Assembled wax mold and production method thereof

An assembled, wax mold technology, applied in casting and molding equipment and other directions, can solve the problems of inconvenient cutting tools, difficult wax chip removal, time-consuming and labor-intensive, etc., and achieve the effects of improving production efficiency, removing mold speed blocks, and shortening trimming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] A method for making an assembled wax model, comprising the following steps:

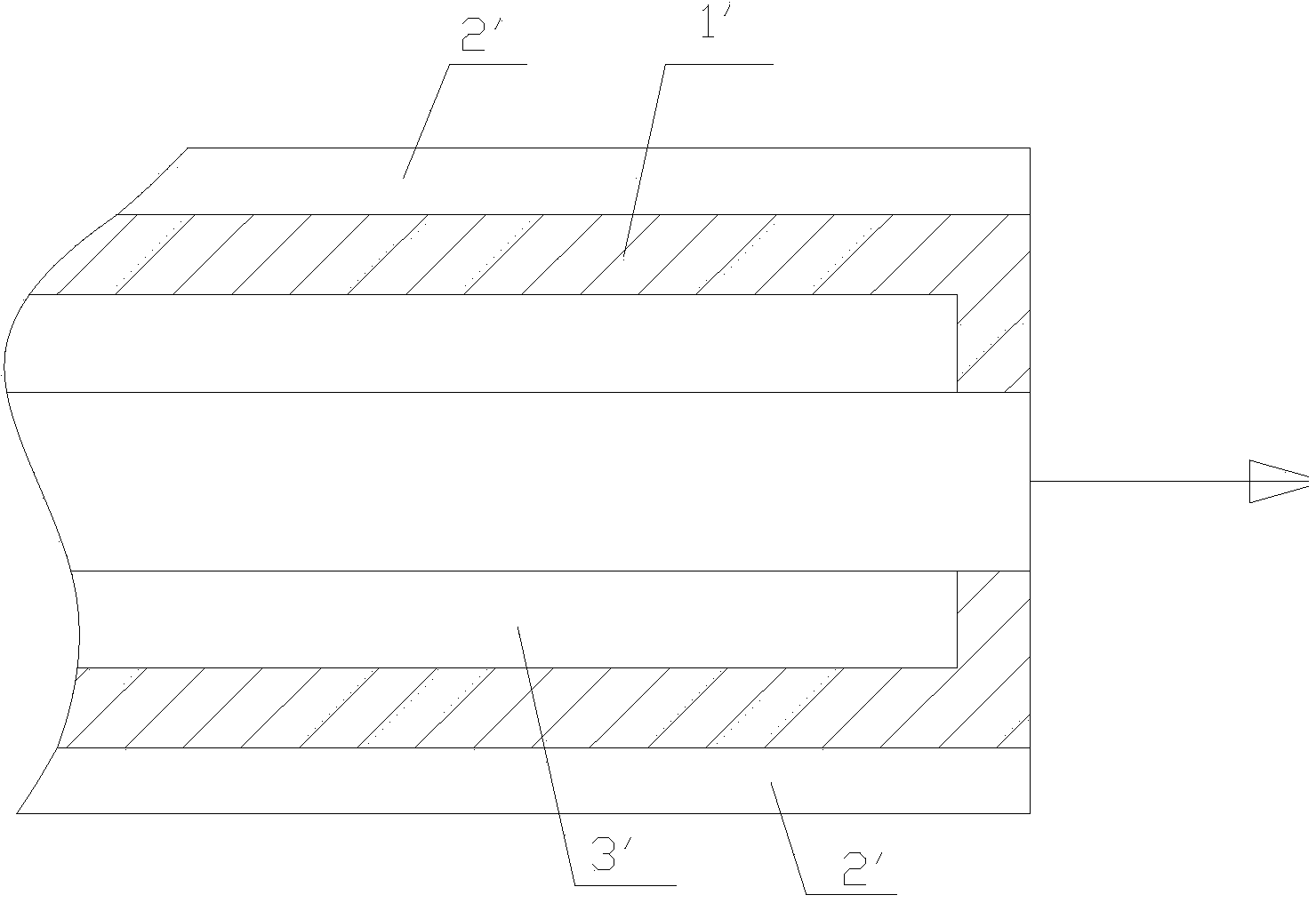

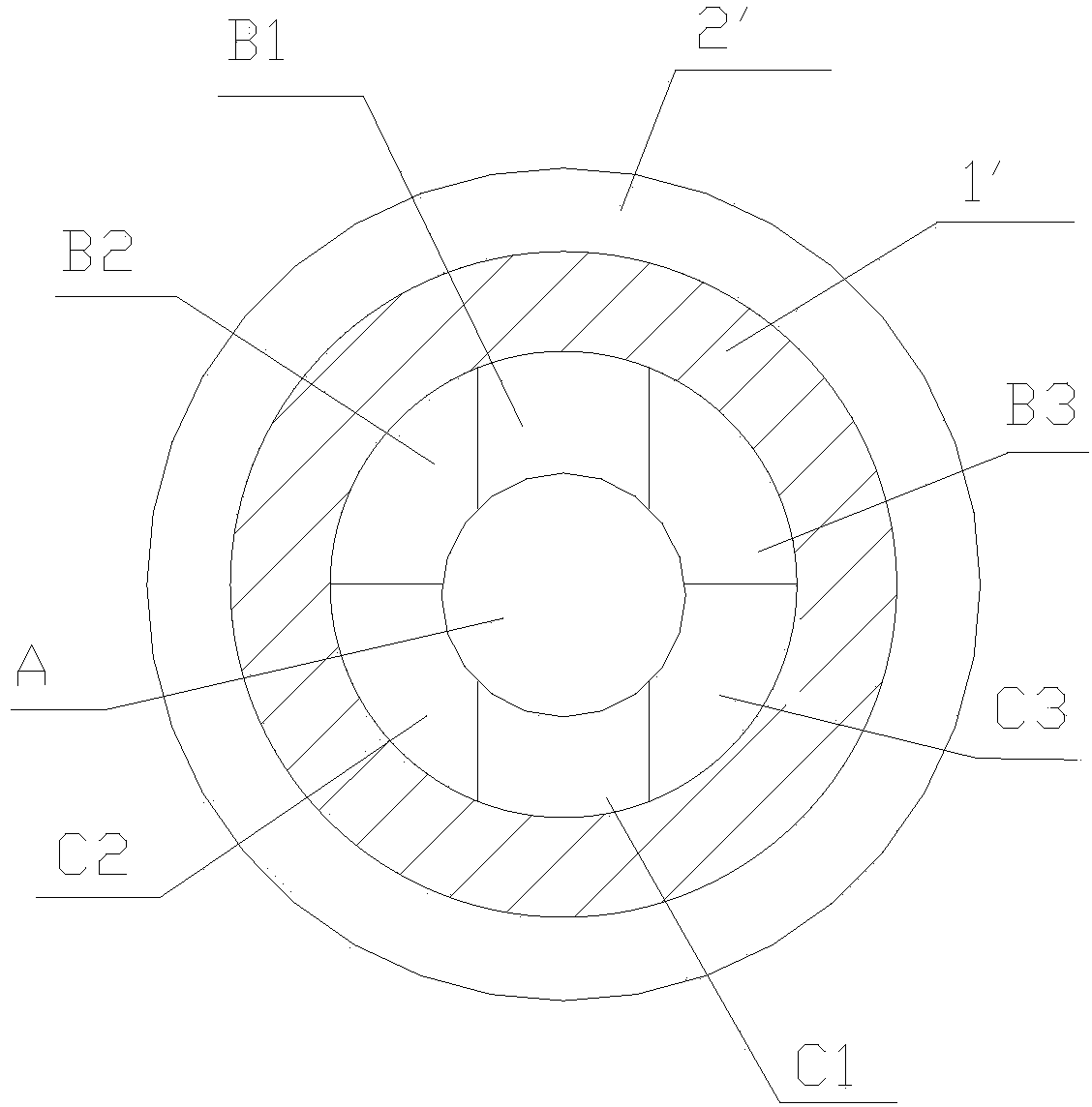

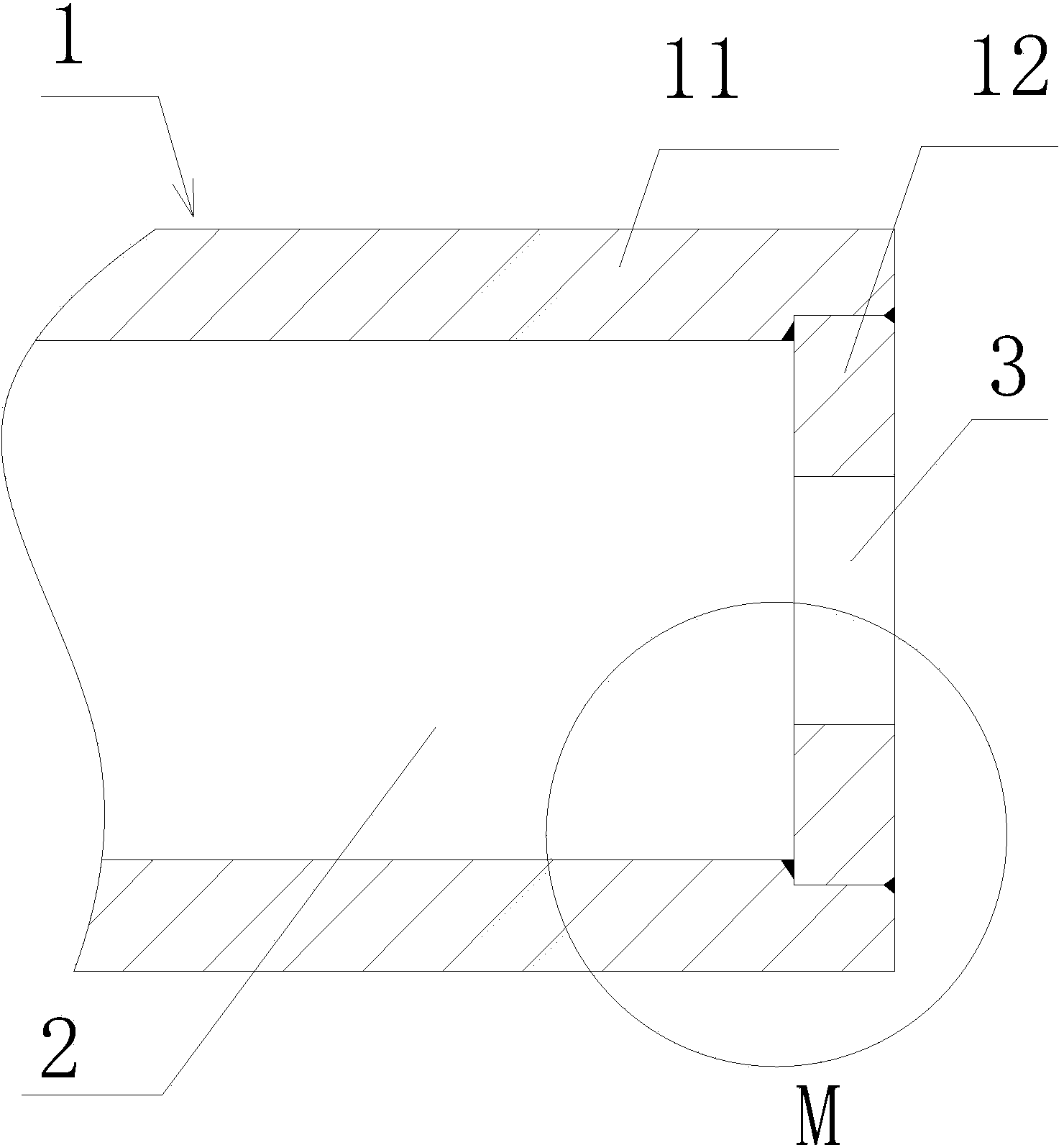

[0035] 1), respectively make the first mold fitting 11 and the second mold fitting 12: as Figure 5 As shown, there is a cavity 2 in the first mold fitting 11, and one end of the first mold fitting 11 is a first splicing portion 111, and the first splicing portion 111 is the maximum size of the first mold fitting 11, and the first splicing portion 111 is a heavy Enter the counterbore in the first mold fitting 11; as Figure 6 As shown, the second mold fitting 12 has a through hole, the second mold fitting 12 has a second splicing portion 121 adapted to the first splicing portion 111, and the second splicing portion 121 is inserted into the first splicing portion 111;

[0036] 2), inserting the second splicing portion 121 of the second mold fitting 12 into the first splicing portion 111 of the first mold fitting 11;

[0037] 3) Wax water melted on the ground in the gap between the first splicing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap