Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Magnetic powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compact, method for producing compact, reactor, converter, and power conversion device

InactiveUS20130322135A1Efficient productionTotal current dropTransportation and packagingInorganic material magnetismMetallurgyIrradiation

A low-loss compact and a method for producing the compact are provided.A method for producing a compact by using coated soft magnetic powder that includes coated soft magnetic particles constituted by soft magnetic particles and insulating coatings coating outer peripheries of the soft magnetic particles includes a raw material preparation step and an irradiation step. In the raw material preparation step, a raw compact is prepared by press-forming coated soft magnetic powder. In the irradiation step, part of a surface of the raw compact is irradiated with a laser. Irradiating a part of a surface of a raw compact with laser increases the number of disrupted portions of conductive portions where constituent materials of the soft magnetic particles at the surface of the raw compact have become conductive to each other, and the loss of the compact can be decreased.

Owner:SUMITOMO ELECTRIC IND LTD +1

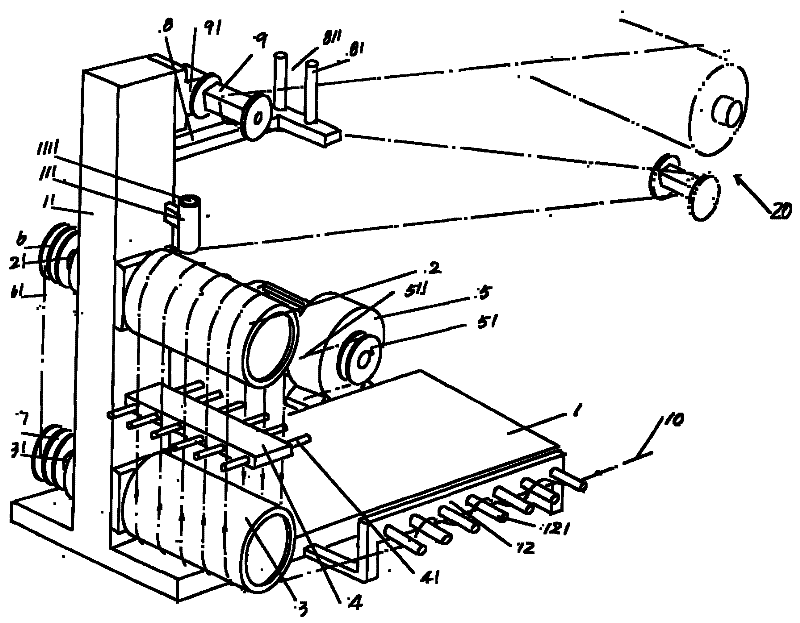

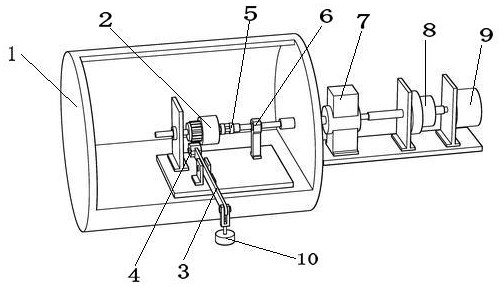

Yarn separating mechanism for yarn separating machine

Owner:常熟市荣伟纺织有限公司

High saturation and magnetic intensity magnetic powder and its preparing method and use

InactiveCN101009151AFerroso-ferric oxidesInorganic material magnetismFerriferrous OxideMagnetic powder

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Pipe punching equipment

Owner:CHONGQING YOUWEI PLASTIC CO LTD

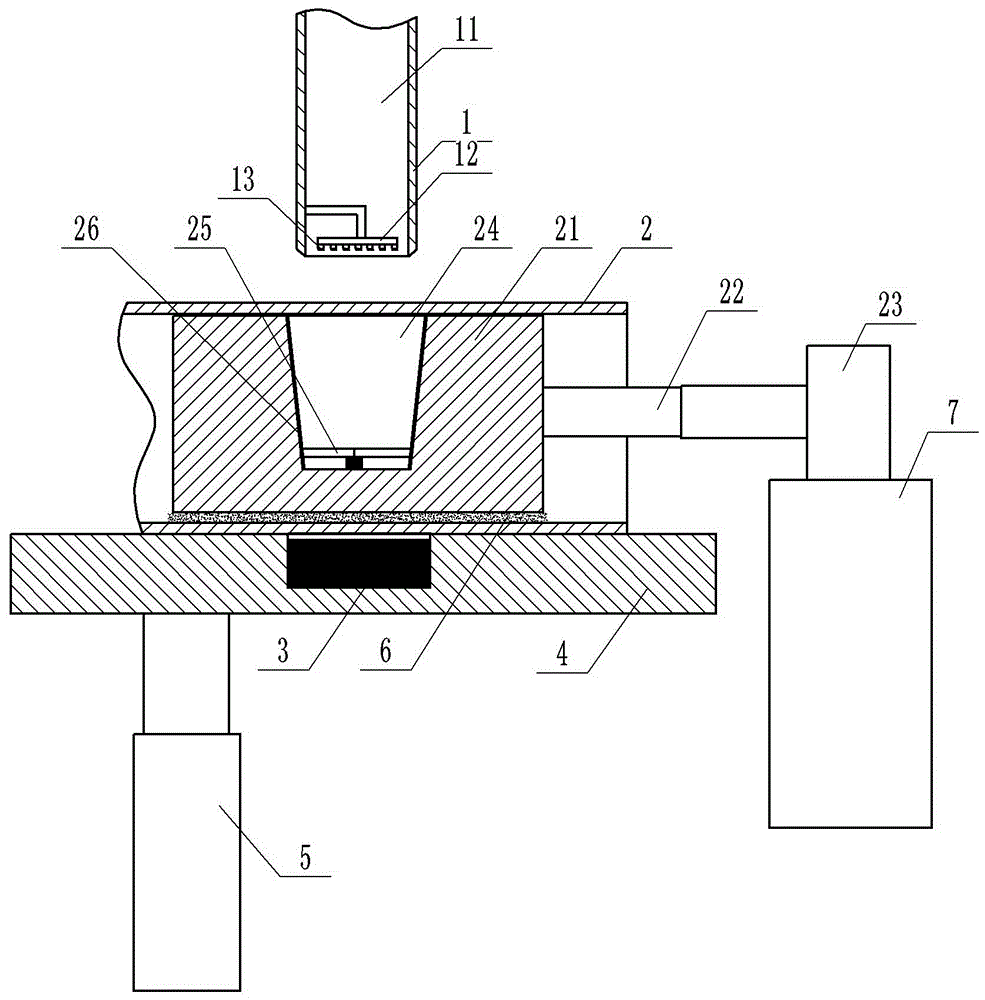

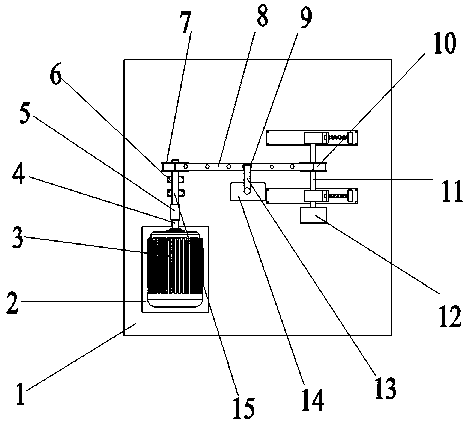

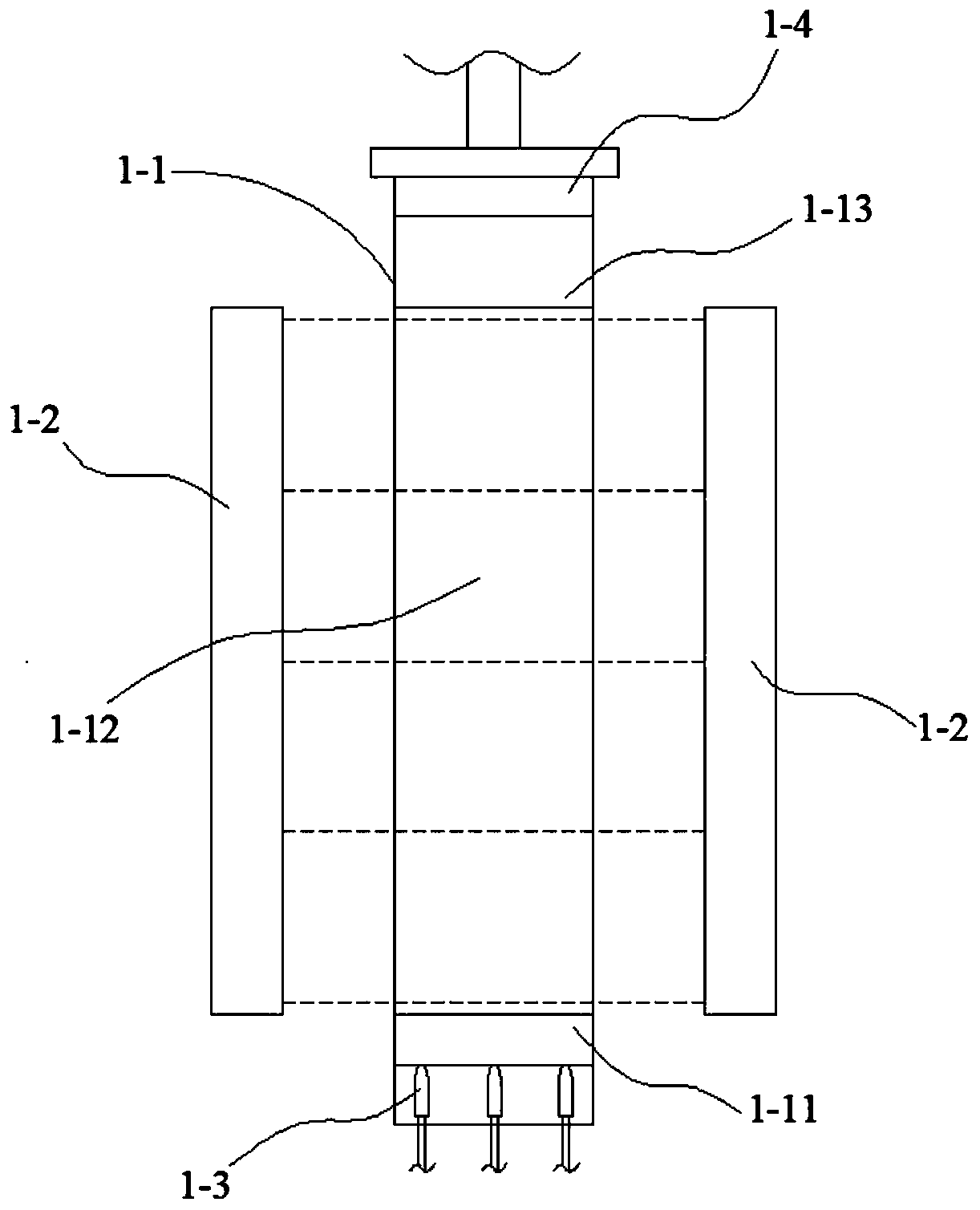

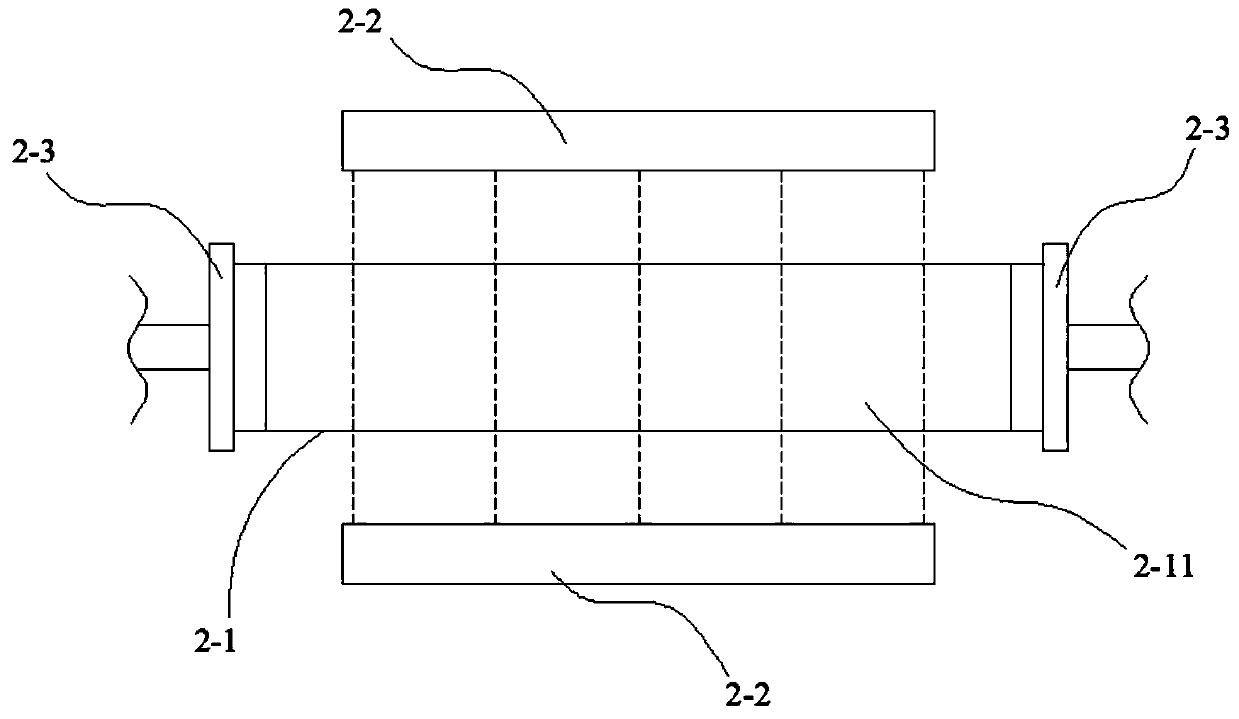

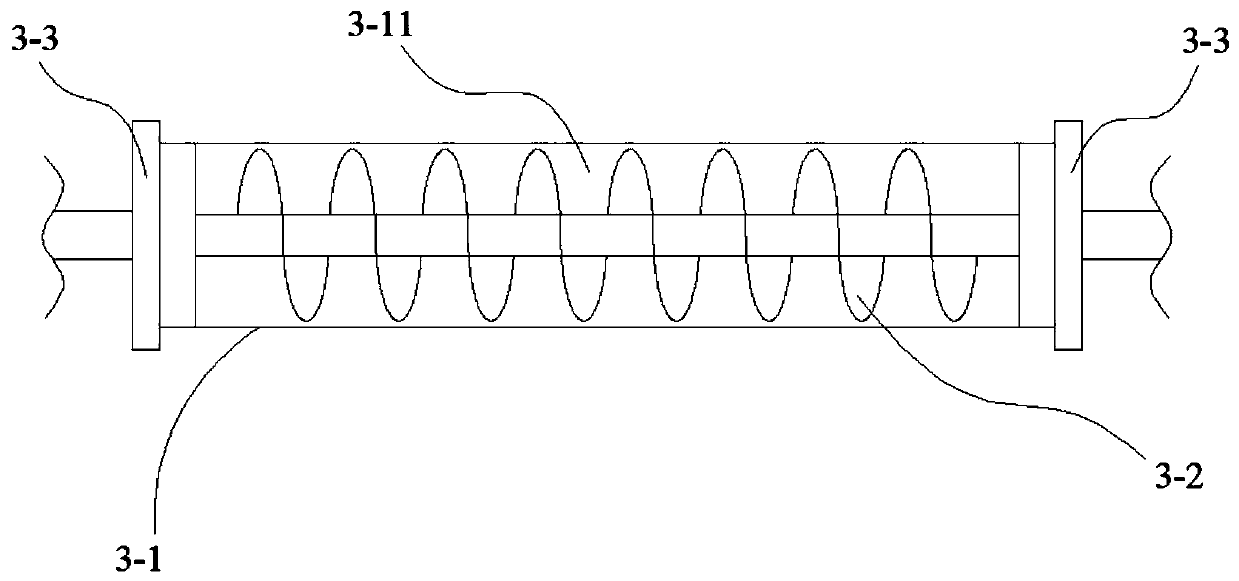

Magnetic powder sensitivity test device and test method

InactiveCN106525854AThe test method is accurateAccurate measurementMaterial analysis by optical meansSensitivity testQuenching

Owner:CRRC QISHUYAN INSTITUTE CO LTD

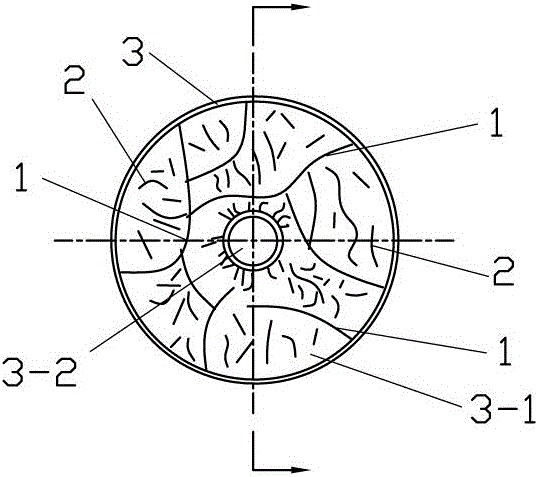

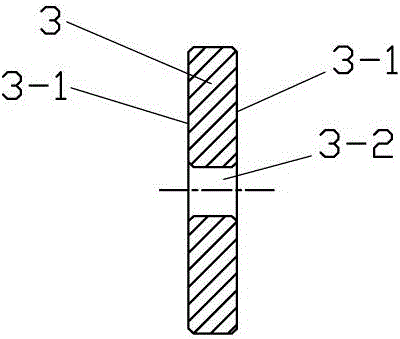

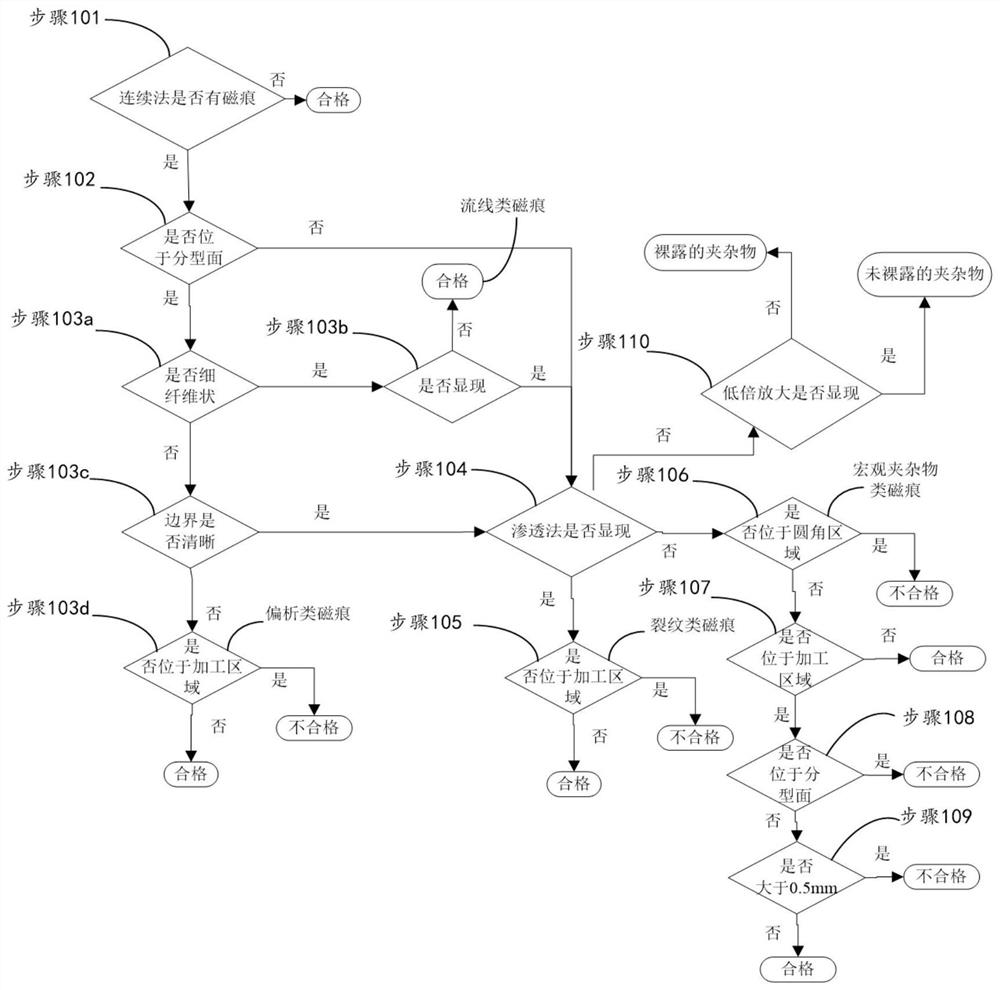

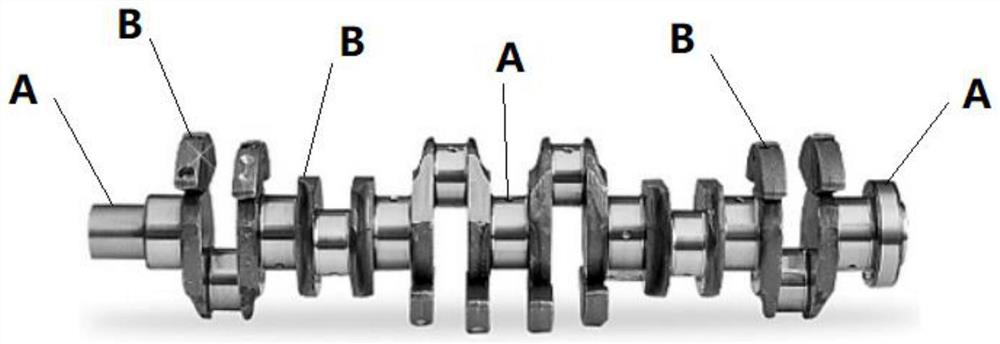

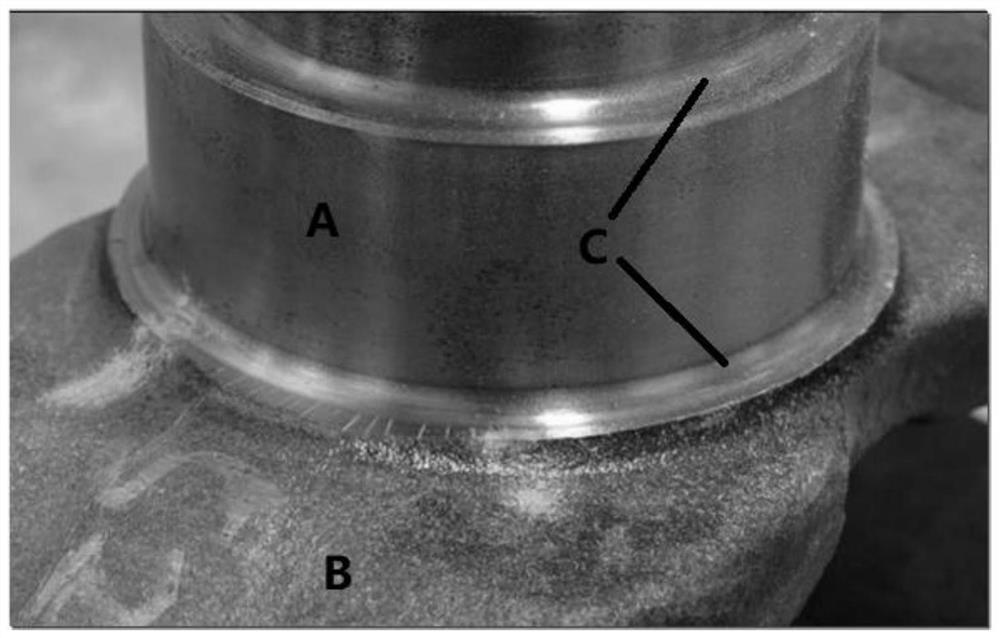

Engine crankshaft inspection method

ActiveCN113740416AAvoid misjudgmentImprove reliabilityInternal combustion piston enginesOptically investigating flaws/contaminationMechanical engineeringCrankshaft

Owner:DONGFENG COMML VEHICLE CO LTD

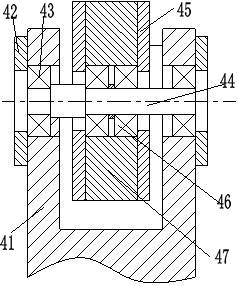

Two-gear transmission of electric automobile

InactiveCN107143645AReduce volumeReduce weightLiquid resistance brakesFluid clutchesMotor speedEngineering

The invention discloses a two-gear transmission of an electric automobile, and belongs to the field of transmissions. The two-gear transmission comprises a shell. A first driven gear, a magnetic powder clutch, a second driven gear and a magnetic powder brake, all of which are sequentially connected, are arranged in the shell. The shell is internally further provided with a planetary gear structure. The planetary gear structure comprises a planet carrier. Four planet wheels are connected to the two ends of the planet carrier. A sun wheel is connected among the four planet wheels. The two-gear transmission further comprises a gear ring. One side of the gear ring is engaged with the planet wheels, and the other side of the gear ring is engaged with the second driven gear. The planet carrier is engaged with the first driven gear through a gear. An electromagnetic brake and an electromagnetic clutch are adopted in the two-gear transmission to replace traditional hydraulic clutches, the size is small, and the weight is small; in combination with the excellent character of motor speed adjusting of a blade electric vehicle, the work slip frequency section between the electromagnetic brake and the electromagnetic clutch is small; and in combination of the rapid response character of the electromagnetic brake and the clutch, the heating amount of the whole transmission is low, and reliability is high.

Owner:NANJING AUTOMOBILE GROUP CORP

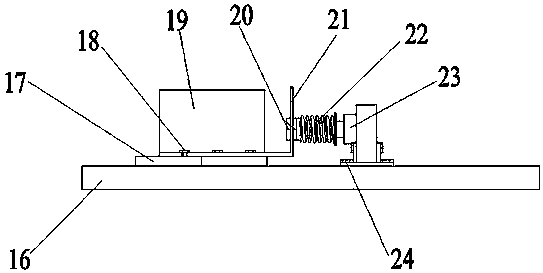

Testing device for fatigue life of steel hole belt

Owner:NORTHWEST A & F UNIV

Preparation method of high-resistance flaky soft magnetic powder

Owner:湖南纳金新材料技术有限公司

Graphene magnetic injection molding masterbatch for nylon electrical appliance plastics, and preparation method thereof

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Aliphatic chain ester metal complex modified material for macromolecule injection molding magnetic material

The invention relates to an aliphatic chain ester metal complex modified material for a macromolecule injection molding magnetic material, which aims at solving the problem of homodisperse of mixture of magnetic powder and binder in production of injection molding magnetic material. The aliphatic chain ester which is compatible to macromolecule is grafted on ferrocene so as to prepare the aliphatic chain ester metal complex modified material. Due to the added modified material, macromolecule and metal magnetic powder are mixed and are compatible more effectively, so that the dispersing evenness is improved, and the processability and usability of the product are further improved.

Owner:SHANGHAI BAOSHUO MAGNETIC MATERIAL CO LTD

Preparation method of rubber sealing material containing nano-magnetic powder modified montmorillonite

Owner:ANHUI WOLONG PUMP & VALVE CO LTD

Vacuum high-low temperature composite loading device

Owner:JILIN UNIV +1

Iron element control method for martensitic stainless steel 2Cr13 blade

PendingCN113084087AAdditive manufacturing apparatusFoundry mouldsMartensitic stainless steelMagnetic powder

Owner:赛普工业研究院(安阳)有限公司

Warm keeping bag

Owner:陈觉明

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap