Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waxes are a diverse class of organic compounds that are lipophilic, malleable solids near ambient temperatures. They include higher alkanes and lipids, typically with melting points above about 40 °C (104 °F), melting to give low viscosity liquids. Waxes are insoluble in water but soluble in organic, nonpolar solvents. Natural waxes of different types are produced by plants and animals and occur in petroleum.

Injectable microdispersions for medical applications

The present invention is directed to microdispersions and pharmaceutical compositions containing a synthetic, bioabsorbable, biocompatible liquid polymer that is the reaction product of a polybasic acid or derivative thereof, a polyol and a fatty acid, the liquid polymer having a melting point less than about 40° C., as determined by differential scanning calorimetry, and a synthetic, bioabsorbable, biocompatible polymeric wax comprising the reaction product of a polybasic acid or derivative thereof, a fatty acid and a polyol, the polymeric wax having a melting point less than about 70° C., as determined by differential scanning calorimetry.

Owner:ETHICON INC

Multiple-effect solid inhibiting anti-scale rod

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

AKD emulsion and preparation method thereof

ActiveCN104499363AThe emulsification process is streamlinedLow impurity contentWater-repelling agents additionWaxStarch gelatinization

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

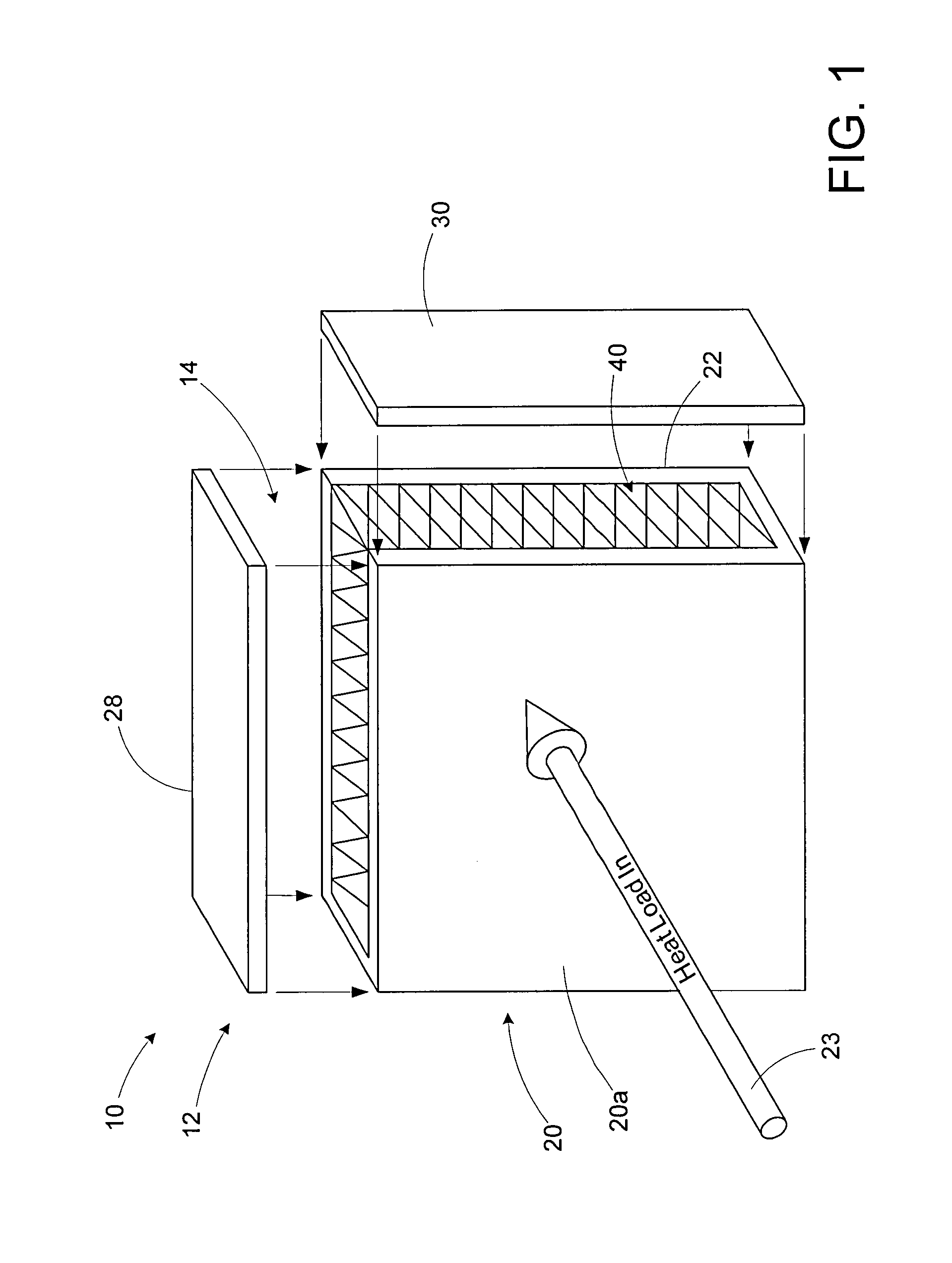

Heat-absorbing structural material

InactiveUS20120061065A1Envelopes/bags making machineryAdditive manufacturing apparatusWaxInterior space

Owner:RAYTHEON CO

Particle coating

Owner:SCHERING PLOUGH HEALTHCARE PRODUCTS INC

Degradable starch composite size

Owner:ZHANGJIAGANG LUYUAN STARCH FACTORY

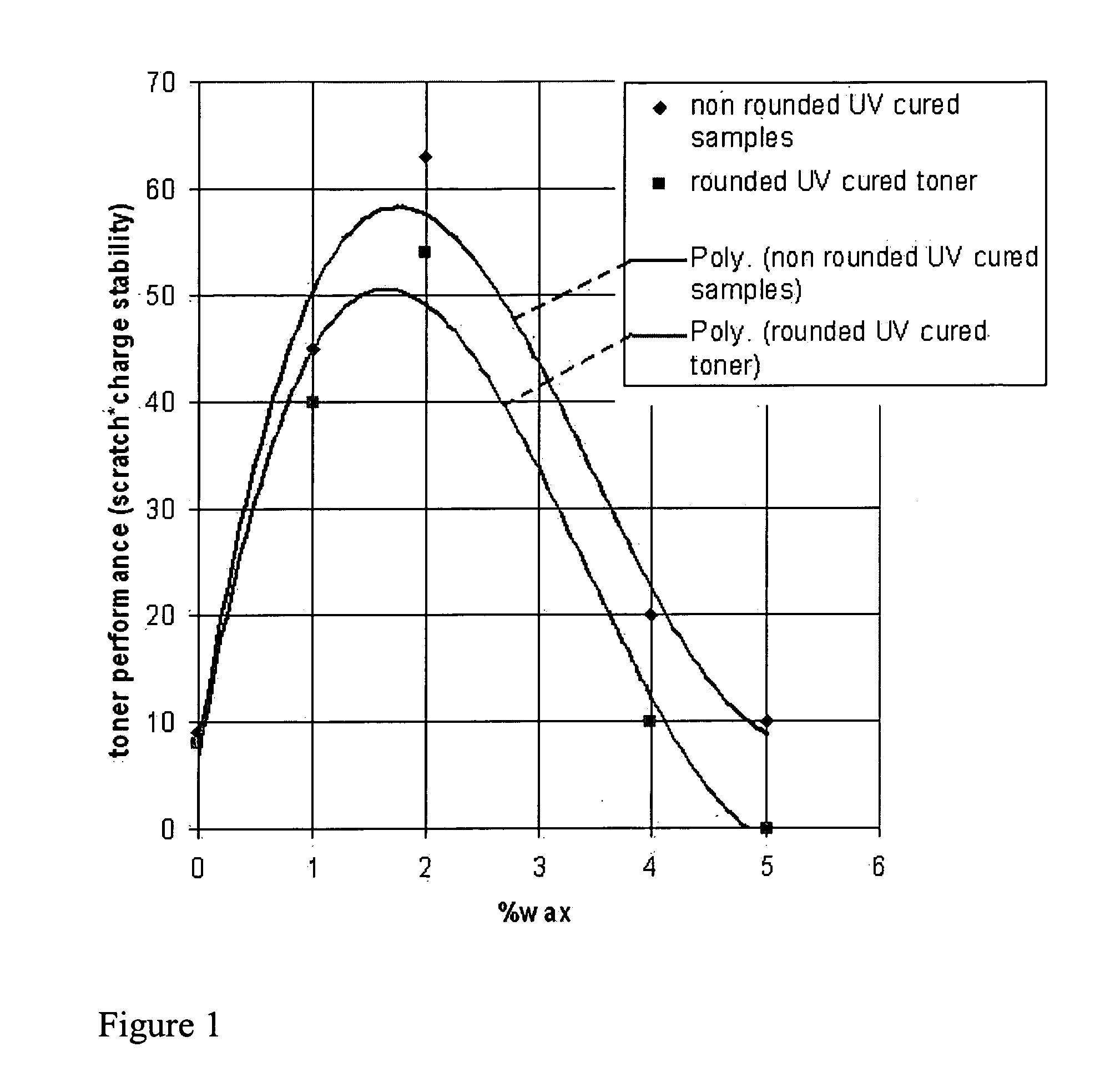

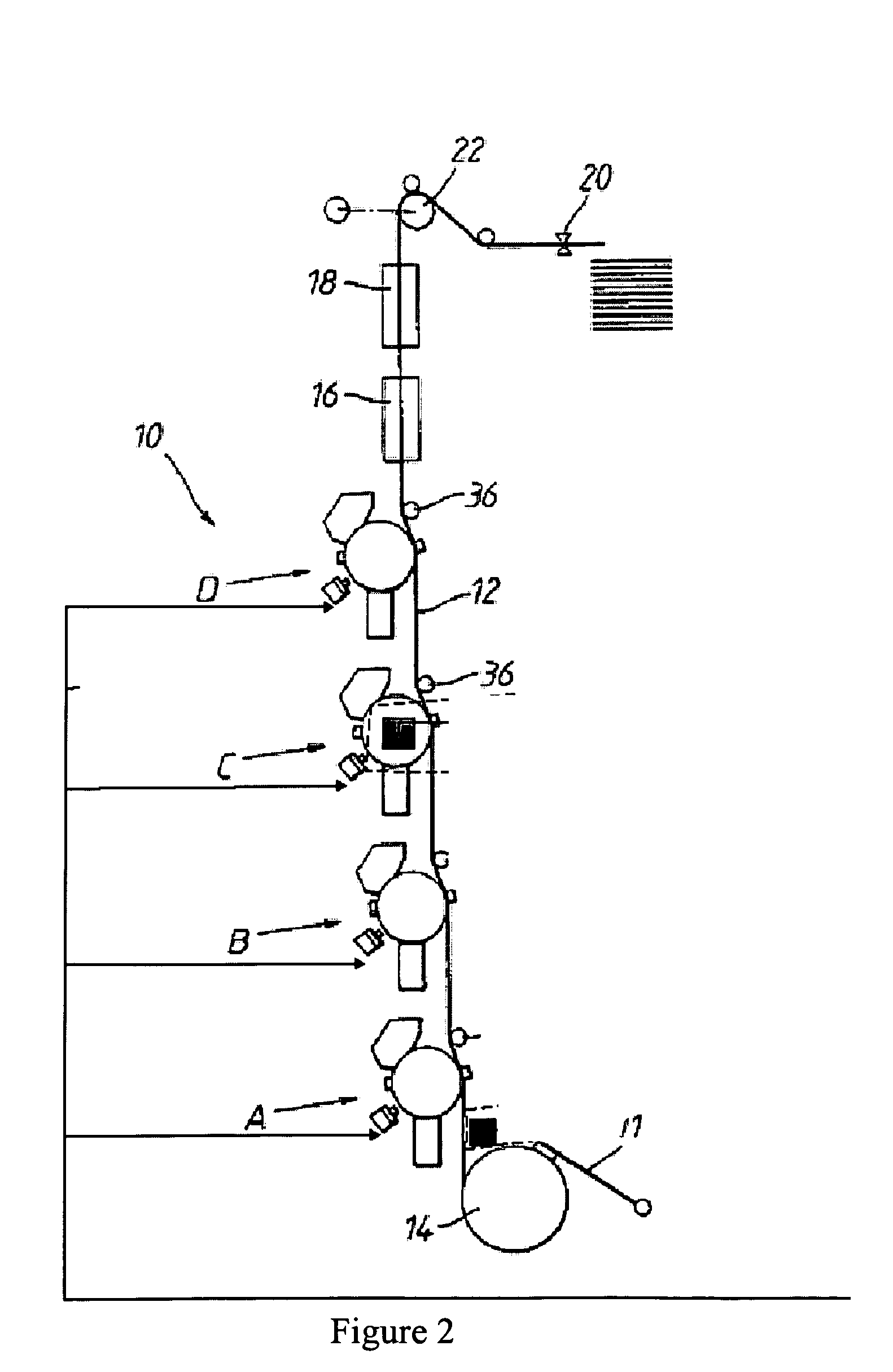

Toner and production process for the same

Owner:KONICA MINOLTA BUSINESS TECH INC

High-toughness high temperature-resistant modified PVC pipe

InactiveCN105440481AImprove toughnessImprove high temperature resistanceAcrylonitrileMaterials science

The invention discloses a high-toughness high temperature-resistant modified PVC pipe. The high-toughness high temperature-resistant modified PVC pipe comprises the following raw materials by weight: 80 to 120 parts of PVC resin, 30 to 60 parts of chlorinated polyethylene, 40 to 80 parts of liquid butadiene-acrylonitrile rubber, 10 to 30 parts of polyurethane elastomer, 2 to 8 parts of modified nanometer calcium carbonate, 1 to 5 parts of kaolin, 2 to 6 parts of fly ash, 4 to 8 parts of glass beads, 4 to 8 parts of glass fiber, 1 to 6 parts of titanium dioxide, 3 to 9 parts of PE wax, 2 to 5 parts of methyl methacrylate, 4 to 8 parts of acrylate, 1 to 5 parts of a heatproof modifier and 2 to 6 parts of a coupling agent. The PVC pipe provided by the invention has excellent toughness and high temperature resistance.

Owner:NINGGUO CITY GAOXIN PIPE CO LTD

Cleaning and antirust agent for secondary processing of casting parts and preparation method thereof

Owner:DALIAN JIESHI CLEANING PRODS +1

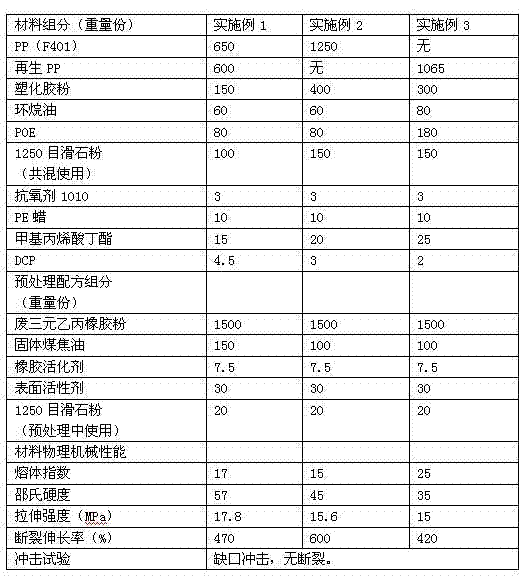

Rubber material and method for machining automobile front auxiliary frame lining with rubber material

The invention relates to a rubber material. The rubber material comprises, by weight, 90-110 parts of natural rubber crude rubber, 45-65 parts of carbon black, 1.2-1.8 parts of sulphur, 1.5-2.2 parts of accelerative activator, 3-5 parts of zinc oxide, 0.5-1 part of stearic acid, 1-1.5 parts of antiager RD, 1-2 parts of antiager 4010 NA, 3-5 parts of plasticizer, 1-2 parts of dispersing agent and 1-2 parts of preservation wax. The invention further discloses a method for machining an automobile front auxiliary frame lining with the rubber material. Manufacturing processes are as follows: preparing synthetic rubber, forming and vulcanization of rubber, and postprocessing and testing. The automobile front auxiliary frame lining manufactured through the method has the advantages of being not prone to aging and hardening, good in heat resistance, low in motion multiplying power, small in compression permanent deformation and long in service life, so that the whole comfort level of an automobile is improved.

Owner:ANHUI ZHONGDING NVH

UV curable toner with improved scratch resistance

Owner:XEIKON MFG NV

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

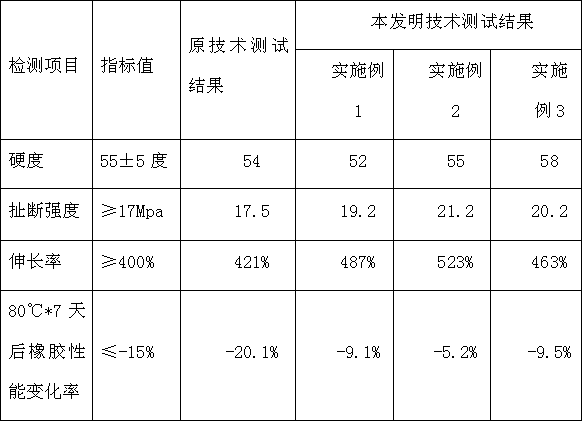

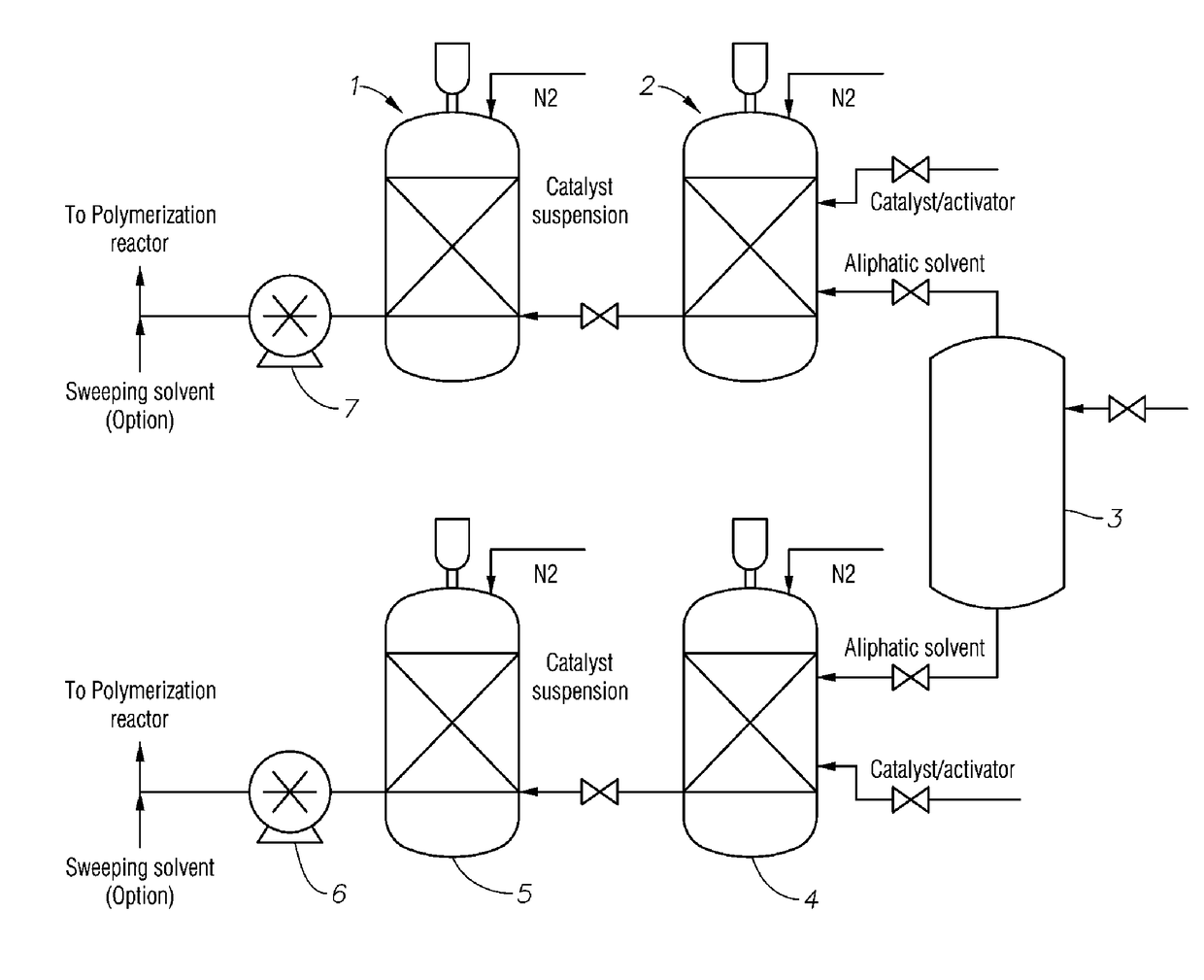

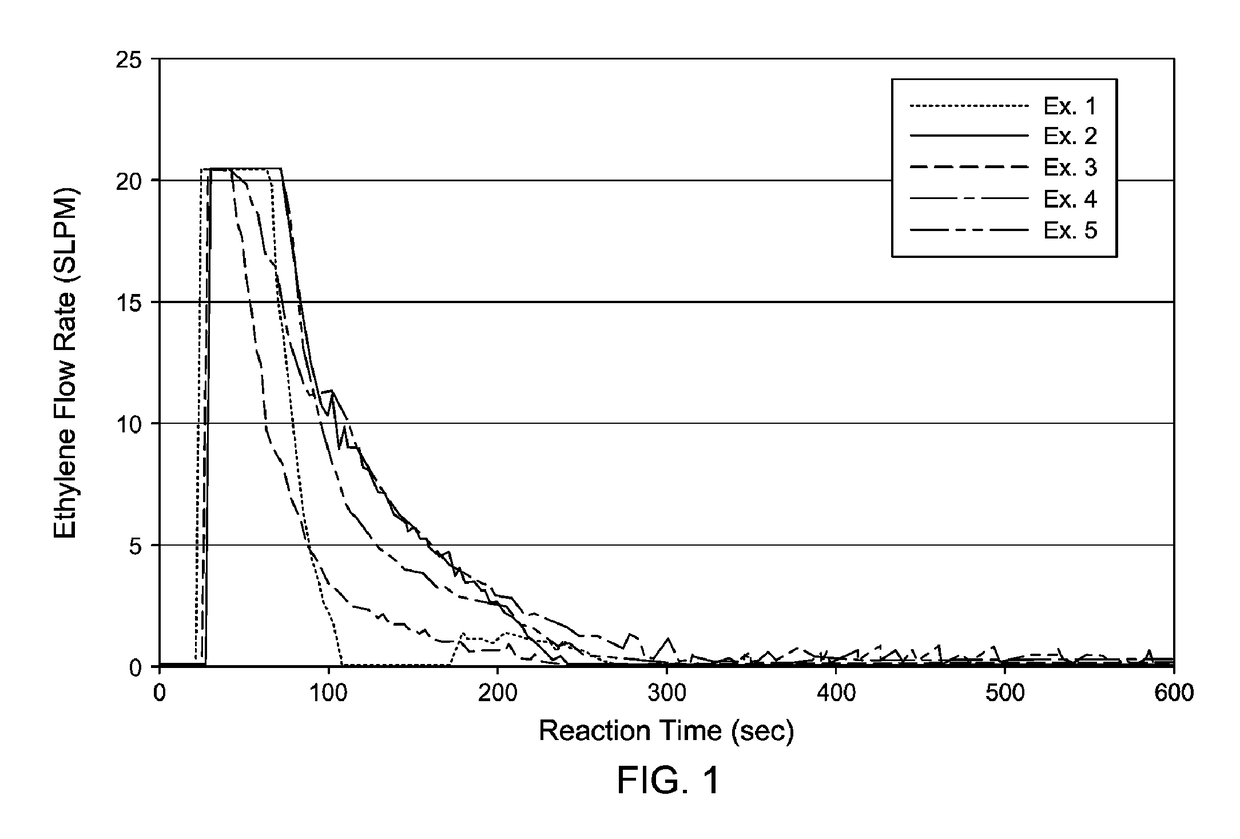

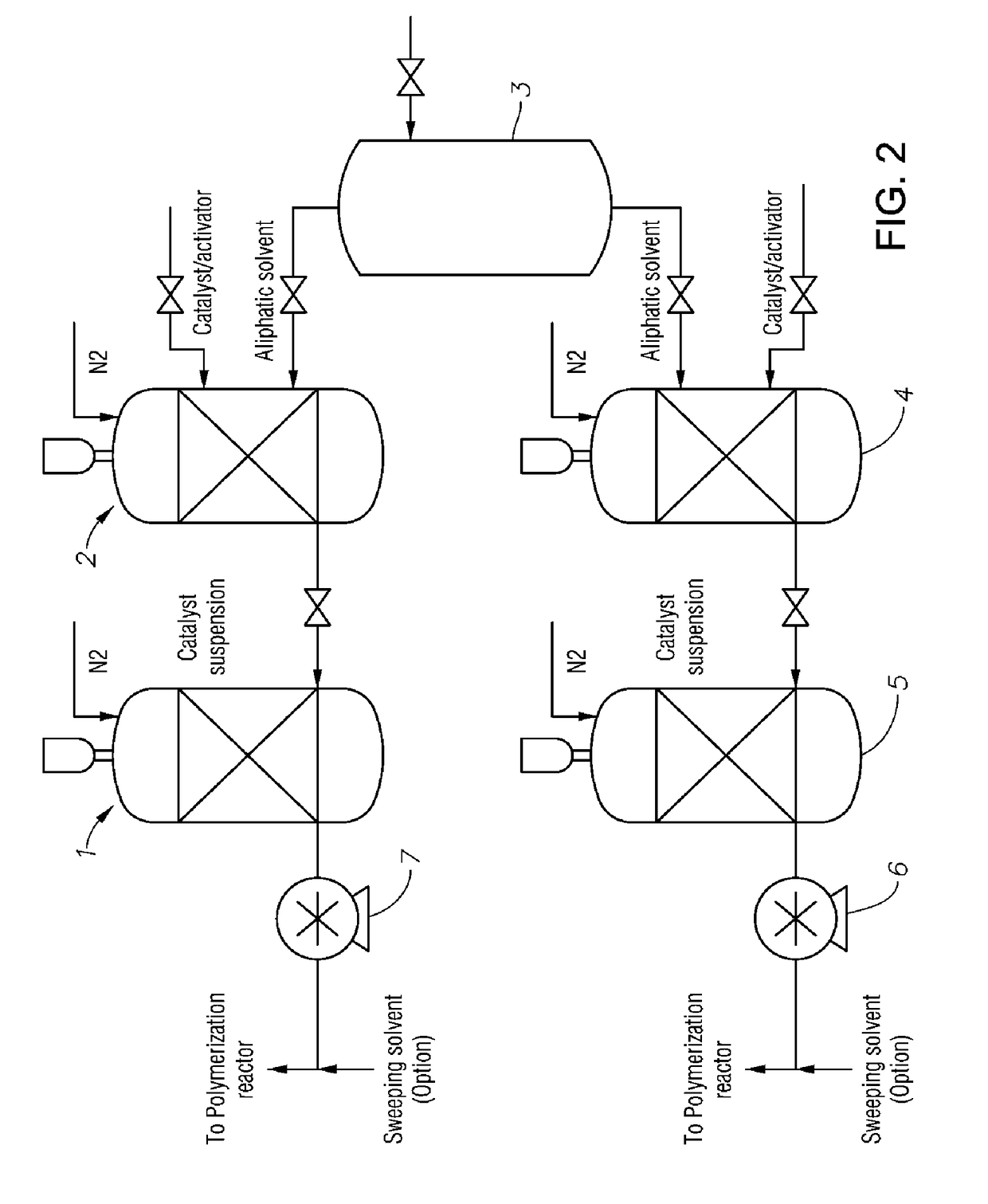

Methods for Supplying Solid Catalysts to a Solution Polymerization Reactor

ActiveUS20180044453A1Chemical liquid solidificationChemical/physical/physico-chemical stationary reactorsWaxSolvent

Owner:EXXONMOBIL CHEM PAT INC

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

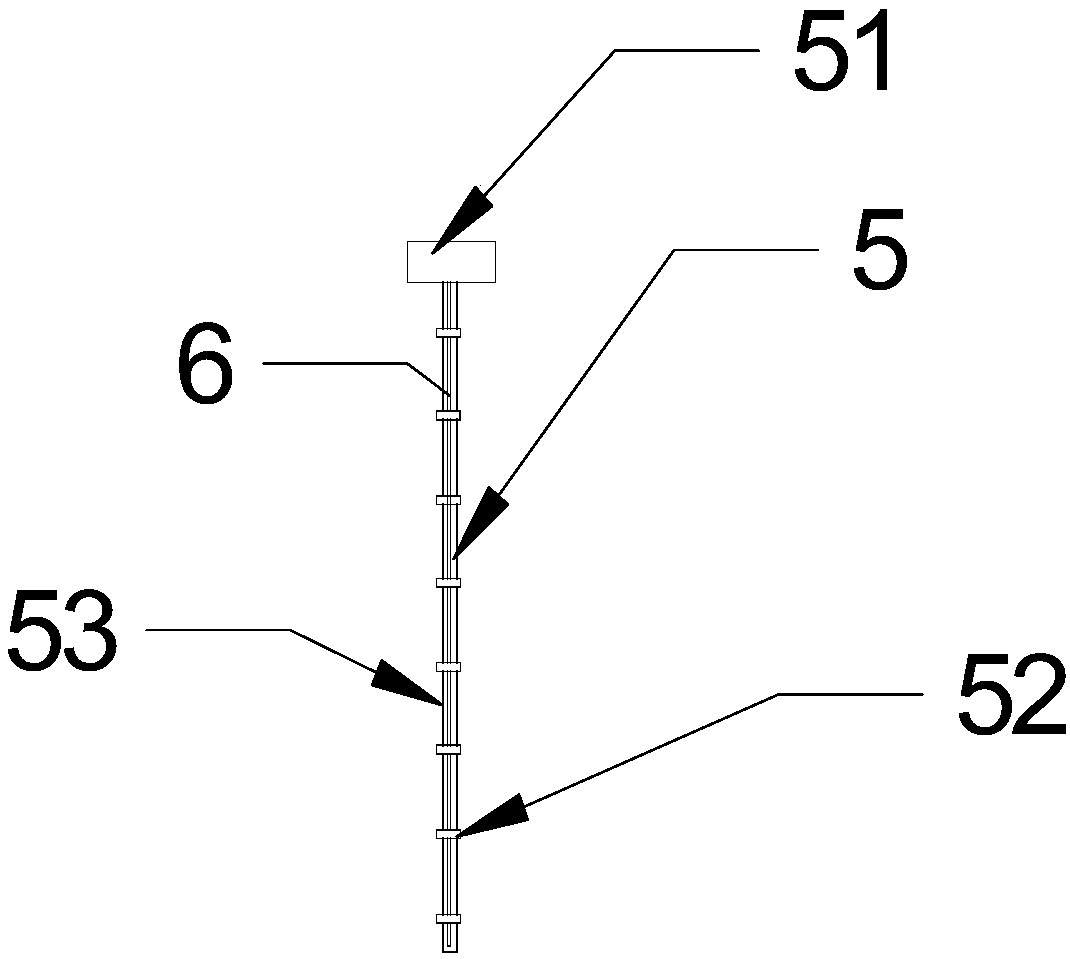

Assembled wax mold and production method thereof

InactiveCN104014732ADemolition speed blockIncrease productivityFoundry moulding apparatusWaxMaterials science

Owner:HUZHOU NANFENG MACHINERY MFG

Treatment method of circulating water with leaking wax oil

ActiveCN102730866AEasy to controlAvoid re-adhesionFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWaxCarboxylic acid

The invention provides a treatment method of circulating water with leaking wax oil. The method comprises the following steps: a) adding an oxidation-type bactericide; b) adding a corrosion and scale inhibitor containing at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor agent and an optional zinc salt; and c) adding at least one polysorbate as a wax oil emulsifier; and d ) adding at least one polyoxyethylene nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Quartz rod cutting process

ActiveCN109795041ANo vibrationThere will be no cutting deformationPolyureas/polyurethane adhesivesWax adhesivesWaxHydrofluoric acid

Owner:扬州美和光电科技有限公司

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Soft solder for SnAgCuNiGe alloy solder paste

InactiveCN101176957AWeldablePrintableWelding/cutting media/materialsSoldering mediaActive agentMetallurgy

Owner:东莞市特尔佳电子有限公司

Piribedil sustained-release tablet and preparation method thereof

Owner:SUZHOU HOMESUN PHARMA

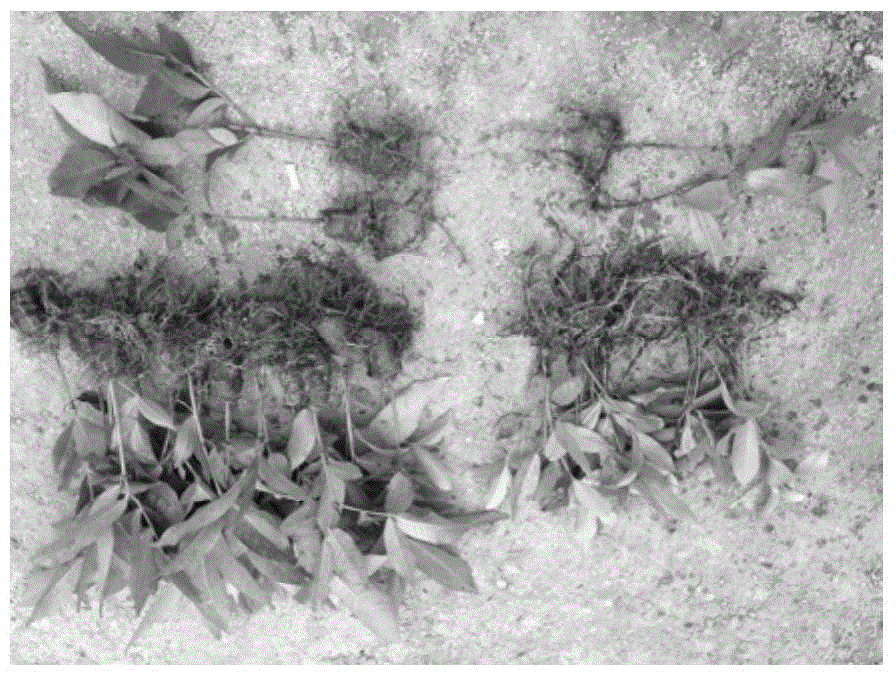

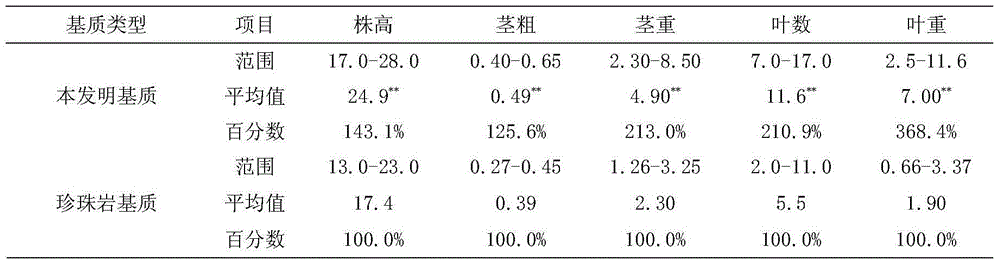

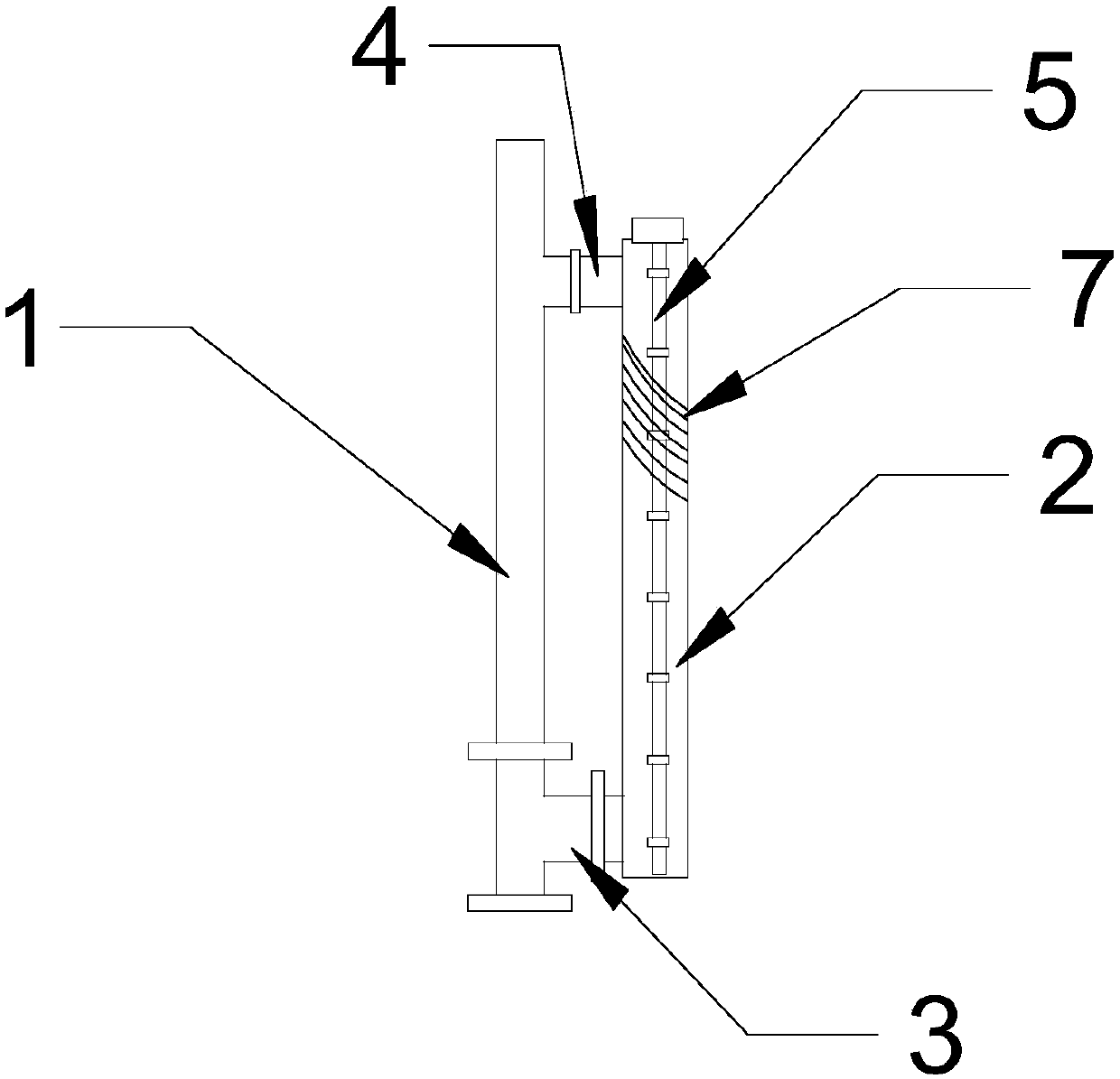

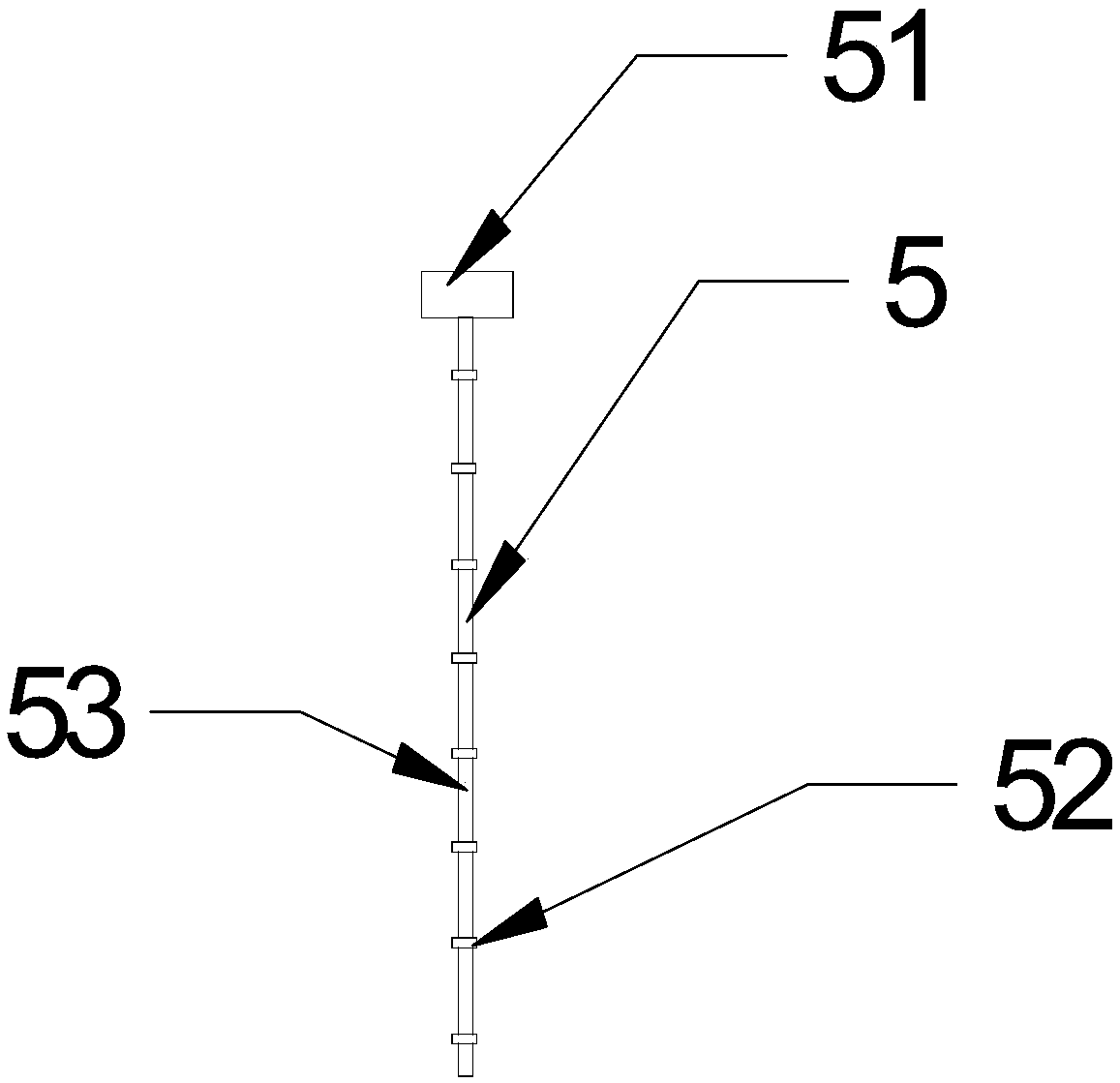

Wax apple seedling fast propagation bag-packed medium and using method thereof

InactiveCN103814802AEasily contagiousRealize bag-type seedling cultivationCultivating equipmentsSoilless cultivationWaxComposite media

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE

Cracking-resistant iron-base powder metallurgy material used for valve and preparation method of cracking-resistant iron-base powder metallurgy material

The invention discloses a cracking-resistant iron-base powder metallurgy material used for a valve. The cracking-resistant iron-base powder metallurgy material used for the valve is prepared from the following raw materials in parts by weight: 0.2-0.4 part of stearic acid boron, 3-4 parts of aluminum nickel alloy powder, 3-4 parts of nickeling silicon carbide crystal whisker, 3-4 parts of TiO2, 1-1.5 parts of fumed silica, 0.4-0.6 part of palm wax, 1-2.6 parts of nanometer boron fiber, 1-1.5 parts of cordierite powder, 2-2.6 parts of aluminium titanate, 0.3-0.4 part of silane coupling agent kh-550, a proper quantity of 1% sodium carbonate solution, a proper quantity of water, 2.5-3.5 parts of sodium hypophosphite, 0.4-0.6 part of polyethylene glycol, 30-35 parts of 2mMol / L copper sulphate solution, 2-3 parts of wetting accessory ingredient and 77-82 parts of iron powder. The nanometer boron fiber and the nickeling silicon carbide crystal whisker are added into the valve material to increase compatibility and prevent cracking while the toughness, the heat resistance and the impact strength resistance of valve materials are increased.

Owner:TONGLING JINGWEI FLUID SCI & TECH

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

Formula of modified polypropylene

The invention discloses a formula of modified polypropylene, which comprises polypropylene, a contrast agent, a photostabilizer, a brightener, lubricating oil and an antioxidant, wherein the contrast agent is barium sulfate, the photostabilizer is zinc oxide, the brightener is synthetic wax, the lubricating oil is 15# white oil, and the antioxidant is 2,6-di-tert-butyl-para-cresol. According to the formula of the modified polypropylene, the modified polypropylene has the effects of no toxicity, aging resistance, bright and clean appearance, lubricating property and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap