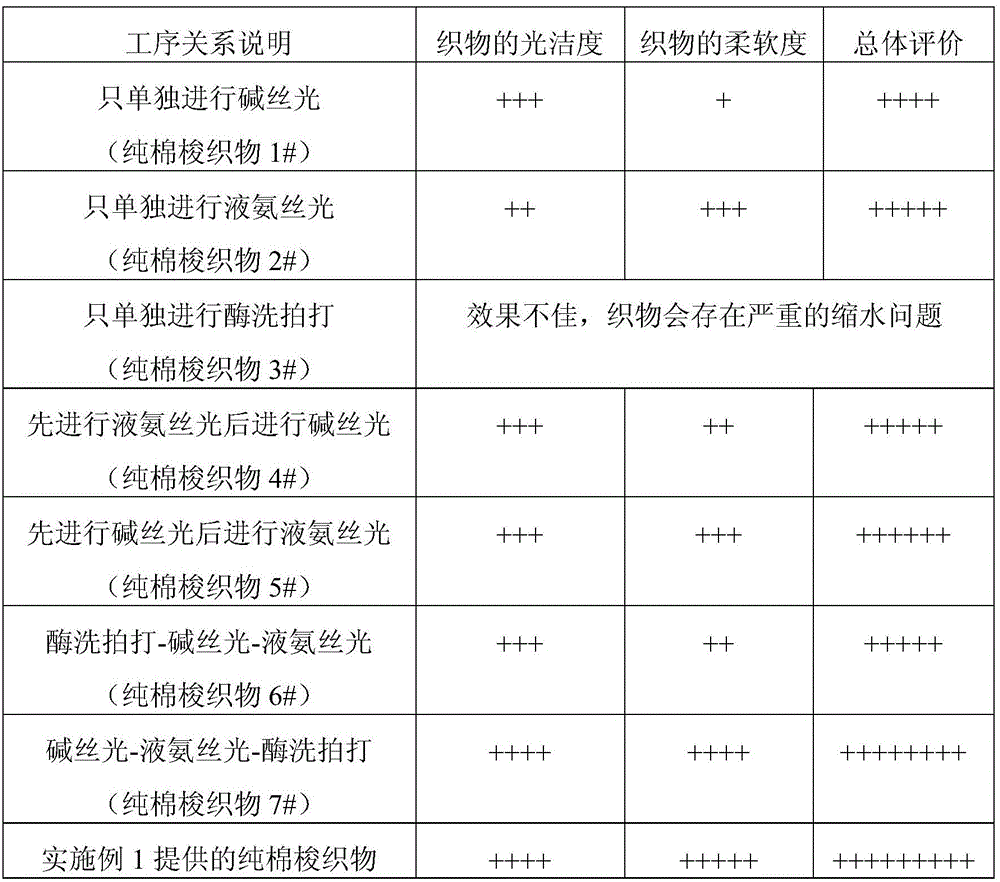

Elastic pure cotton woven fabric with smooth surface and soft handle and preparation method thereof

ActiveCN106012494AObvious bodyIncrease elasticityBiochemical treatment with enzymes/microorganismsGrip property fibresCellulaseProcess time

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

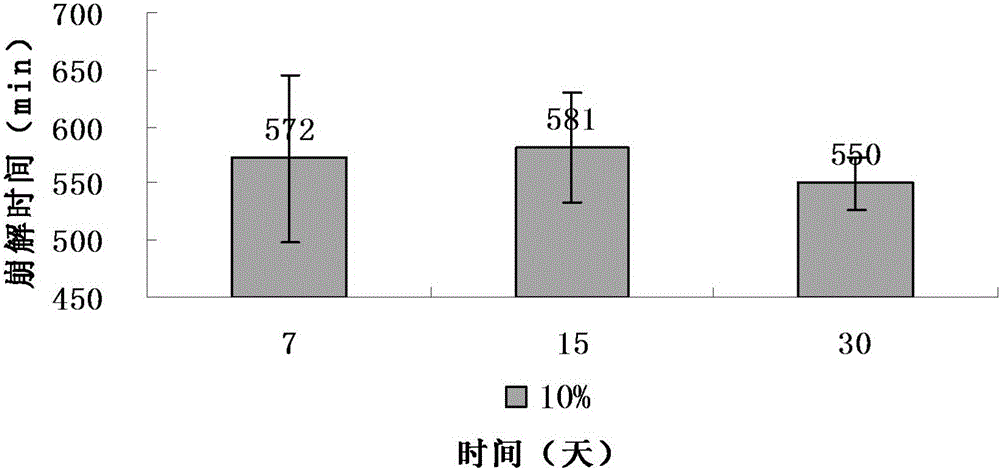

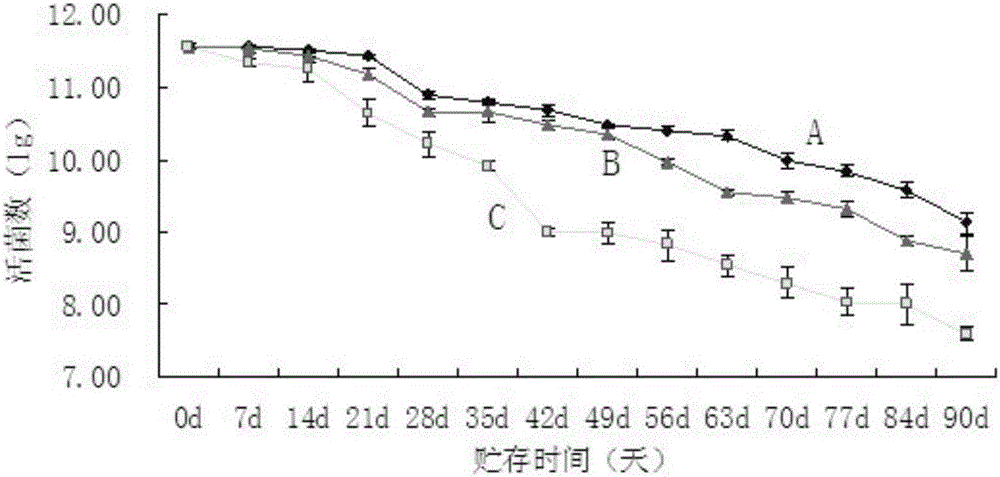

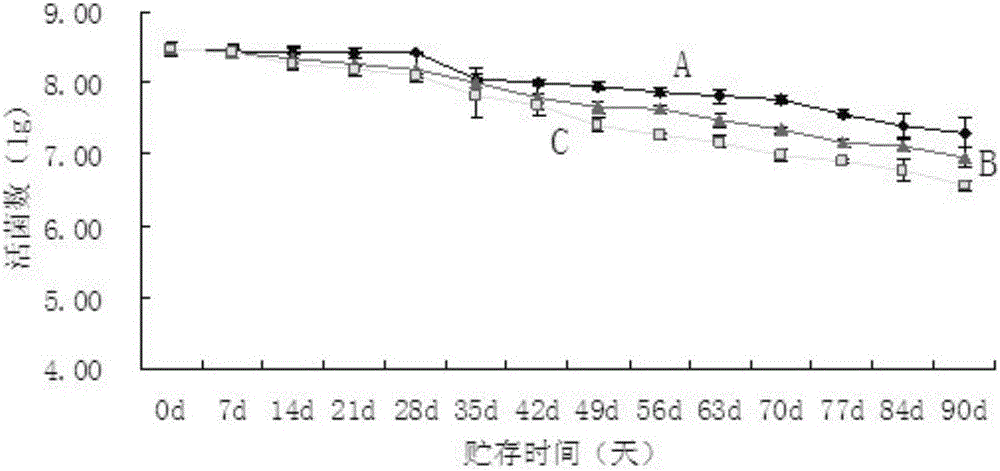

Bifidobacterium colonic-dissolving soft capsule and preparation method thereof

InactiveCN105997926AEasy to storeEasy to transportPowder deliveryDigestive systemBifidobacteriumSolubility

Owner:HEILONGJIANG UNIV

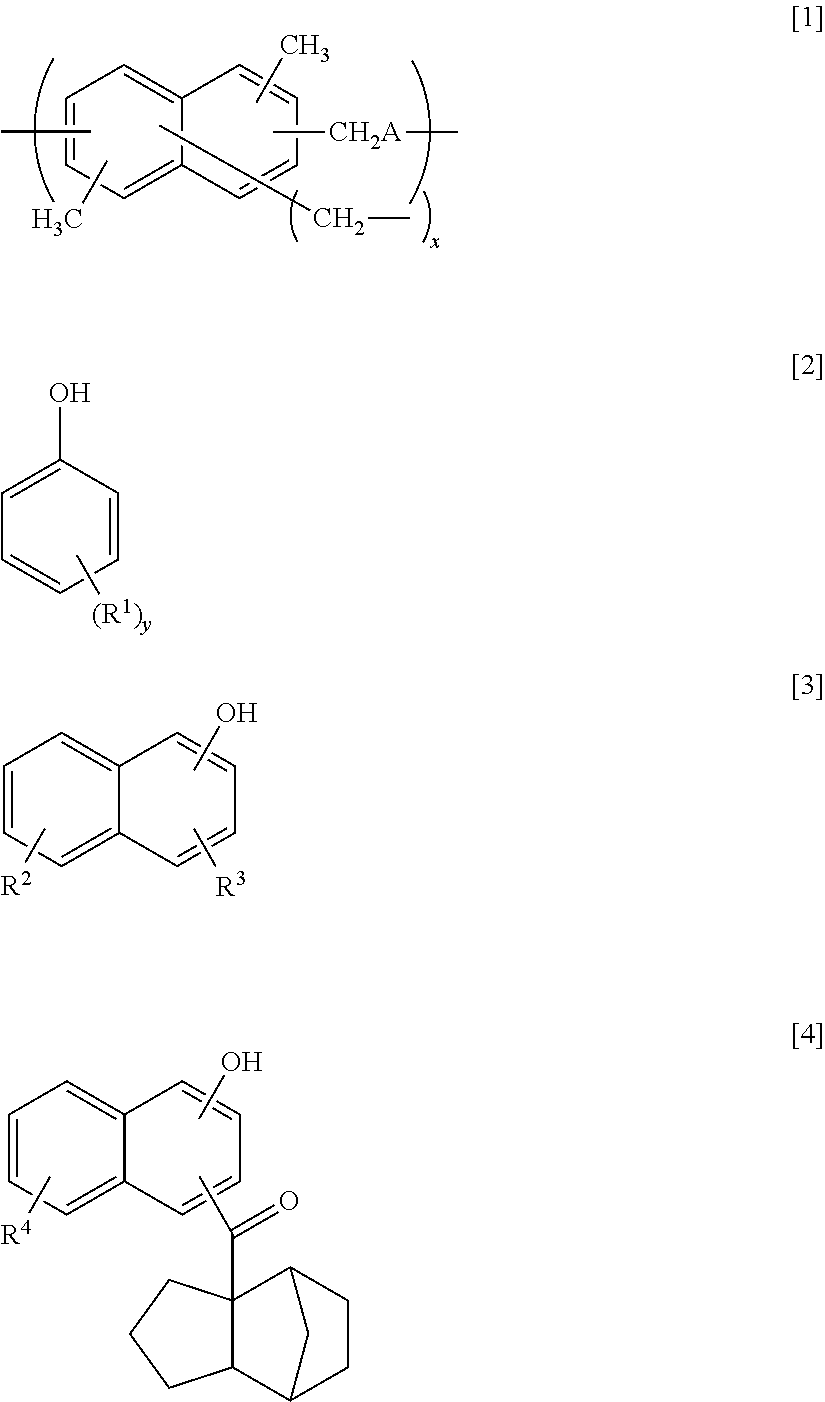

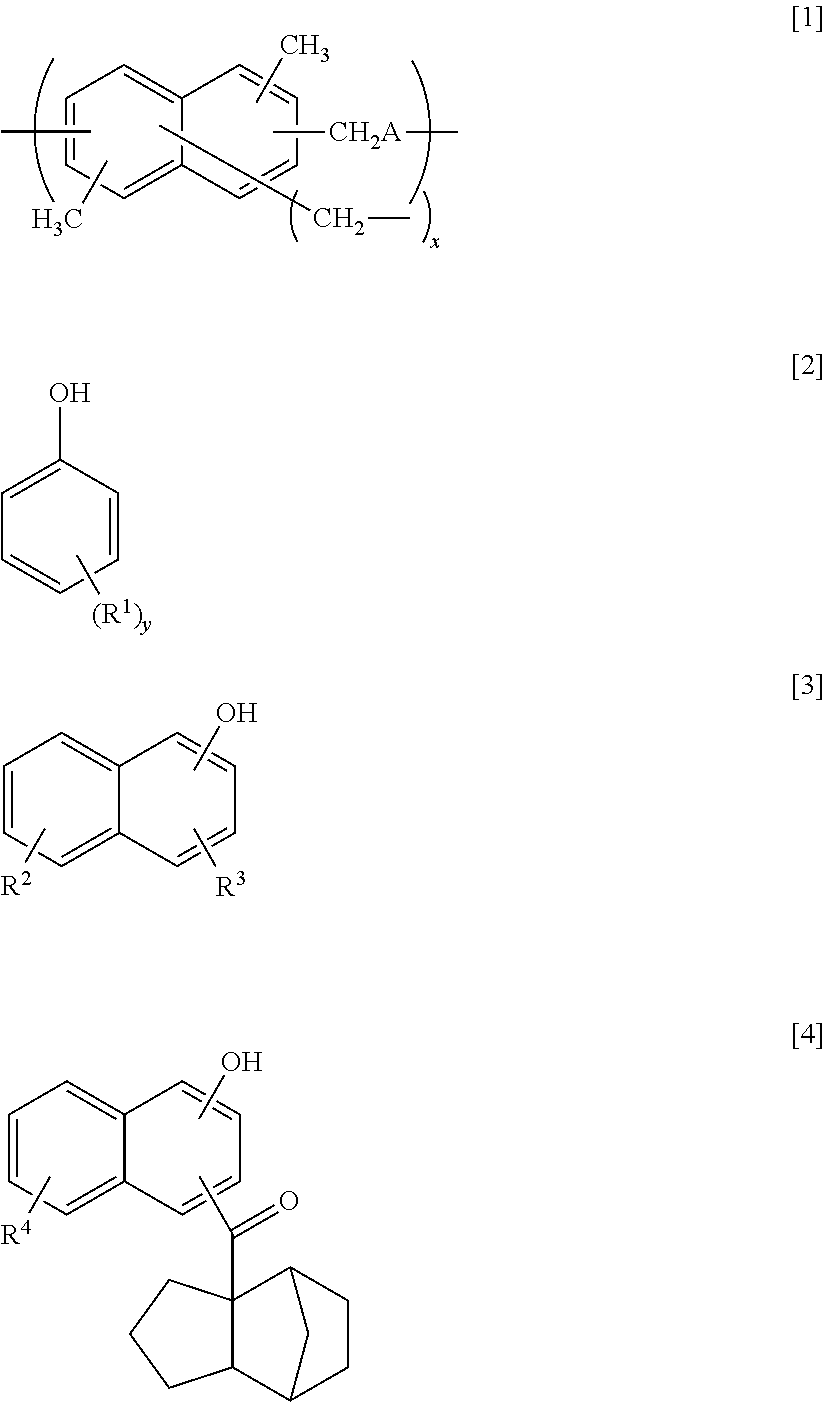

Modified naphthalene formaldehyde resin, tricyclodecane skeleton-containing naphthol compound and ester compound

ActiveUS20110009574A1Improve heat resistancePreparation from carboxylic acid halidesOrganic compound preparationFiberResist

Owner:MITSUBISHI GAS CHEM CO INC

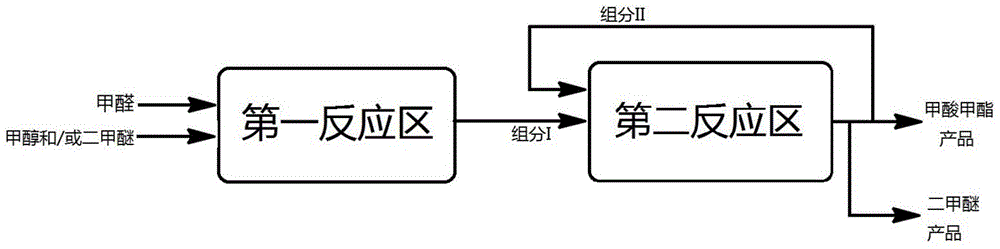

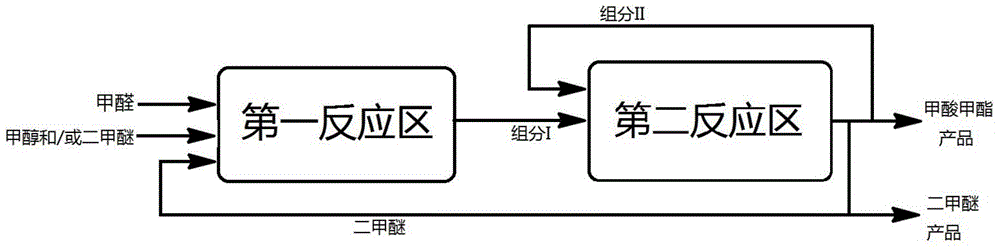

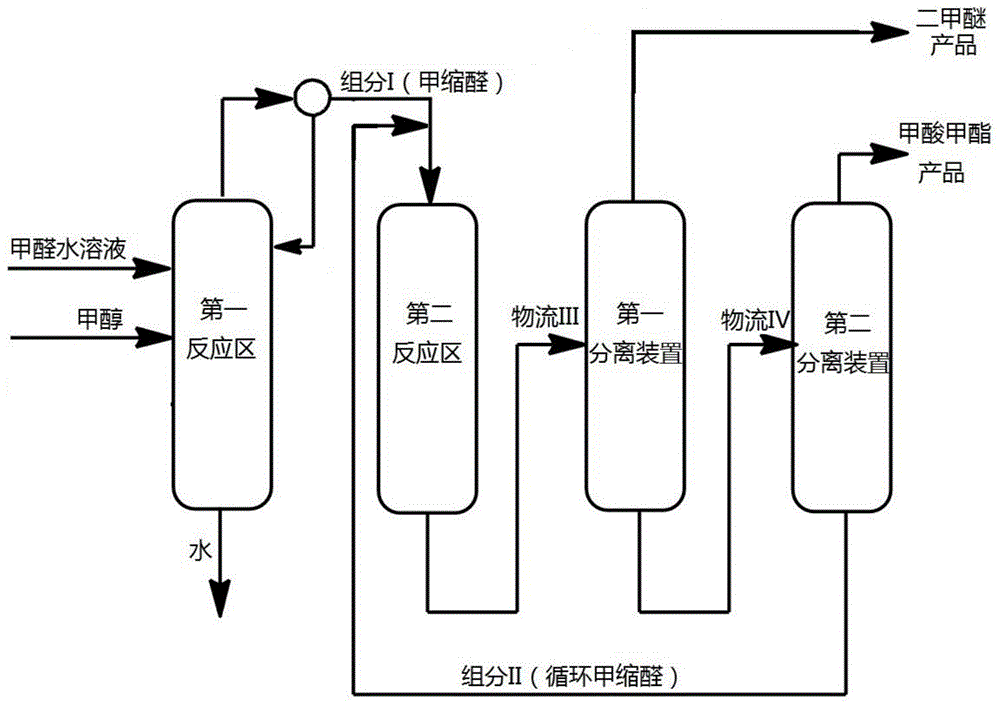

Method for preparing methyl formate and coproducing dimethyl ether

ActiveCN105669452AEasy to separateReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationGas phaseReaction zone

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Bi-component polyurethane coating

InactiveCN104987819AReduces pungent odorsIncrease crosslink densityPolyurea/polyurethane coatingsHydrogenToluene diisocyanate

The invention provides a bi-component polyurethane coating, and relates to the field of coating. The bi-component polyurethane coating is composed of a component A and a component B. The component A comprises, by weight, 5-10 parts of acrylic resin dispersoid, 4-6 parts of glycol ether acetate, 5-9 parts of resin containing active hydrogen, 12-15 parts of padding, 8-10 parts of chitin derivative formaldehyde removal additives, 1-4 parts of anti-settling agents, 1-3 parts of defoaming agents and 2-3 parts of dryer. The component comprises, by weight, 7-13 parts of isocyanate and 10-12 parts of toluene diisocyanate capable. The bi-component polyurethane coating can reduce harm to the environment and the human body effectively and is suitable for being widely popularized.

Owner:SICHUAN ZHENFUTANG TRADING CO LTD

Rapid analysis method for sodium hydroxide and ammonia content in sodium cyanide reaction solution and its liquid products

InactiveCN102269753AReduce consumptionAvoid interferenceChemical analysis using titrationLiquid productSodium cyanide

The invention discloses a rapid analysis method for sodium hydroxide and ammonia content in sodium cyanide reaction solution and its liquid products, which uses excess formaldehyde and ammonia to react to generate hexamethylenetetramine, and then divides into two groups of titration with hydrochloric acid, Obtain two sets of values of ammonia-containing acid consumption and ammonia-removing acid consumption, and then calculate the content of sodium hydroxide and ammonia in the sample through data measurement, thereby effectively reducing the interference of free ammonia on the analysis of sodium hydroxide content, and quickly and accurately analyzing cyanide. Sodium hydroxide content and ammonia content in sodium chloride reaction liquid and its liquid products. The method of the invention is fast and effective, has obvious mutations in analysis and titration, accurate and reliable measured values, simple and convenient operation and easy mastery.

Owner:ANQING NEW SHUGUANG FINE CHEM CO LTD

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Photocatalytic concrete prepared with phosphogypsum-based hydraulic composite binding material and preparation method of photocatalytic concrete

Owner:TONGJI UNIV

Novel fire retardant microencapsulated red phosphorus and preparation method thereof

The invention discloses a novel fire retardant microencapsulated red phosphorus which is formed by wrapping phenol-formaldehyde prepolymer (PFP) on the surface of superfine red phosphorus powder. Due to addition of a high-efficient catalyst in the preparation process, the surface activity of the red phosphorus is improved, the surface of the red phosphorus is tightly wrapped with a PFP layer, and meanwhile as methanol is added to prevent formaldehyde auto-agglutination and the pH value of a reaction solution in the wrapping process is controlled to be 1-6, the stability and the resistivity of the red phosphorus are improved, the machining property is improved, and meanwhile the moisture absorption rate and the PH3 release amount are greatly reduced.

Owner:NANJING UNIV OF SCI & TECH

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

InactiveCN102516710ALow thermal conductivityImprove insulation effectPolymer sciencePolyvinyl alcohol

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

Method for establishing animal model for senile dementia, special liquid medicine and dosing device

InactiveCN103284980ATypical behaviorTypical pathological symptomsHydroxy compound active ingredientsMedical devicesSterile environmentSenile dementia

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

Biological comprehensive treatment method of indoor decoration pollution

InactiveCN104707472ANo secondary pollutionPracticalLiquid surface applicatorsDispersed particle separationSolid woodEnzyme

Owner:于清奎

Anticorrosive coating material for reinforced concrete, preparation method and applications thereof

ActiveCN108300166AAvoid corrosionReduce film thicknessAnti-corrosive paintsEpoxy resin coatingsRebarPhenol

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Seal primer added polymer with formaldehyde catching function and preparation method of polymer

InactiveCN104311737ASignificant and durable capture and removal capabilitiesClosed influencePolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterOrganic solvent

The invention discloses a seal primer added polymer with a formaldehyde catching function. The seal primer comprises acrylamide, an acrylate soft monomer, an acrylate hard monomer, an acrylate long-chain monomer, an initiator and an organic solvent. The invention further discloses a preparation method of the seal primer added polymer with the formaldehyde catching function. Resin prepared by adopting the seal primer added polymer with the formaldehyde catching function and the preparation method thereof has good compatibility with existing wooden ware primers (nitro wooden ware primer, polyester two-component wooden ware primer, acrylic emulsion type wooden ware primer, epoxy two-component wooden ware primer and the like); according to the formaldehyde content of a wooden ware base material, the polymer is added into the traditional wooden ware primer; and the wooden ware seal primer prepared by adding the polymer has obvious and lasting formaldehyde catching and clearing capability on the premise that obvious poor influence is not produced on the aspects of closure, adhesion, flexibility, polishing property and the like.

Owner:GUANGZHOU UNIVERSITY

Novel rubber good in oil resistance and preparation method thereof

InactiveCN105061953AMethacrylateRubber material

Owner:苏州凯欧曼新材料科技有限公司

Reinforcing eyelet fabric and preparation method thereof

ActiveCN103993481AOvercome defects that reduce its reinforcing propertiesOvercoming the defects of reinforcing performanceFibre typesFiberVulcanization

Owner:HEBEI YUNHE TEXTILE

Manufacturing technology of curtain fabric capable of releasing negative ions

InactiveCN111893755AConducive to fixationUniform fixationCurtain accessoriesWoven fabricsFlax fiberChemistry

The invention discloses a manufacturing technology of a curtain fabric capable of releasing negative ions. The manufacturing technology comprises the following steps that S1, flax fibers and polyesterfibers are blended into warps and wefts; S2, the warps and the wefts are woven into a main fabric through warp-weft knitting; S3, bleaching is carried out, wherein the main fabric obtained in S2 is bleached; S4, a finishing liquid is prepared, and the main fabric bleached in S3 is added into the finishing liquid and subjected to dipping; S5, residual liquid is discharged, wherein the residual liquid of the main fabric subjected to dipping in S4 is discharged; and S6, the main fabric without the residual liquid is dried to obtain the main fabric capable of releasing the negative ions. The finishing liquid in S4 comprises, by weight, 6-7 parts of tourmaline ultra-fine powder, 5-7 parts of seaweed carbon ultra-fine powder; 3-4 parts of dispersant, 2-4 parts of a fixing agent, 1-2 parts of apermeating agent and 30-40 parts of deionized water. The curtain fabric has the function of releasing the negative ions, so that volatile gases such as formaldehyde and ammonia in new furniture can beeliminated, and the damage of gases such as formaldehyde to the human body can be reduced.

Owner:SHANGHAI YUQI IND CO LTD

Wood wax oil timber modifier and preparation method thereof

InactiveCN105881684AMaintain colorGuaranteed anti-corrosionWood impregnation detailsMoisture absorptionPolymerization

The invention discloses a wood wax oil timber modifier and a preparation method thereof. The modifier comprises the following components by mass percentage: 28-32% of tung oil, 8-12% of camphor wood oil, 17-22% of rosin-modified resin, 9-11% of orange oil, 4-6% of glass powder, and 22-27% of ethanol. The preparation method comprises the following steps: the tung oil, the camphor wood oil, rosin-modified resin, orange oil, and glass powder are placed in a reaction vessel, are subjected to a polymerization at the high temperature of 260-300 DEG C, then cooled to the temperature of 70-90 DEG C, ethyl alcohol is added for being stirred, and then the materials are cooled to the room temperature to obtain the product. The preparation method has simple process, the modifier does not contain toxic components such as triphenyl, formaldehyde and heavy metals, has no pungent smell, can keep original color when used on the timber, has the advantages of anticorrosion, insect resistance, non moisture absorption, non moistening, non deformation, and no influence on glues and paints.

Owner:董学明

Plant-origin reagent with formaldehyde removing function and preparation method thereof

InactiveCN109621668AImprove respiratory diseasesRelieve coughGas treatmentDispersed particle separationPolygonum fagopyrumArbutin

Owner:杭州合辰环境有限公司

Environment-friendly abrasion-resistant and scratch-resistant paint for wooden doors

ActiveCN109354955AHigh hardnessImprove stabilityAntifouling/underwater paintsPaints with biocidesAcrylic resinMoisture

Owner:陕西森尚建材科技有限公司

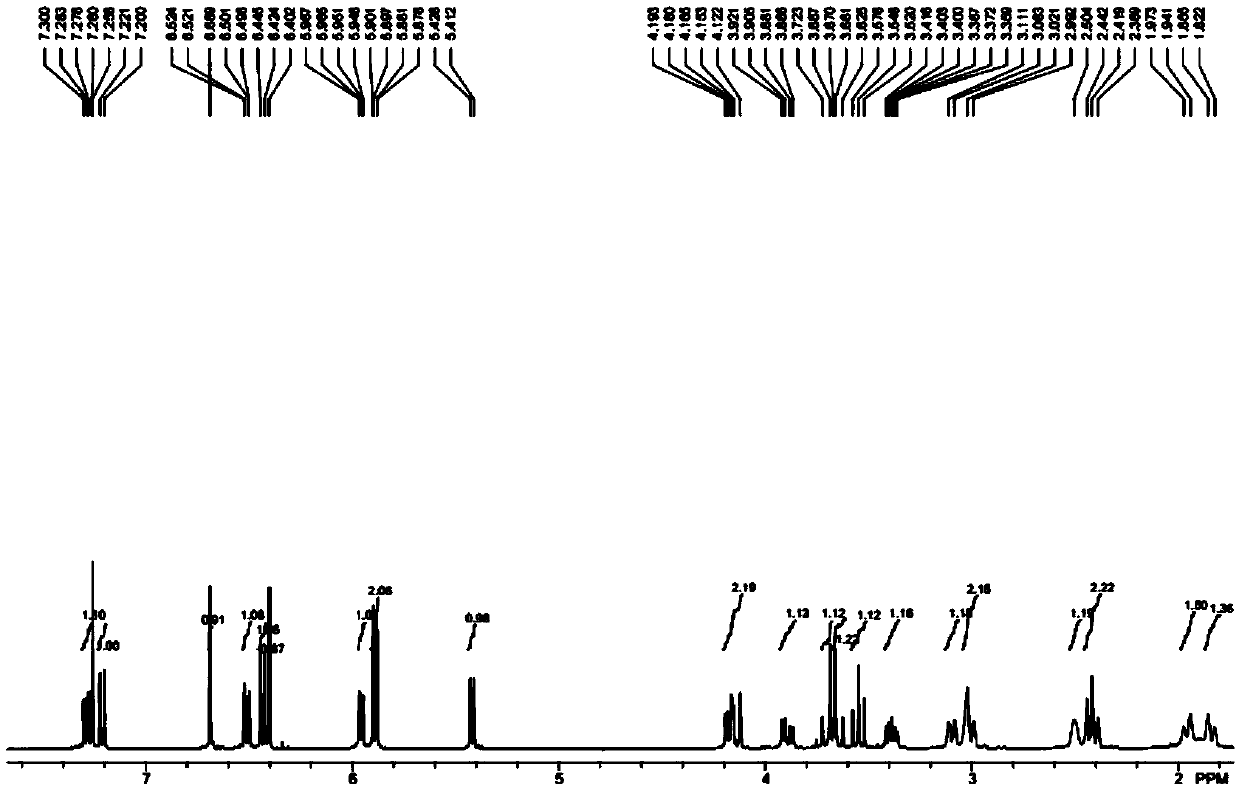

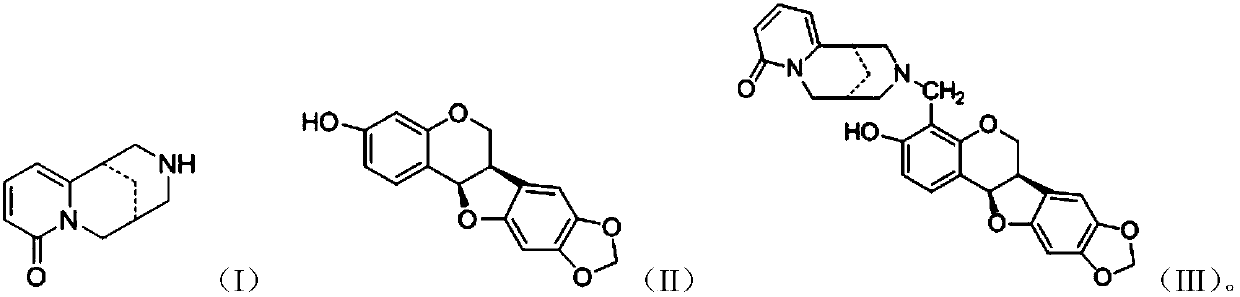

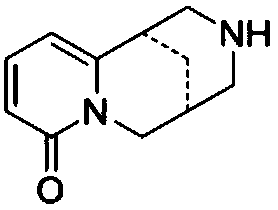

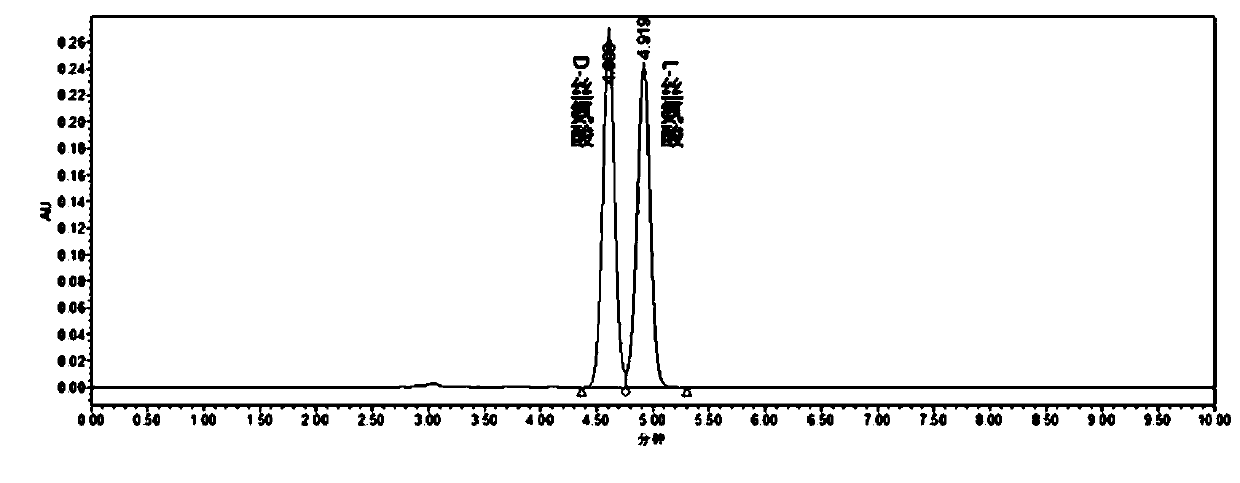

A kind of synthetic method of sorghine

ActiveCN107880063BThe preparation process is simpleShort timeOrganic chemistryOrganic solventSynthesis methods

Owner:ZHEJIANG UNIV OF TECH

An adhesive used for moisture-proof fiberboards

InactiveCN106554737AShort curing timeImprove waterproof and water resistanceNon-macromolecular adhesive additivesStarch adhesivesAdhesiveMoisture

Owner:SHIFANG MIDEE WOOD IND

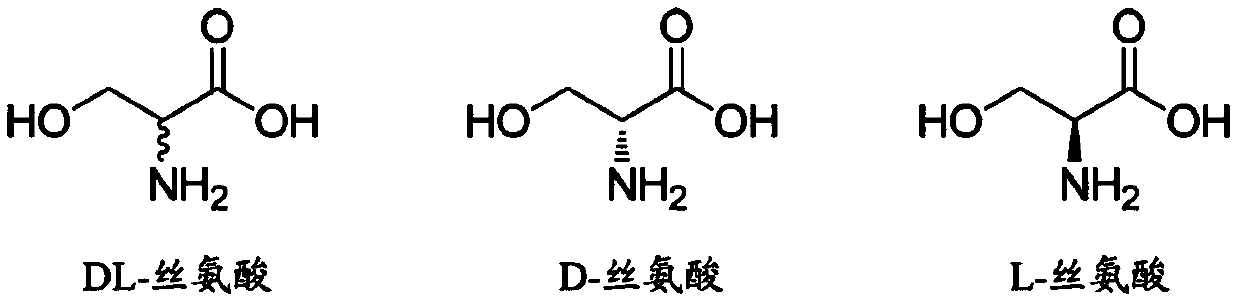

Method for preparing DL-serine by one-pot enzyme method

ActiveCN110373440ARealize resource reuseReduce "three wastes" emissionsFermentationAlanine racemaseD-threonine aldolase

Owner:CHANGXING PHARMA

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap