Anisotropic permanent magnetic ferrite and preparation method thereof

A technology of permanent magnet ferrite and ferrite magnet, which is applied in the field of heterosexual permanent magnet ferrite and its preparation, can solve problems such as poor lubricity, difficulty in obtaining both solutions, and decreased bonding effect of products, and achieve good molding effects , the effect of good magnetic comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

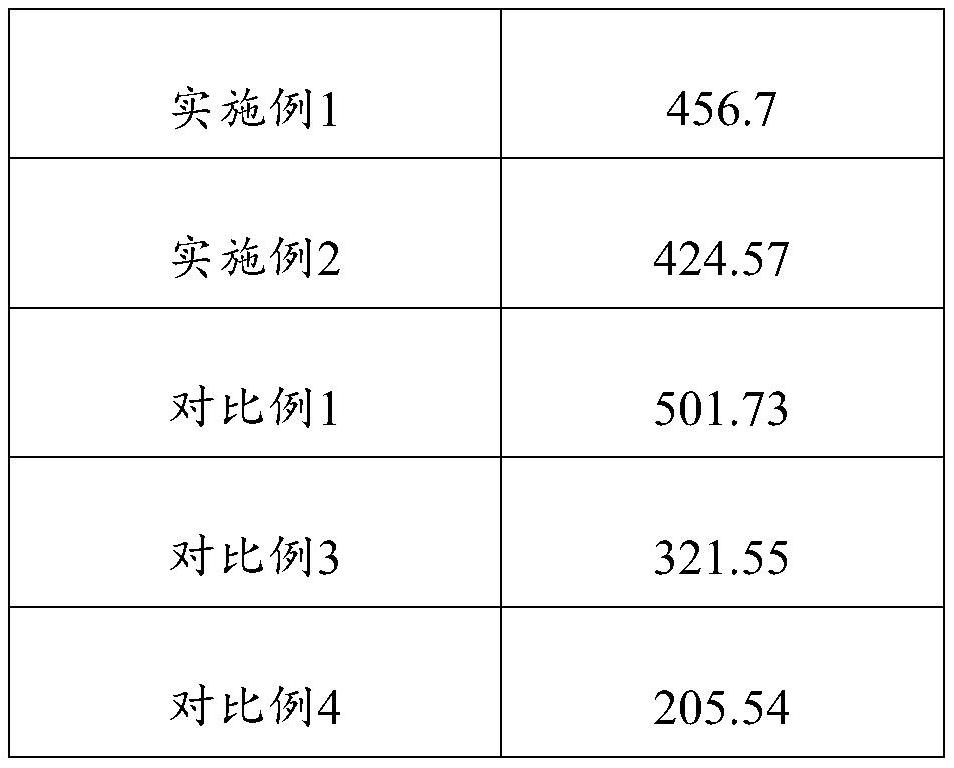

Embodiment 1

[0026] This embodiment provides a kind of heterosexual permanent magnet ferrite, and its preparation method comprises the following steps:

[0027] (1) 0.6 parts by weight of polyvinyl alcohol are added to 135 parts by weight of water to obtain a dilute polyvinyl alcohol solution, that is, the proportion of polyvinyl alcohol in the dilute polyvinyl alcohol solution is 0.44wt%;

[0028] (2) Add 300 parts by weight of ferrite magnetic powder (with a particle size of 0.65-0.85 μm) into the dilute polyvinyl alcohol solution in step (1), stir and mix with a mixer to obtain a slurry;

[0029] (3) Dry the slurry in step (2) at a low temperature of 75° C., pulverize it with a disperser after drying, add 0.9 parts by weight of lubricant calcium stearate, stir and disperse, and disperse for a total of 3 times to obtain Anisotropic permanent magnet ferrite powder;

[0030] (4) Place the anisotropic permanent magnet ferrite powder in step (3) in a magnetic field of 6000Oe, perform dry press

Embodiment 2

[0032] This embodiment provides a kind of heterosexual permanent magnet ferrite, and its preparation method comprises the following steps:

[0033] (1) Add 0.6 parts by weight of polyvinyl alcohol to 255 parts by weight of water to obtain a dilute polyvinyl alcohol solution, that is, the proportion of polyvinyl alcohol in the dilute polyvinyl alcohol solution is 0.23wt%;

[0034] (2) Add 300 parts by weight of ferrite magnetic powder (with a particle size of 0.65-0.85 μm) into the dilute polyvinyl alcohol solution in step (1), stir and mix with a mixer to obtain a slurry;

[0035] (3) Dry the slurry in step (2) at a low temperature of 80° C., pulverize it with a disperser after drying, then add 0.9 parts by weight of lubricant calcium stearate, stir and disperse, and disperse for a total of 3 times to obtain Anisotropic permanent magnet ferrite powder;

[0036] (4) Place the anisotropic permanent magnet ferrite powder in step (3) in a magnetic field of 7000Oe, carry out dry pres

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap