Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about "Laser beam welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

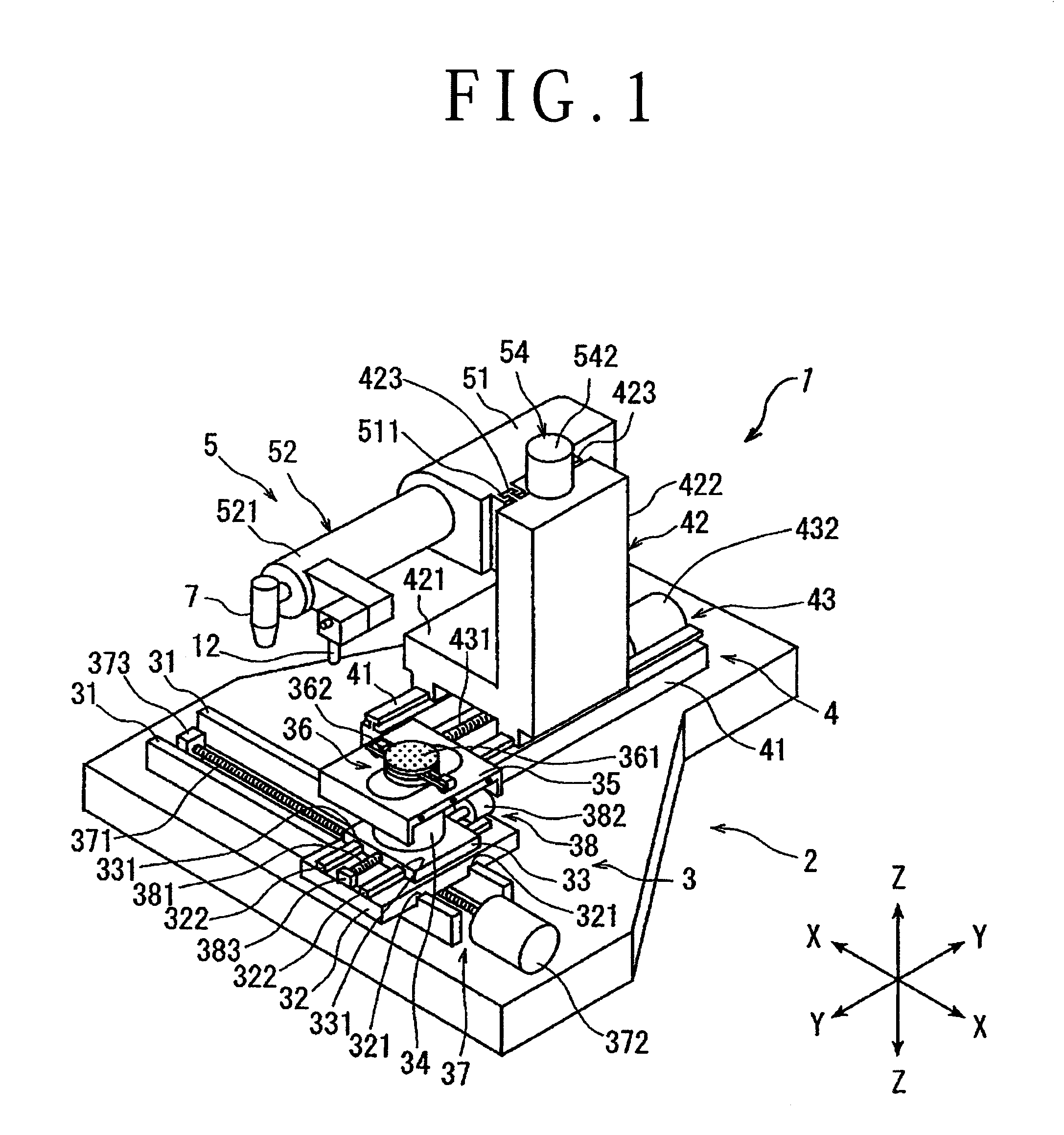

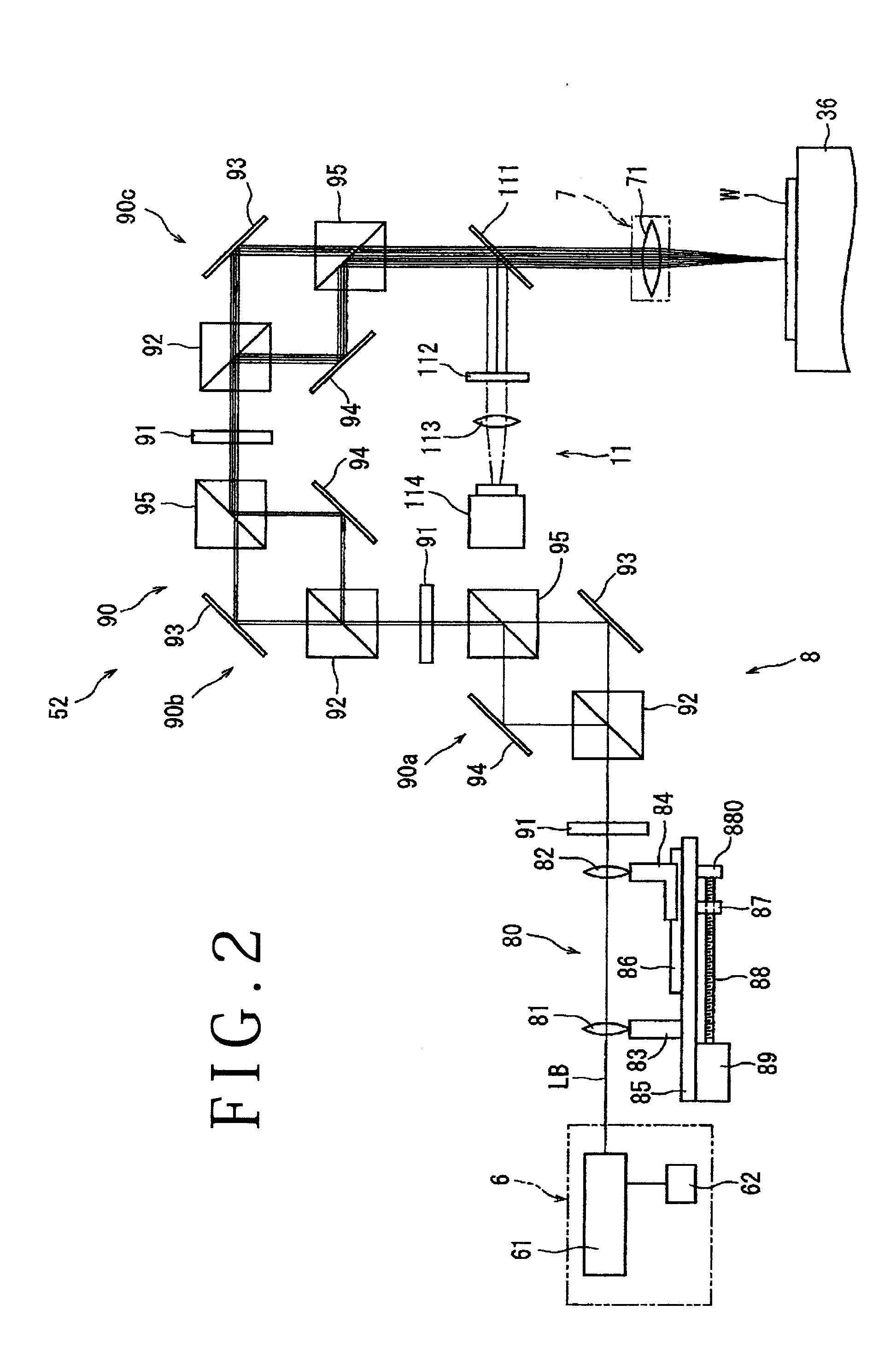

Laser processing apparatus

ActiveUS20130334185A1Welding/soldering/cutting articlesLaser beam welding apparatusOptical pathOptoelectronics

Owner:DISCO CORP

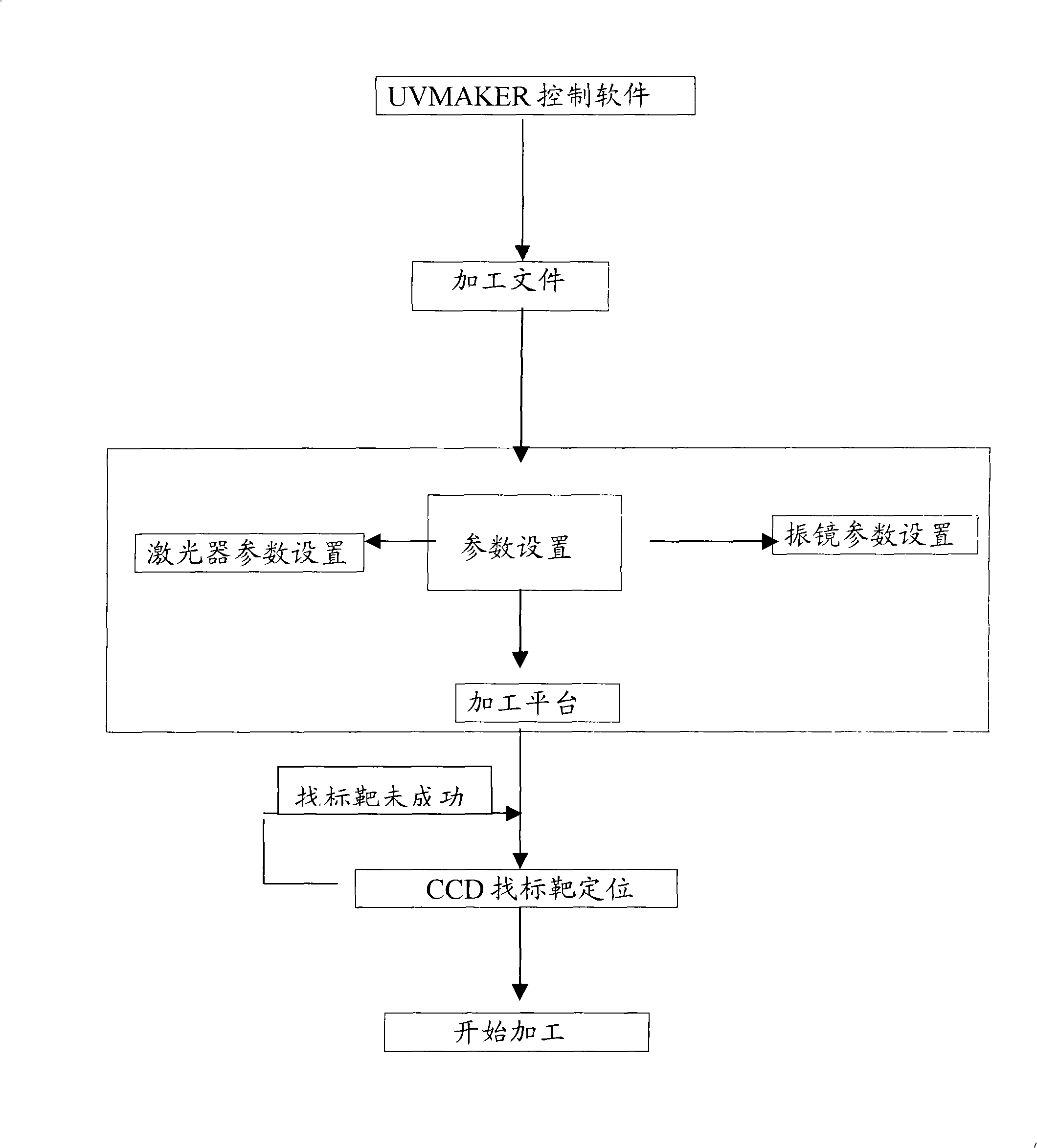

Laser device for cutting

Owner:HANS CNC SCI & TECH

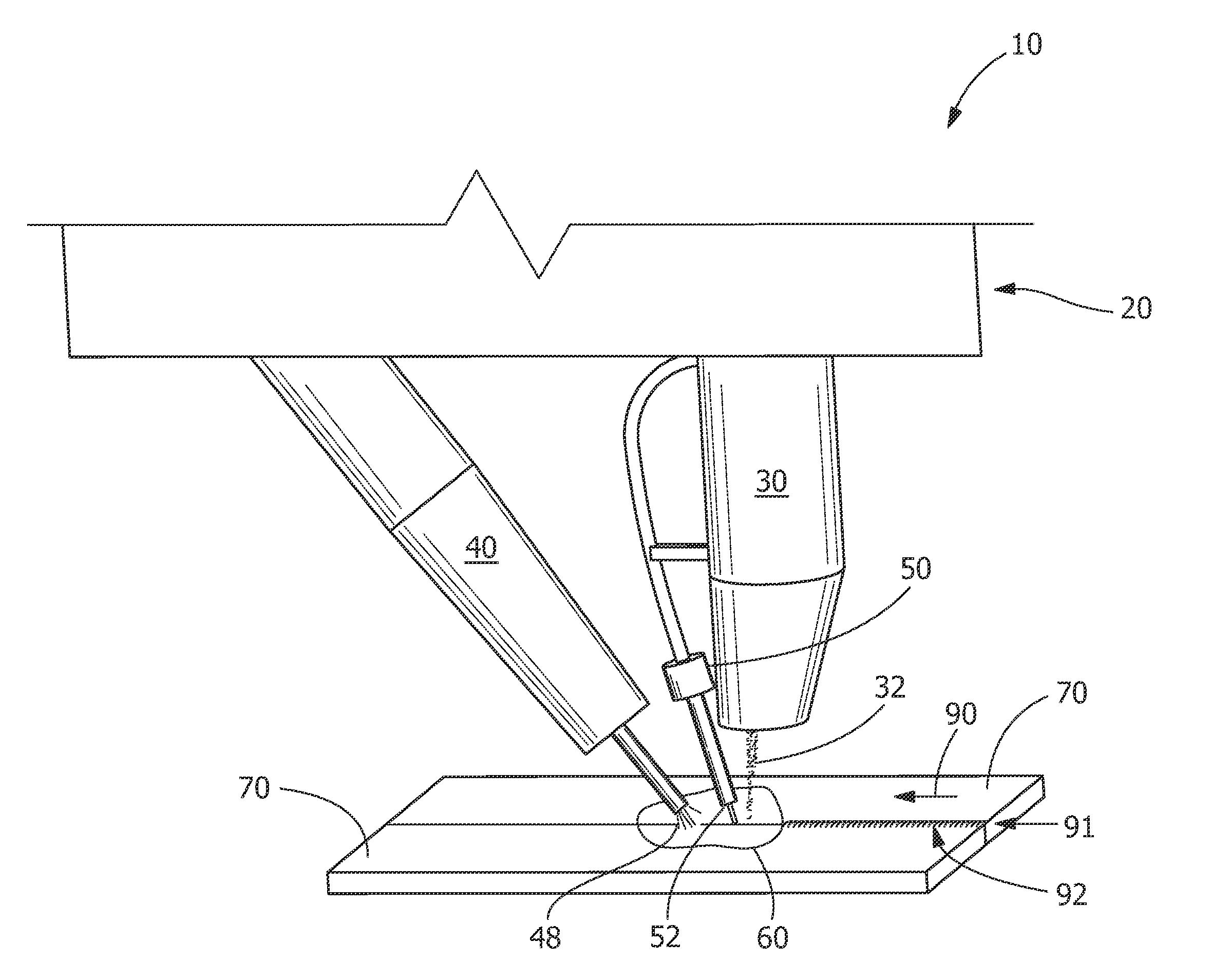

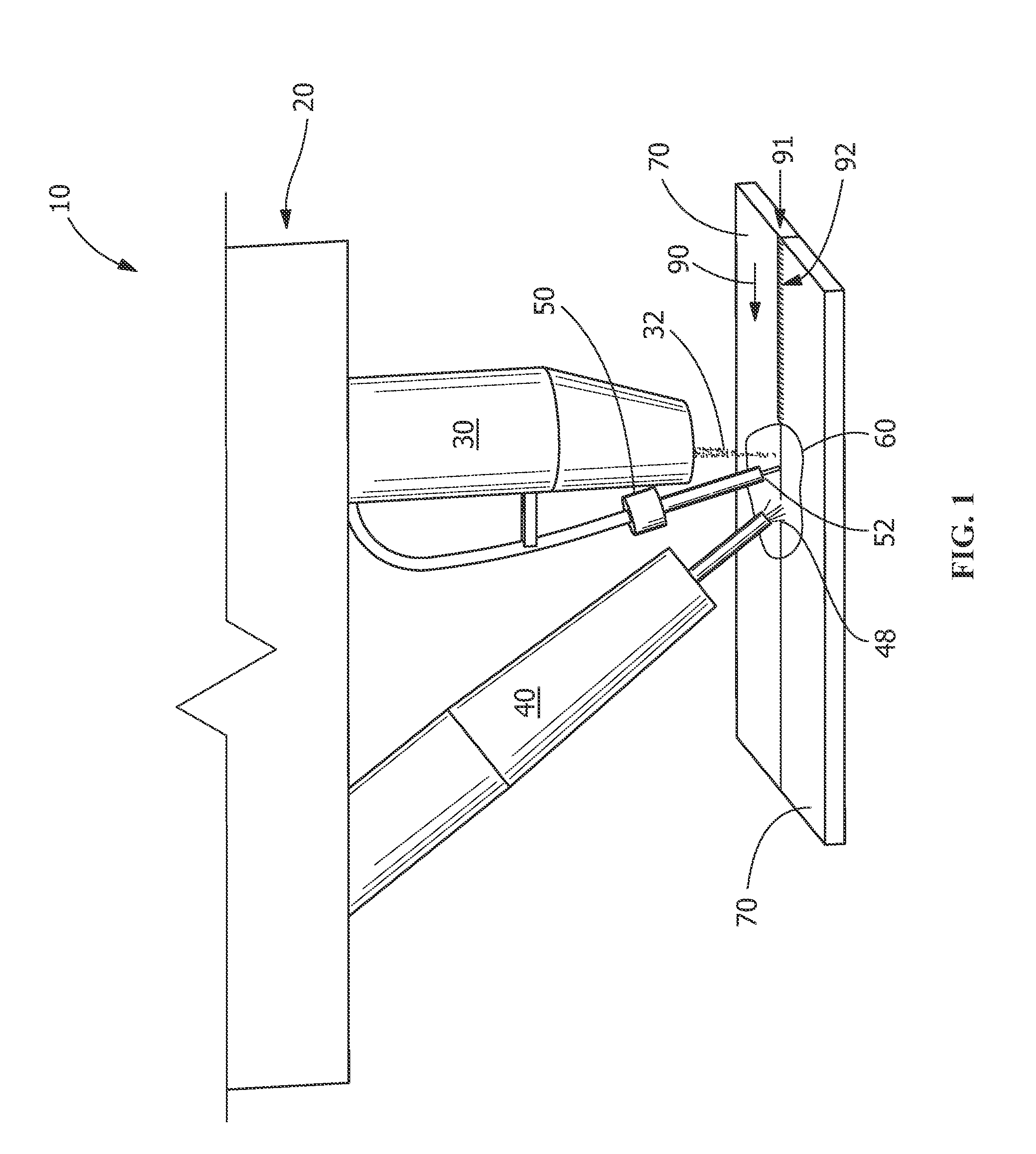

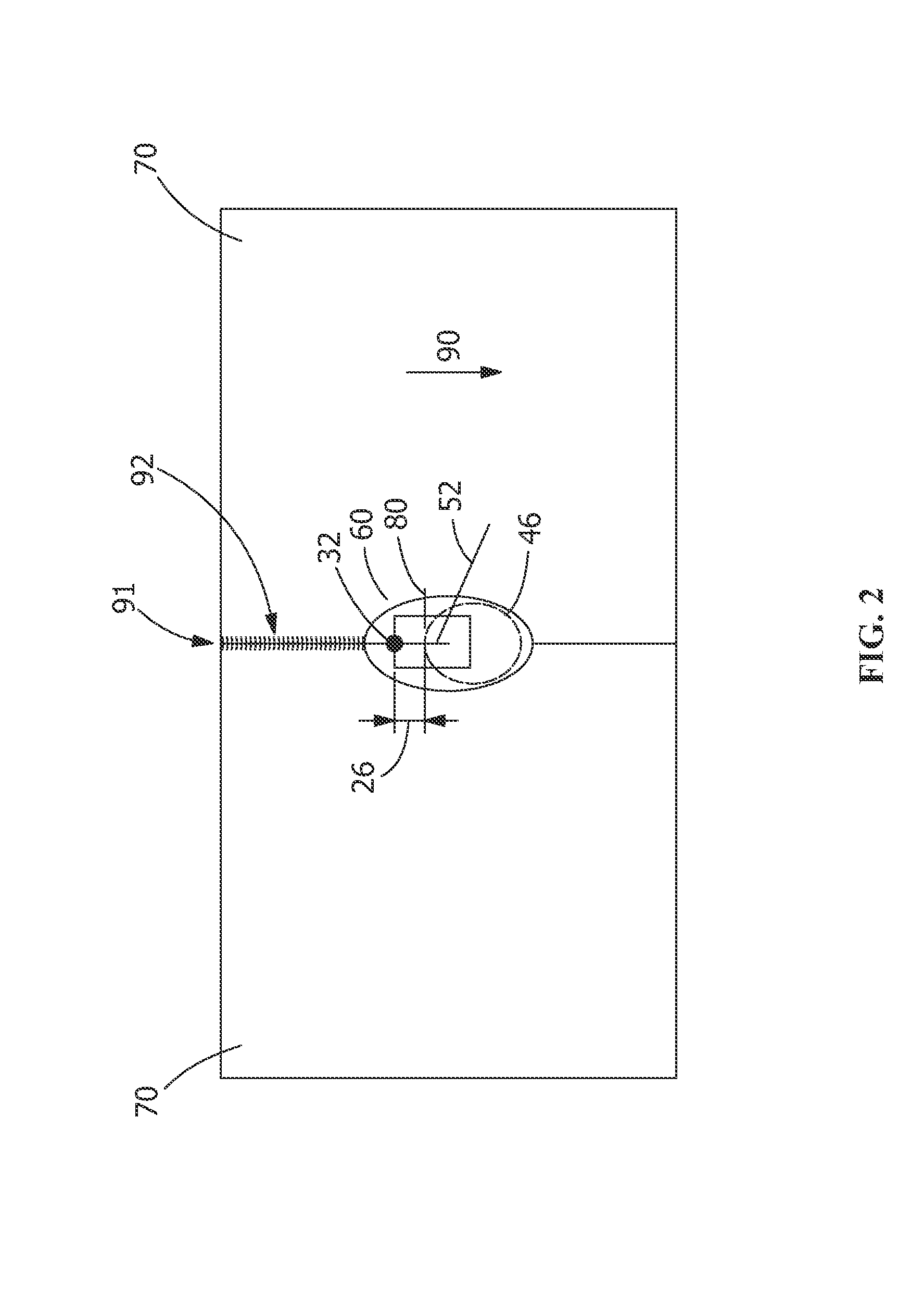

Hybrid welding system and method of welding

InactiveUS20140027414A1High constant weld speedArc welding apparatusLaser beam welding apparatusElectric arcEngineering

Owner:GENERAL ELECTRIC CO

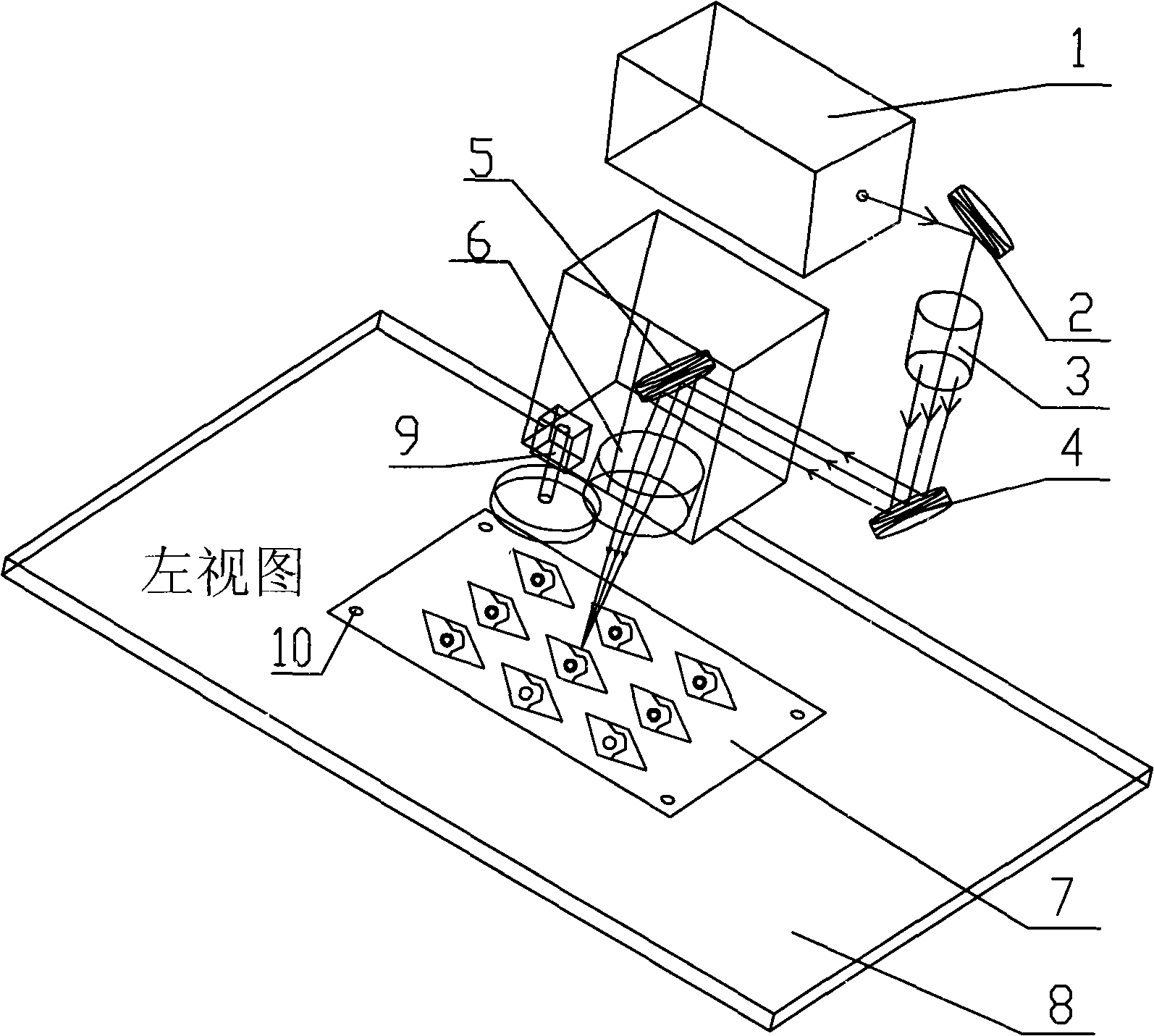

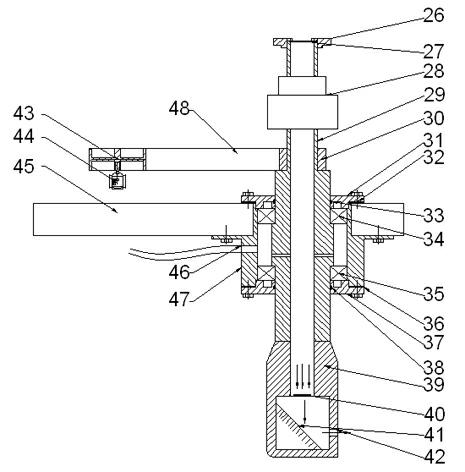

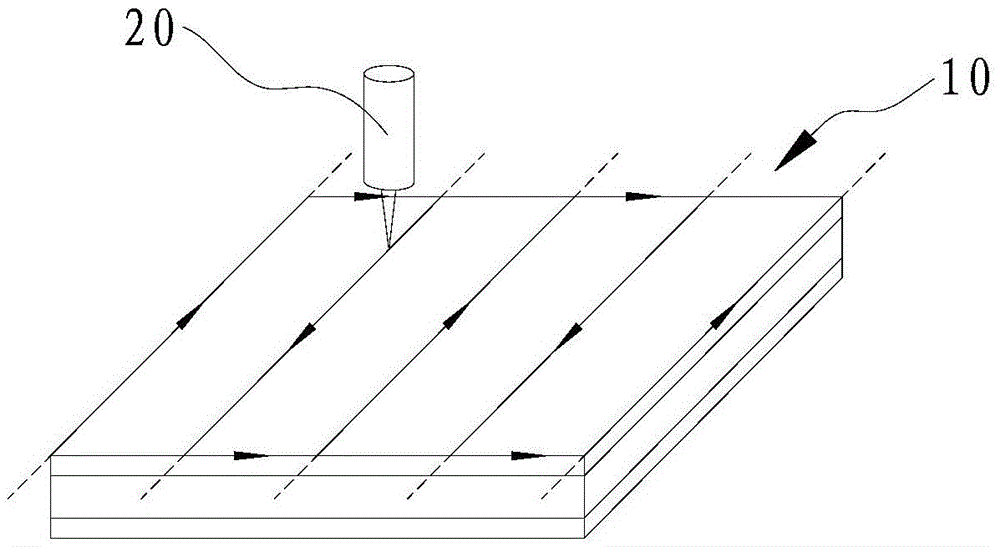

Laser micromachining device for surface of engine cylinder and machining method of laser micromachining device

Owner:JIANGSU UNIV

Method for preparing two-dimensional metallic photonic crystal structure in large area through femtosecond laser direct writing

InactiveCN105108342AAvoid complicated proceduresThe technical method is simpleLaser beam welding apparatusBirefringent crystalTime delays

Owner:NANKAI UNIV

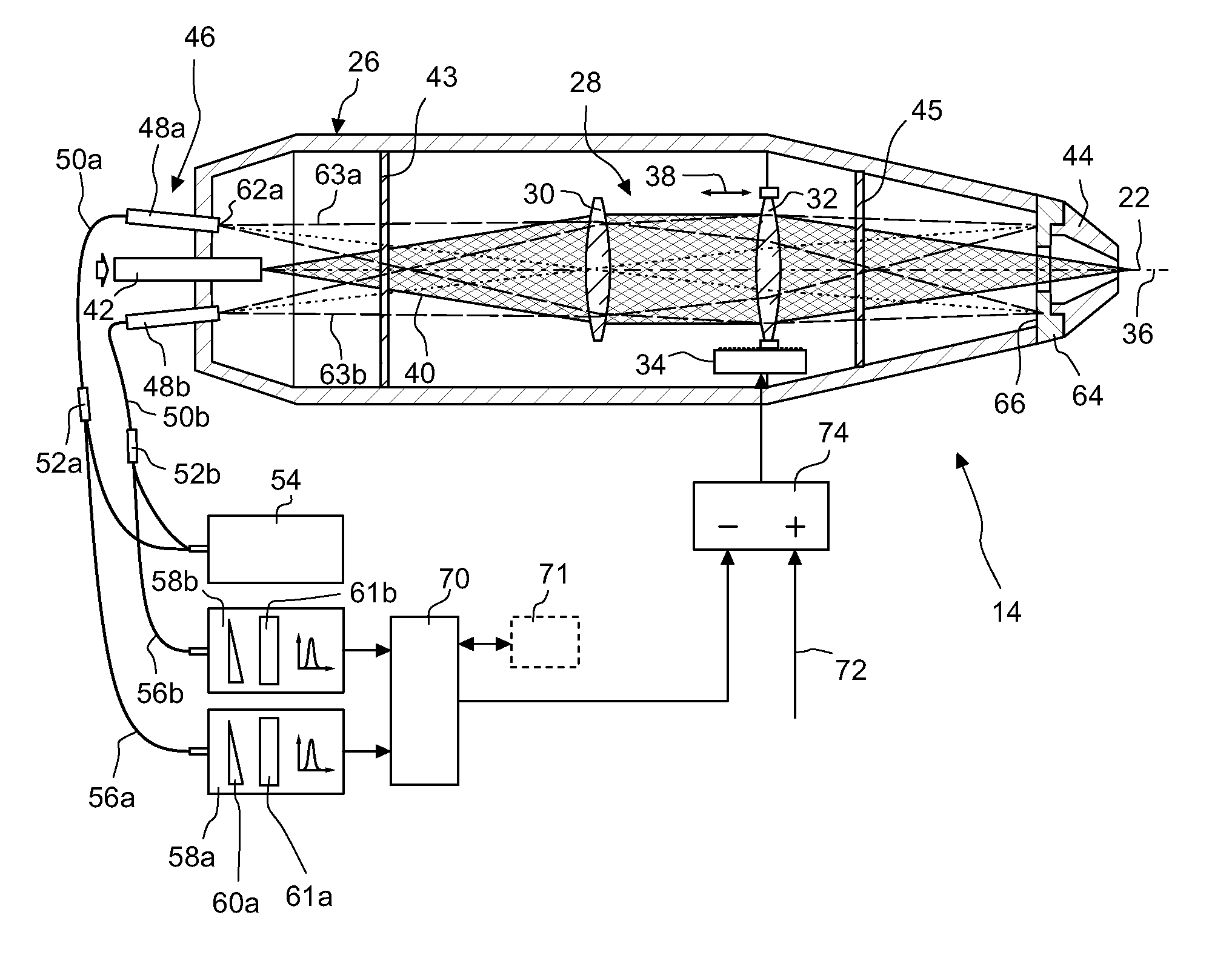

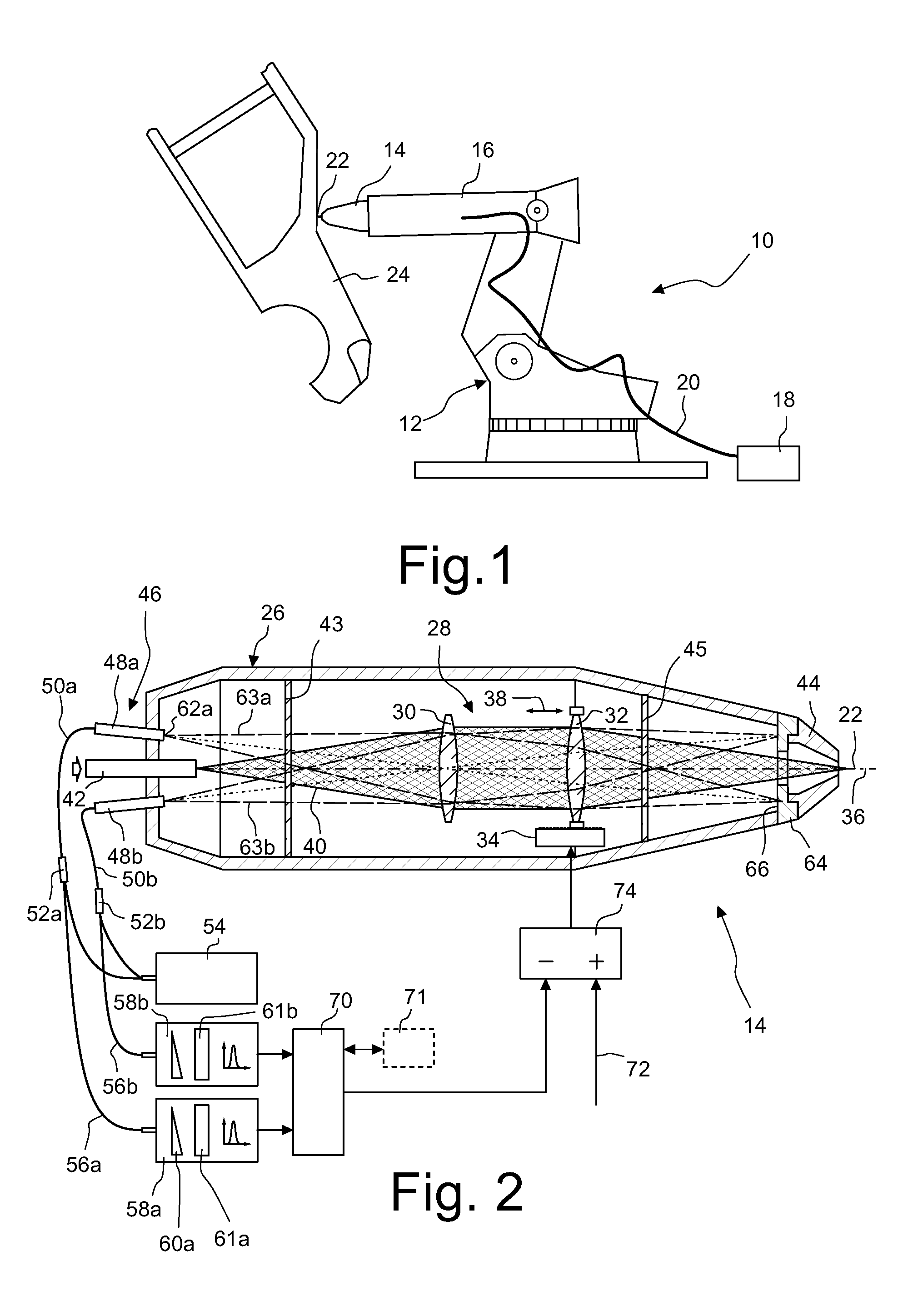

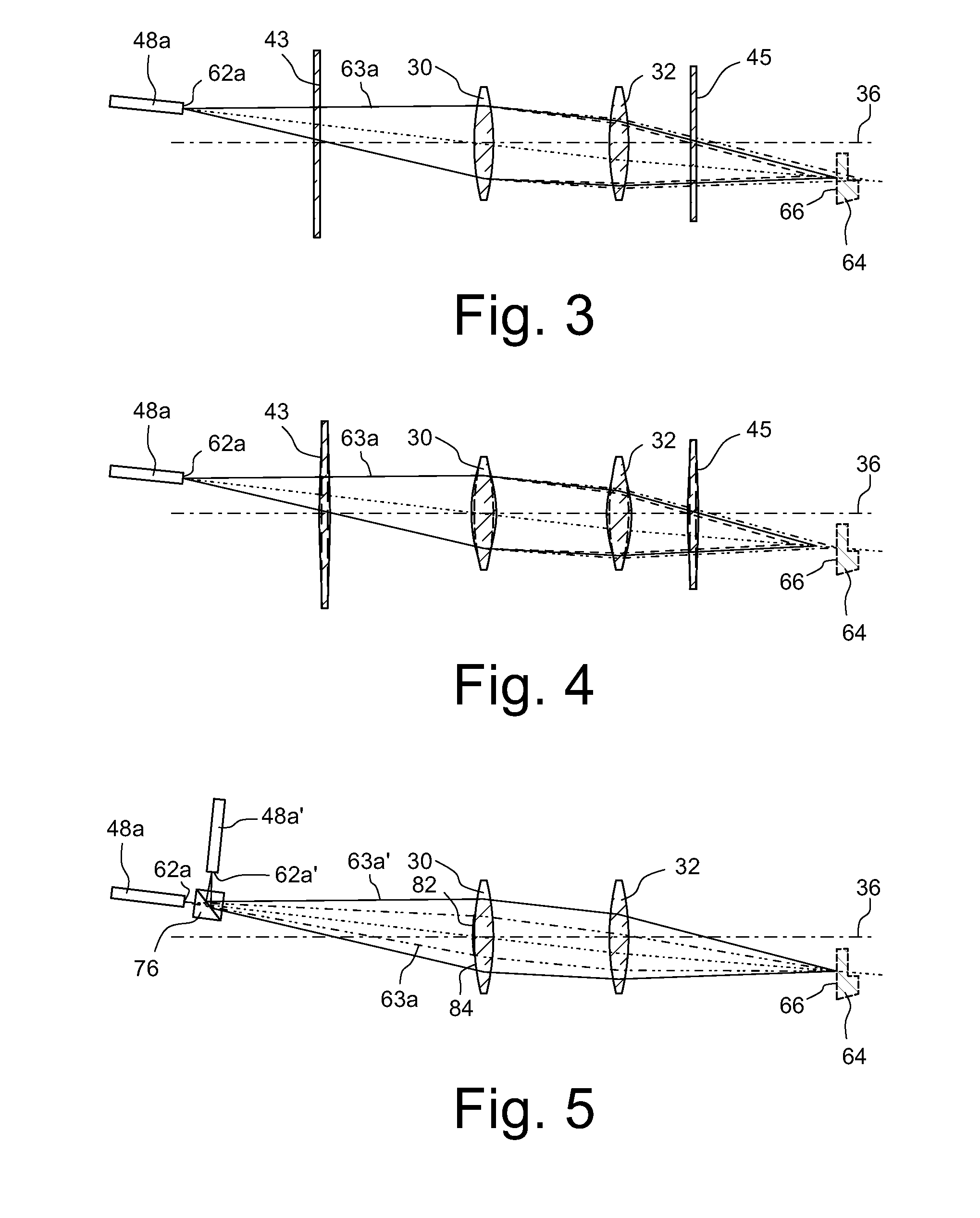

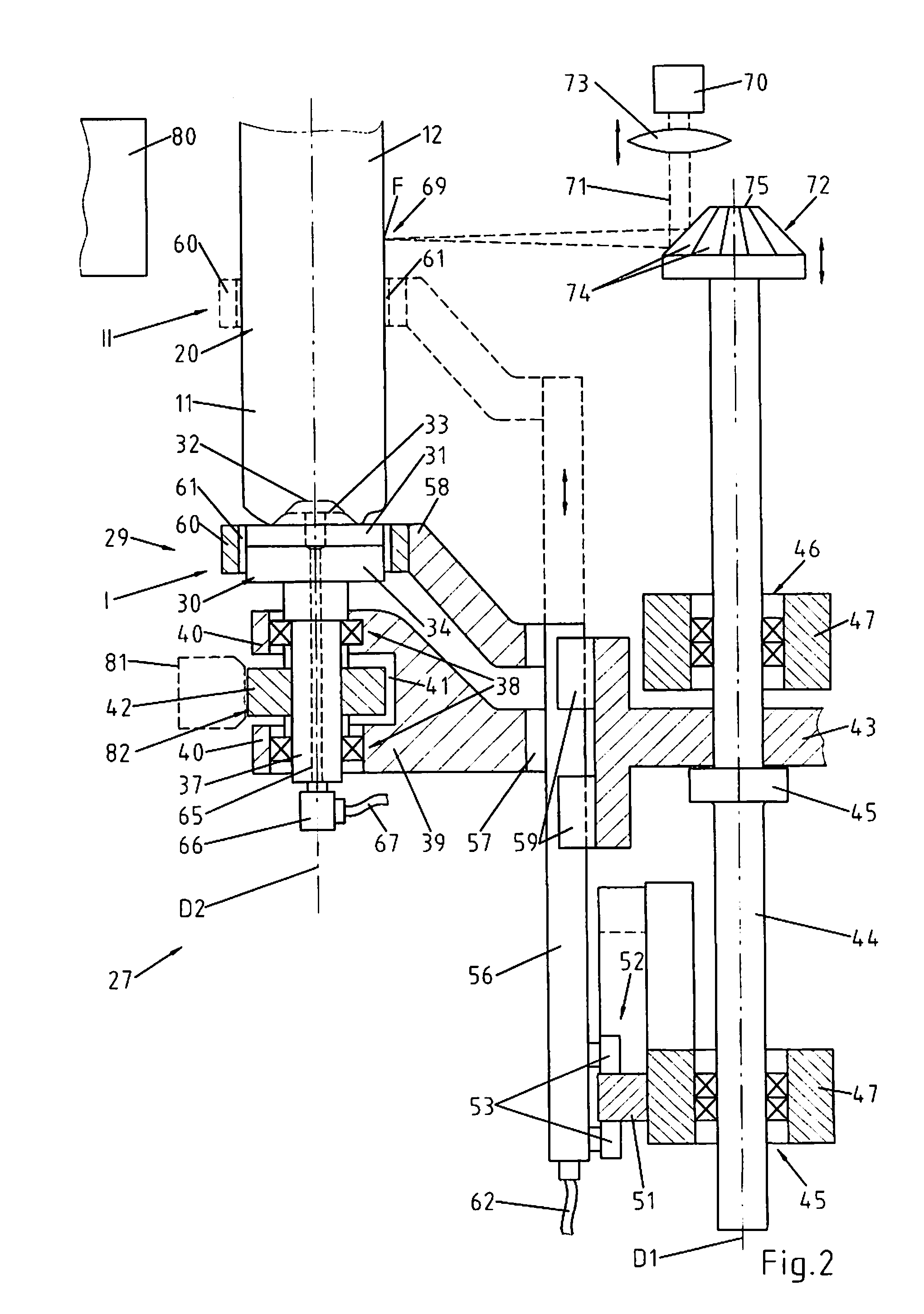

Laser Machining Apparatus with Adaptive Mirror

ActiveUS20140346155A1Stabilised betterSimple adaptationLaser beam welding apparatusOptoelectronicsInternal pressure

A laser machining apparatus comprises a laser radiation source that generates laser radiation. A first and a second adaptive mirror are provided each having a pressure chamber connected to a pressure source and a mirror substrate that bounds the pressure chamber. An internal pressure in the pressure chamber can be changed with the aid of the pressure source in such a way that the mirror substrate deforms if the internal pressure in the pressure chamber changes. The mirror substrate of the first adaptive mirror has a thickness which varies at least within a region of the mirror substrate that bounds the pressure chamber. The mirror substrate of the second adaptive mirror has a thickness which is constant over the entire region over which the mirror substrate is deformable.

Owner:LT ULTRA PRECISION TECH

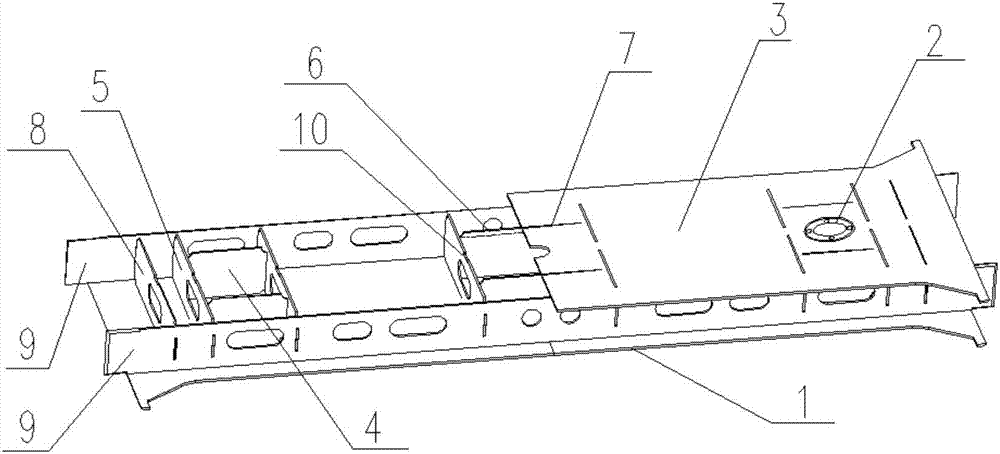

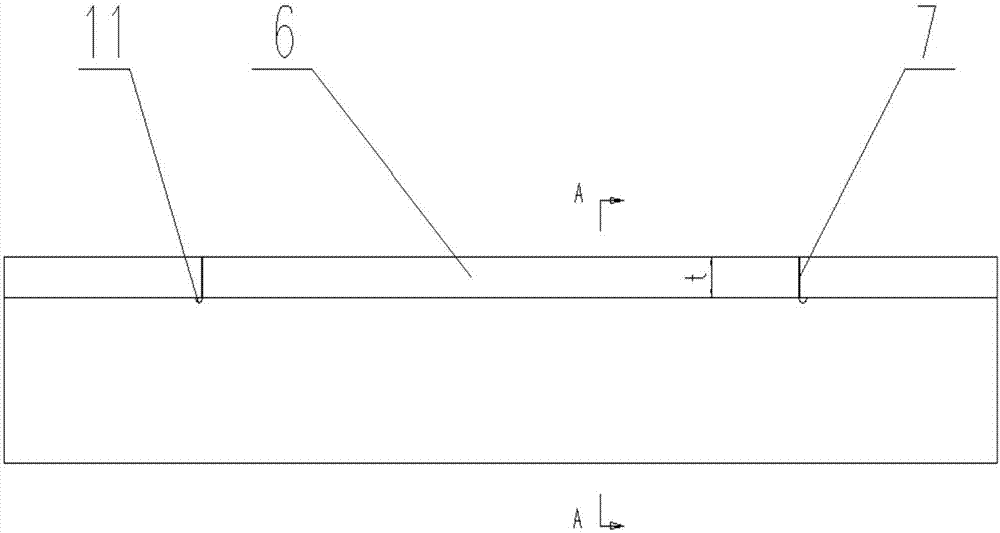

Composite welding method of pillow beam, pillow beam and rail vehicle with pillow beam

InactiveCN106964902AAchieve lightweightImprove corrosion resistanceUnderframesWorkpiece edge portionsManufacturing technologyEngineering

Owner:CRRC QINGDAO SIFANG CO LTD

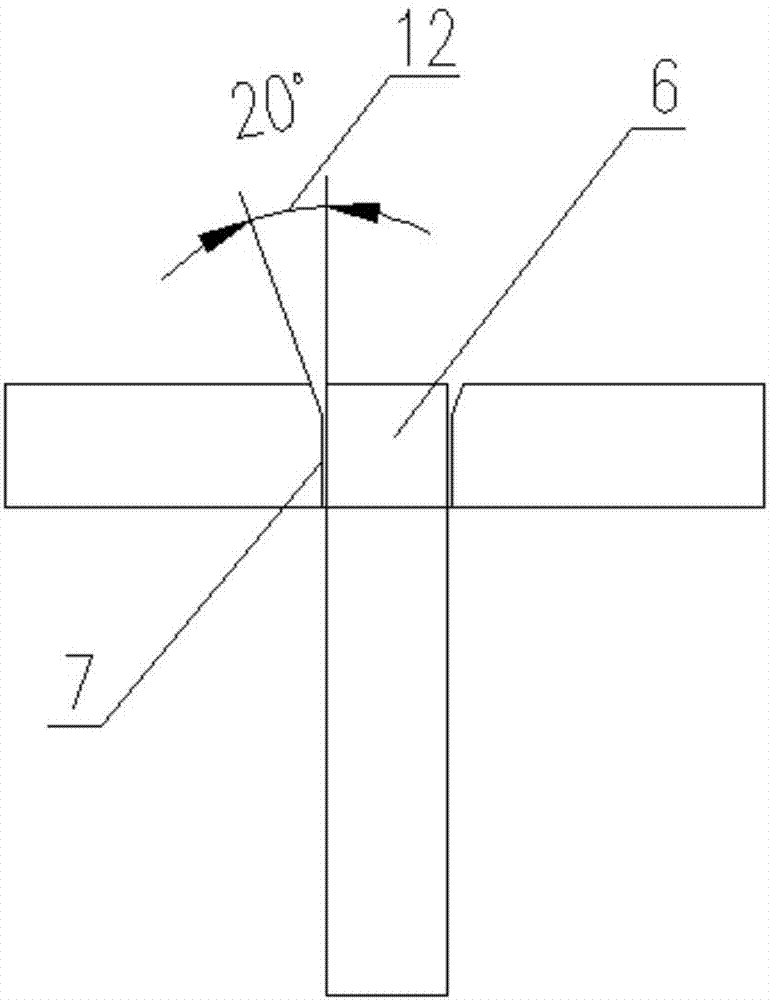

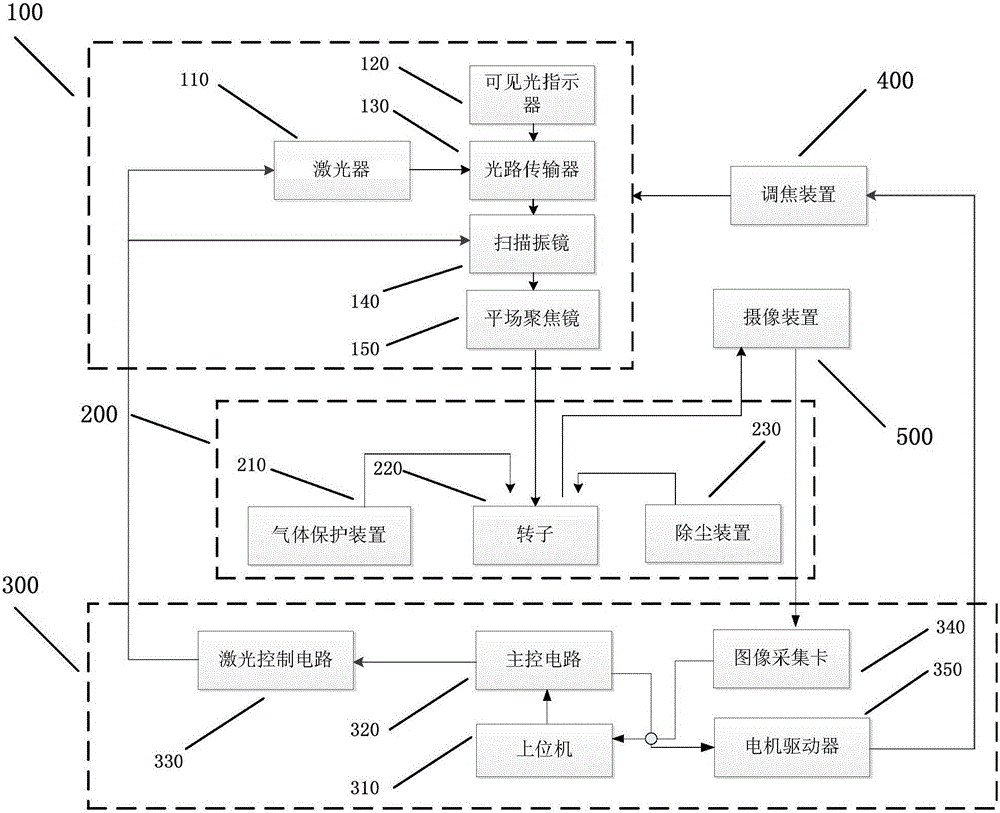

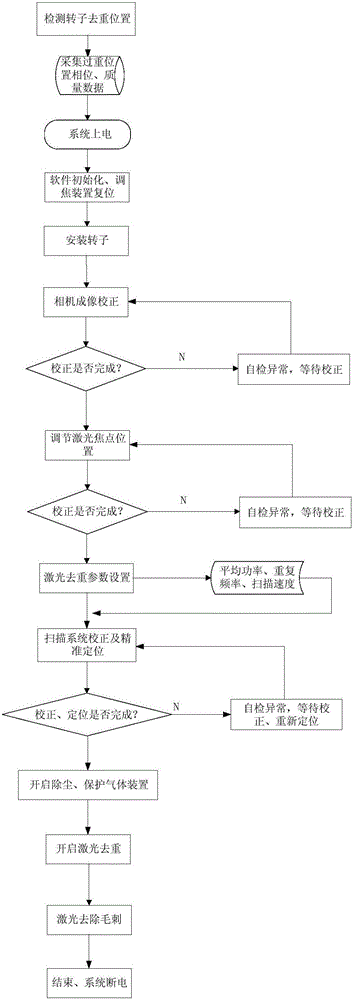

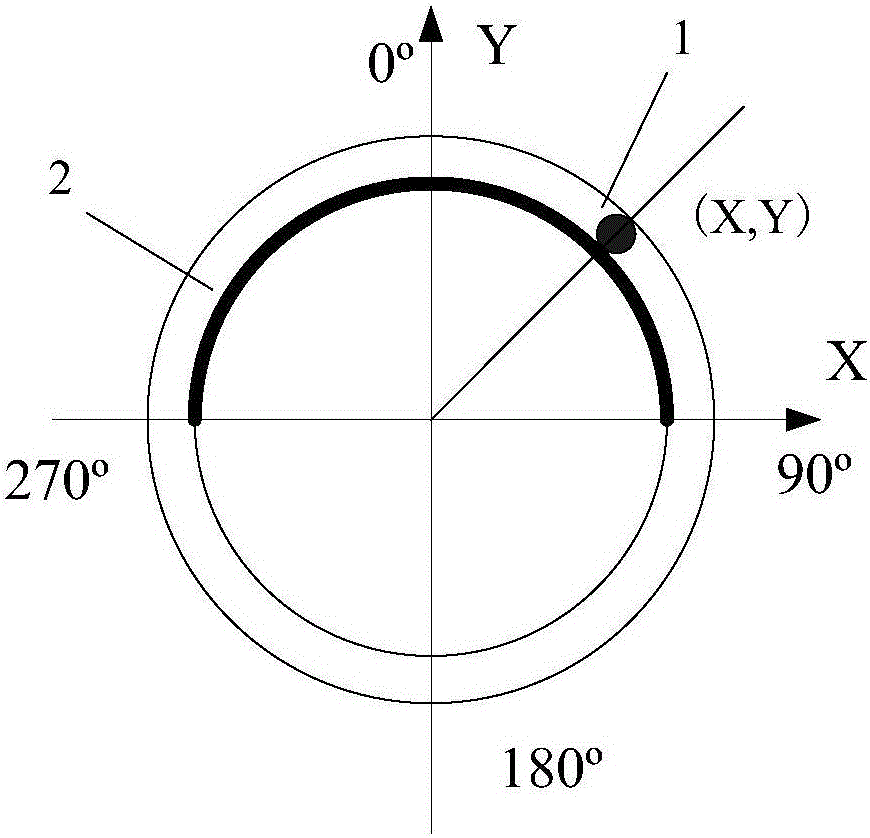

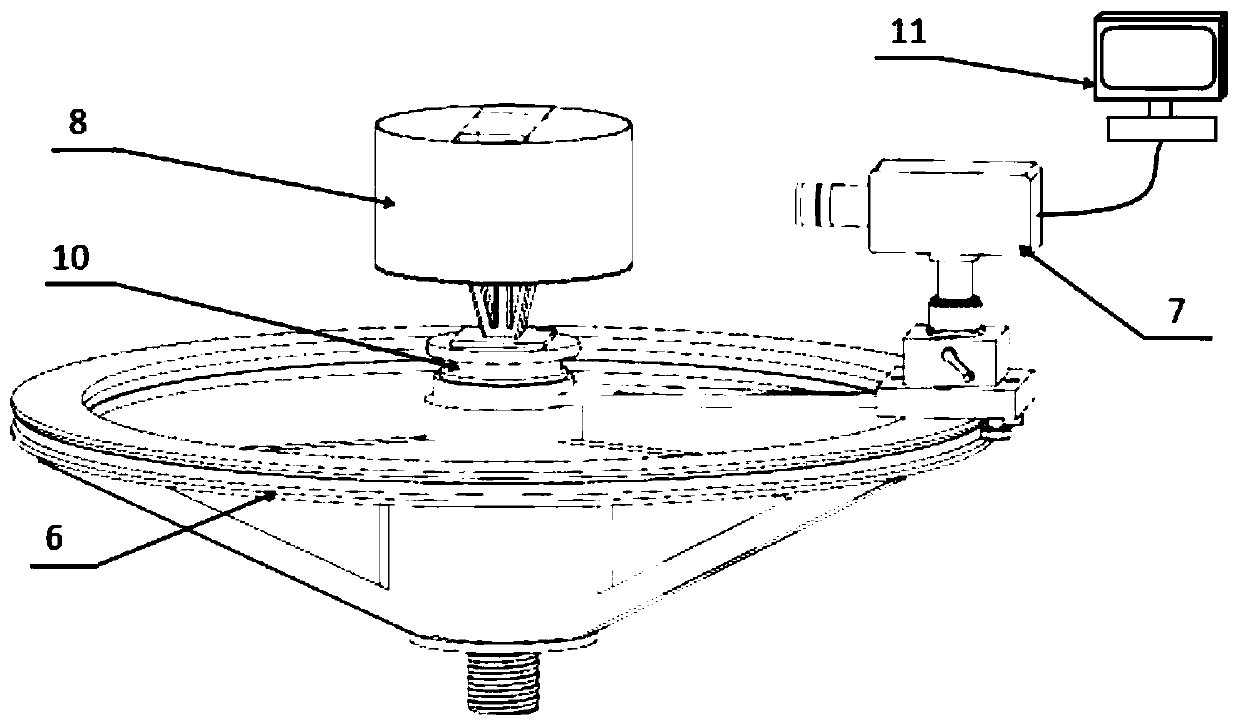

Laser precision de-weight system and method

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

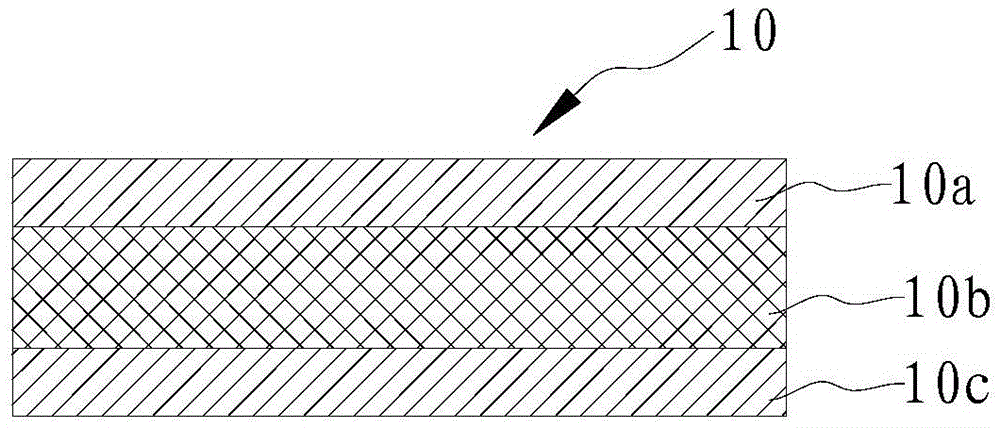

Polysilicon thin film transistor and method of fabricating the same

A method of fabricating a polycrystalline silicon thin film transistor is disclosed. One embodiment of the method includes: forming an amorphous silicon layer on a panel; scanning a continuous wave laser beam having a wavelength range of about 600 to about 900 nm between a visible light range of a red color and a near infrared range onto the amorphous silicon layer to preheat the amorphous silicon layer; overlappingly scanning a pulse laser beam having a wavelength range of about 100 to about 550 nm between a visible light range and an ultraviolet range in addition to the continuous wave laser beam on the panel to melt the preheated amorphous silicon layer; and stopping scanning the pulse laser beam to crystallize the molten silicon layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Laser etched trim

Owner:ADIENT LUXEMBOURG HLDG SARL

Device and method for cutting off an end section of a can blank

InactiveUS20140346154A1Sufficient time availableStock shearing machinesMetal working apparatusEngineeringLaser cutting

Owner:SCHULER PRESSEN GMBH & CO KG

Multi-wavelength femtosecond laser scanning type etching method for printed circuit board

InactiveCN105562939AEasy to processImprove machining accuracyPrinted circuitsMetal working apparatusEtchingLine width

Owner:SUZHOU UNIV

Particle control in laser processing systems

ActiveUS20130087547A1Reduce pollutionElectric heating for furnacesLaser beam welding apparatusLaser processingOxygen

Owner:APPLIED MATERIALS INC

Compact, method for producing compact, reactor, converter, and power conversion device

InactiveUS20130322135A1Efficient productionTotal current dropTransportation and packagingInorganic material magnetismMetallurgyIrradiation

A low-loss compact and a method for producing the compact are provided.A method for producing a compact by using coated soft magnetic powder that includes coated soft magnetic particles constituted by soft magnetic particles and insulating coatings coating outer peripheries of the soft magnetic particles includes a raw material preparation step and an irradiation step. In the raw material preparation step, a raw compact is prepared by press-forming coated soft magnetic powder. In the irradiation step, part of a surface of the raw compact is irradiated with a laser. Irradiating a part of a surface of a raw compact with laser increases the number of disrupted portions of conductive portions where constituent materials of the soft magnetic particles at the surface of the raw compact have become conductive to each other, and the loss of the compact can be decreased.

Owner:SUMITOMO ELECTRIC IND LTD +1

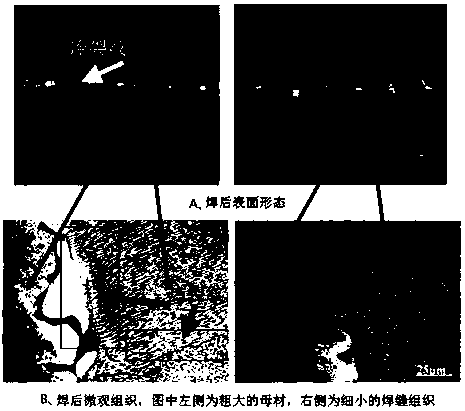

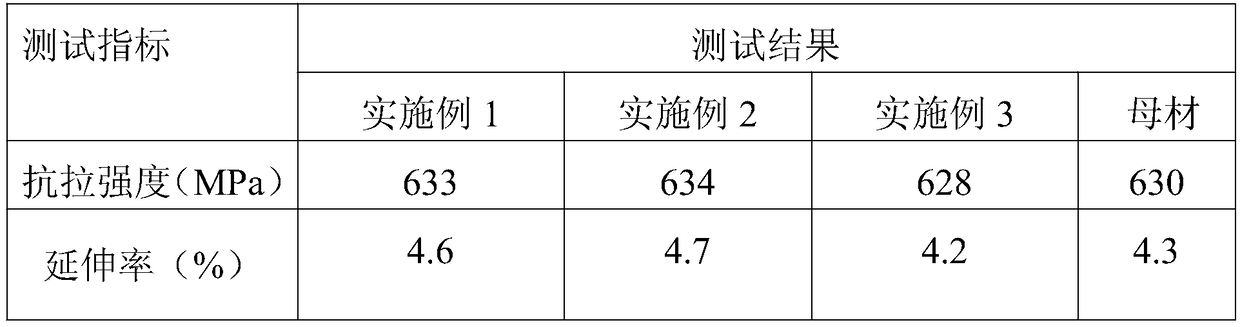

Laser welding method of CoCrCuFeNi high-entropy alloy

ActiveCN108747006AHigh strengthImprove plasticityLaser beam welding apparatusCrazingHigh entropy alloys

Owner:GUIZHOU INST OF TECH

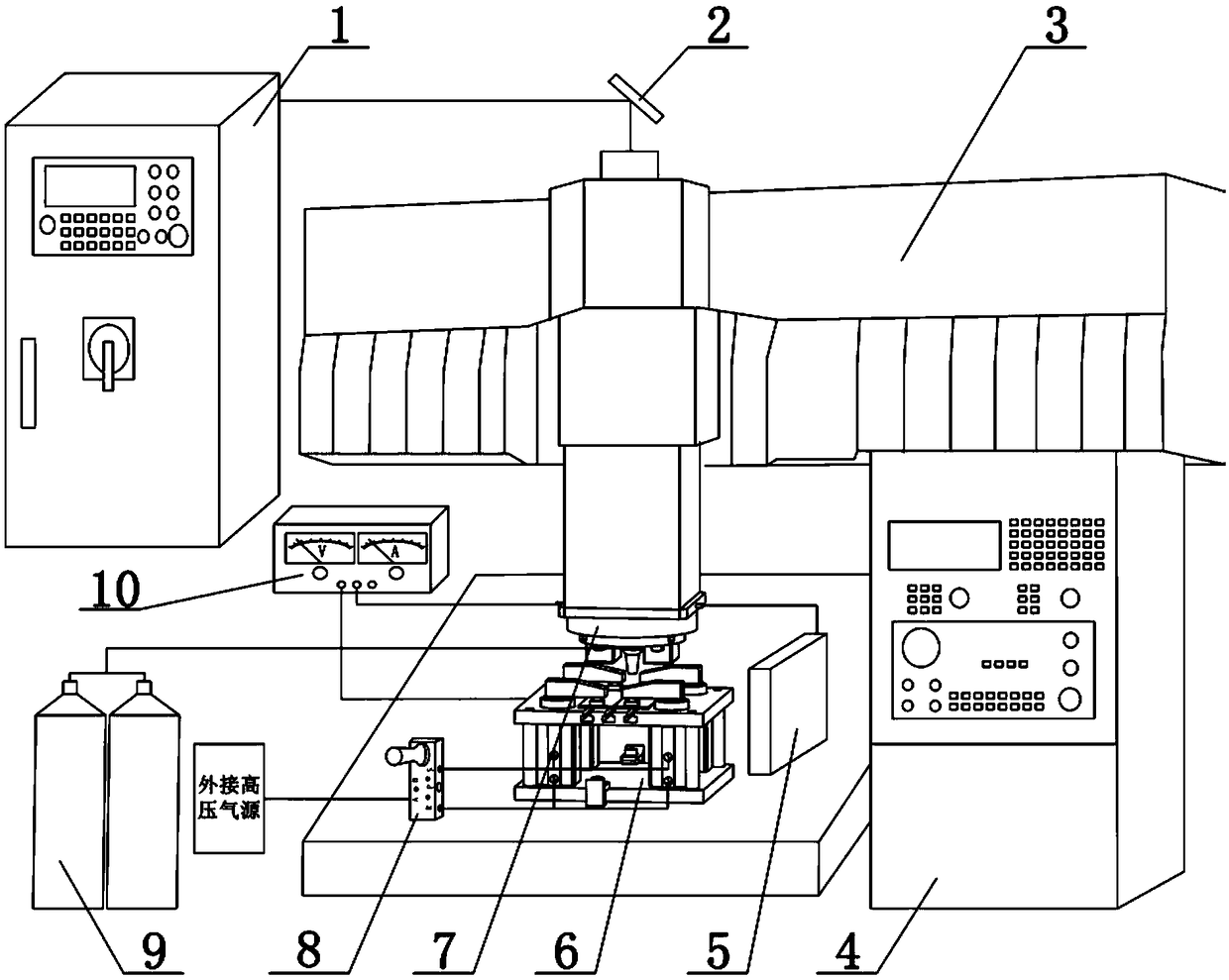

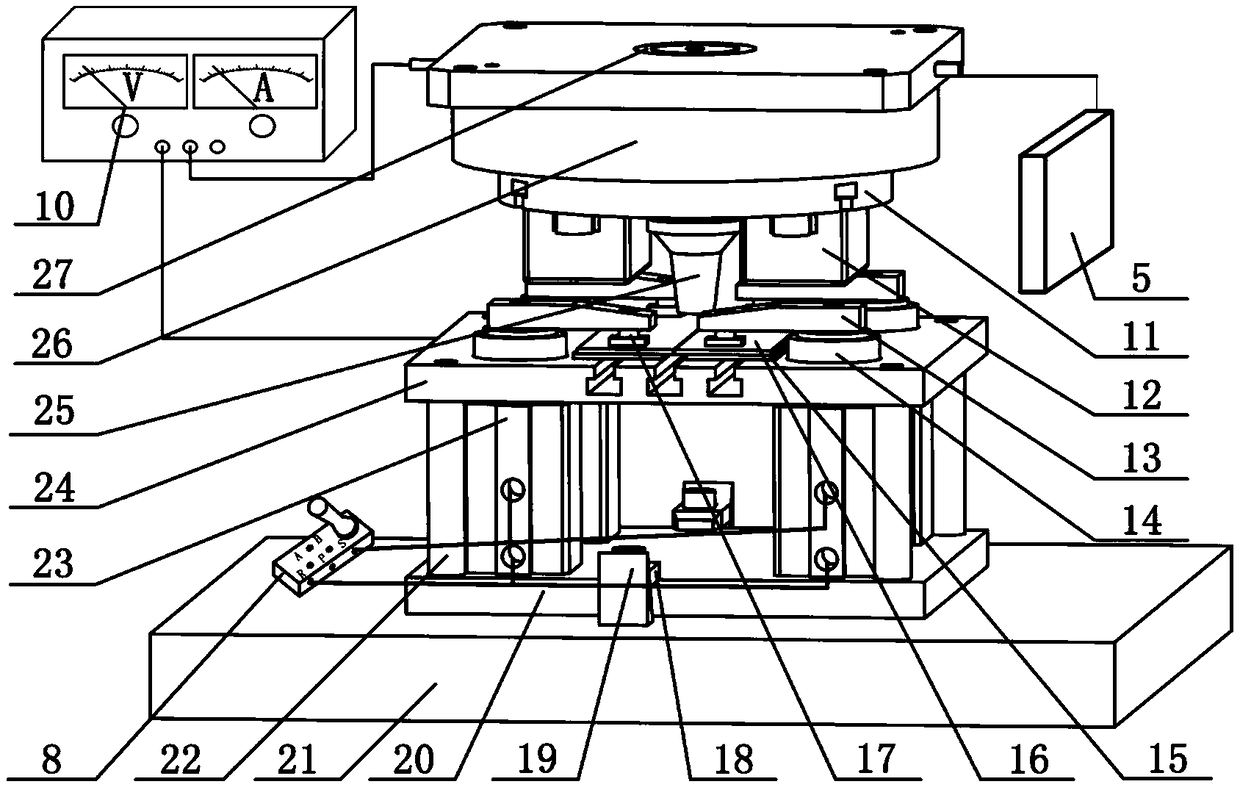

Rotary electric field and magnetic field synchronously assisted laser welding device and method

Owner:CHANGCHUN UNIV OF SCI & TECH

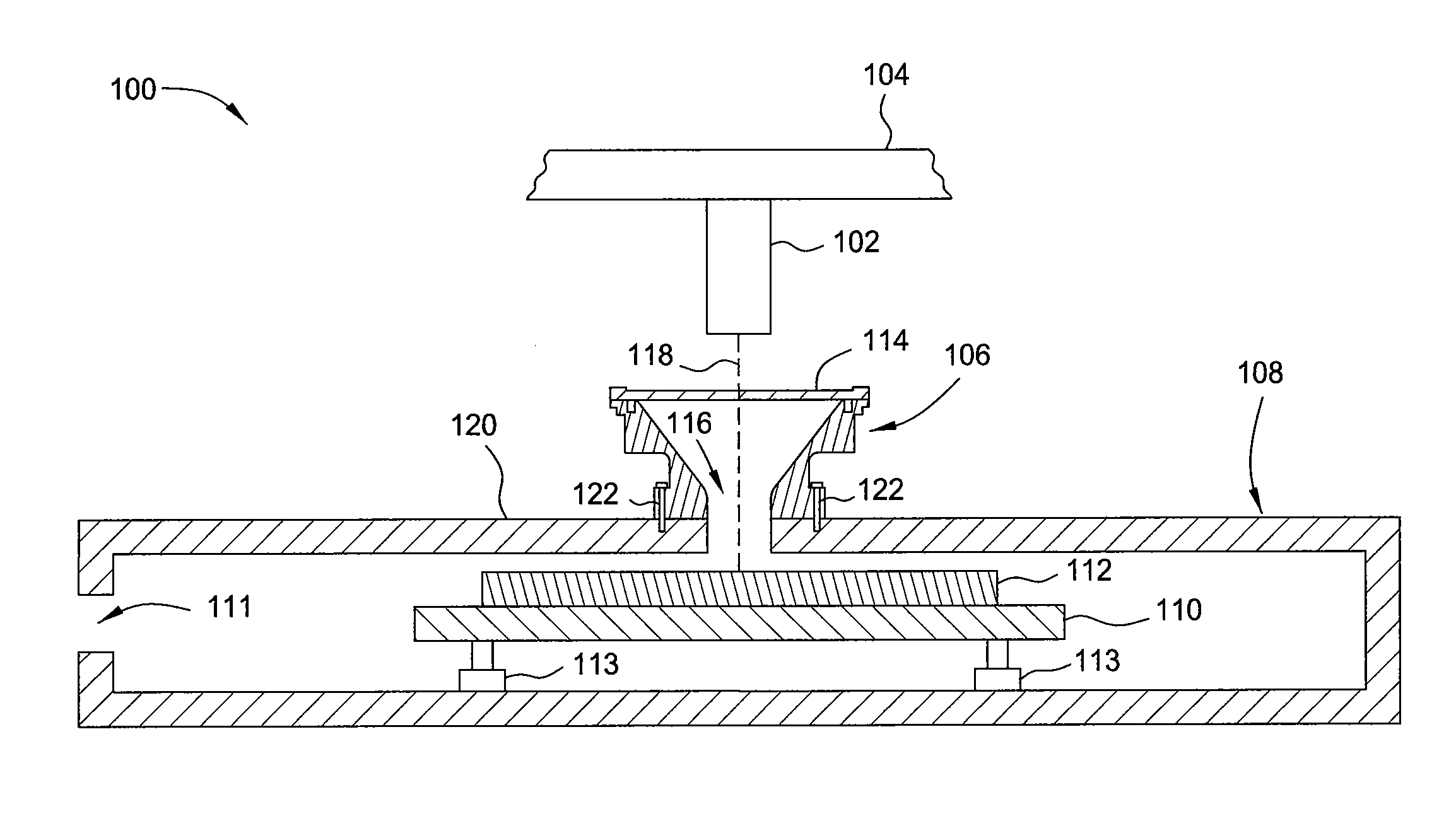

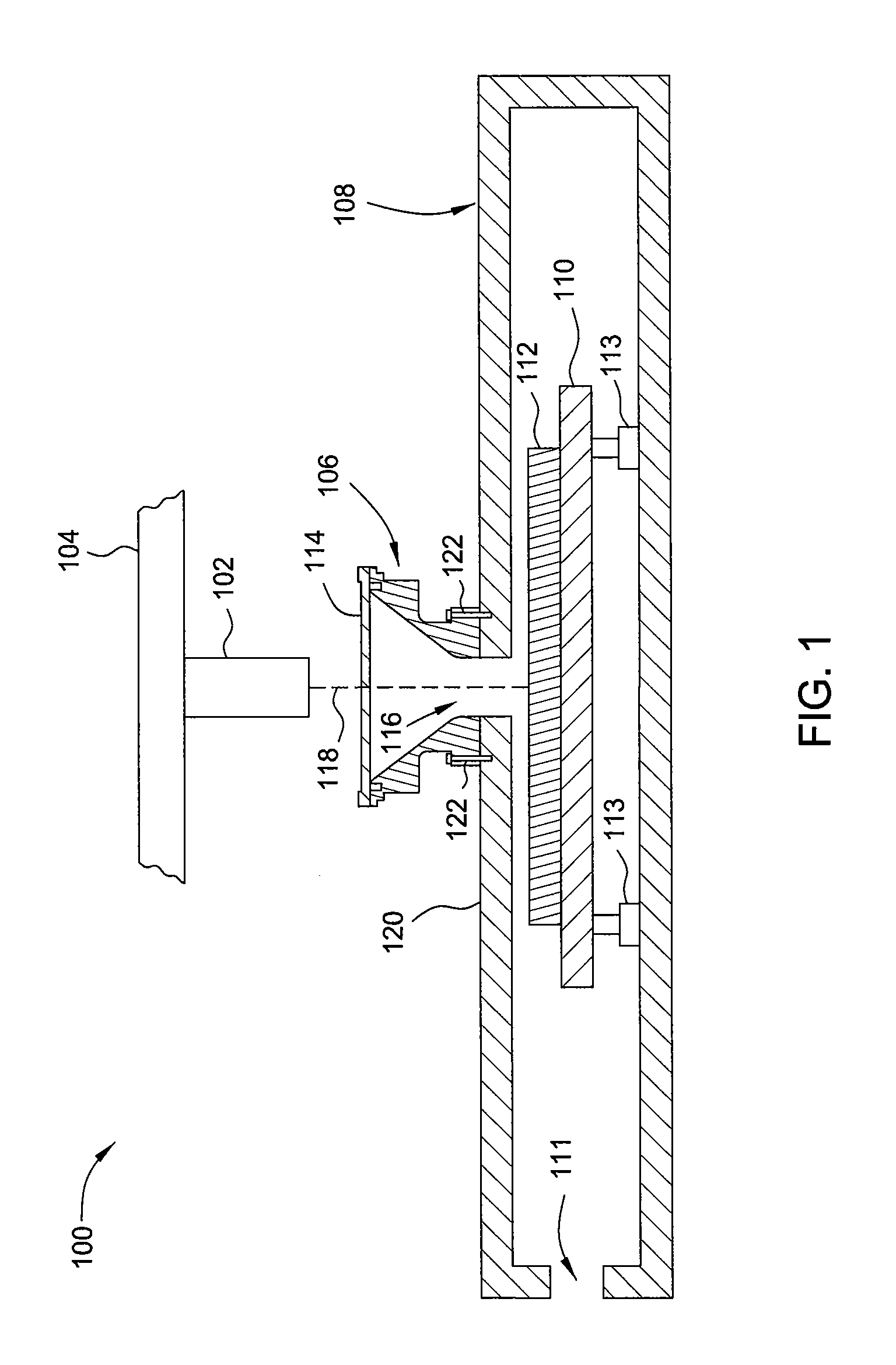

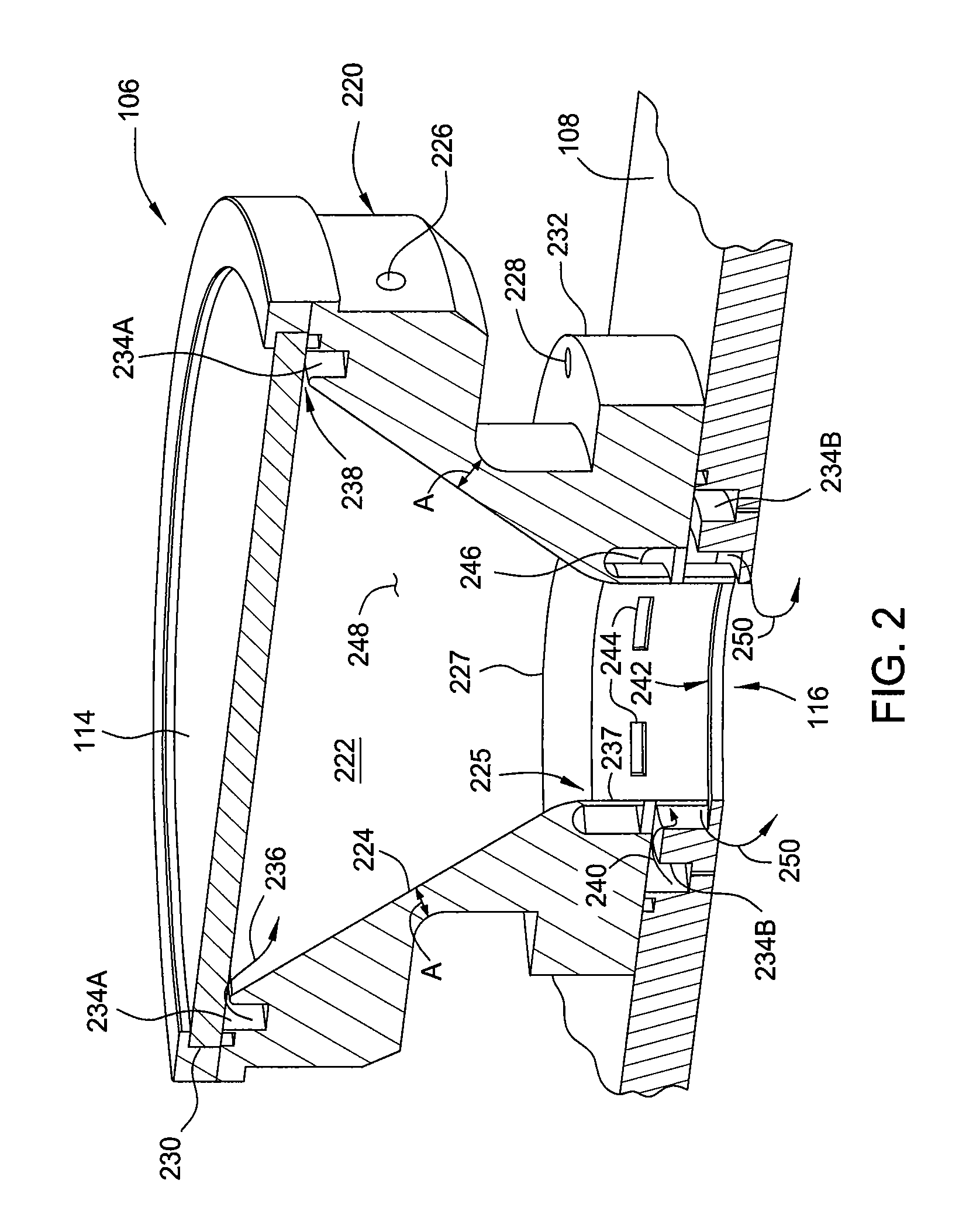

Avoiding hot cracks during laser welding of a workpiece stack-up assembly of aluminum alloy workpieces

ActiveUS20180243861A1Vehicle componentsWelding/soldering/cutting articlesIntermediate stageOptoelectronics

A method of laser welding a workpiece stack-up that includes two or more overlapping aluminum alloy workpieces is disclosed. The method involves controlling the power level of the laser beam during at least one of an initial stage or a final stage of advancing the laser beam along a weld path so as to limit a line energy of the laser beam during such stage or stages to being no greater than 10% above a line energy of the laser beam during an intermediate stage of laser beam advancement that is performed between the initial and final stages. By limiting the line energy during the initial and / or final stages of laser beam advancement along the weld path, excessive fusion of the workpiece stack-up assembly can be avoided in those locations to help protect against hot-cracking in the resultant laser weld joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

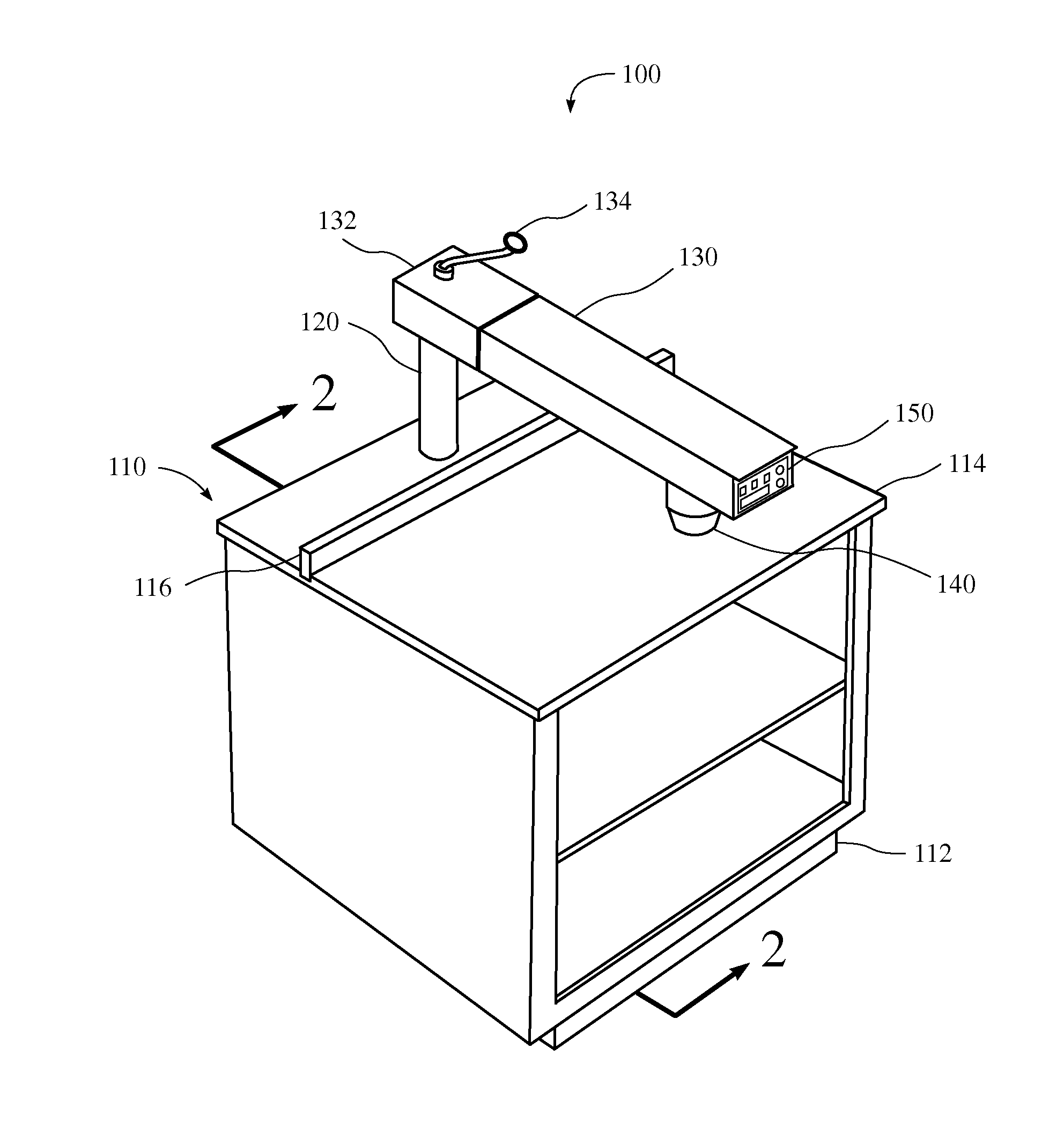

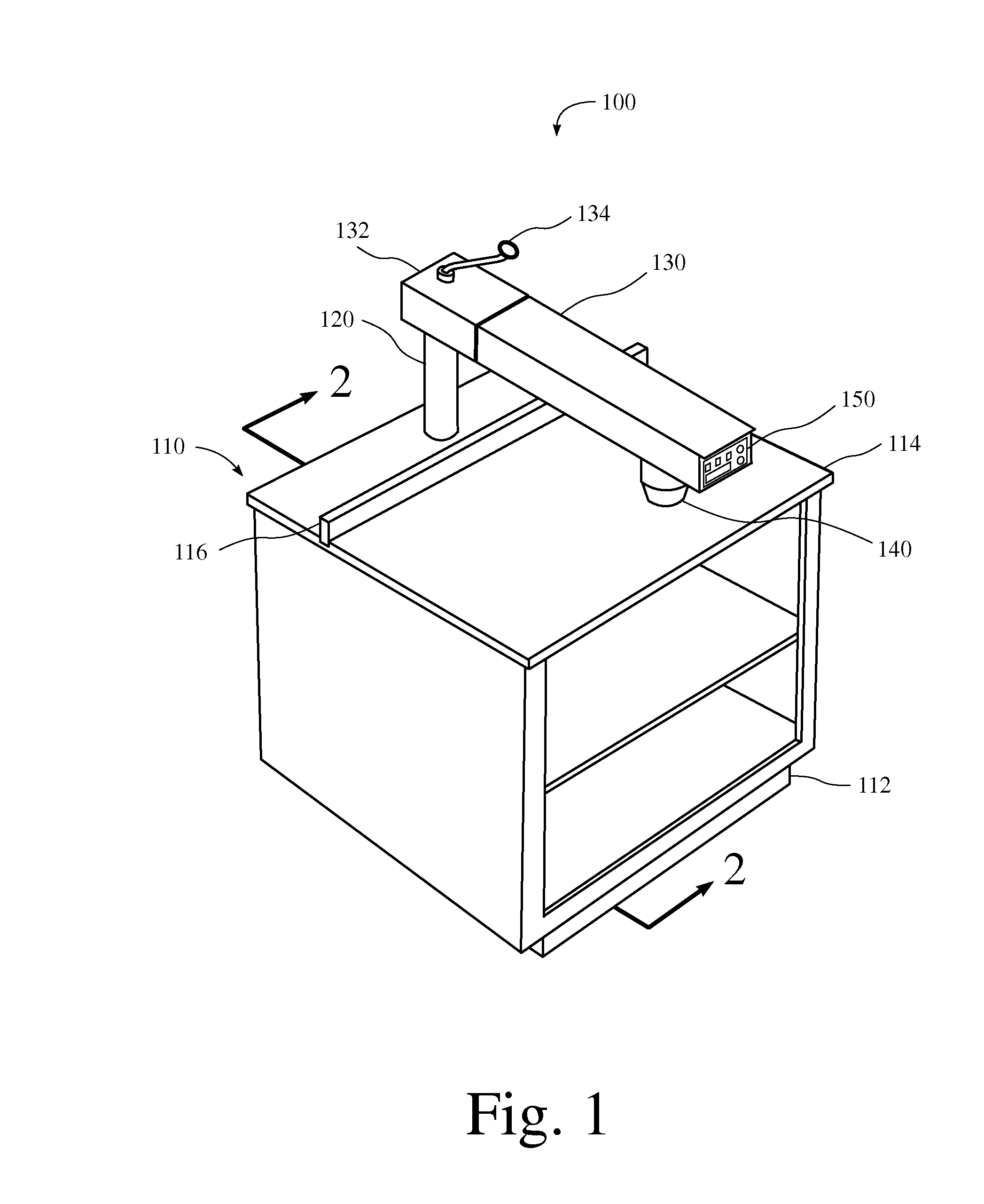

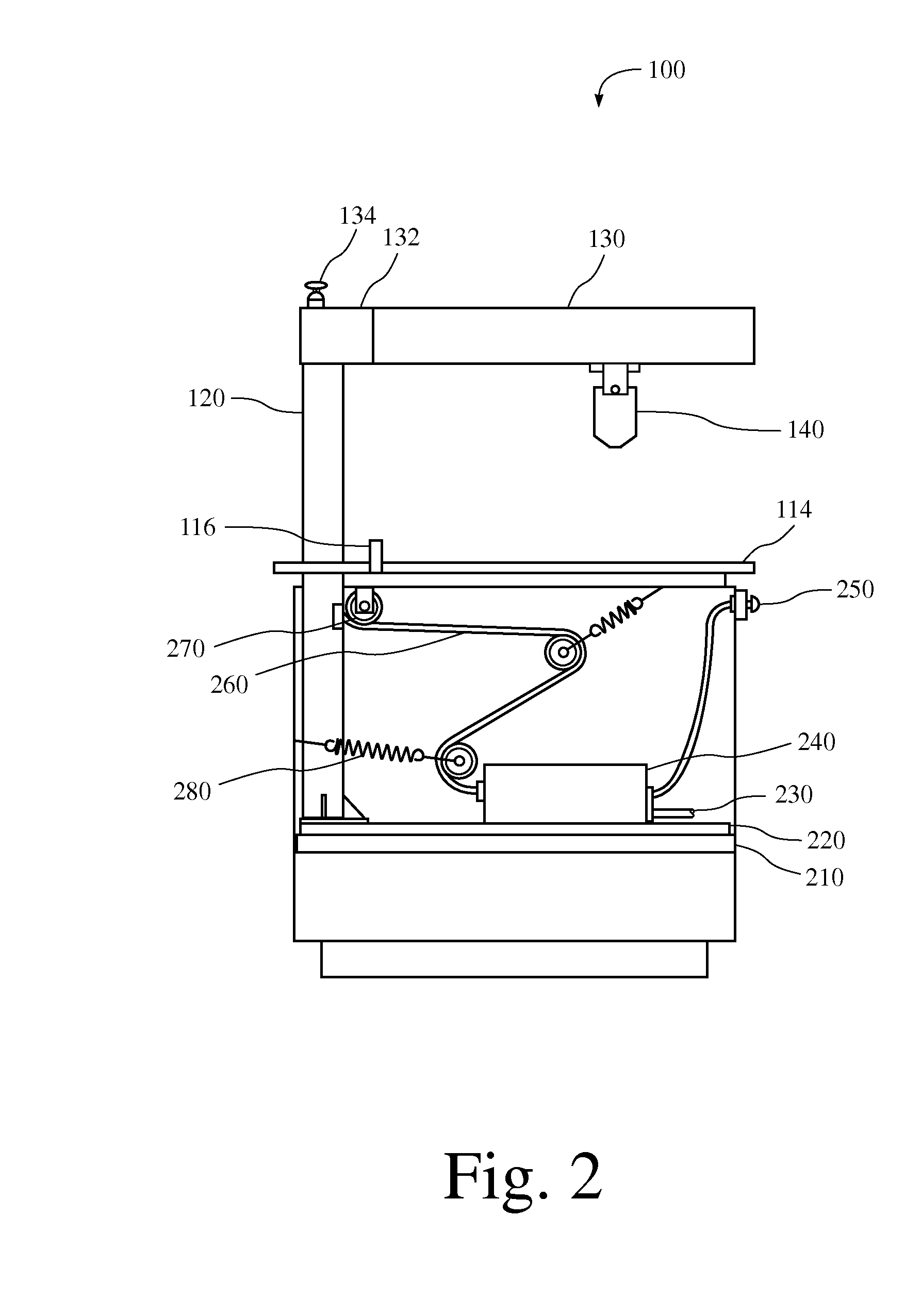

Laser Woodworking Machine

InactiveUS20120037274A1Reasonable space requirementImprove the security environmentWooden sticks manufactureMulti-purpose machinesEngineeringLaser cutting

Owner:HENDERSON CHARLES L

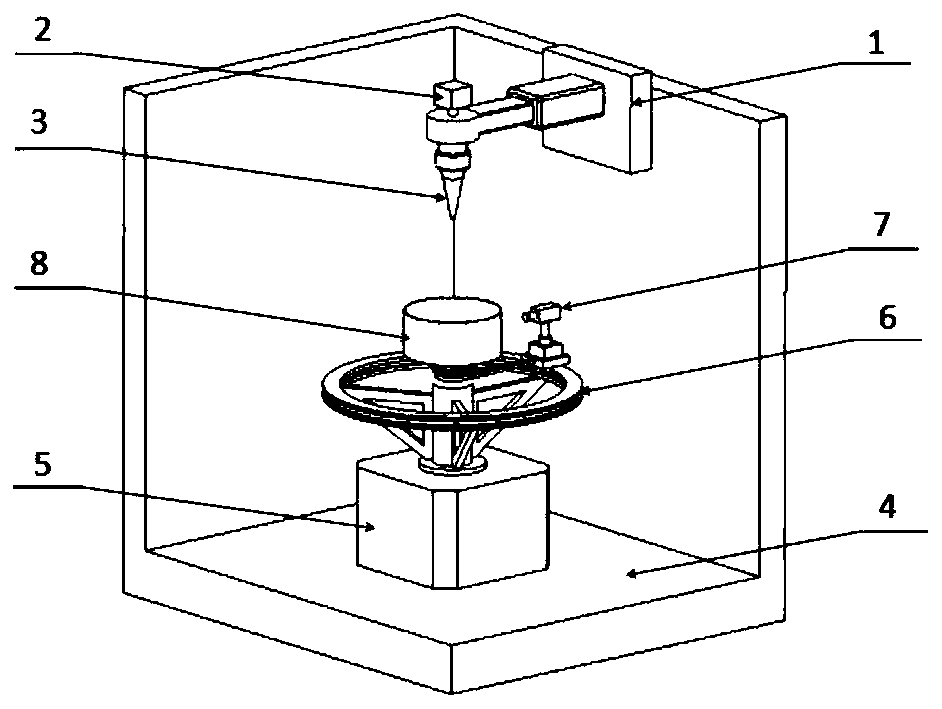

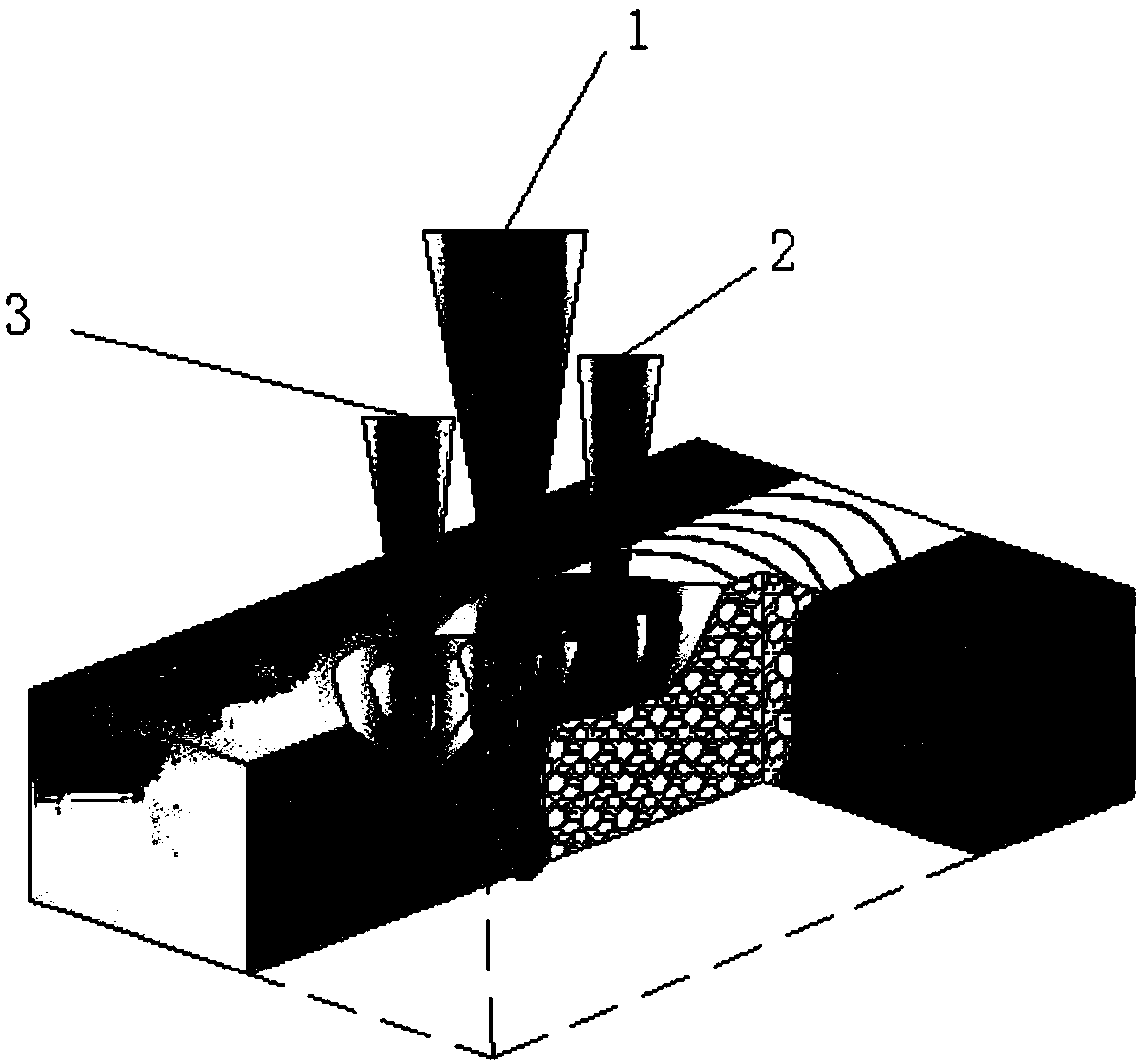

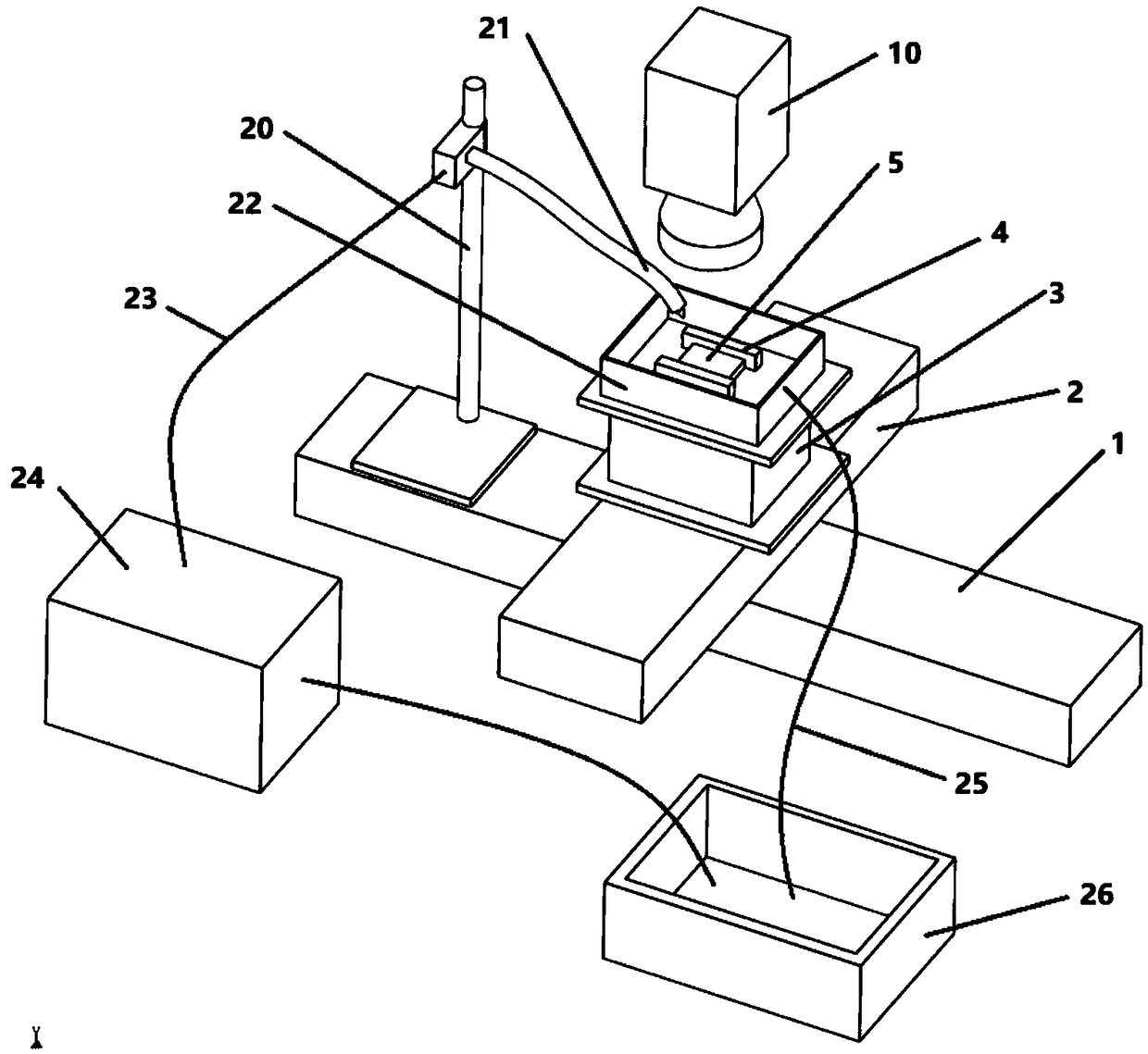

Adjustable magnetic field coupling and ultrasonic-assisted laser additive manufacturing and monitoring device

InactiveCN110280904AWide range motion captureComprehensive perspectiveLaser beam welding apparatusUltrasonic assistedLaser Nozzle

Owner:JIANGSU UNIV

Flow adjuster and processing devices

InactiveCN1406707ALow priceImprove reliabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTraffic volume

This invention provides a flow amount adjustment apparatus able to adjust flow amount with high reliability at a low cost without being oversized. The flow amount adjustment apparatus has a plurality of orifices having different bore diameter for a predetermined flow amount, respectively, the orifices being opened and closed by an open-close member, respectively; a primary piping connected to each of the orifices for supplying gas adjusted to a prescribed pressure; and a secondary piping connected to each of the orifices for gathering gas passed through an opened orifice or a plurality of opened orifices, wherein one orifice or a plurality of orifices capable of satisfying a prescribed flow amount are selected and opened.

Owner:KOIKE SANSO KOGYO CO LTD

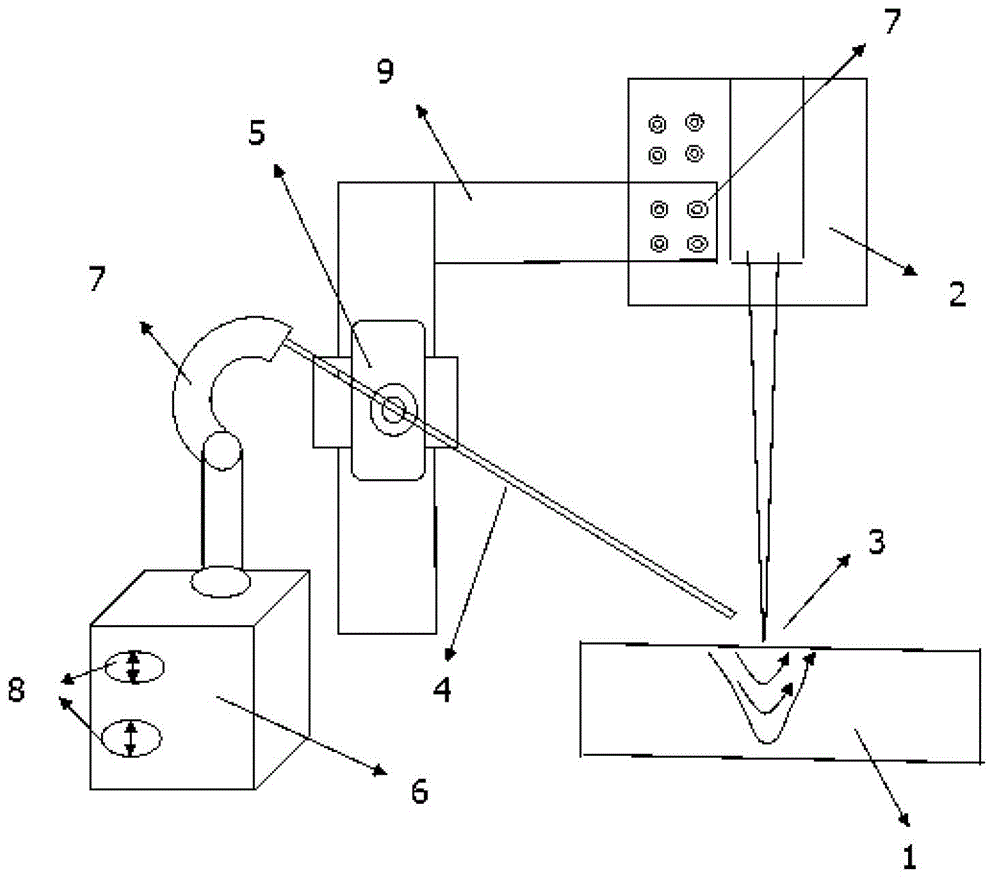

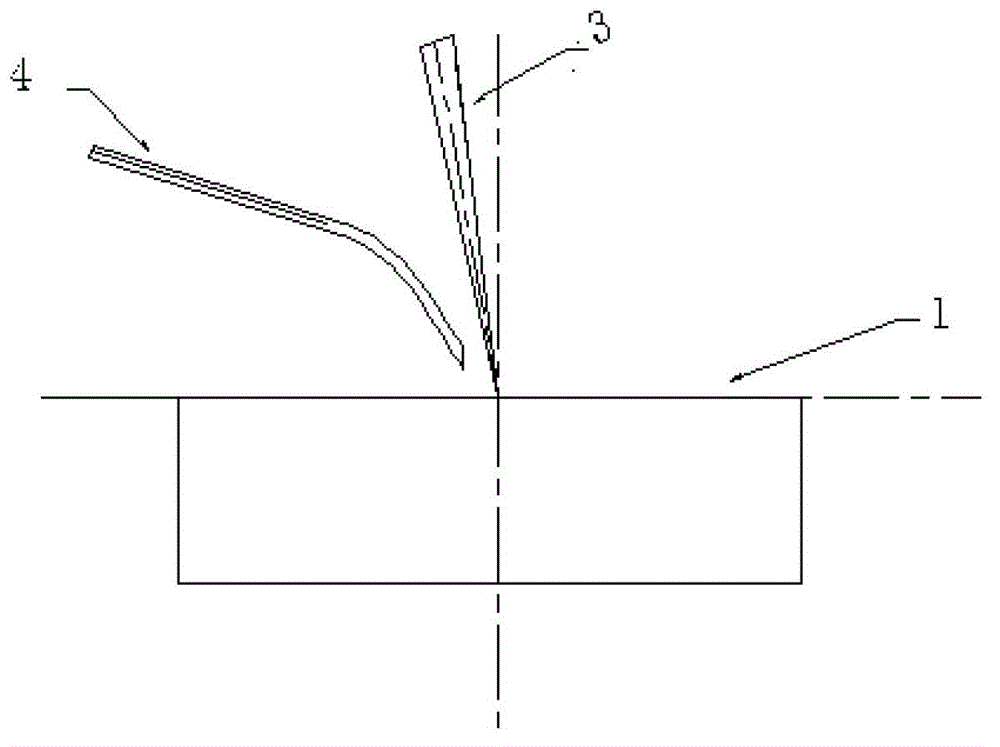

Method and device for controlling laser welding seam holes

InactiveCN102941412AGuaranteed patencyAvoid formingLaser beam welding apparatusThick plateEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

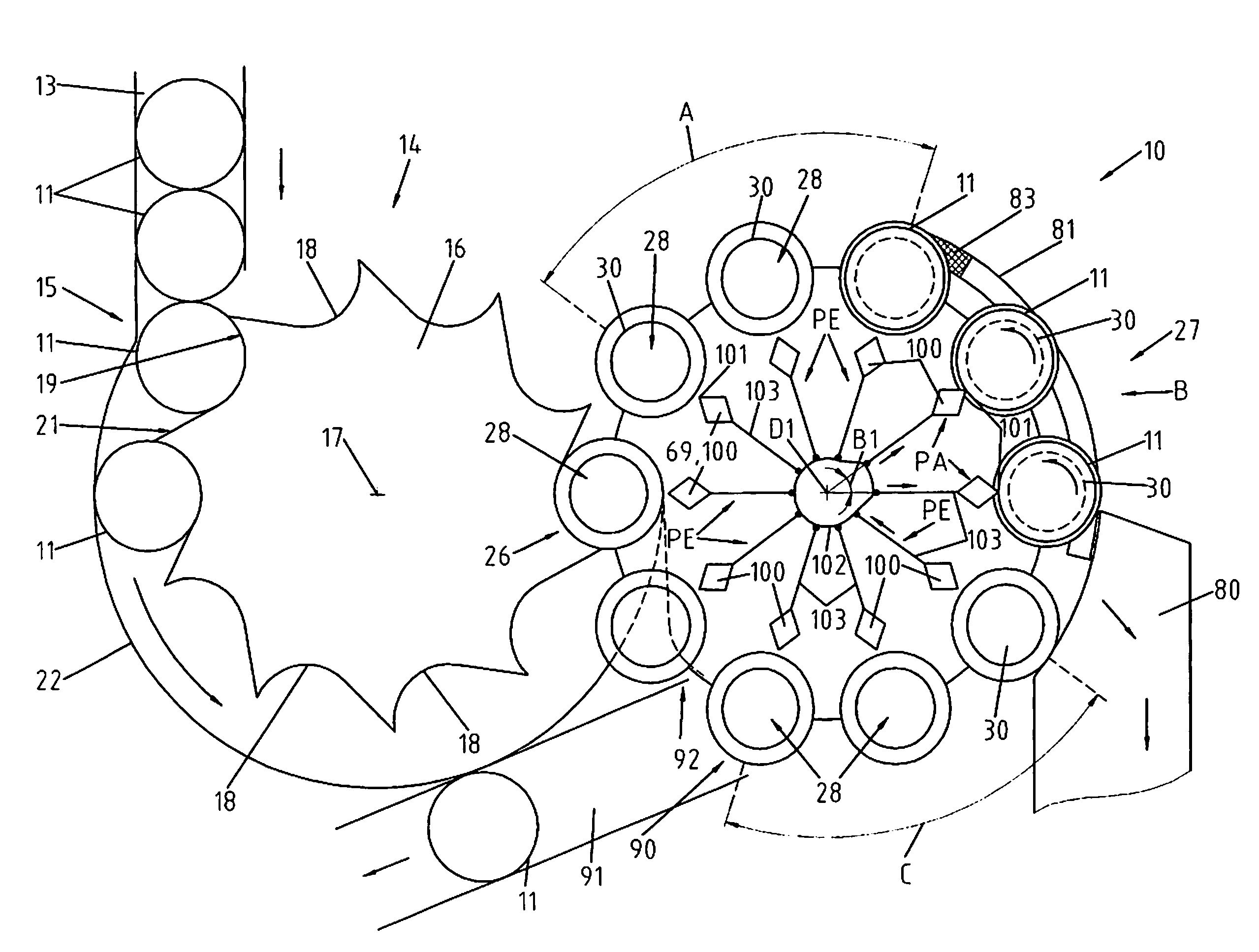

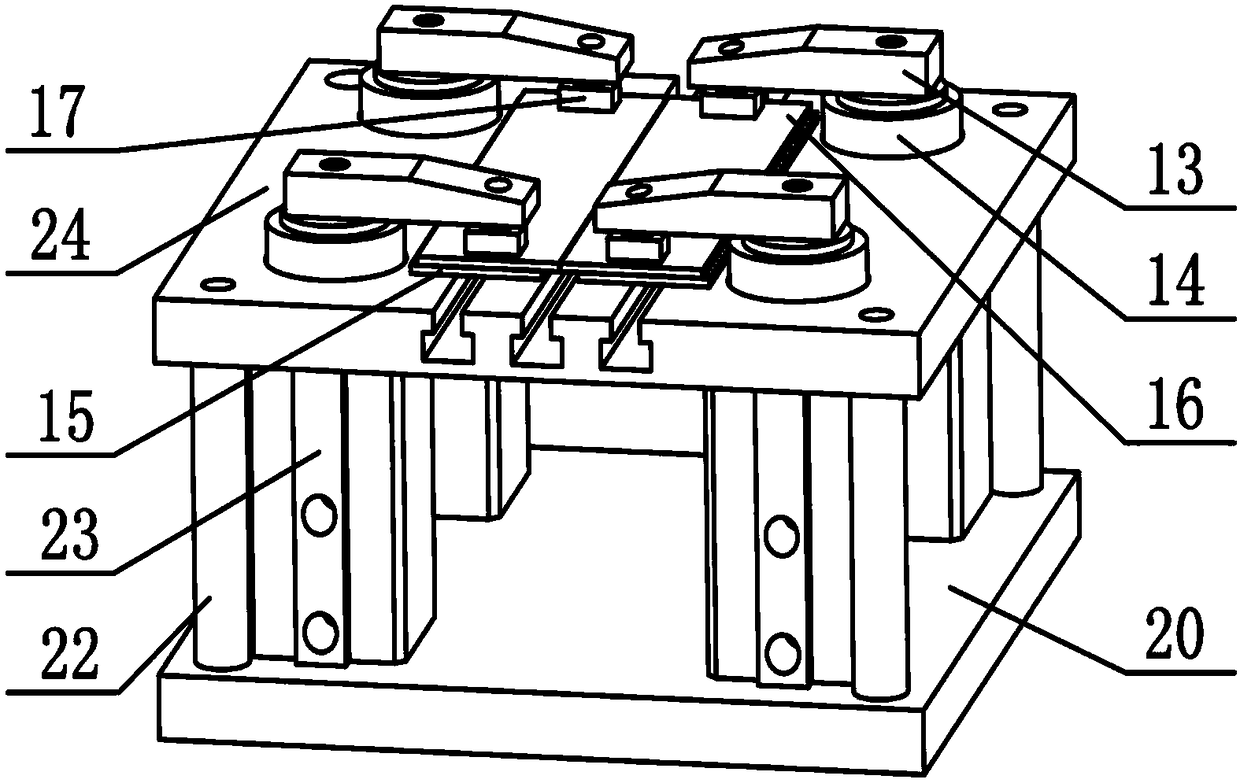

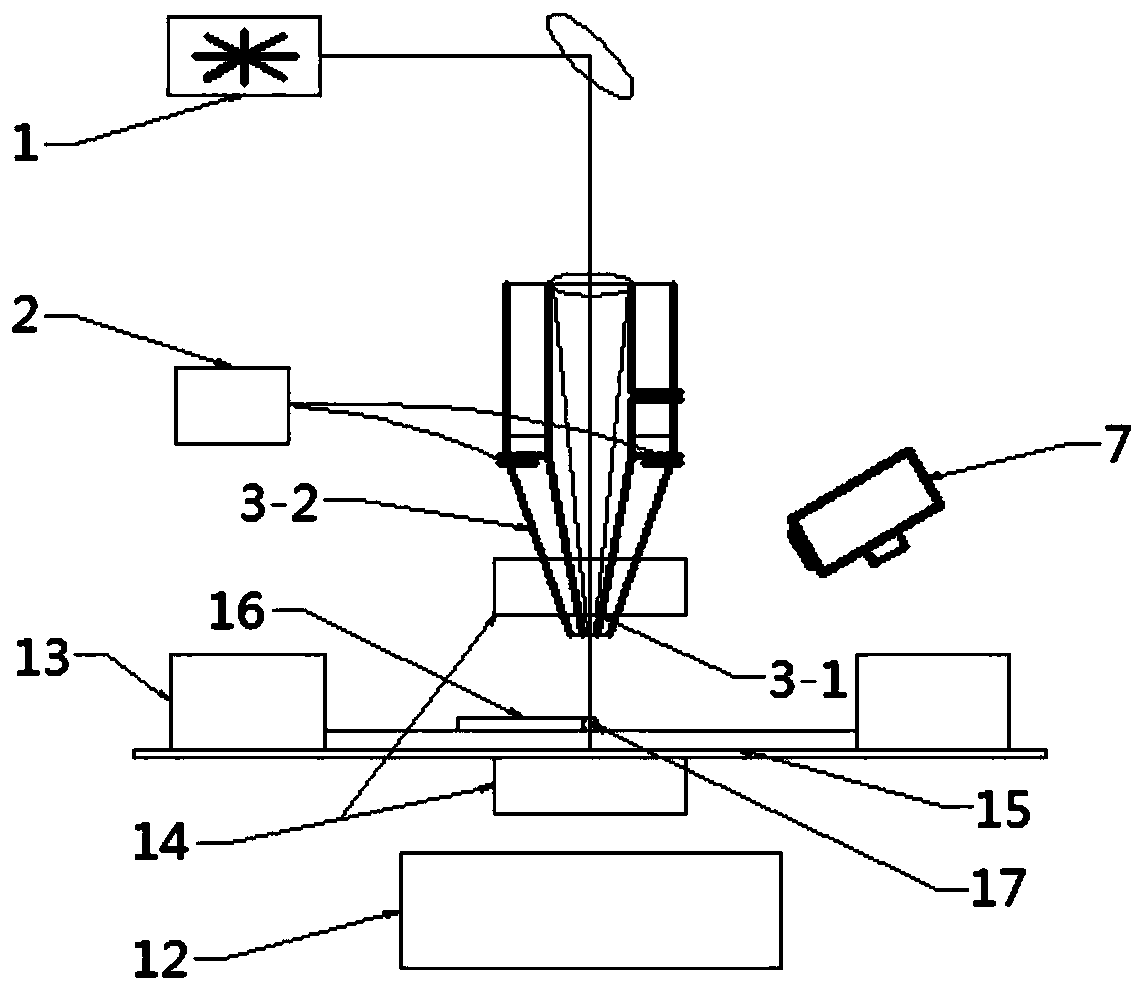

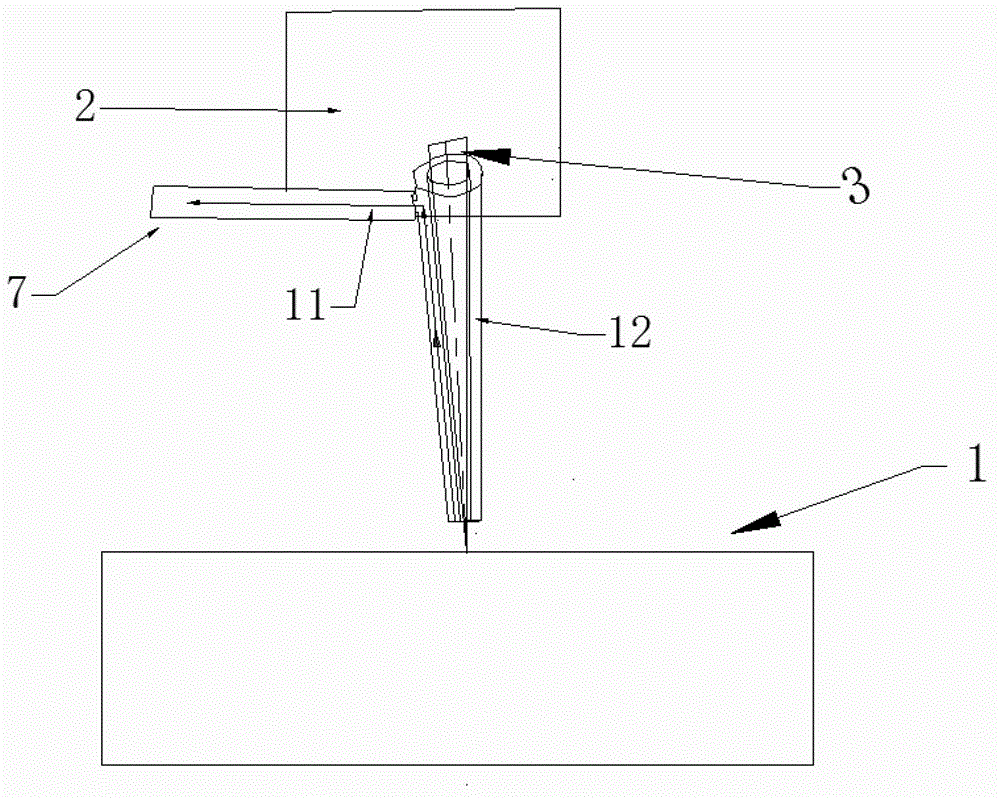

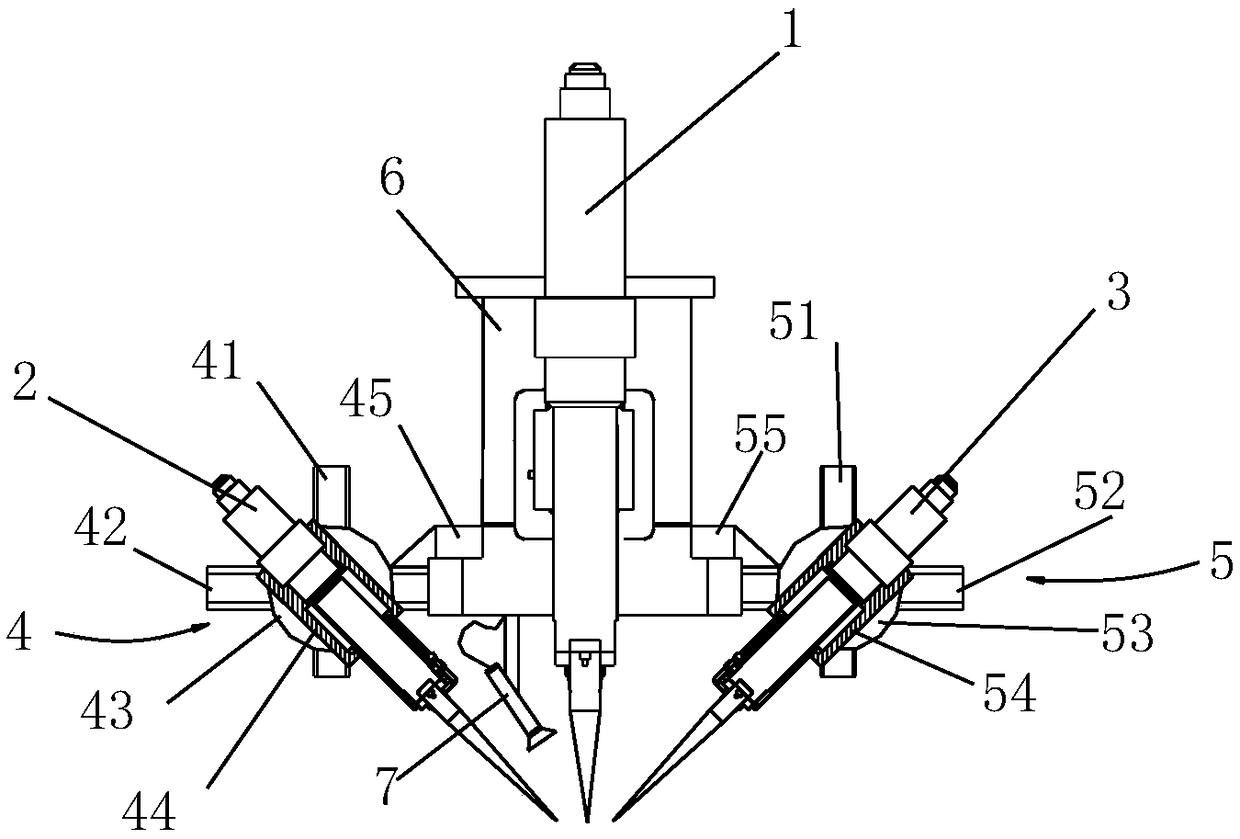

Laser multi-beam compound temperature field welding device

ActiveCN108890128AHigh quality weldingGood reference valueLaser beam welding apparatusFusion weldingOptoelectronics

The invention relates to a laser multi-beam compound temperature field welding device. The device at least comprises a deep penetration welding laser head, a preheating laser head, a slow cooling laser head and an infrared temperature field measuring device, wherein the deep penetration welding laser head is arranged on a spindle and used for emitting main welding laser beam for fusion welding onwelding parts; the preheating laser head is used for emitting preheating laser beam in the fusion welding process of the welding parts and is adjustably arranged on the periphery of the spindle through the position of a first movement mechanism; the slow cooling laser head is used for emitting slow cooling laser beam in the fusion welding process of the welding parts and is adjustably arranged onthe periphery of the spindle through the position of a second movement mechanism; the infrared temperature field measuring device is arranged in a preset range of the deep penetration welding laser head, and used for measuring the temperature in a compound temperature field formed by the main welding laser beam, the preheating laser beam and the slow cooling laser beam through fusion welding during welding in real time.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

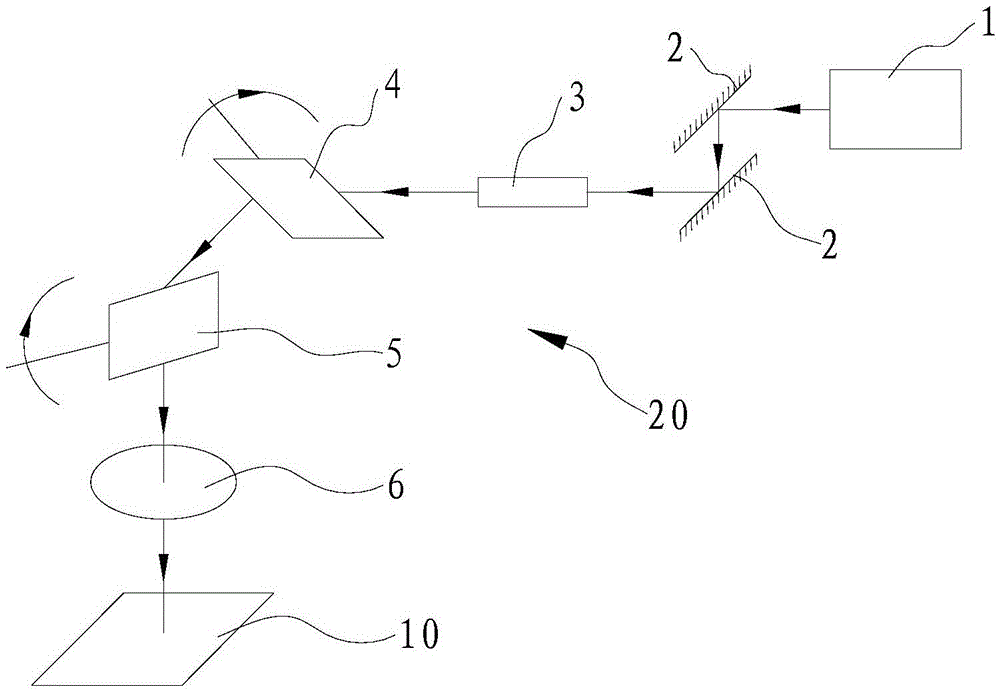

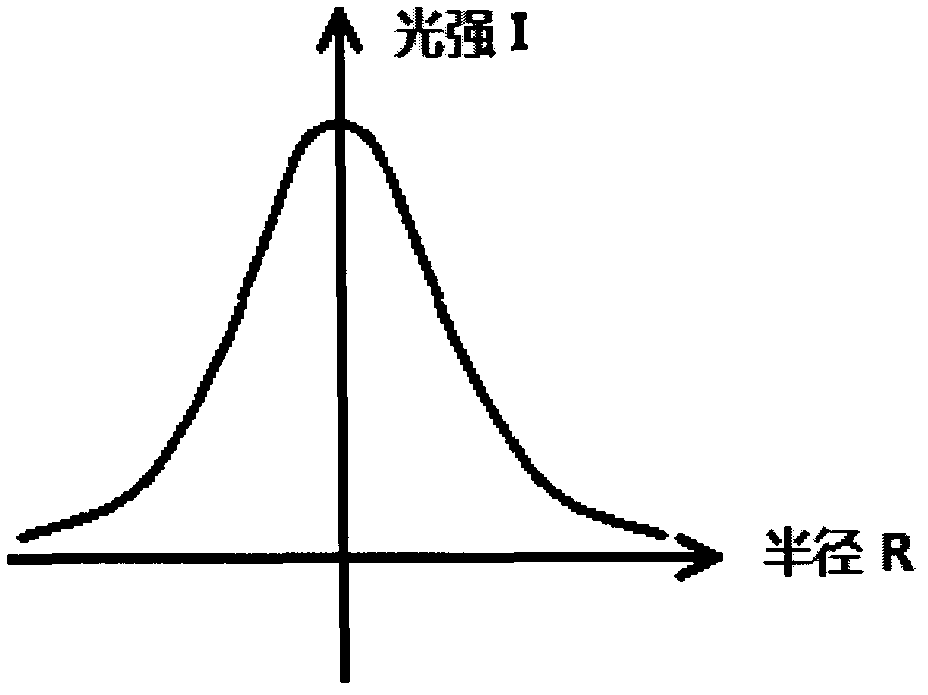

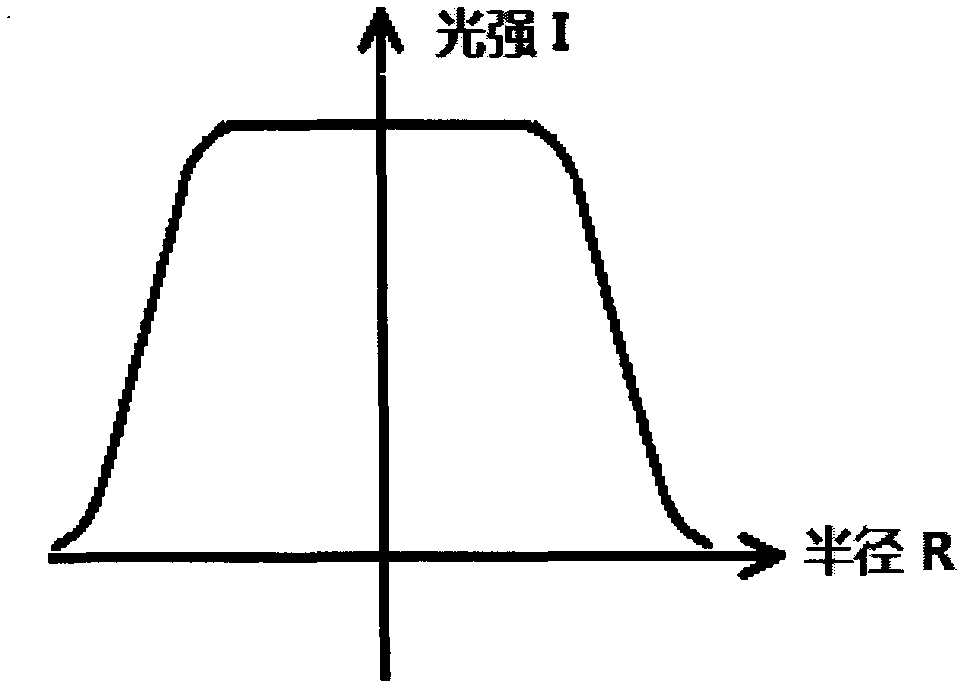

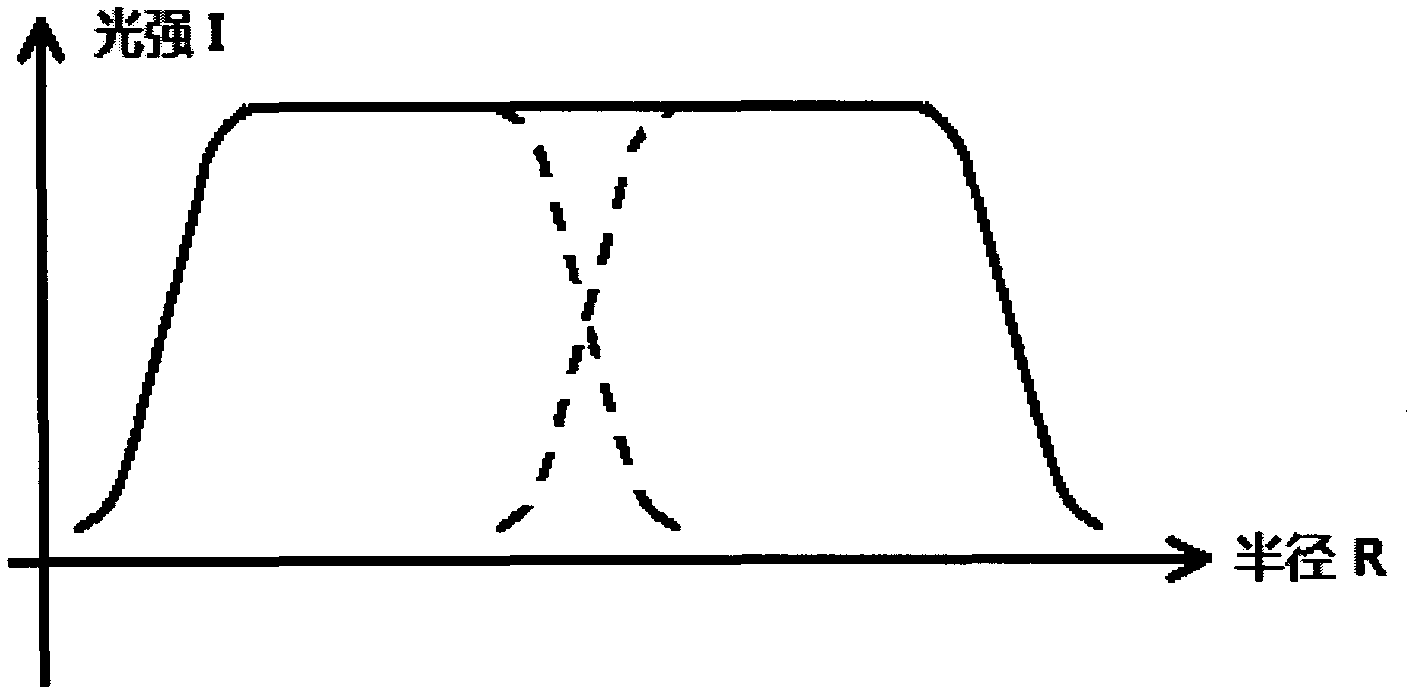

Flattened Gaussian beam picopulse laser processing system

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI +1

Method for conductively connecting a component on a transparent substrate

InactiveUS20120266461A1Avoid cleaningFast solderingPrinted circuit assemblingLight absorption dielectricsEnergy supplyLength wave

The invention relates to a method to conductively connect an electrical component with at least one conductive layer, whereby the conductive layer is applied to a substrate which is essentially transparent in the visible wavelength zone of light, comprising the following steps: the electrical component or the conductive layer is provided with a soldering material in the area where the component is to be connected to the conductive layer; the soldering material is provided with energy supplied by an energy source, such that the soldering material melts and a non-detachable, material-bonded conductive connection between the electrical component and the conductive layer is established.

Owner:SCHOTT AG

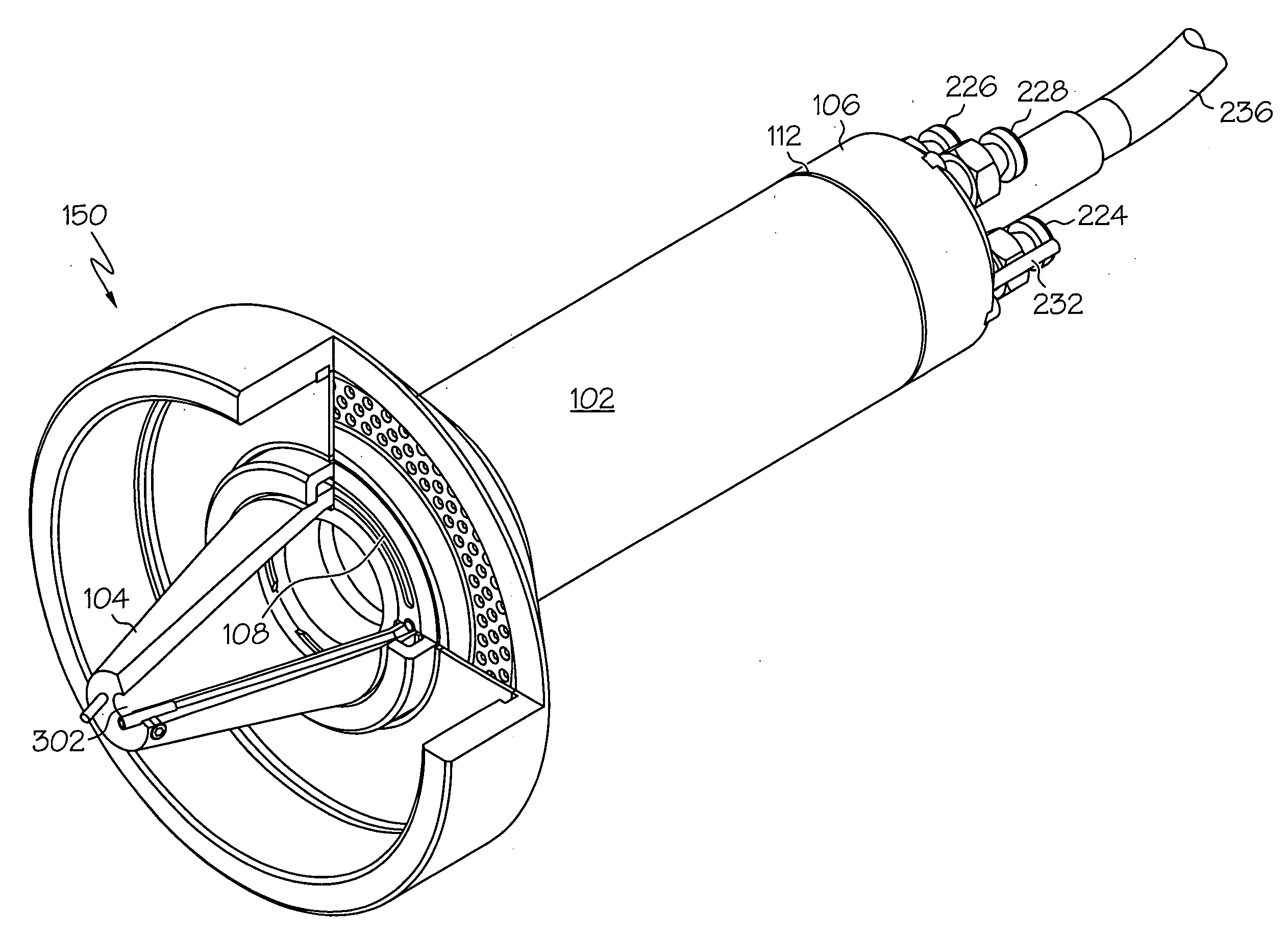

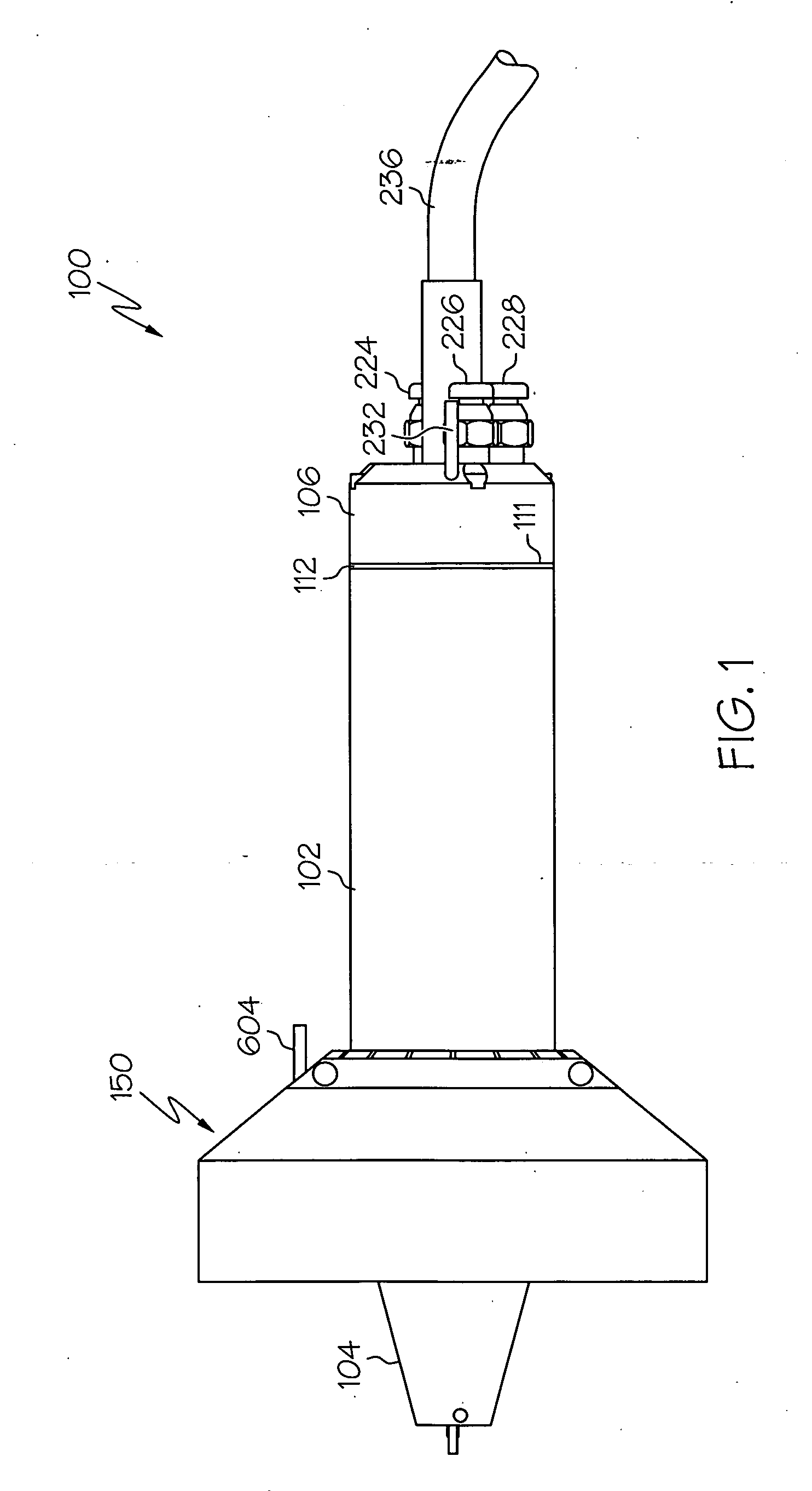

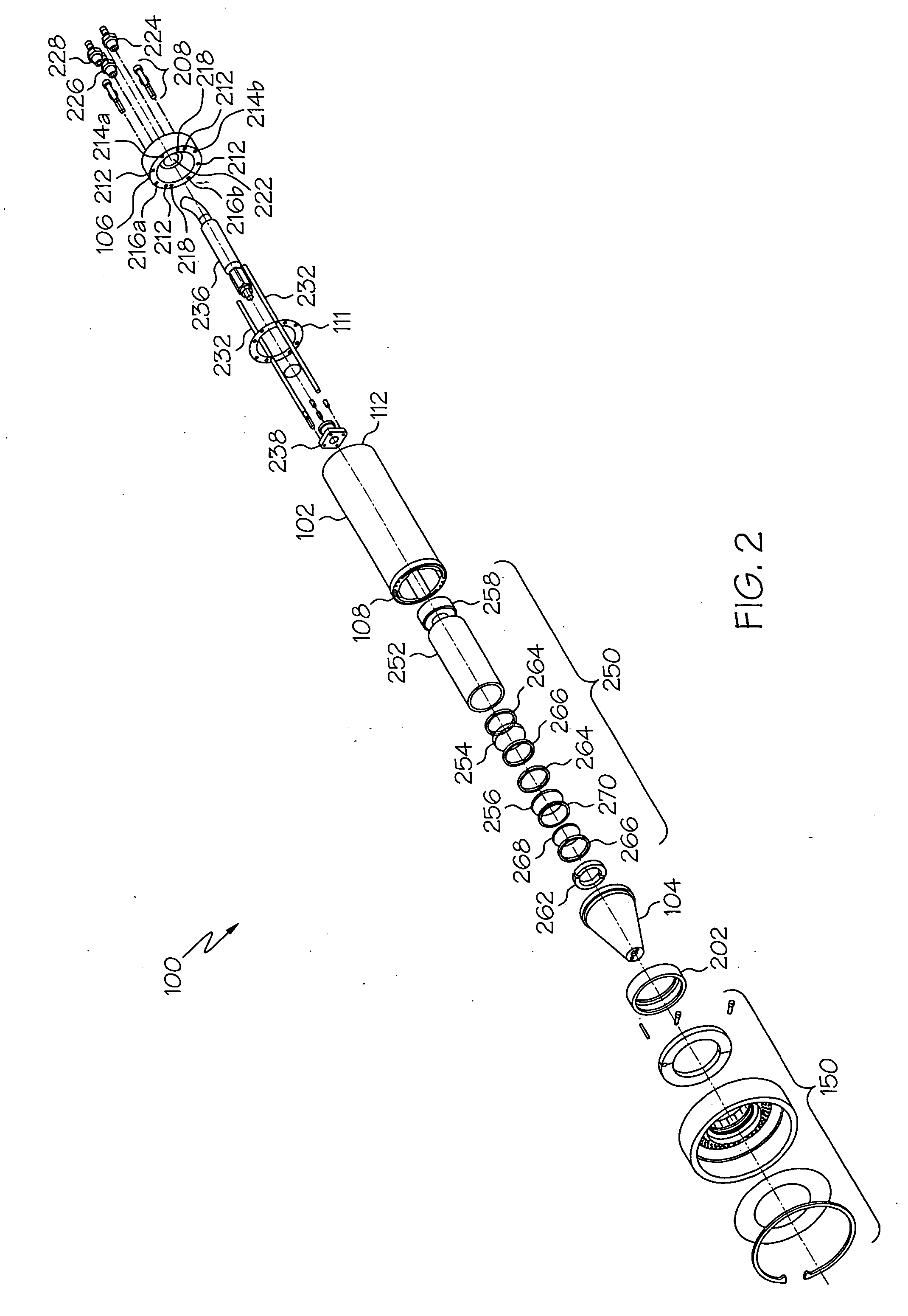

Device and method for conducting superfast laser machining of air film hole in water jet environment

Owner:SHANGHAI JIAO TONG UNIV

Hand-held laser welding wand gas lens

Owner:HONEYWELL INT INC

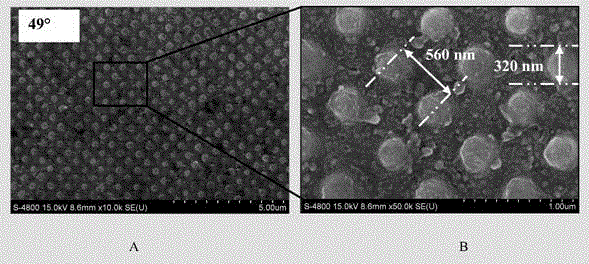

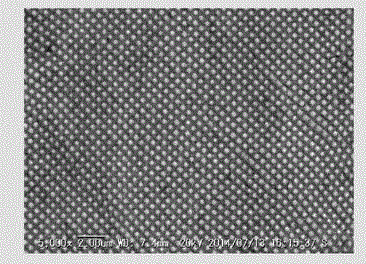

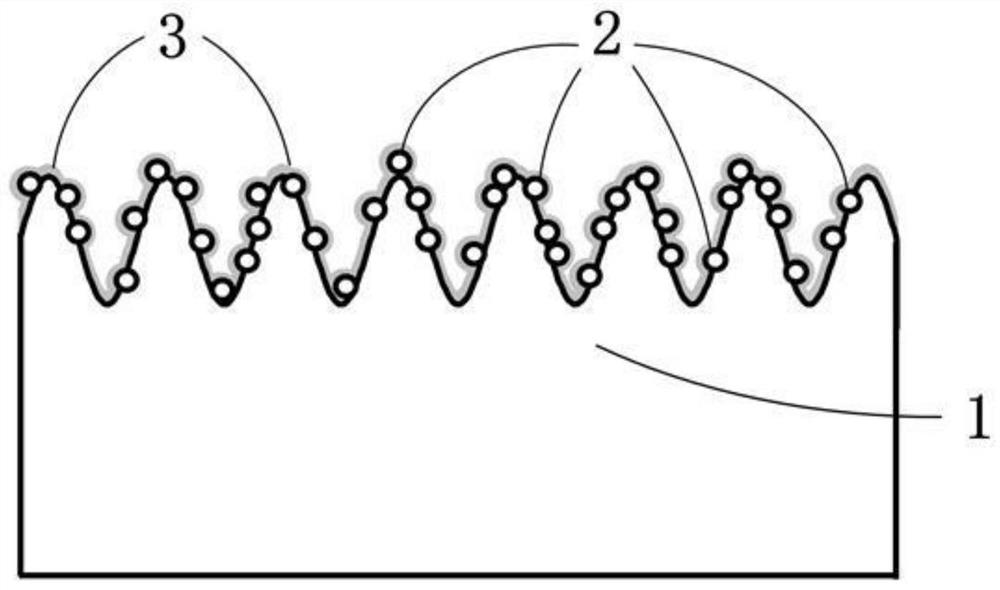

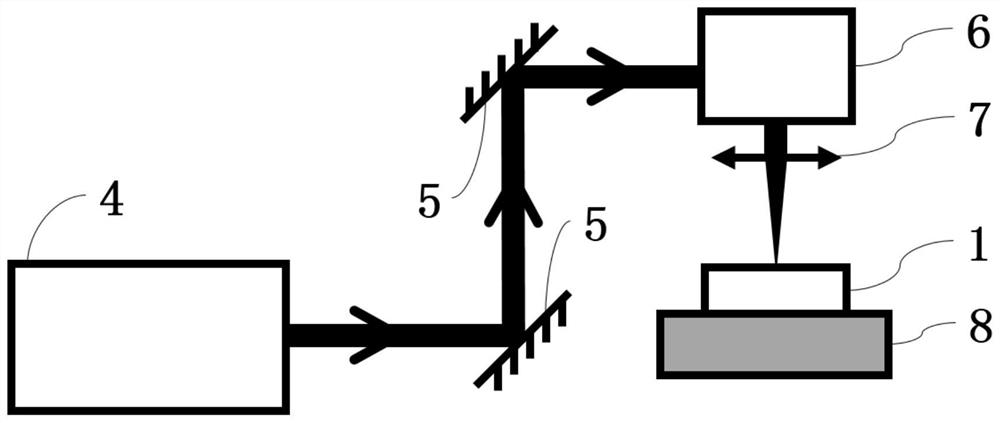

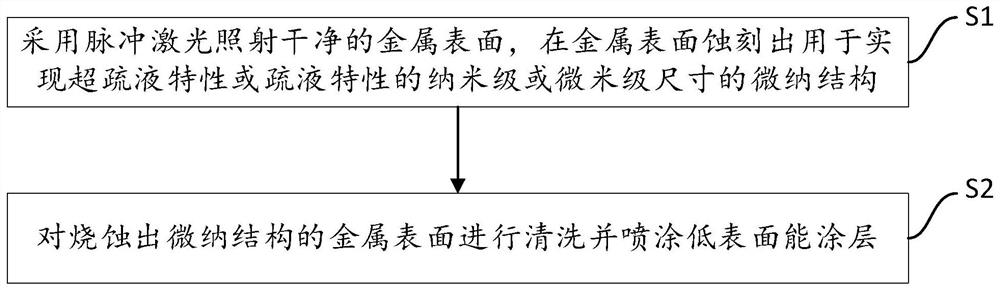

Non-stick metal surface and preparation method thereof

PendingCN113634909AWith characteristicsLong-lasting non-stick performanceSpecial surfacesCoatingsMicron scaleNano structuring

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Laser welding apparatus and method of laser welding

ActiveCN102196879AAvoid meltingInhibitionWelding/cutting auxillary devicesAuxillary welding devicesThick wallLaser beams

Owner:MITSUBISHI SHIPBUILDING CO LTD

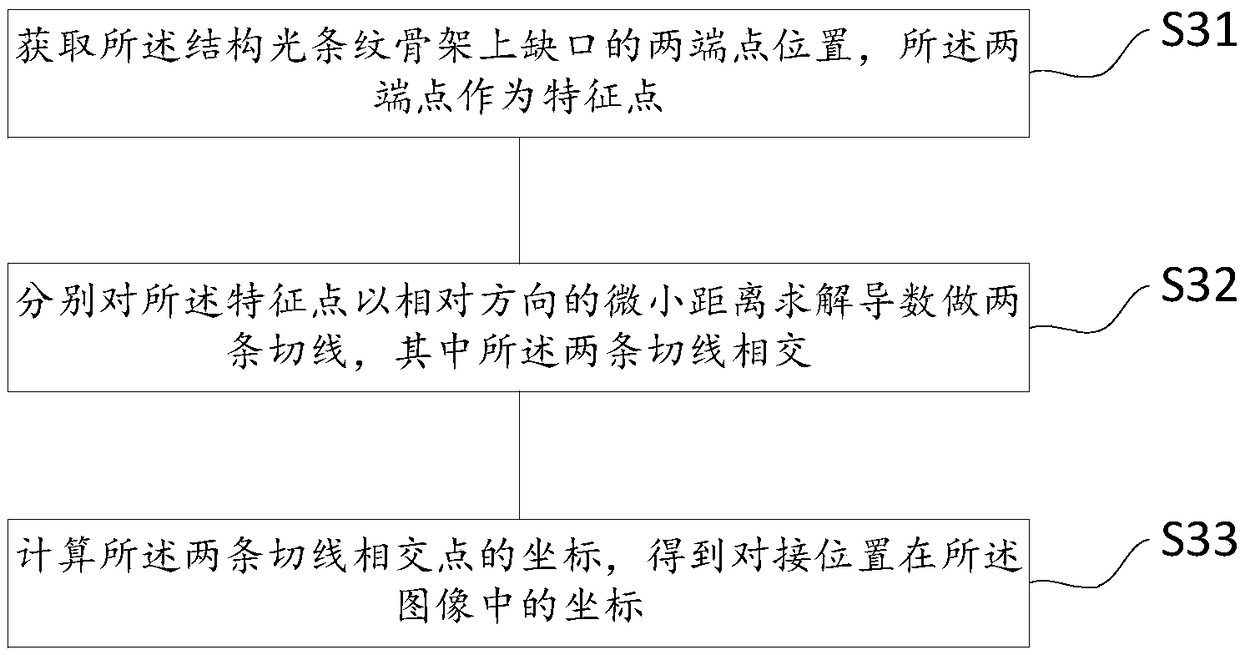

Welding line positioning method and system applied to welding line positioning

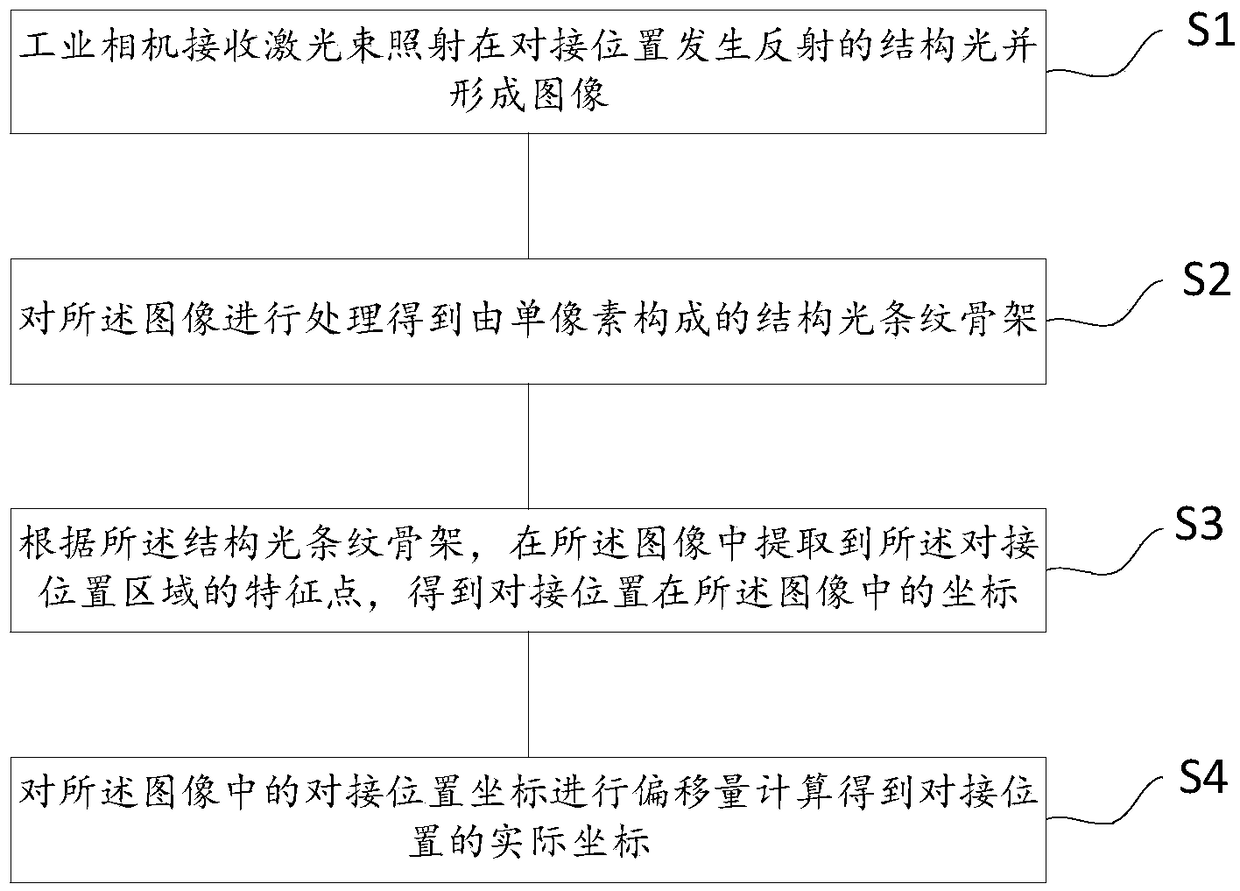

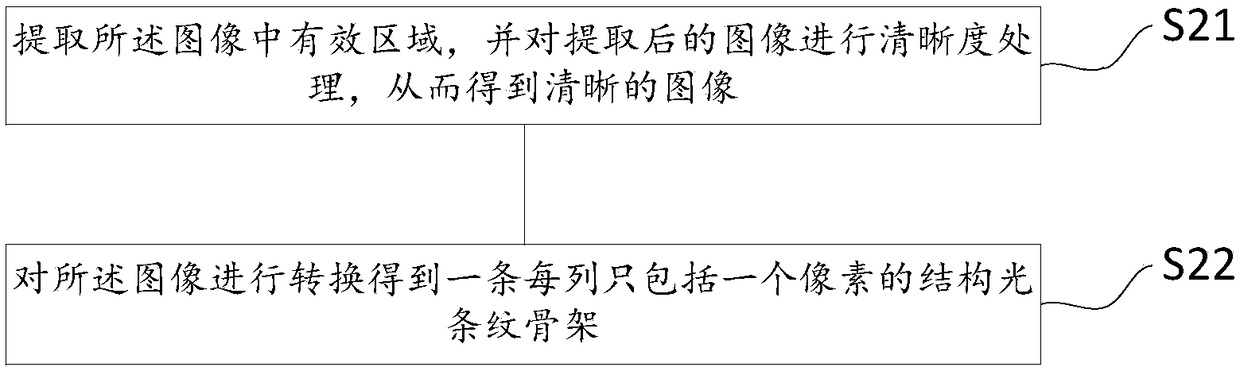

InactiveCN109202284AFix inaccurate positioningHigh positioning accuracyLaser beam welding apparatusButt jointEngineering

Owner:HANS LASER TECH IND GRP CO LTD +1

Manufacturing method of semiconductor device

InactiveCN102468153AEfficient reorganizationIncrease etch ratePolycrystalline material growthAfter-treatment detailsPulsed laser beamCrystalline silicon

In a manufacturing method of a semiconductor device, a substrate including single crystalline silicon is prepared, a reformed layer that continuously extends is formed in the substrate, and the reformed layer is removed by etching. The forming the reformed layer includes polycrystallizing a portion of the single crystalline silicon by irradiating the substrate with a pulsed laser beam while moving a focal point of the laser beam in the substrate.

Owner:DENSO CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap